Patents

Literature

112results about How to "Guaranteed welding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

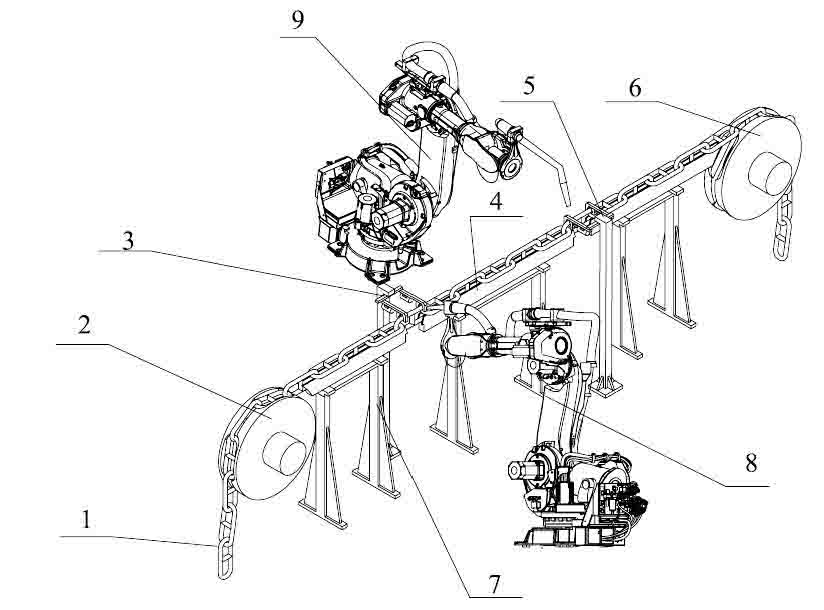

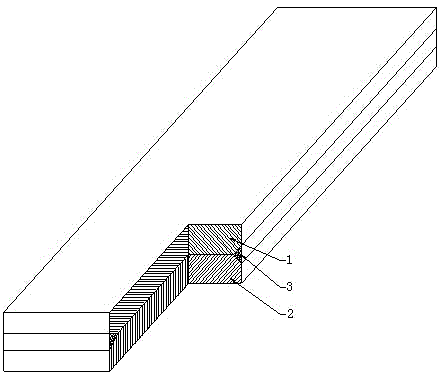

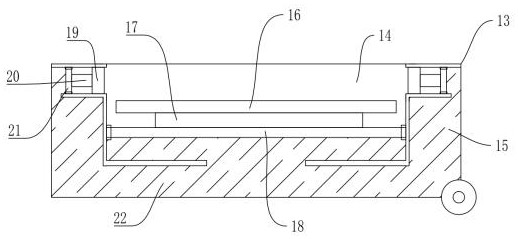

Automatic anchor chain transom welding device

InactiveCN102166699AGuaranteed positioning accuracyGuaranteed Attitude AccuracyWelding/cutting auxillary devicesAuxillary welding devicesTransfer procedureEngineering

The invention relates to an automatic anchor chain transom welding device, comprising an active guide wheel, a passive guide wheel, a transmission working table, a support, clamp mechanisms and a welding robot, wherein the active guide wheel and the passive guide wheel are respectively positioned at two ends of the transmission working table (4); the active guide wheel drives an anchor chain to move on the transmission working table; the transmission working table is provided with an opening at intervals; the opening is a welding working position of the robot; a plurality of welding working positions can be arranged according to requirements; and each welding working position comprises a welding clamp mechanism. According to the anchor chain transom automatic welding device, the precise positioning of the chain in the transmission process and the chain posture precision can be ensured, thus the welding quality is ensured; and the device is suitable for transmitting, clamping and welding the chain in the automatic anchor chain welding process.

Owner:SHANGHAI UNIV

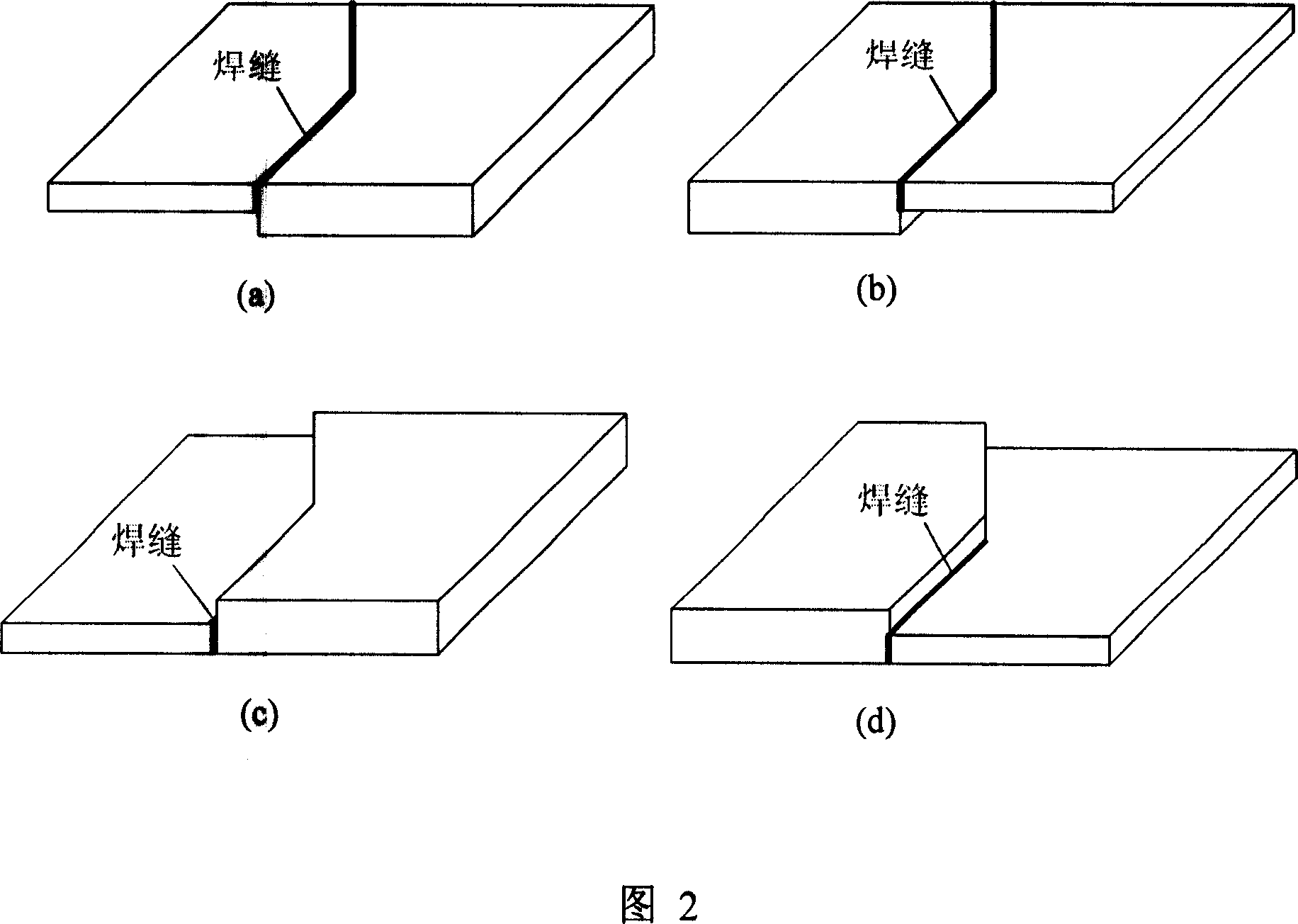

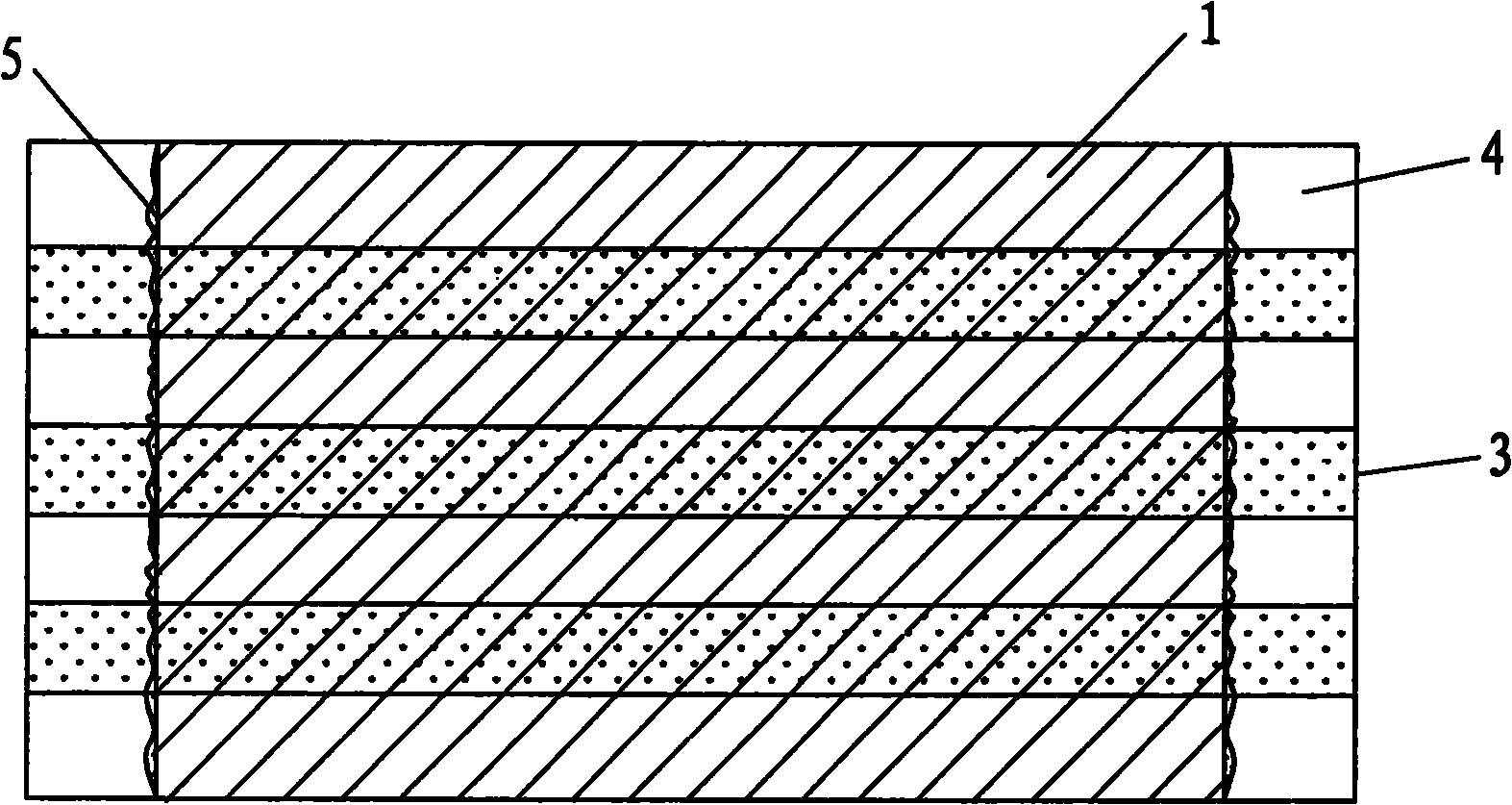

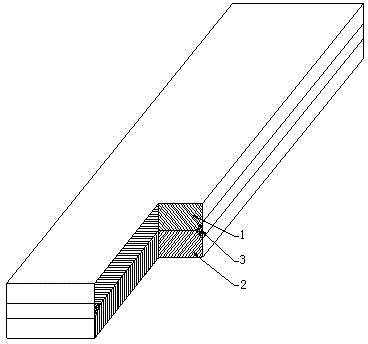

Deformable welding fixture for plate splicing welding with linear and curved weld seams

InactiveCN101020281AEasy clampingAvoid deformationWelding/cutting auxillary devicesAuxillary welding devicesSheet steelEngineering

The present invention is a double-purpose deformable welding fixture for welding linear and curved weld seams, and the fixture has linear welding slot and curved welding slot integrated onto one pedestal to reach the double-purpose aim. The double-purpose deformable welding fixture consists of one pedestal height difference structure comprising one thickness difference step and one height regulating tab for fitting different welding thickness, and one clamping screw mechanism comprising right and left pressing boards with screw holes and corresponding cap screws. It can regulate clamping force and control welding deformation by means of novel flexible location mode, and is suitable for linear and curved welding of common steel plate, high strength steel plate, aluminum plate, etc of different sizes.

