Patents

Literature

148 results about "International Annealed Copper Standard" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The International Annealed Copper Standard (IACS) is a standard established in 1914 by the United States Department of Commerce. It is an empirically derived standard value for the electrical conductivity of commercially available copper.

High-conductivity aluminum alloy material for cable and preparation method thereof

InactiveCN101886198ALittle impact on electrical performanceEasy to stretchMetal/alloy conductorsRare-earth elementPliability

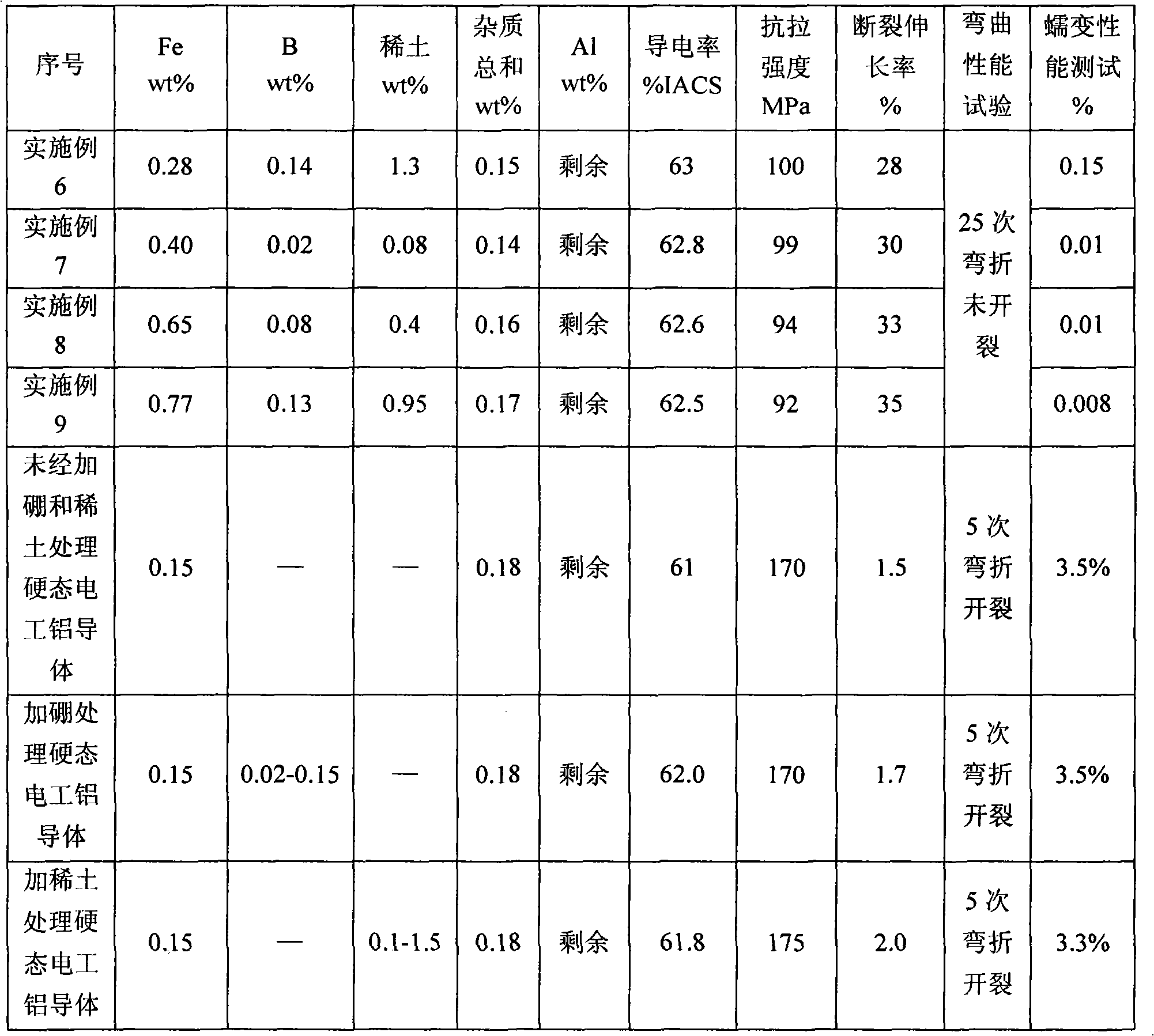

The invention relates to a high-conductivity aluminum alloy material for a cable and a preparation method thereof. The aluminum alloy material comprises the following components in percentage by weight: 0.25-0.80 percent of iron element, 0.02-0.15 percent of boron element, 0.1-1.5 percent of rare earth element and the balance of aluminum and inevitable impurities. The aluminum alloy is formed by adding an aluminum alloy intermediate alloy, an aluminum-boron alloy and an aluminum-rare earth intermediate alloy into an aluminum ingot of which the purity is more than 99.80 percent by weight and carrying out a casting process and annealing treatment on the mixture. Compared with a common electric aluminum conductor, the prepared aluminum alloy conductor has more excellent conductive performance and the conductivity reaching or exceeding 62.5 percent IACS (International Annealed Copper Standard); the aluminum alloy conductor treated by using a special process has excellent flexibility and creep resistance; and compared with a common electric aluminum conductor, the prepared aluminum alloy material used as a cable extrusion insulating lead core is more energy-saving and safer.

Owner:ANHUI JOY SENSE CABLE

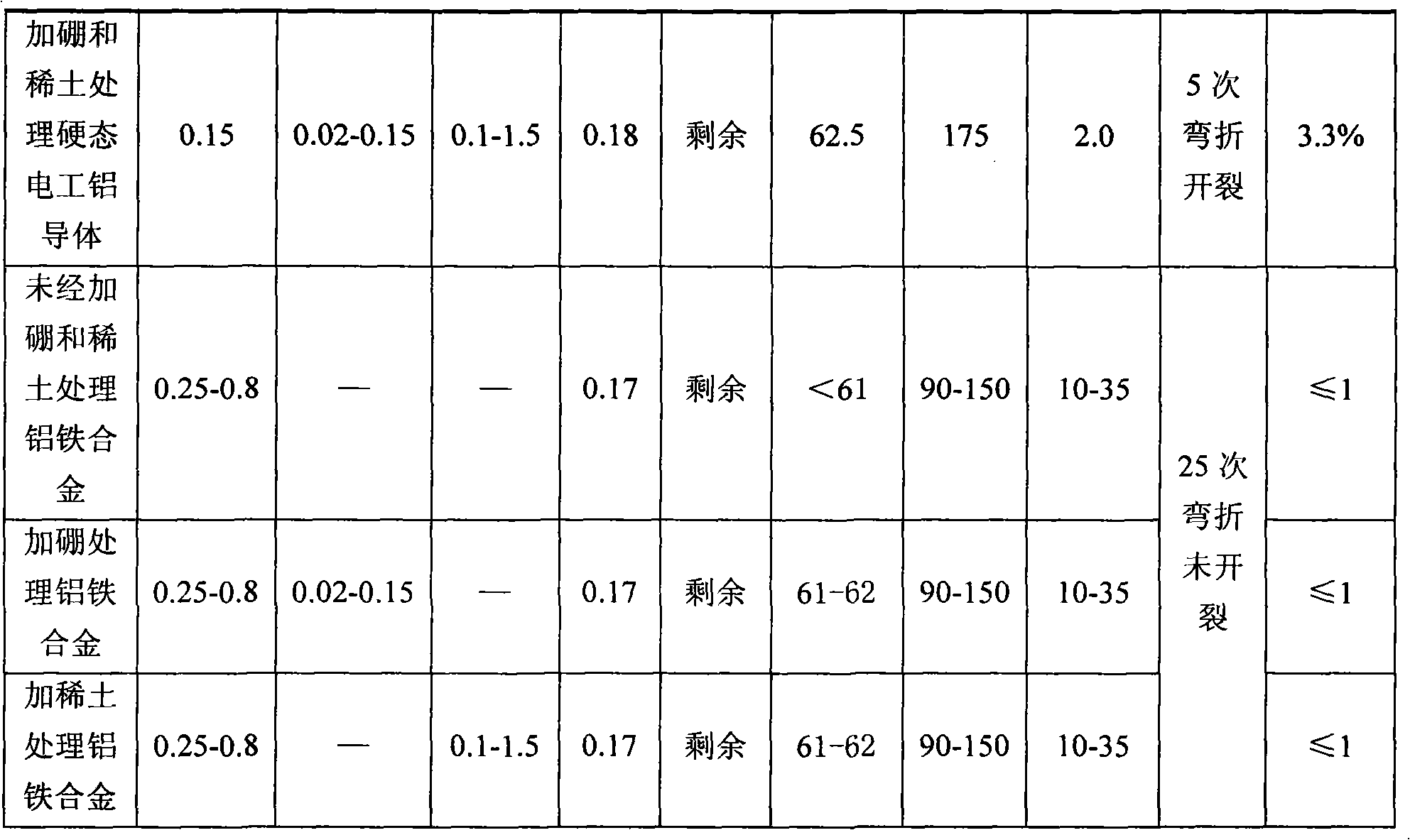

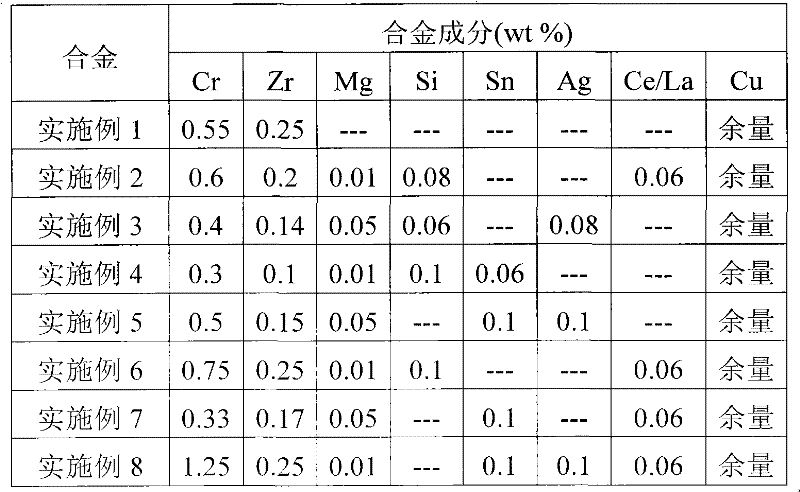

CuCrZr alloy with high strength and high conductivity, and preparation and processing method thereof

The invention relates to a CuCrZr alloy with high strength and high conductivity, and a preparation and processing method thereof. The alloy comprises the basic ingredients in percentage by mass: 0.3 percent to 1.4 percent of Cr, 0.02 percent to 0.25 percent of Zr and the balance Cu, wherein the ingredients in the CuCrZr alloy are needed to meet the following requirements: (a) Cr / Zr is less than or equal to 5 and is greater than or equal to 1.9; and (b) Cr+Zr is less than or equal to 1.5 percent and is greater than or equal to 0.4 percent. The preparation and processing method comprises the following steps of: a, compounding, feeding, smelting and casting according to mass percent; b, surface milling; c, hot rolling; d, solution treatment; e, primary cold rolling; f, primary aging; g, secondary cold rolling; and h, secondary aging. The CuCrZr alloy has the tensile strength sigma b being 600-700 MPa, the plasticity elongation rate delta being 4-10 percent, and the conductivity being greater than 80 percent of IACS (International Annealed Copper Standard), can be widely applied to occasions with high strength and high conductivity for preparing resistance welding electrodes, liners of crystallizers of continuous casting machines, integrated circuit lead frame and the like.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

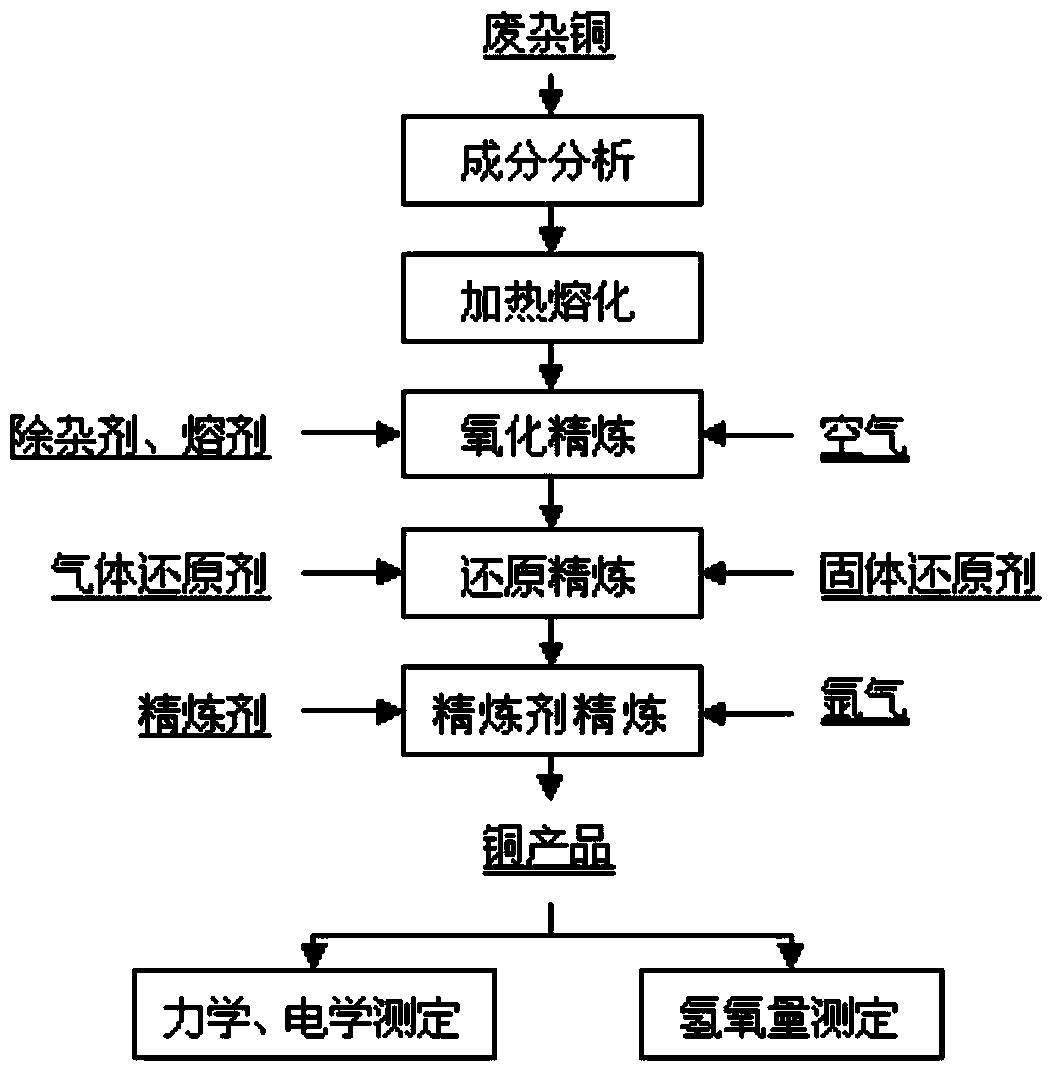

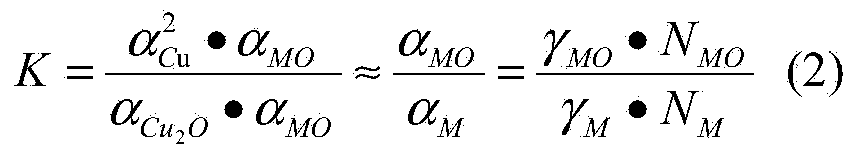

Method for directly producing high-purity oxygen-free copper by pyrogenic process continuous refining of scrap copper

