Intermediate strength aluminum alloy wire for overhead conductor

A medium-strength aluminum alloy, overhead wire technology, used in metal/alloy conductors, conductors, conductive materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Aluminum ingots, aluminum-silicon alloy ingots, aluminum-magnesium master alloys, aluminum-copper master alloys and aluminum-yttrium master alloys are selected as raw materials.

[0045] The composition requirements of aluminum ingots are as follows : Silicon ≤ 0.07wt%, iron ≤ 0.23wt%, magnesium ≤ 0.02wt%, (manganese + titanium + chromium + vanadium) ≤ 0.02wt%, and the content of each other impurity element is not more than 0.03wt%.

[0046] The silicon content in the aluminum-silicon master alloy is 20wt%, the magnesium content in the aluminum-magnesium master alloy is 50wt%, the copper content in the aluminum-copper master alloy is 10wt%, and the yttrium content in the aluminum-yttrium master alloy is 10wt%.

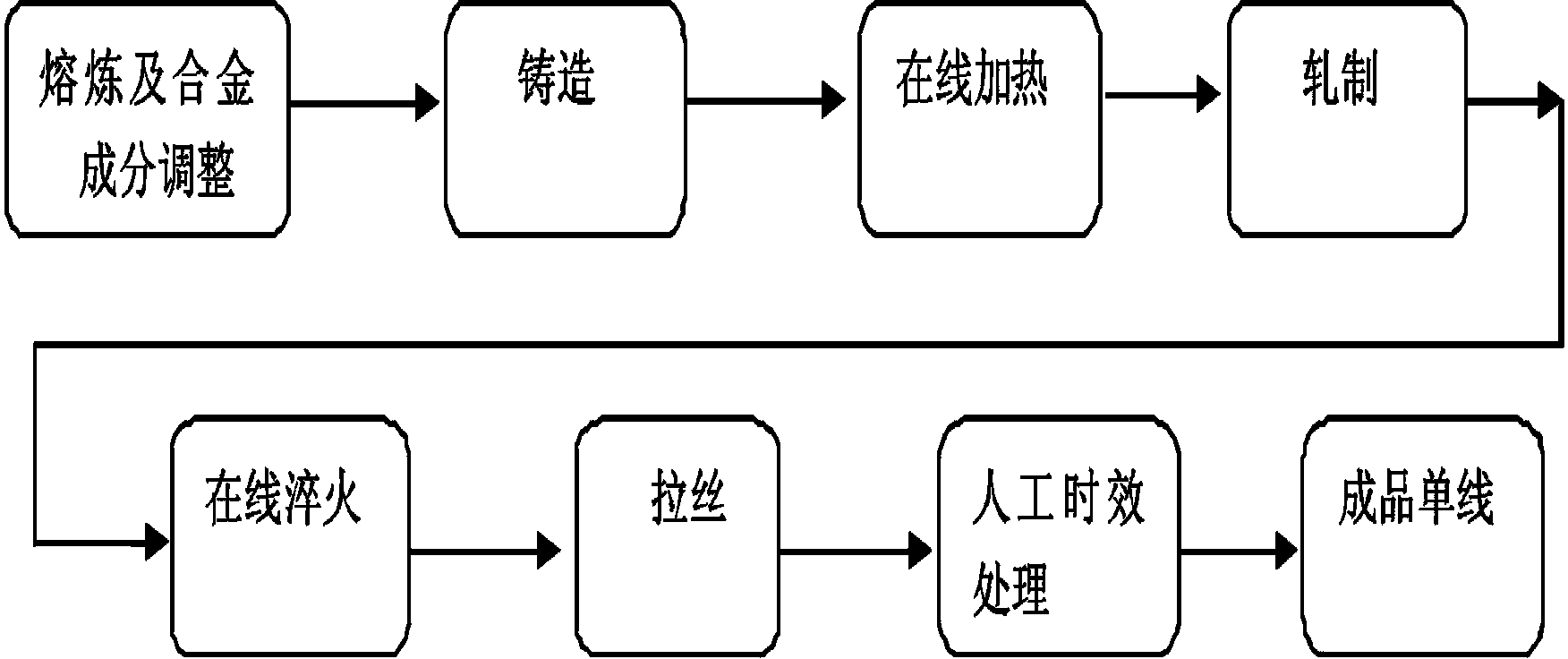

[0047] according to figure 1 In the process flow shown, the aluminum ingot is melted in the melting furnace, and then flows into the holding furnace for heat preservation. Add the amount of aluminum-silicon, aluminum-magnesium, aluminum-copper and aluminum-yt...

Embodiment 2

[0057] Aluminum ingots, aluminum-silicon alloy ingots, aluminum-magnesium master alloys, aluminum-copper master alloys and aluminum-yttrium master alloys are selected as raw materials.

[0058] The composition requirements of aluminum ingots are as follows: silicon ≤ 0.40wt%, iron ≤ 0.18wt%, magnesium ≤ 0.48wt%, (manganese + titanium + chromium + vanadium) ≤ 0.02wt%, and the content of each other impurity element is not more than 0.03wt% %. The silicon content in the aluminum-silicon master alloy is 20wt%, the magnesium content in the aluminum-magnesium master alloy is 50wt%, the copper content in the aluminum-copper master alloy is 10wt%, and the yttrium content in the aluminum-yttrium master alloy is 10wt%.

[0059] according to figure 1 In the process flow shown, the aluminum ingot is melted in the melting furnace, and then flows into the holding furnace for heat preservation. Add the amount of aluminum-silicon, aluminum-magnesium, aluminum-copper and aluminum-yttrium ma...

Embodiment 3

[0069] Aluminum ingots, aluminum-silicon alloy ingots, aluminum-magnesium master alloys, aluminum-copper master alloys and aluminum-yttrium master alloys are selected as raw materials.

[0070] The composition requirements of aluminum ingots are as follows: silicon ≤ 0.50wt%, iron ≤ 0.20wt%, magnesium ≤ 0.50wt%, (manganese + titanium + chromium + vanadium) ≤ 0.02wt%, and the content of each other impurity element is not more than 0.03wt% %. The silicon content in the aluminum-silicon master alloy is 20wt%, the magnesium content in the aluminum-magnesium master alloy is 50wt%, the copper content in the aluminum-copper master alloy is 10wt%, and the yttrium content in the aluminum-yttrium master alloy is 10wt%.

[0071] according to figure 1 In the process flow shown, the aluminum ingot is melted in the melting furnace, and then flows into the holding furnace for heat preservation. Add the amount of aluminum-silicon, aluminum-magnesium, aluminum-copper and aluminum-yttrium ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com