Owner:JIANGSU UNIV

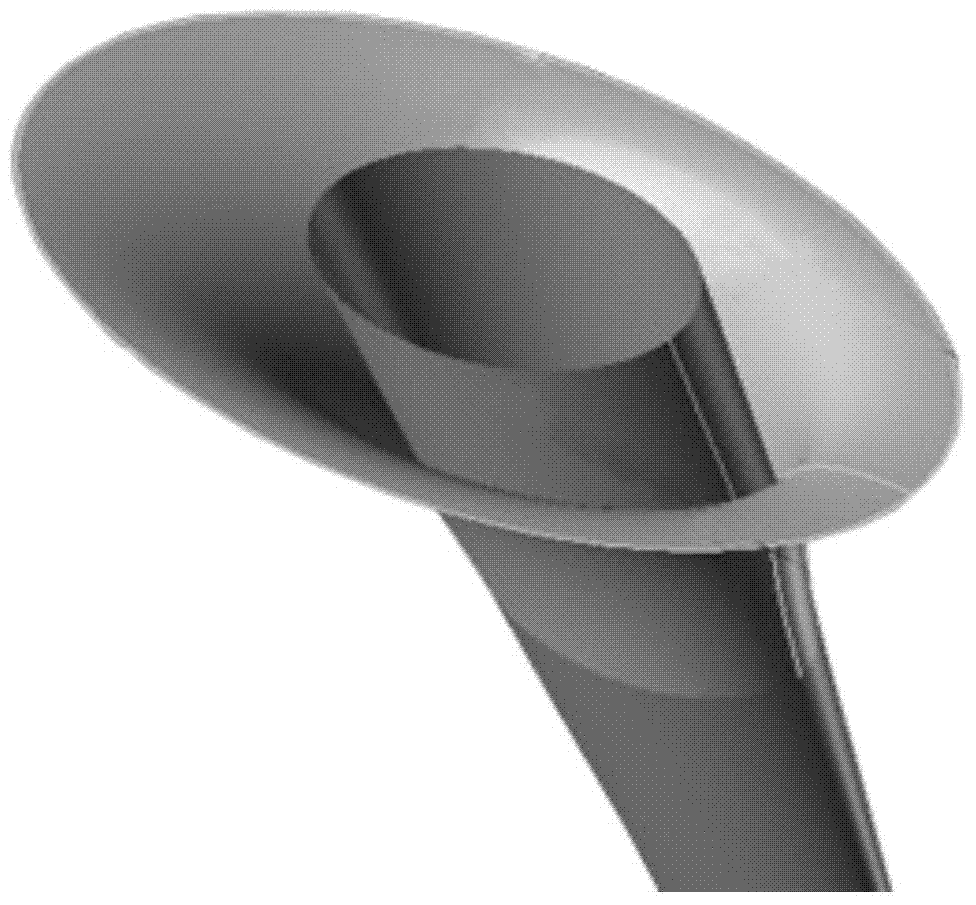

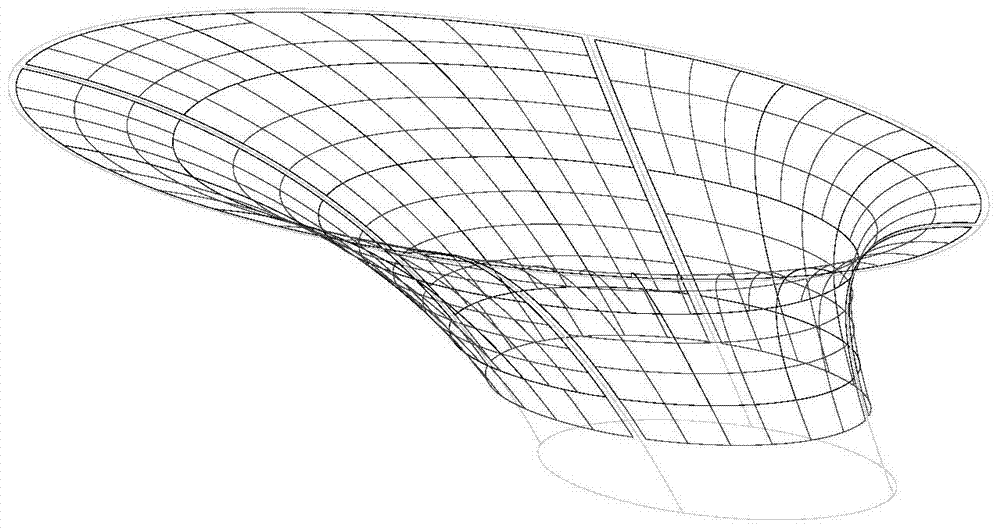

Construction method for using layering method to construct double-curved-surface stainless steel curtain wall

ActiveCN103541474AFast Construction CompletedSafe construction completedWallsBuilding material handlingSurface layerKeel

The invention discloses a construction method for using a layering method to construct a double-curved-surface stainless steel curtain wall. The method includes: building a double-curved-surface stainless steel curtain wall three-dimensional model and deepen drawing; decomposing the double-curved-surface curtain wall structure according to the model and deepen drawing into a surface layer and a keel layer; deepening construction drawings of the surface layer and the keel layer; machining and constructing the surface layer of the double-curved-surface stainless steel curtain wall; cutting and transporting the surface layer; constructing the keel layer of the double-curved-surface stainless steel curtain wall; mounting and seam welding the surface layer; processing the facing of the double-curved-surface stainless steel curtain wall. The construction method has the advantages that the layering method is used to construct the double-curved-surface stainless steel curtain wall, the surface layer with large welding and splicing work load is constructed in a factory, the keel layer is welded on site, filed structural features are combined to adjust and eliminate construction errors reasonably, coordinating and unifying of the curtain wall structure and a main body structure are guaranteed, and accurate curved surfaces and radian smoothness of the curtain wall are guaranteed.

Owner:ZHEJIANG CONSTR ENG GRP CO LTD

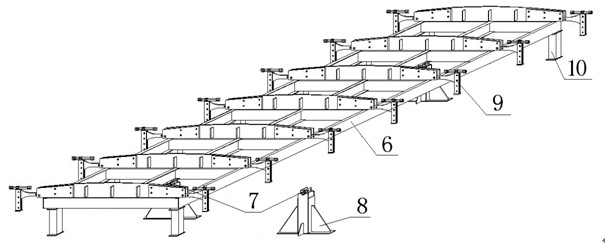

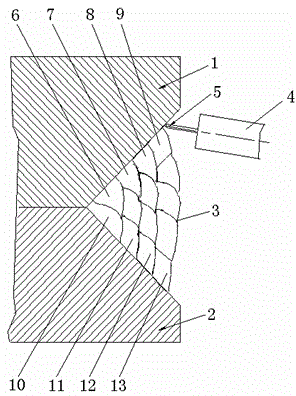

Construction method for improving fatigue strength of welding joint of orthotropic steel bridge deck

InactiveCN102407397ASimple structureEasy to manufactureWelding/cutting auxillary devicesAuxillary welding devicesBridge deckEngineering

The invention relates to a construction method for improving fatigue strength of a welding joint of an orthotropic steel bridge deck, mainly aiming at welded toes of a welded joint of an orthotropic steel bridge deck unit U-shaped longitudinal rib and a longitudinal angle joint of the bridge deck. The construction key point of the construction method comprises the following steps of: firstly fixing a bridge deck unit on a construction jig at a horizontal position, rotating the construction jig to enable the bridge deck unit and the ground to form an inclined included angle of 15-25 degrees so that the welded joint on one side of the U-shaped longitudinal rib is arranged at a ship-like position, re-melting all welded toes of the welded joint at the ship-like position by full-automatic argon tungsten-arc welding without welding wires through a welding tractor, and re-rotating the construction jig so that the bridge deck unit re-welds the welded toes on the other side at a position of the same included angle by a same process. During construction, an argon tungsten-arc welding gun is clamped on the welding tractor and ensures reasonable angles and distances of the welding gun and the welded toes by regulating clamping states of the welding gun. On the construction jig, the full automatic welding operation has high efficiency and is easy to control, and the quality of the re-molten welding joint is stable and reliable.