ActiveCN103725897AOptimizing Process ParametersReduce manufacturing costProcess efficiency improvementElectrolysisCopper wire

The invention relates to a method for directly producing high-purity oxygen-free copper by pyrogenic process continuous refining of scrap copper, and belongs to the technical field of non-ferrous metallurgy. The method comprises the following steps: by taking scrap copper as a raw material; analyzing the component characteristics of each batch of raw material, and then preparing into a mixture, wherein the mass percent of a copper element in the mixture is greater than or equal to 93%; adding metaphosphate or phosphorus pentoxide and flux to the mixture; refining by oxidation; stewing and drossing after oxidation is finished, and then orderly carrying out reduction refining and refining agent refining under an agitation state, so as to obtain the high-purity oxygen-free copper of which the copper content is greater than or equal to 99.95% and the oxygen content is smaller than 0.003%, wherein the electrical resistivity of the obtained copper wire after drawing is below 0.017241omega / (mm), and the relative electrical conductivity is over 100% of International annealed copper standard (IACS). The method is strong in flexibility, significant in refining effect, and applicable to different components of scrap copper materials; the scrap copper can be used for directly making a rod after being refined. Compared with the traditional pyrogenic process smelting-electrolytic refining-copper cathode purification process, the method disclosed by the invention has the beneficial effects that the flow is shortened, the cost is reduced, the energy is saved, and continuous operation is achieved.

Owner:CENT SOUTH UNIV

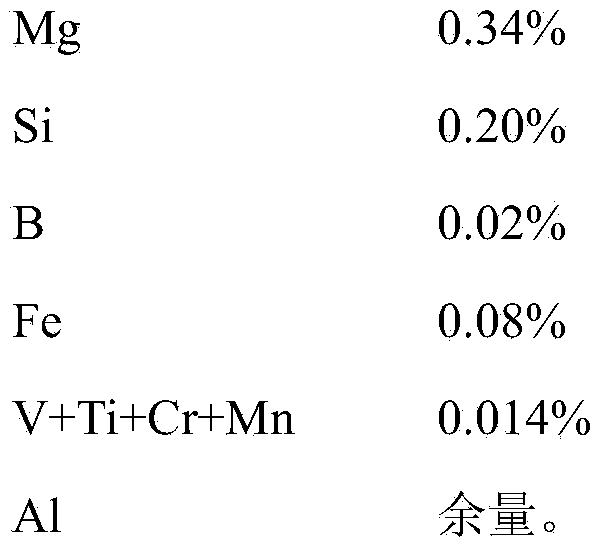

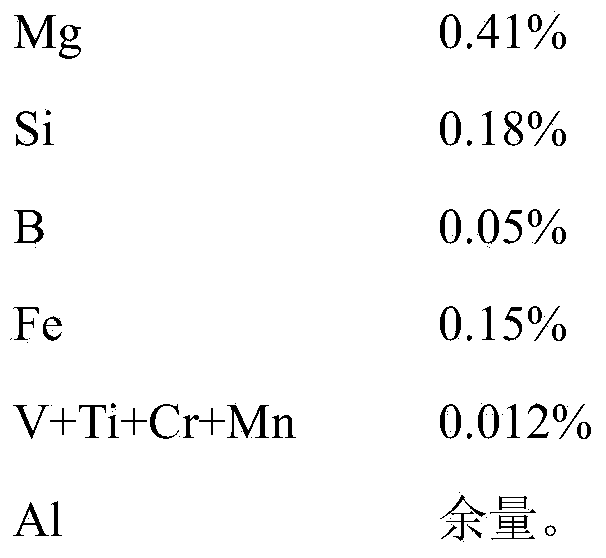

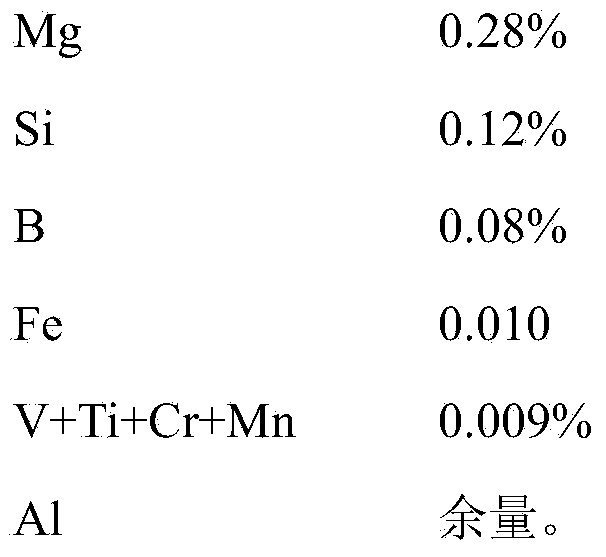

Manufacture method of electroconductive aluminum alloy section

The invention discloses a manufacture method of an electroconductive aluminum alloy section. The manufacture method comprises the following steps: cast ingot component control, fusion casting, extruding, quenching and aging heat treatment; in the step of quenching, the water entry temperature of the section is 520-530 DEG C, the cooling rate is 180-350 DEG C / min; and in the step of aging heat treatment, the heat-insulation temperature of the section is 160-180 DEG C and the heat-insulation time is 10-16 hours. The aluminum alloy section manufactured by the manufacture method disclosed by the invention has tensile strength of more than 245 MPa, electrical conductivity of more than 55%IACS (International Annealed Copper Standard), and hardness of more than 80HB.

Owner:SNTO TECH GRP

Al-Fe-Cu alloy material and preparation method thereof

The invention particularly relates to an Al-Fe-Cu alloy material and a preparation method thereof. The Al-Fe-Cu alloy material comprises the following components in percentage by weight: 0.20-1.30 wt% of Fe, 0.01-0.08 wt% of Cu, 0.06-0.15 wt% of Si, 0.02-0.10 wt% of rare-earth element and the balance of Al and unavoidable impurities. The aluminum alloy is prepared by casting and semi-annealing raw materials. When the aluminum alloy is prepared, the alloy material is semi-annealed, and thus, the adverse effects of stress on a conductor structure in the process of drawing and twisting are reduced, the electric conductivity reaches and even exceeds 61% of IACS (International Annealed Copper Standard) (the electric conductivity standard of an aluminum conductor for a general electrician is 61% of IACS), and the performances of elongation and the flexibility of the aluminum alloy are improved greatly by annealing. The performances of the elongation of a cable made of the aluminum alloy wire can reach 30%, the flexibility is 25% higher than that of a copper cable, and the resistivity maintains in a lower level.

Owner:安徽省惠尔电气有限公司

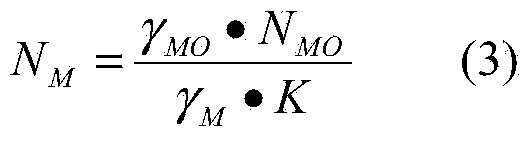

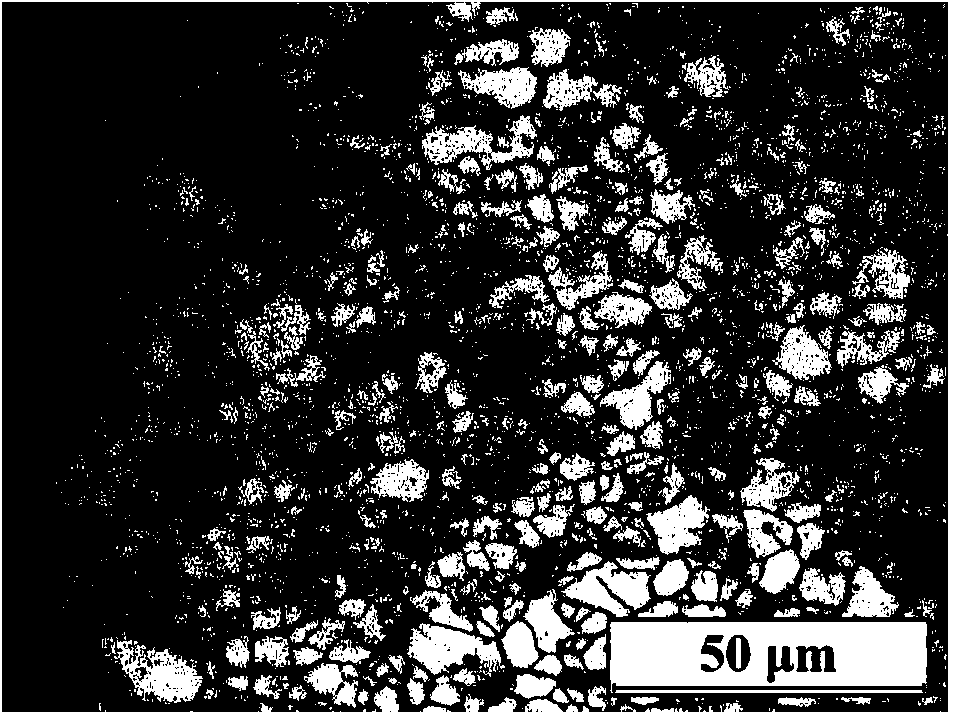

Preparation method of fine-grained CuCr alloy

The invention provides a preparation method of a fine-grained CuCr alloy, which comprises the processing steps that (1) an oxygen-free copper block and a chromium block are subjected to induction heating to be molten and dissolved mutually, molten liquid is ejected by argon gas pressure and subjected to centrifugal atomization by a copper roller rotation quenching melt spinning or a water-cooling rotating disk; (2) a fine-grained CuCr alloy material is subjected to ball milling by a high-energy ball mill under argon shield; (3) fine-grained composite CuCr alloy powder is loaded into a mould briquette to be made into a green blank; and (4) the green blank is loaded into a graphite drying pot, and placed in a vacuum sintering furnace to be sintered to form the fine-grained CuCr alloy. In the fine-grained CuCr alloy prepared by the method, the particle sizes of chromium particles are 0.5-10 micrometers, the surface hardness is 65-162HV, and the conductivity is 26.0-80.8% IACS (International Annealed Copper Standard); compared with the existing CuCr alloy with the equivalent chromium content, the particle sizes are reduced obviously, and the alloy performance is improved significantly; and the fine-grained CuCr alloy has more excellent effect in an application of an electrical contact material.

Owner:NORTHEASTERN UNIV

Method for manufacturing medium-strength aluminum alloy wire with electric conductivity of 59 percent

ActiveCN102162050AQuick checkControl contentManufacturing extensible conductors/cablesMetal/alloy conductorsAluminium matrixIngot

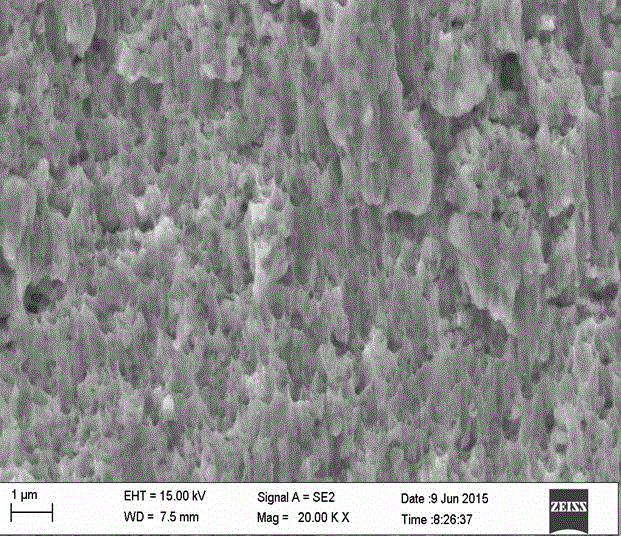

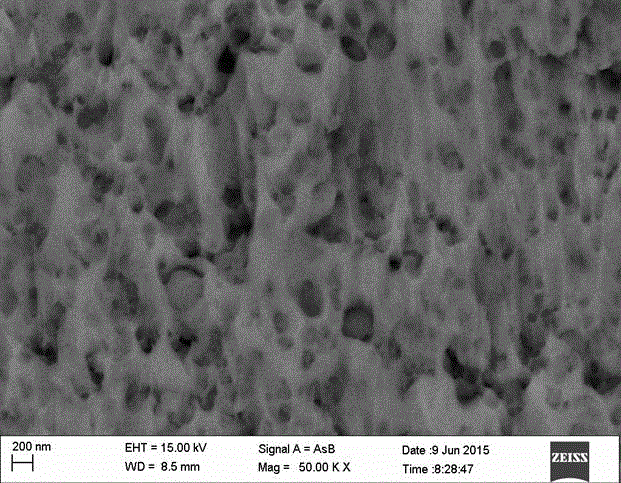

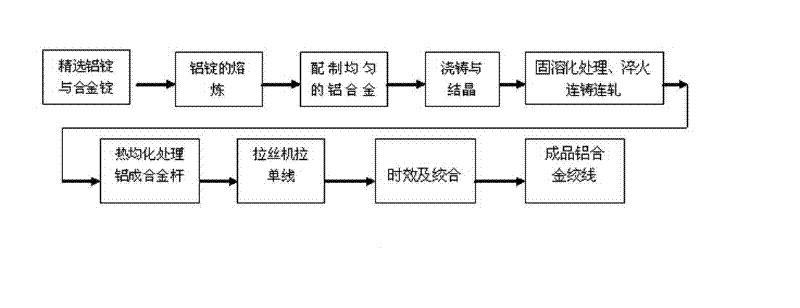

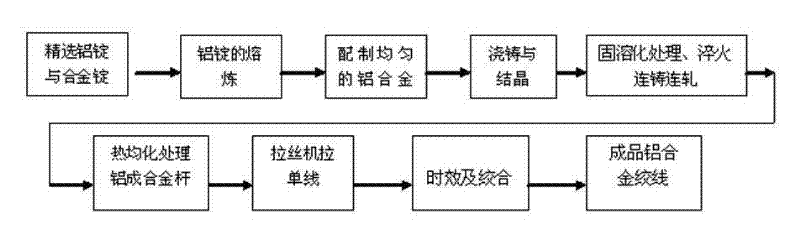

The invention discloses a method for manufacturing a medium-strength aluminum alloy wire with the electric conductivity of 59 percent (International Annealed Copper Standard, IACS), and relates to a method for manufacturing a medium-strength aluminum alloy wire with high conductivity. The method is characterized by comprising the following steps of: (1) selecting an aluminum matrix and an aluminum intermediate alloy ingot; (2) performing on-the-spot sample analysis and adjustment, namely putting the selected aluminum ingot into a shaft furnace, melting to form molten aluminum, and refining by using a refining agent; (3) casting and crystallizing, namely allowing molten aluminum alloy in a kettle furnace to pass through a runner and filtering by using a ceramic filtering plate, adding rare earth to ensure that the content of the rare earth is 0.05 to 0.15 percent, feeding into an aluminum alloy continuous casting machine, performing continuous casting to form an aluminum alloy cast ingot, and rolling a medium-strength alloy rod by using an aluminum alloy continuous mill; (4) performing solid solution treatment and quenching, namely performing thermal homogenization treatment on the aluminum alloy rod; and (5) drawing, aging and twisting, namely drawing the aluminum alloy rod treated in the previous working procedure into an aluminum alloy wire with the required diameter on an aluminum alloy wire drawing machine, and twisting on a frame type wire twisting machine to obtain the medium-strength aluminum alloy wire with the electric conductivity of 59 percent IACS.

