Patents

Literature

323results about "Pressure electrodes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

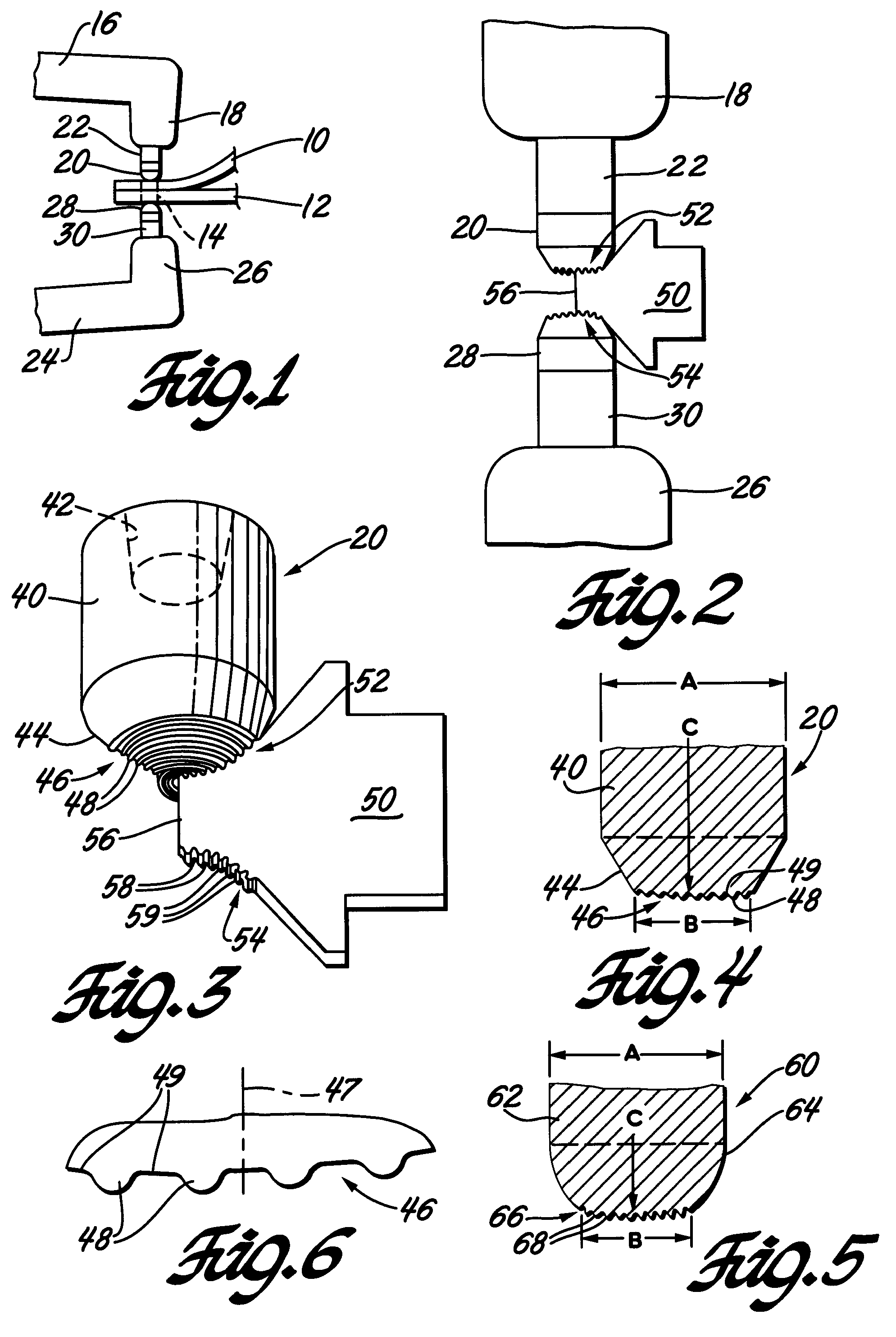

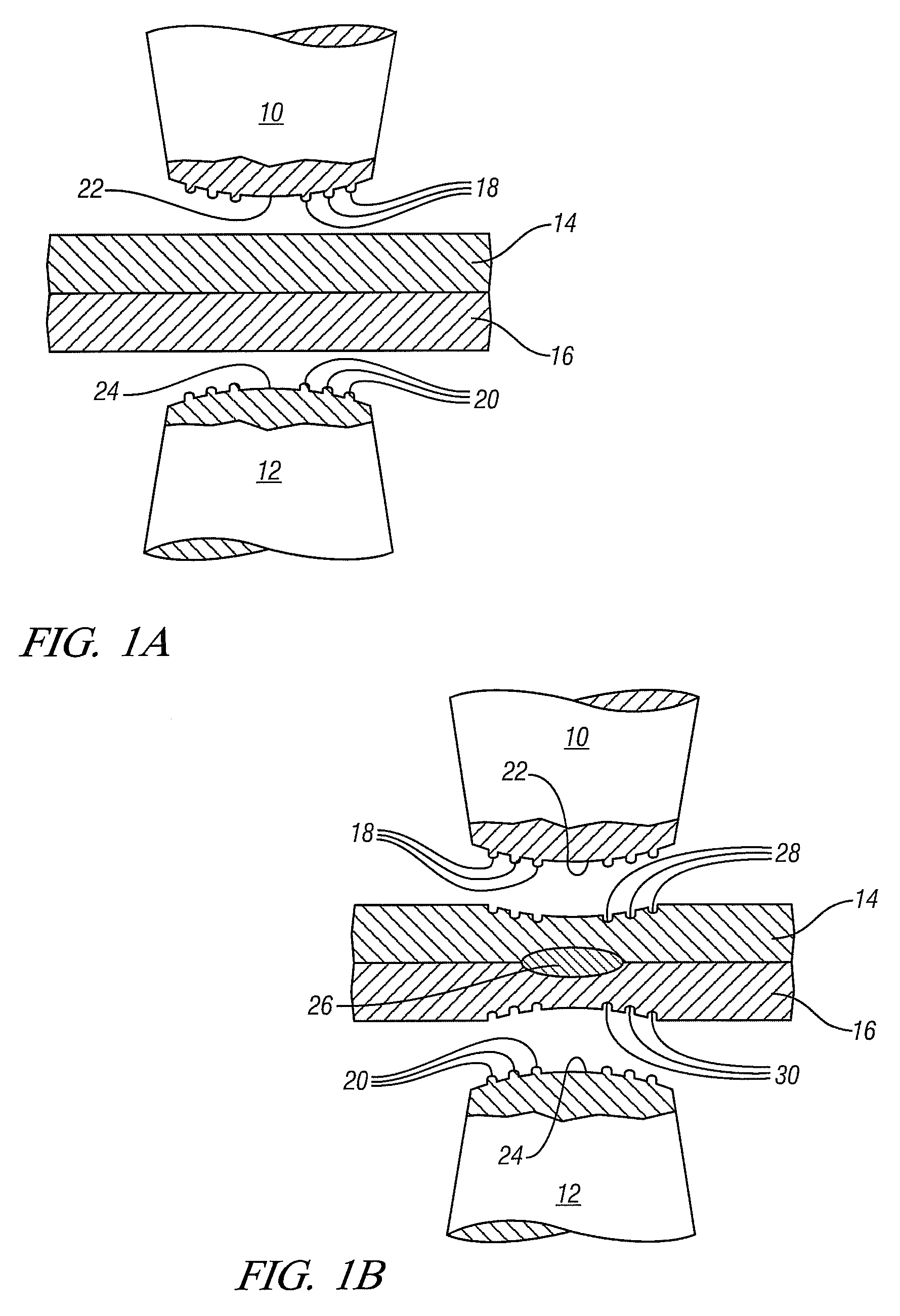

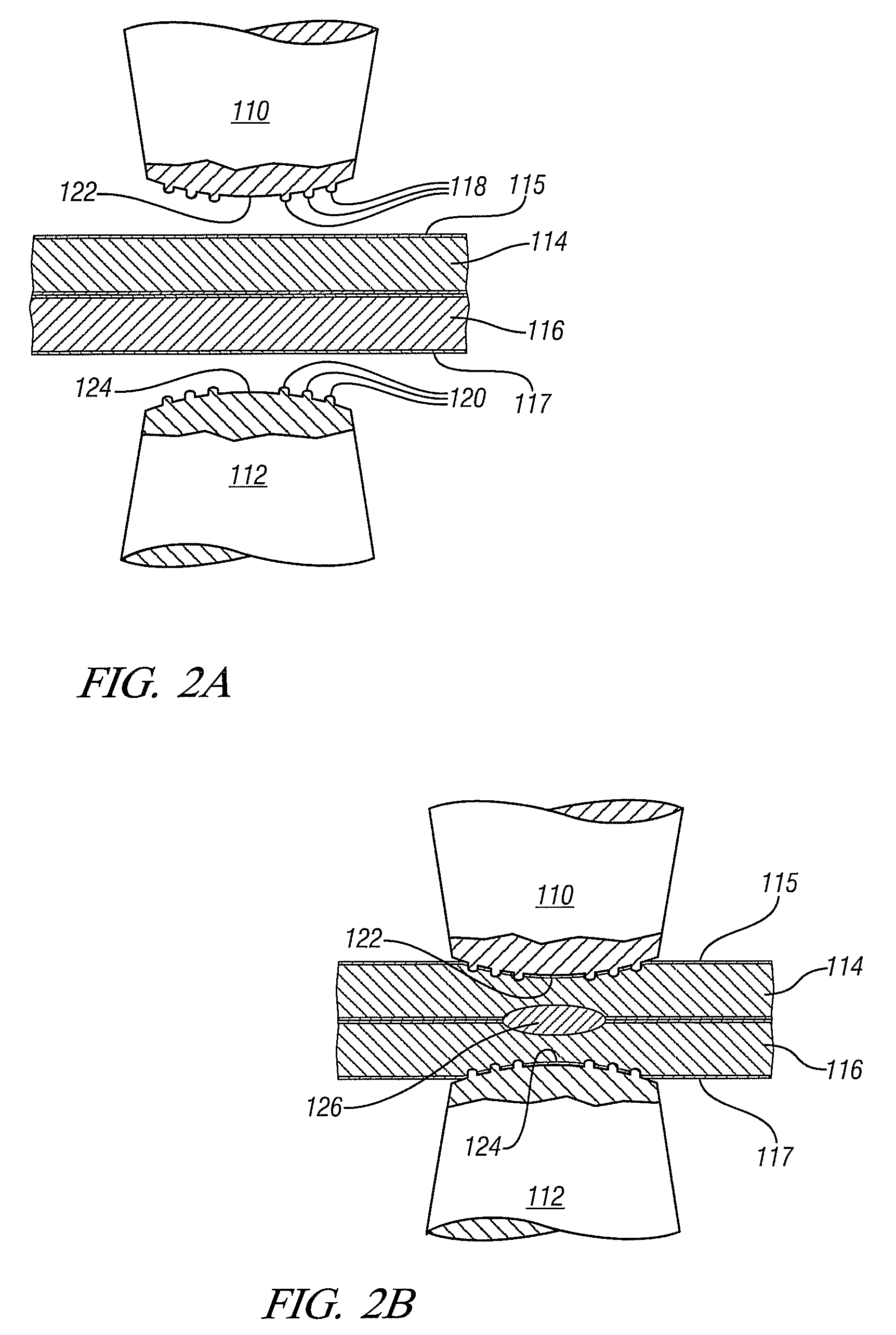

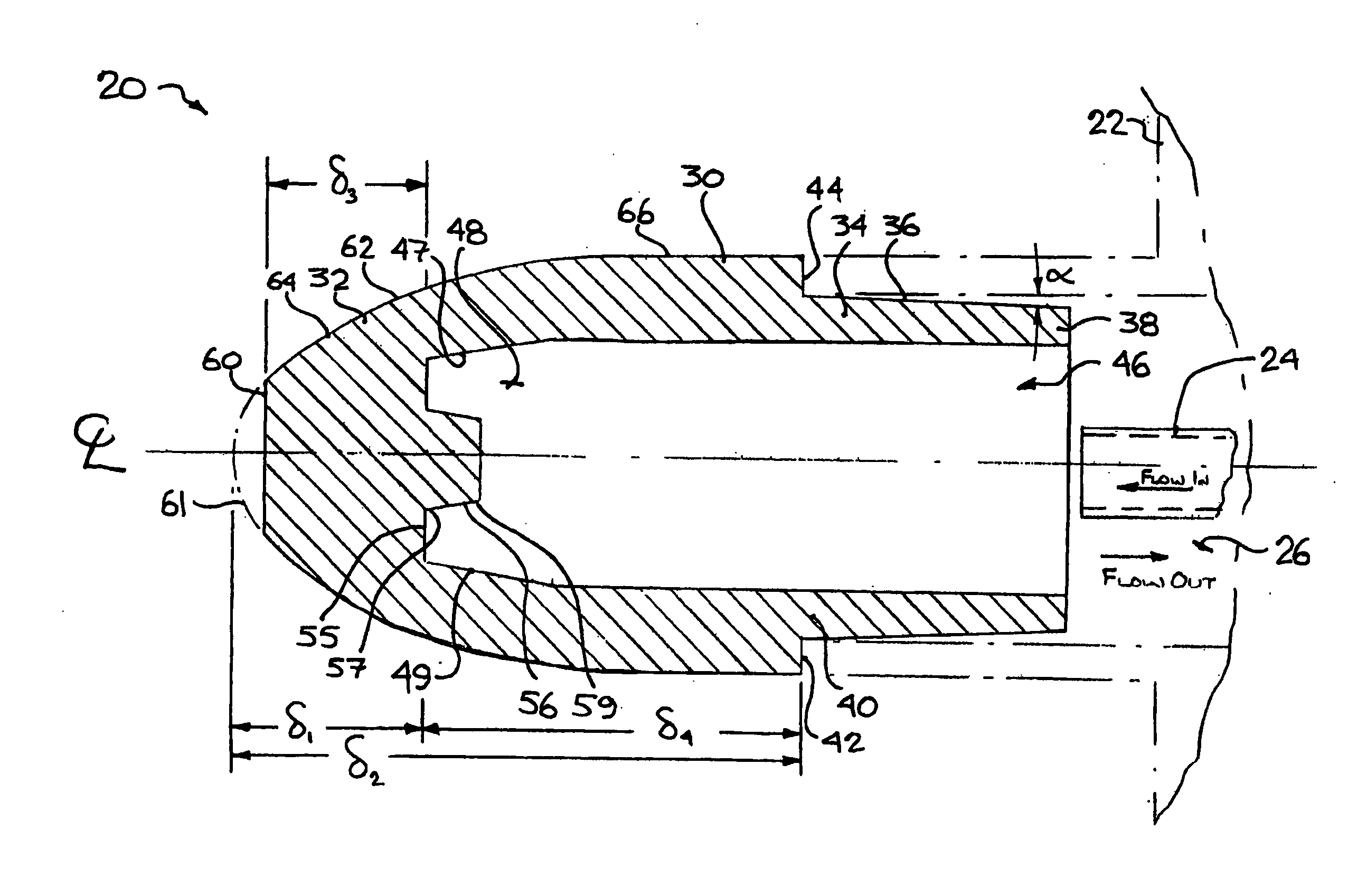

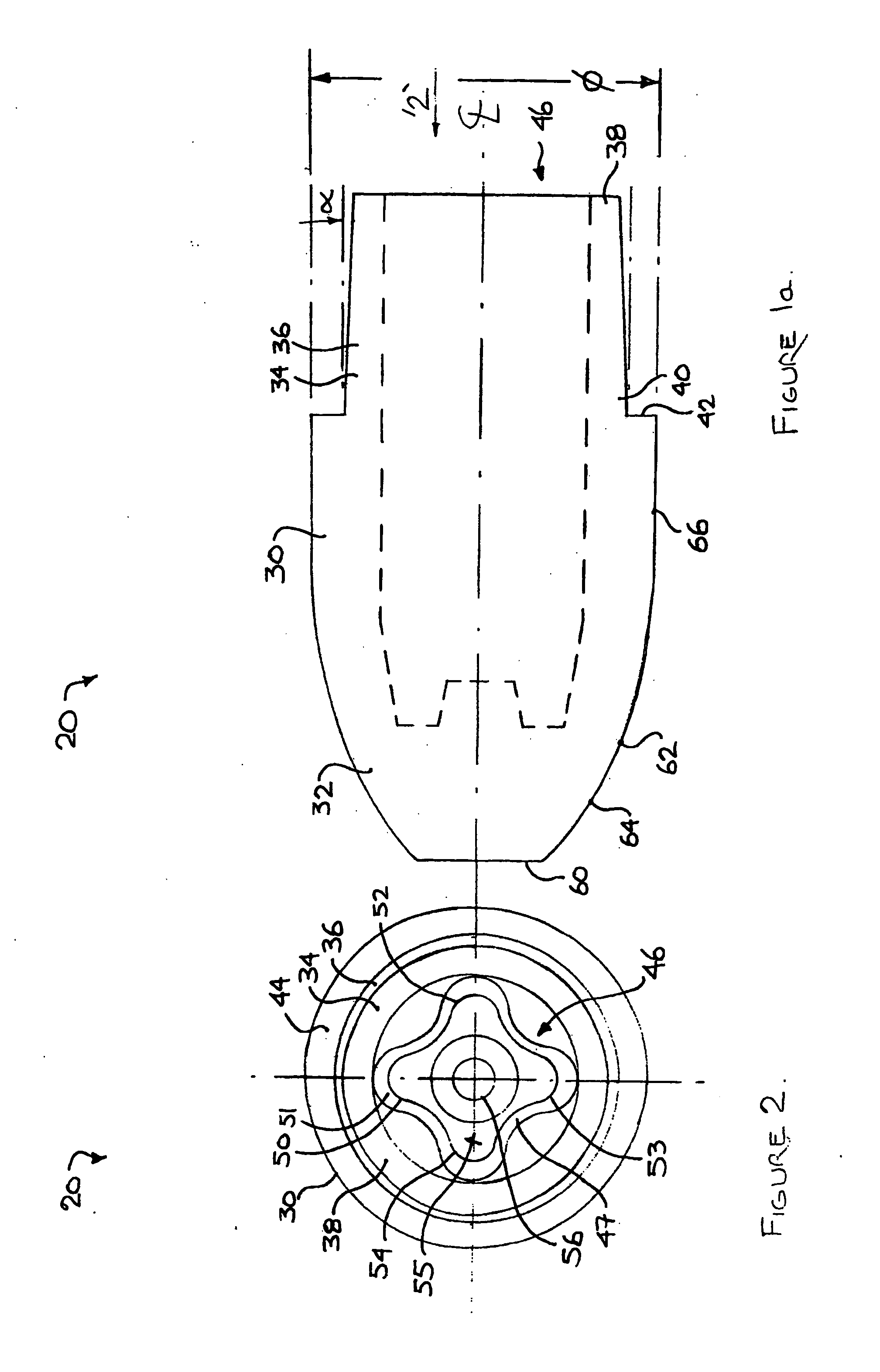

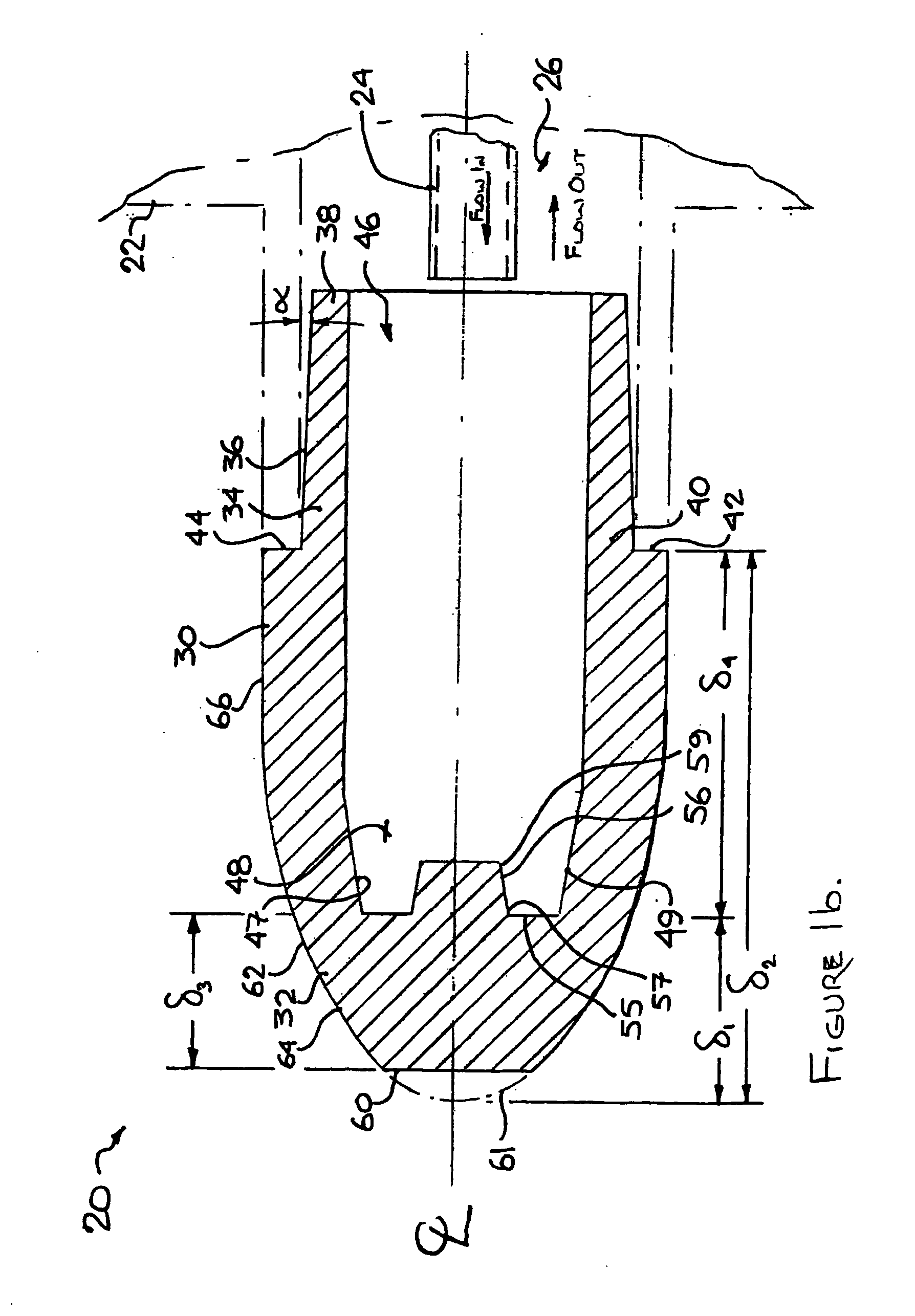

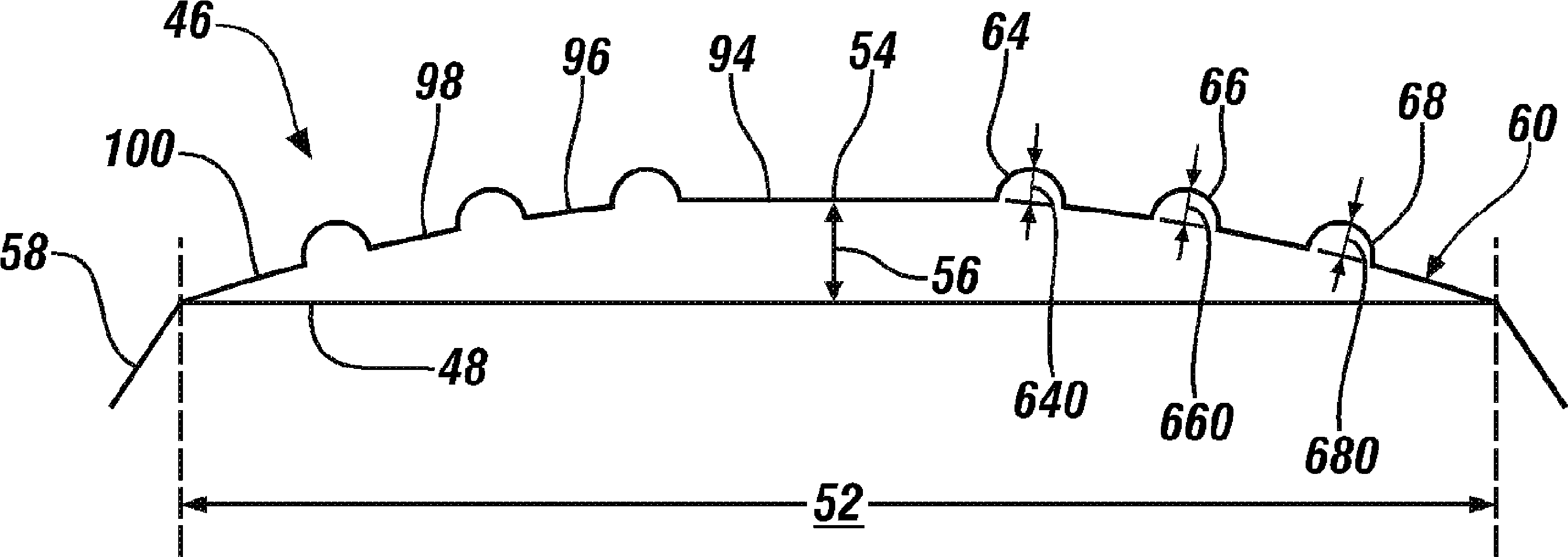

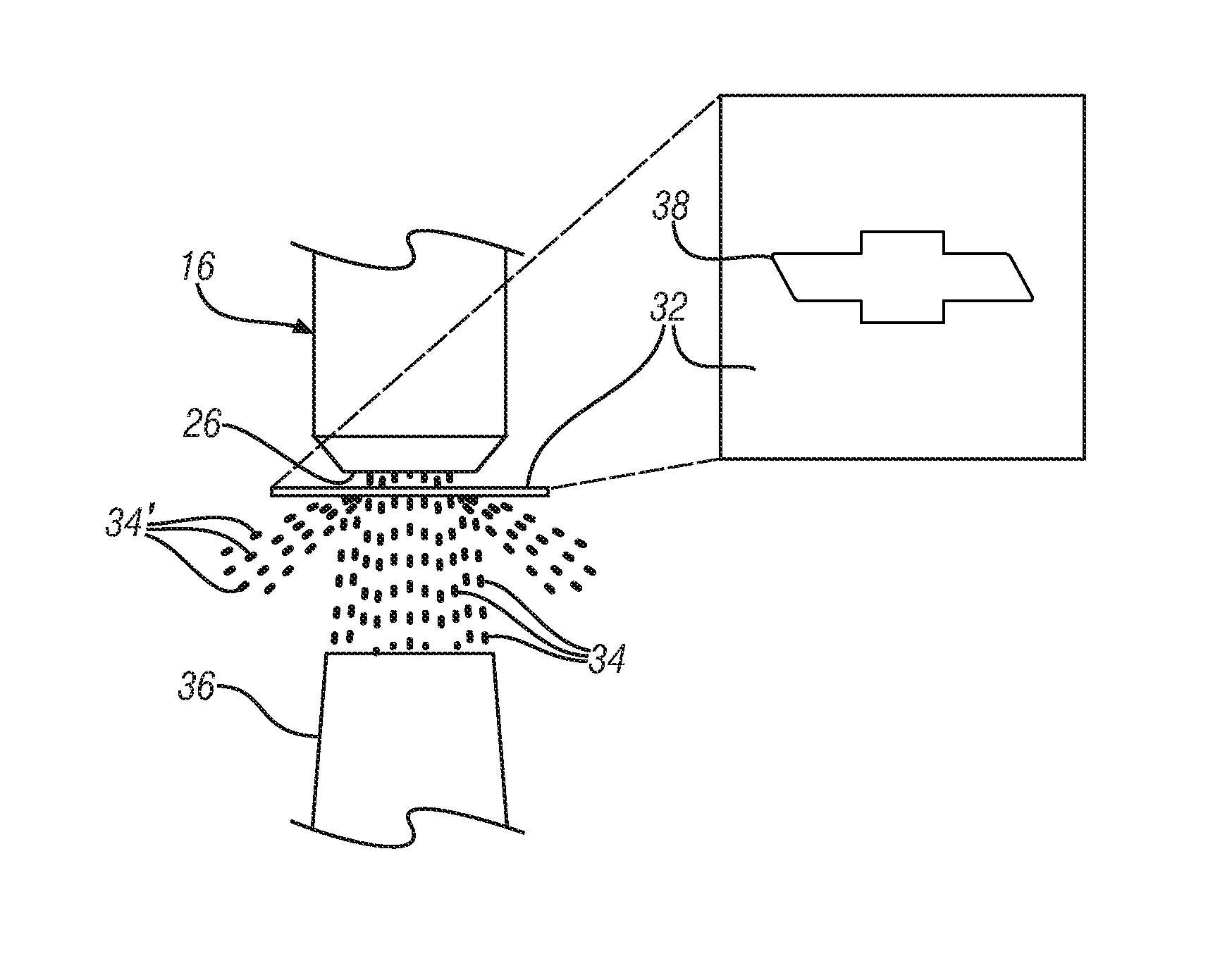

Welding electrode with contoured face

ActiveUS20080078749A1Well formedEasy alignmentTurning machine accessoriesOhmic-resistance electrodesElectrical resistance and conductanceEngineering