Owner:HAIOD HEAVY ENG TECH

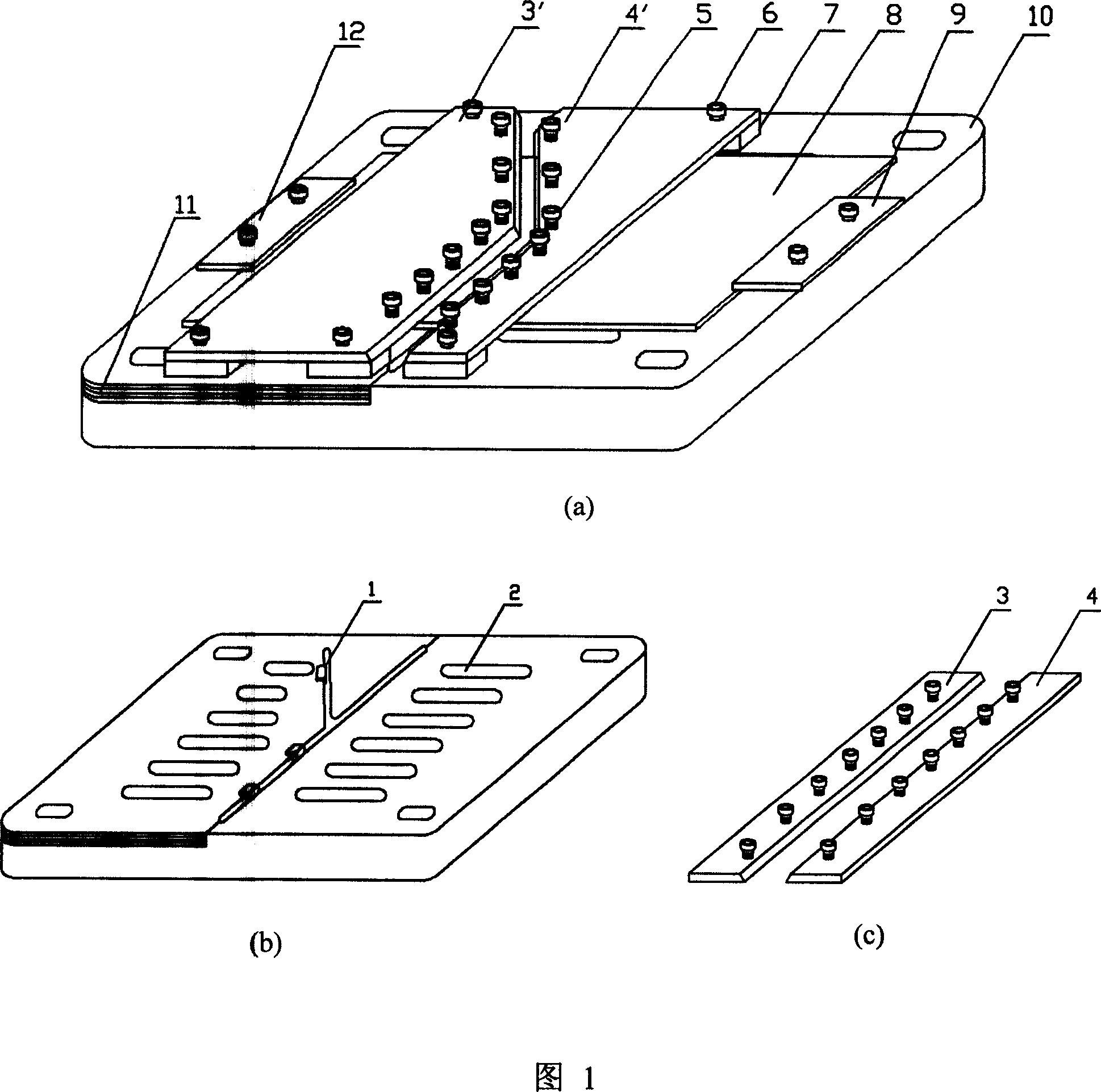

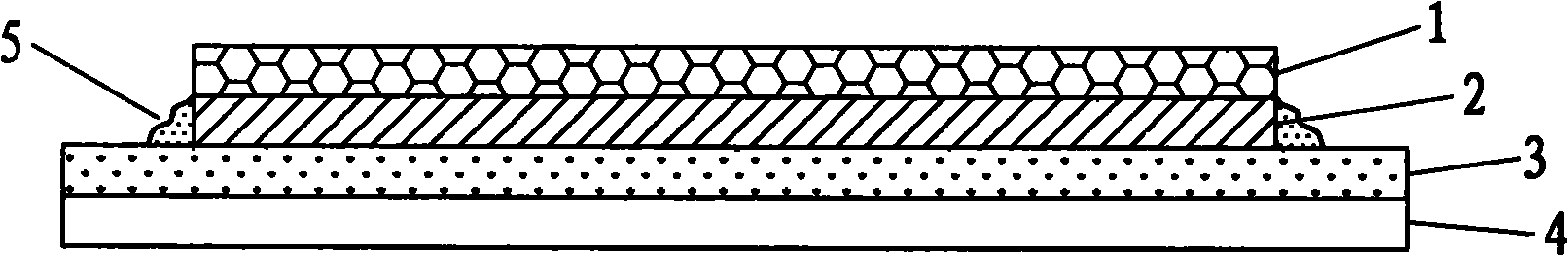

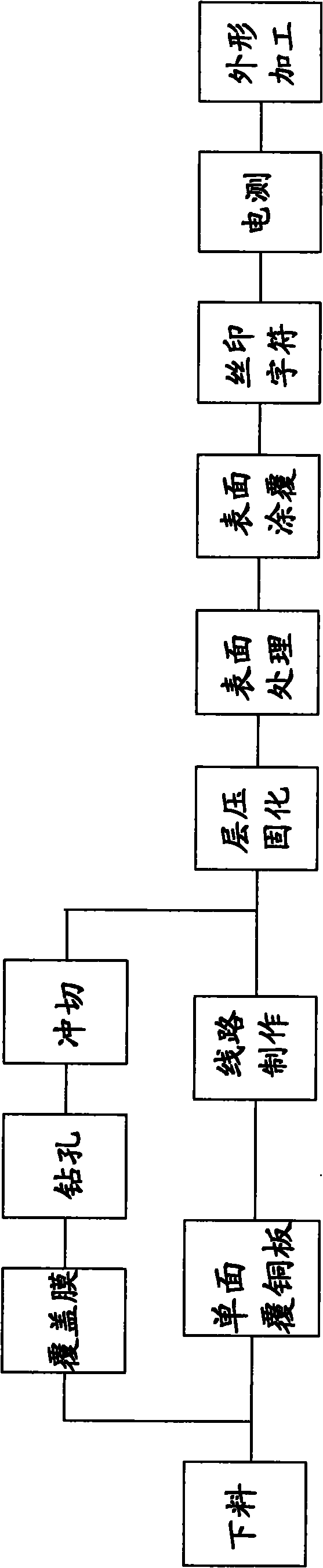

Manufacture method of single-sided flexible circuit board

ActiveCN101917824ASimple structureGuaranteed weldingPrinted circuit secondary treatmentPunchingFlexible circuits

The invention relates to a manufacture method of a single-sided flexible circuit board. The method comprises the following steps of: baiting; then, making a circuit and a laser alignment cross target on a copper foil layer of an S-CCL (Single-sided Copper Clad Laminate); attaching a cover film drilled with cover film alignment holes and other auxiliary holes onto the circuit surface to laminate and solidify; adopting laser to cut a bottom substrate opening at a copper-exposed part on a substrate layer of the S-CCL; then, removing residues of the copper-exposed part through plasma treatment; and finally obtaining a single-sided flexible circuit board through the processes of surface treatment, surface coating, electrical measurement, punching and molding. The finger region substrate can be fully removed through laser cutting to avoid the influence of an overflowing adhesive of the cover film on golden fingers; since the accuracy of laser cutting and alignment is high, the accuracy of the opening size of the bottom substrate is improved so as to ensure the welding and splicing areas of the golden fingers; in addition, since the golden fingers ar protected by the surrounding substrate, the antistripping strength of the golden fingers is improved so as to improve the manufacture yield rate of the single-sided flexible circuit board product.