Owner:JIANGSU ZHONGTIAN TECH CO LTD +1

Heat-resistant aluminum alloy conductor with high strength and high conductivity and preparation method thereof

The invention discloses a heat-resistant aluminum alloy conductor with high strength and high conductivity and a preparation method thereof. The conductor comprises the following elements in percentage by weight: 0.15-0.60% of zirconium (Zr), 0.03-0.30% of lanthanum (La), 0.03-0.30% of cerium (Ce), 0.01-0.30% of yttrium (Y), 0.05-0.20% of ferrum (Fe), 0.01-0.10% of silicon (Si), not more than 0.10% of other impurity elements and the balance of aluminum. The method comprises the following steps of: preparing raw materials; putting the raw materials into a smelting furnace; heating, degassing and smelting the raw materials; making slag; removing the slag; continuously casting and rolling the raw materials to obtain a heat-resistant aluminum alloy rod; carrying out heat treatment on the heat-resistant aluminum alloy rod; and drawing the heat-resistant aluminum alloy rod by using a wire drawing machine so as to obtain a single heat-resistant aluminum alloy wire. The heat-resistant aluminum alloy conductor disclosed by the invention has the characteristics as follows: the tensile strength reaches 160 MPa, the electric conductivity can reach more than 61% IACS (International Annealed Copper Standard), the long-term operation temperature can reach 180 DEG C, the conductor stands up to examining operation while being heated for one hour at 280 DEG C, and strength survival rate is more than 90%.

Owner:SHANGHAI JIAO TONG UNIV +1

Interlocking type armored optical fiber composite low-voltage cable of creep-resistant aluminum alloy conductor

ActiveCN102222546AReduce installation costsReduce installation and construction costsNon-insulated conductorsCommunication cablesElectrical conductorLow voltage

The invention provides an interlocking type armored optical fiber composite low-voltage cable of a creep-resistant aluminum alloy conductor. The interlocking type armored optical fiber composite low-voltage cable comprises a conductor, an optical unit and an armor, wherein the conductor is the creep-resistant aluminum alloy conductor; and the armor is aluminum alloy strip interlocking type armor. The interlocking type armored optical fiber composite low-voltage cable has the advantages that: the conductivity can reach over 61 percent of International annealed copper standard (IACS); the conductor has excellent mechanical property; the rebound performance of the conductor is 40 percent lower than that of a copper cable; the flexible performance is 25 percent higher than that of the copper cable; and the weight of the conductor is half of that of the copper cable; when an alloy cable is used, the installation cost is directly reduced for a construction organization; an S-type interlocking type armor structure is used; the armored cable has high softness, and high strength; the minimum bending radius of the armored cable is 7D; the cable is reliable in connection, light in weight, small in bending radius, convenient for installation, good in radiation, bridge saving and resource saving; compared with common copper core low-voltage cable, the cable has obvious cost advantage, and saves large amount of copper; and the economical efficiency of the creep-resistant aluminum alloy interlocking type armored optical fiber composite low-voltage cable (OPLC) is adaptable to tendency of establishing the resource-saving society in China.

Owner:WUHAN RUIQI SPECIAL CABLE

High-performance elastic copper alloy and preparation and processing method thereof

The invention relates to high-performance elastic copper alloy and a preparation and processing method thereof. According to the weight percentage, the high-performance elastic copper alloy comprises the basic components as follows: 1 to 4 percent of Ni, 0.4 to 1 percent of Si, 0.5 to 1.5 percent of Co, and the rest percent of Cu, wherein the components in a copper alloy product need to satisfy the conditions as follows: (a) the content of Ni or Si is larger than or equal to 2.5 percent and smaller than or equal to 5 percent; (b) the content of Ni plus Si is larger than or equal to 1.4 percent and smaller than or equal to 4.0 percent; (c) the content of Ni plus Co is larger than or equal to 1.5 percent and smaller than or equal to 4 percent; and (d) the content of Ni plus Si or the content of C is larger than or equal to 1 percent and smaller than or equal to 5.0 percent. The preparation and processing method of the high-performance elastic copper alloy comprises the step: a, material burdening, material feeding, melting and casting which are conducted according to the weight percent; b, surface milling; c, hot rolling; d, solid solution treatment; e, cold processing; f, primary aging; g, cold processing; h, secondary ageing; i, pickling; and j, finished product annealing. The tensile strength Sigma b of the copper alloy is 780 to 950MPa, the plastic elongation rate Delta of the copper alloy is 4 to 10 percent, and the electric conductivity of the copper alloy is 35 to 55 percent according to an international annealed copper standard (IACS). The copper alloy has the advantages of high elasticity, high strength, high fatigability, good heat resistance and high electric conductivity.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

High-strength and high-conductivity rare-earth copper alloy and preparation method thereof

The invention discloses a high-strength and high-conductivity rare-earth copper alloy and a preparation method of the high-strength and high-conductivity rare earth copper alloy. The high-strength and high-conductivity rare-earth copper alloy belongs to the technical field of an alloy material. Silver, phosphorus and a trace of rare-earth elements are added on the basis of a traditional Cu-Cr-Zr alloy. The copper alloy is prepared from the following components in percentage by weight: 0.2-1.0% of chrome, 0.1-0.4% of zirconium, 0.1-0.2% of silver, 0.02-0.03% of phosphorus, 0.02-0.16% of the rare-earth elements, and the balance of copper and inevitable impurity elements; the rare-earth elements are one or two or three of cerium, iridium and neodymium; a material is carried out processes such as hot forging, solid-solution treatment, cold rolling and aging treatment; prepared copper alloy has a good overall performance; tensile strength is greater than 550MPa; hardness is greater than 150HV; an elongation rate is greater than 10%; electric conductivity is greater than 80% IACS (International Annealed Copper Standard), and a softening temperature is greater than 450 DEG C. A requirement of the material for an electronic industrial field on the performance of the copper alloy can be better met; the high-strength and high-conductivity rare-earth copper alloy can be used for a lead frame material for a large-scale integrated circuit, a contact line of an electric car or an electric locomotive, an electrode alloy connector and the like.

Owner:HENAN UNIV OF SCI & TECH

Preparation method of intermediate strength aluminum alloy monofilament

ActiveCN103952605AHigh strengthImprove conductivityPower cablesMetal/alloy conductorsThermal treatmentMechanical property

The invention provides a preparation method of an intermediate strength aluminum alloy monofilament with 59% IACS (International Annealed Copper Standard) conductivity and belongs to the technical field of overhead conductors of electric transmission lines in the power industry. The intermediate strength aluminum alloy monofilament provided by the invention solves the technical problem that the existing intermediate strength aluminum alloy is complex in production process, high in cost and poor in mechanical property and conductivity of the product. The intermediate strength aluminum alloy monofilament is developed mainly by adding microalloying elements to control the content of impure elements in the alloy and adjusting the microstructure of the alloy in a thermal treatment process, wherein the conductivity is not less than 59% IACS (20 DEG C), the tensile strength is not less than 240MPa and the ductility is not less than 3.5%.