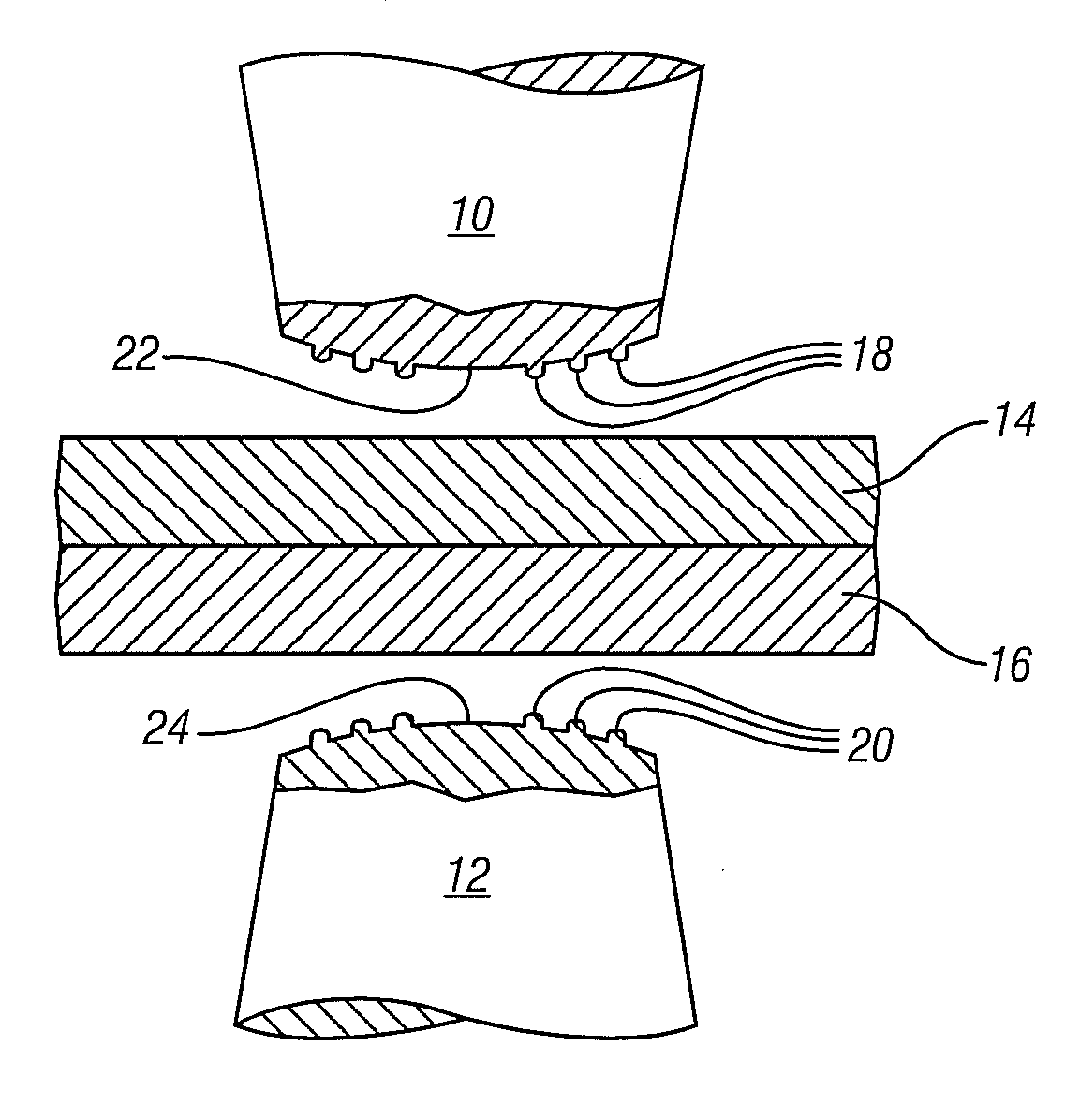

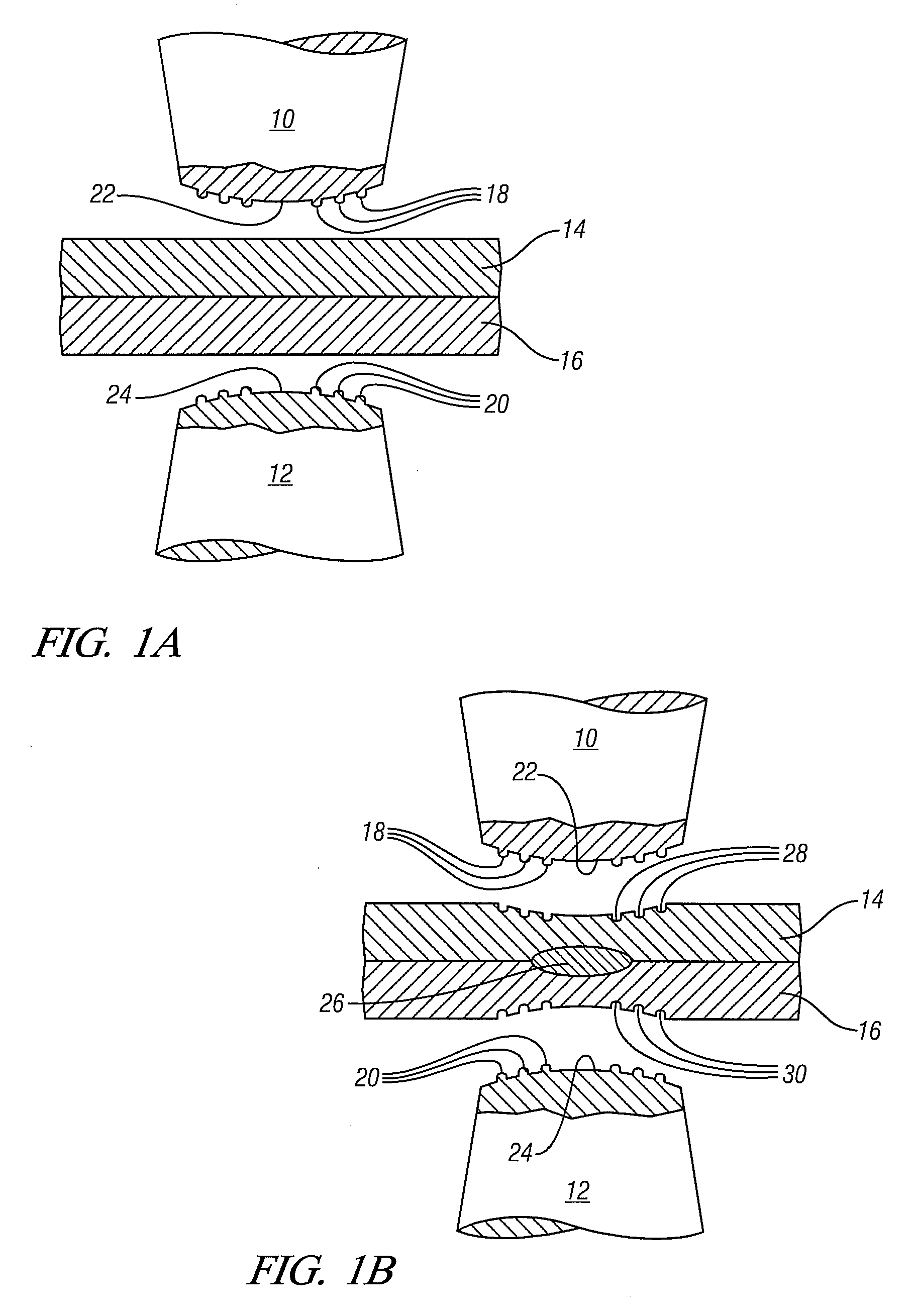

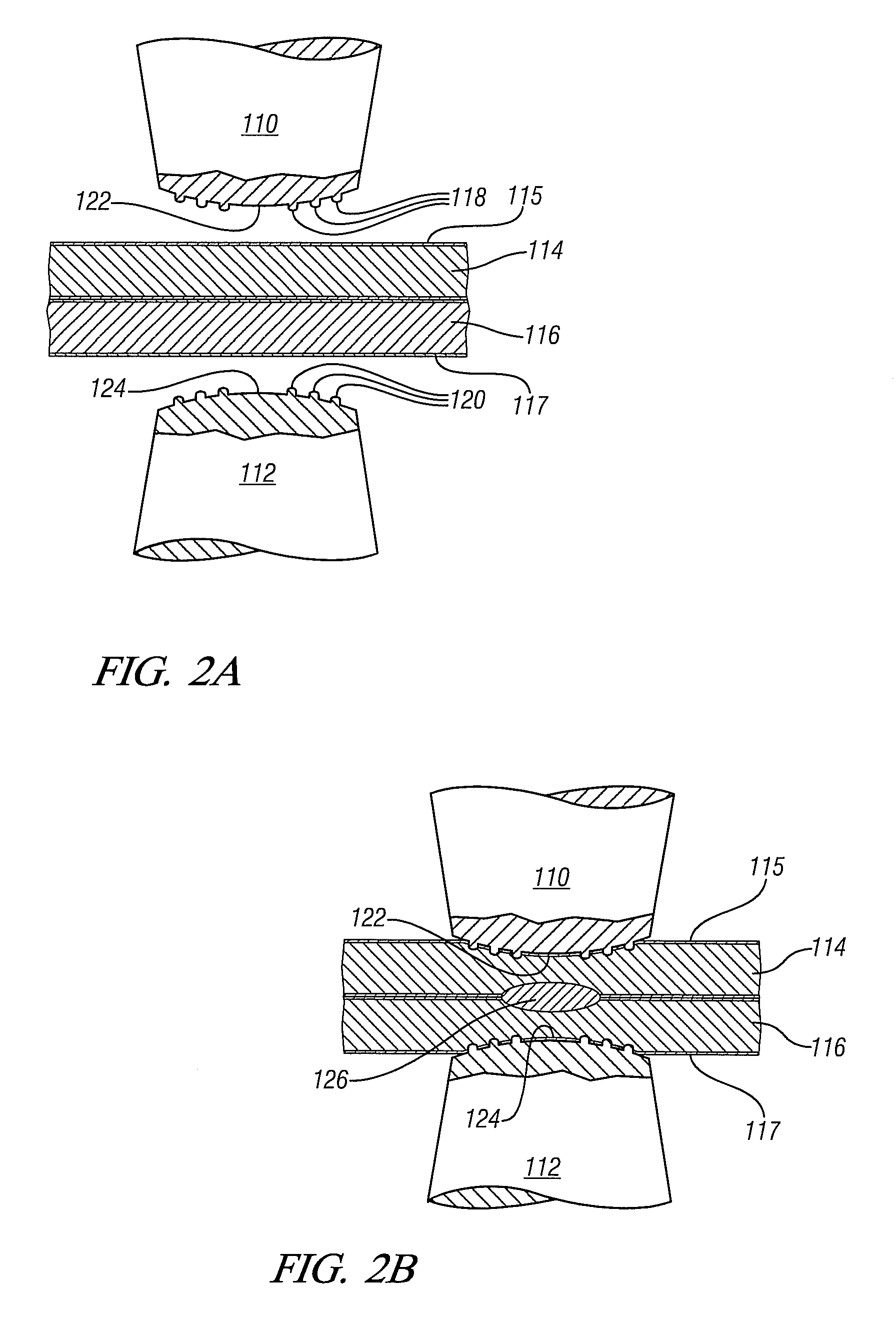

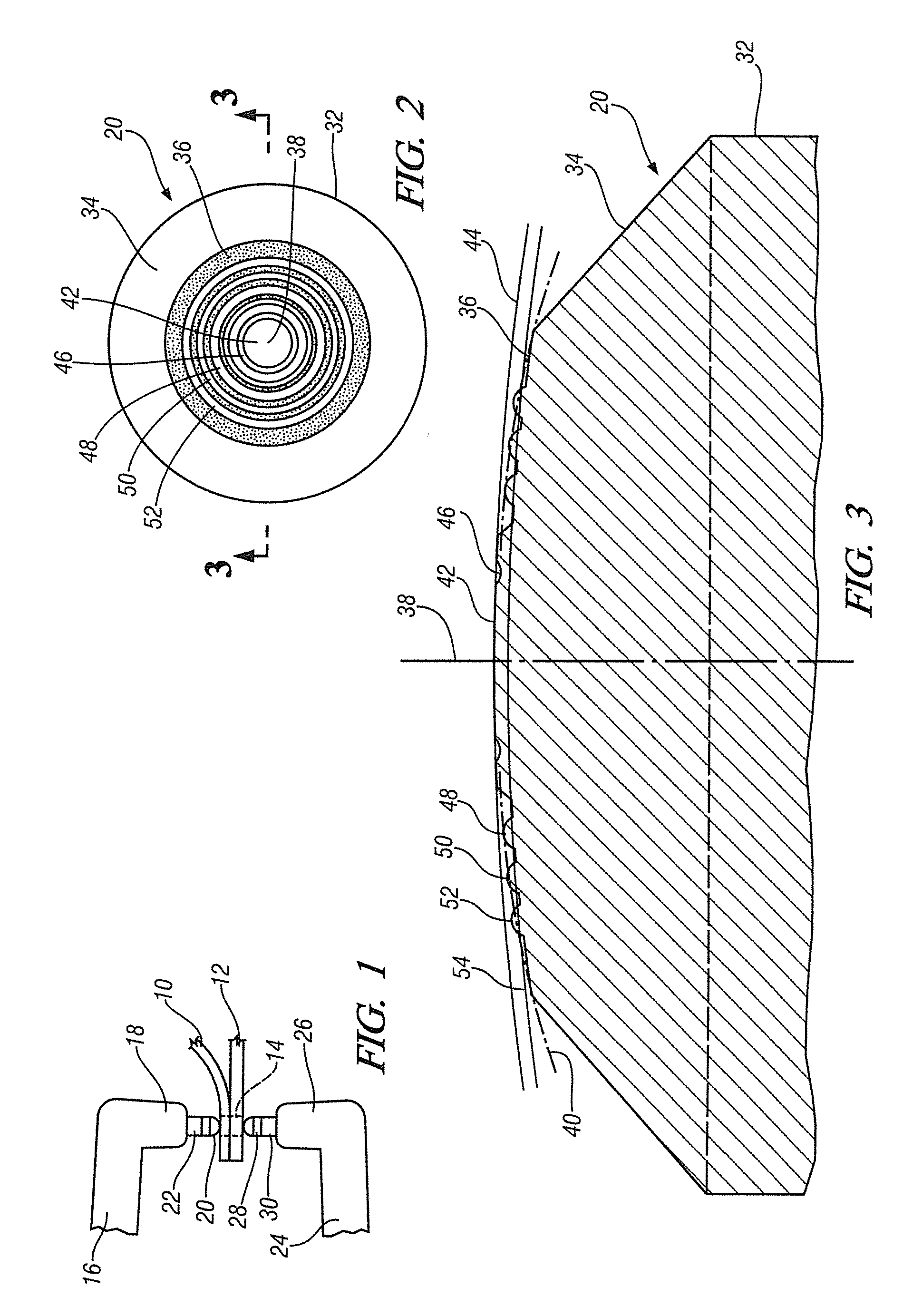

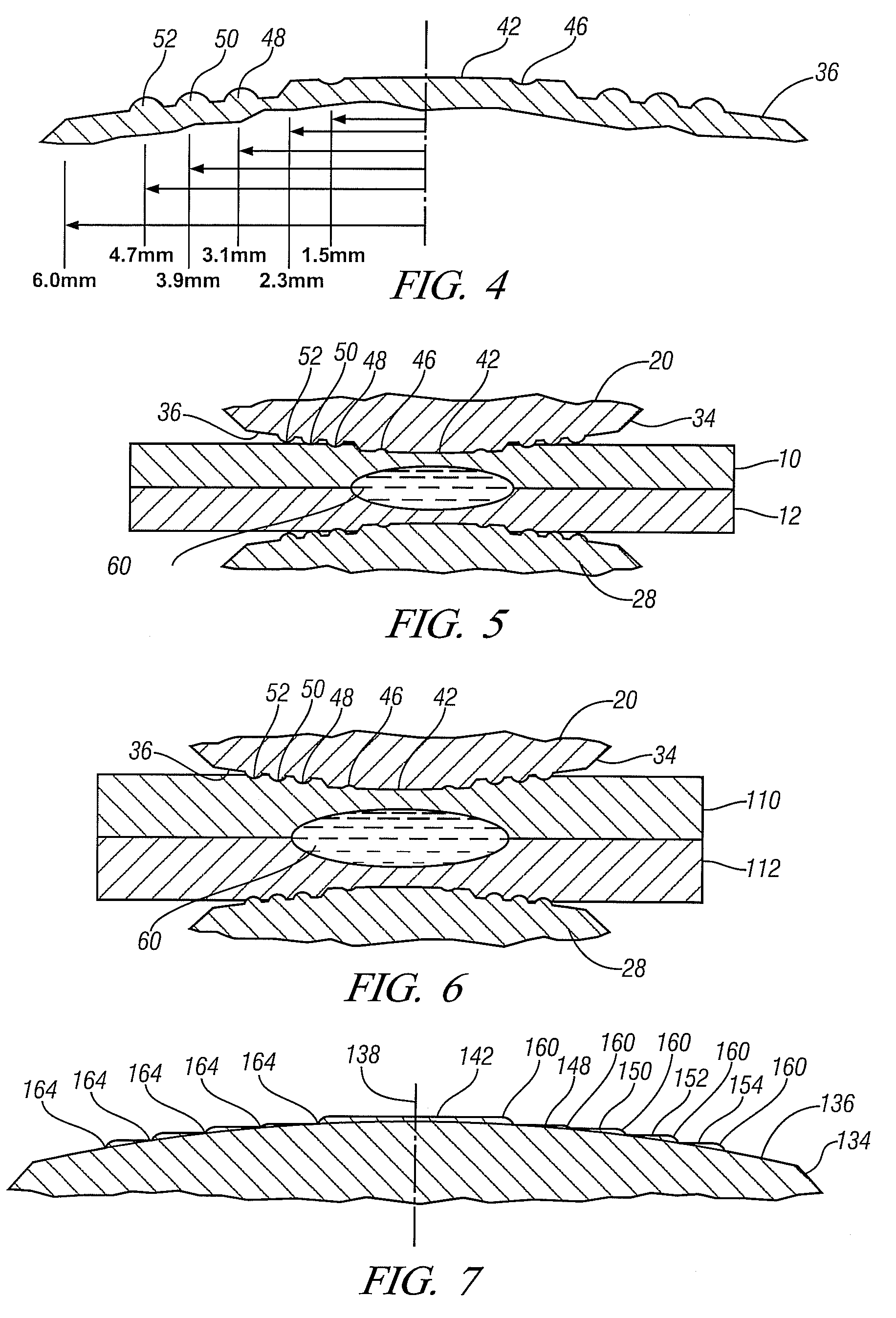

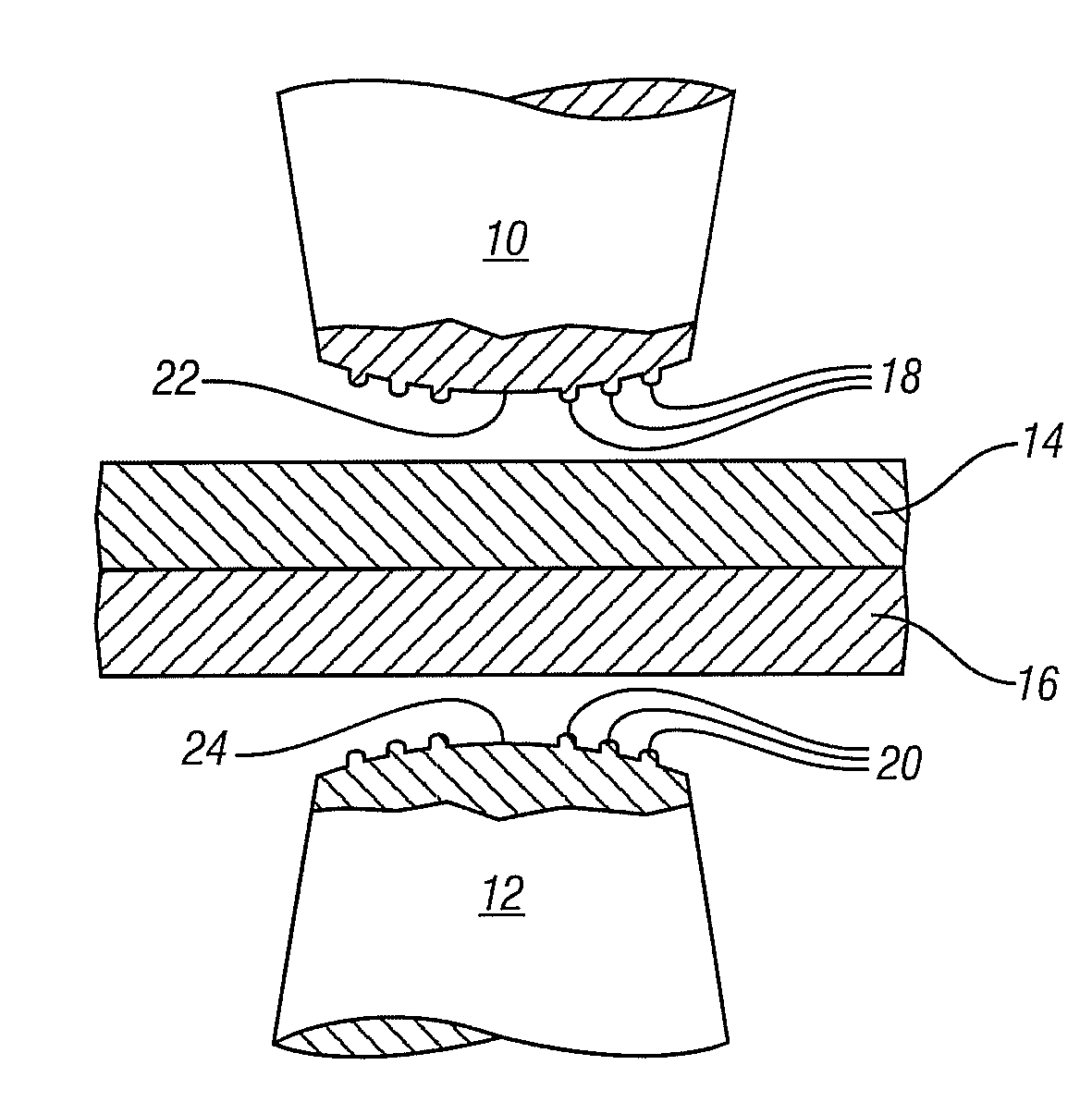

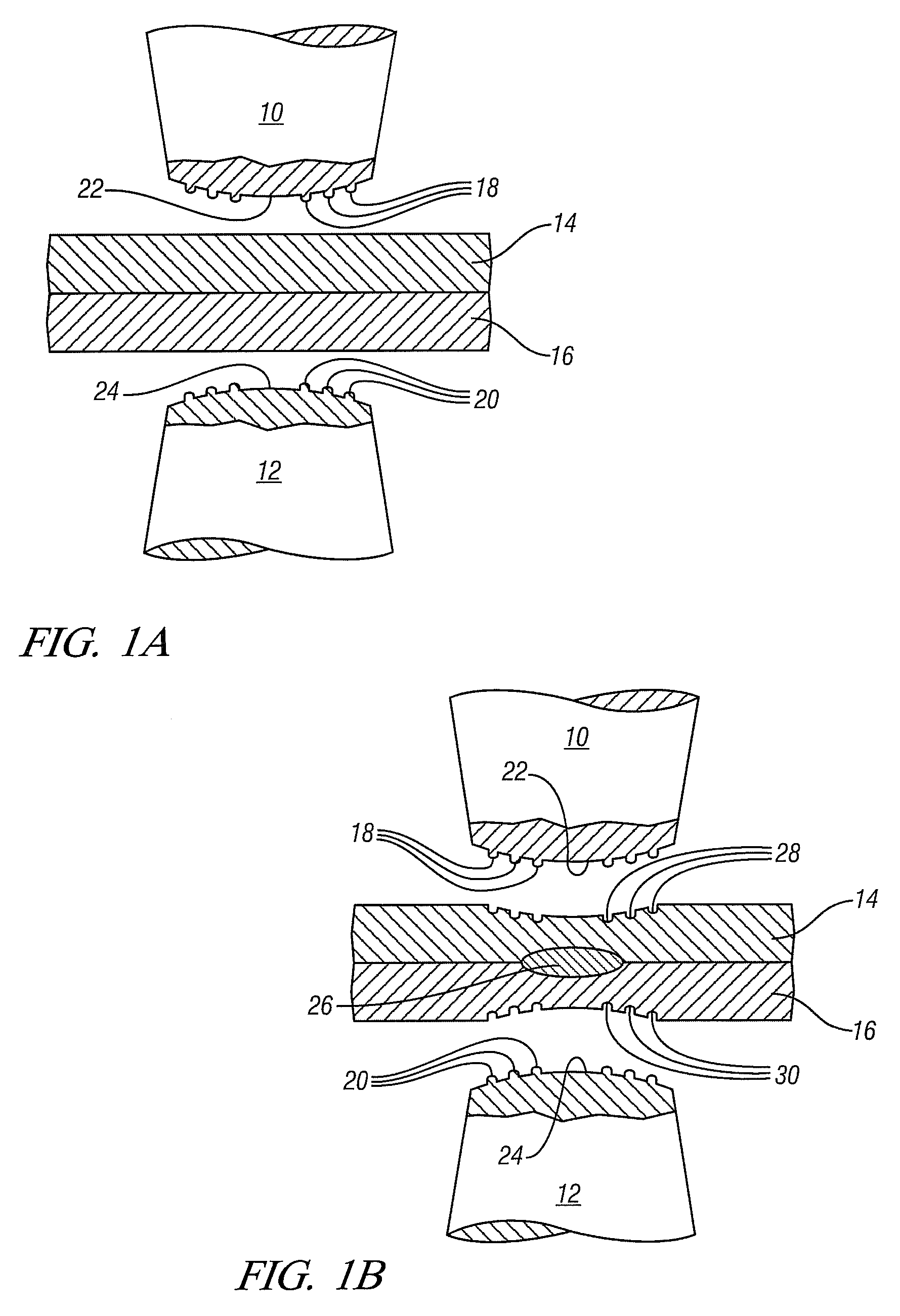

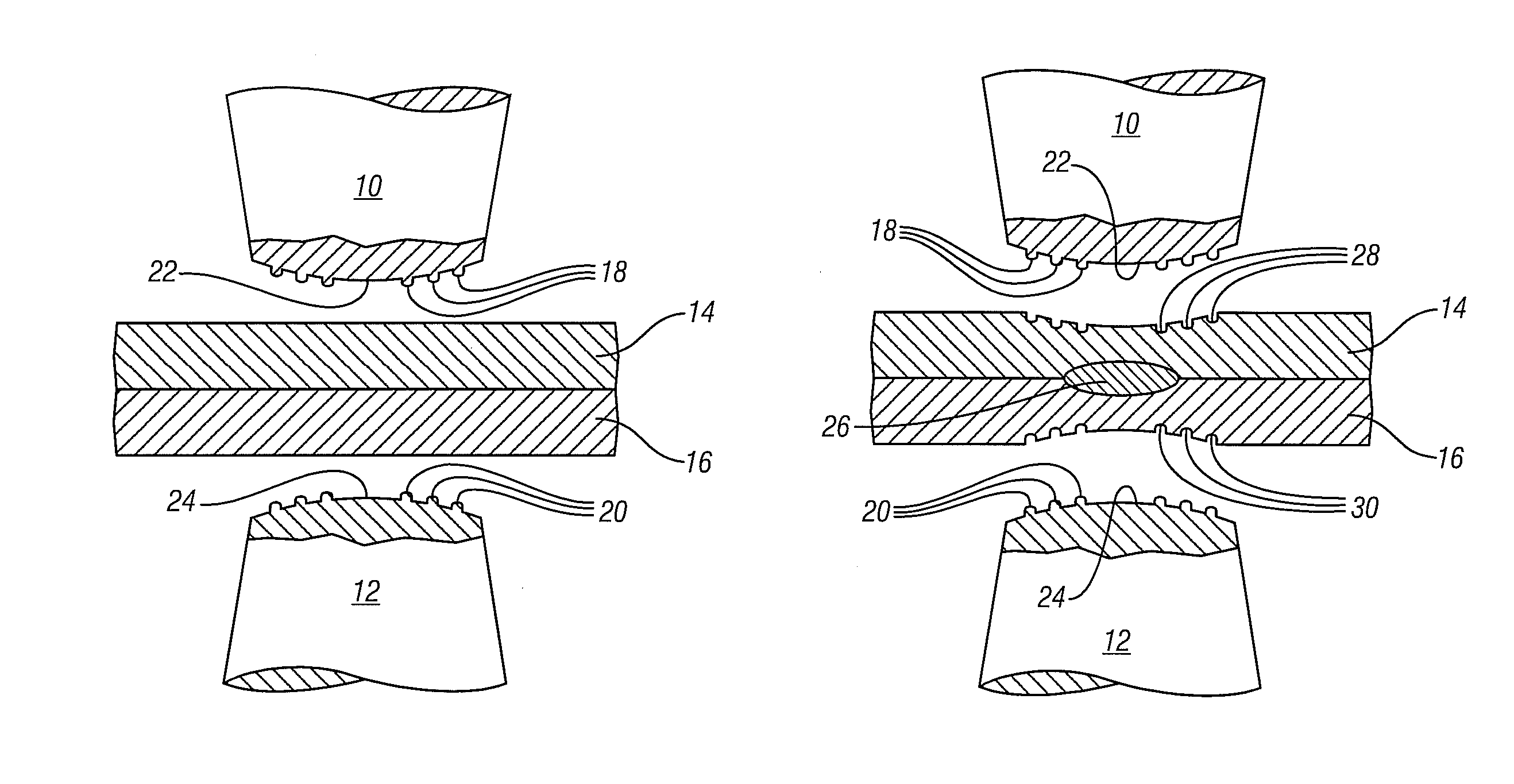

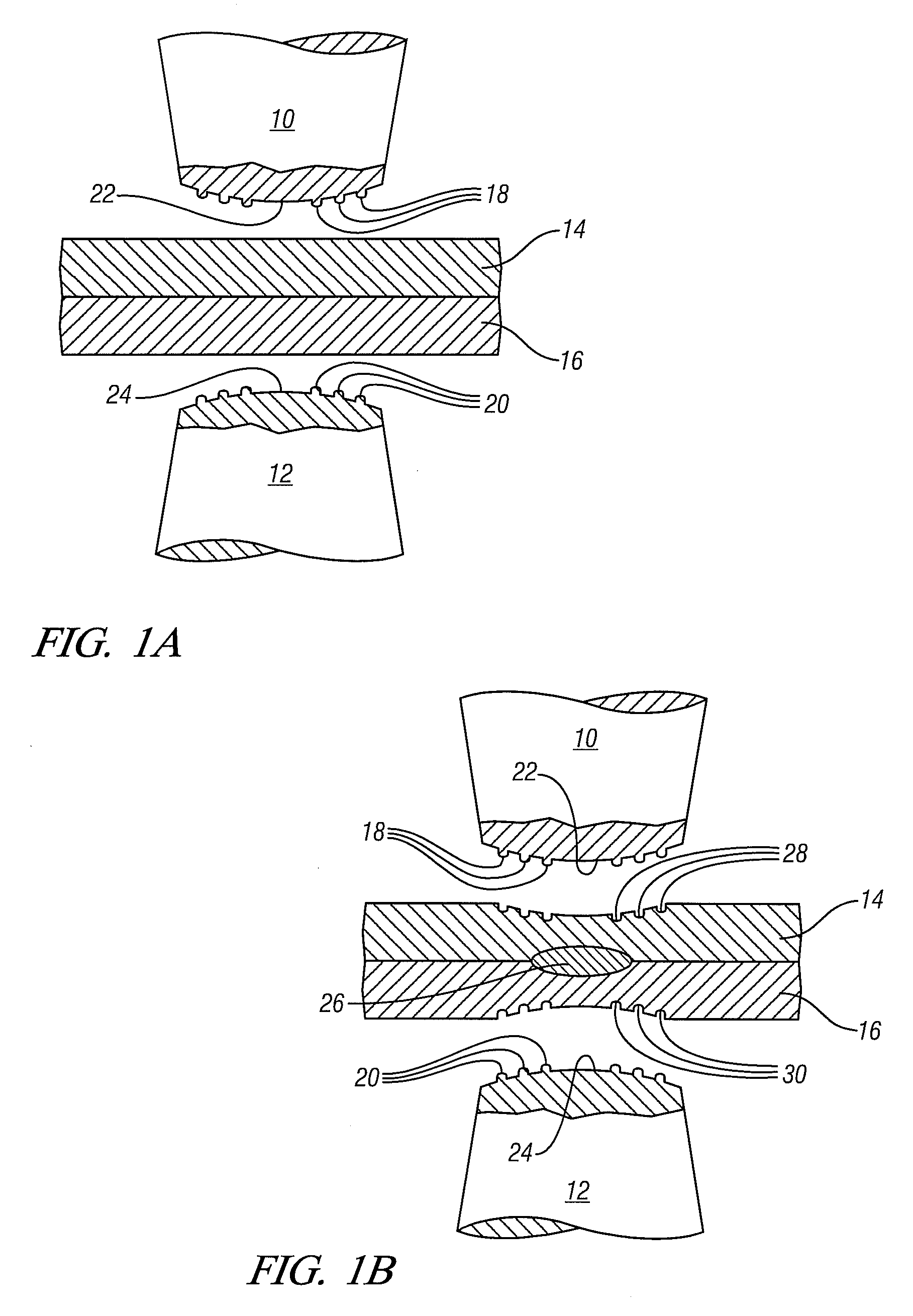

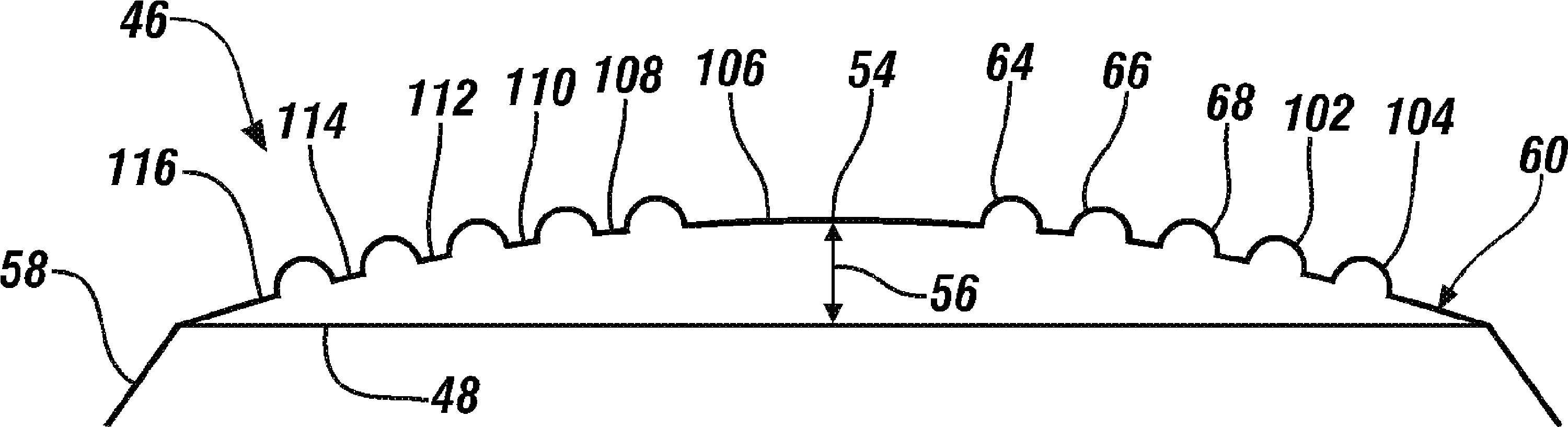

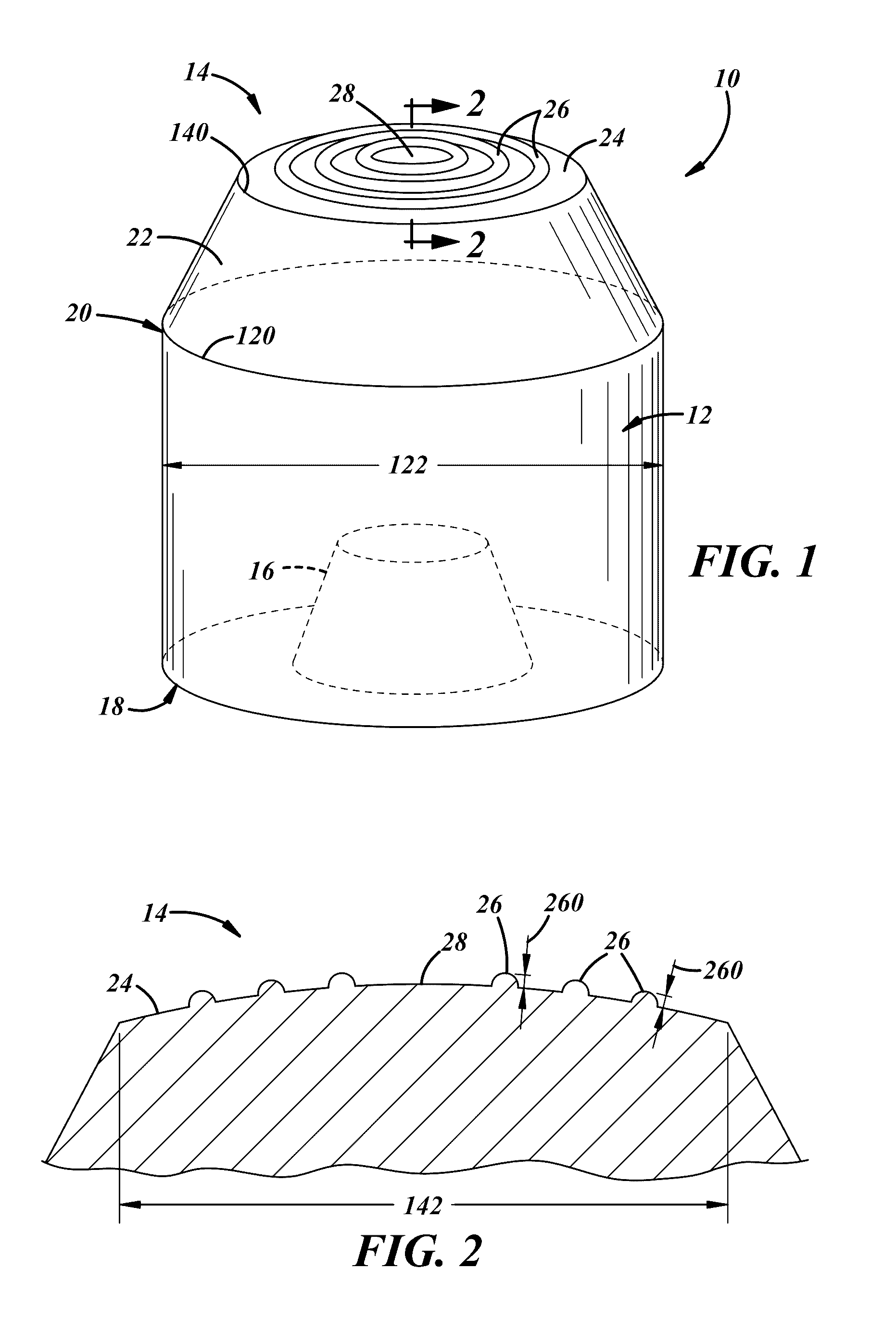

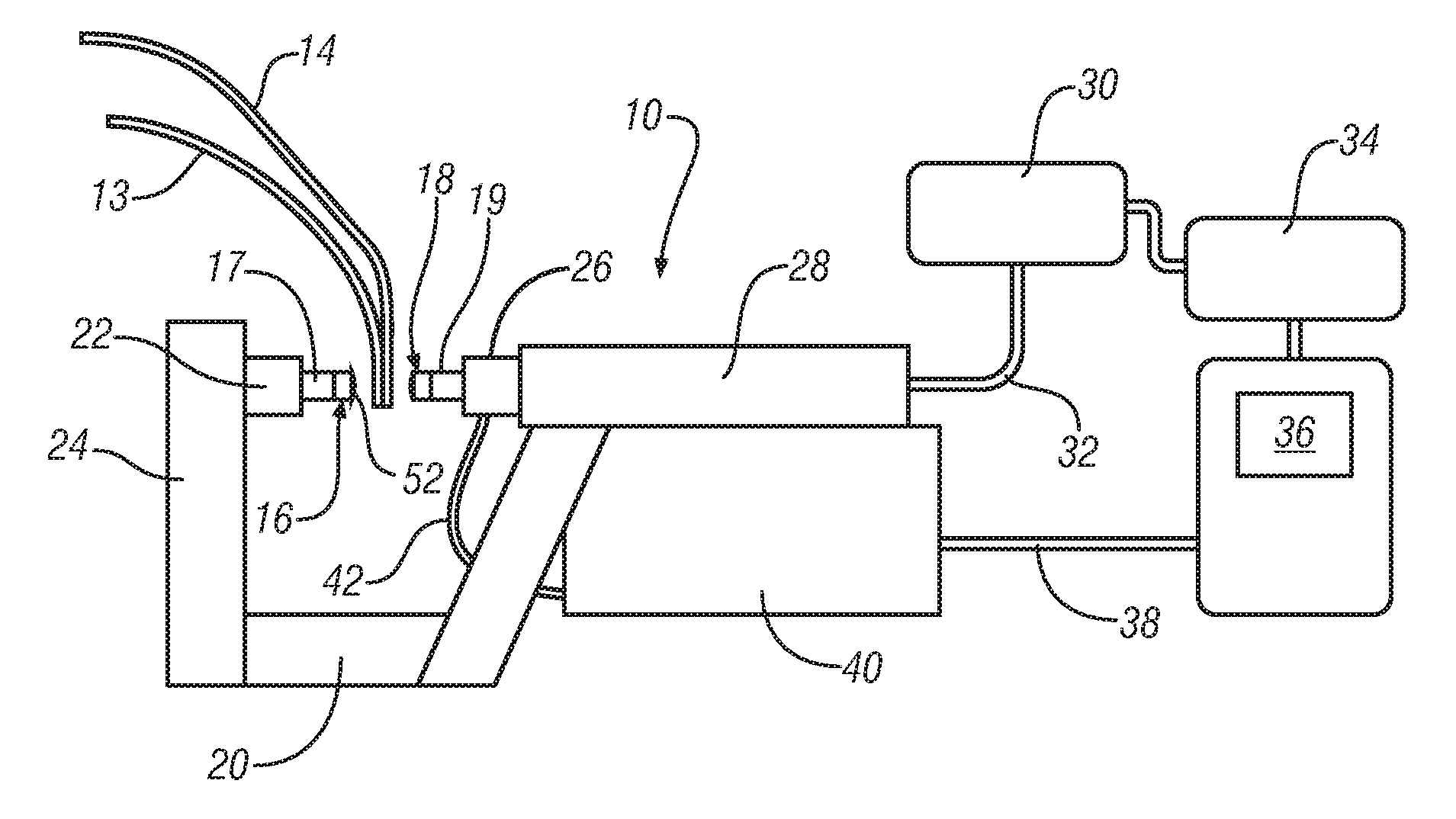

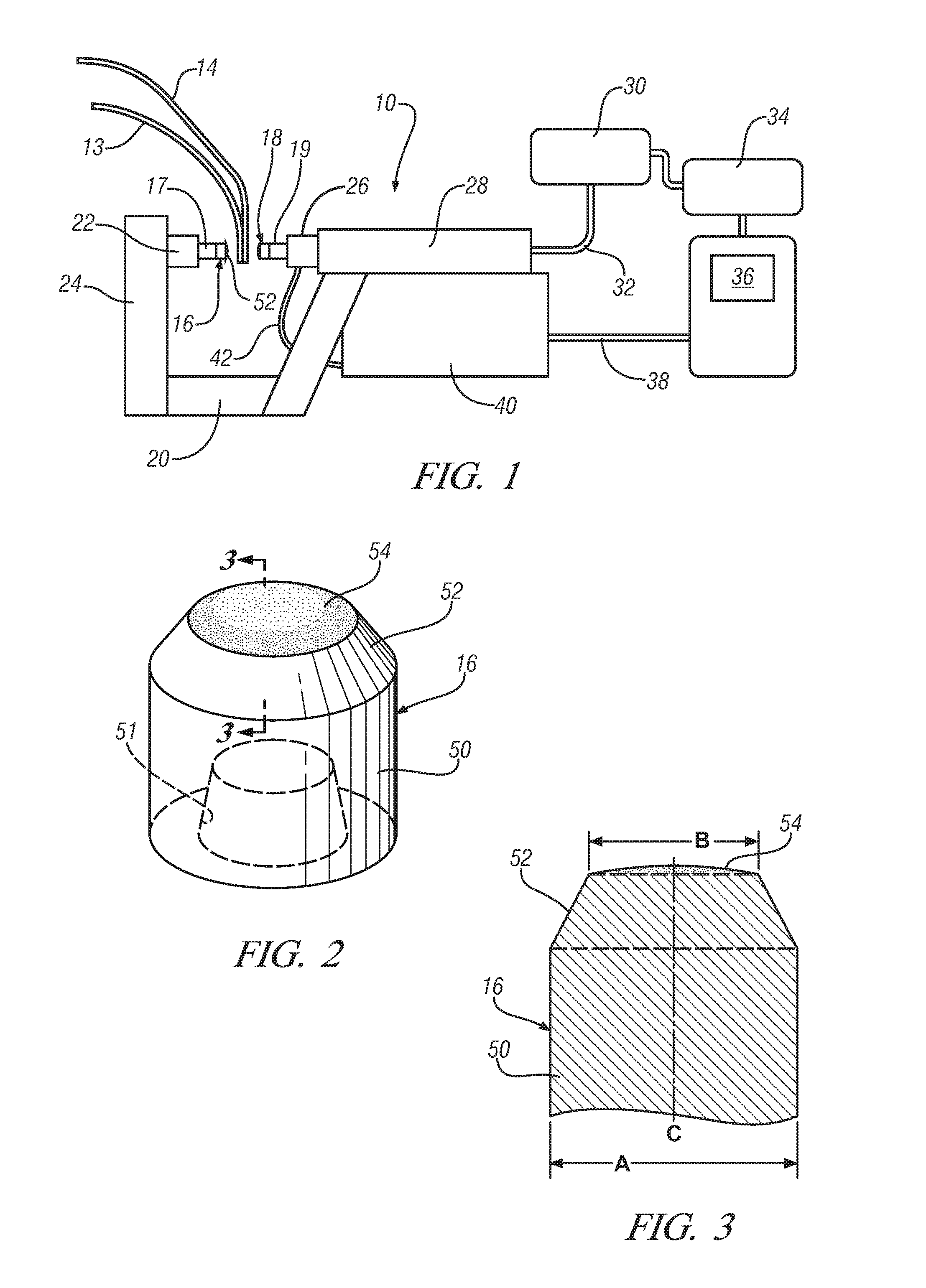

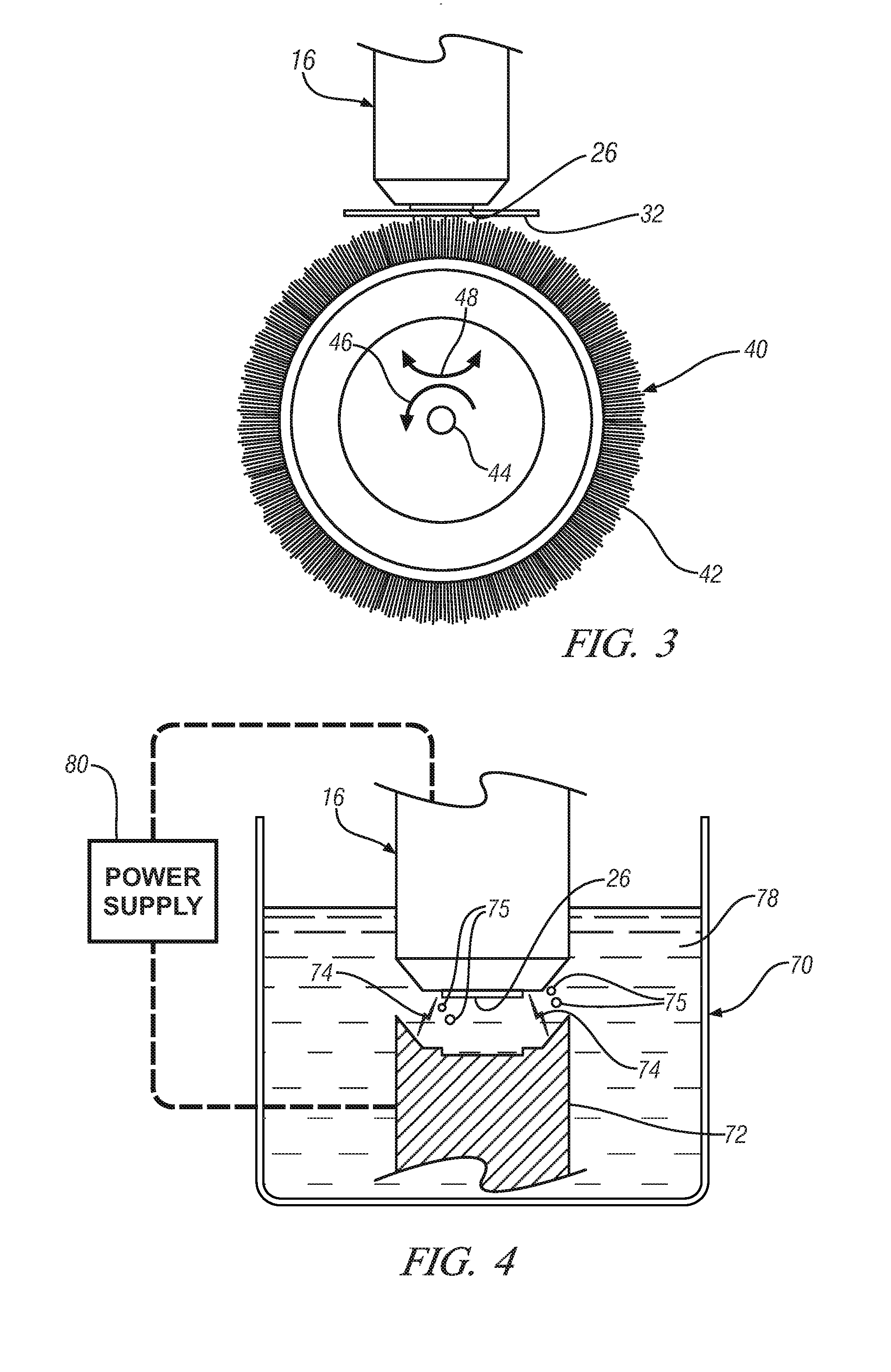

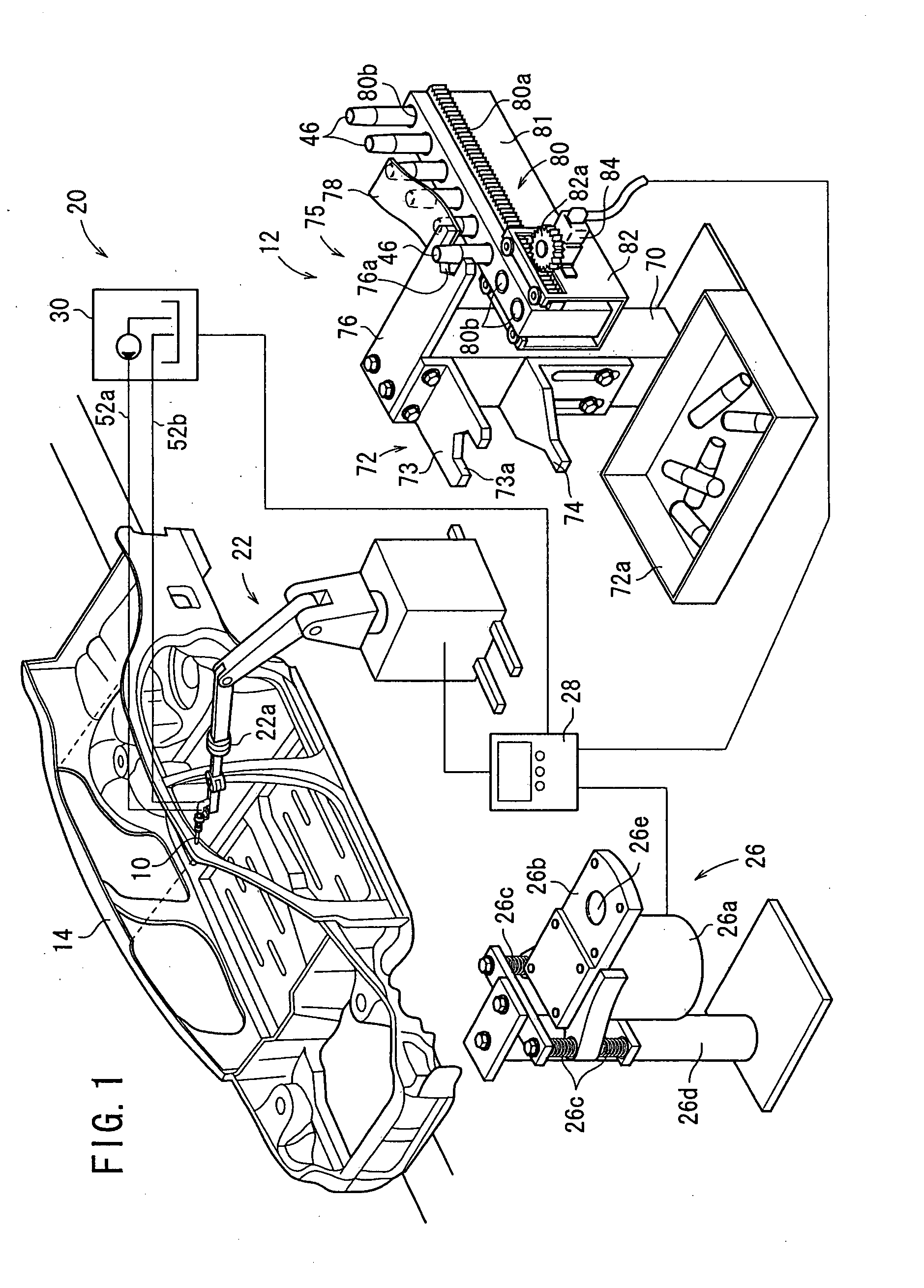

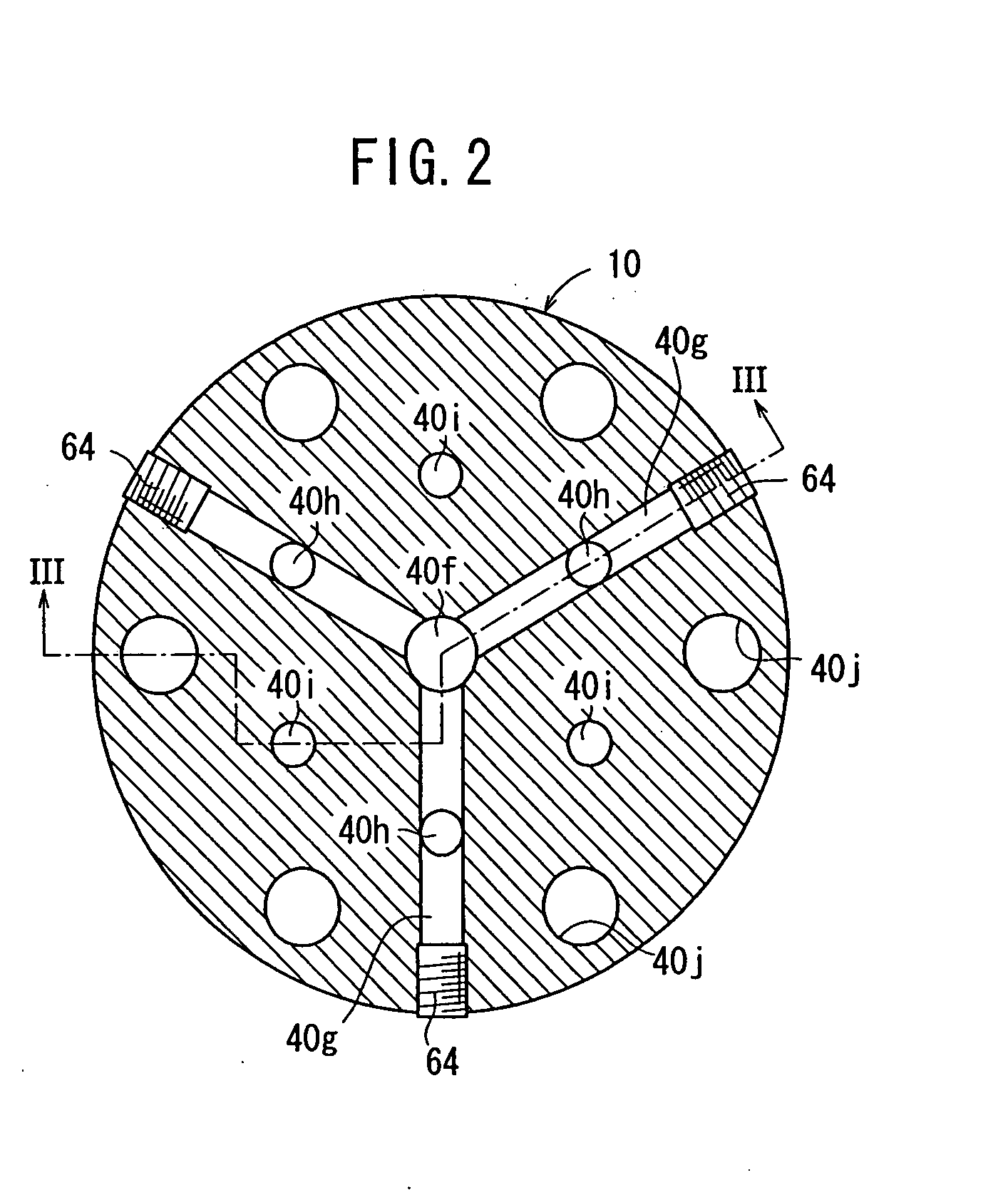

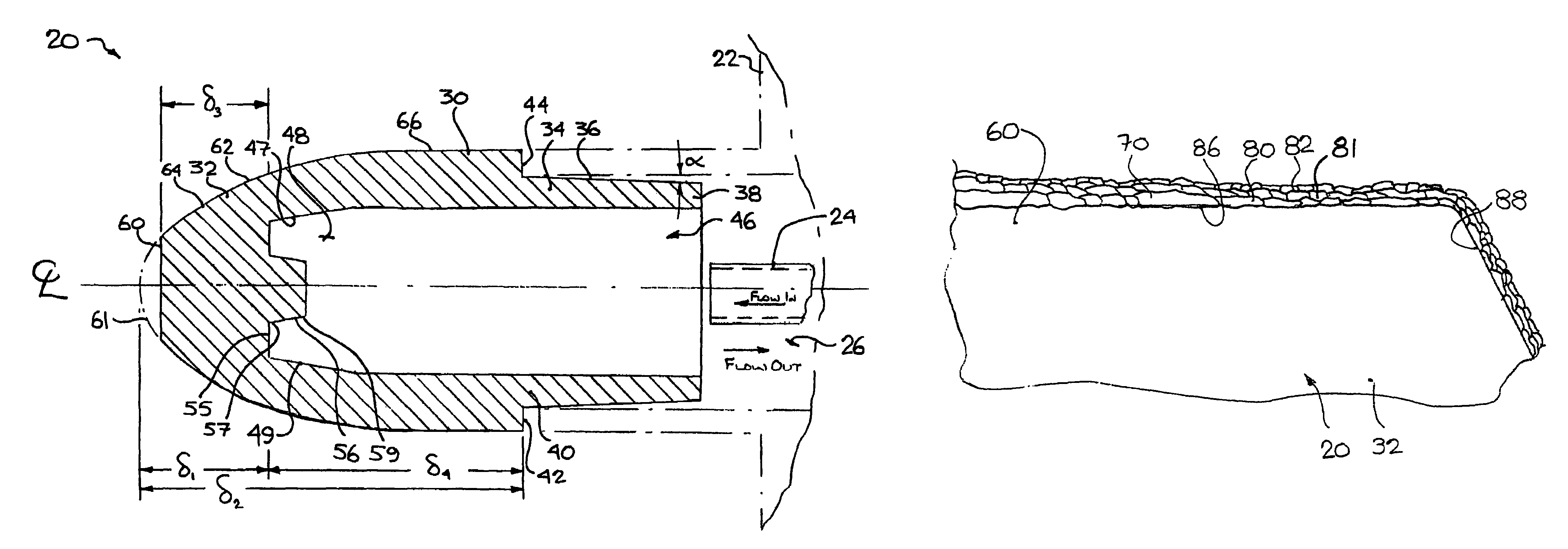

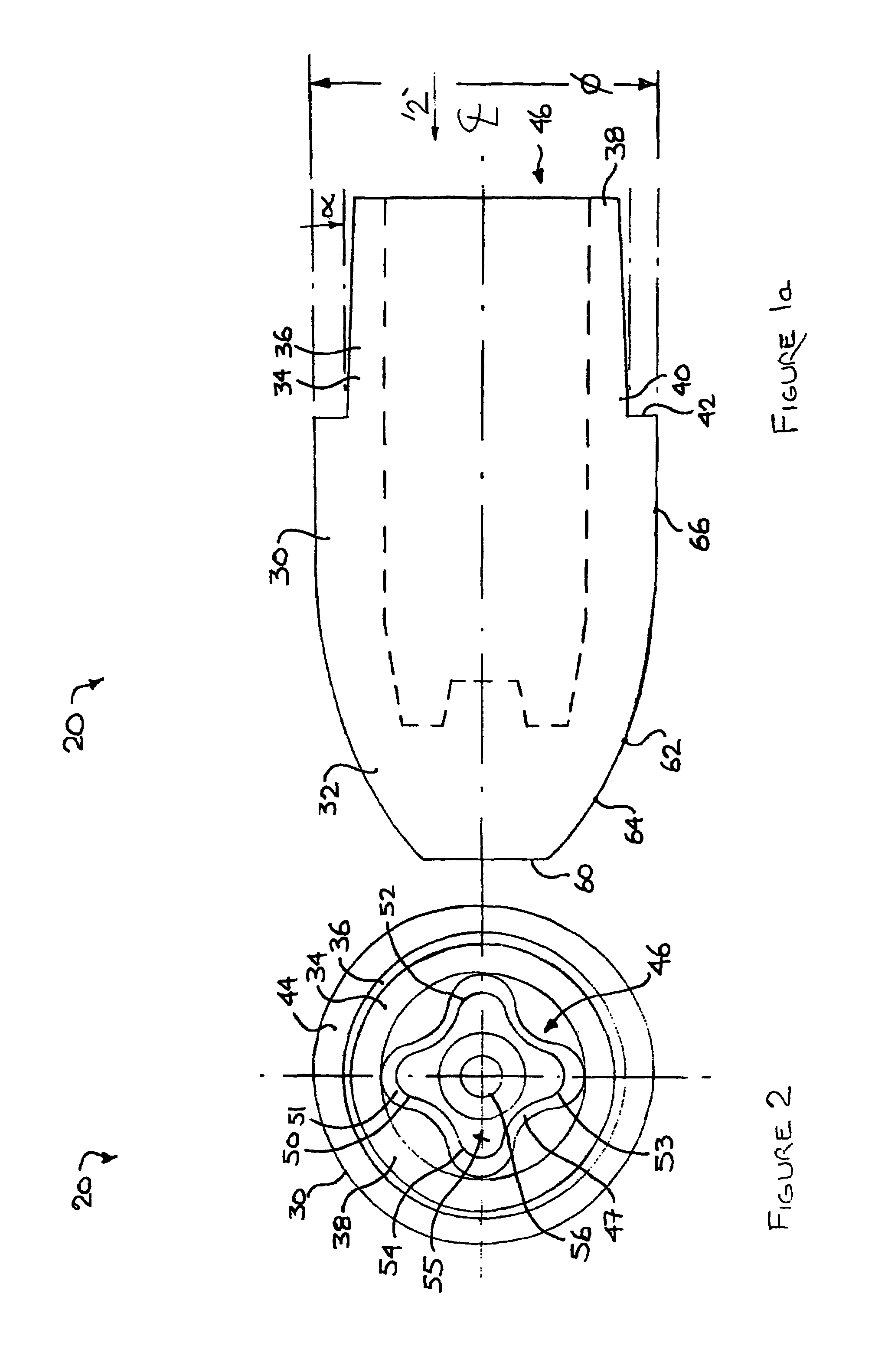

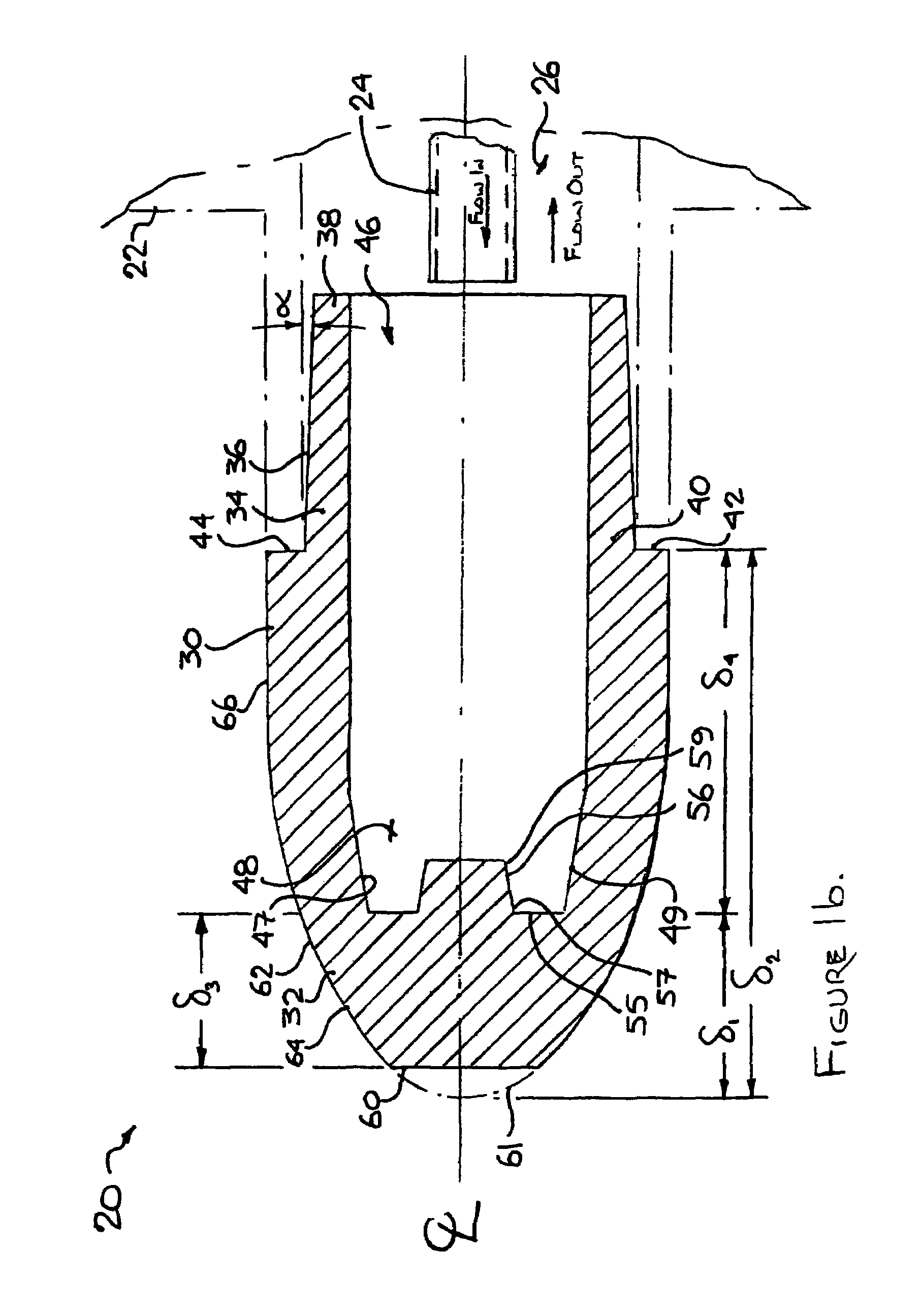

Welding electrodes with a welding face for contact with a metal surface for electrical resistance welding are provided with concentric contoured rings formed into the face. The rings may, for example, be ridges upstanding in the face or grooves depressed into the face. The contoured rings may be radially spaced with relatively flat (depending on the curvature of the face) intervening rings. When the electrode is pressed into contact with the surface of the workpiece for delivery of a welding current, the features of the concentric rings penetrate surface oxides or other conductivity barriers. When ongoing welding operations have eroded the contoured rings they may be rapidly reformed in the weld face in a surface re-dressing operation.

Owner:GM GLOBAL TECH OPERATIONS LLC

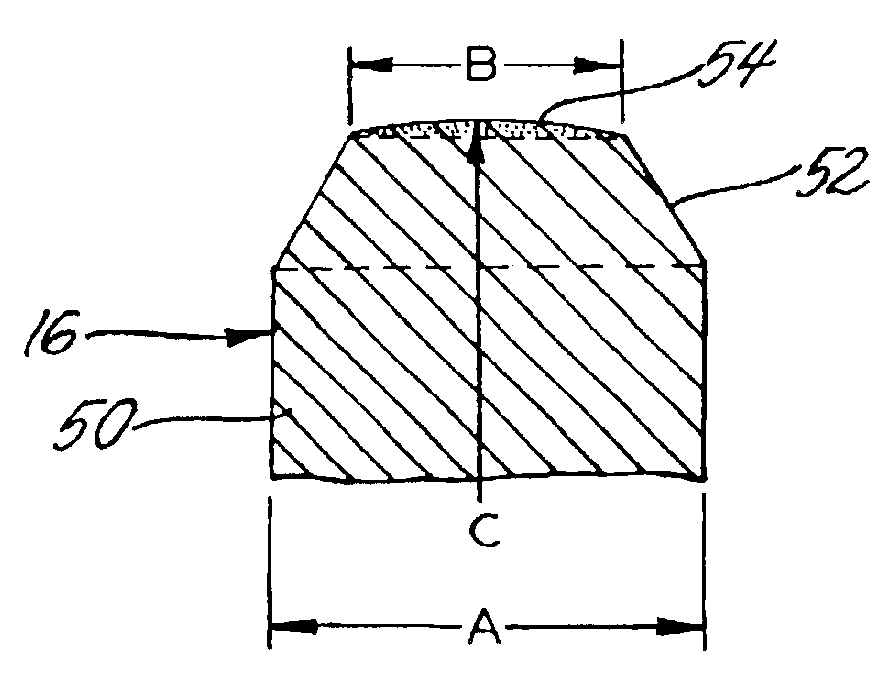

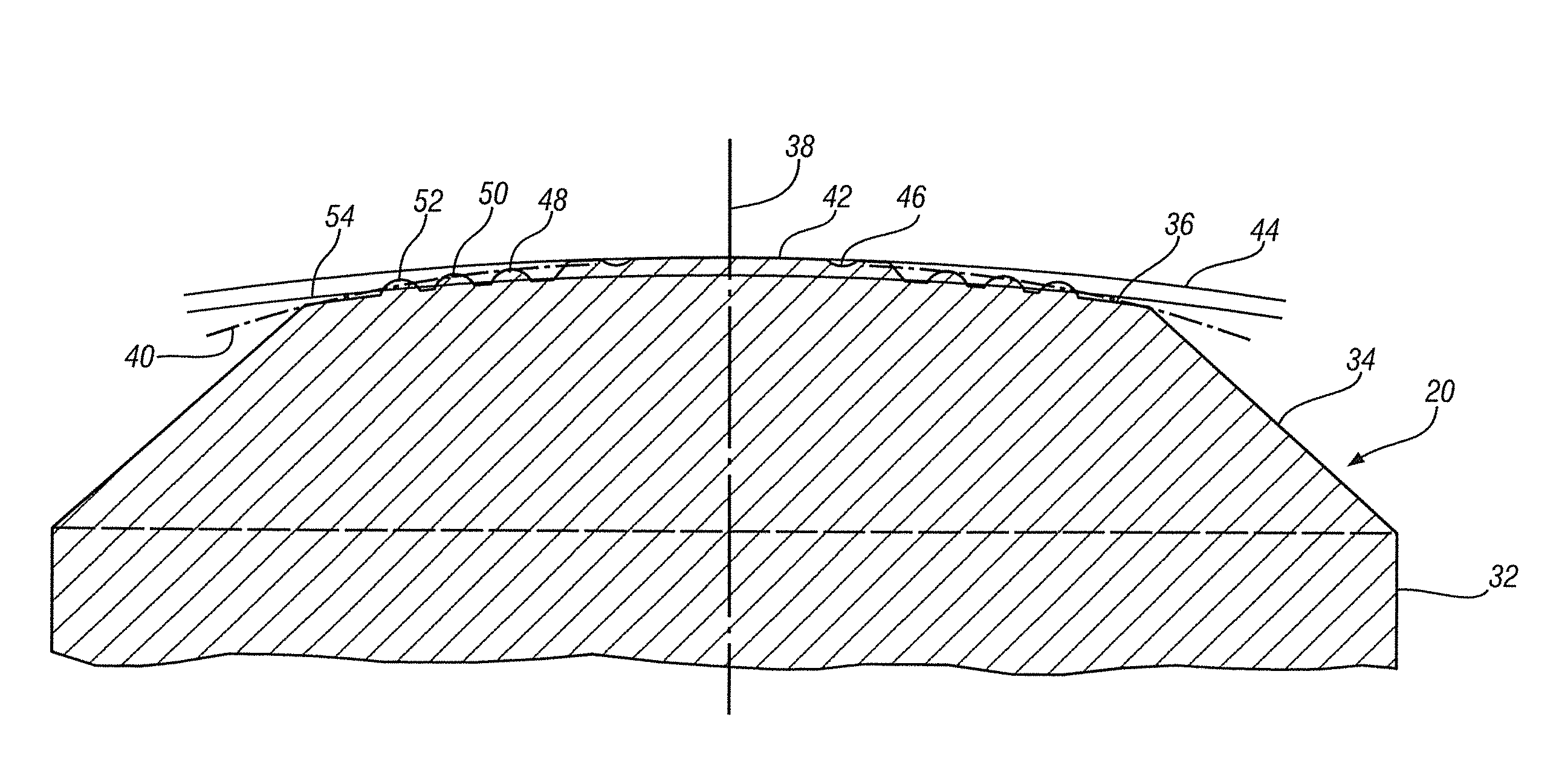

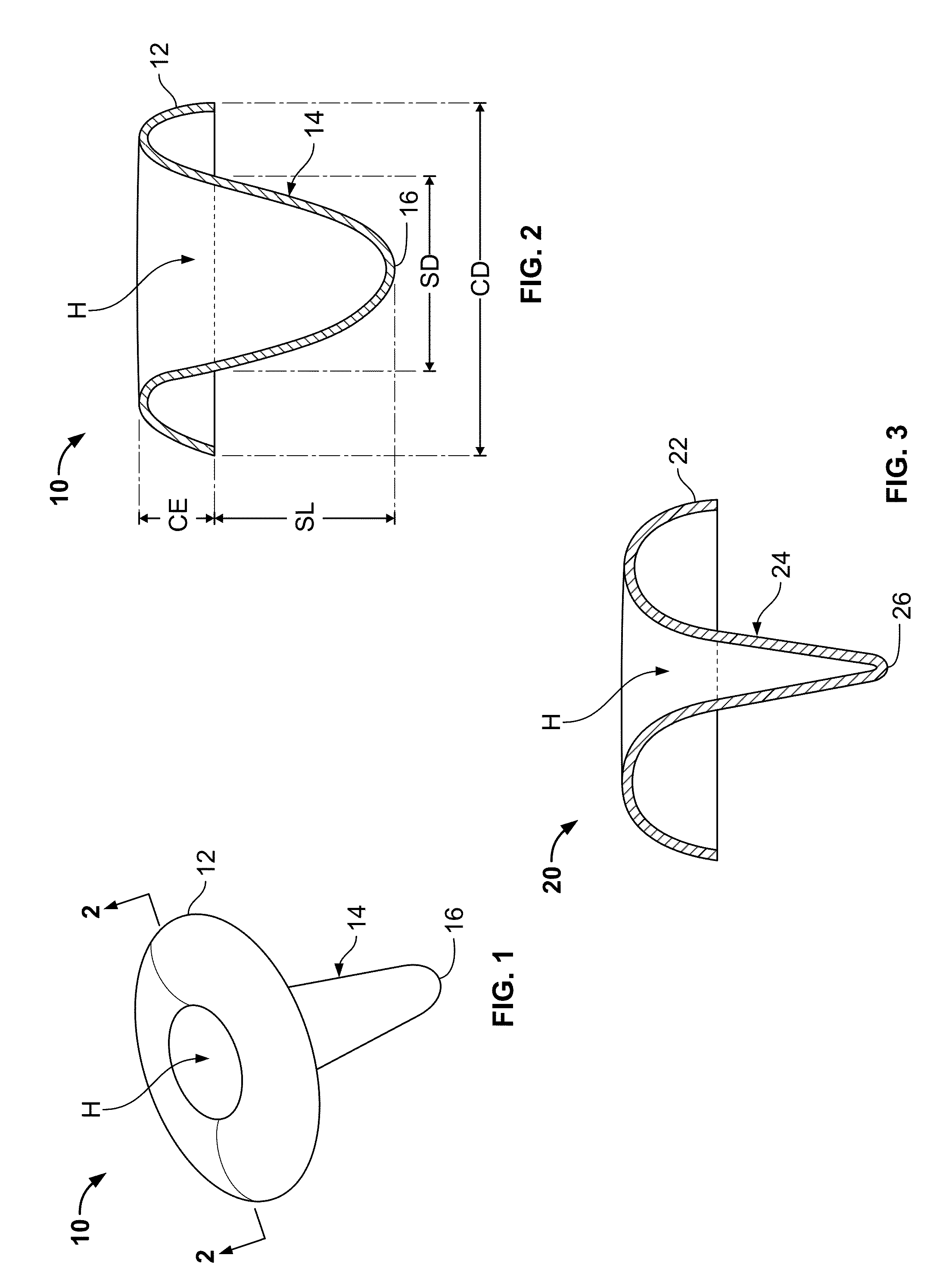

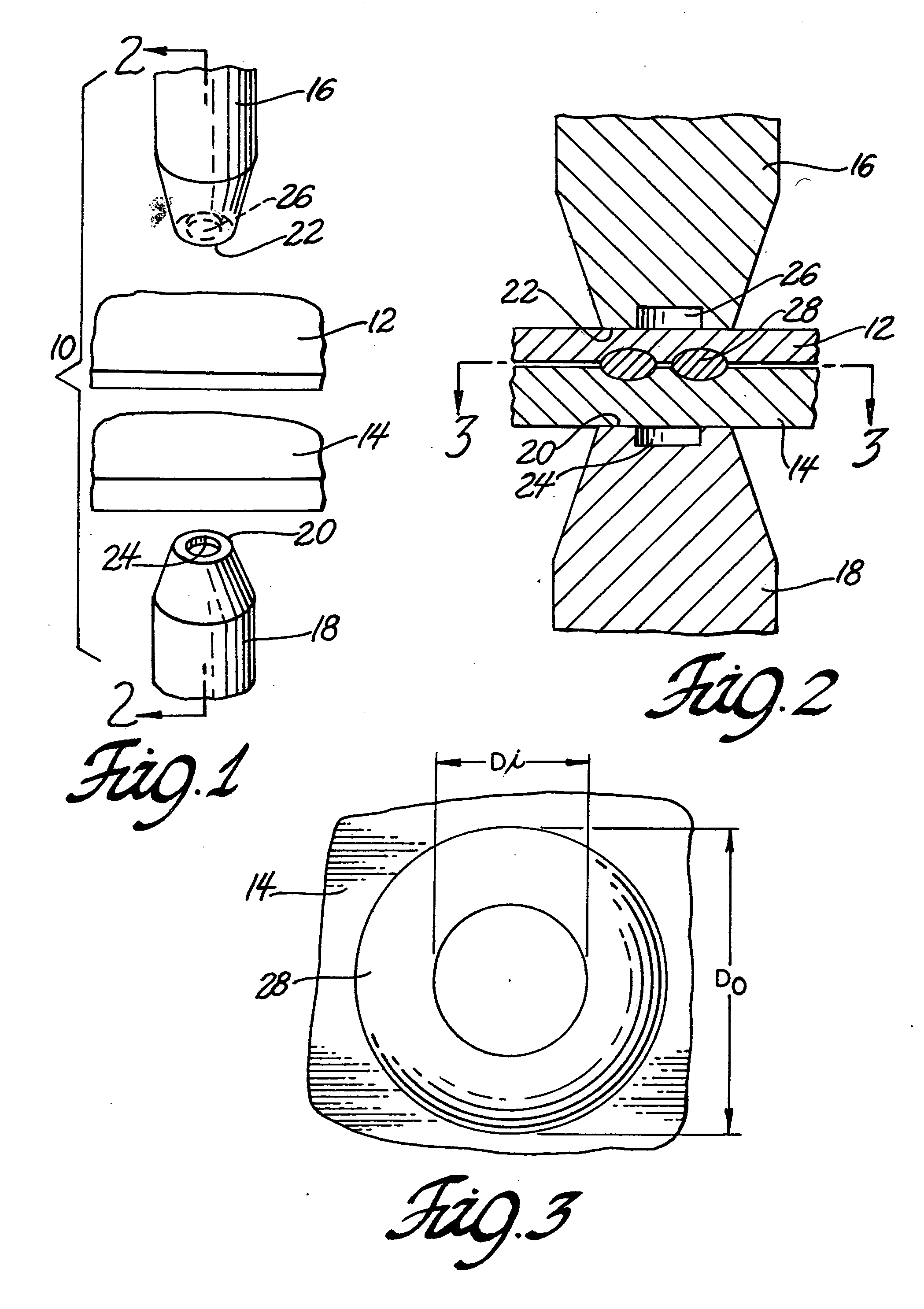