Owner:厦门弘信智能科技有限公司

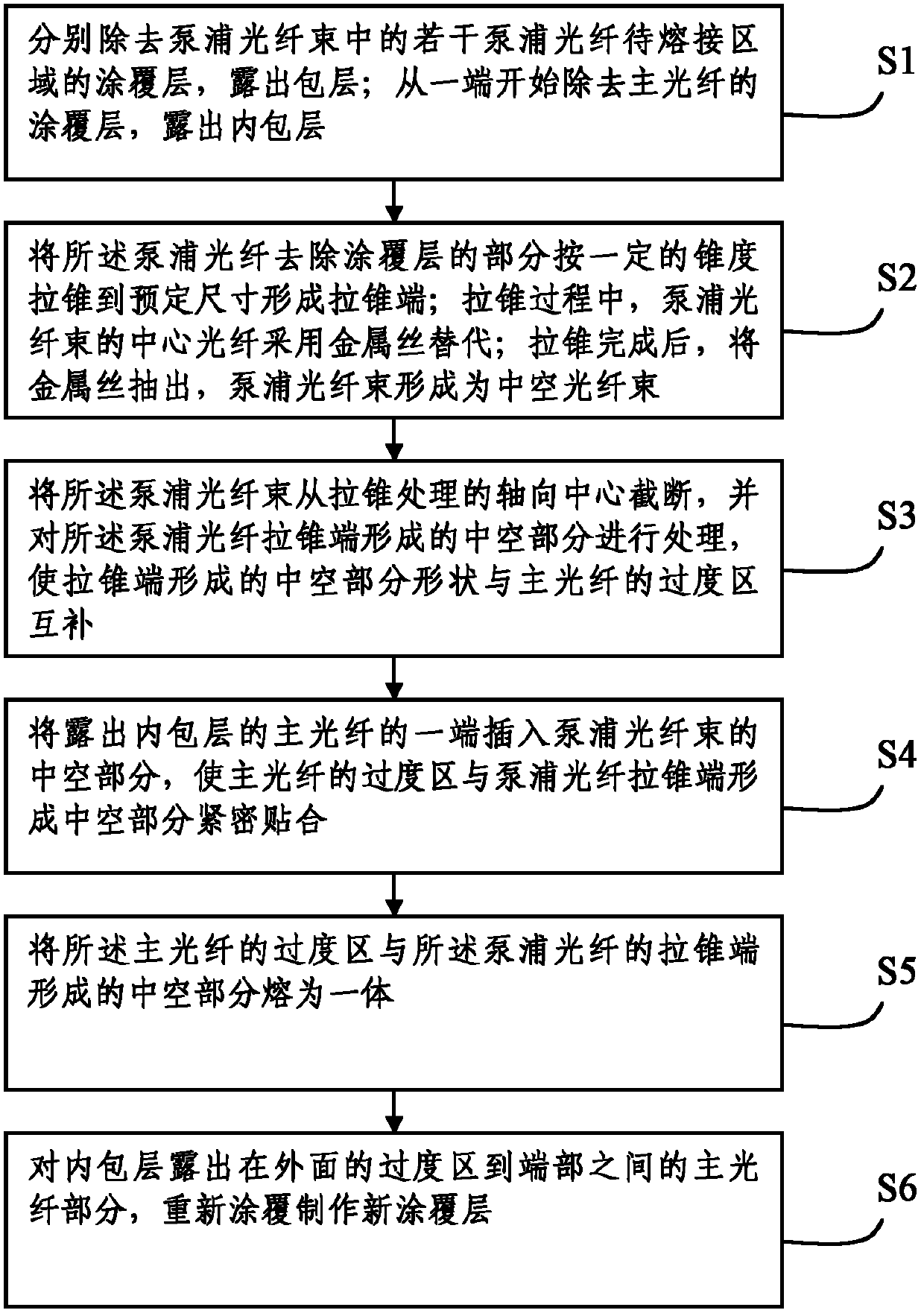

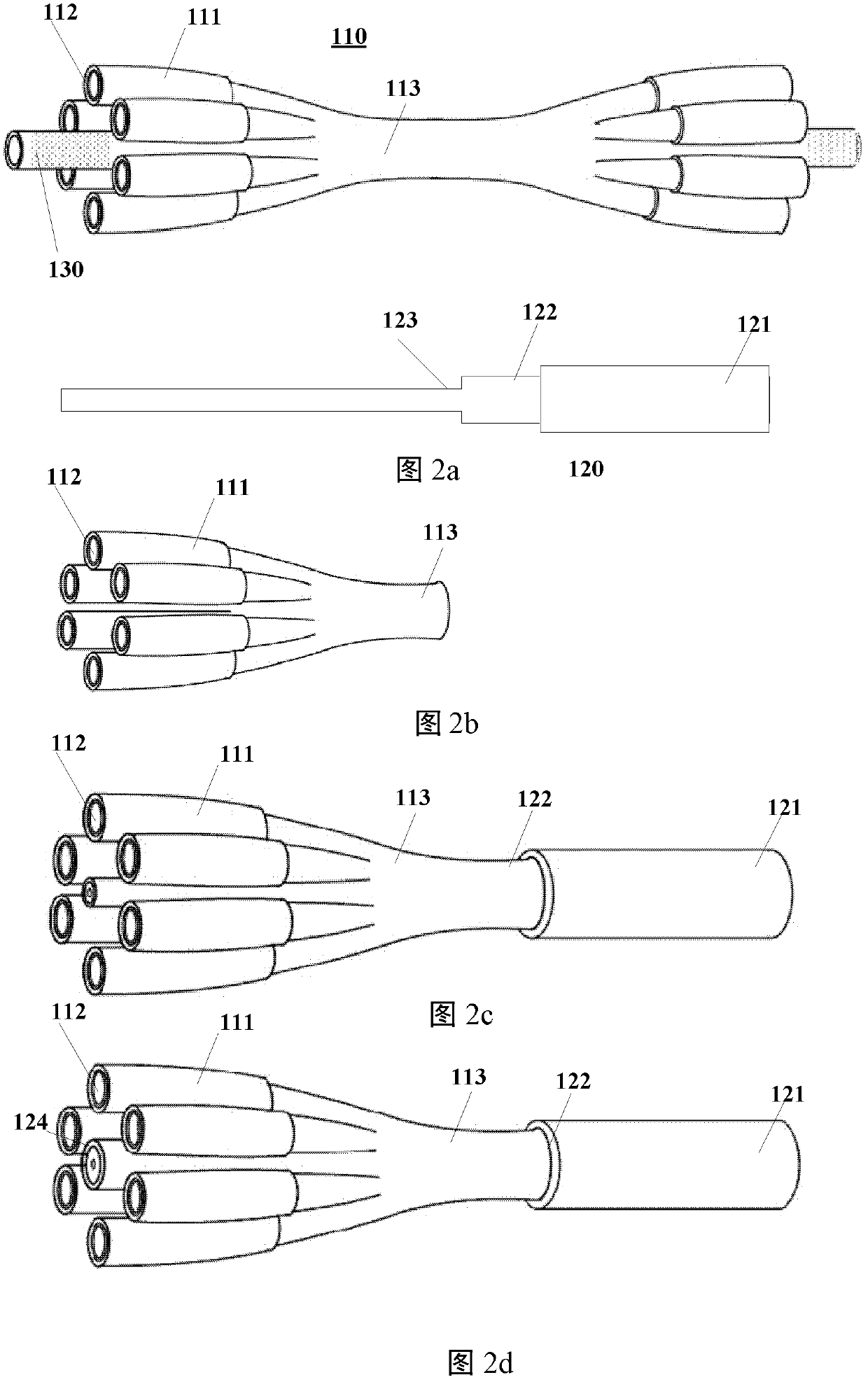

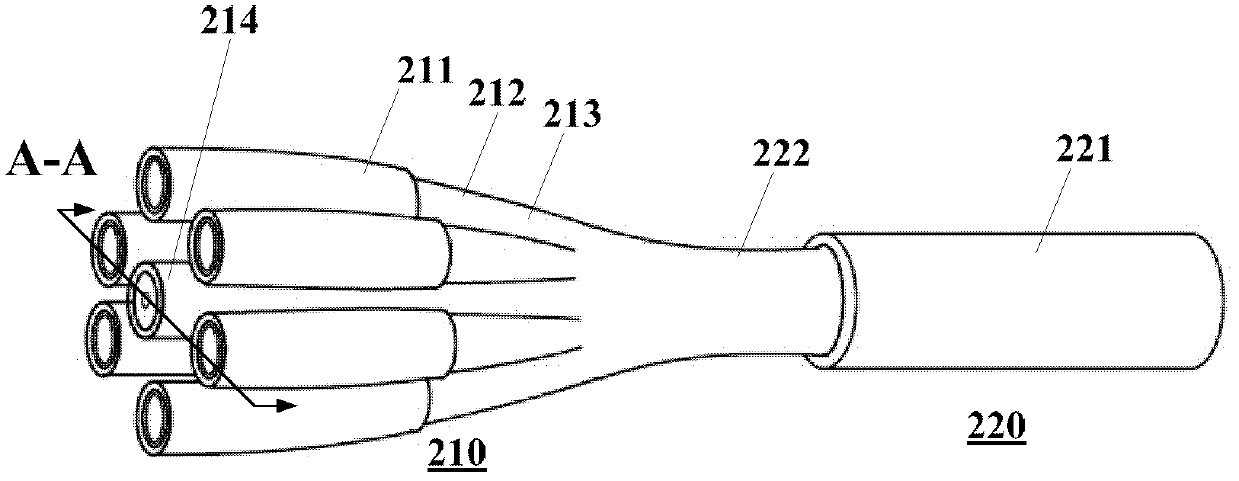

Large-mode-field fiber pumped coupler and manufacturing method thereof

ActiveCN102890312AGuaranteed weldingHelp with transmissionOptical fibre with multilayer core/claddingCoupling light guidesFiber bundleOptoelectronics

The invention discloses a large-mode-field fiber pumped coupler and a manufacturing method thereof. The coupler comprises a main fiber and a pumped fiber bundle containing a plurality of pumped fibers, wherein the hollow fiber bundle is defined by a plurality of pumped fibers; one end of the main fiber is provided with a transition zone which exposes an inner cladding and is inserted into a hollow part of the pumped fiber bundle; the corresponding part of the pumped fibers and the transition zone of the main fiber is a tapering end which exposes a cladding; and the cladding of the tapering end of the pumped fibers is in close contact with and integrally fused with the inner cladding of the transition zone of the main fiber. The manufacturing method comprises the following steps of: preprocessing a plurality of pumped fibers to form the hollow fiber bundle, and cutting at an appropriate position; reducing or not reducing the diameter of the inner cladding of the main fiber; inserting the preprocessed main fiber into the hollow pumped fiber bundle to ensure that the main fiber is in close fit with the fiber bundle; and integrally fusing the main fiber with the fiber bundle, and recoating the main fiber. On the premise of not damaging a fiber core structure of the large-mode-field main fiber, signal coupling efficiency is improved.

