Device and method for continuous smelting of high-purity high-conductivity copper

A high-conductivity, high-purity technology, applied in furnace types, furnaces, lighting and heating equipment, etc., can solve the problems of mechanical properties of copper rods, fracture, and electrical conductivity of oxygen-free copper rods, and achieve stable production process and production. The process is simple and the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

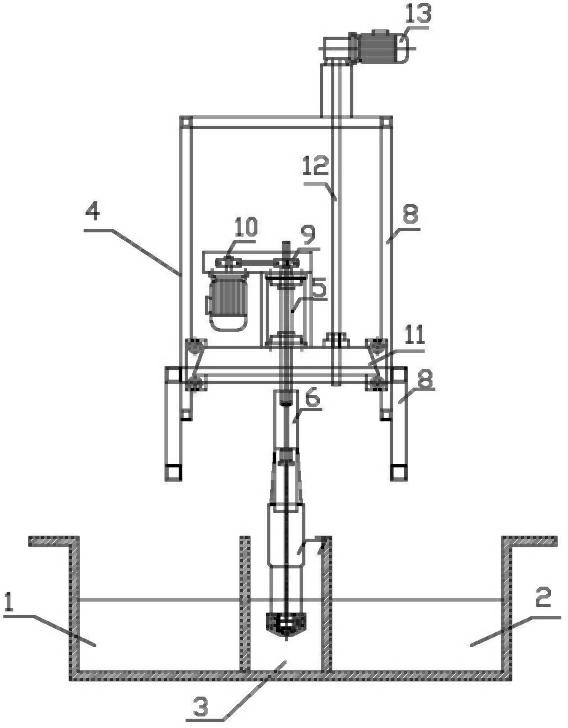

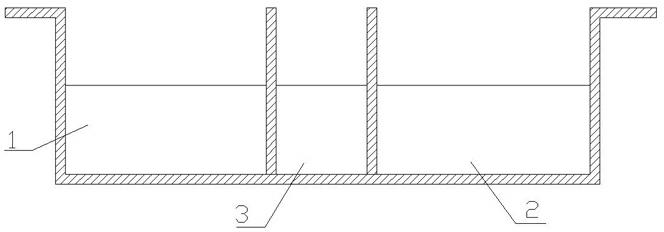

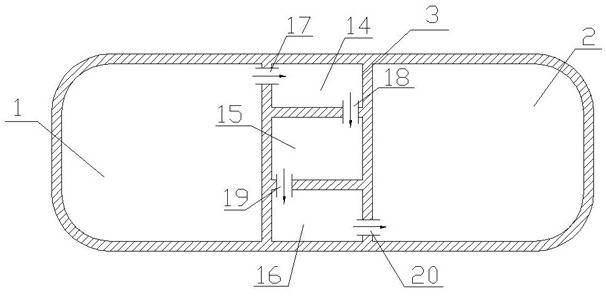

[0029] Such as figure 1 , figure 2 , image 3 The shown continuous smelting device for high-purity and high-conductivity copper includes a melting furnace 1, a holding furnace 2 and a degassing device 4, and a compartment 3 is installed between the melting furnace 1 and the holding furnace 2; A degassing device 4 is installed on the upper part of the compartment 3; the degassing device 4 includes a frame 8, and the frame 8 is vertically fitted with a main shaft 5; the main shaft 5 is connected to the main shaft motor 10 through a rotary joint 9 The lower end of the main shaft 5 is covered with a metal rotating rod 6; the metal rotating rod 6 is covered with a graphite rotating rod 7; the described main shaft 5 is movably connected with the heat insulating device 11; Lifting screw mandrel 12 links to each other with lifting motor 13. The compartment 3 includes a first compartment 14, a second compartment 15 and a third compartment 16; the melting furnace 1 is connected to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com