Owner:STATE GRID CORP OF CHINA +2

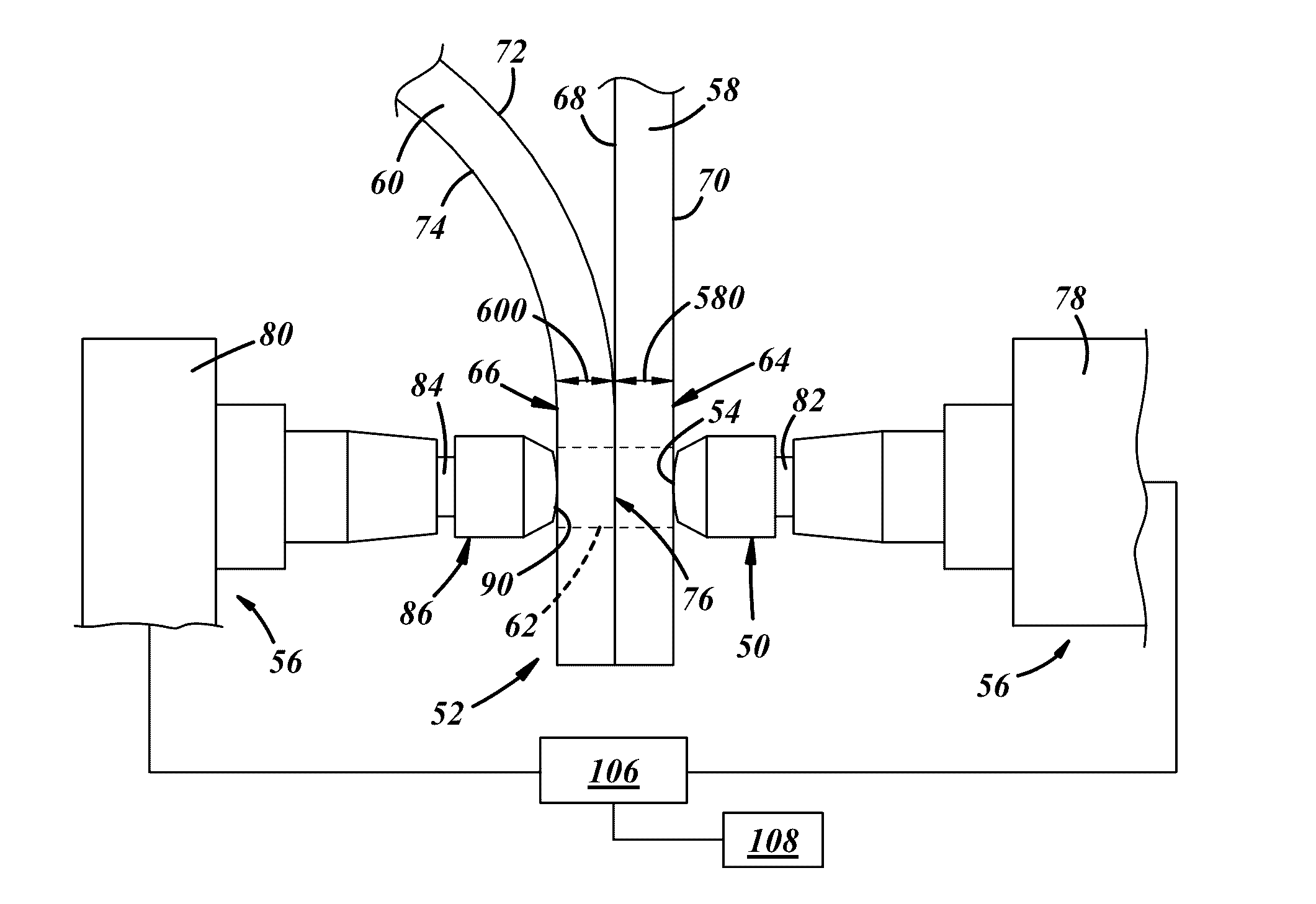

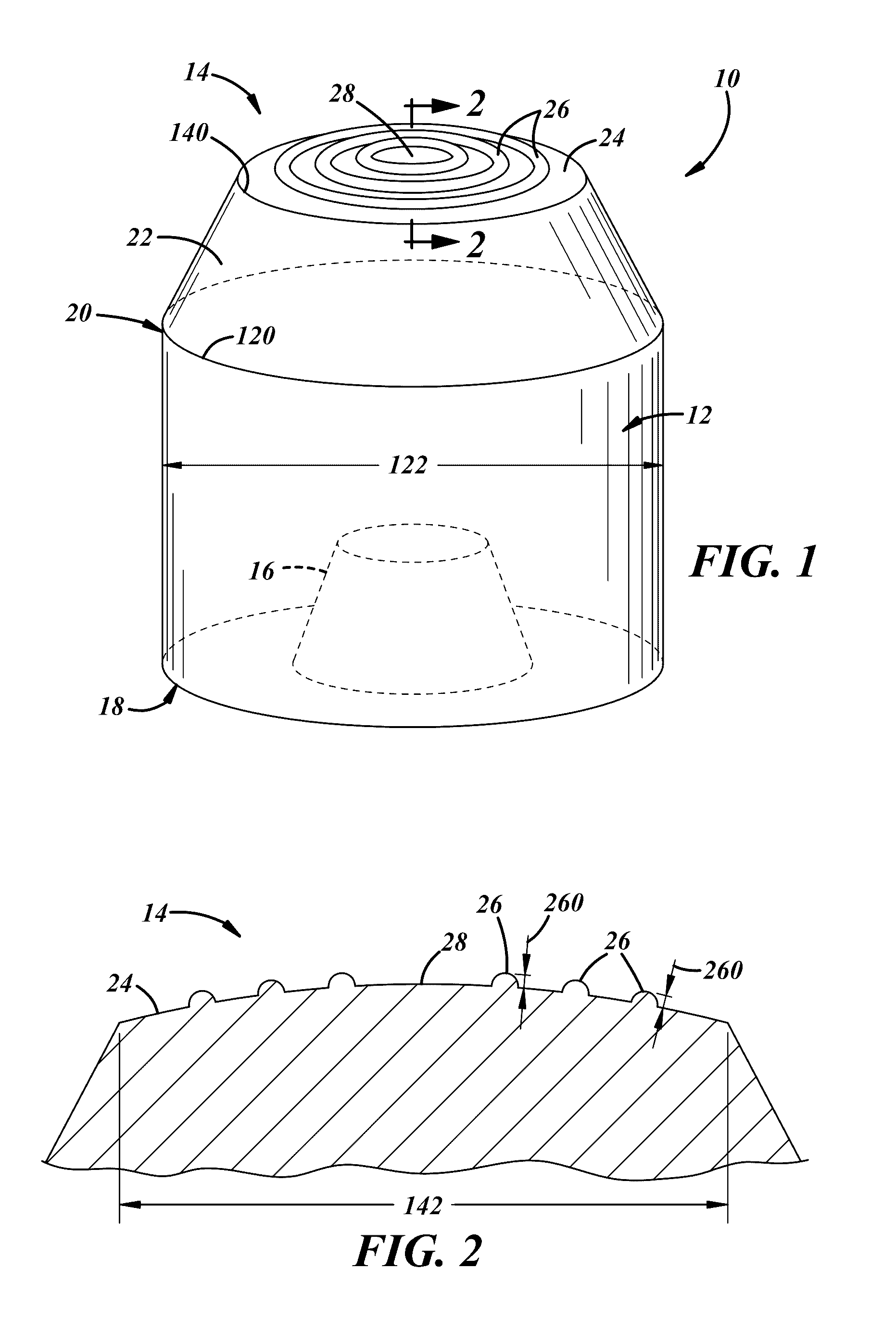

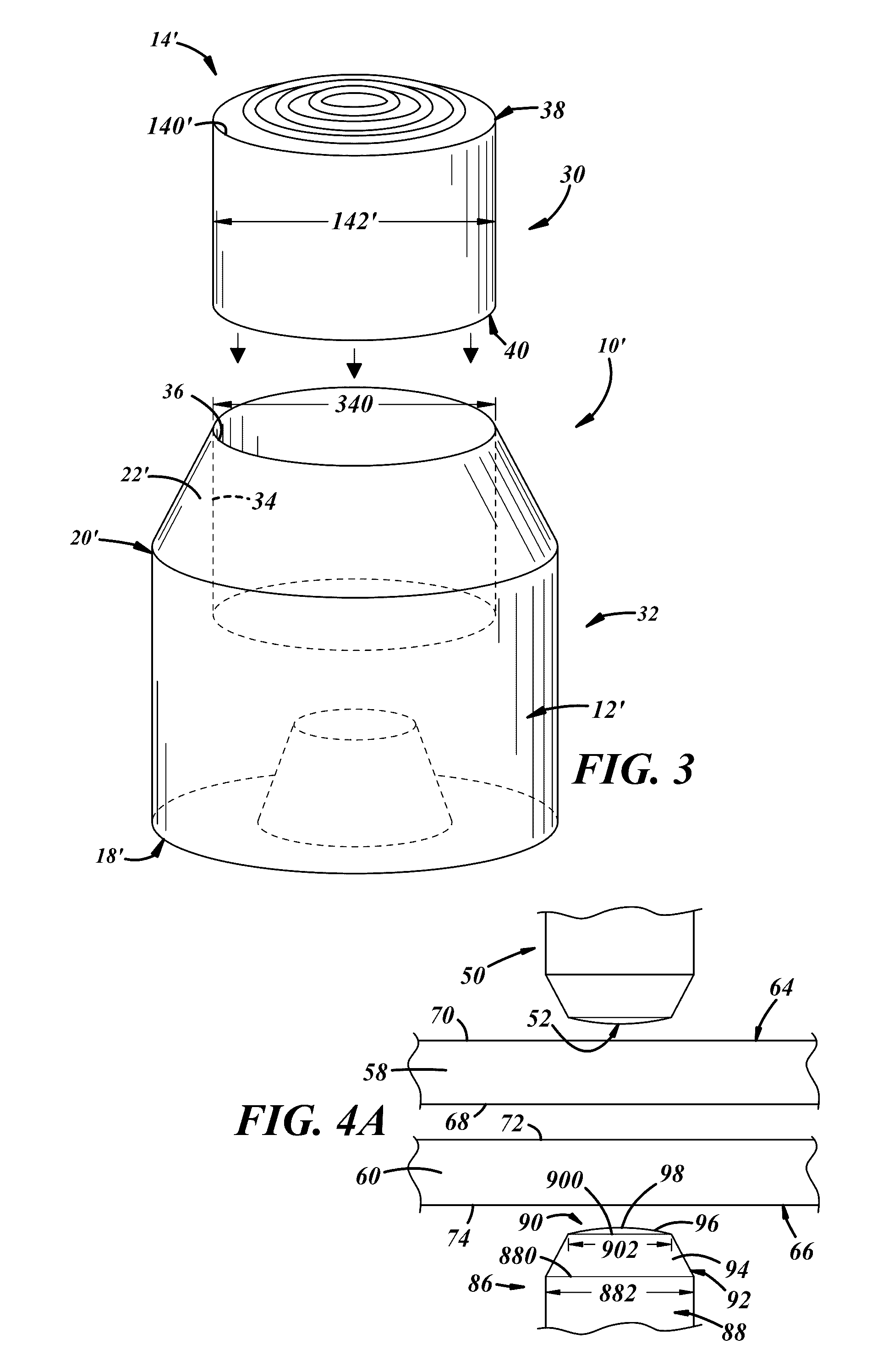

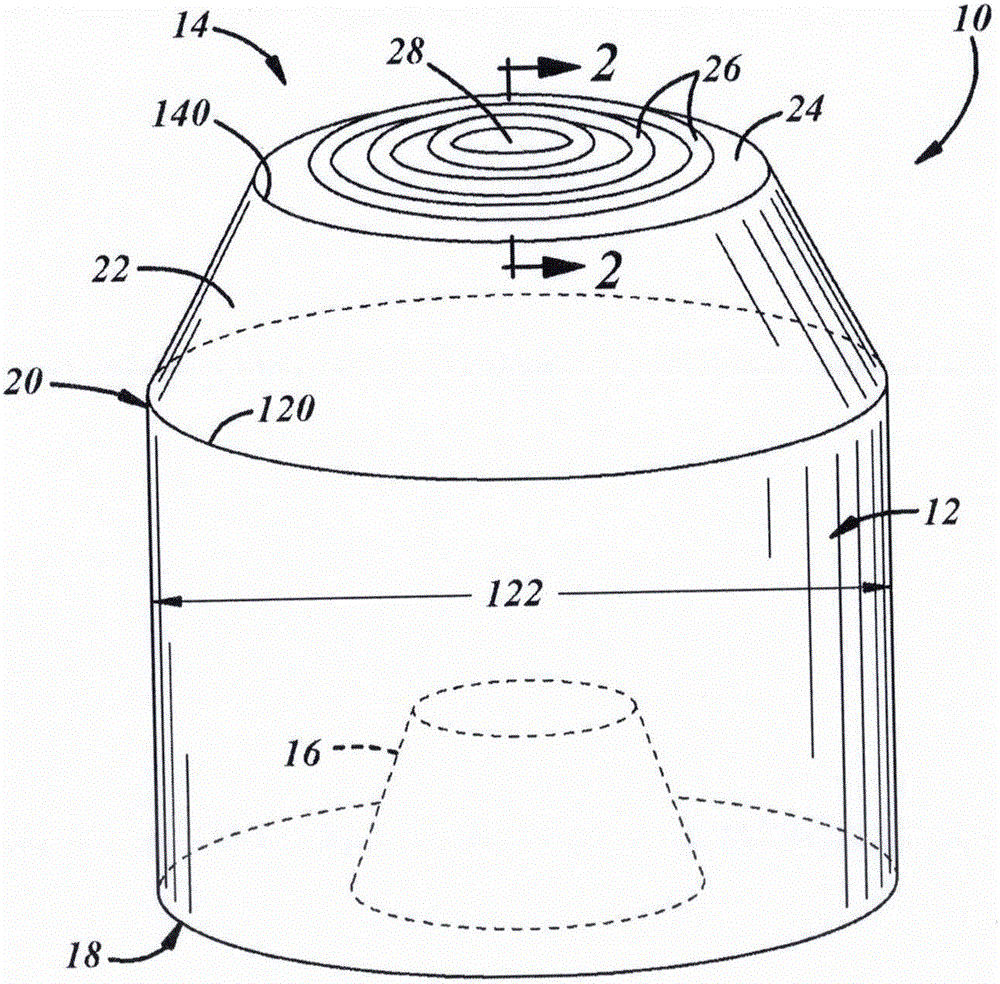

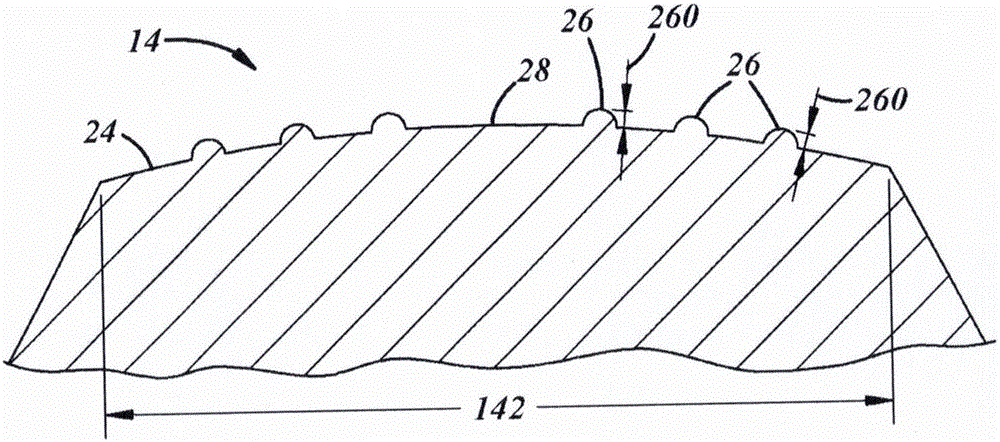

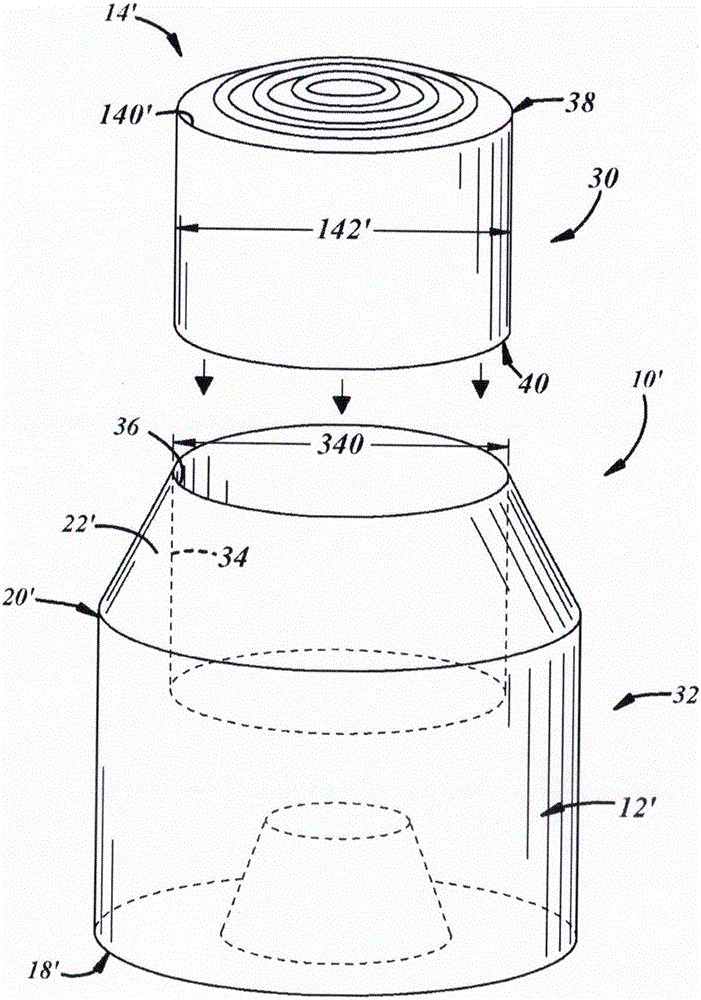

Resistive welding electrode and method for spot welding steel and aluminum alloy workpieces with the resistive welding electrode

ActiveUS20160279732A1Increase contact areaHigh densityWelding/cutting media/materialsPressure electrodesElectrical resistance and conductanceRefractory

A resistive welding electrode includes at least a weld face constructed of a refractory-based material that exhibits an electrical conductivity that is less than or equal to 65% of the electrical conductivity of commercially pure annealed copper as defined by the International Annealed Copper Standard (IACS). A method of using the resistive welding electrode to resistance spot weld a workpiece stack-up that includes an aluminum alloy workpiece and steel workpiece that overlap and contact each other at a faying interface is also disclosed.