Owner:TSINGHUA UNIV

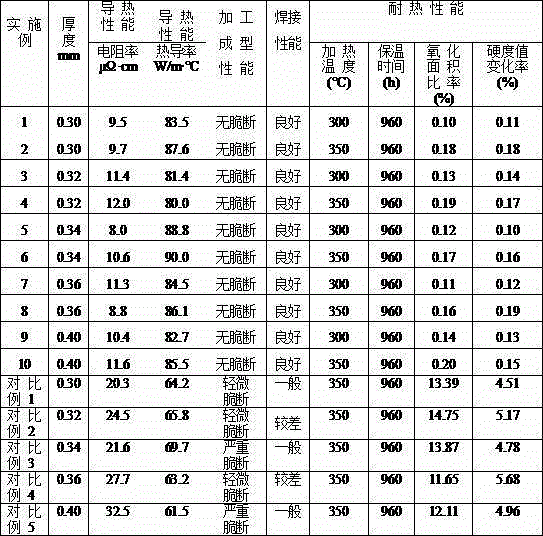

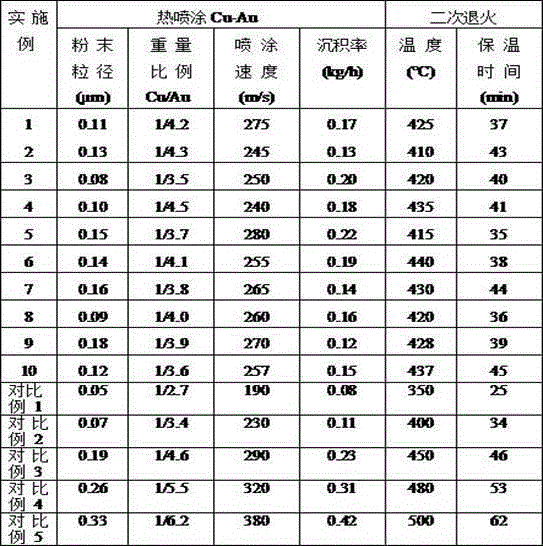

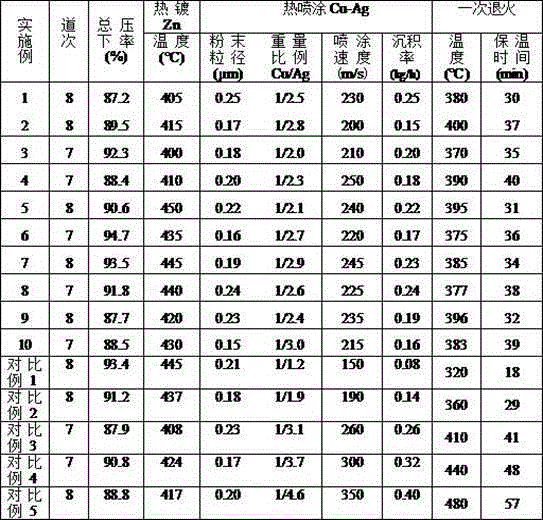

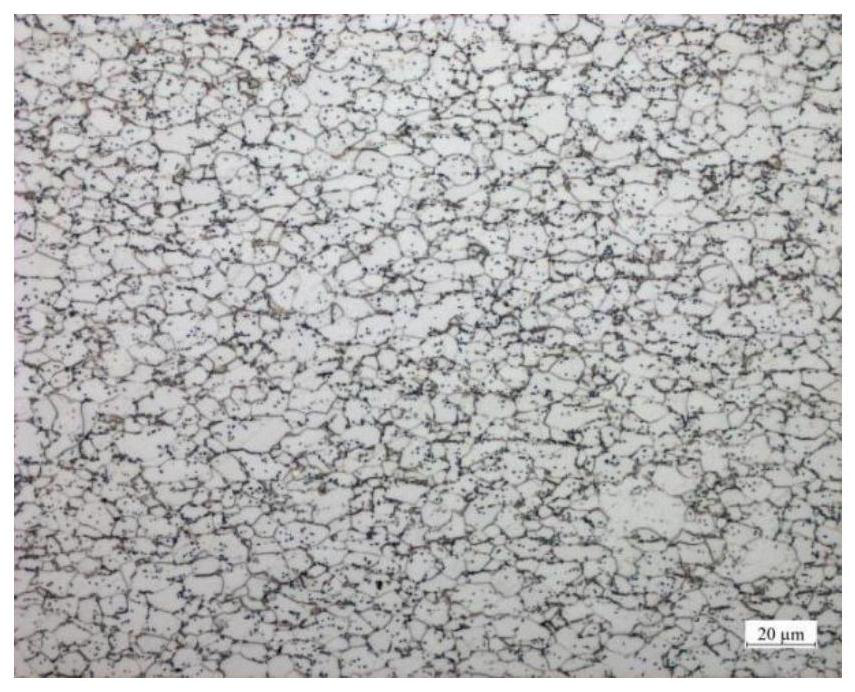

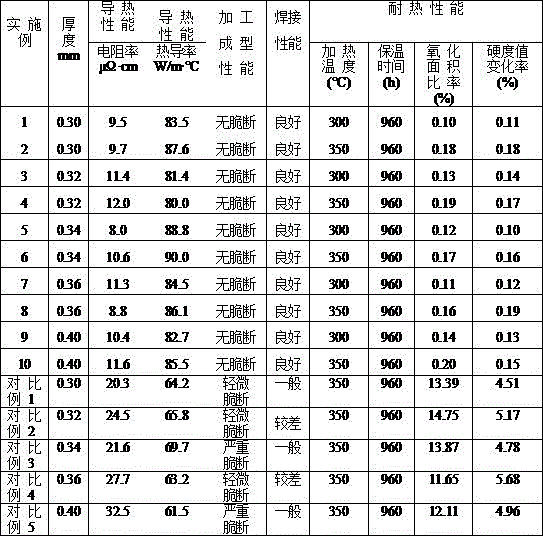

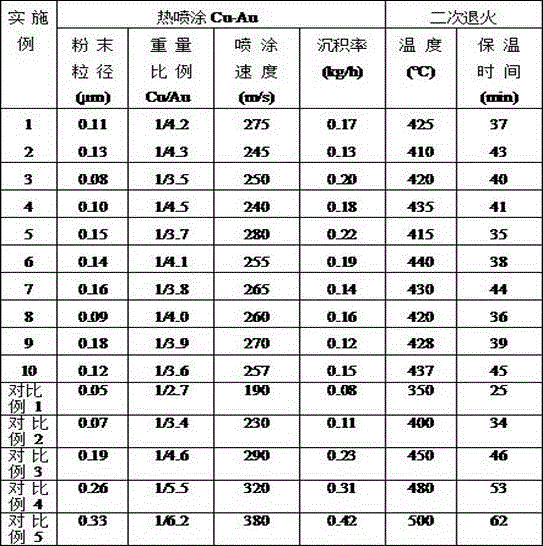

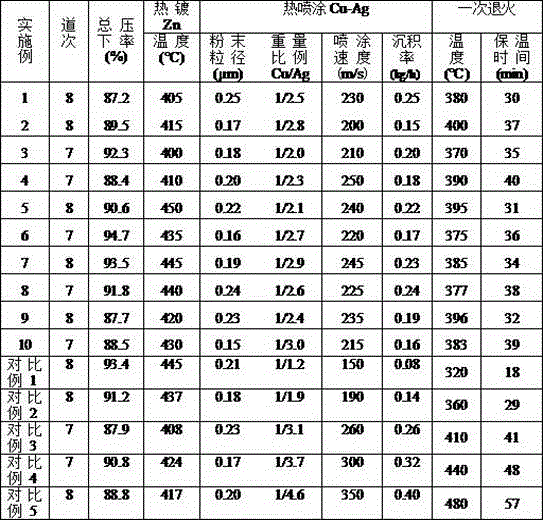

Production method of Zn/Cu-Ag/Cu-Au composite coating steel band for photoelectric material

ActiveCN105063620AReduce internal stressGuaranteed surface finishSuperimposed coating processLoss rateHydrogen

A production method of a Zn / Cu-Ag / Cu-Au composite coating steel band for a photoelectric material comprises the following steps: using a 08Al cold-rolled steel sheet as a raw material and carrying out cold rolling; after conventional degreasing, carrying out uncoiling, splitting and deburring; hot-dipping Zn; thermally spraying Cu-Ag; carrying out primary annealing at a pure nitrogen protective atmosphere; thermally spraying Cu-Au; carrying out secondary annealing at a pure nitrogen protective atmosphere; and air-cooling to a room temperature and coiling. The tensile strength is 250-300MPa, and the elongation percent is 42-48%. One Zn / Cu-Ag / Cu-Au composite coating is generated on the surface. After the Zn / Cu-Ag / Cu-Au composite coating steel band is placed under an indoor conventional atmospheric condition for 960 days, the gloss loss rate of the coating is not larger than 0.3%, and the surface corroded area is not larger than 0.3%. The product has excellent electricity and heat conductivity. After the Zn / Cu-Ag / Cu-Au composite coating steel band is kept at 300-350 DEG C for 960 days, the surface oxidized area is not larger than 0.2%, and the hardness variation rate is not larger than 0.2%. The product also has excellent welding and machining performance.

Owner:武汉钢铁有限公司

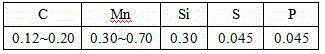

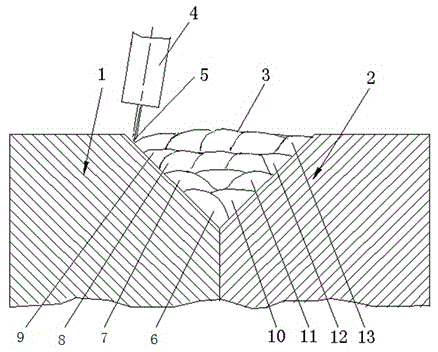

Abrasion resistant steel and low-carbon steel dissimilar metal consumable electrode gas shielded welding technology

ActiveCN104625352AGuaranteed weldingGuaranteed not to crackArc welding apparatusWelding/soldering/cutting articlesManganeseHeating furnace

The invention relates to an abrasion resistant steel and low-carbon steel dissimilar metal consumable electrode gas shielded welding technology and belongs to the technology field of dissimilar metal welding technologies. According to the technology, by the adjustment and controlling to welding positions, welding parameters, interlayer-temperature and the like, when the high-carbon and high-manganese abrasion resistant steel is welded with the low-carbon steel dissimilar metal, the purposes of preheating before welding and slow cooling after welding are achieved, so that no cracks occur in welding seams after welding is completed, the welding seams do not crack after being heated again through a heating furnace, and it is guaranteed that rolling goes on smoothly. Compared with a traditional abrasion resistant steel and low-carbon steel dissimilar metal welding technology, the abrasion resistant steel and the low-carbon steel dissimilar metal consumable electrode gas shielded welding technology has no special requirements for raw materials and equipment, so that the manufacturing cost is lowered.

Owner:云南昆钢新型复合材料开发有限公司

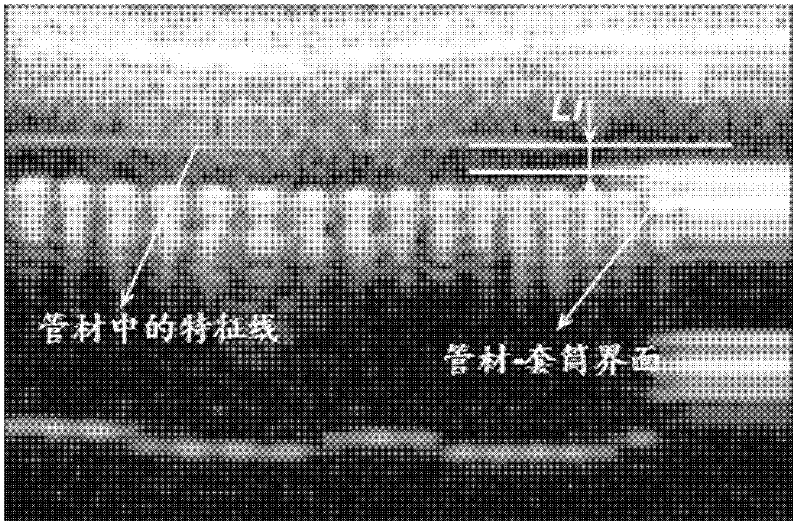

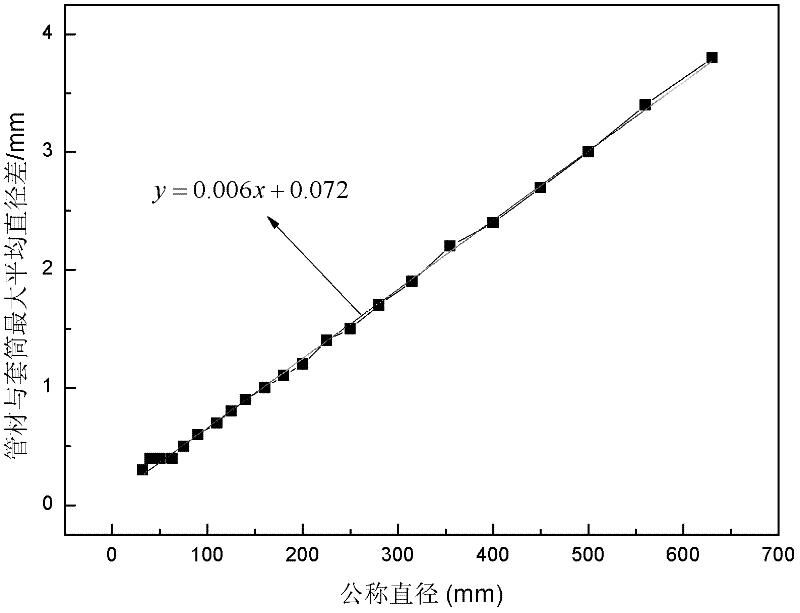

Judgment method for cold welding defects of electrofusion joints

ActiveCN102285120AGreat practicabilitySuitable for cold welding inspectionAnalysing solids using sonic/ultrasonic/infrasonic wavesElectricityFusion joints

The invention relates to a technology for welding a plastic pipeline and aims to provide a method for determining electro-fusion joint cold-welding defects. The method comprises the following steps of: detecting from an inner surface of a pipe on an electro-fusion joint welding part through an ultrasonic phased array detection imaging instrument to obtain an ultrasonic detection graph; and measuring a distance Li between a characteristic line in the ultrasonic detection graph and a pipe-sleeve interface in different directions, wherein no cold-welding defect is present at the detected electro-fusion joint if the minimum Lm accords with the set criteria. The method for detecting the electro-fusion joint cold-welding defects is higher in practicality, is generally applicable to different types of electro-fusion sleeves by different welding processes in different manufacturers and can be applied to cold-welding detection of electro-fusion joints formed by the pipes and the electro-fusionsleeves in different matching relationships; and the cold-welding conditions can be determined by measuring welding conditions of one electro-fusion joint only, a normal welding joint is not needed to be welded to perform secondary measurement, and the cost of welding joint preparation and ultrasonic detection is saved.

