Method for realizing Gigabit network transmission in precision conductive slip ring

A technology of conductive slip ring and implementation method, which is applied in the field of gigabit network transmission, can solve the problems of fast signal transmission rate of gigabit network, easy mutual interference of digital signals, etc., and achieve the effect of reducing transmission space and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

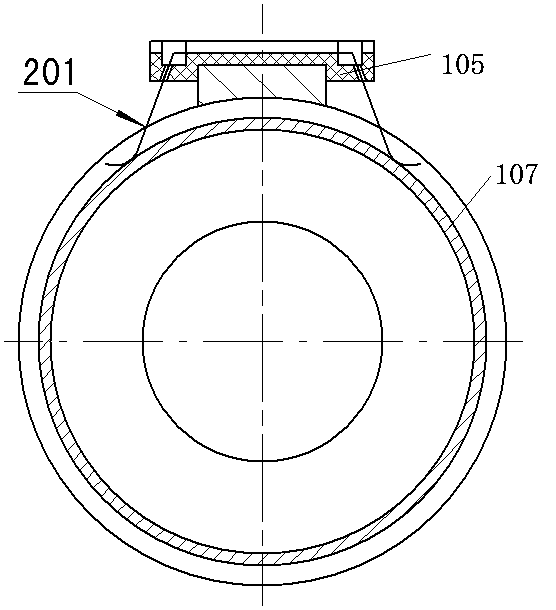

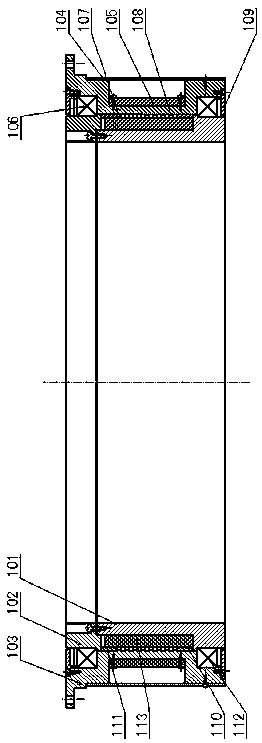

[0046] The present invention will be described in further detail below in conjunction with the embodiments and with reference to the accompanying drawings.

[0047]A method for realizing gigabit network transmission in a precision conductive slip ring, including a method for preparing a ring body assembly, a method for preparing a brush assembly, a method for preparing a combined bracket, and a method for preparing a gigabit network conductive slip ring. The specific steps are as follows:

[0048] 1. The preparation method of the ring body assembly:

[0049] A. Material selection: choose super-hard aluminum material for the center shaft, brass material for the ring piece, non-metallic material with the smallest possible dielectric constant for the insulating medium material, here choose polytetrafluoroethylene material, and choose super hard for the bearing seat aluminum material;

[0050] B. Central shaft forming: According to the requirements of the drawings, the duralumin ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com