Owner:GM GLOBAL TECH OPERATIONS LLC

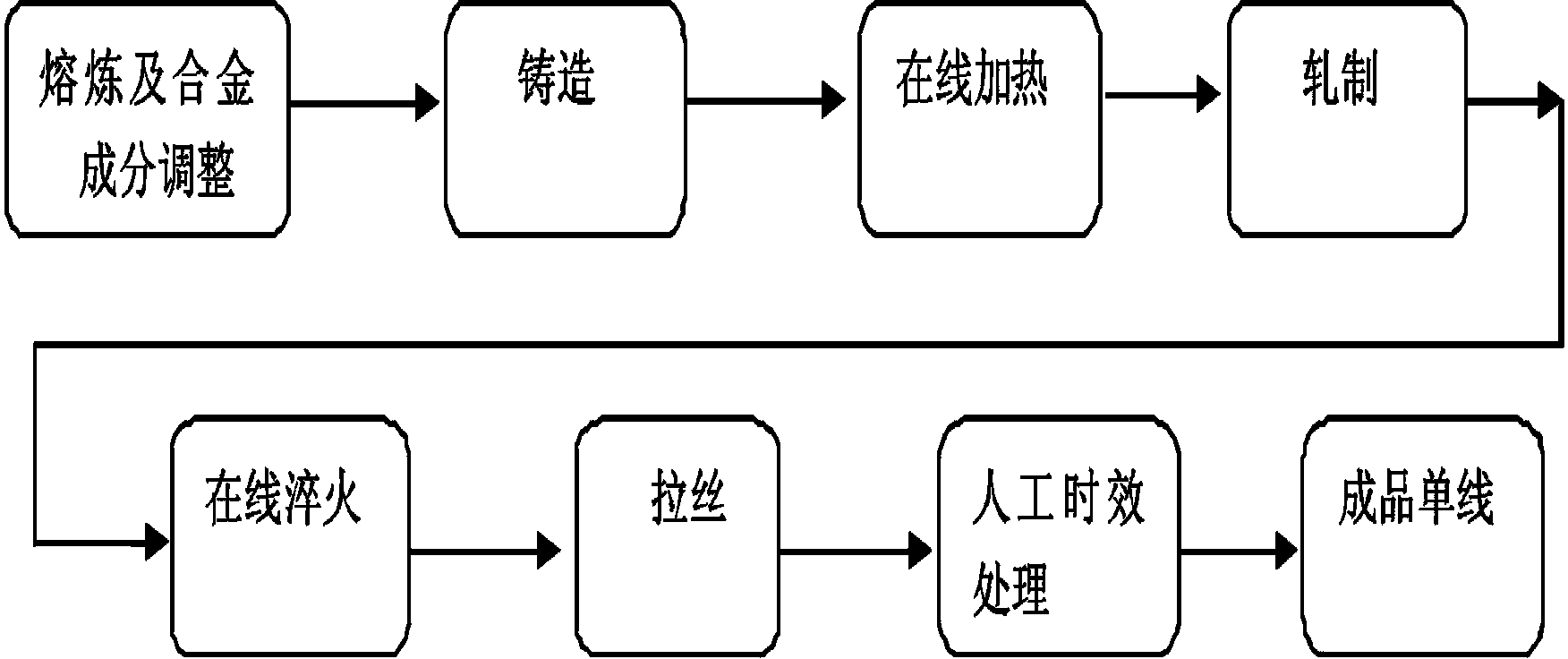

Intermediate strength aluminum alloy wire for overhead conductor

ActiveCN103451498AHigh elongationEffective solution treatmentSingle bars/rods/wires/strips conductorsConductive materialElectrical resistance and conductanceSolution treatment

The invention belongs to the technical field of overhead conductors of electric transmission lines, and particularly relates to an intermediate strength aluminum alloy wire for an overhead conductor. According to the intermediate strength aluminum alloy wire provided by the invention, solution treatment is effectively carried out on an aluminum alloy rod and subsequent aging treatment realizes a better effect through certain alloy composition adjustment, rolling and control of online quenching, so that the intermediate strength aluminum alloy wire with the elongation which is not less than 3.5%, the electric conductivity which is not less than 58.5%IACS (International Annealed Copper Standard) and the tensile strength which is not less than 245MPa is finally obtained. The elongation of the intermediate strength aluminum alloy wire provided by the invention is remarkably superior to that of aluminum alloy wires in the prior art. The intermediate strength aluminum alloy wire has the advantages that the wire is great in pulling weight ratio, good in sag characteristic, good in high temperature characteristic and damage- resistant in the surface. As no steel cores are available, magnetic hysteresis loss and eddy loss are avoided. In operation, the alternating current resistance of the wire is lower than that of aluminum cable steel reinforced, so that the electric energy loss is reduced. The intermediate strength aluminum alloy wire provided by the invention is used more and more in electric transmission lines and has a wider range of application.

Owner:STATE GRID CORP OF CHINA +1

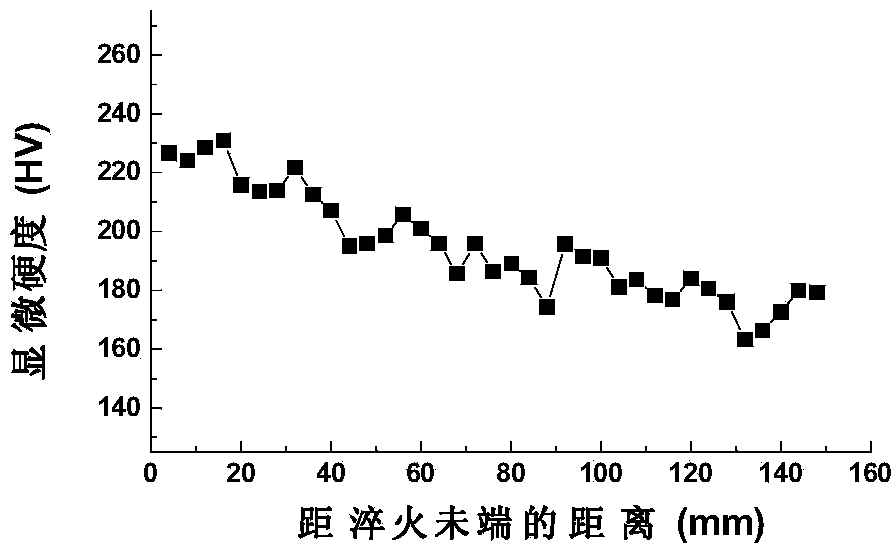

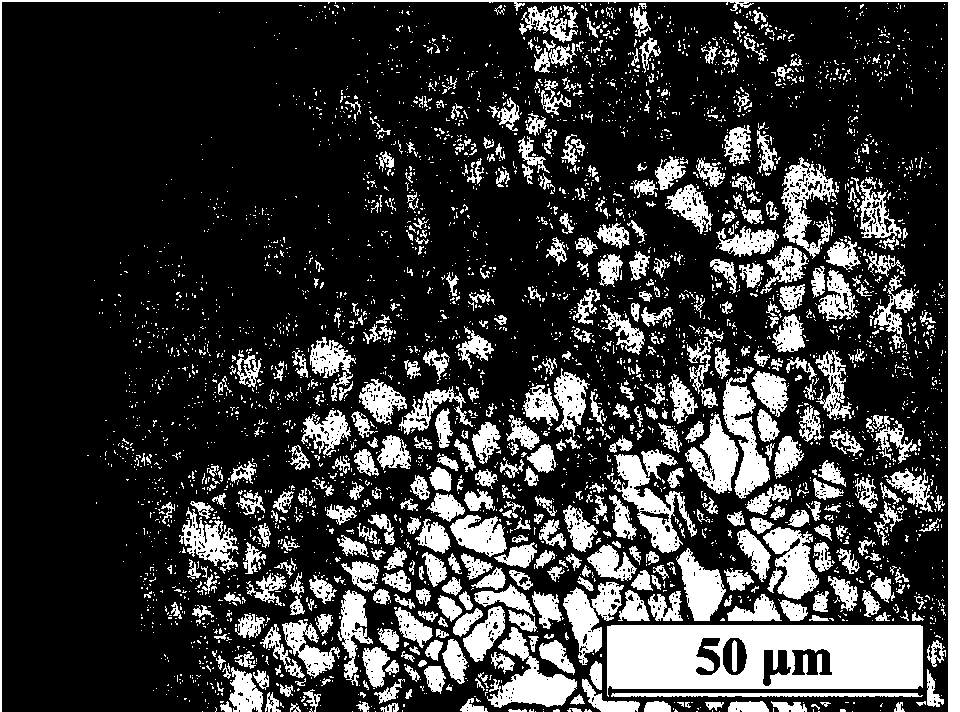

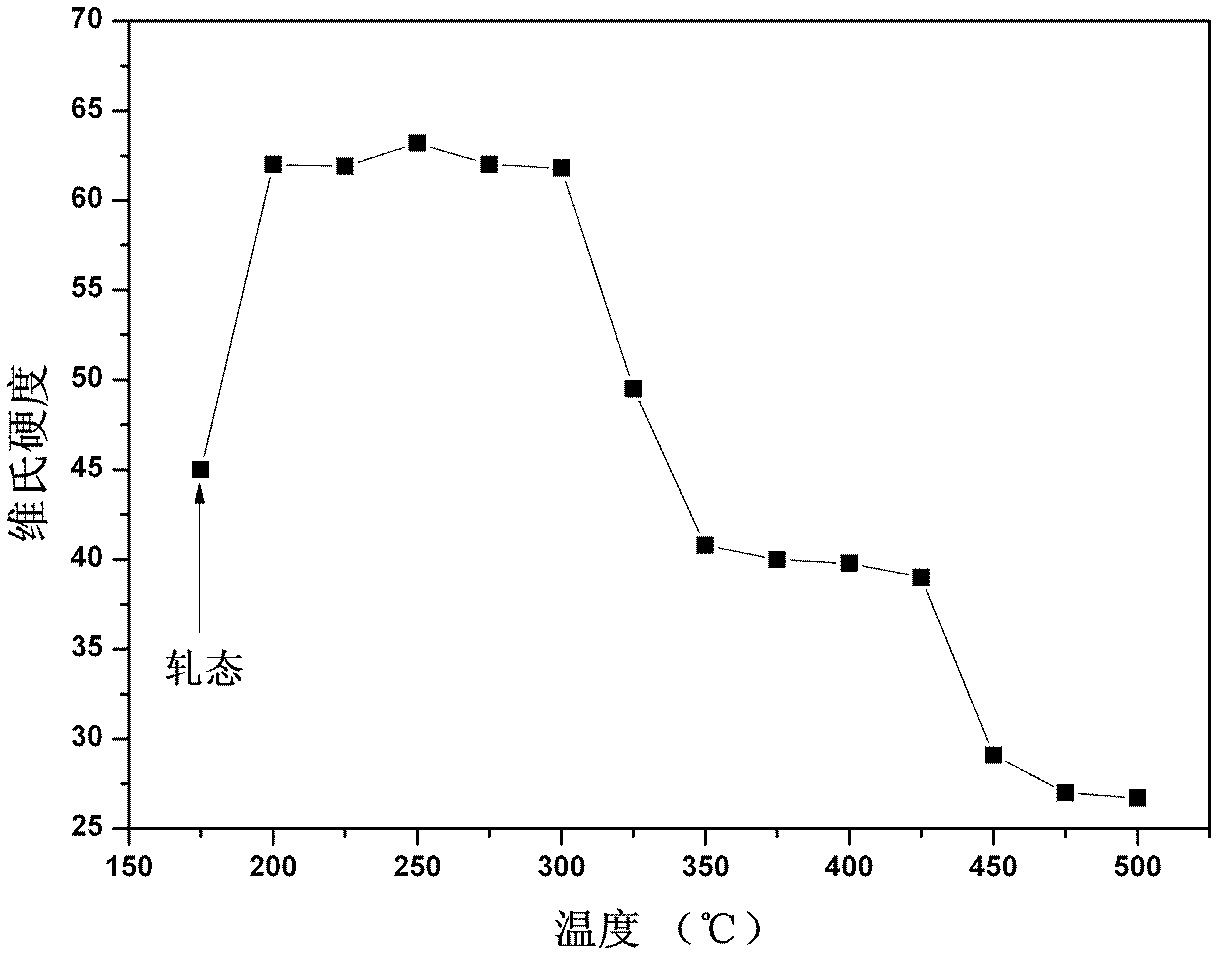

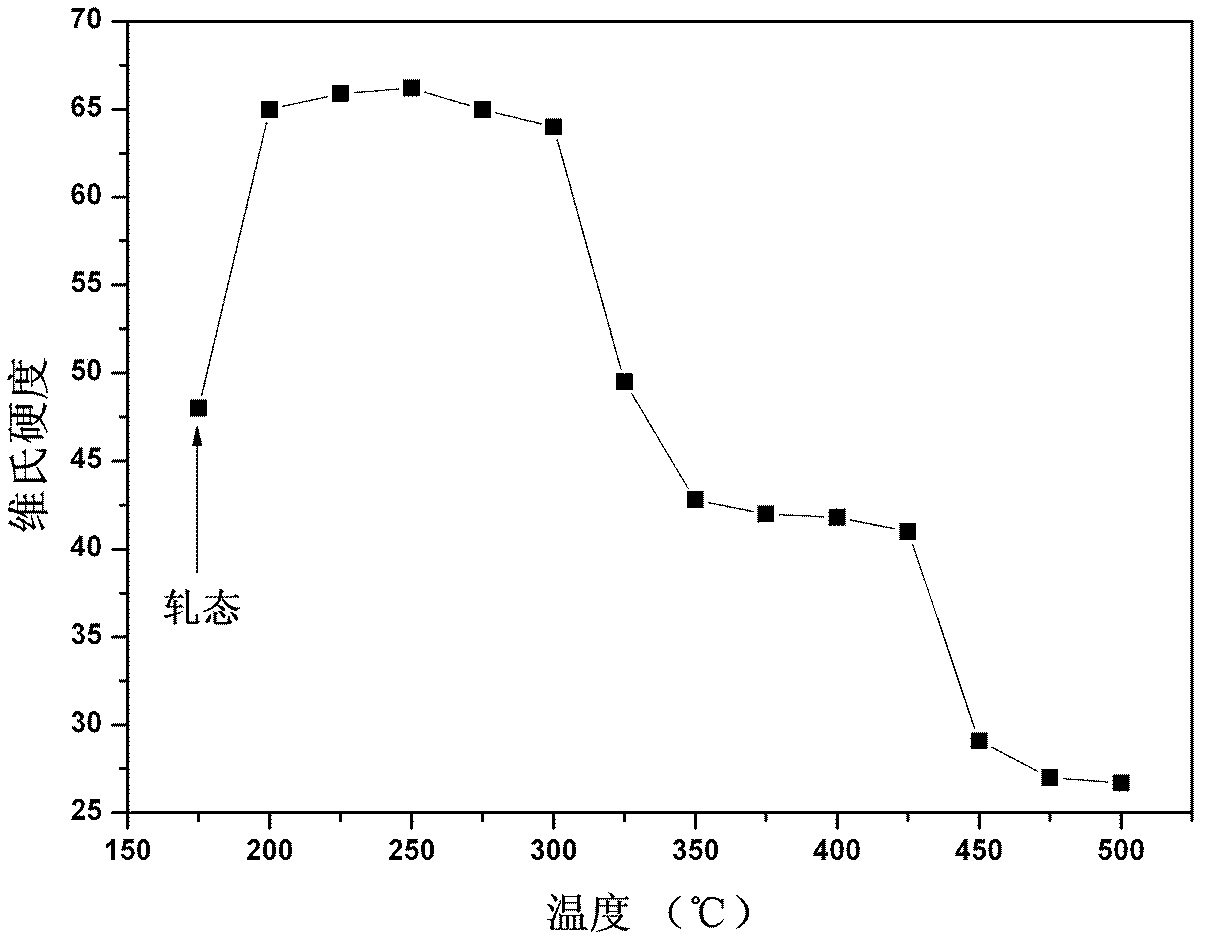

80-100mm hardenability aluminium alloy with super strength of 690-730Mpa and preparation method thereof

The invention provides 80-100mm hardenability aluminium alloy with the super strength of 690-730Mpa and a preparation method thereof. The 80-100mm hardenability aluminium alloy is characterized by mainly comprising aluminum, zinc, magnesium, copper, zirconium and strontium, wherein the mass percent of the zinc is 10.78-13.01%, the mass percent of the magnesium is 2.78-3.51%, the mass percent of the copper is 2.26-2.80%, the mass percent of the zirconium is 0.204-0.24%, the mass percent of the strontium is 0.0025-0.0751%, and the rest is aluminium and few impurity elements. The preparation method comprises the following steps: (1) casting; (2) carrying out homogenizing annealing (400 DEG C*6h+420 DEG C*6h+440 DEG C*6h+460 DEG C*12h); (3) carrying out hot extrusion (the extrusion ratio is 12); (4) carrying out solution treatment (450 DEG C*2h+460 DEG C*2h+470 DEG C*2h); and (5) carrying out aging treatment (121 DEG C*24h). The aluminium alloy has the advantages that the crystal particles of the aluminium alloy are very small (the average crystal particle size is less than 10 micrometers), the highest actual measurement strength of the aluminium alloy can reach 731 Mpa, meanwhile, the percentage of elongation of the aluminium alloy is 6.6%, the hardness of the aluminium alloy is 231.1HV, the electrical conductivity of the aluminium alloy is 25.9% IACS (International Annealed Copper Standard), and the end-quenching hardenability of the aluminium alloy in water is 80mm.