Owner:ZHEJIANG UNIV

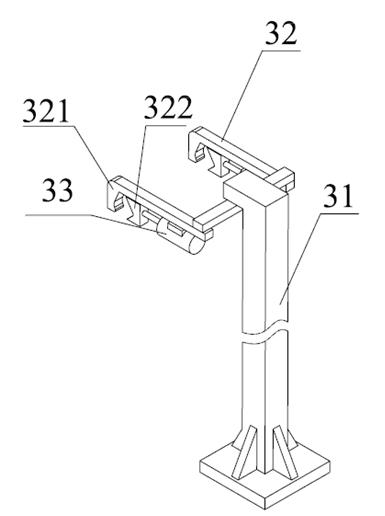

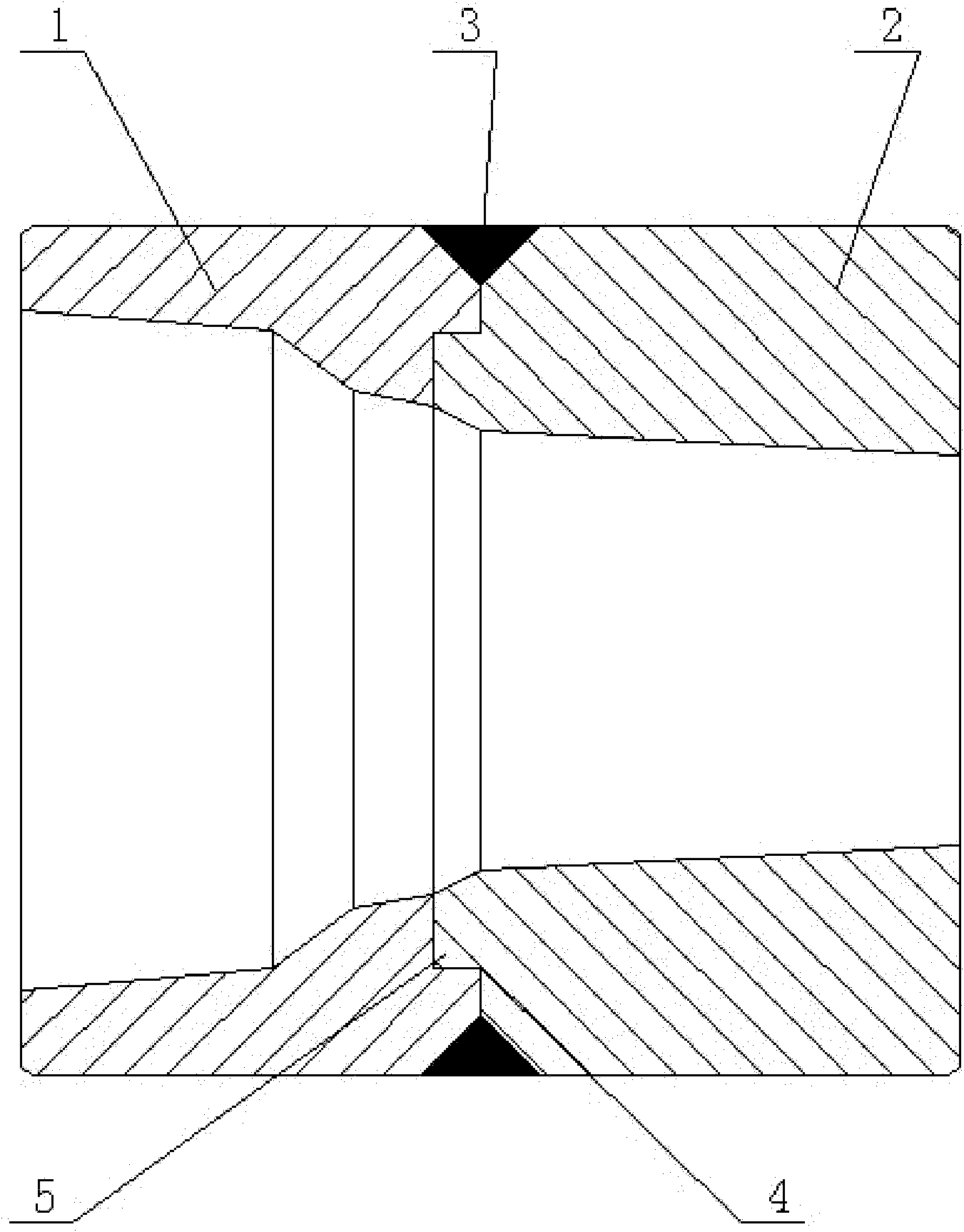

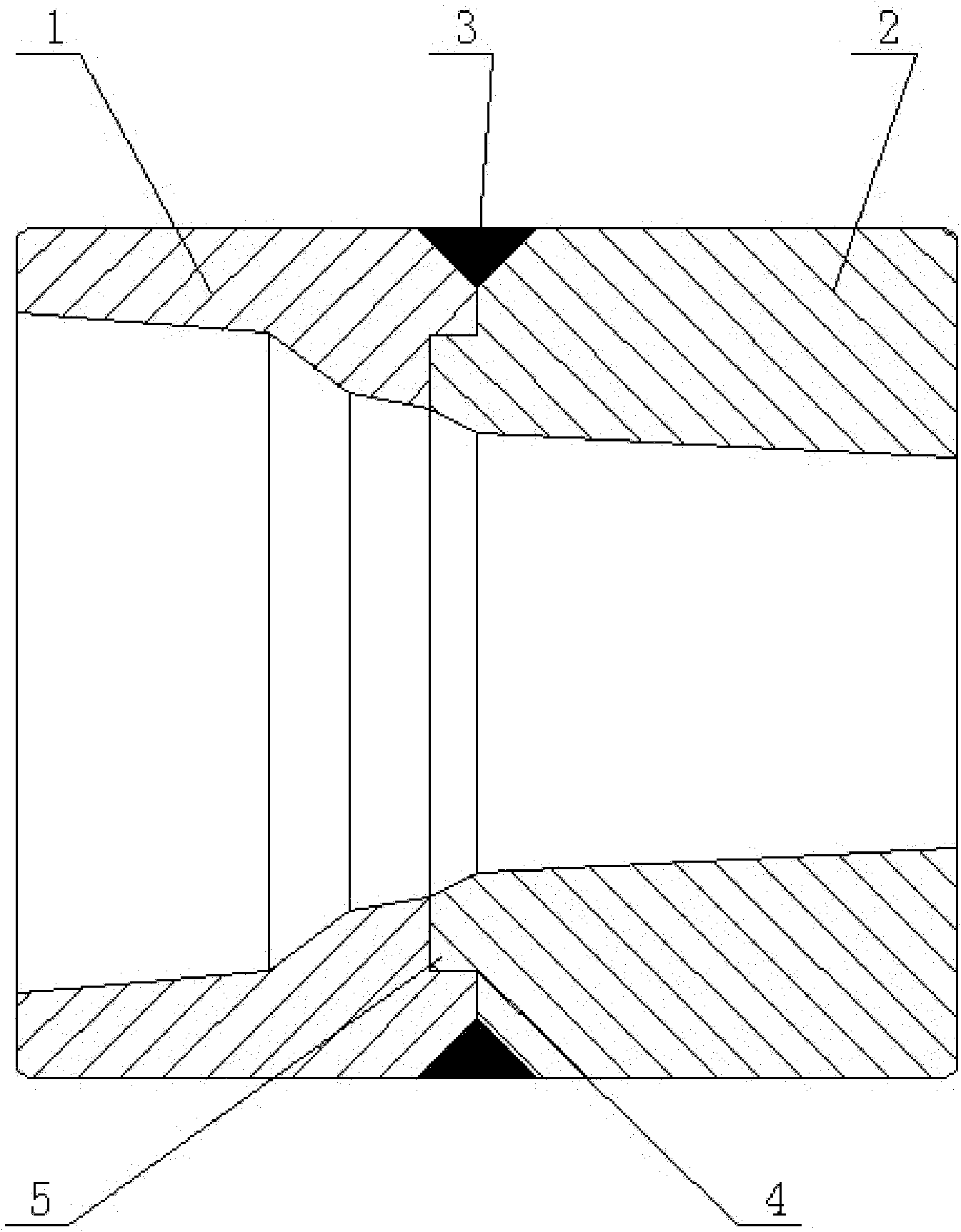

Clamp facilitating both-side welding

InactiveCN107470837AGuaranteed accuracyEasy to holdWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding

The invention discloses a fixture for double-sided welding, which includes a mounting support, a guide seat, a main connecting block and a moving connecting block. A connecting arm is arranged on the moving connecting block, and a connecting arm is fixed on the connecting arm. Gripper head. The invention can clamp the workpiece well, and the clamping is firm; by connecting the upper splint through the rotating shaft and the cylinder, it can play the role of lifting or pressing the upper splint through the cylinder, and it can be gradually welded during welding. The upper splint is lifted up, and the upper splint is driven down by the cylinder after welding, which can ensure that the clamping is firm, and it can also ensure that the surface of the welded workpiece is completely welded; the lower splint and the upper splint adopt a symmetrical structure, The fixture can be turned over directly for reverse welding without removing the workpiece from the fixture, which can ensure the accuracy of subsequent welding.