Welding electrode for aluminum sheets

InactiveUS6861609B2Good welding performanceCurvature of the face is more pronouncedOhmic-resistance electrodesPressure electrodesEngineeringAlloy

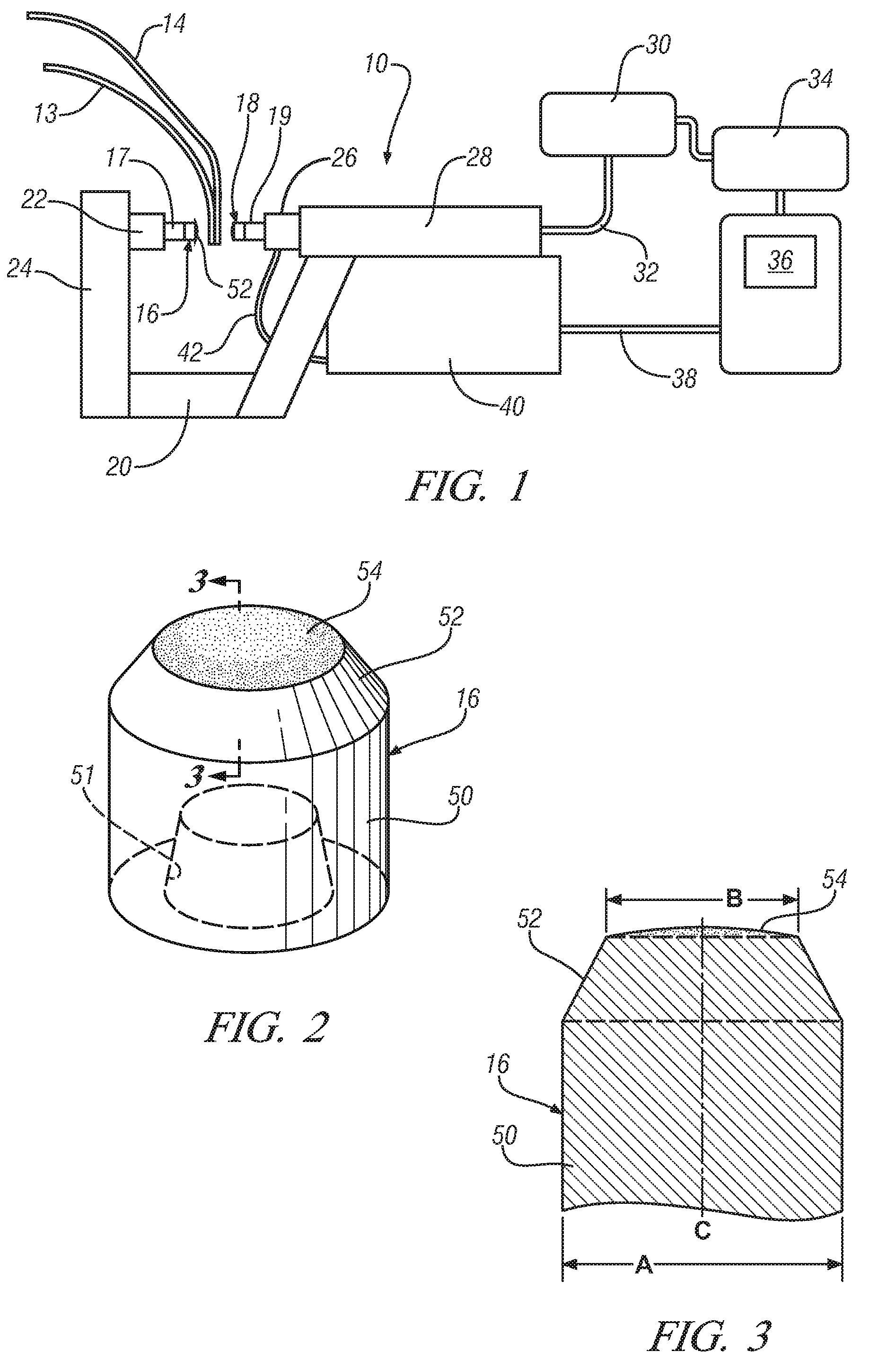

A design of copper welding electrode is disclosed. The electrode can be used in successive spot welding operations on assembled aluminum alloy sheet parts of widely varying thicknesses, e.g., from 0.9 to 4+ mm. The electrode has a round body terminating in a truncated cone with a crowned face. The face has a diameter of about eleven millimeters up to the diameter of the body and the radius of the crowned face is about twenty to thirty millimeters. The dimensions and shape of the electrode provide robust welding performances despite varying part thicknesses and off angle electrode positioning, and the textured surface provides good electrical contact.

Owner:GM GLOBAL TECH OPERATIONS LLC

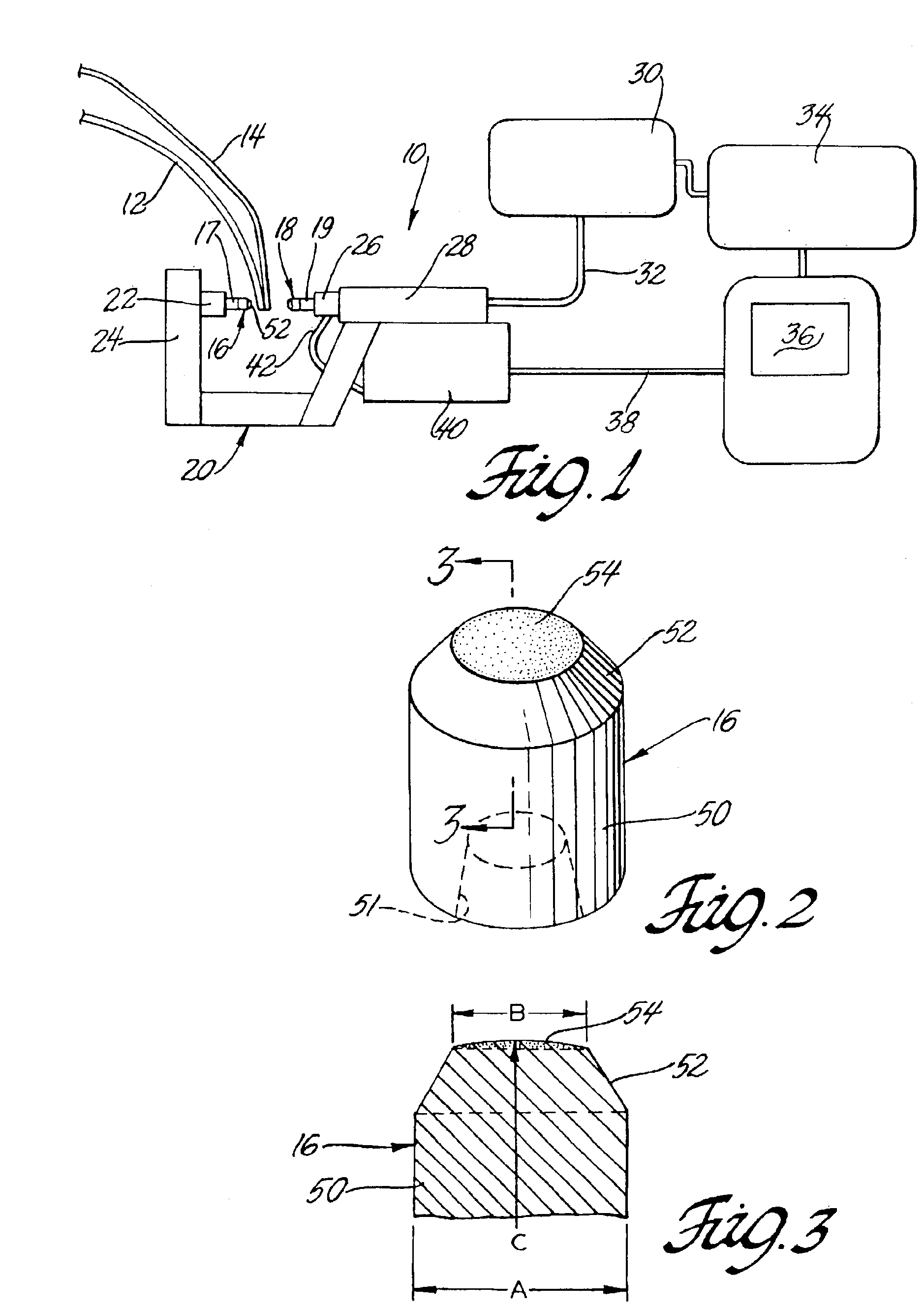

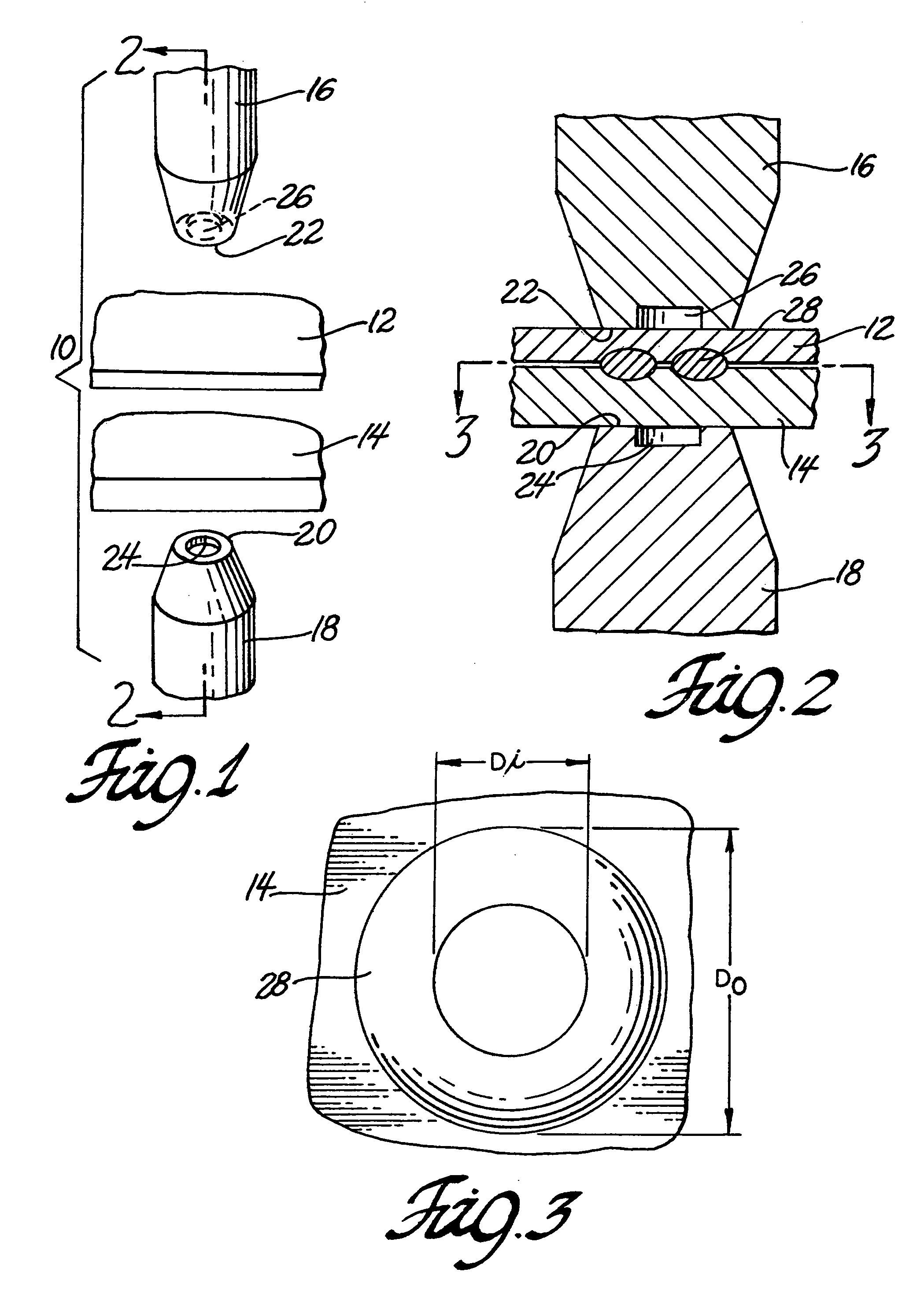

Weld electrode for attractive weld appearance

ActiveUS20090255908A1High thermal and electrical resistivityHigh melting pointPressure electrodesSheet steelSpot welding

Weld faces of electrodes for resistance spot welding are formed with a suitable area of protrusions and / or intrusions. The size, shape, and elevation or depths of the protrusions or intrusions are determined for the formation of suitable spot welds in and between metal workpieces such as aluminum or steel panels for vehicle bodies. The protrusions or intrusions are also conceived and used to form an image on at least a visible surface of the welded article to produce an attractive appearance on the surface of the welded sheet.