Owner:JIANGSU TIANNAN ELECTRIC POWER EQUIP

Copper alloy and fabrication method thereof

The invention relates to the field of a metal alloy, in particular to a Cu-Ni-Si alloy. A fabrication method of a copper alloy comprises the steps as follows: A) casting, B) hot rolling, C) face milling and D) cold rolling and annealing. The copper alloy comprises the following chemical components by mass percent: 1.8-2.1% of nickel, 0.4-0.68% of silicon, 0-0.2% of iron, 0-0.1% of manganese, 0-0.2% of zinc, 0-0.005% of cadmium, 0-0.02% of lead, 0-0.3% of other impurities and the balance of cooper, wherein iron, manganese, zinc, cadmium and lead are all impurities; the tensile strength Rm of the copper alloy is greater than or equal to 600MPa; the broken elongation A11.3 is greater than or equal to 8%; the Vickers hardness HV is greater than or equal to 180; and the electrical conductivity is greater than or equal to 46% IACS (International Annealed Copper Standard). The ideal performance of a copper alloy material for a lead frame can be obtained by the fabrication method for the copper alloy.

Owner:山西春雷铜材有限责任公司

High-strength, high-conductivity and heat-resistant aluminum alloy conductor material and preparation method thereof

InactiveCN102534318AImprove conductivitySufficient precipitationMetal/alloy conductorsHeat resistanceIngot

The invention relates to a high-strength, high-conductivity and heat-resistant aluminum alloy conductor material and a preparation method thereof, and belongs to the technical field of alloy materials. The conductor material comprises the following components in percentage by weight: 0.2 to 0.3 percent of Zr, 0.15 to 0.25 percent of Er, less than 0.3 percent of impurities and the balance of aluminum. The preparation method comprises the following steps of: adding an AlEr intermediate alloy and an AlZr intermediate alloy in the process of smelting the aluminum, smelting at the temperature of 780+ / -10 DEG C, preserving heat for 30 minutes, and casting; and performing homogenization treatment, rolling and heat treatment on an ingot in turn. Er and Zr in the component ratio are compositely microalloyed, a large number of precipitated phases which are distributed in a dispersed mode can be precipitated by the process, a large number of deformation structures can be stored, and the high conductivity (59.6 to 60 percent international annealed copper standard IACS), high strength (Vickers hardness 62.5 to 66.5) and heat resistance (capability of resisting the temperature of 375 DEG C in a short term and resisting the temperature of 225 DEG C in a long term) of the alloy are kept simultaneously.

Owner:BEIJING UNIV OF TECH

Lead wire frame and production method thereof

ActiveCN102983083AExcellent mechanical propertiesLow costSemiconductor/solid-state device detailsSolid-state devicesHardnessWork in process

The invention relates to the field of electronic packaging manufacturing, in particular to a lead wire frame for packaging a chip. Particularly, the lead wire frame is mainly applied to an SOT (Small-outline Transistor) series. A production method of the lead wire frame comprises the steps of A) stamping, B) electroplating and C) forming, wherein in Step A), a copper alloy sheet is taken for stamping through a male die and a female die of a cutting die to form a semi-finished lead wire frame; the tensile strength Rm of the copper alloy sheet is greater than or equal to 600MPa; the elongation after rupture A11.3 is greater than or equal to 8%; the vickers hardness HV is greater than or equal to 180; the electrical conductivity is greater than or equal to 46% IACS (International Annealed Copper Standard); and the thermal conductivity is greater than or equal to 190w / m*k; in Step B), the semi-finished lead wire frame is subjected to the following treatment sequentially: namely preelectrosilvering, electrosilvering and silver drawing; and in Step C), the electroplated semi-finished lead wire frame is subjected to cutting forming. The lead wire frame has a better mechanical property and a better thermoelectrical property.

Owner:XIAMEN YONGHONG TECH

High-strength high-conductivity heat-resistant aluminum alloy wire and preparation method thereof

The invention relates to a high-strength high-conductivity heat-resistant aluminum alloy wire. The wire consists of the following raw materials by weight percent: 98.5 to 99.6% of aluminum Al, 0.1 to 0.4% of lanthanum La, 0.1 to 0.4% of cerium Ce, 0.1 to 0.4 % of scandium Sc, 0.01 to 0.2% of Ferrum Fe, 0.01 to 0.1% of silicon Si, and less than 0.01% of titanium Ti, vanadium V, manganese Mn, chromium Cr and other impurity elements all together. Compared with the aluminum alloy wire in the prior art, the aluminum alloy wire of the invention has high strength and high conductivity simultaneously, the tensile strength reaches over 255 Mpa, the electric conductivity can reach over 60.0% IACS (International Annealed Copper Standard), and the high-strength high-conductivity heat-resistant aluminum alloy wire with the heat resistance reaching more than 180 DEG C during long-term running can effectively improve the power transmission capability of conducting wire and simultaneously widen the spacing between conducting wire towers, thereby furthering lowering the investment cost. The aluminum alloy wire has small sag, and the span of an iron tower can be increased by 30% in general. The high-strength high-conductivity heat-resistant aluminum alloy wire can be used in densely populated urban areas. In the process of the invention, both the burning loss of a variety of elements and the oxidation of materials can be reduced by adopting an intermediate frequency furnace for smelting, the smelting time is relatively short so as to raise the productivity, and long-time thermal treatment is not required in the production process, so the cost is saved.

Owner:安徽和电普华电气有限公司

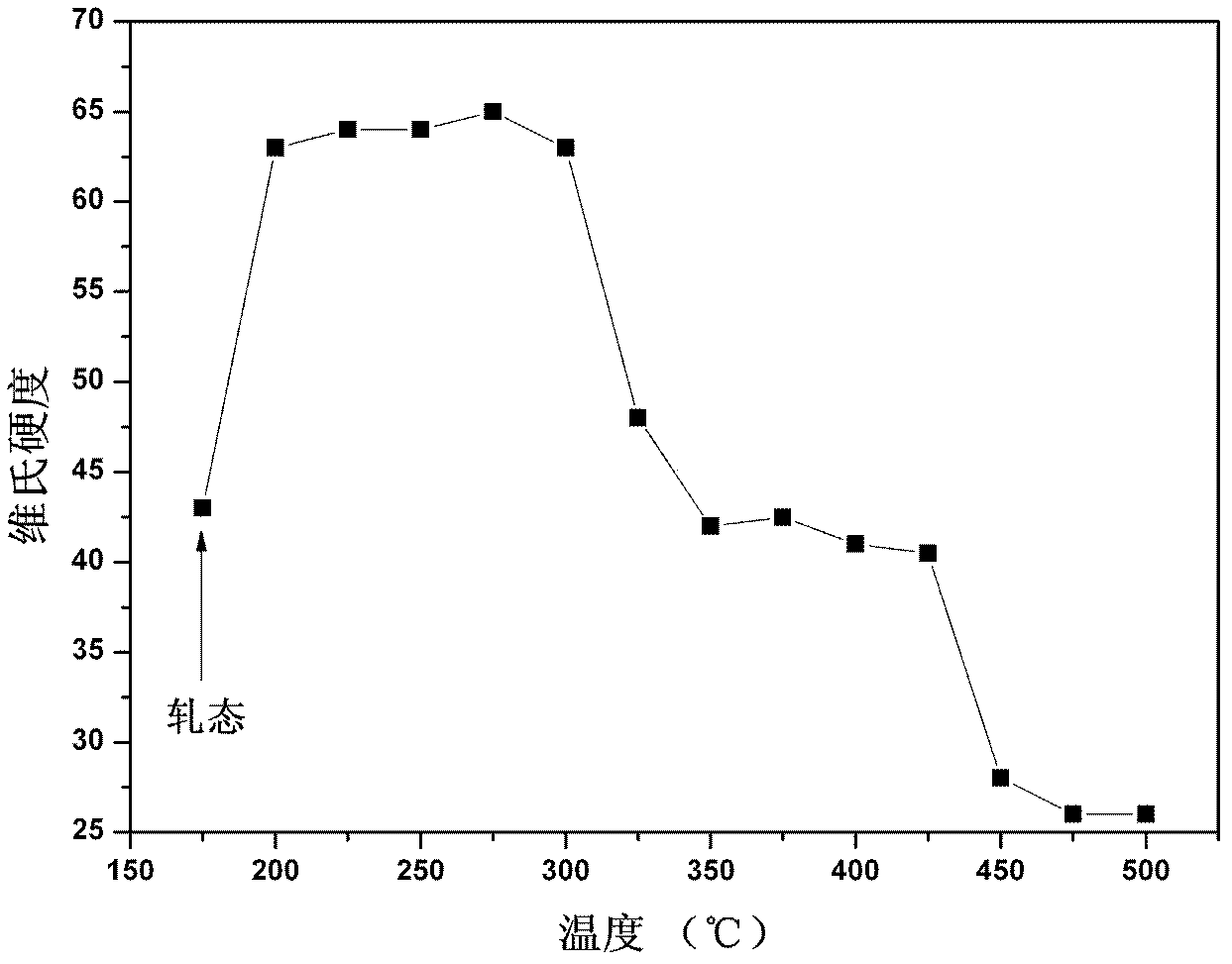

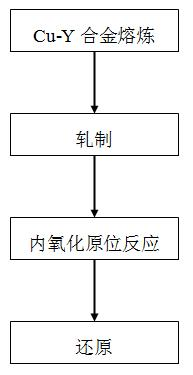

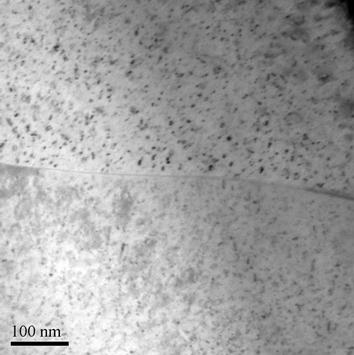

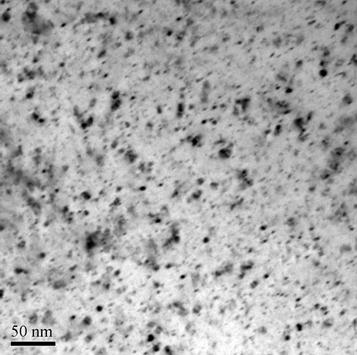

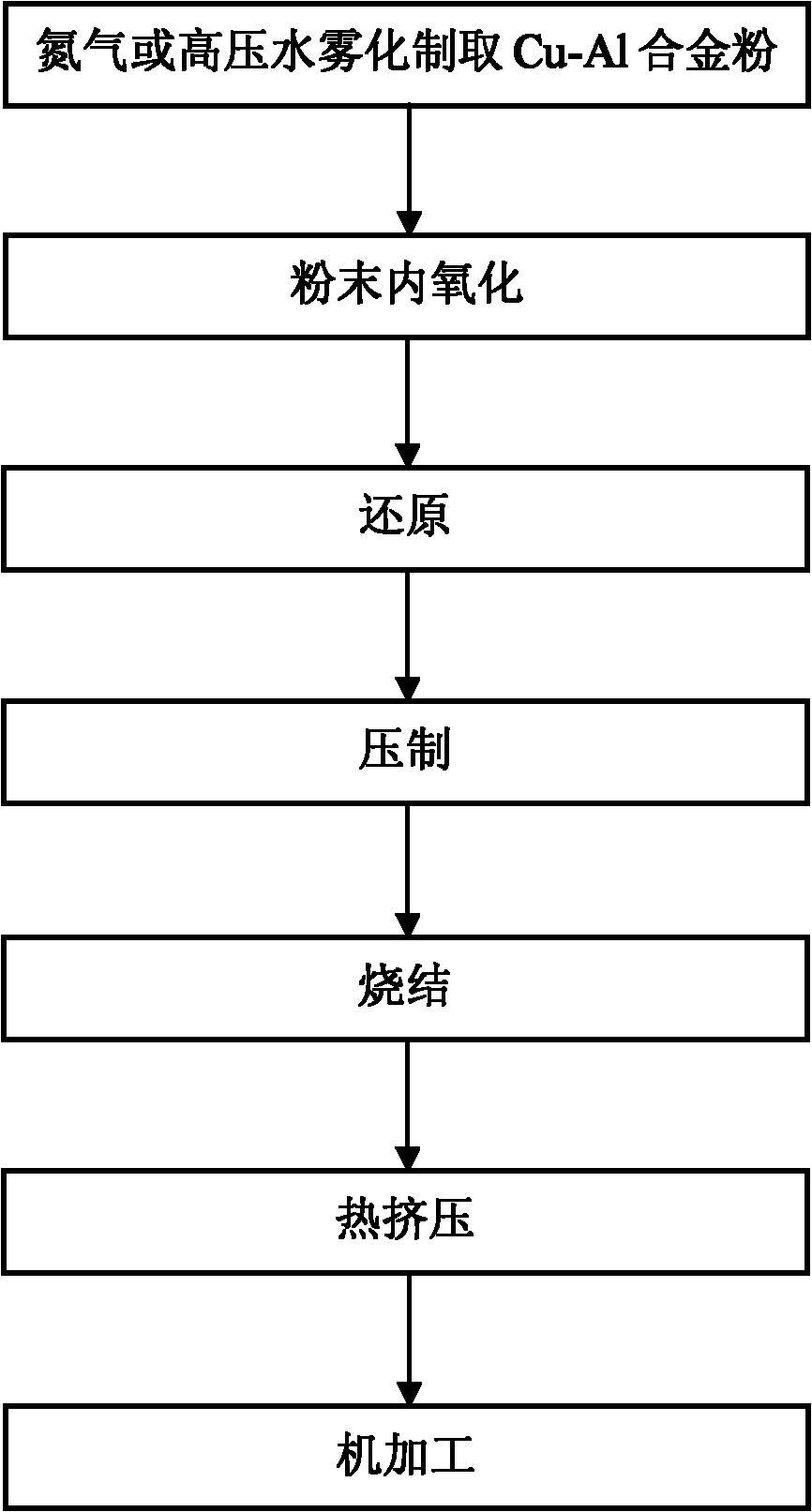

Dispersion strengthening copper-based composite material and preparation method thereof

The invention relates to a dispersion strengthening copper-based composite material and a preparation method thereof. The dispersion strengthening copper-based composite material and the preparation method thereof are characterized in that A dispersion strengthening phase is yttrium oxide, and the content of yttrium oxide in copper is 1-2.5 percent by weight, and the preparation method comprises the processes of alloy smelting, rolling, internal oxidation, reduction and the like. The preparation method has the advantages of short process and low production cost. The tensile strength of the product is greater than 550 MPa, the conductivity exceeds 90 percent IACS (international annealed copper standard), and the softening temperature is higher than 900 DEG C. The dispersion strengthening copper-based composite material has higher mechanical property, excellent electrical conductivity and high-temperature softening resistance. The Y2O3 granulate dispersion strengthening copper-based composite material prepared in the invention can be applied to computer integrated circuit lead frames, resistance welding electrodes for automobile industry, linings of crystallizers of continuous casting machines for metallurgical industry, equipment and carrier rockets, electric car and electric power train aerial conductor and the like, and the character of service and the service life can be obviously improved.