Owner:贾恒宏

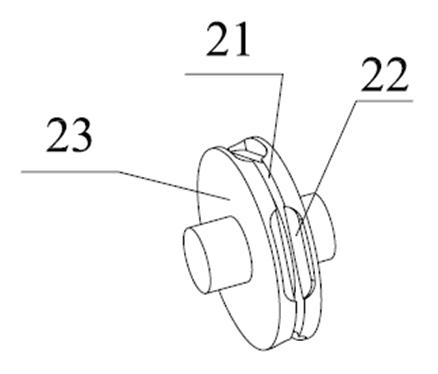

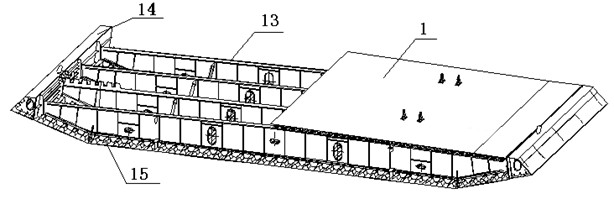

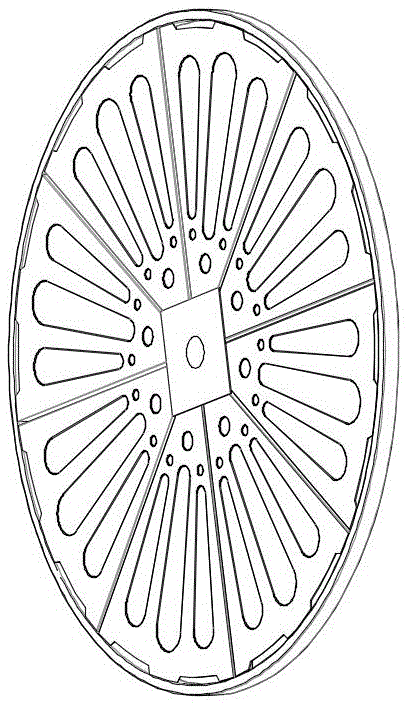

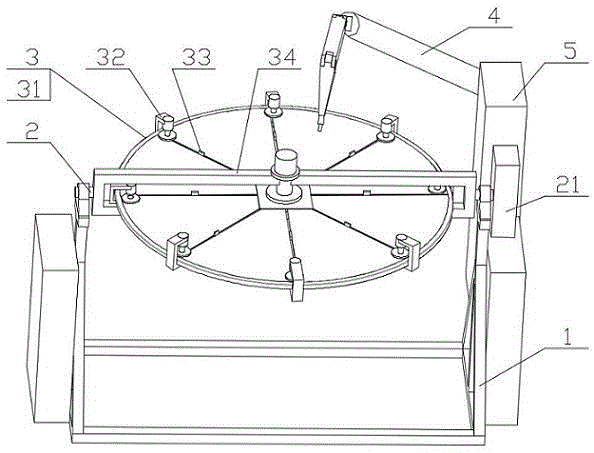

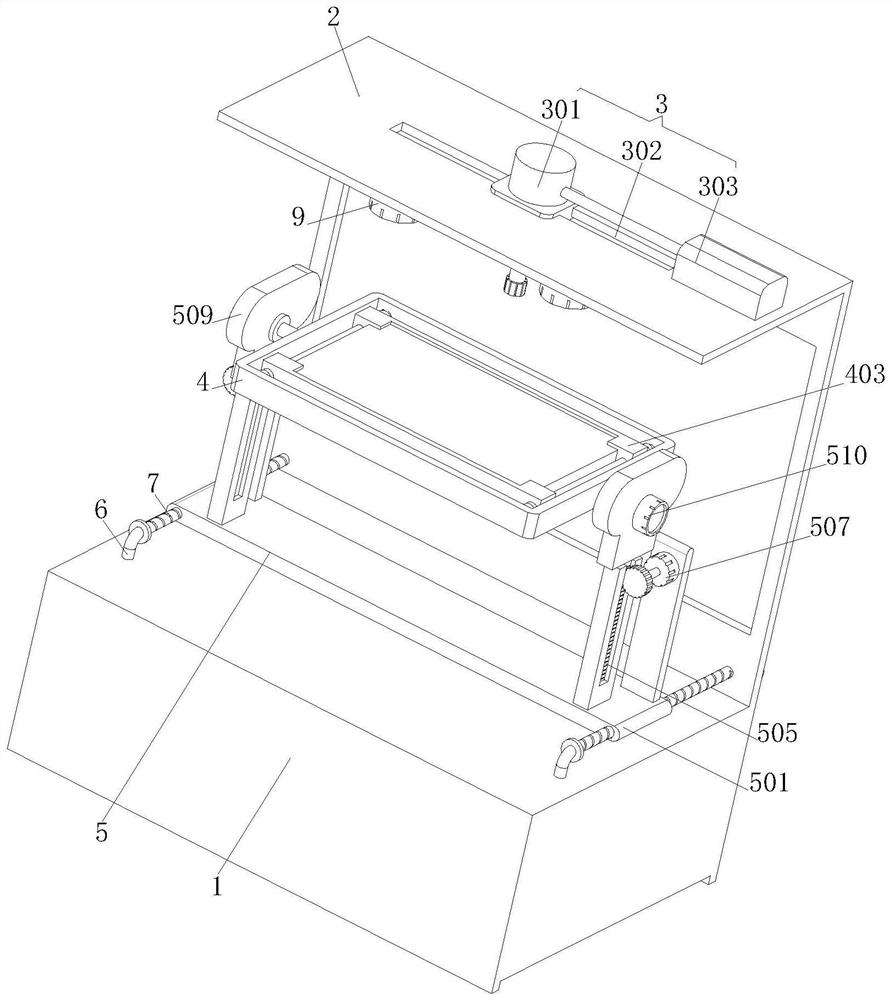

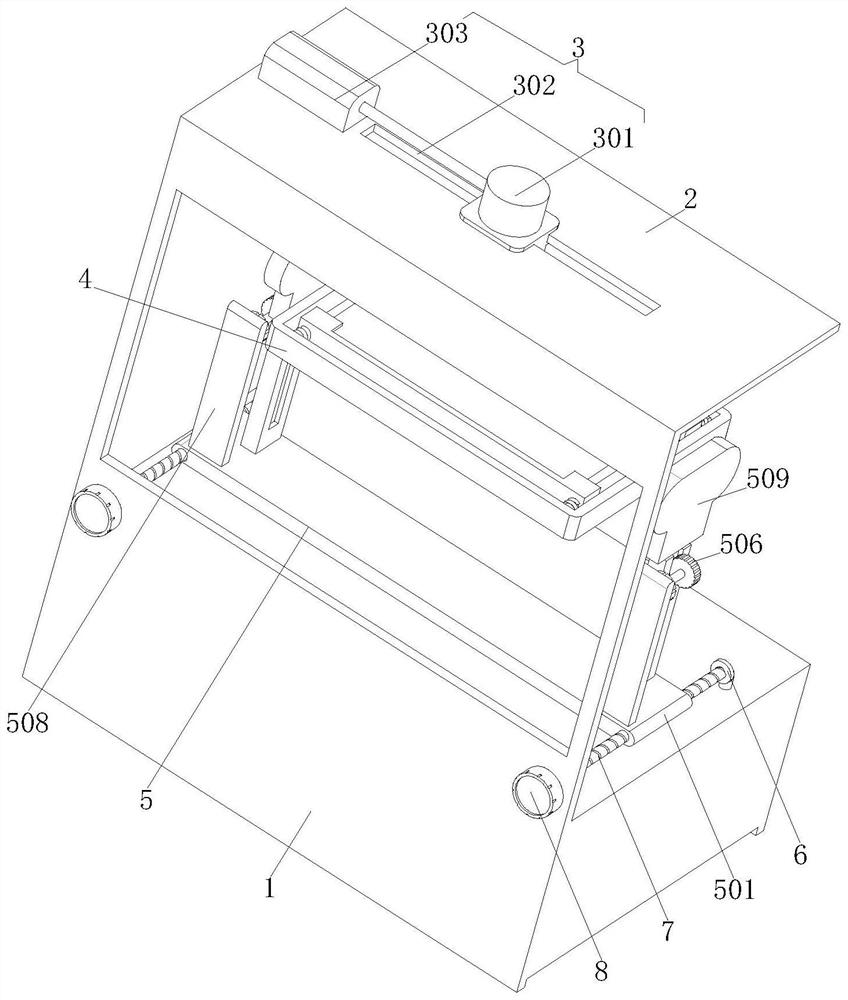

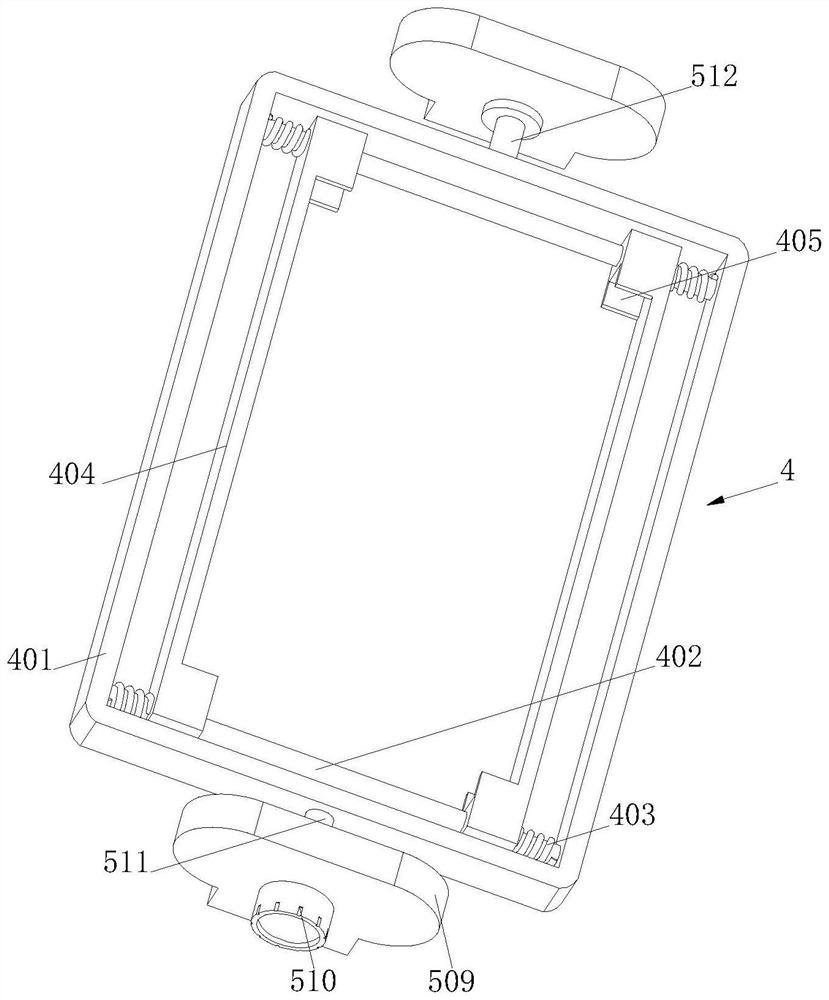