Owner:GM GLOBAL TECH OPERATIONS LLC

Weld electrode for attractive weld appearance

ActiveUS8222560B2High thermal and electrical resistivityHigh melting pointOhmic-resistance electrodesPressure electrodesSpot weldingVisible surface

Weld faces of electrodes for resistance spot welding are formed with a suitable area of protrusions and / or intrusions. The size, shape, and elevation or depths of the protrusions or intrusions are determined for the formation of suitable spot welds in and between metal workpieces such as aluminum or steel panels for vehicle bodies. The protrusions or intrusions are also conceived and used to form an image on at least a visible surface of the welded article to produce an attractive appearance on the surface of the welded sheet.

Owner:GM GLOBAL TECH OPERATIONS LLC

Electrode for spot welding

ActiveUS8525066B2Readily re-shapedOhmic-resistance electrodesWelding/cutting media/materialsSheet steelSpot welding

Owner:GM GLOBAL TECH OPERATIONS LLC

Welding electrode with contoured face

Owner:GM GLOBAL TECH OPERATIONS LLC

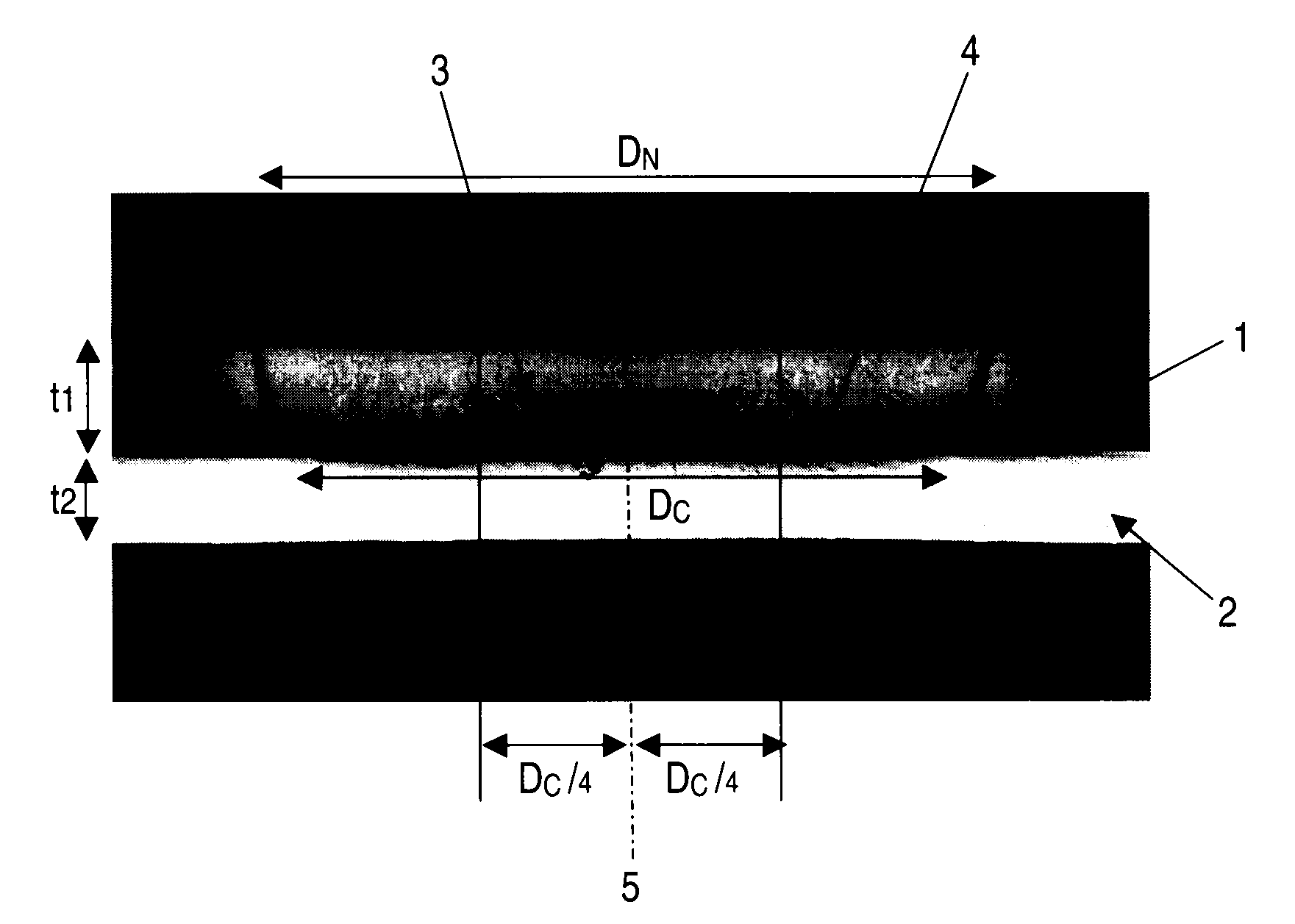

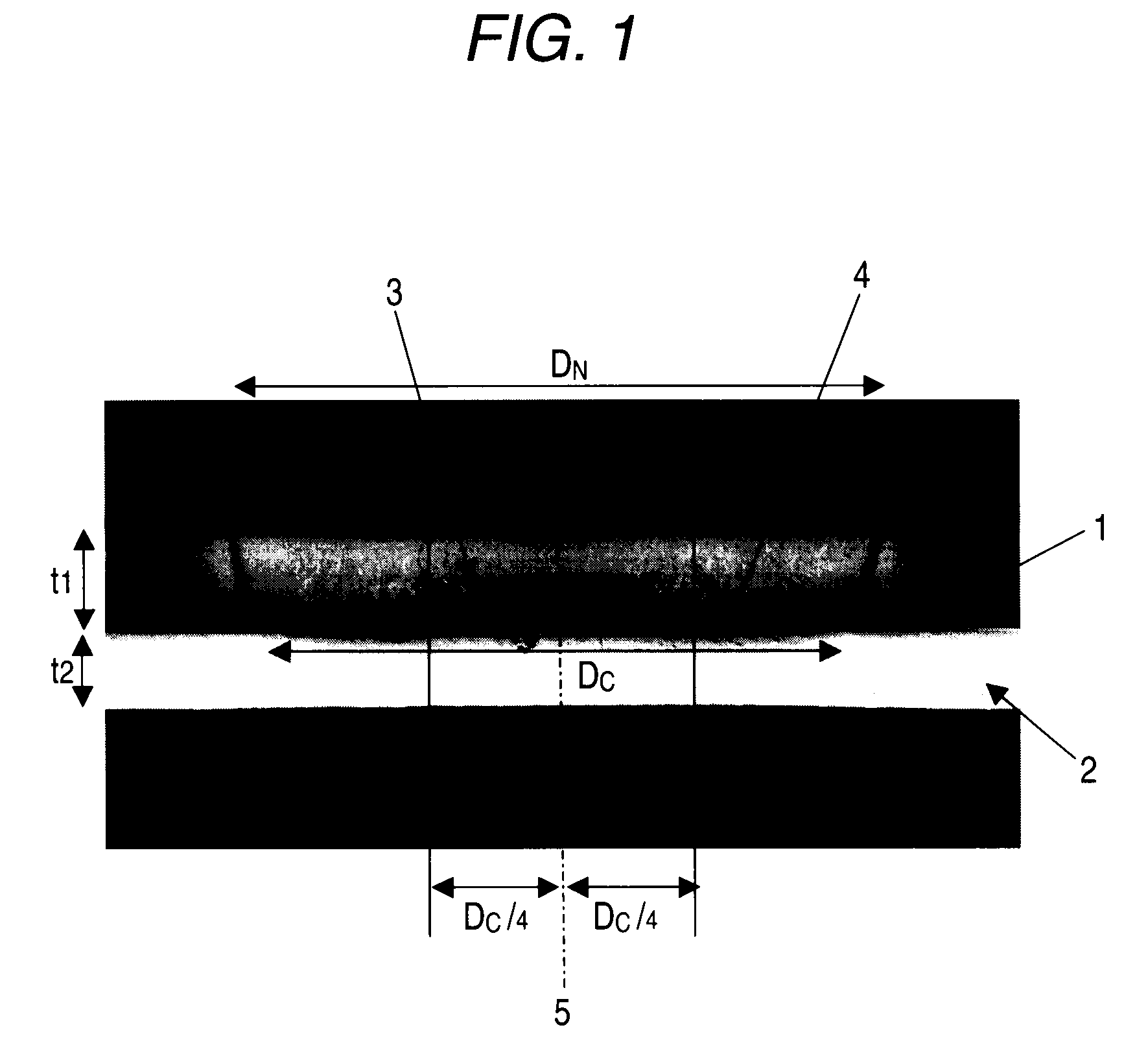

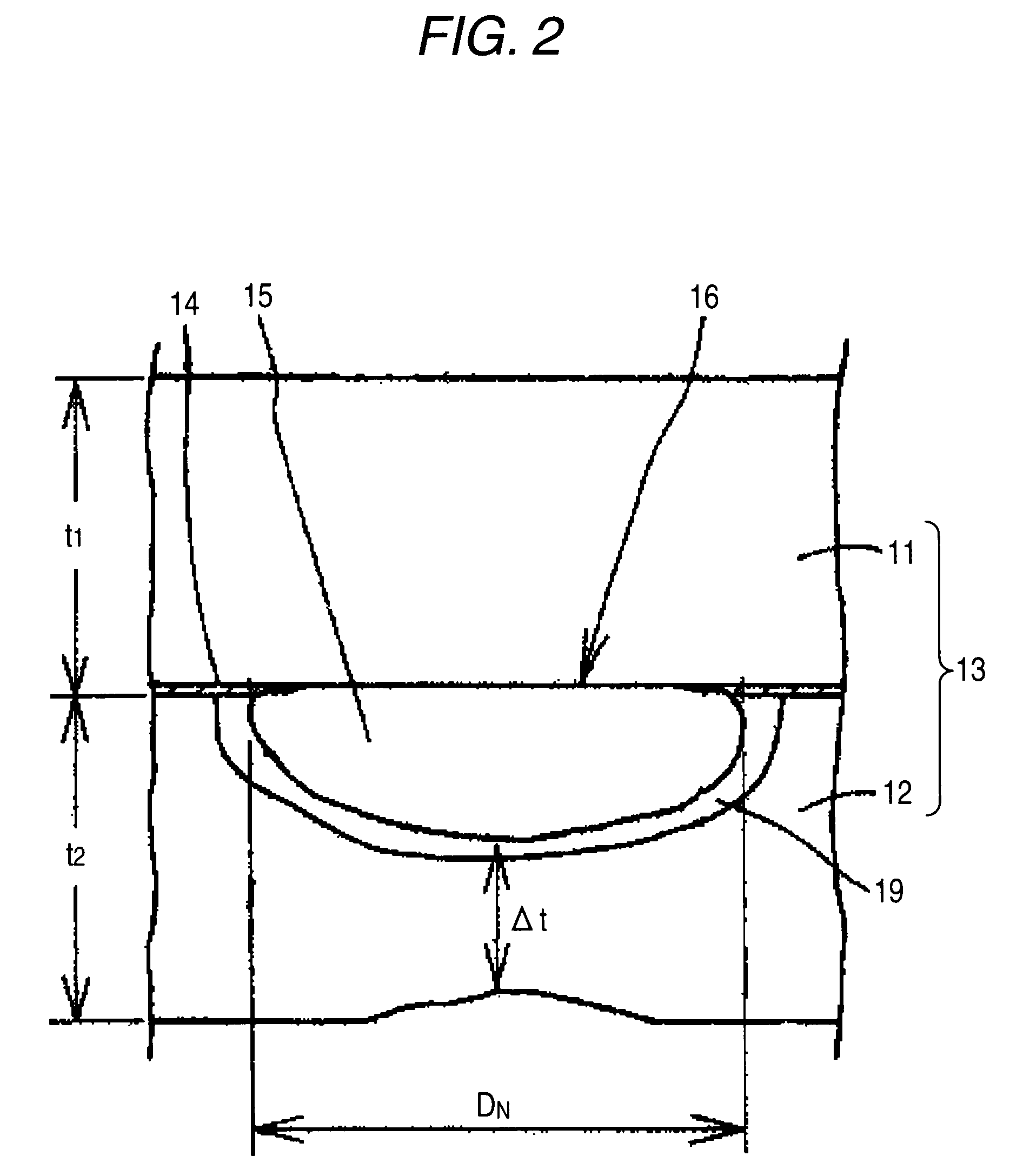

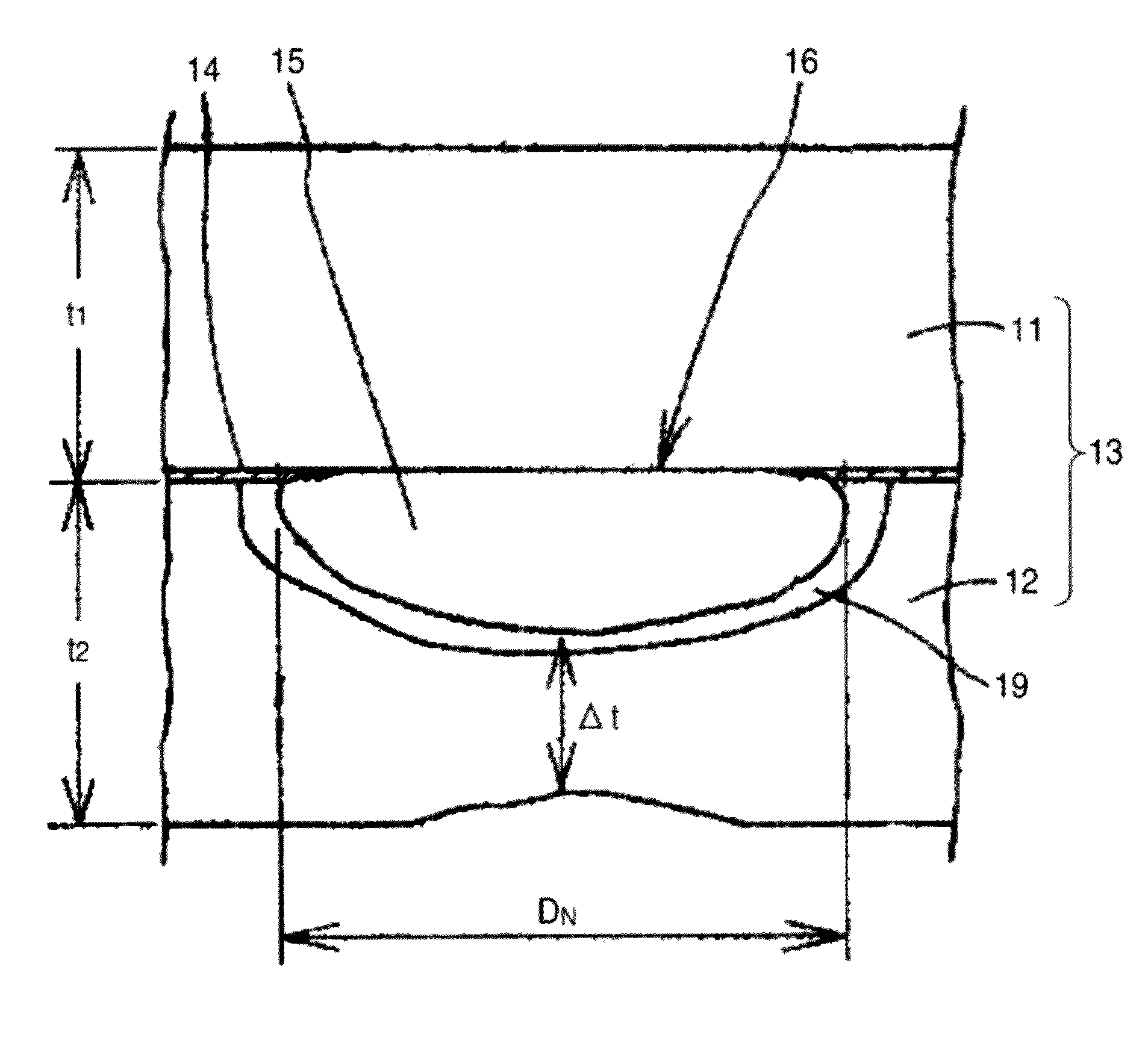

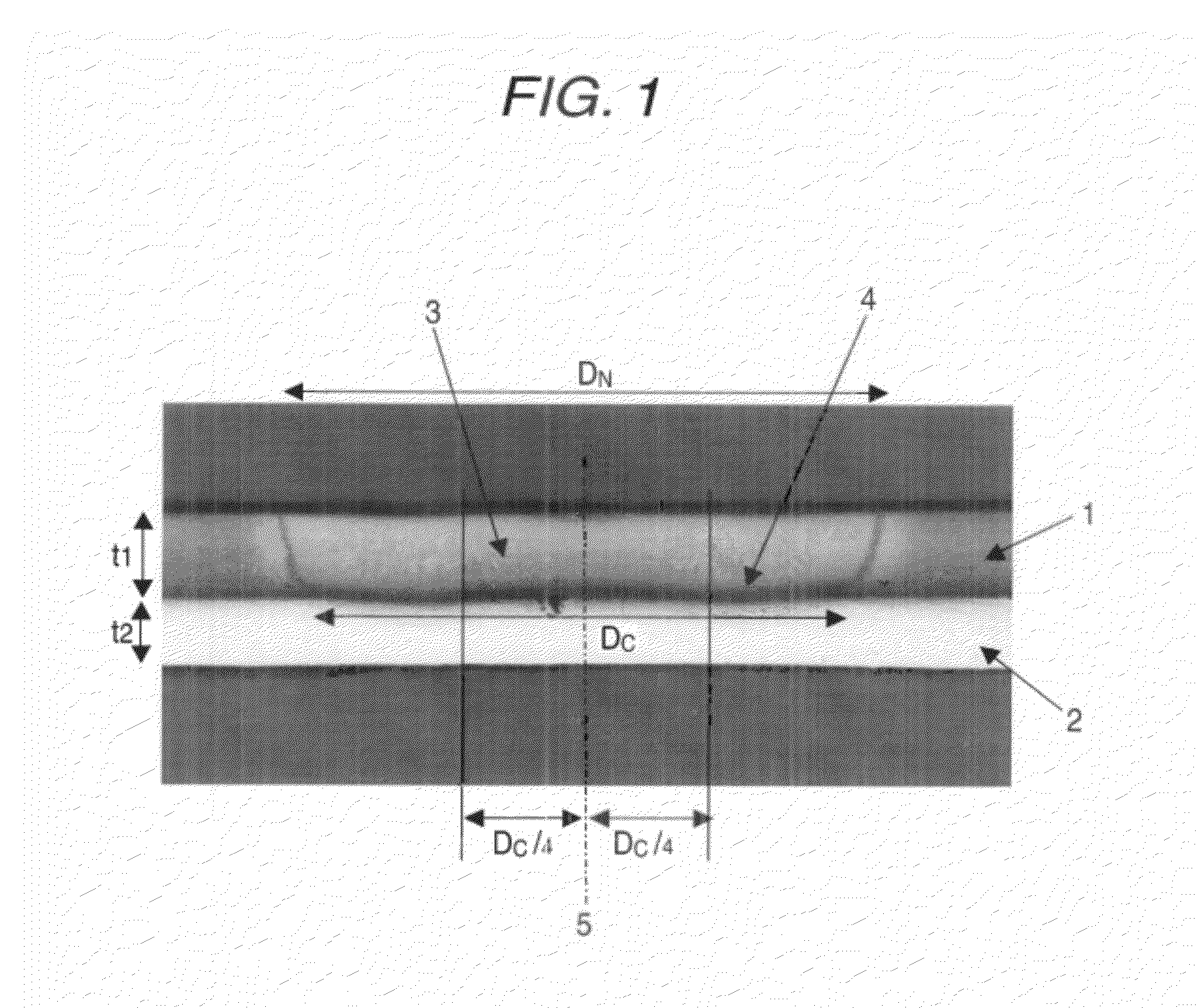

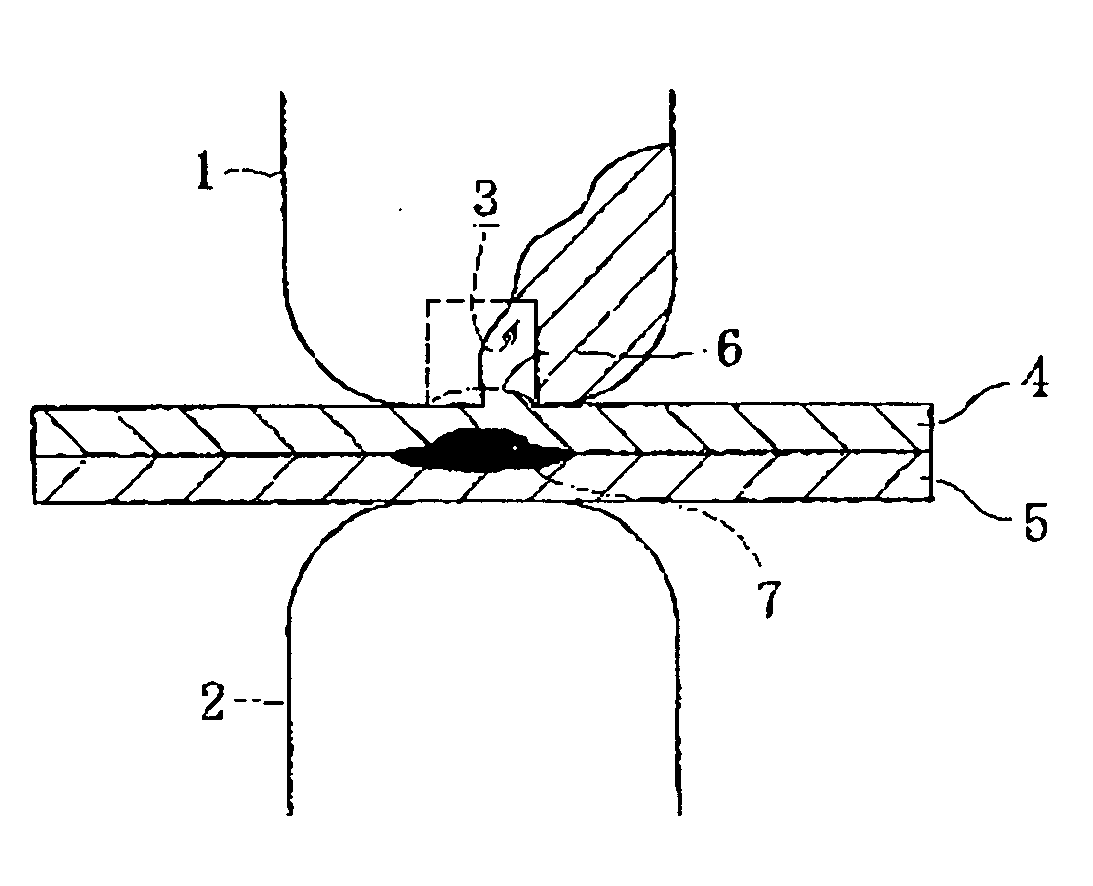

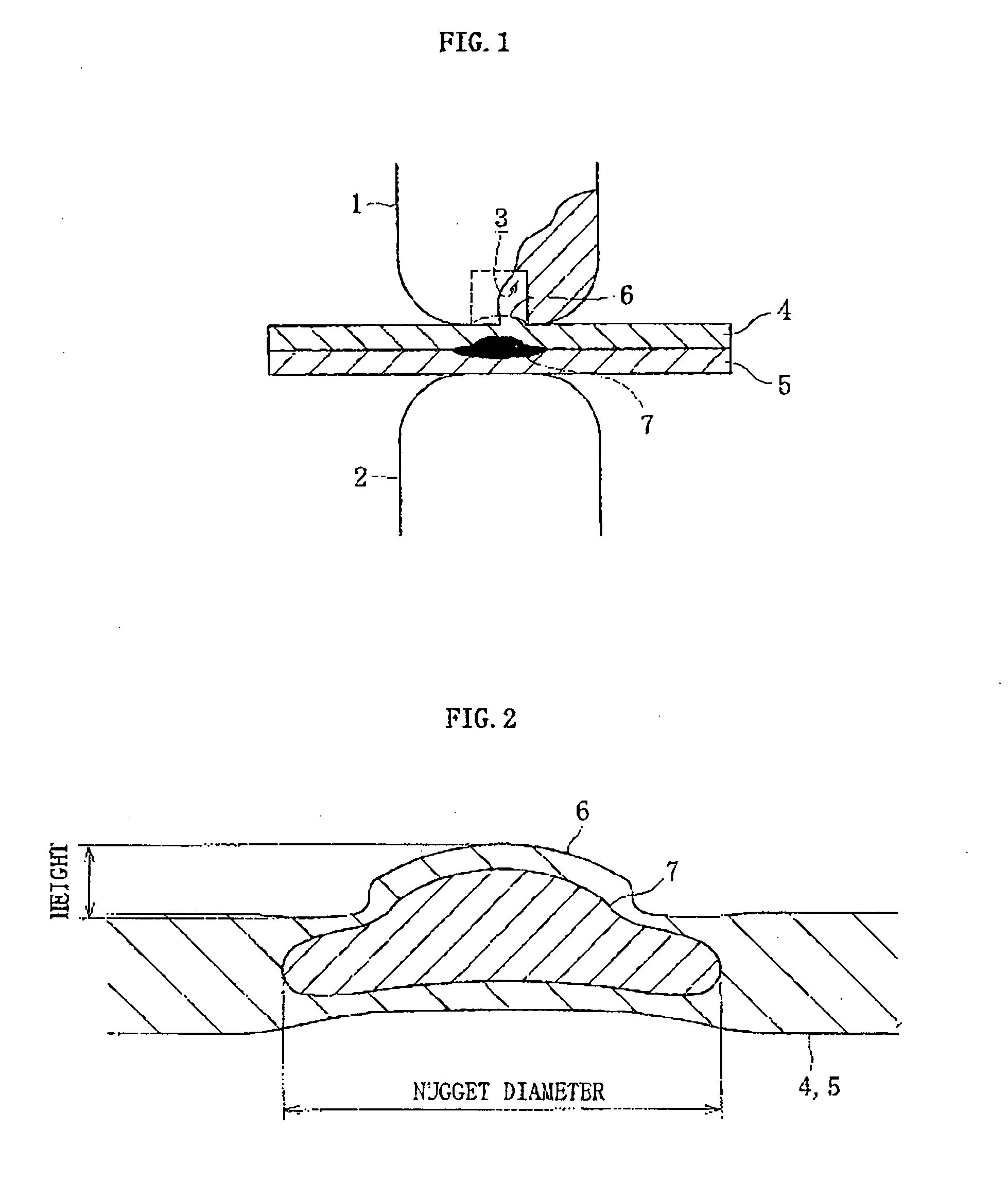

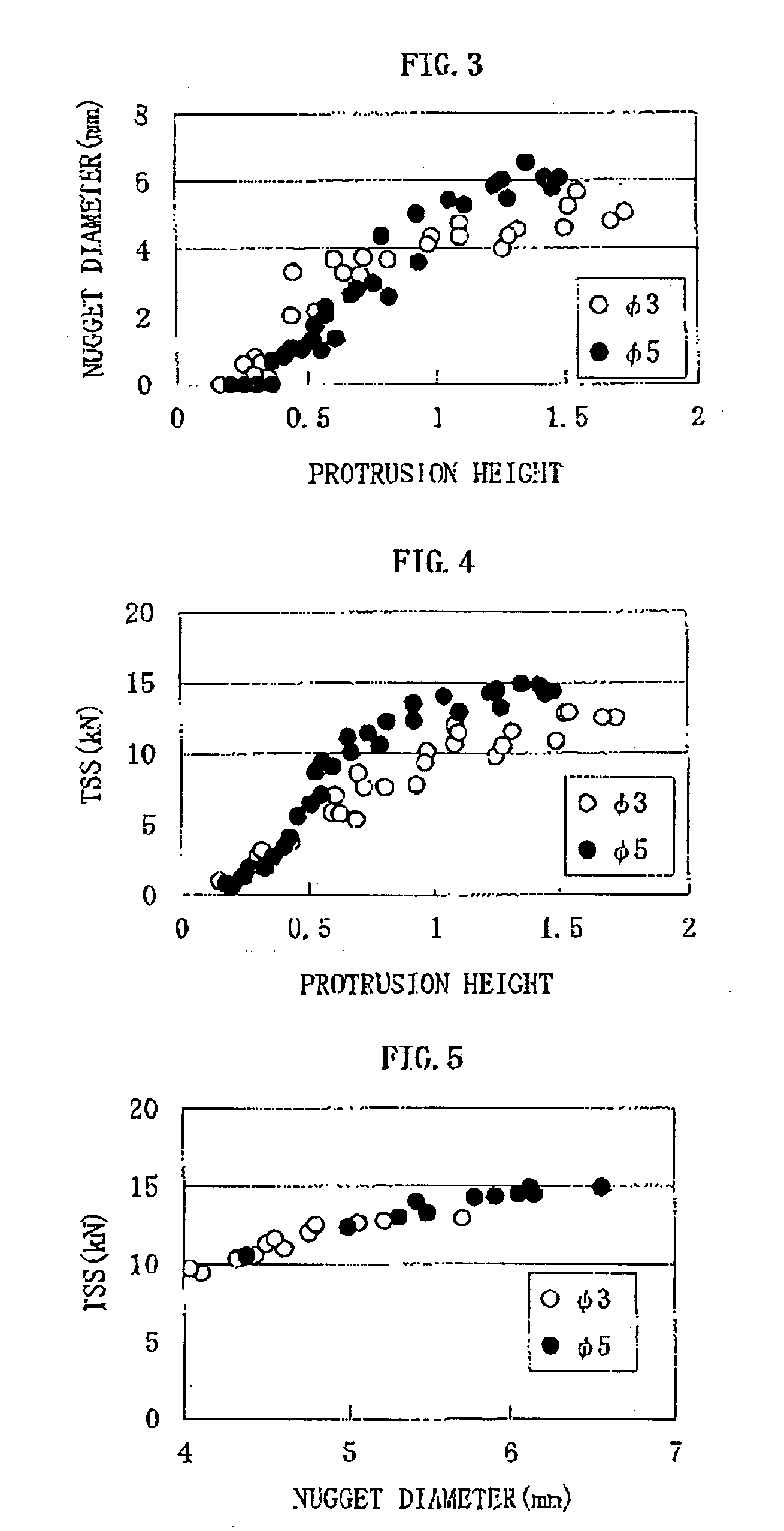

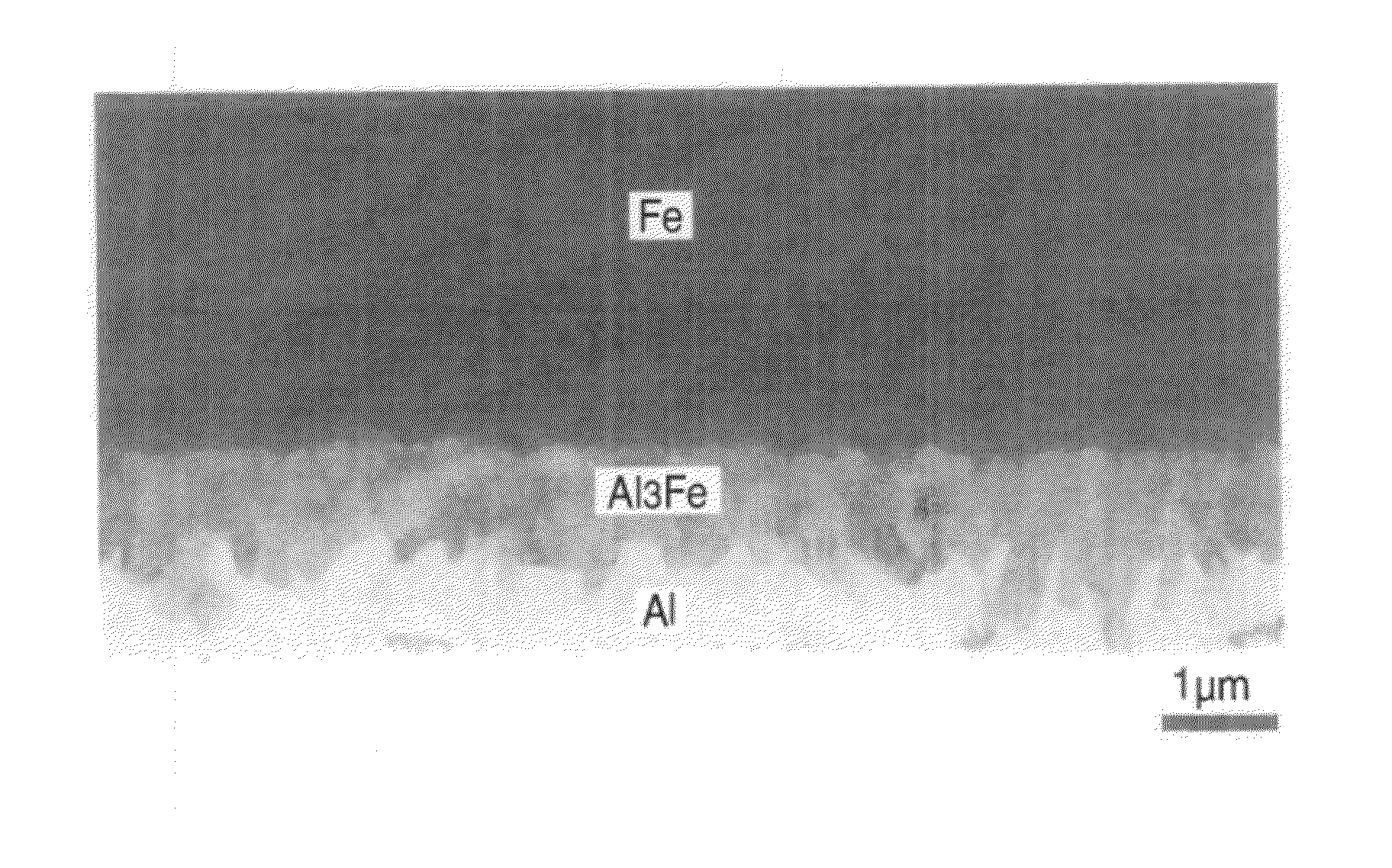

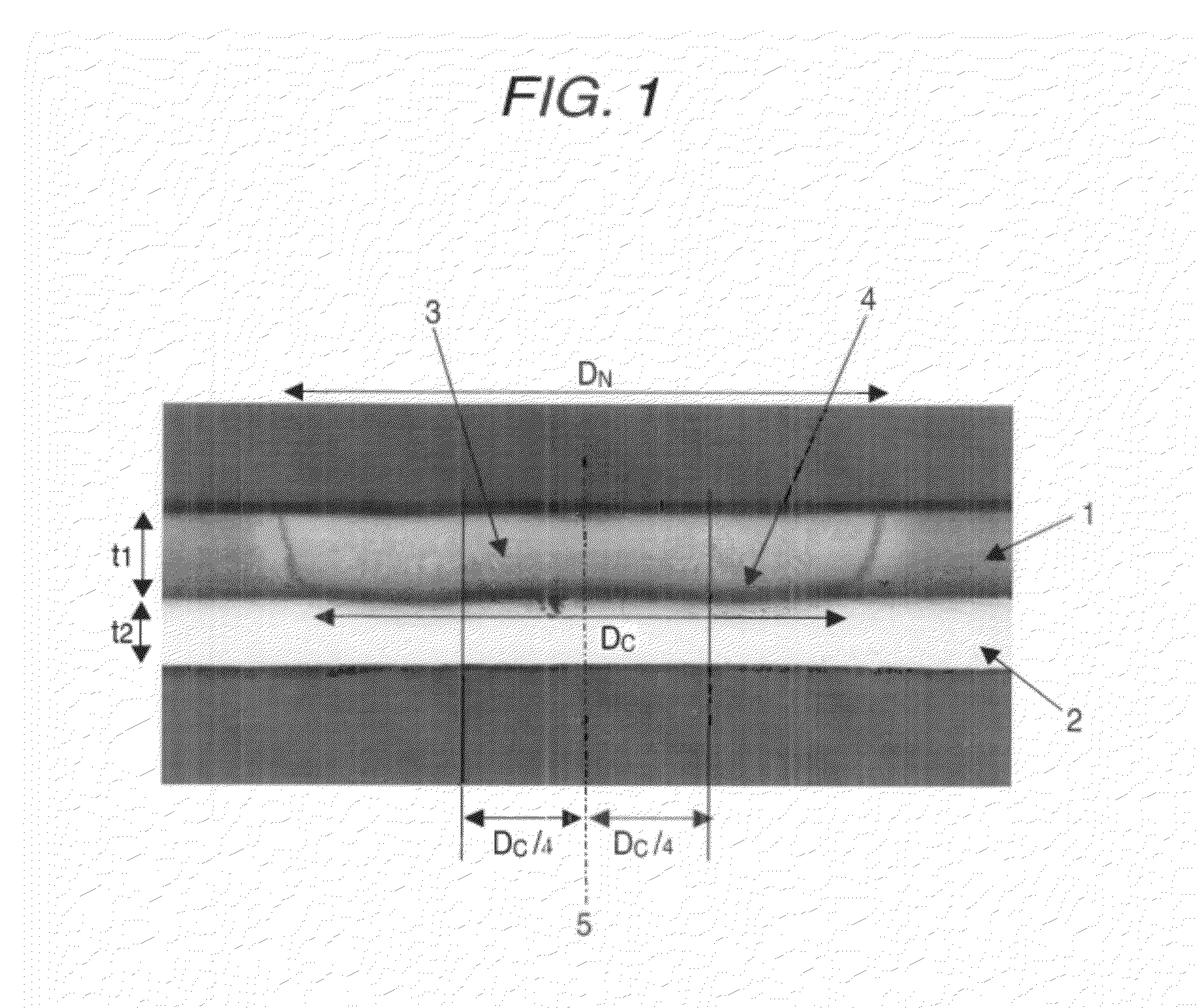

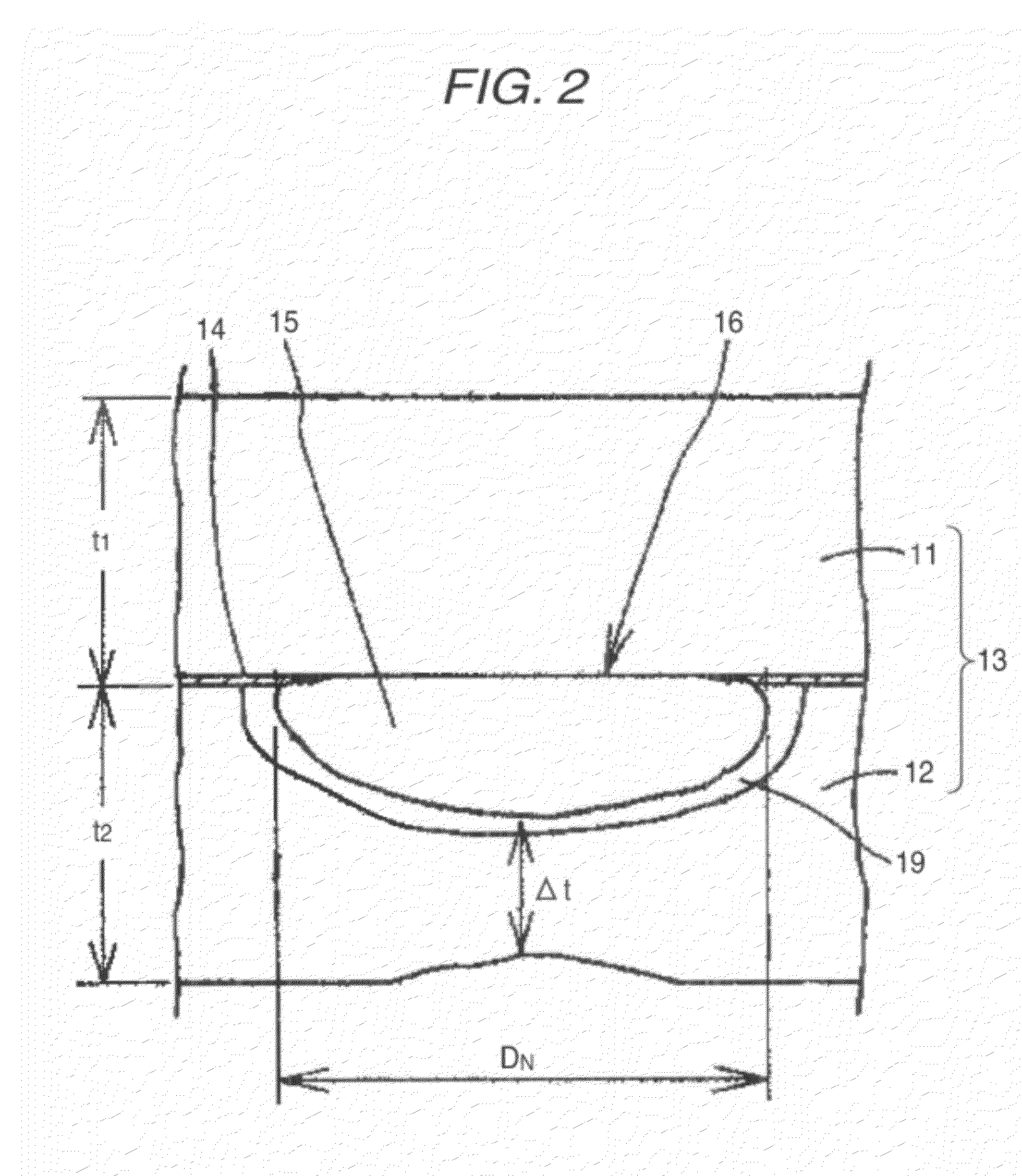

Joint product between steel product and aluminum material, spot welding method for the joint product, and electrode chip for use in the joint product