Owner:NANCHANG UNIV

Rare-earth aluminum alloy conductor for cable and manufacturing method thereof

InactiveCN102864344AHigh tensile strengthHigh elongationMetal/alloy conductorsRare-earth elementElectrical conductor

The invention discloses a rare-earth aluminum alloy conductor for a cable and a manufacturing method thereof. The rare-earth aluminum alloy conductor comprises the following components in percentage by weight: 0.05 to 0.15 percent of copper, 0.40 to 1.0 percent of ferrum, 0.03 to 0.15 percent of silicon, 0.02 to 0.12 percent of rare-earth elements and the balance of aluminum. The prepared rare-earth aluminum alloy conductor is subjected to tempering, the stress effect in the processes of drawing and stranding and the adverse effect of strain hardening on an organization structure of the conductor are improved, so that electric conductivity reaches and even exceeds 61 percent International annealed copper standard (IACS); and the elongation and flexibility of rare-earth aluminum alloy can be improved greatly, and the resistance of the conductor can be reduced by annealing treatment. According to the aluminum alloy conductor for the cable, the strength is improved 10 percent compared with pure aluminum, the elongation is 30 percent, the flexibility is 25 percent higher than that of a copper cable, and the resistance of the conductor is kept at a low level.

Owner:ANHUI PACIFIC CABLE GROUP

Resistive welding electrode and method for spot welding steel and aluminum alloy workpieces with the resistive welding electrode

The invention discloses a resistive welding electrode and method for spot welding steel and aluminum alloy workpieces with the resistive welding electrode. A resistive welding electrode includes at least a weld face constructed of a refractory-based material that exhibits an electrical conductivity that is less than or equal to 65% of the electrical conductivity of commercially pure annealed copper as defined by the International Annealed Copper Standard (IACS). A method of using the resistive welding electrode to resistance spot weld a workpiece stack-up that includes an aluminum alloy workpiece and steel workpiece that overlap and contact each other at a faying interface is also disclosed.

Owner:GM GLOBAL TECH OPERATIONS LLC

Creep-resistant and corrosion-resistant aluminum alloy conductor

ActiveCN103680670AImprove conductivityGood flexibilityMetal/alloy conductorsRare-earth elementElectrical conductor

Owner:四川鑫电电缆有限公司

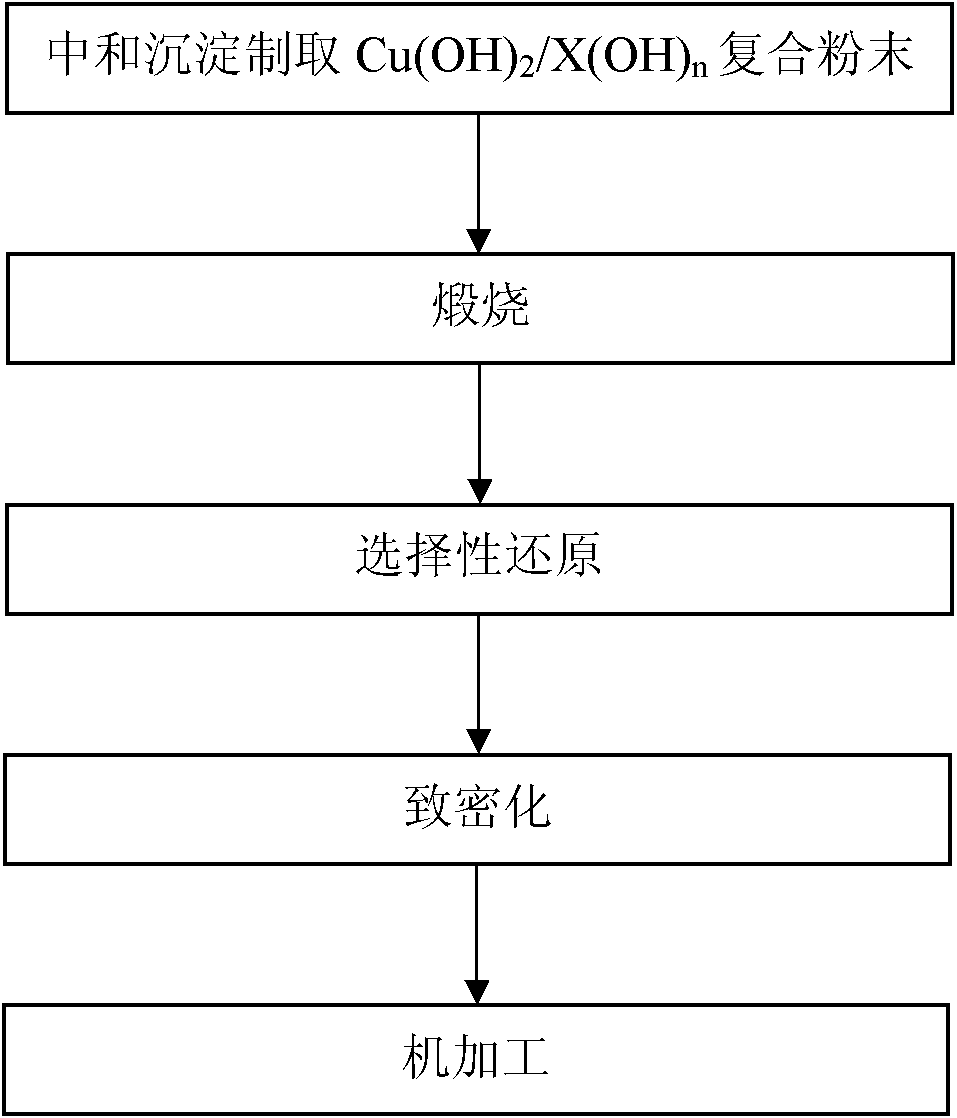

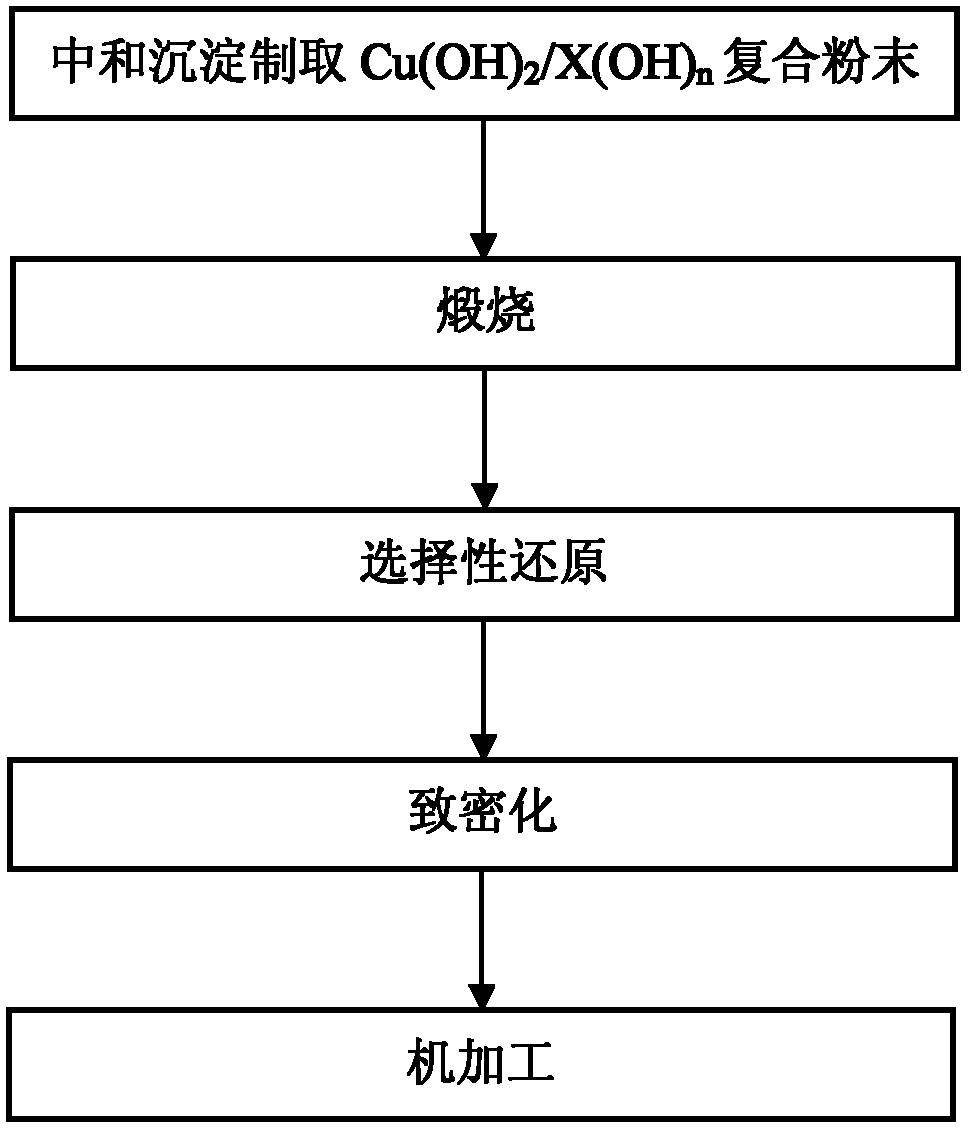

Method for preparing dispersion-strengthened copper with high strength and high conductivity

ActiveCN102560172AAbundant and easy to get raw materialsLow costTransportation and packagingMetal-working apparatusRoom temperatureSelective reduction

The invention provides a method for preparing dispersion-strengthened copper with high strength and high conductivity and belongs to the technical field of an oxide dispersion-strengthened material. The method comprises the following steps of: taking an electronic circuit board containing copper etching effluent (HW22) as a raw material; adding a soluble salt corresponding to a dispersion phase (one, two or more of Al2O3, Y2O3, MgO2, ZrO2 and ThO2); preparing Cu(OH)2 / X(OH)n compound powder according to a chemical neutralizing sediment technology; and performing roasting, selective reduction and compacting technology, thereby obtaining the nanometer oxide dispersion-strengthened copper. The prepared nanometer oxide dispersion-strengthened copper has high strength, high conductivity and excellent high-temperature softening resistance, wherein the tensile strength at room temperature is above 600MPa, the electric conductivity is more than 80% of IACS (International Annealed Copper Standard), and the softening temperature is above 700 DEG C. The method provided by the invention has the advantages of simple process, short flow, low energy consumption, rich and easily obtained raw material and low cost, and is suitable for large-scale industrial production.

Owner:天钛隆(天津)金属材料有限公司

Manufacturing method of highly-conductive and heat-resisting electrode cross beam component

The invention provides a casting method of a highly-conductive and heat-resisting electrode cross beam component. The method comprises the following steps of: 1. selecting alloy materials; 2. manufacturing a metal mold according with sizes of the component; 3. founding and forming casting alloy materials; 4. and performing thermal process to cast formed pieces; wherein the composition ingredientsof the adopted alloy materials include elements of Al, Mg, Si, Zr, Ce and B; the mass percent content of each composition ingredient contains 0.5-1.0% of Mg, 0.4-0.8% of Si, 0.6-0.8% of Zr, 0.05-0.1%of Ce, and 0.03-0.06% of B; the allowance is Al and inevitable impurities; the mass percent ratio of the impurity elements contained in the alloy materials is that: Fe is less than or equal to 0.2%, Cu is less than or equal to 0.05%, Mn is less than or equal to 0.02%, Cr is less than or equal to 0.02%, Zn is less than or equal to 0.05% and Ti is less than or equal to 0.05%. With the casting method, the aluminum alloy electrode cross beam component with good thermal resistance, mechanical property and high electrical conductivity performance can be cast, the electric conductivity can be up to 45% IACS (International Annealed Copper Standard), the temperature can be up to 250 DEG C in long-term application, and the casting method can be used for manufacturing the electrode cross beam components needed by the industrial field of electrolytic zinc.

