Welding surface design of spot welding

A welding surface and surface part technology, applied in welding equipment, welding equipment, resistance welding equipment, etc., can solve problems such as fragmentation, damage to welding performance, and complicated electrode dressing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

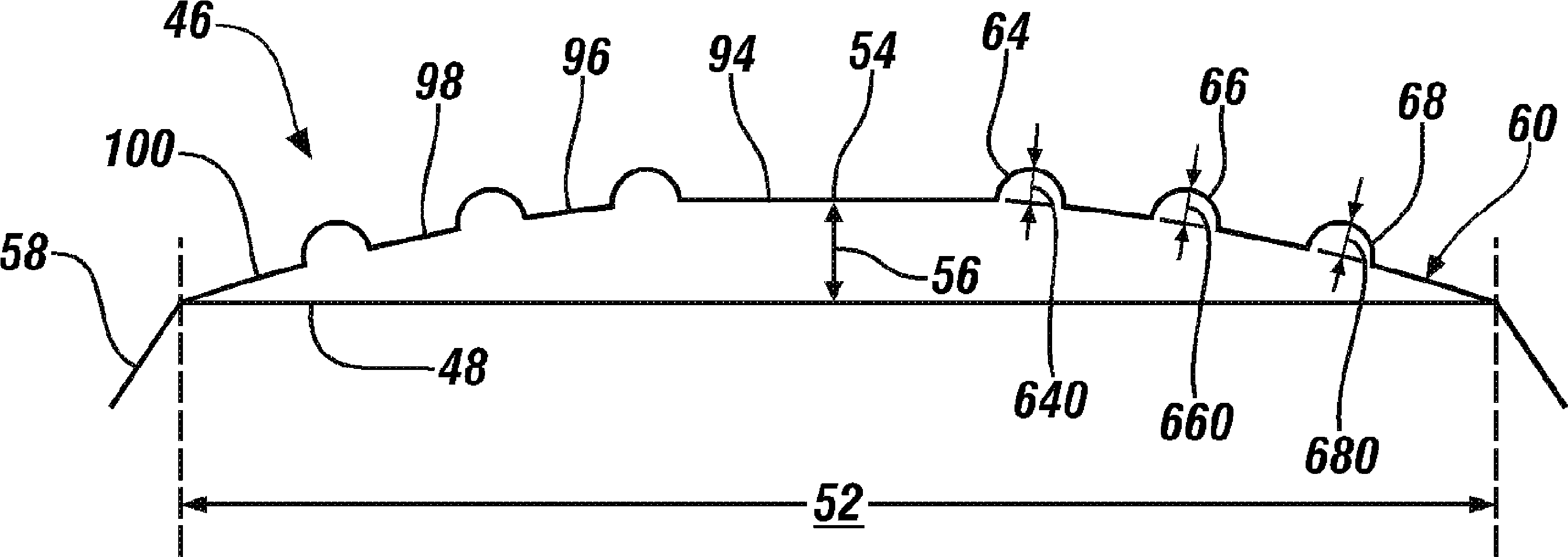

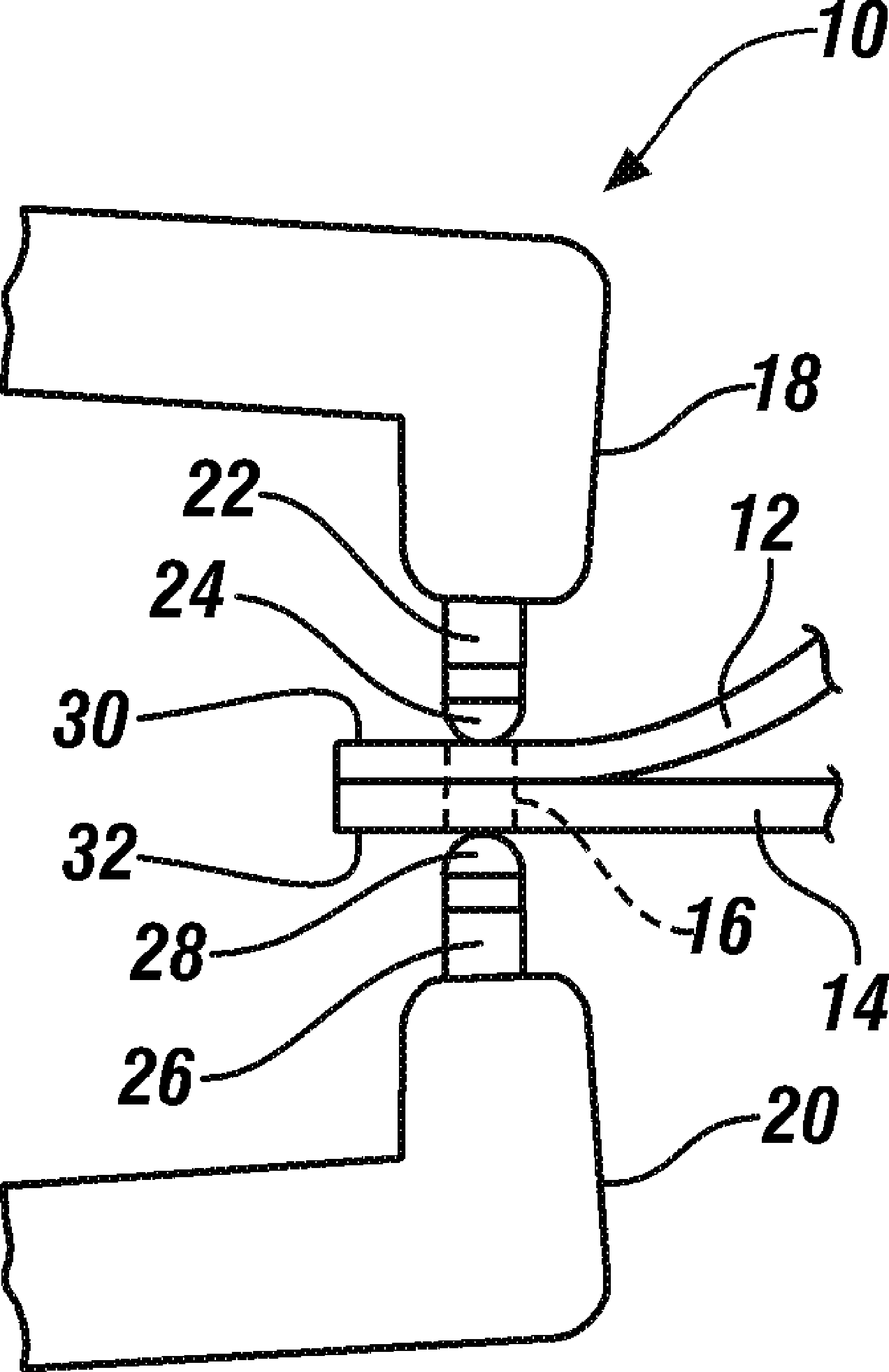

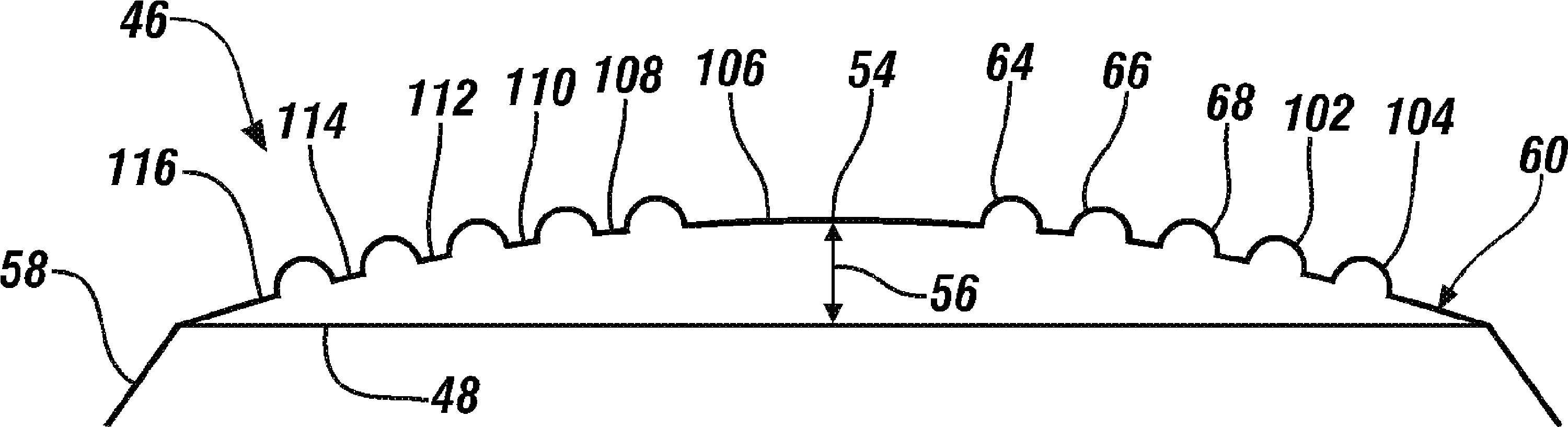

[0040] figure 1 A welding torch 10 is shown that may be used to resistance spot weld a first aluminum alloy workpiece 12 and a second aluminum alloy workpiece 14 at a welding location 16 . The first and second aluminum alloy workpieces 12, 14 are composed of an aluminum alloy such as an aluminum magnesium alloy, an aluminum silicon alloy, or an aluminum magnesium silicon alloy, and may be anywhere from about 0.5 mm to about 6.0 mm thick. A specific example of an aluminum alloy workpiece is 1.0 mm thick 5754-O aluminum alloy. But other aluminum alloys and specific workpiece thicknesses are possible. For this reason, the term "workpiece" as used herein refers broadly to include sheet metal layers, protrusions, castings, and other aluminum alloy pieces that are resistance spot weldable.

[0041] The welding gun 10 is typically part of a larger automated welding operation and includes a first gun arm 18 and a second gun arm 20 that are mechanically and electrically configured to r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com