InactiveUS20090011269A1High bonding strengthLow costOhmic-resistance electrodesOther manufacturing equipments/toolsReaction layerSpot welding

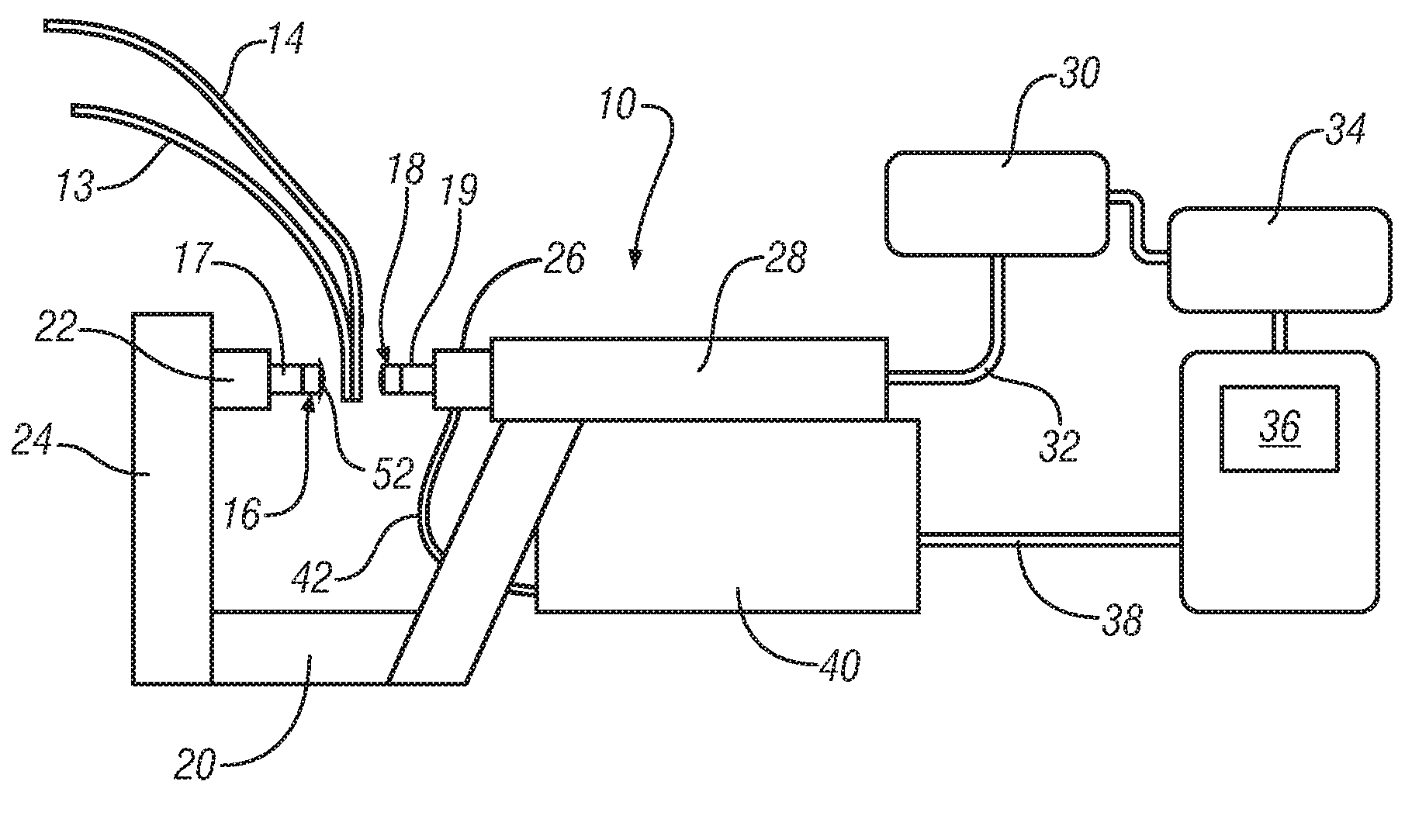

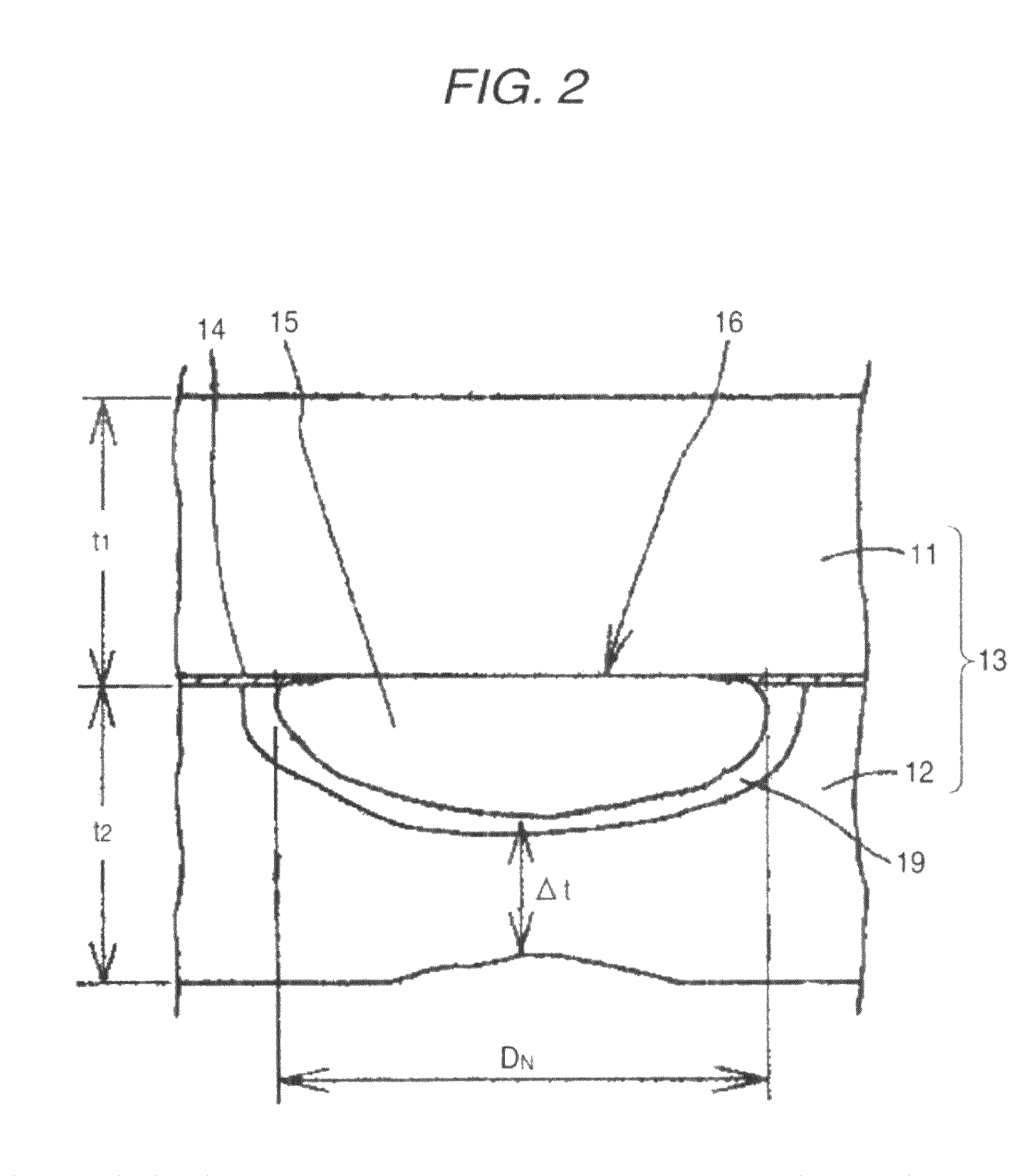

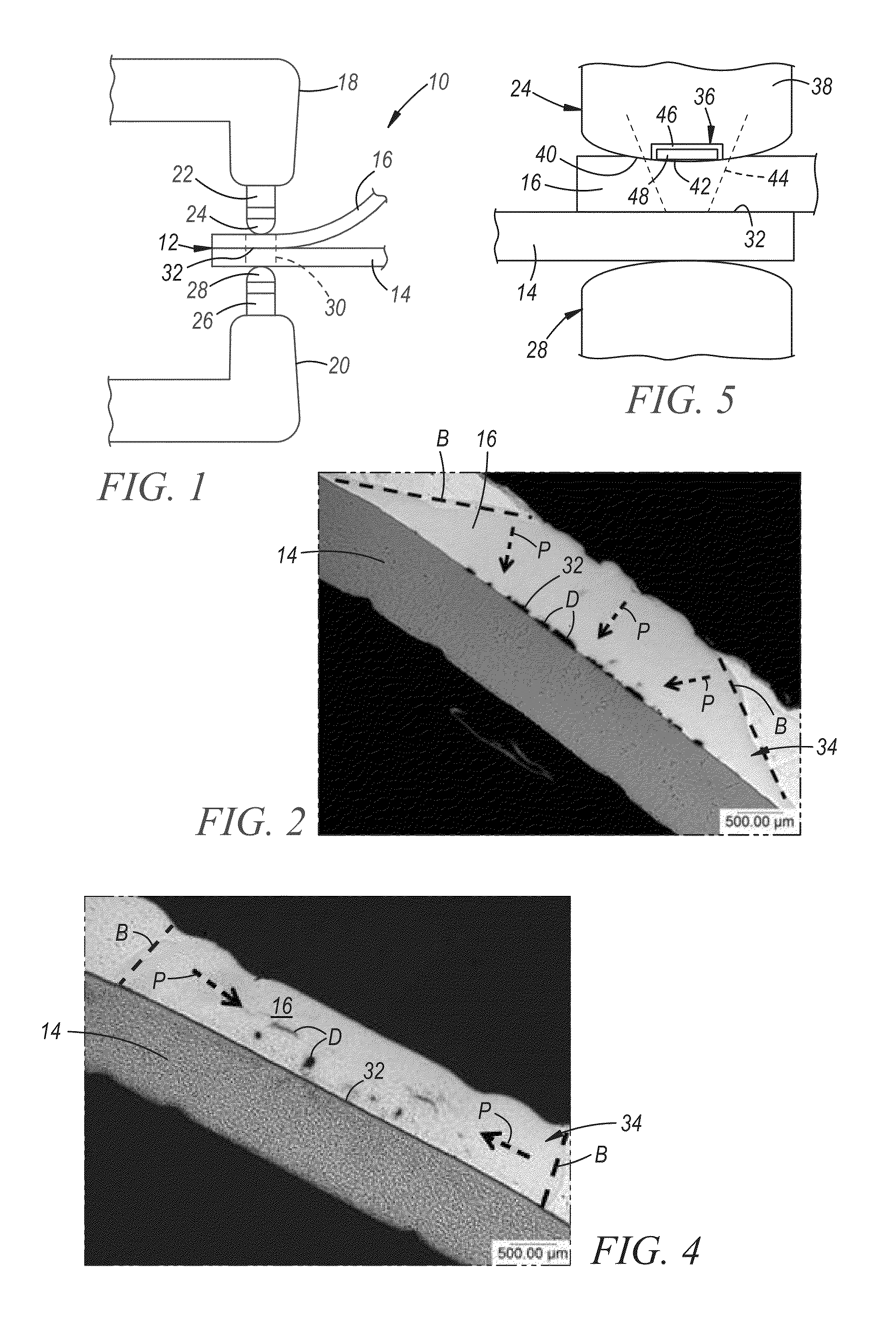

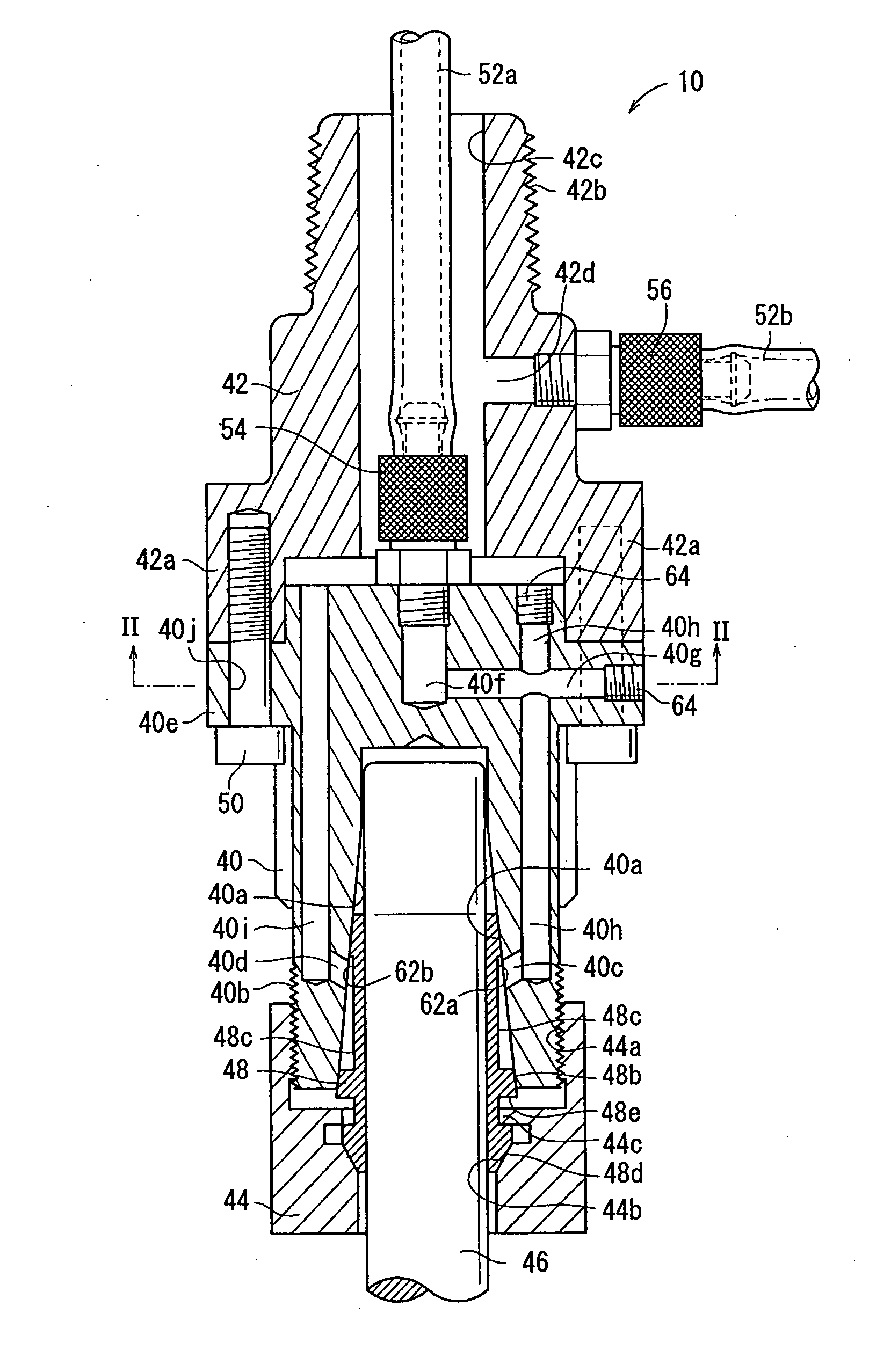

To provide a joint product of a steel product and an aluminum material, and a spot welding method for the joint product, ensuring that spot welding with high bonding strength can be performed. In one embodiment, a steel product 1 having a sheet thickness t1 of 0.3 to 3.0 mm and an aluminum material 2 having a sheet thickness t2 of 0.5 to 4.0 mm are joined together by spot welding to form a joint product of a steel product and an aluminum produce. In this joint product, the nugget area in the joint part is from 20×t20.5 to 100×t20.5 mm2, the area of a portion where the thickness of the interface reaction layer is from 0.5 to 3 μm is 10×t20.5 mm2 or more, and the difference between the interface reaction layer thickness at the joint part center and the interface reaction layer thickness at a point distant from the joint part center by a distance of one-fourth of the joint diameter Dc is 5 μm or less. According to this construction, there can be provided a dissimilar material joint product with excellent bonding strength, which can be formed by an existing spot welding apparatus at a low cost without newly using other materials such as clad material or without newly adding a separate step, and a spot welding method for the dissimilar material joint product.

Owner:KOBE STEEL LTD

Weld electrode for attractive weld appearance

ActiveUS20090127232A1High thermal and electrical resistivityHigh melting pointOhmic-resistance electrodesPressure electrodesSheet steelSpot welding

Weld faces of electrodes for resistance spot welding are formed with a suitable area of protrusions and / or intrusions. The size, shape, and elevation or depths of the protrusions or intrusions are determined for the formation of suitable spot welds in and between metal workpieces such as aluminum or steel panels for vehicle bodies. The protrusions or intrusions are also conceived and used to form an image on at least a visible surface of the welded article to produce an attractive appearance on the surface of the welded sheet.

Owner:GM GLOBAL TECH OPERATIONS LLC

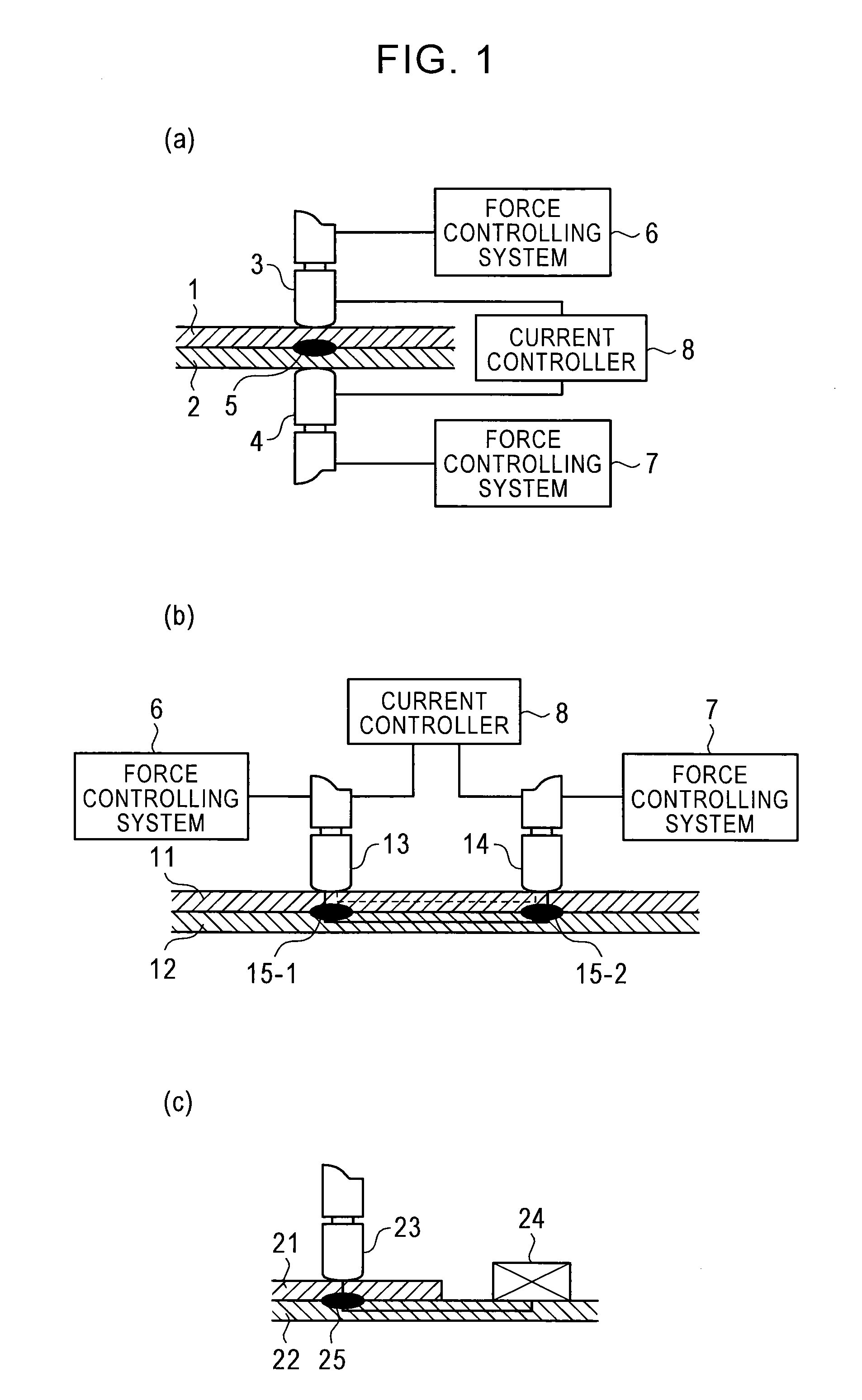

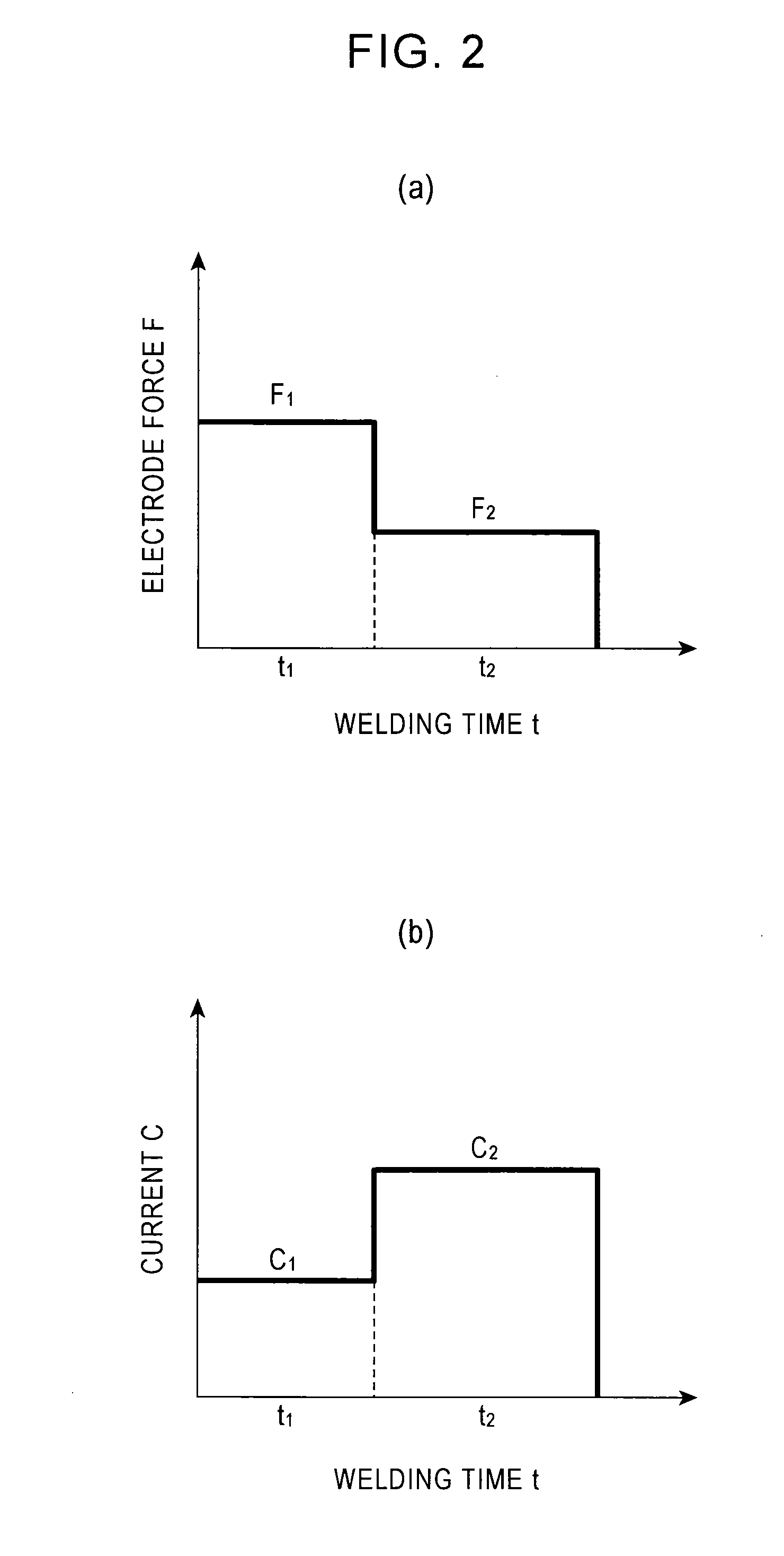

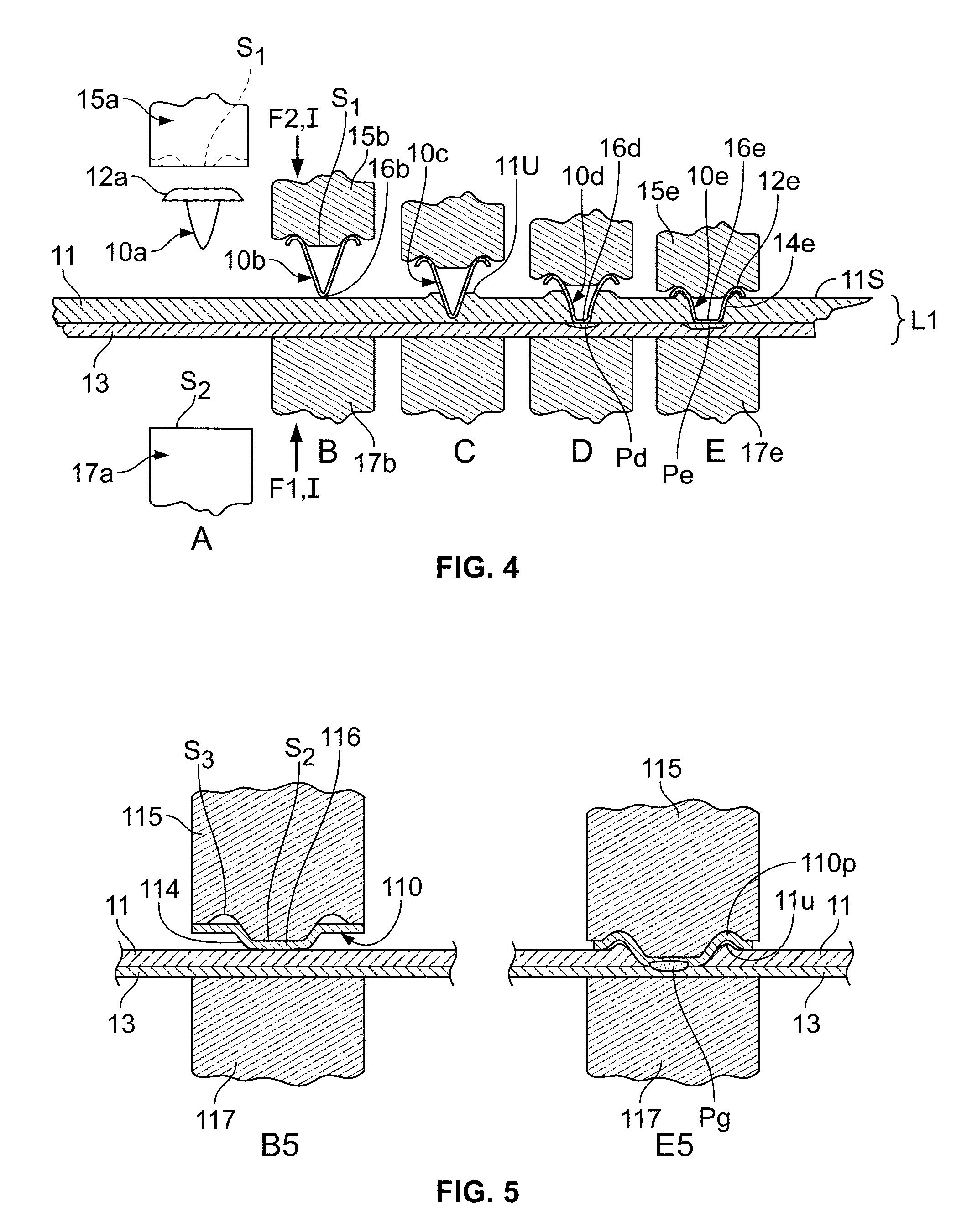

Indirect spot welding method

ActiveUS20110272384A1Get stableStable formationWelding electric supplyPressure electrodesEngineeringSpot welding

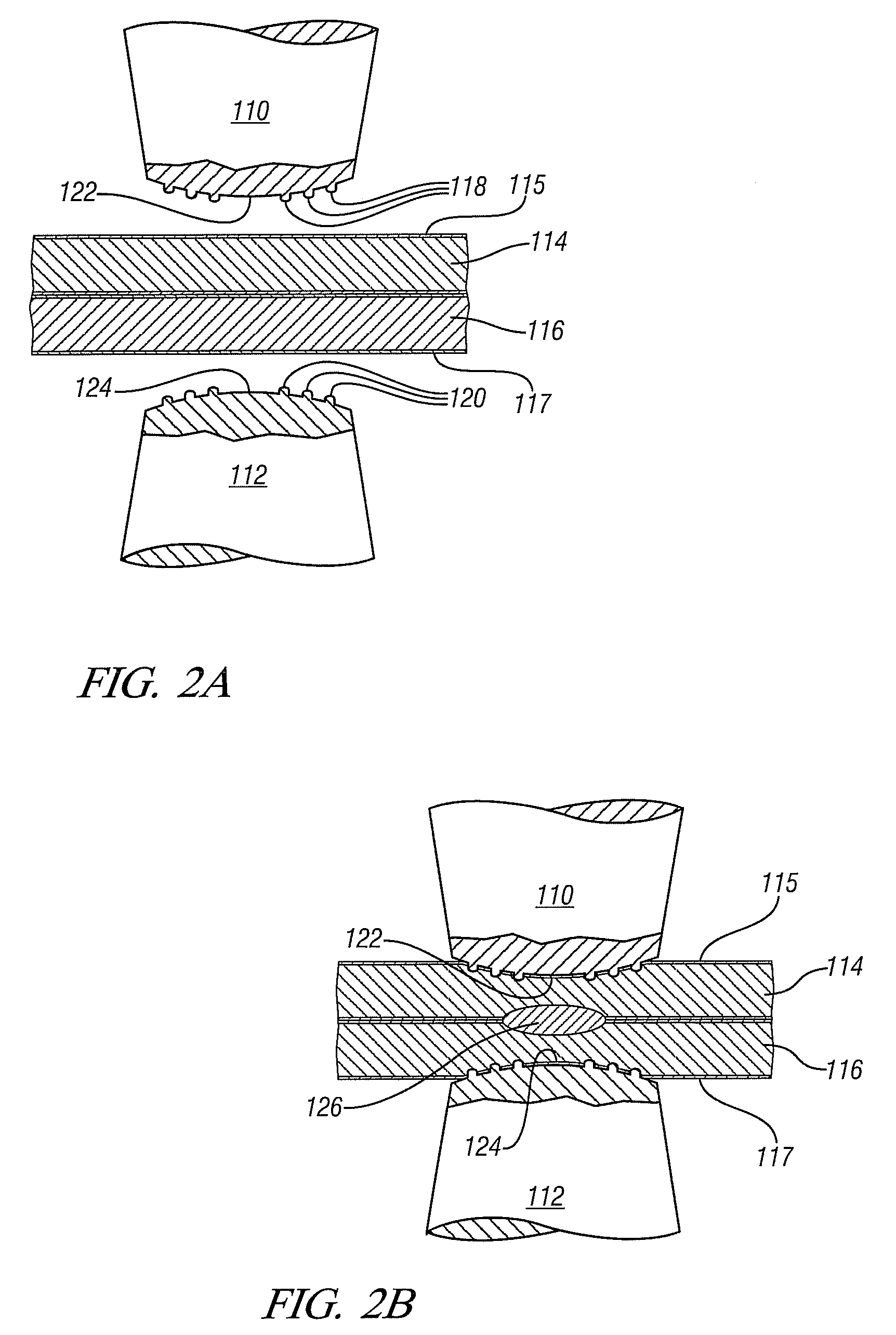

An indirect spot welding method is provided in which, in indirect spot welding, nuggets formed in a fused state can be stably obtained. In the indirect spot welding method, the welding time is divided into two time periods t1 and t2, where electrode force F1 and current C1 are applied in the first time period t1, and electrode force F2 lower than electrode force F1 and current C2 higher than current C1 are applied in the next time period t2.

Owner:JFE STEEL CORP

Joint product between steel product and aluminum material, spot welding method for the joint product, and electrode chip for use in the joint product

ActiveUS8487206B2High bonding strengthLow costOther manufacturing equipments/toolsVehicle componentsReaction layerSpot welding

Provided is a joint product of a steel product and an aluminum material, the joint product being formed by joining the steel product having a sheet thickness t1 of 0.3 to 3.0 mm with the aluminum material having a sheet thickness t2 of 0.5 to 4.0 mm by spot welding, wherein a nugget area in a joint part is from 20×t20.5 to 100×t20.5 mm2, an area of a portion where a thickness of an interface reaction layer is from 0.5 to 3 μm is 10×t20.5 mm2 or more, and a difference between the thickness of the interface reaction layer at a joint part center and the thickness of the interface reaction layer at a point distant from the joint part center by a distance of one-fourth of a joint diameter is 5 μm or less, and wherein the aluminum material is pure aluminum or an aluminum alloy material.