Owner:沈阳铸研科技有限公司

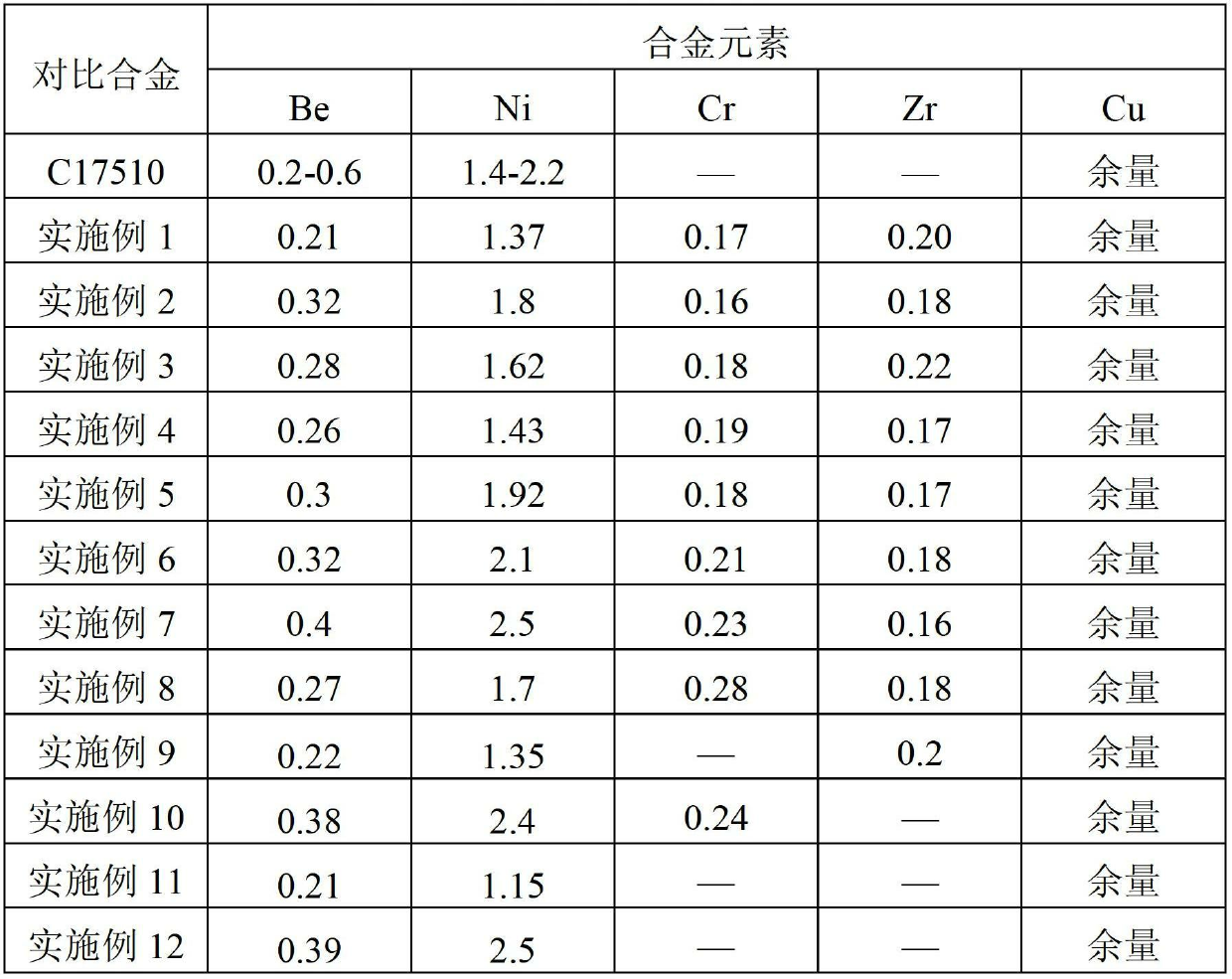

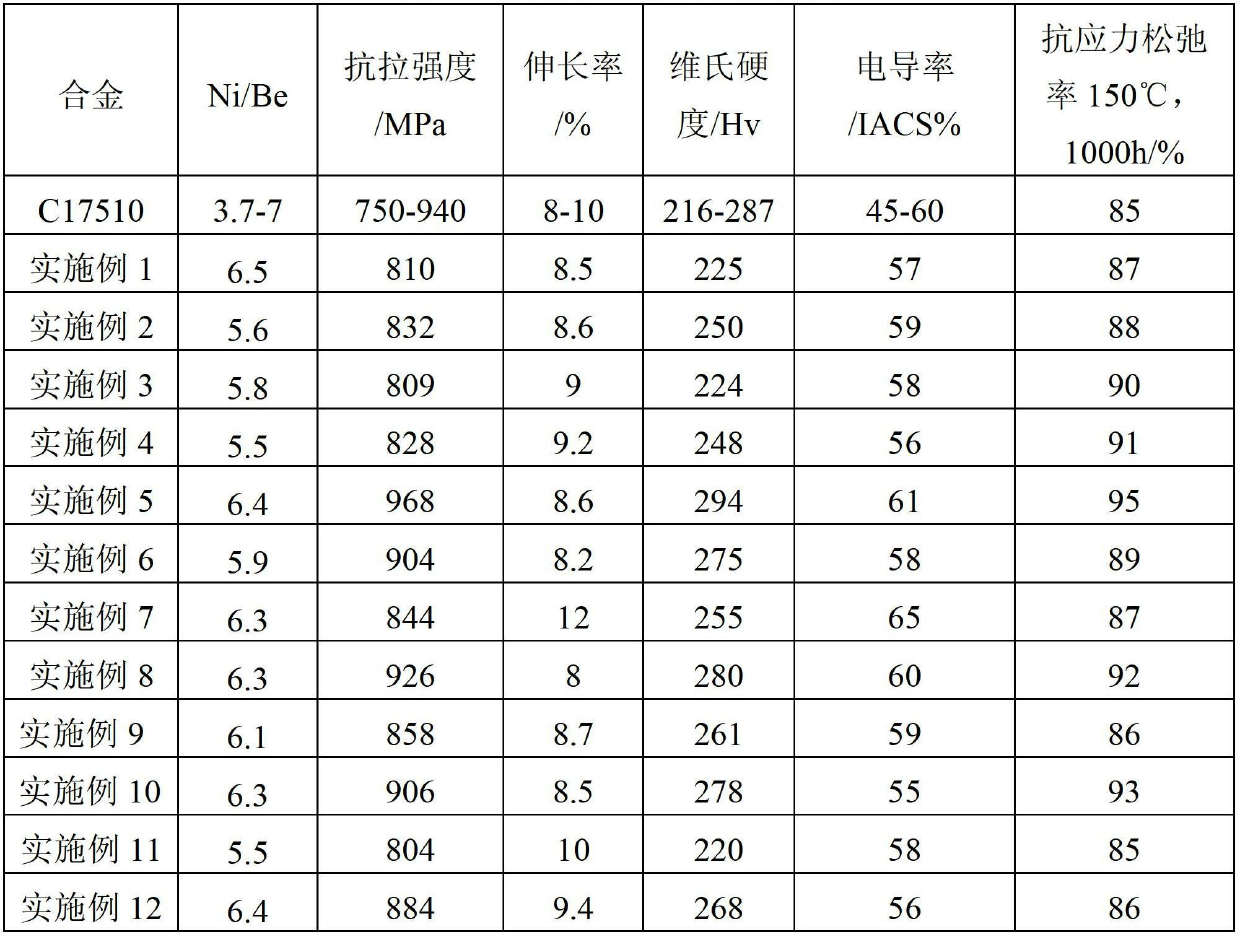

Low-beryllium elastic copper alloy and preparation and manufacture method thereof

InactiveCN102676878AReduce the difficulty of productionSimple preparation processSolution treatmentStress relaxation

The invention relates to low-beryllium elastic copper alloy and a preparation and manufacture method thereof. The low-beryllium elastic copper alloy comprises by mass: 0.2-0.4% of Be, 1.3-2.6 % of Ni and the balance Cu, wherein the mass ratio of the Ni to the Be in the beryllium copper alloy is larger than or equal to 5.5 and smaller than or equal to 6.5. The alloy can further contain Cr and Zr. The preparation method of the low-beryllium elastic copper alloy comprises alloy component design, casting, hot rolling, solution treatment, rolling deformation and ageing treatment. The alloy is low in Be content (smaller than 0.5%) and can effectively save metal beryllium, the tensile strength of the alloy after deformation ageing treatment can reach 968MPa, conductivity is larger than 55% according to the international annealed copper standard (IACS), and the rate of resistance to stress relaxation is larger than 85%. Therefore, the low-beryllium elastic copper alloy can serve as a conductive elastic material which has high elasticity, high strength and excellent resistance to stress relaxation, can be applied to electrical contact components, connectors, relays and the like, and has wide application prospects.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG +2

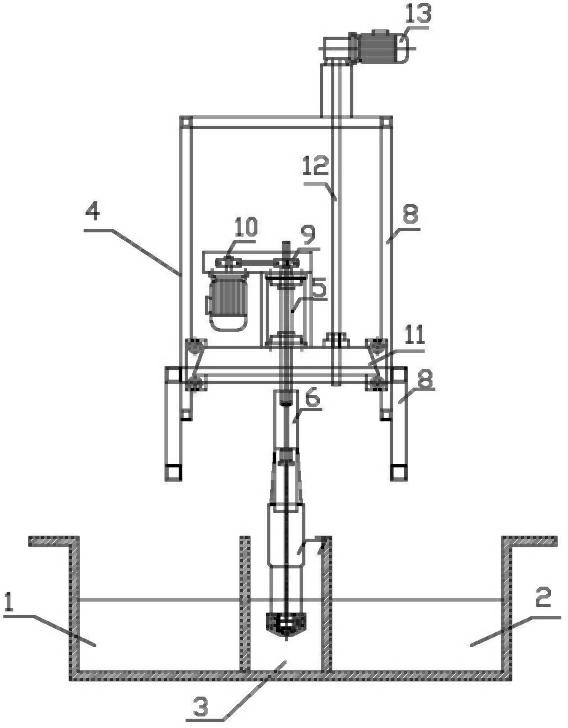

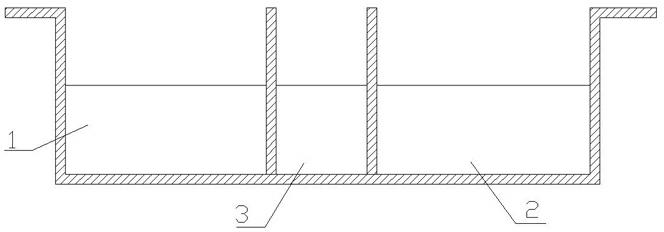

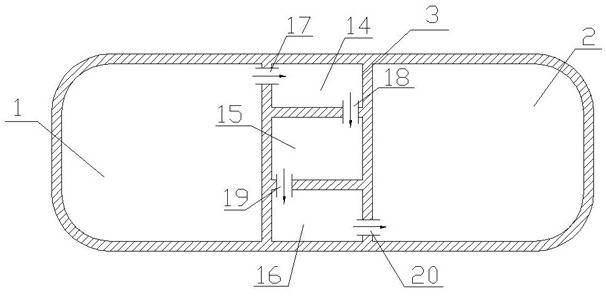

Device and method for continuous smelting of high-purity high-conductivity copper

The invention discloses a device and a method for continuous smelting of high-purity high-conductivity copper, which comprises a smelting furnace, a heat preserving furnace and a degassing device. A compartment is mounted between the smelting furnace and the heat preserving furnace, the degassing device is mounted on the upper portion of the compartment and comprises a frame, and a spindle is vertically sleeved on the frame and connected with a spindle motor through a rotary connector. A metal rotary rod is sleeved to the lower end of the spindle, a graphite rotary rod is sleeved on the metal rotary rod, and the spindle is movably connected with a heat insulating device which is connected with a lifting motor through a lifting screw. The production process is simple while production is stable by using the continuous smelting device, and the continuous degassing device is mounted in the compartment II which is additionally arranged between the smelting furnace and the heat preserving furnace, so that degassing and deoxidizing effects can be fully guaranteed, and stability of liquid level of the heat preserving furnace can be further guaranteed. Oxygen-free copper produced by the device and the method is low in oxygen content and high in conductivity, the oxygen content is smaller than or equal to 5ppm, and the conductivity is larger than or equal to 101% of IACS (international annealed copper standard).

Owner:浙江力博实业股份有限公司

Preparation method for rare earth oxide particle reinforced high-conductivity copper alloy

The invention discloses a preparation method for a rare earth oxide particle reinforced high-conductivity copper alloy. The preparation method comprises the following steps: after copper oxide, rare earth oxide powder, stearic acid serving as a PCA (Process Control Agent) and zirconia grinding media are dried, placing the dried copper oxide, the rare earth oxide powder, the stearic acid serving as the PCA and the zirconia grinding media into a ball grinding tank for performing ball grinding; placing powder which is subjected to the ball grinding into a tube furnace, introducing reducing atmosphere, heating and performing heat preservation, wherein the heat preservation temperature is 500 + / - 10 DEG C, and the heat preservation time is 4+ / -0.5 h; sintering a graphite mould which is filled with the reduced powder in a discharge plasma sintering furnace, and cooling to obtain the rare earth oxide particle reinforced high-conductivity copper alloy. Through testing of comprehensive performance, the maximum yield strength is 269.8 MPa, and the electrical conductivity at normal temperature is 82.5 percent IACS (International Annealed Copper Standard).

Owner:JIANGXI UNIV OF SCI & TECH

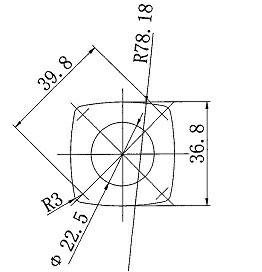

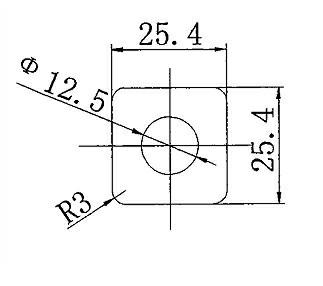

Method for processing copper tube having circular inside and quadrate outside

InactiveCN102581060AOmit the heating processReduce energy consumptionOxygenInternational Annealed Copper Standard

The invention discloses a method for processing a copper rube having a circular inside and a quadrate outside. The method comprises the steps of: 1) adopting high-pure cathode copper as a raw material and vacuum up-drawing in a clutch type way and continuously casting an oxygen-free copper rod by using a dragger group; 2) processing the oxygen-free copper rod from step 1) to form a copper tube blank having the circular inside and the quadrate outside by a continuous extruding machine group; 3) stretching the copper tube blank having the circular inside and the quadrate outside formed in step 2) by a high-precision stretcher; 4) annealing the stretched copper tube blank having the circular inside and the quadrate outside obtained in step 3) by bright annealing equipment; and 5) inspecting and packing the annealed copper tube blank having the circular inside and the quadrate outside obtained in step 4). The method provided by the invention has the characteristics of being low in energy consumption, high in yield, high in production efficiency, and long in the product length. In the method, the sum of content of copper and silver is not less than 99.99%; the content of oxygen is not more than 5ppm, and the electric conductivity is not less than 101% IACS (International Annealed Copper Standard).

Owner:浙江力博实业股份有限公司

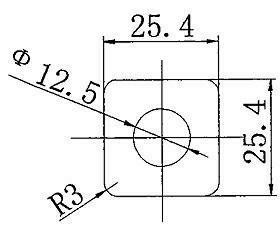

Preparation method of high-strength and high-conductivity copper alloy

ActiveCN102839341AHigh strengthGuaranteed electrical conductivitySolution treatmentInternational Annealed Copper Standard

The invention relates to a preparation method of high-strength and high-conductivity copper alloy. The preparation method comprises the following steps: (1) solid-solution treatment and hot rolling; (2) cold rolling and annealing at a normal temperature; (3) low-temperature treatment; and (4) quick deformation treatment and final annealing. According to the preparation method of the high-strength and high-conductivity copper alloy, low-temperature quick deformation treatment is carried out at a temperature lower than a temperature, at which the copper alloy slips and deforms; compared with a sample piece which is not subjected to low-temperature quick deformation treatment, not only is the strength of the copper alloy improved, but also the conductivity of the copper alloy is kept well. The copper alloy prepared in the invention has performances better than those of the copper alloy which is not prepared by the method in the invention, wherein the tensile strength is bigger than 600 MPa, the elongation is bigger than 10% and the conductivity is higher than 80% IACS (international annealed copper standard).

Owner:HEFEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com