80-100mm hardenability aluminium alloy with super strength of 690-730Mpa and preparation method thereof

An ultra-high-strength, hardenable technology, applied in the field of aluminum alloy materials, can solve the problem of lack of ultra-high-strength and high-hardenability lightweight aluminum alloys, and achieve the effect of fine grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

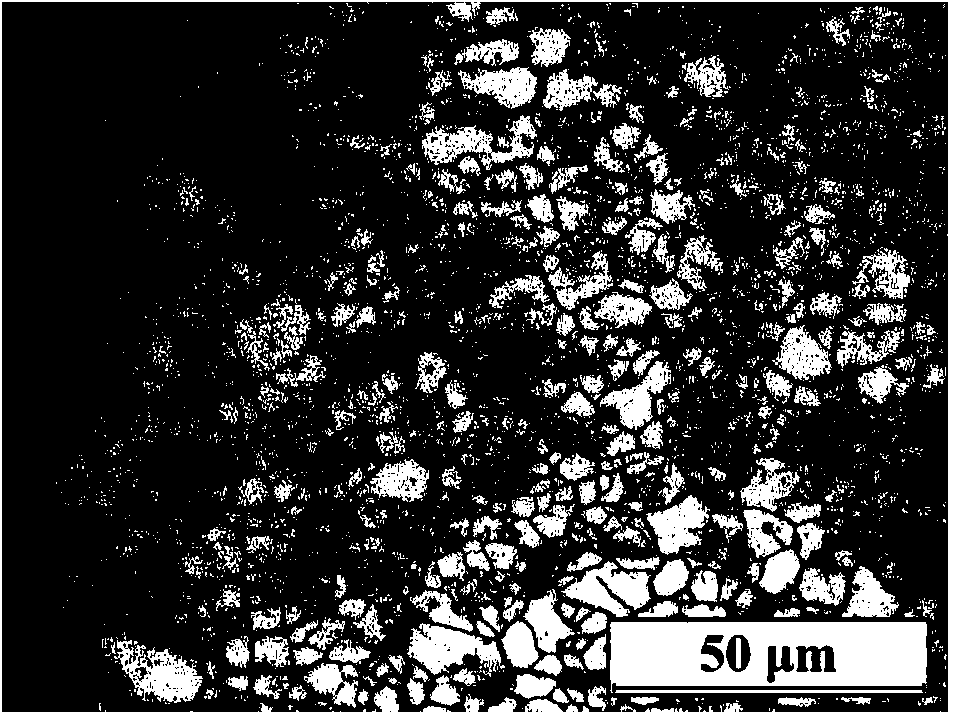

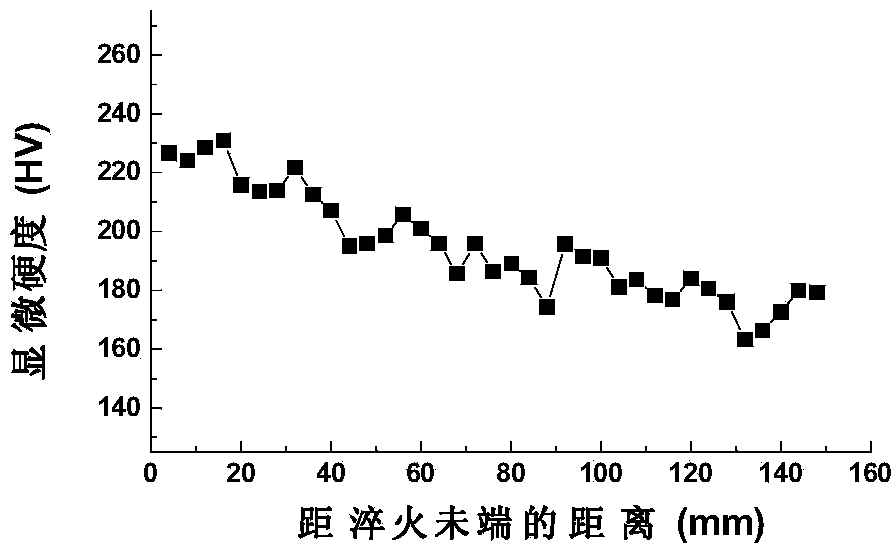

[0032] Such as figure 1 , 2 shown.

[0033] A 690-730MPa ultra-high strength 80-100mm hardenable aluminum alloy, the preparation method of which is:

[0034] Take 28kg aluminum alloy as an example.

[0035] First, 20.55 kg of A00 grade pure Al (composition: 99.79%Al, 0.14%Fe, 0.04%Si, all components in the present invention are represented by mass percentage, the same below, and the parts where the sum of components is less than 100% are impurities ) after melting, add 1.54 kg Al-Cu (49.62%Al, 50.12%Cu, 0.15%Fe, 0.11%Si ) master alloy (the loss rate of Cu is about 6.25%), 0.53 kg Al-Sr (89.86%Al, 9.89% %Sr, 0.15%Fe, 0.10%Si ) master alloy (the loss rate of Sr is about 75%), 1.64 kg Al-Zr master alloy (95.69%Al, 4.11%Zr, 0.20%Fe, 0.10%Si ) (Zr The loss rate of Zn is about 8%), 3.28 kg of pure Zn (the loss rate of Zn is about 8%), 0.97 kg of pure Mg (the loss rate of Mg is about 20%), and the master alloy can be purchased directly from the market , can also be self-prepared...