Owner:KOBE STEEL LTD

Weld electrode for attractive weld appearance

ActiveUS8927894B2High thermal and electrical resistivityHigh melting pointElectrode supporting devicesPressure electrodesElectrical resistance and conductanceSheet steel

Owner:GM GLOBAL TECH OPERATIONS LLC

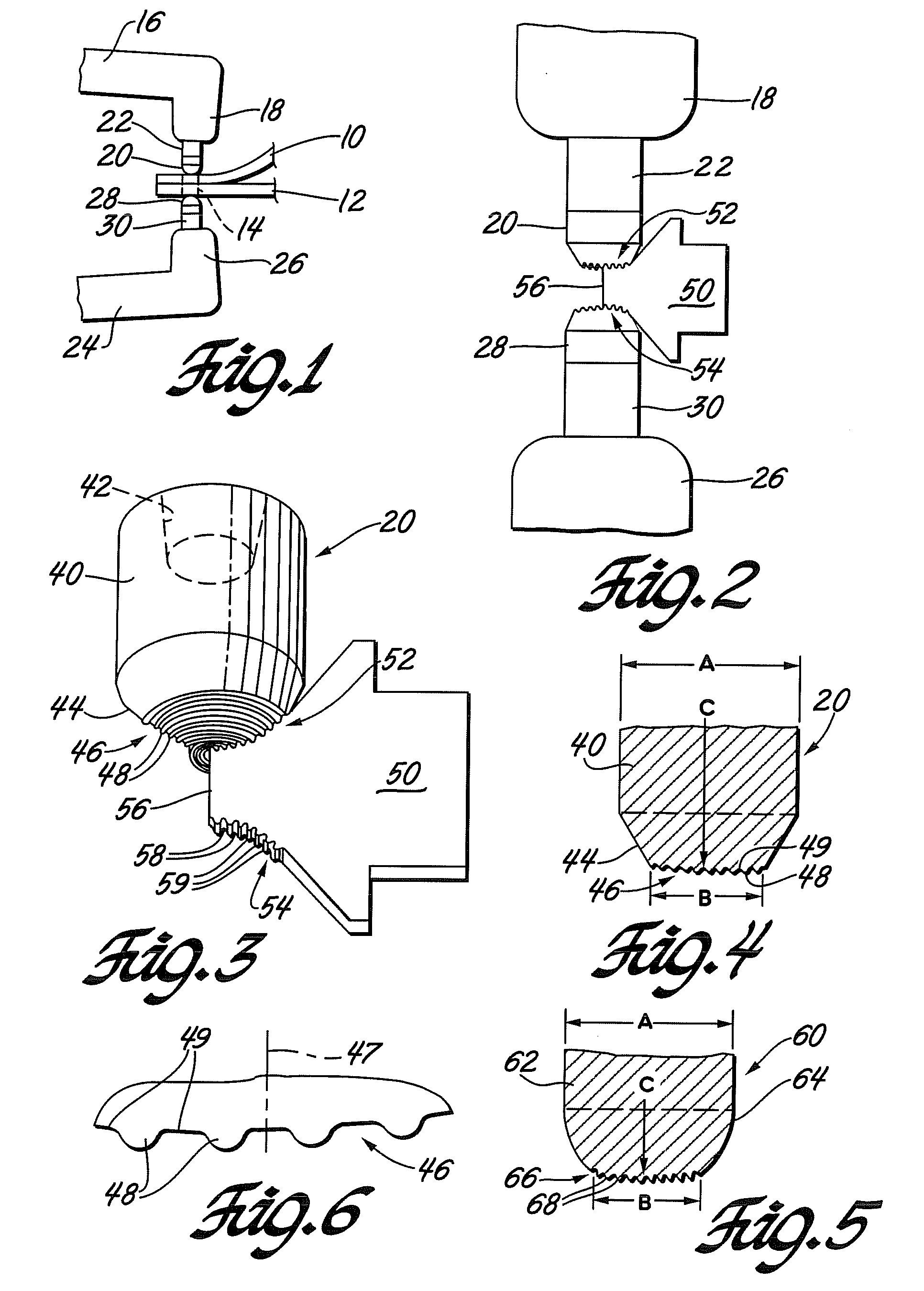

Resistance welding fastener, apparatus and methods for joining similar and dissimilar materials

ActiveUS20160167158A1Improve the immunitySheet joiningWelding/cutting media/materialsConductive materialsAlloy

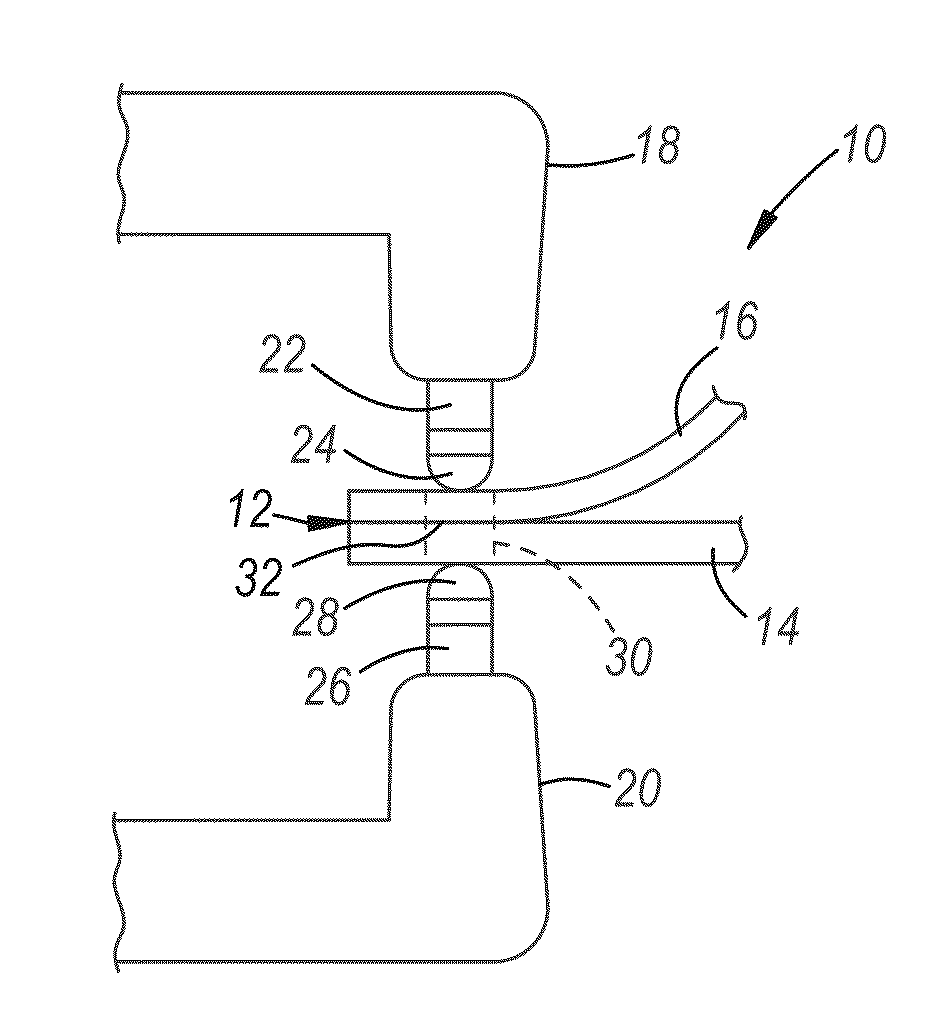

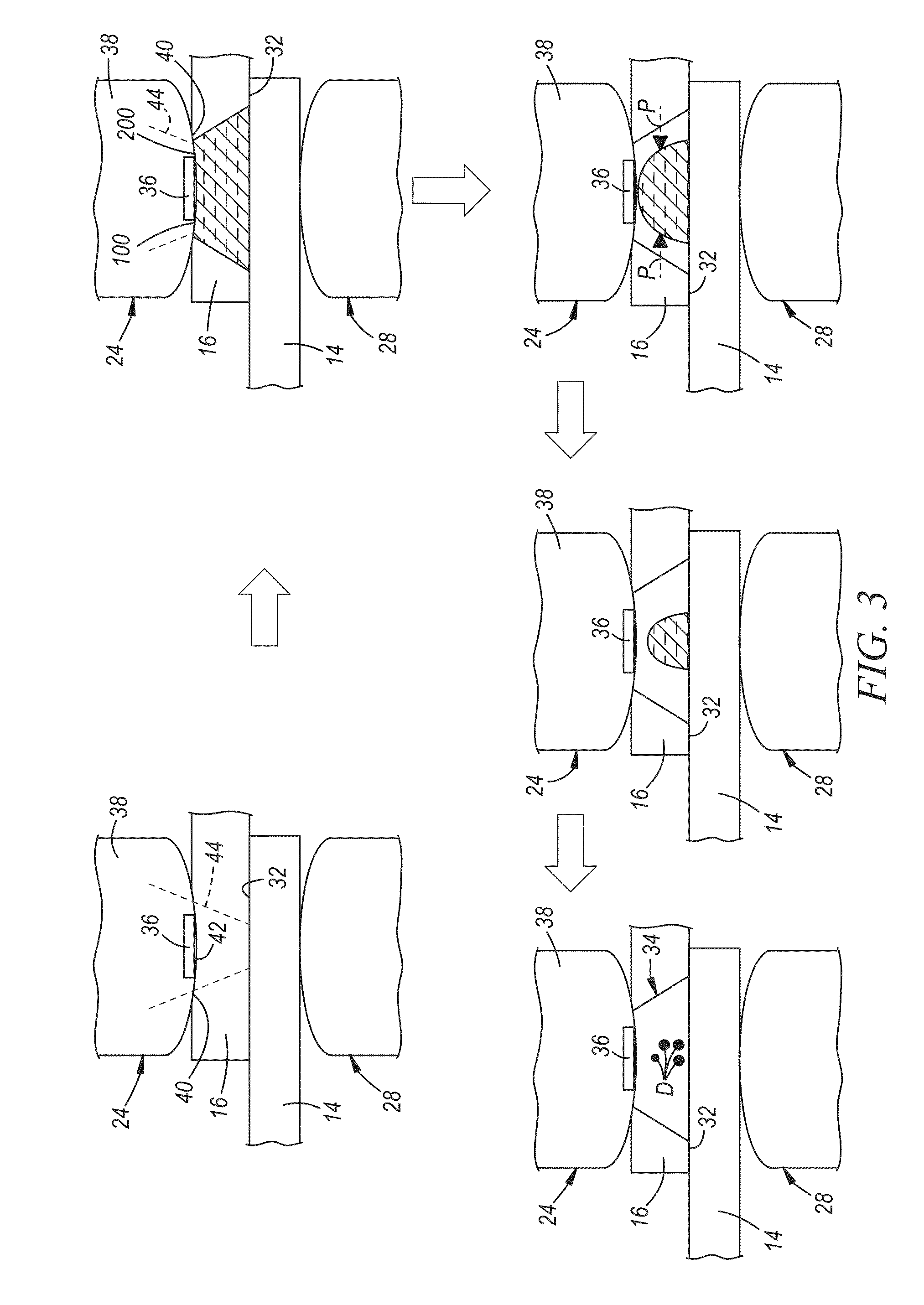

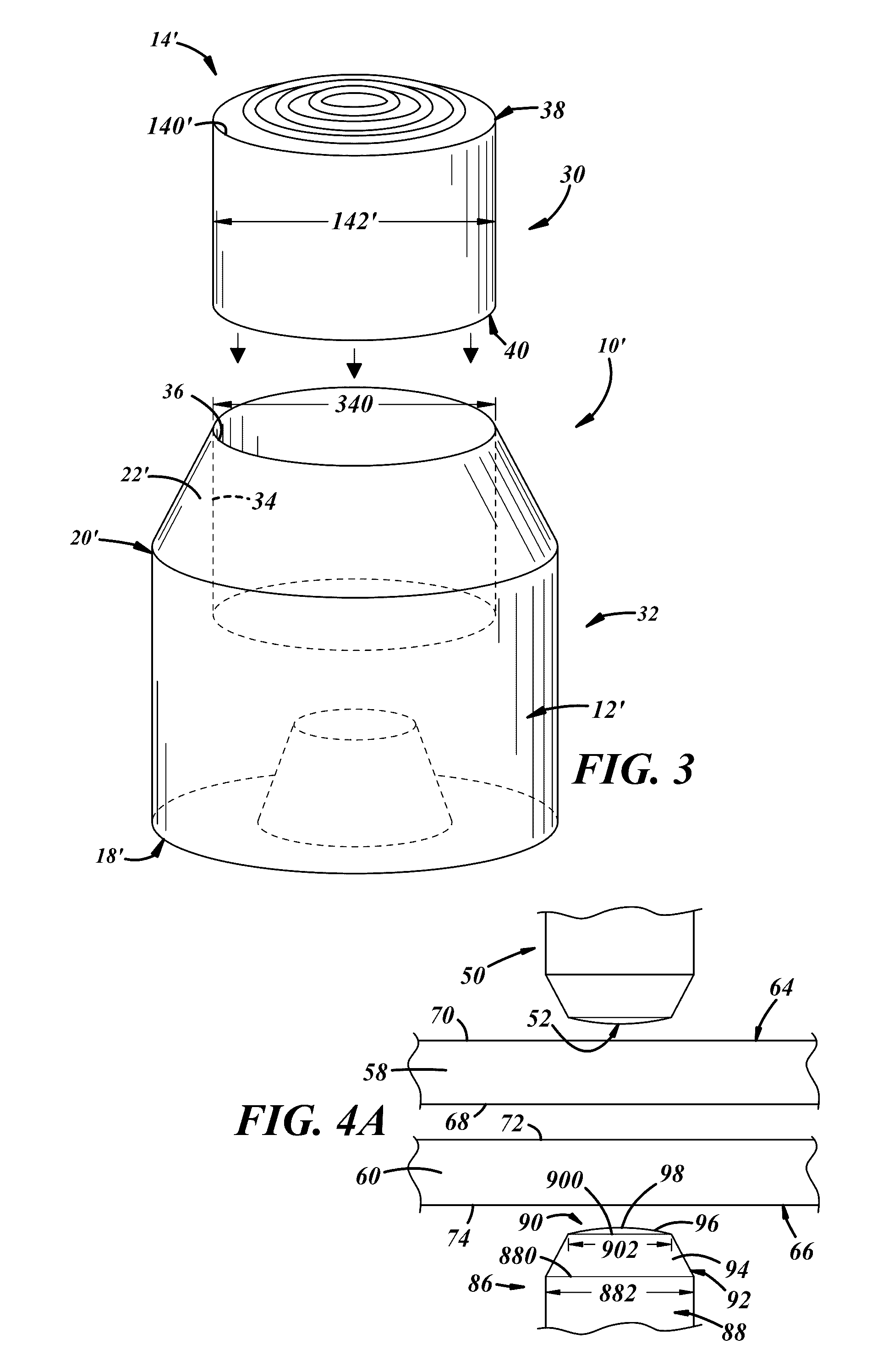

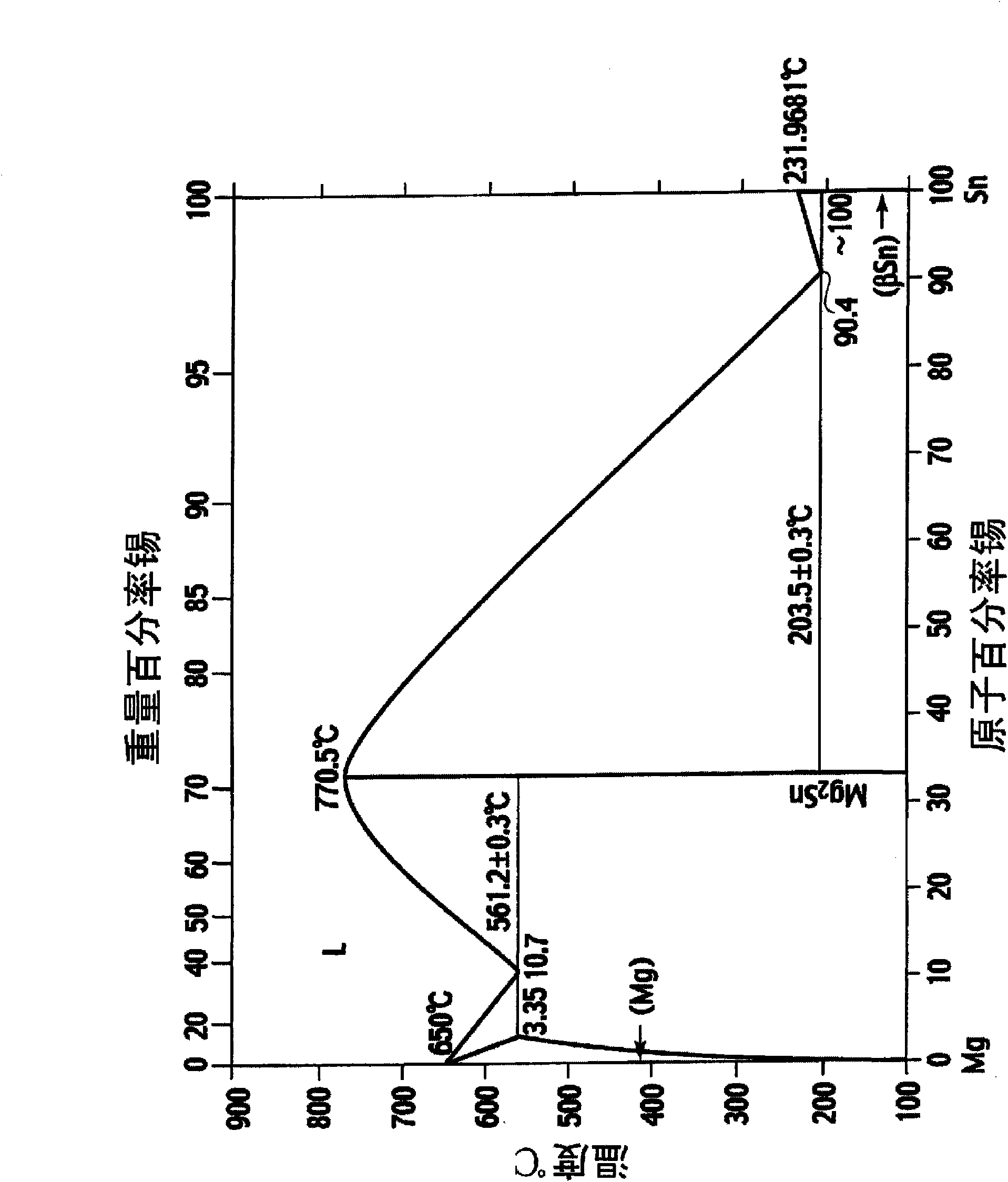

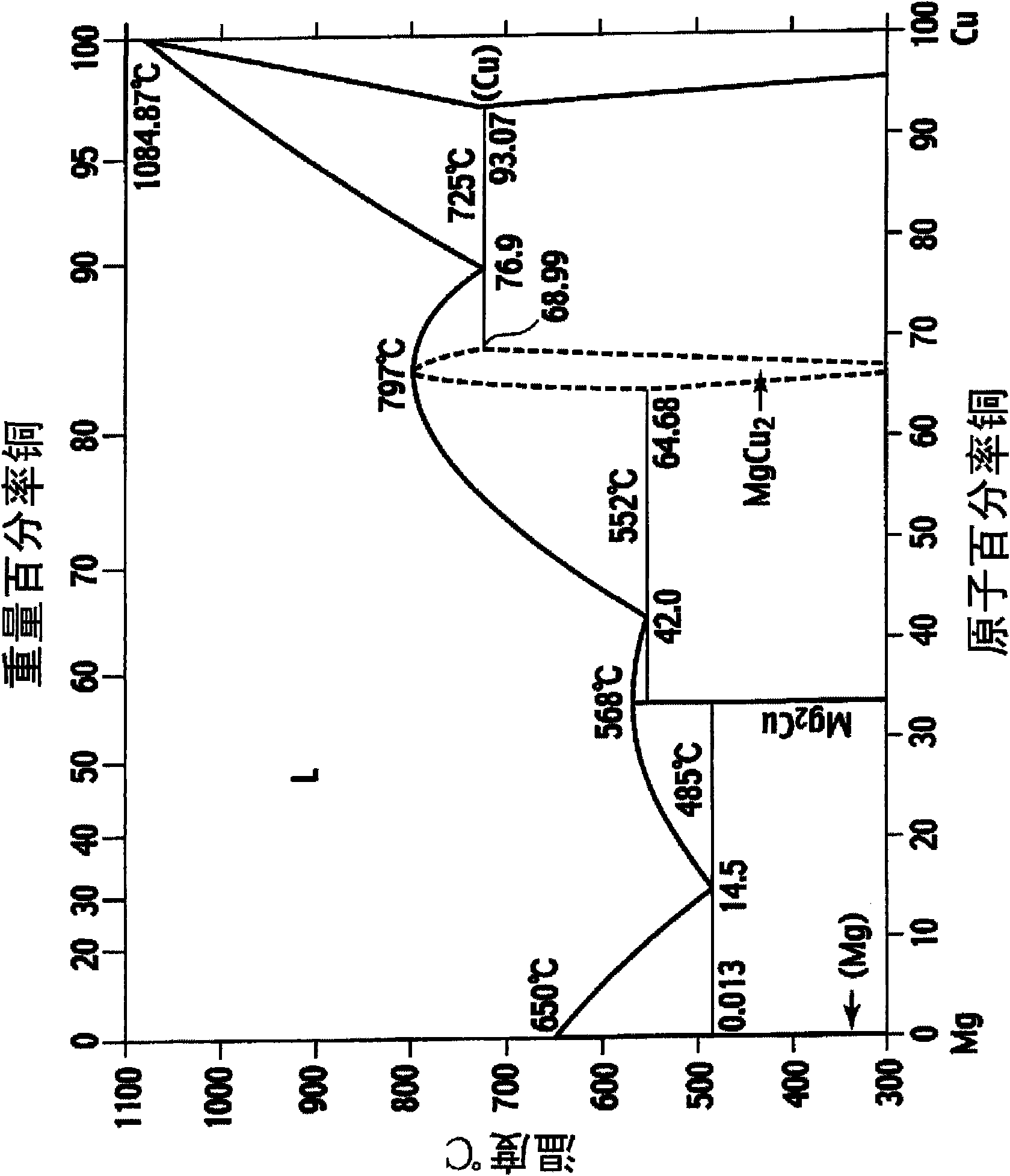

An apparatus and method for fastening layers of non-ferrous alloys, like aluminum, magnesium and copper utilizes a steel fastener and a spot welding machine. The fastener and metals are stacked and the heat from the welder's electric current softens the lower melting point aluminum allowing the fastener to penetrate the aluminum. A weld zone between the fastener and the various layers creates an internal weld. The fastener has a rough shaft that is coated by the molten weld zone and is hard to withdraw on solidification. Layers of non-conductive materials like plastics and ceramics may also be affixed to a conductive layer using a fastener made from a compatible material that extends through a pilot hole and welds to or penetrates a conductive layer. The fastener may have projections that initially reduce contact area with the stack.

Owner:HOWMET AEROSPACE INC

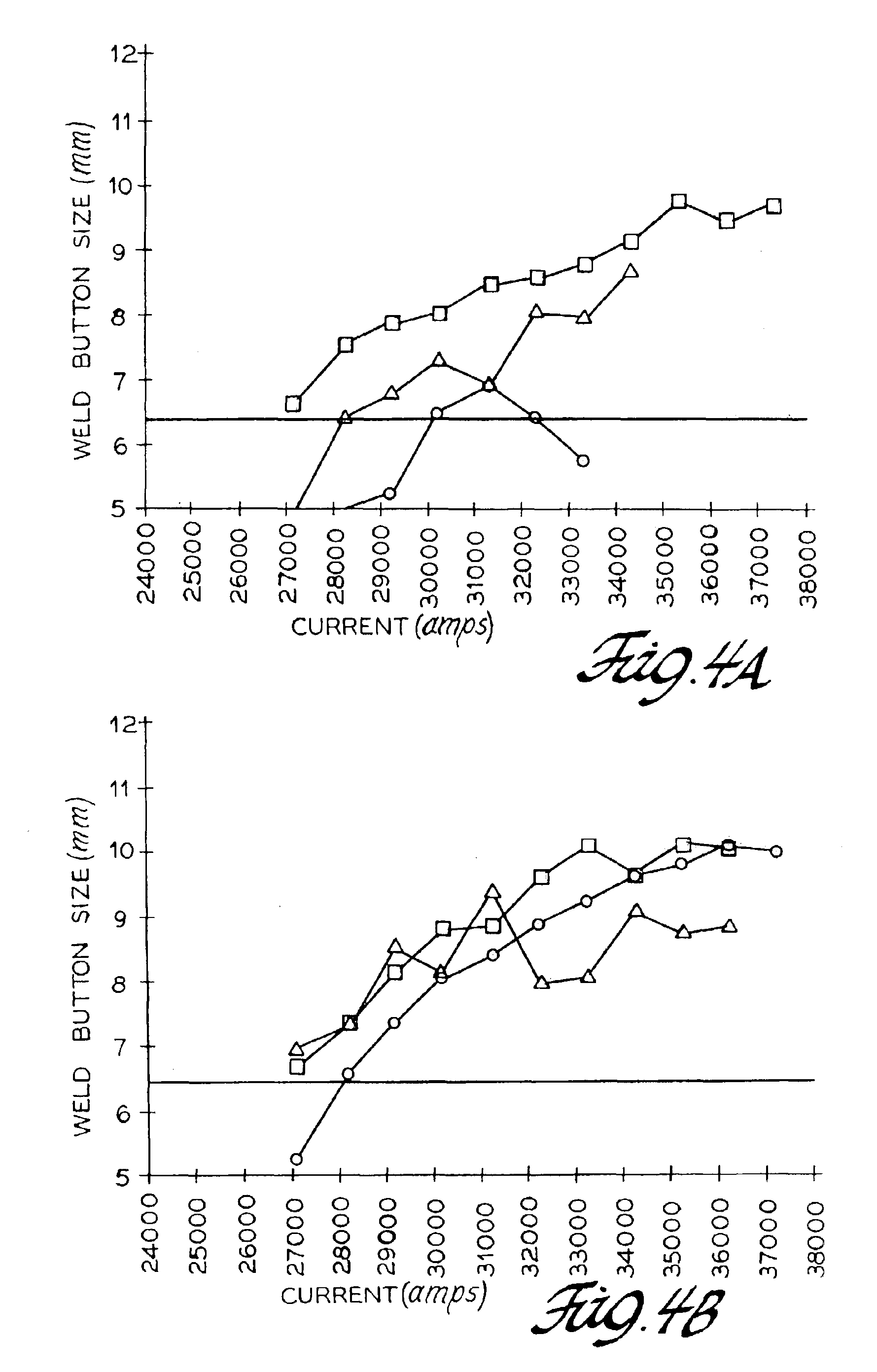

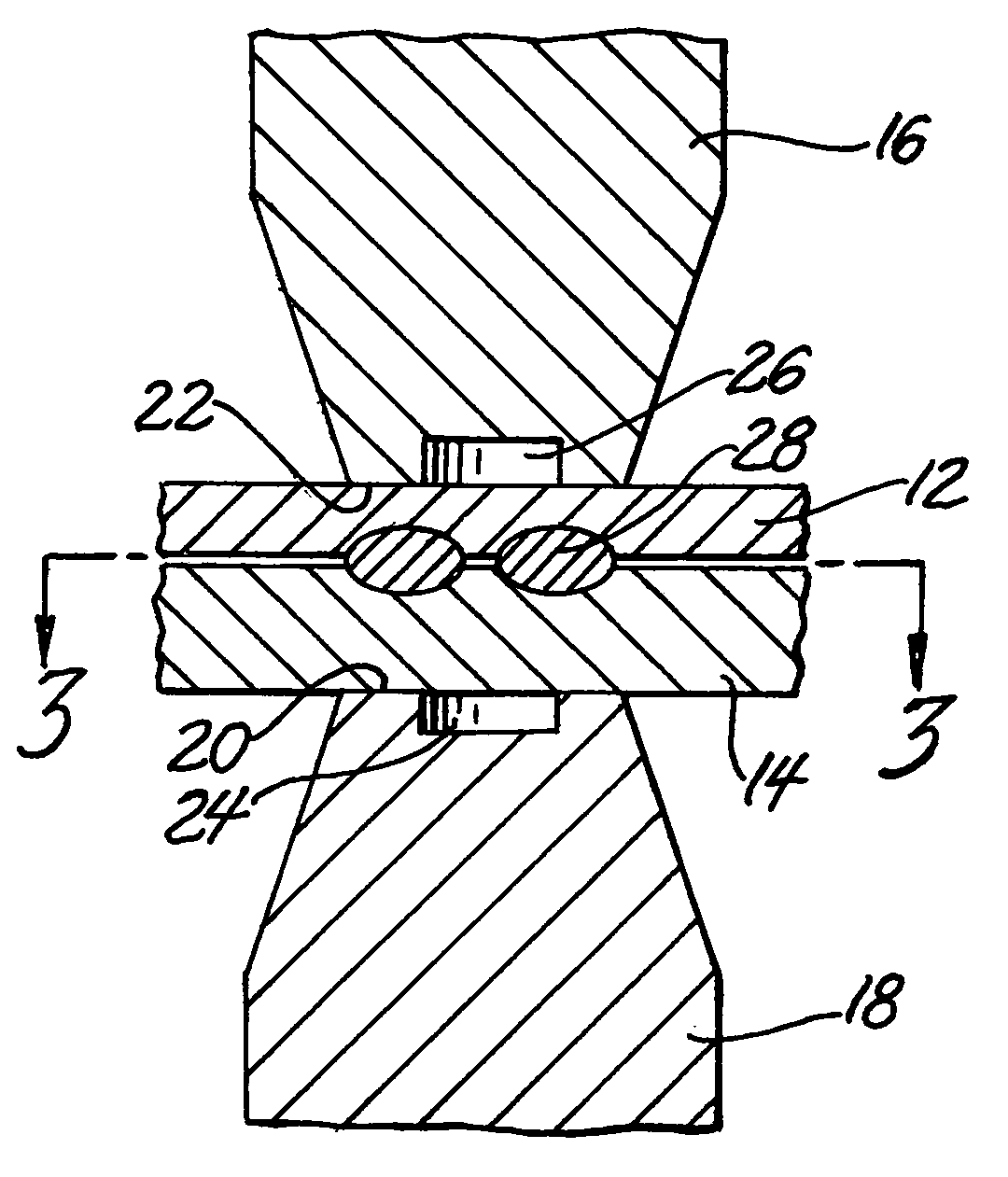

Resistance welding of high strength steels

InactiveUS20050247679A1Improve propertiesHigh strengthOhmic-resistance electrodesVehicle componentsElectrical resistance and conductanceHigh intensity

The formation of spot welds in high strength steel workpieces is improved by using welding electrodes with annular, or donut shaped welding tips for the formation of the molten metal weld pool at the weld site. The annular poll solidifies to form an annular weld nugget. Preferably the donut shaped nugget has an internal diameter that is no more than three-quarters of the outside diameter. The method is applicable to carbon steel workpieces with allowing elements for strengthening, and to thick sheets of mild carbon steels.

Owner:GM GLOBAL TECH OPERATIONS LLC

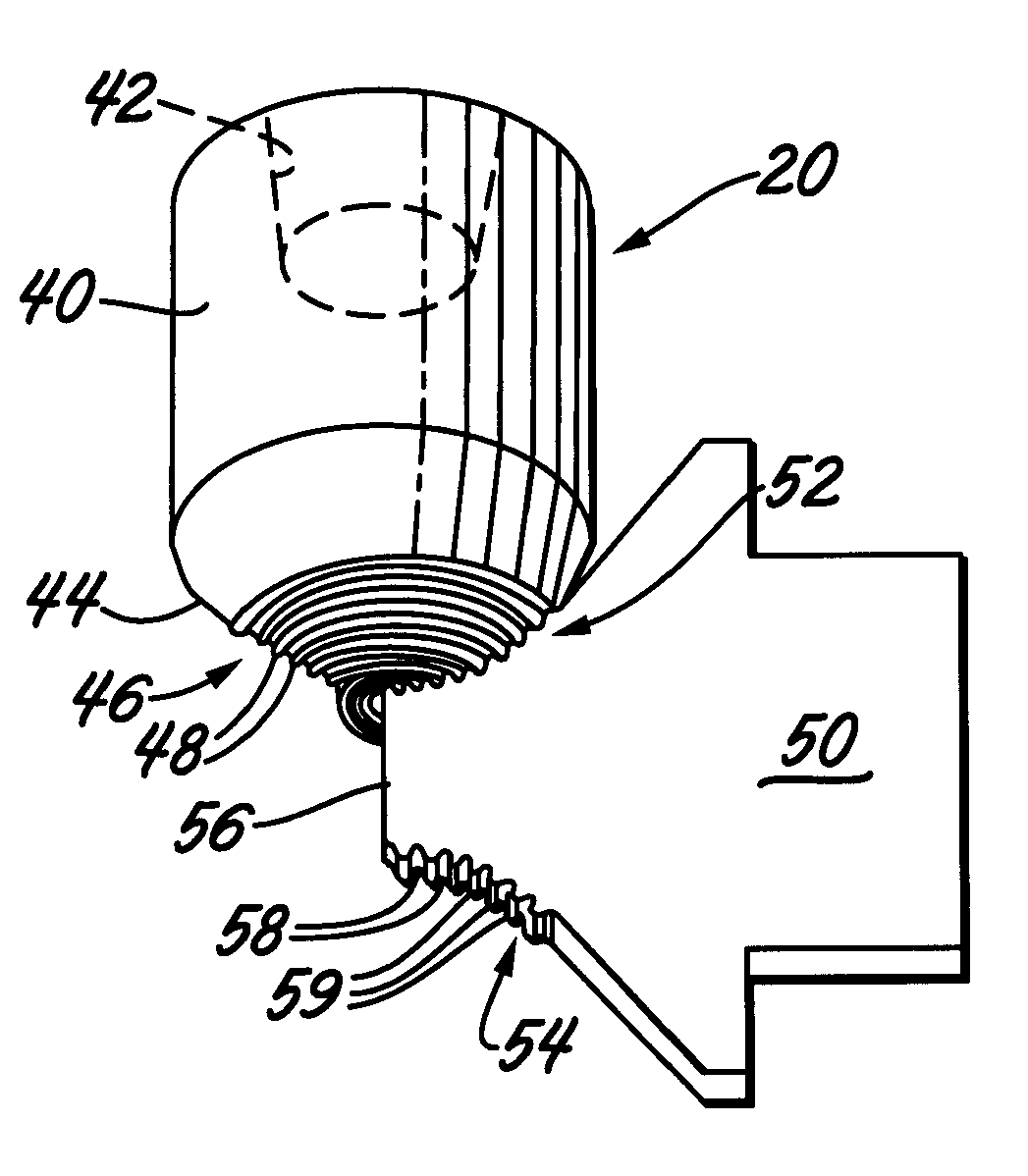

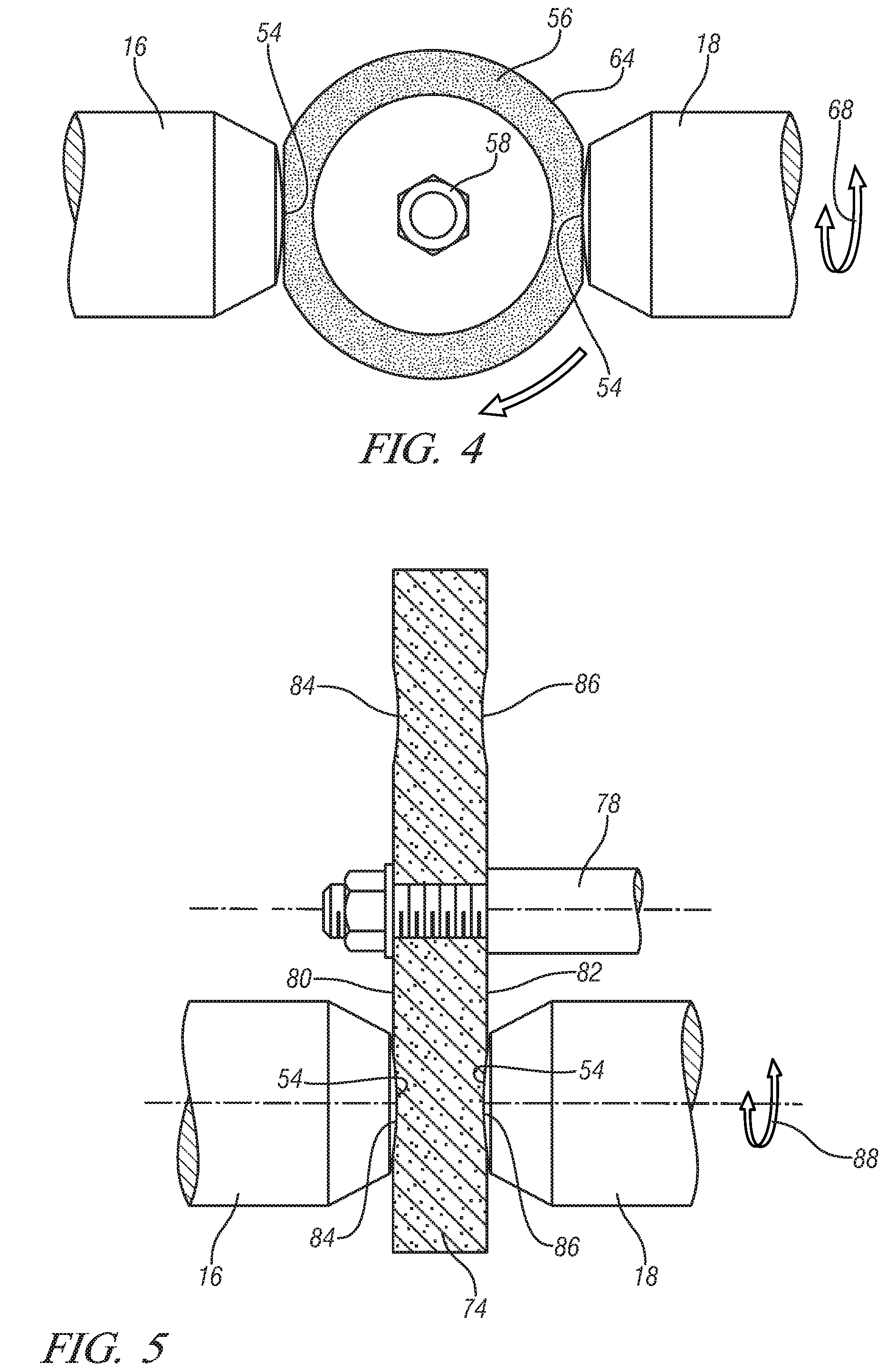

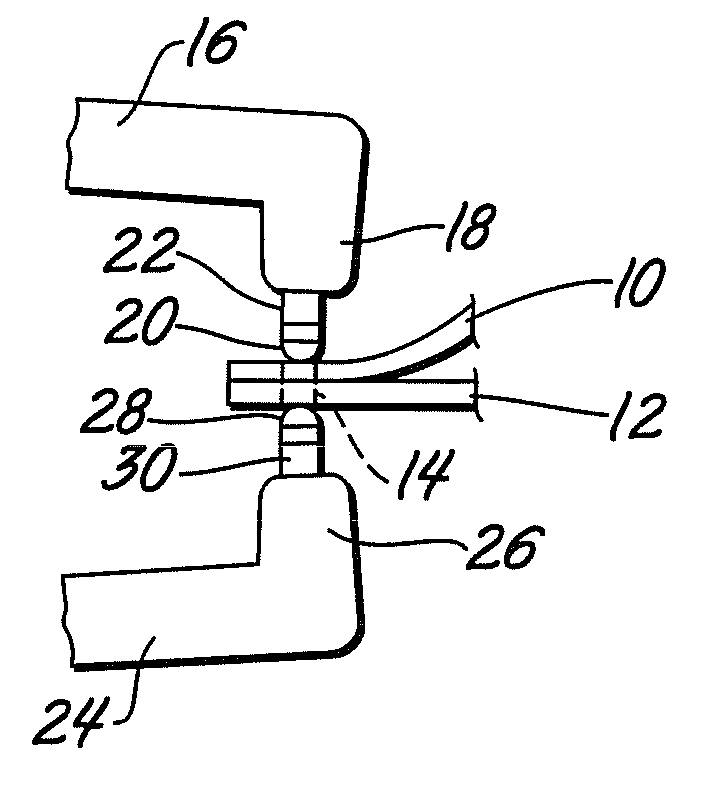

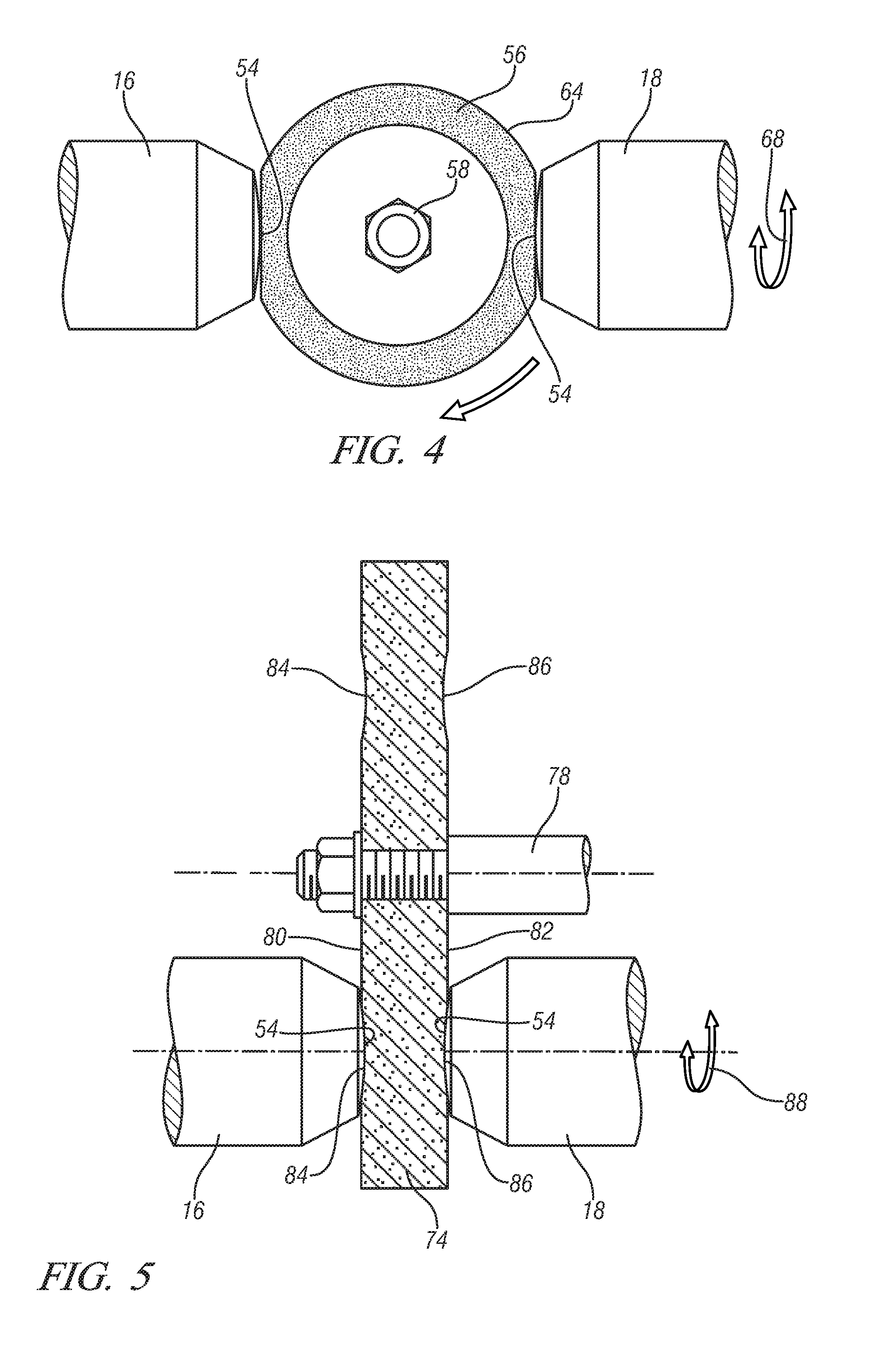

Forming and re-forming welding electrodes with contoured faces

ActiveUS20100258536A1Easily fowled on new electrodesEasy alignmentTurning machine accessoriesPressure electrodesSurface geometryMechanical engineering

A method is disclosed for using welding electrodes with a spherically-domed welding face having concentric contoured features formed into the face for better contact with workpiece surfaces. The concentric contoured features may be initially formed by rotating a cutting tool with a contoured cutting edge, the cutting edge being in engagement with the electrode face. A similar practice may be followed to re-create the weld face surface geometry if it becomes eroded or malformed during welding use. A suitable tool may have a blade-like geometry, with a mounting portion for supporting and positioning the tool in a rotating holder and a cutting edge. The cutting edge may have a contour complementary to that of the weld face and extend at least from the center of the weld face to at least the radial extent of the concentric contoured features.

Owner:GM GLOBAL TECH OPERATIONS LLC

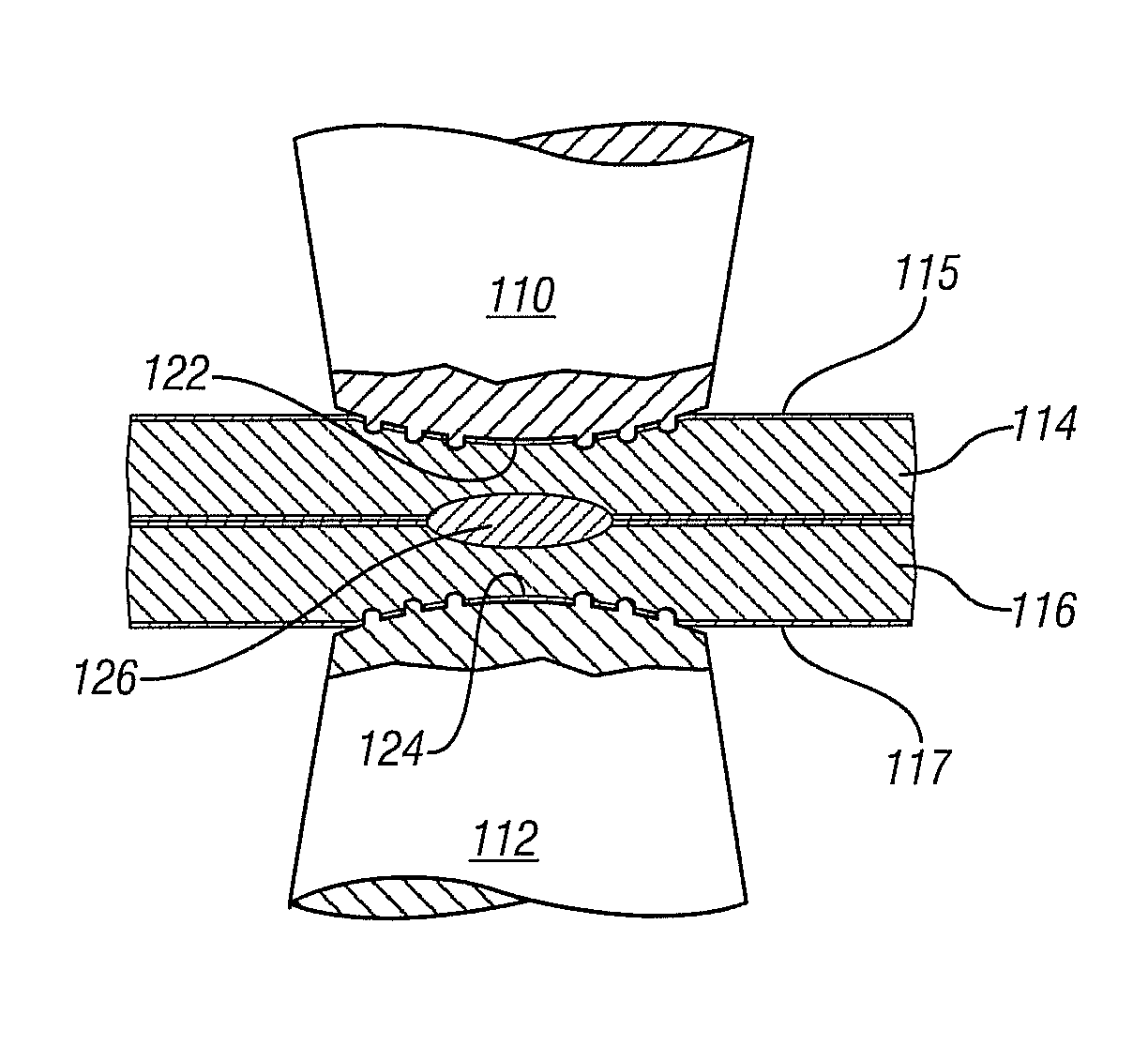

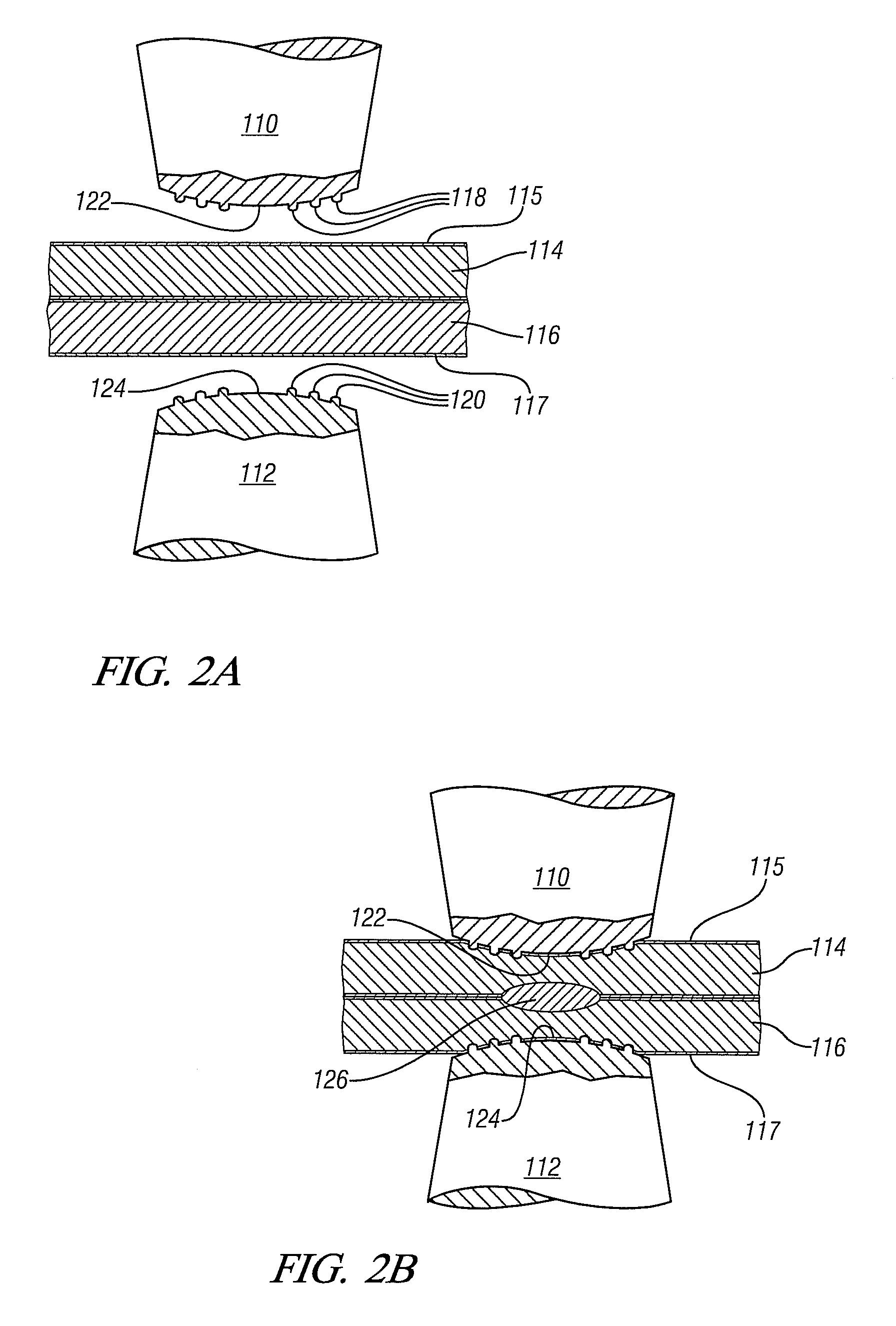

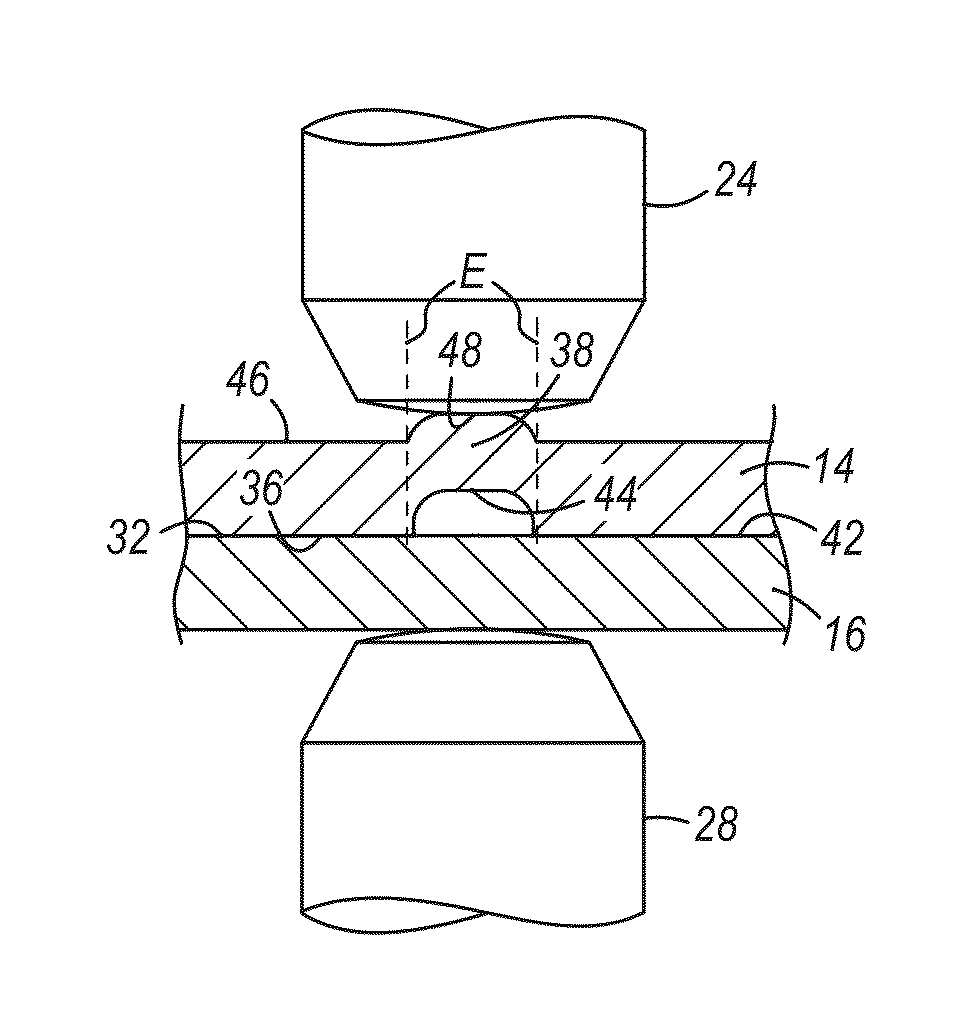

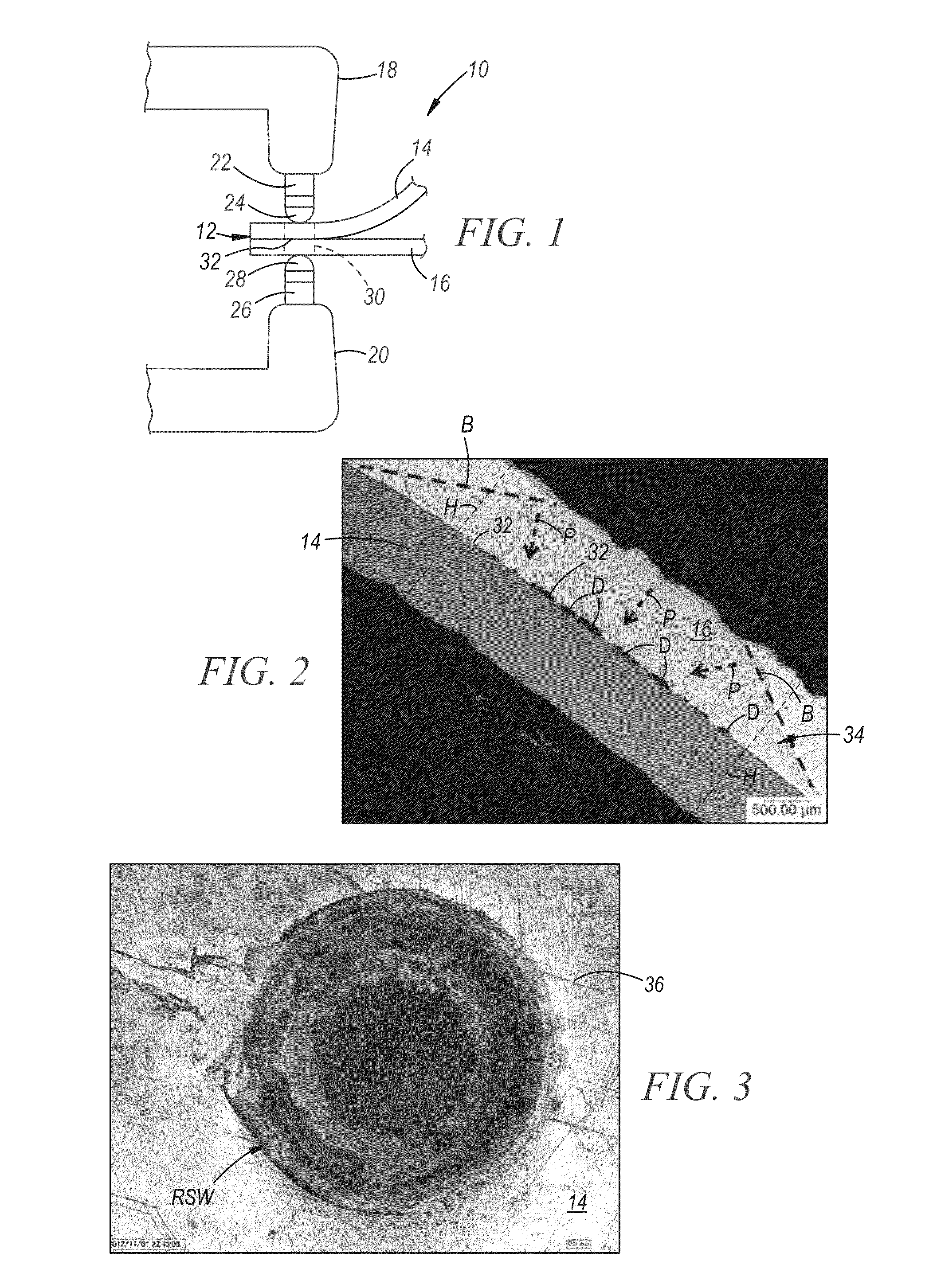

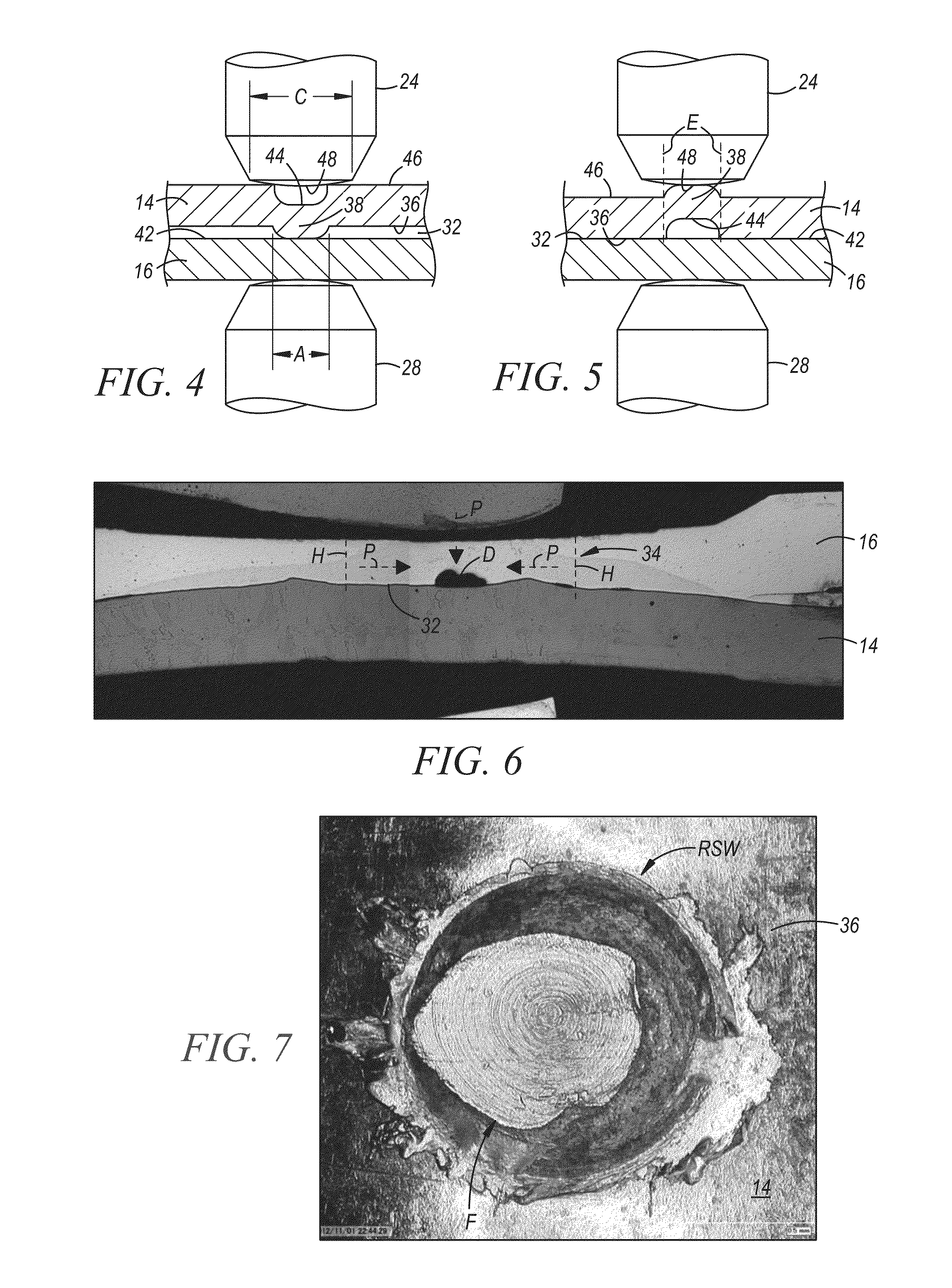

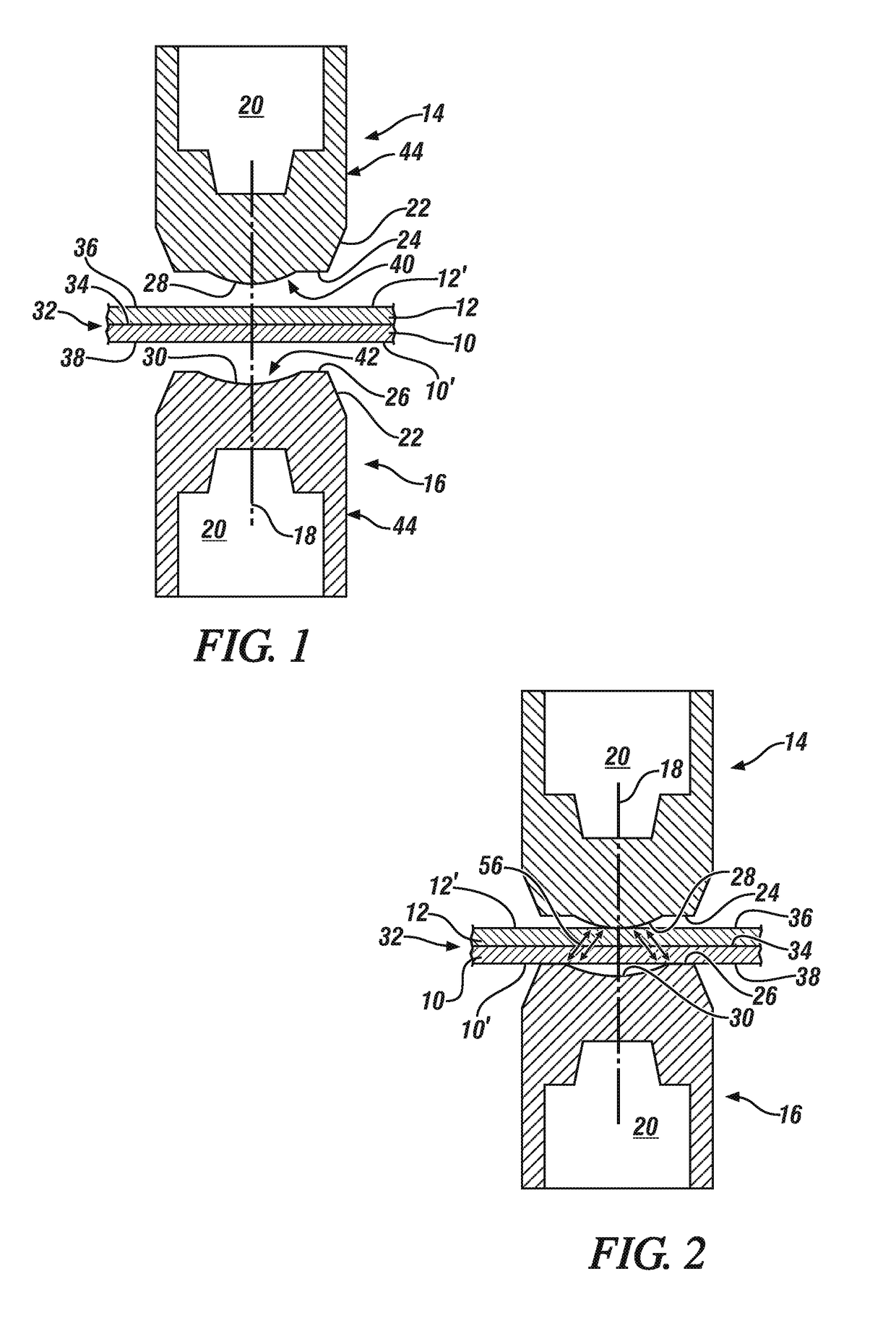

Resistance spot welding steel and aluminum workpieces with protuberance

InactiveUS20150231730A1Pressure electrodesWelding/soldering/cutting articlesSpot weldingAluminium alloy

A method of resistance spot welding a steel workpiece and an aluminum or aluminum alloy workpiece (“aluminum workpiece”) together includes several steps. In one step a workpiece stack-up is provided. The workpiece stack-up includes a steel workpiece and an aluminum workpiece. Another step involves forming a protuberance in the steel workpiece. In another step a first and second welding electrode is provided. Yet another step involves clamping the first and second welding electrodes over the workpiece stack-up and over the protuberance. And another step involves performing one or more individual resistance spot welds to the workpiece stack-up.

Owner:GM GLOBAL TECH OPERATIONS LLC

Spot welding method, method for judging shape of nugget, spot welding machine and spot welding electrode

InactiveUS20090218323A1Simple equipmentImprove reliabilityOhmic-resistance electrodesPressure electrodesEngineeringSpot welding

An electrode whose electrode surface is a substantially convex curved surface and which has at a center portion a recess set at a predetermined depth allowing a welding trace formed on a metal body surface to reach a deepest portion when a nugget is formed in a satisfactory manner by the spot welding is used as at least an electrode for performing the spot welding. The spot welding quality is judged based on a shape of the welding trace formed on the metal body surface by the spot welding in correspondence with the recess.

Owner:DAIHATSU MOTOR CO LTD +1

Welding electrode and method

ActiveUS20060261046A1High weight percentagePoor adhesionOhmic-resistance electrodesPressure electrodesBiomedical engineeringLiquid cooling system

A welding electrode has a body having a shank and a contact region for placement against a workpiece during welding. A portion of the body may be formed on a parabolic profile. A coating is formed on the contact region. The coating may have a first layer, and a second layer formed over the first layer. The first and second layers may have different compositions. The electrode may have internally formed cooling finwork for interaction with a liquid cooling system.

Owner:HUYS IND

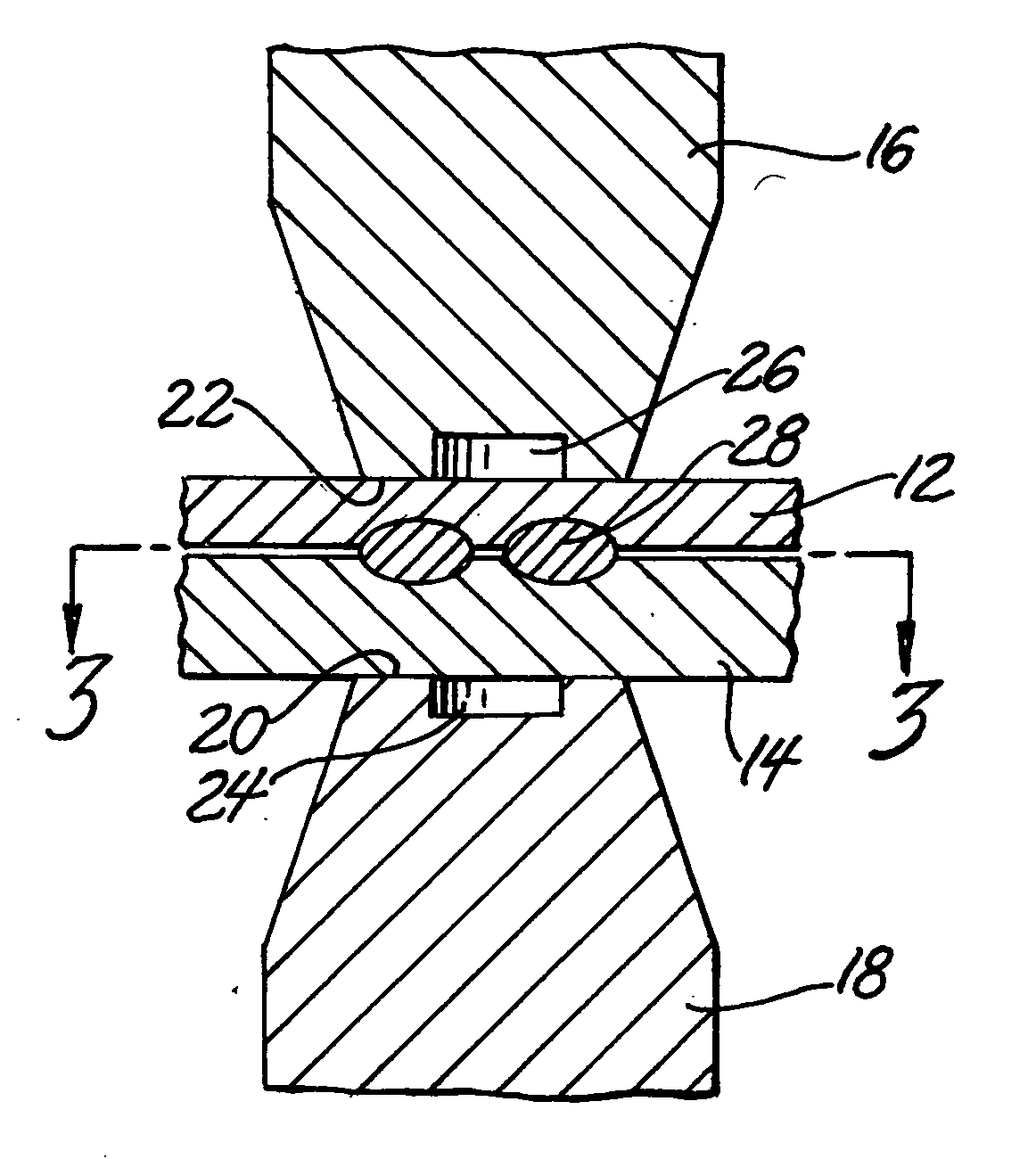

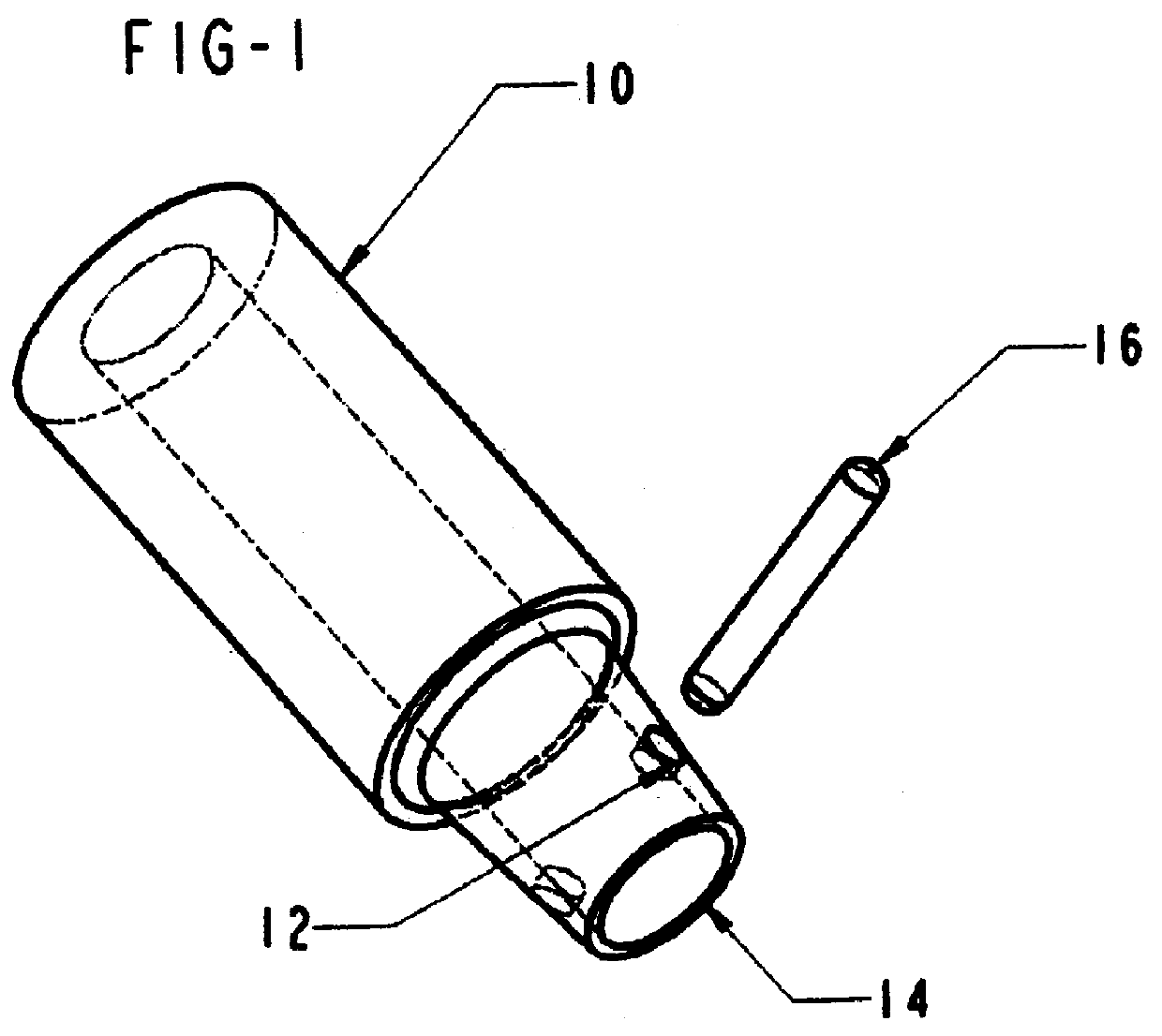

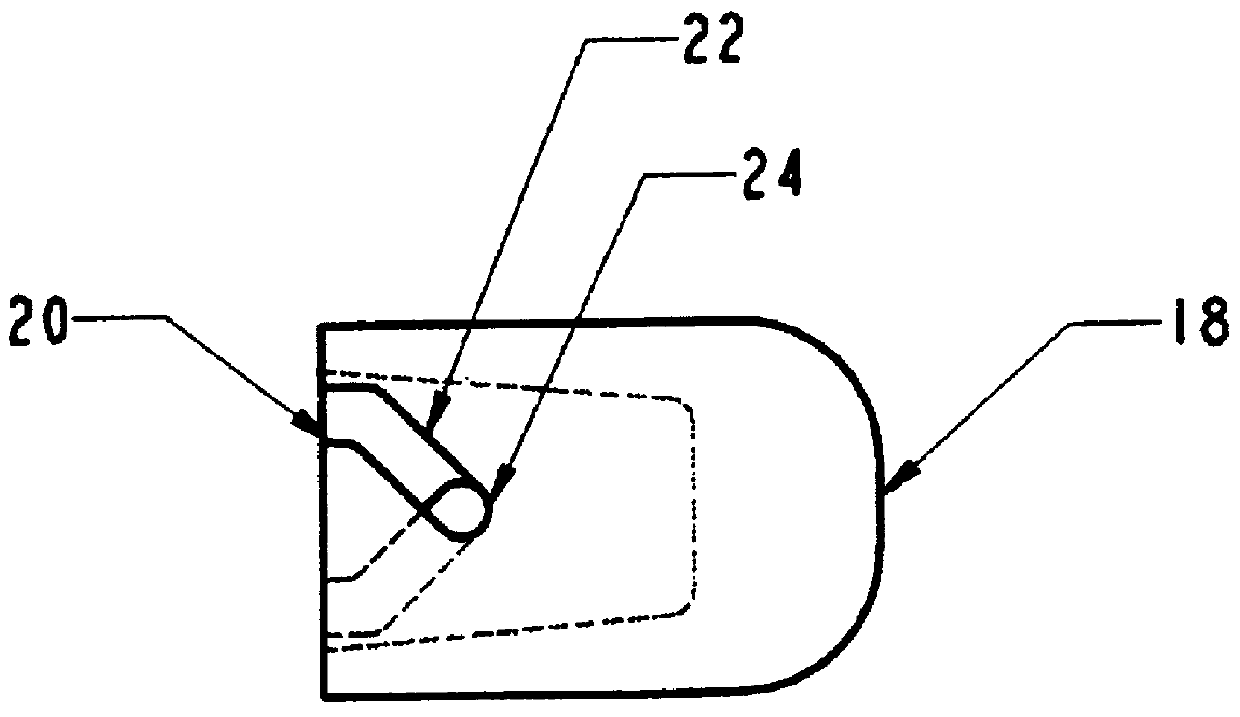

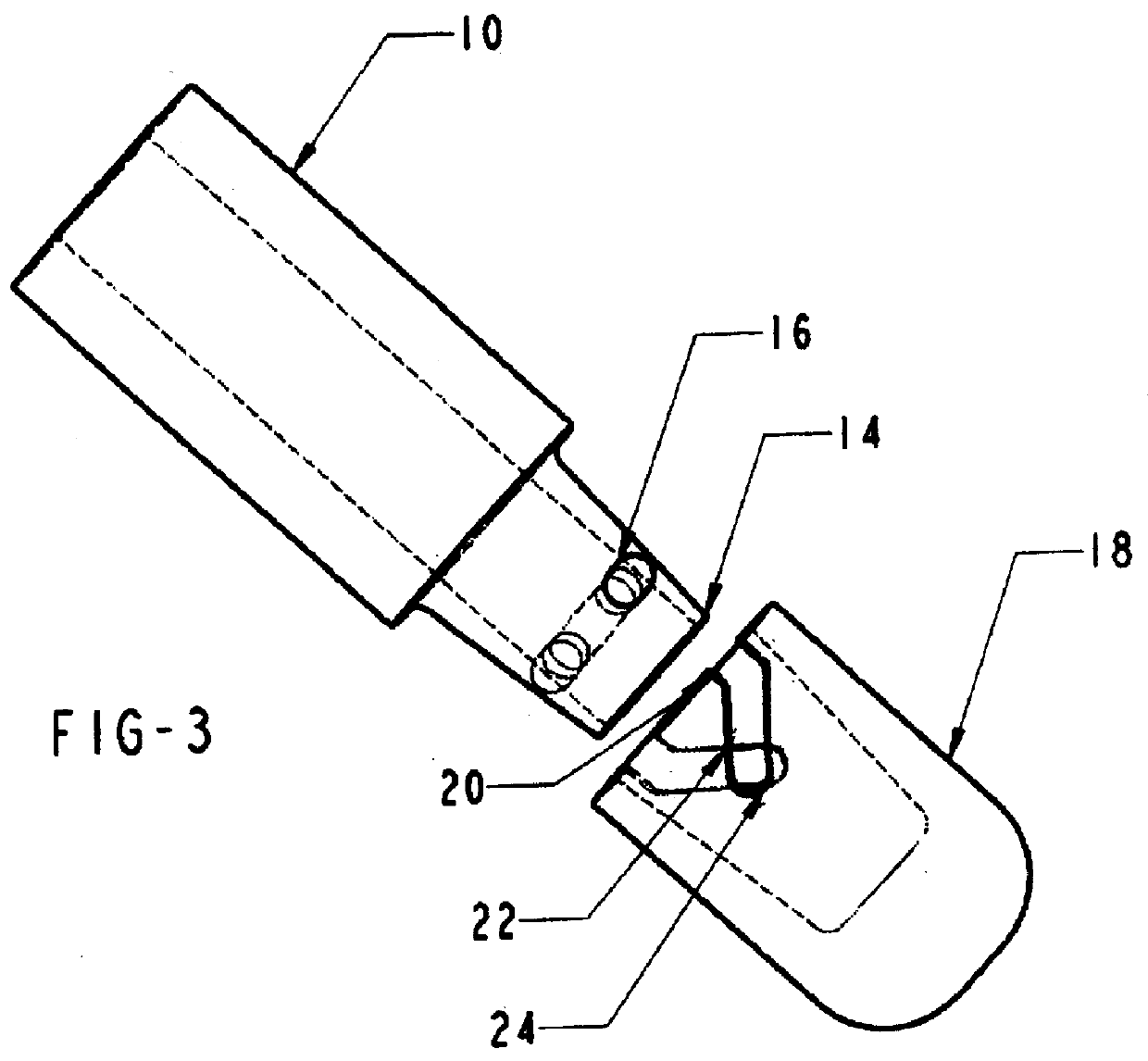

Locking electrode tip for resistance spot-welding

InactiveUS6011237AOhmic-resistance electrodesPressure electrodesElectrical resistance and conductanceSpot welding

A resistance welding electrode body is fitted with a metal pin which serves as an anchor point for an electrode welding tip. The electrode welding tip contains two lead-in notches and diagonal grooves that allow the electrode tip to be locked onto the electrode body. This form of electrode has been found advantageous in terms of retaining the electrode tip onto the electrode body during resistance spot welding.