Embodiment 2

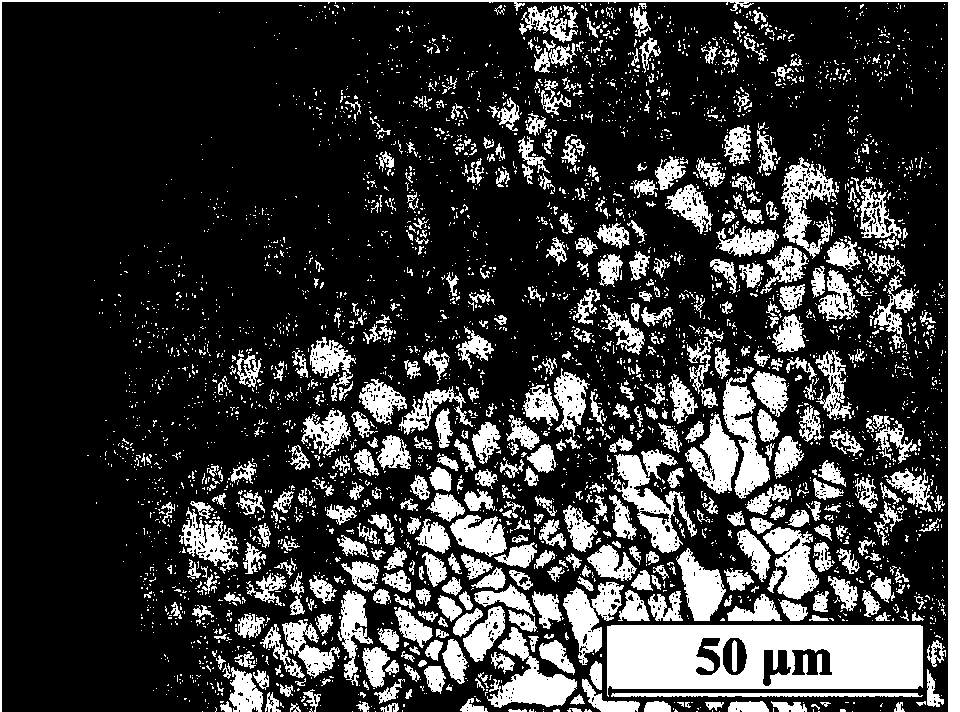

[0039] Such as image 3 , 4 shown.

[0040] A 700-750MPa grade high-strength 80-100mm grade hardenable aluminum alloy, the preparation method of which is:

[0041] Take 28kg aluminum alloy as an example.

[0042] First, 20.65 kg A00 grade pure Al (ingredients: 99.79%Al, 0.14%Fe, 0.04%Si, all components in the present invention are represented by mass percentage, the same below, and the parts where the sum of components is less than 100% are impurities ) after melting, add 1.35 kg Al-Cu (49.62%Al, 50.12%Cu, 0.15%Fe, 0.11%Si ) master alloy (the loss rate of Cu is about 6.25%), 0.028 kg Al-Sr (89.86%Al, 9.89% %Sr, 0.15%Fe, 0.10%Si ) master alloy (the loss rate of Sr is about 75%), 1.78 kg Al-Zr master alloy (95.69%Al, 4.11%Zr, 0.20%Fe, 0.10%Si ) (Zr The loss rate of Zn is about 8%), 3.51 kg of pure Zn (the loss rate of Zn is about 8%), 1.23 kg of pure Mg (the loss rate of Mg is about 20%), and the master alloy can be purchased directly from the market , can also be self-prepar...

Embodiment 3

[0046] Such as Figure 5-6 shown.

[0047] A 690-730MPa ultra-high strength 80-100mm hardenable aluminum alloy, the preparation method of which is:

[0048] Take 28kg aluminum alloy as an example.

[0049] First, 19.42 kg A00 grade pure Al (composition: 99.79%Al, 0.14%Fe, 0.04%Si, all components in the present invention are represented by mass percentage, the same below, and the parts where the sum of components is less than 100% are impurities ) after melting, add 1.67 kg Al-Cu (49.62%Al, 50.12%Cu, 0.15%Fe, 0.11%Si ) master alloy (the loss rate of Cu is about 6.25%), 0.85 kg Al-Sr (89.86%Al, 9.89% %Sr, 0.15%Fe, 0.10%Si ) master alloy (the loss rate of Sr is about 75%), 1.51 kg Al-Zr master alloy (95.69%Al, 4.11%Zr, 0.20%Fe, 0.10%Si ) (Zr The loss rate of Zn is about 8%), 3.96 kg of pure Zn (the loss rate of Zn is about 8%), 1.11 kg of pure Mg (the loss rate of Mg is about 20%), and the master alloy can be purchased directly from the market , can also be self-prepared by c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average grain size | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com