Owner:YANG DANIEL

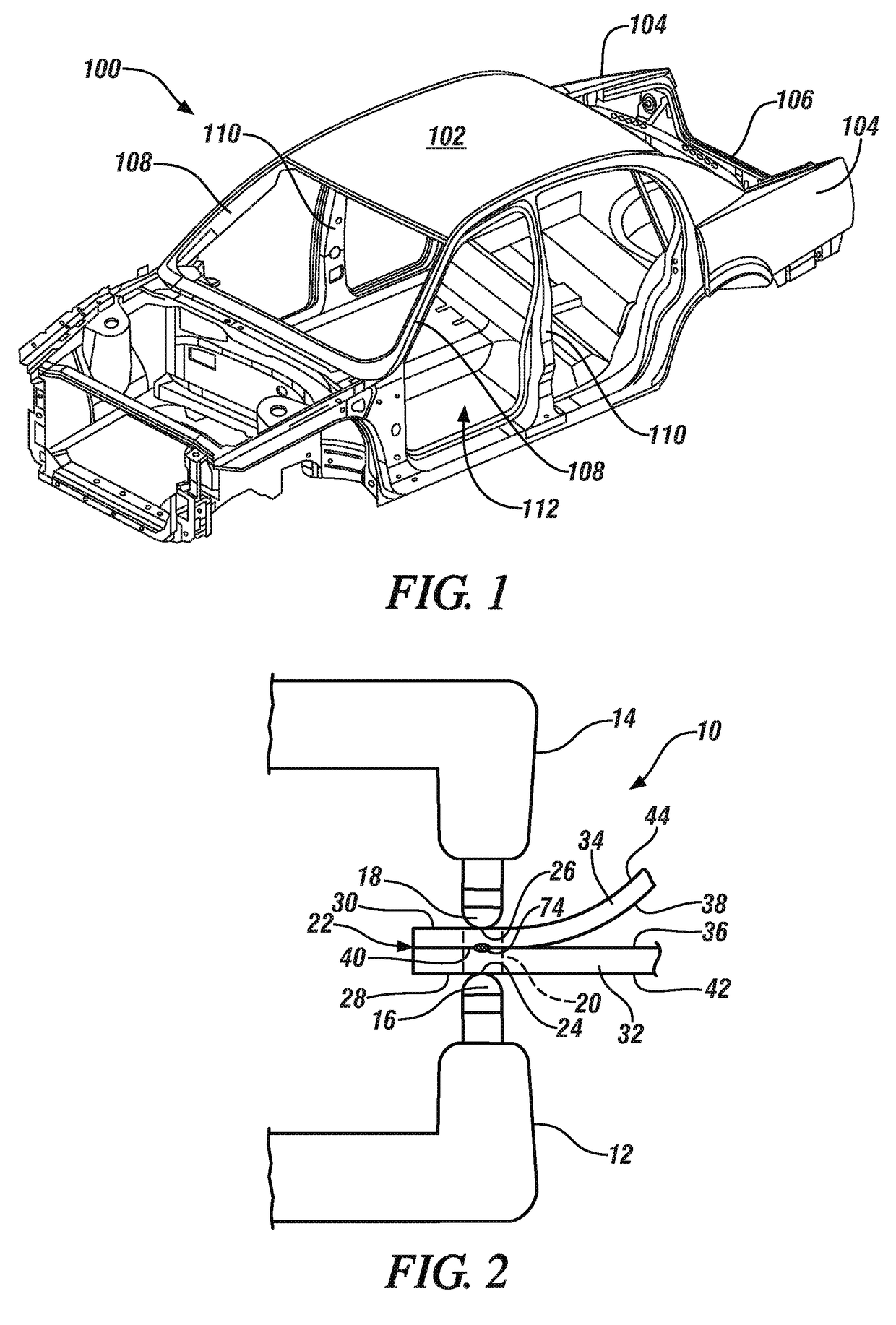

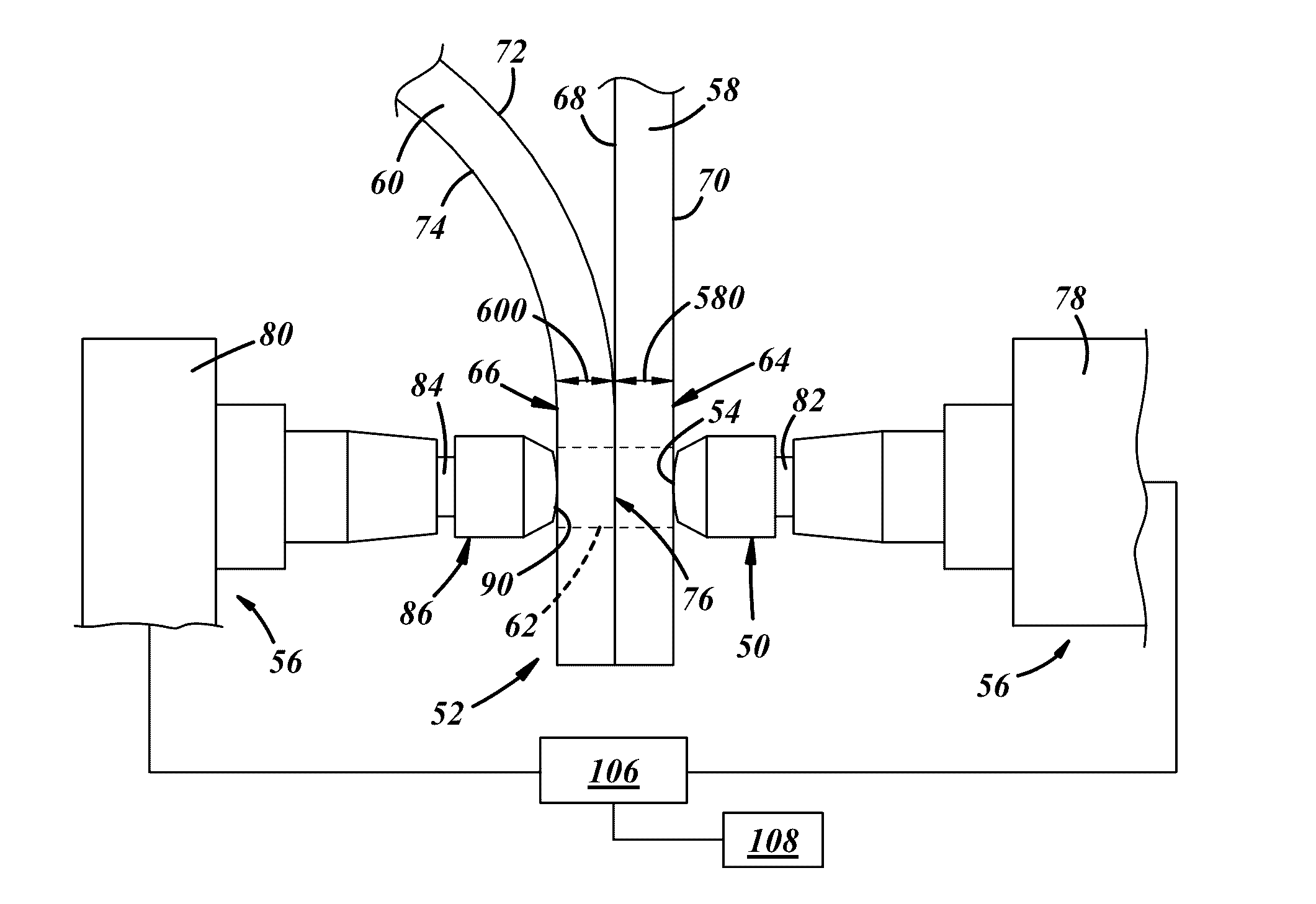

Resistance spot welding of aluminum-to-aluminum, aluminum-to-steel, and steel-to- steel in a specified sequence and using a cover

A series of many electrical resistance spot welds is to be formed in members of an assembled, but un-joined, body that presents workpiece stack-ups of various combinations of metal workpieces including all aluminum workpieces, all steel workpieces, and a combination of aluminum and steel workpieces. A pair of spot welding electrodes, each with a specified weld face that includes oxide-disrupting features, is used to form the required numbers of aluminum-to-aluminum spot welds, aluminum-to-steel spot welds, and steel-to-steel spot welds. A predetermined sequence of forming the various spot welds may be specified for extending the number of spot welds that can be made before the weld faces must be restored. And, during at least one of the aluminum-to-steel spot welds, a cover is inserted between the weld face of one of the welding electrodes and a side of a workpiece stack-up that includes the adjacent aluminum and steel workpieces.

Owner:GM GLOBAL TECH OPERATIONS LLC

Welding surface design of spot welding

The invention relates to the welding surface design of spot welding. Specifically, a welding electrode for being engaged with an aluminum alloy workpiece during a spot welding process includes a welding surface, the welding surface comprises a base surface and a plurality of circular ridges projecting from the base surface to the outside, the circular ridges are dull and their presence on the welding surface provides some useful abilities for a first welding electrode, including the ability to make a better mechanical and electrical contact with the aluminum alloy workpiece.

Owner:GM GLOBAL TECH OPERATIONS LLC

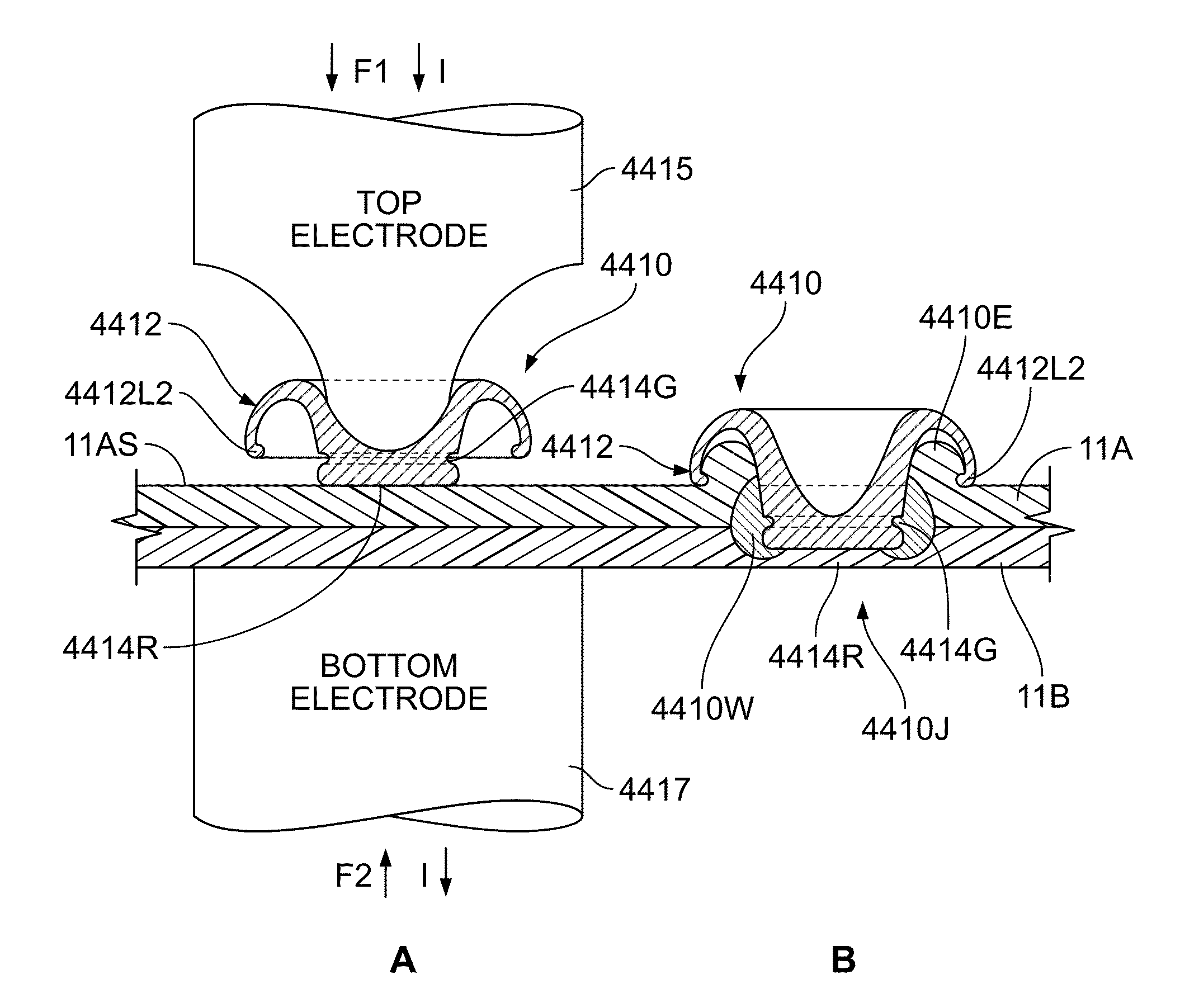

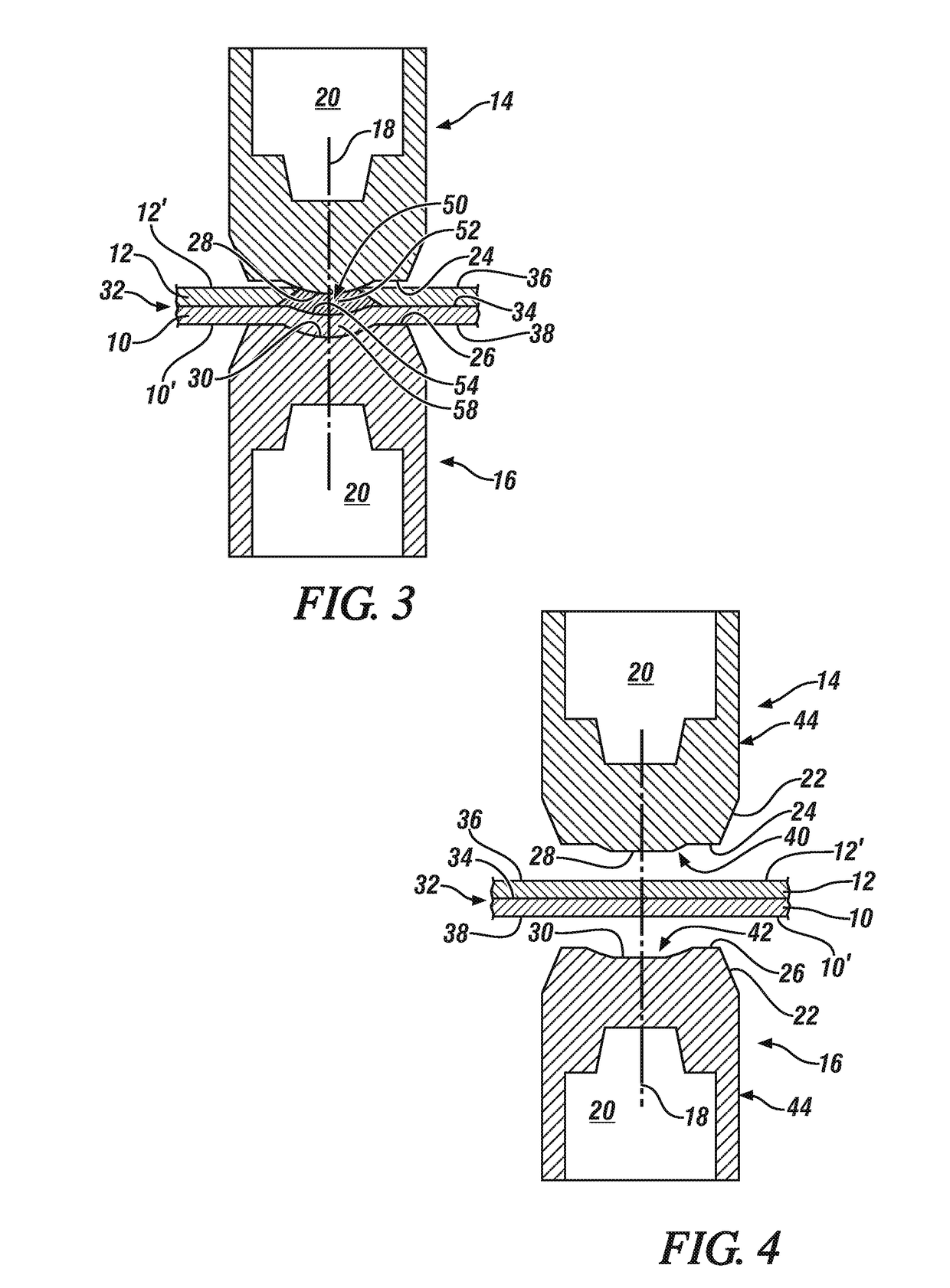

Resistance spot welding steel and aluminum workpieces with electrode insert

ActiveUS20160158874A1Low thermal conductivityHigh resistivityOhmic-resistance electrodesPressure electrodesElectrical resistance and conductanceHeat flux

A method of resistance spot welding a steel workpiece and an aluminum or aluminum alloy workpiece together includes several steps. In one step a workpiece stack-up is provided. The workpiece stack-up includes a steel workpiece and an aluminum or aluminum alloy workpiece. Another step involves providing a first welding electrode that confronts the aluminum workpiece, and providing a second welding electrode that confronts the steel workpiece. The first welding electrode has an electrode body and an insert that functions to limit or eliminate heat flux into the electrode body. Other steps of the method involve bringing the first and second welding electrodes into contact with opposite sides of the workpiece stack-up and resistance spot welding the stack-up.

Owner:GM GLOBAL TECH OPERATIONS LLC

Resistive welding electrode and method for spot welding steel and aluminum alloy workpieces with the resistive welding electrode

ActiveUS20160279732A1Increase contact areaHigh densityWelding/cutting media/materialsPressure electrodesElectrical resistance and conductanceRefractory

A resistive welding electrode includes at least a weld face constructed of a refractory-based material that exhibits an electrical conductivity that is less than or equal to 65% of the electrical conductivity of commercially pure annealed copper as defined by the International Annealed Copper Standard (IACS). A method of using the resistive welding electrode to resistance spot weld a workpiece stack-up that includes an aluminum alloy workpiece and steel workpiece that overlap and contact each other at a faying interface is also disclosed.

Owner:GM GLOBAL TECH OPERATIONS LLC

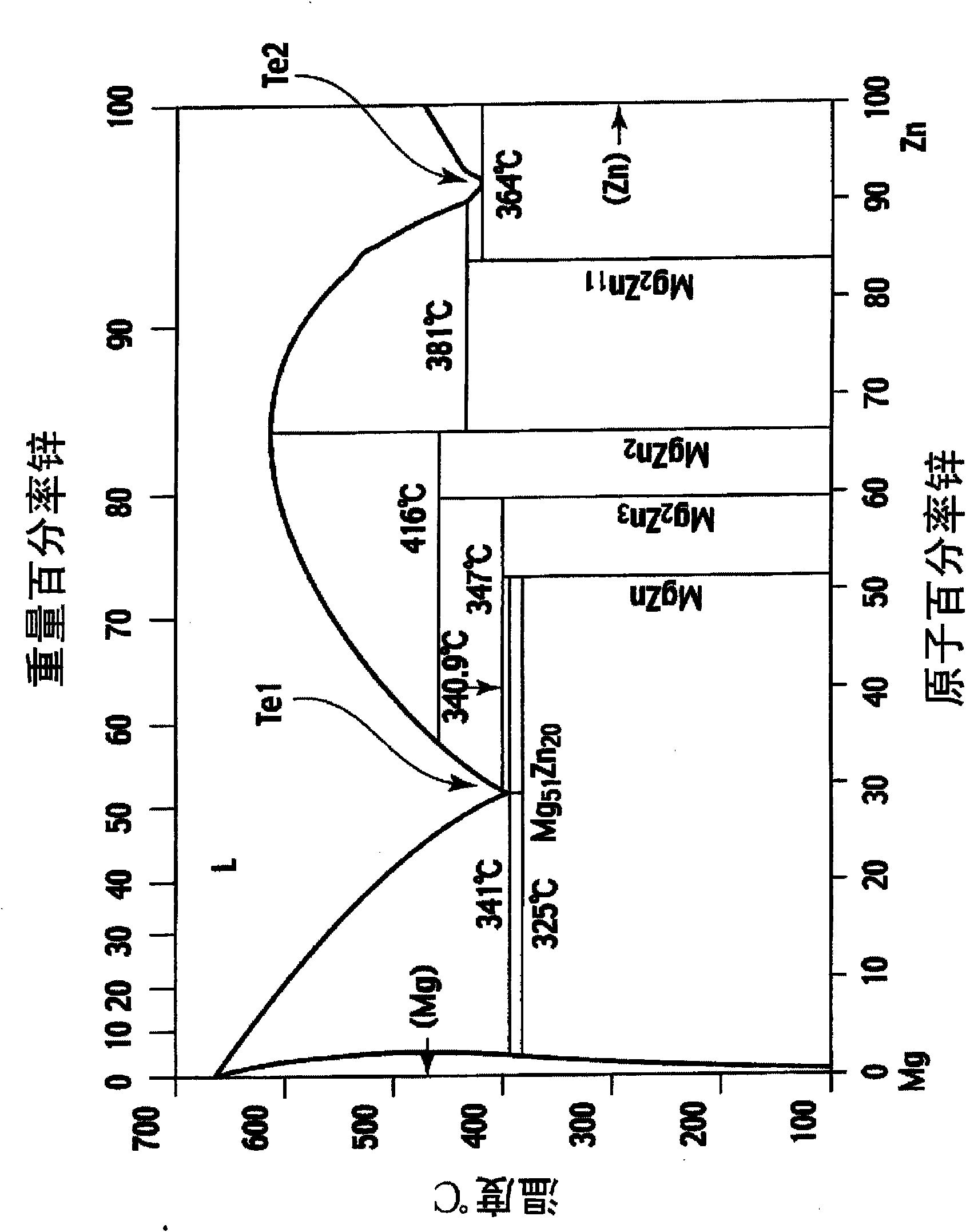

Method of bonding different metals and bonded structure

ActiveCN101918168AEasy to removeStrong jointSoldering apparatusHigh frequency current welding apparatusSheet steelChemical compound

A magnesium alloy material (1) (first material) is bonded to a steel material (second material). The steel material to be used is a galvanized steel plate (2), which has a deposit of zinc (metal (C)); and the magnesium alloy material (1) contains aluminum (metal (D)). In bonding the two materials, a magnesium-zinc eutectic melt is generated and the melt is discharged from the bonding interface together with an oxide coating film (1f), impurities, etc. Simultaneously therewith, an aluminum-magnesium intermetallic compound such as Al3Mg2 and an iron-aluminum intermetallic compound such as FeAl3 are generated. Thus, newly formed surfaces of the two materials (1) and (2) are bonded to each other through a compound layer (3) containing these intermetallic compounds.

Owner:NISSAN MOTOR CO LTD

Welding Electrode With Contoured Face

ActiveUS20110266260A1Improve high temperature strengthLow efficiencyWelding with roller electrodesWelding/cutting media/materialsMaterials scienceElectrode

A method for welding a plurality of aluminum to aluminum welds and a plurality of steel to steel welds using the same welder includes providing a resistance spot welder with a pair of weld electrodes having an electrode face radius of curvature in the range between 20 mm and 40 mm. The series of aluminum to aluminum welds is first made, and then, after completing the aluminum to aluminum welds, the series of steel to steel welds are made. After completing the steel to steel welds the weld electrodes are cleaned by an abrasive to remove any buildup or contamination of aluminum on the electrodes. In the event the electrodes have mushroomed, then dressing of the electrodes is provided and then the abrasive cleaning is performed to restore the surface texture.

Owner:GM GLOBAL TECH OPERATIONS LLC

Joint product between steel product and aluminum material, spot welding method for the joint product, and electrode chip for use in the joint product

ActiveUS20120021240A1High bonding strengthLow costArc welding apparatusOther manufacturing equipments/toolsReaction layerSpot welding

Provided is a joint product of a steel product and an aluminum material, the joint product being formed by joining the steel product having a sheet thickness t1 of 0.3 to 3.0 mm with the aluminum material having a sheet thickness t2 of 0.5 to 4.0 mm by spot welding, wherein a nugget area in a joint part is from 20×t20.5 to 100×t20.5 mm2, an area of a portion where a thickness of an interface reaction layer is from 0.5 to 3 μm is 10×t20.5 mm2 or more, and a difference between the thickness of the interface reaction layer at a joint part center and the thickness of the interface reaction layer at a point distant from the joint part center by a distance of one-fourth of a joint diameter is 5 μm or less, and wherein the aluminum material is pure aluminum or an aluminum alloy material.

Owner:KOBE STEEL LTD

Resistance welding of high strength steels

InactiveUS7126077B2Improved propertyHigh strengthOhmic-resistance electrodesVehicle componentsHigh intensityElectric resistance welding

The formation of spot welds in high strength steel workpieces is improved by using welding electrodes with annular, or donut shaped welding tips for the formation of the molten metal weld pool at the weld site. The annular poll solidifies to form an annular weld nugget. Preferably the donut shaped nugget has an internal diameter that is no more than three-quarters of the outside diameter. The method is applicable to carbon steel workpieces with allowing elements for strengthening, and to thick sheets of mild carbon steels.

Owner:GM GLOBAL TECH OPERATIONS LLC

Application of surface relief to spot welding electrodes

ActiveUS20110094999A1Avoid deformationPrevent removalArc welding apparatusPressure electrodesElectrical resistance and conductanceEngineering

The workpiece-contacting surface of the spot welding electrode may be suitably modified to incorporate a desired shape or form, generally comprising a depressed region outlining a recognizable shape, to form aesthetically-pleasing or functional features in the surface of a workpiece during resistance spot welding. Methods for creating the desired form in the spot welding electrode including abrasion, upsetting, and electrical discharge machining are disclosed. Preferably the electrode face is shaped and subsequently redressed during welding operations at the welding station.

Owner:GM GLOBAL TECH OPERATIONS LLC

Electrode Tip Holder, Welding Method, and Electrode Tip Adjusting Device

InactiveUS20080190899A1Improve welding efficiencyThe process is convenient and fastPressure electrodesWelding accessoriesScrew threadBiomedical engineering

An electrode tip holder, a welding method, and an electrode tip adjusting device. The electrode tip holder comprises a chuck body having an inner diameter hole with a first tapered inner peripheral surface diverging toward the tip thereof, a lock nut threaded with the tip male screw part of the chuck body, and a collet fitted to the inner diameter hole. The collet is axially pressed since the lock nut is threaded with the tip male screw part and reduced in diameter by the elastic deformation of a slit to hold an electrode tip fitted to the inside thereof. The chuck body comprises a coolant supply port supplying a coolant to a groove part and a coolant recovery port recovering the coolant from the groove part which are opened at positions facing the groove part.

Owner:HONDA MOTOR CO LTD

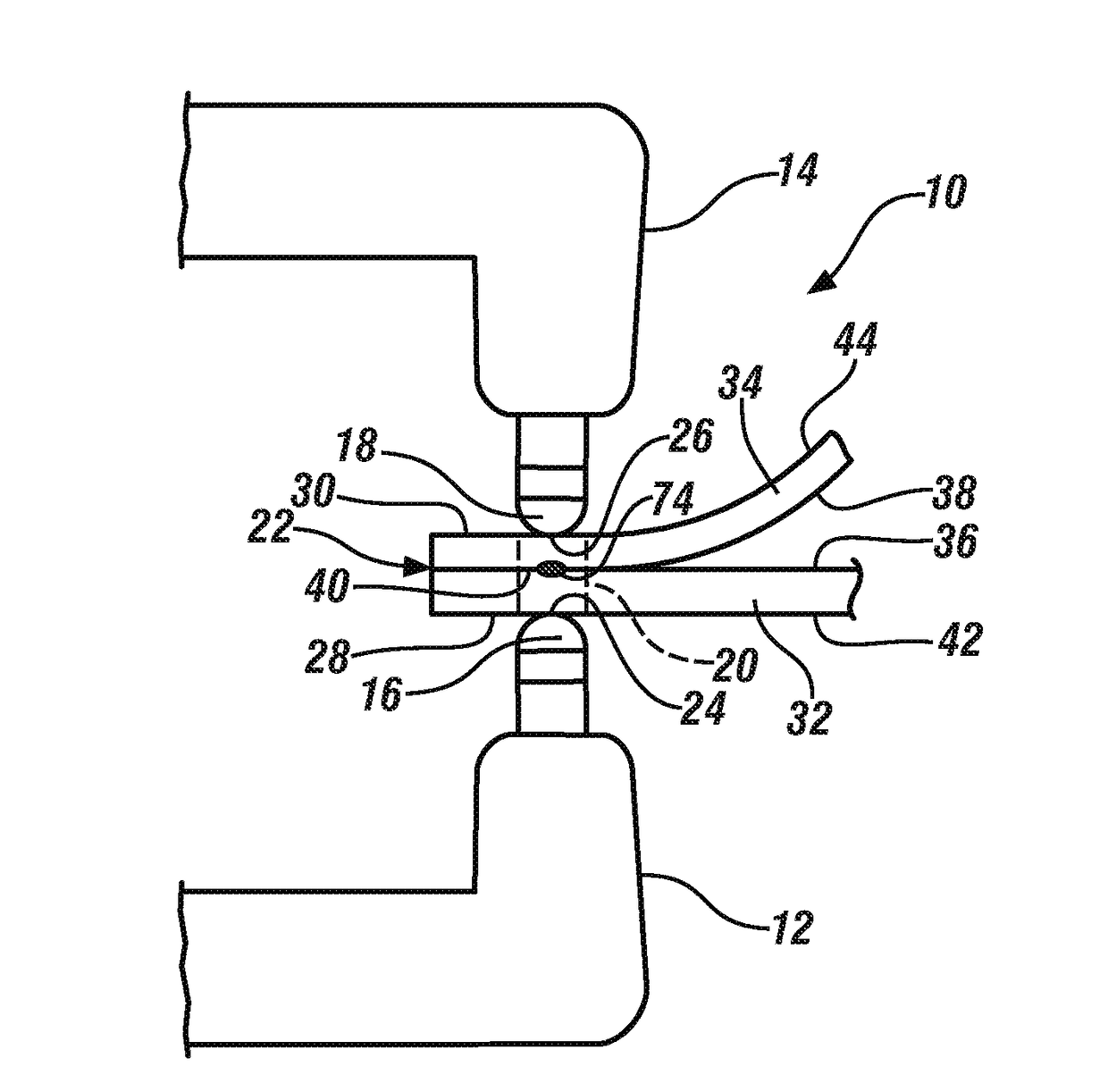

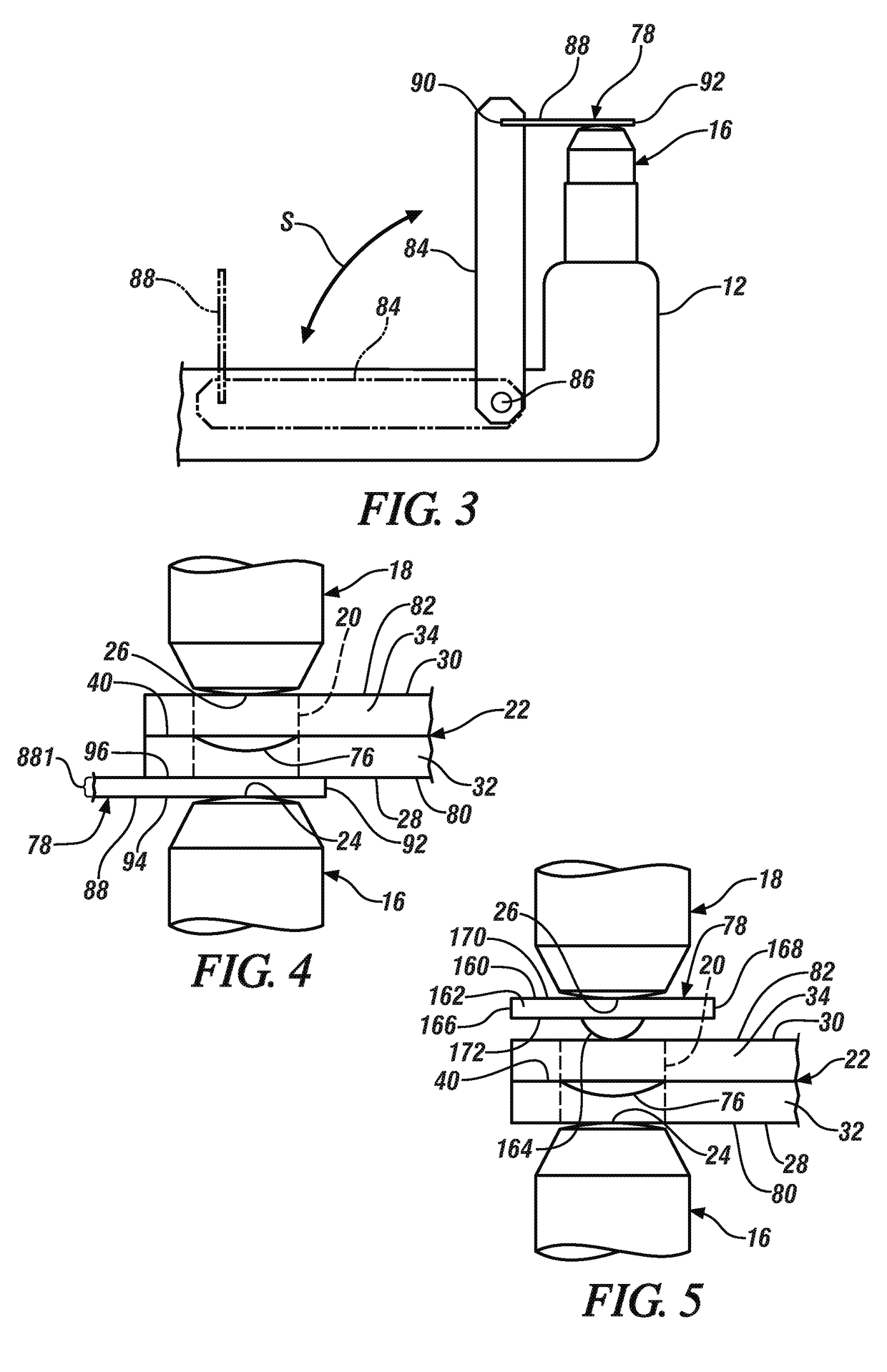

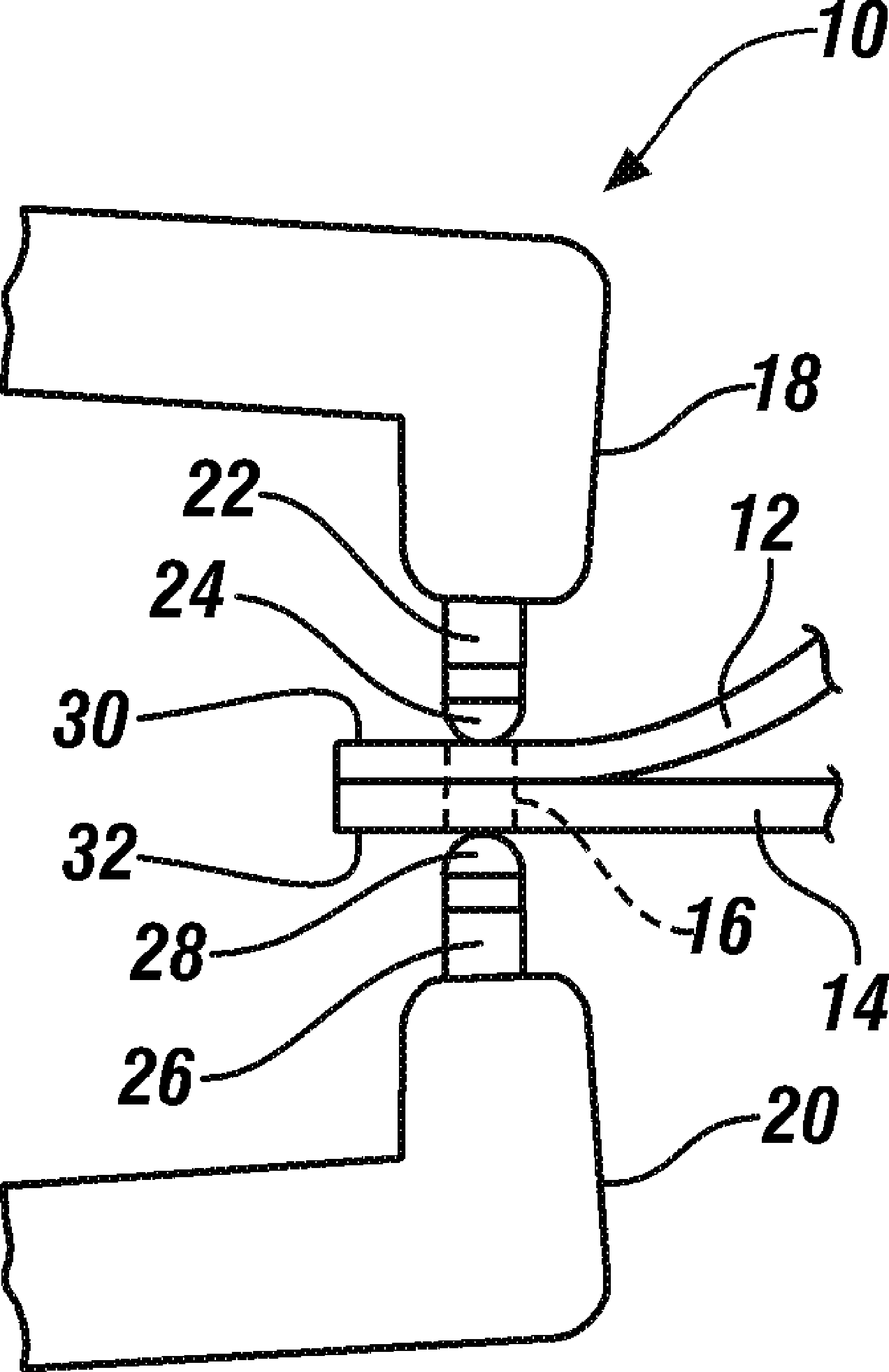

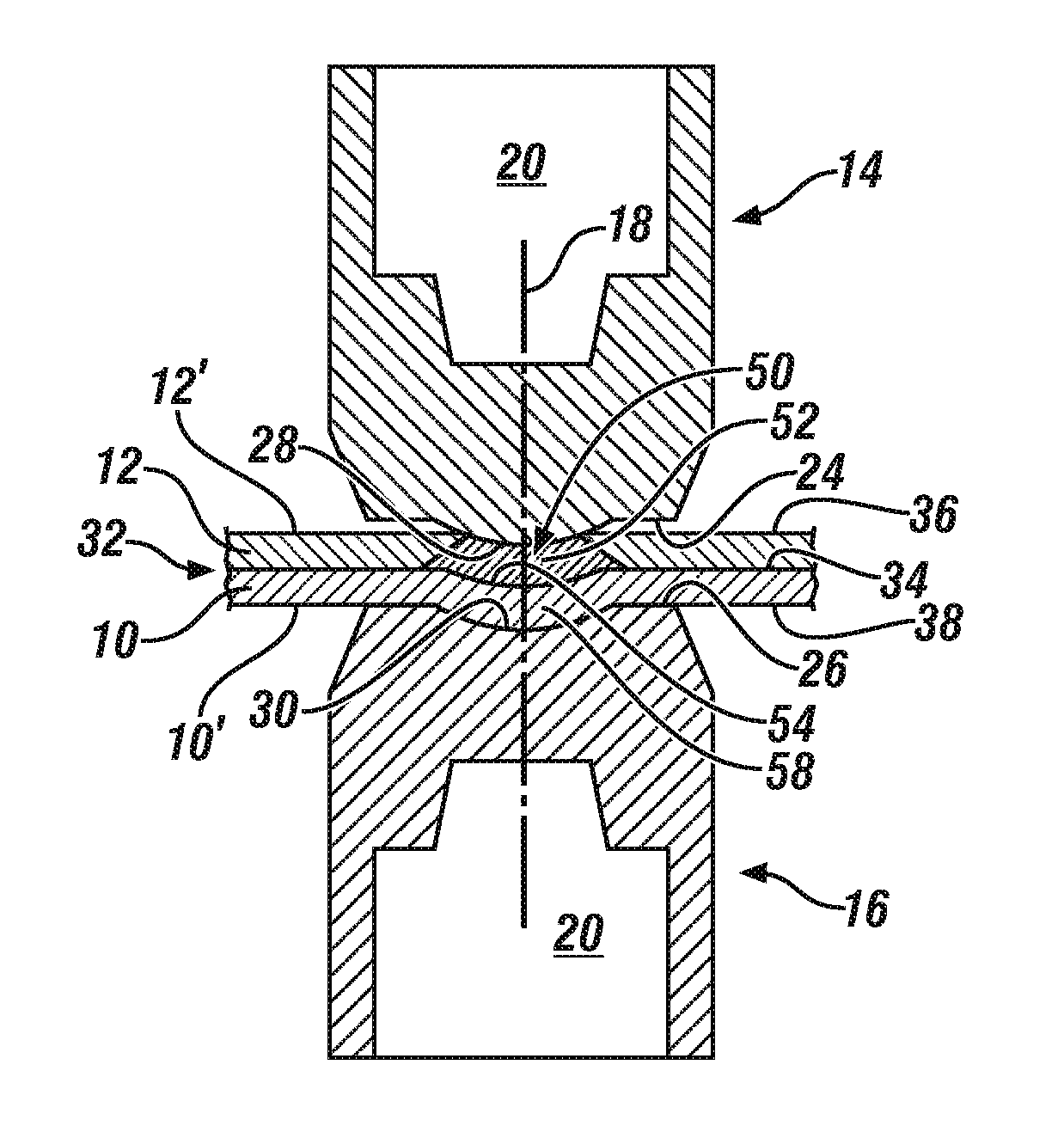

Mating electrodes for resistance spot welding of aluminum workpieces to steel workpieces

ActiveUS20170252853A1Appropriate strengthStrong and stable structurePressure electrodesWelding/soldering/cutting articlesEngineeringSpot welding

A spot weld may be formed between an aluminum workpiece and an adjacent overlapping steel workpiece with the use of opposed spot welding electrodes that have mating weld faces designed for engagement with the outer surfaces of the workpiece stack-up assembly. The electrode that engages the stack-up assembly proximate the aluminum workpiece includes a central ascending convex surface and the electrode that engages the stack-up assembly proximate the steel workpiece has an annular surface. The mating weld faces of the first and second spot welding electrodes distribute the passing electrical current along a radially outwardly expanding flow path to provide a more uniform temperature distribution over the intended spot weld interface and may also produce a deformed bonding interface within the formed weld joint. Each of these events can beneficially affect the strength of the weld joint.

Owner:GM GLOBAL TECH OPERATIONS LLC

Welding electrode and method

ActiveUS7538294B2Ohmic-resistance electrodesPressure electrodesLiquid cooling systemBiomedical engineering

A welding electrode has a body having a shank and a contact region for placement against a workpiece during welding. A portion of the body may be formed on a parabolic profile. A coating is formed on the contact region. The coating may have a first layer, and a second layer formed over the first layer. The first and second layers may have different compositions. The electrode may have internally formed cooling finwork for interaction with a liquid cooling system.

Owner:HUYS IND LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com