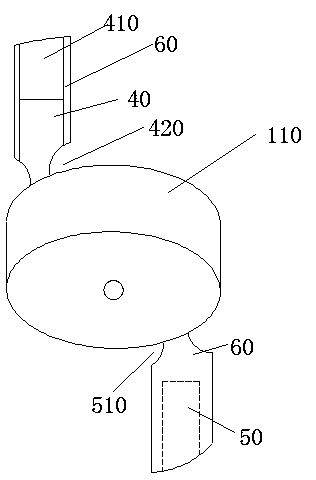

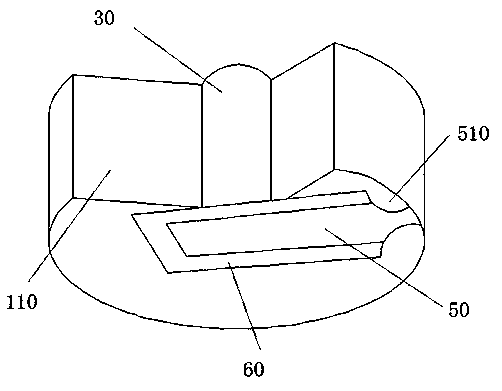

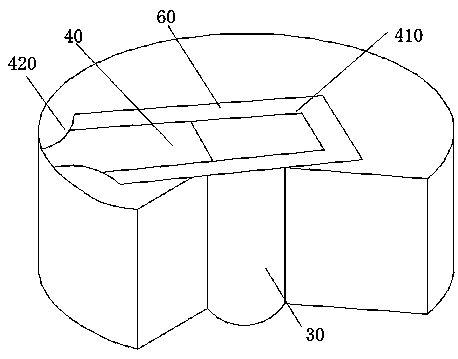

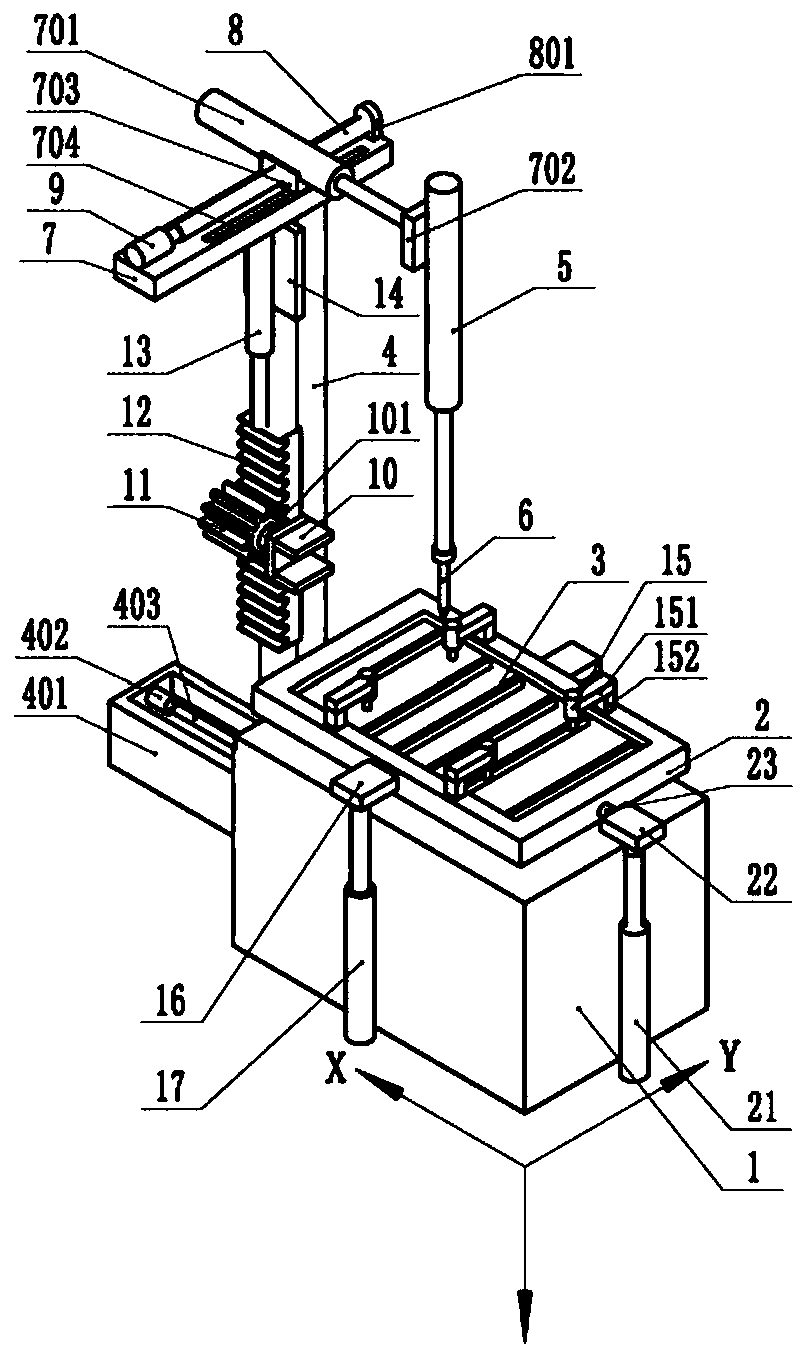

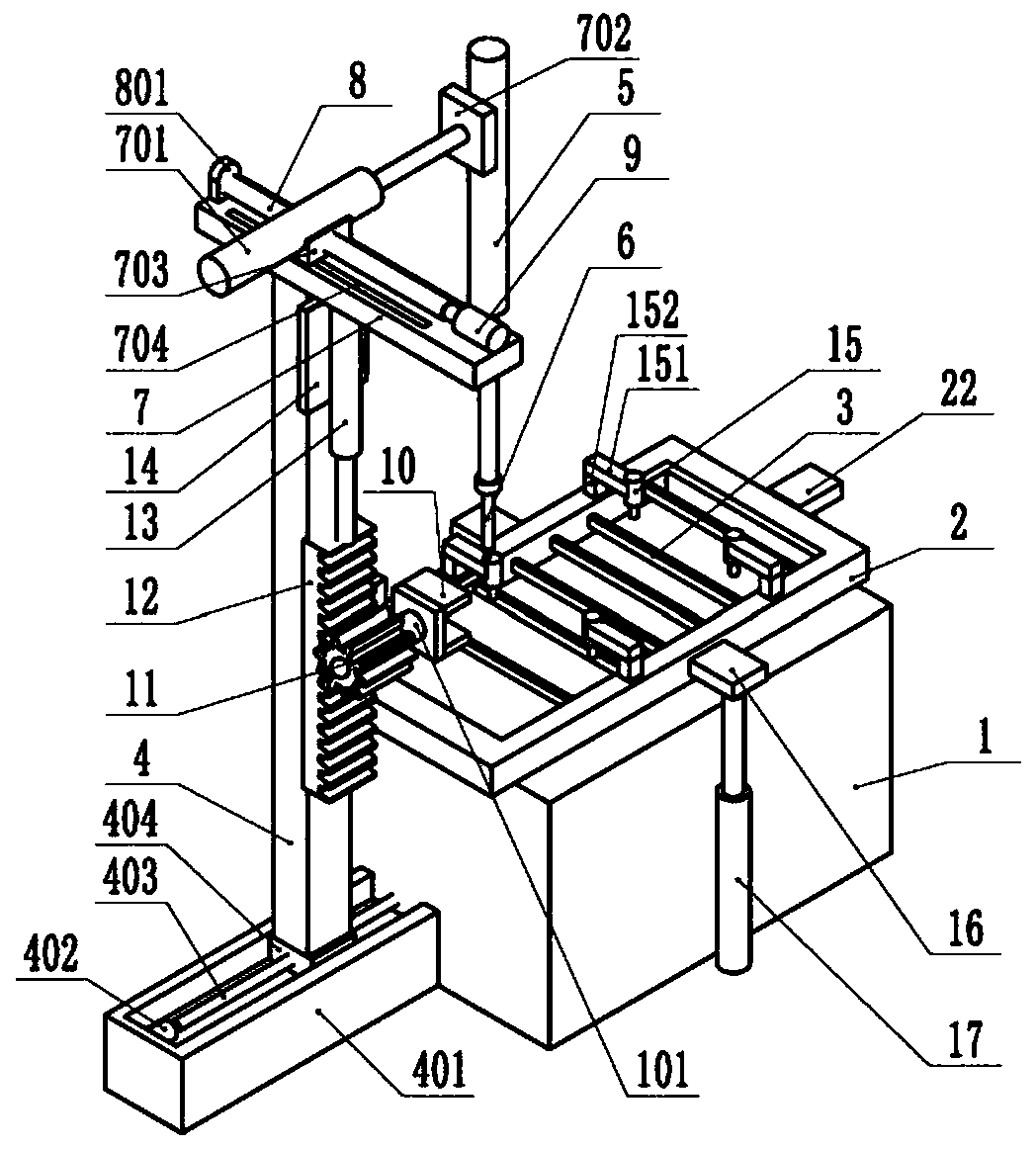

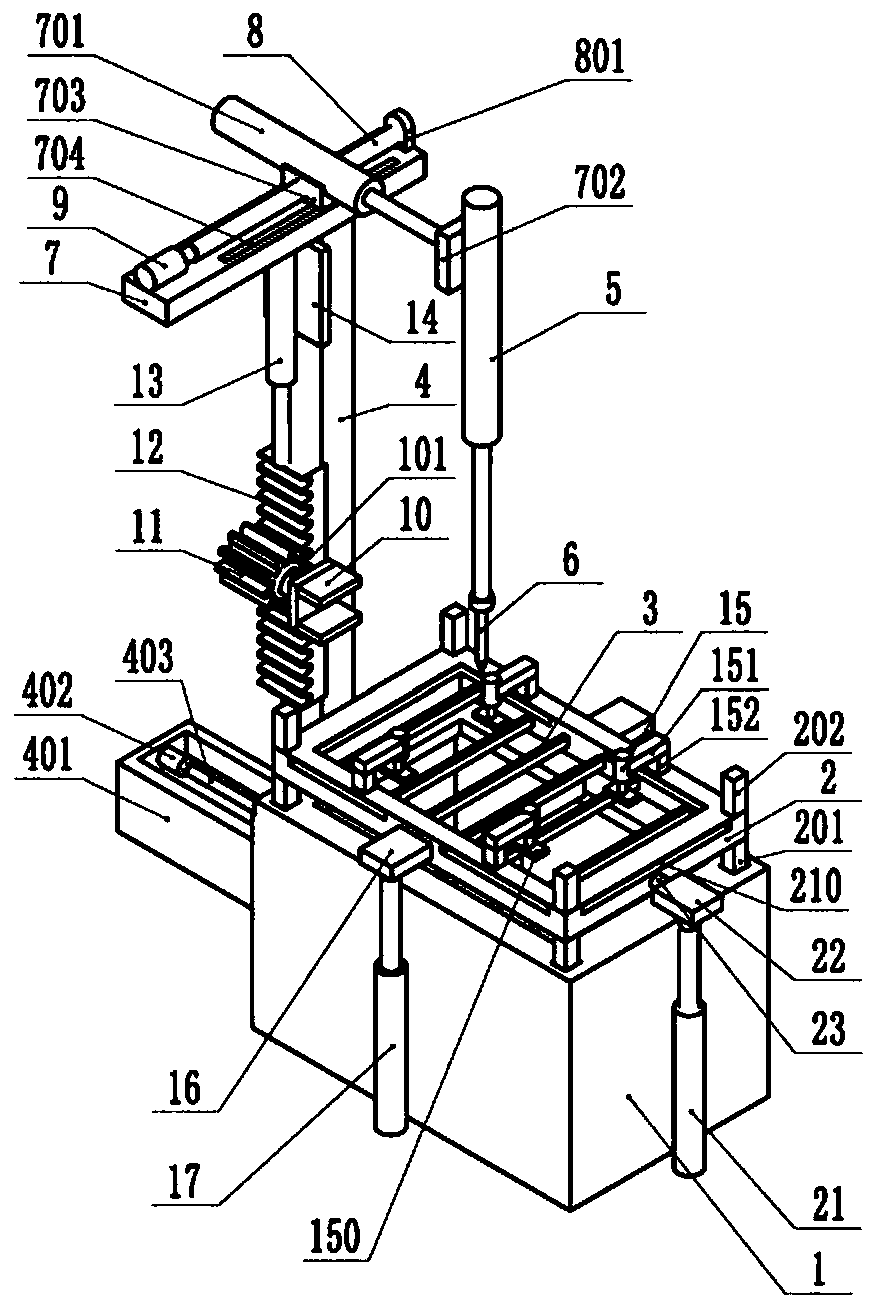

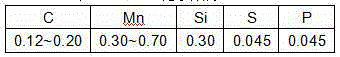

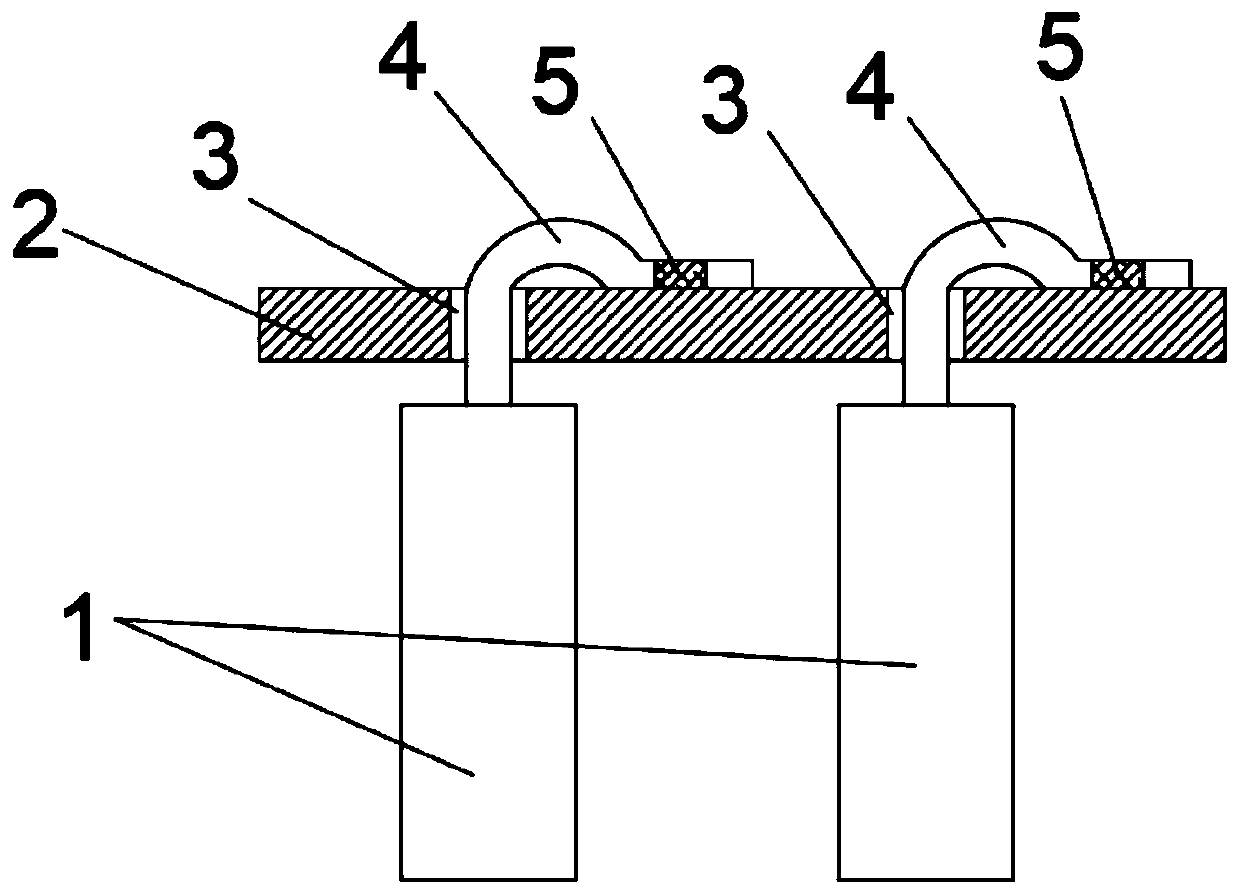

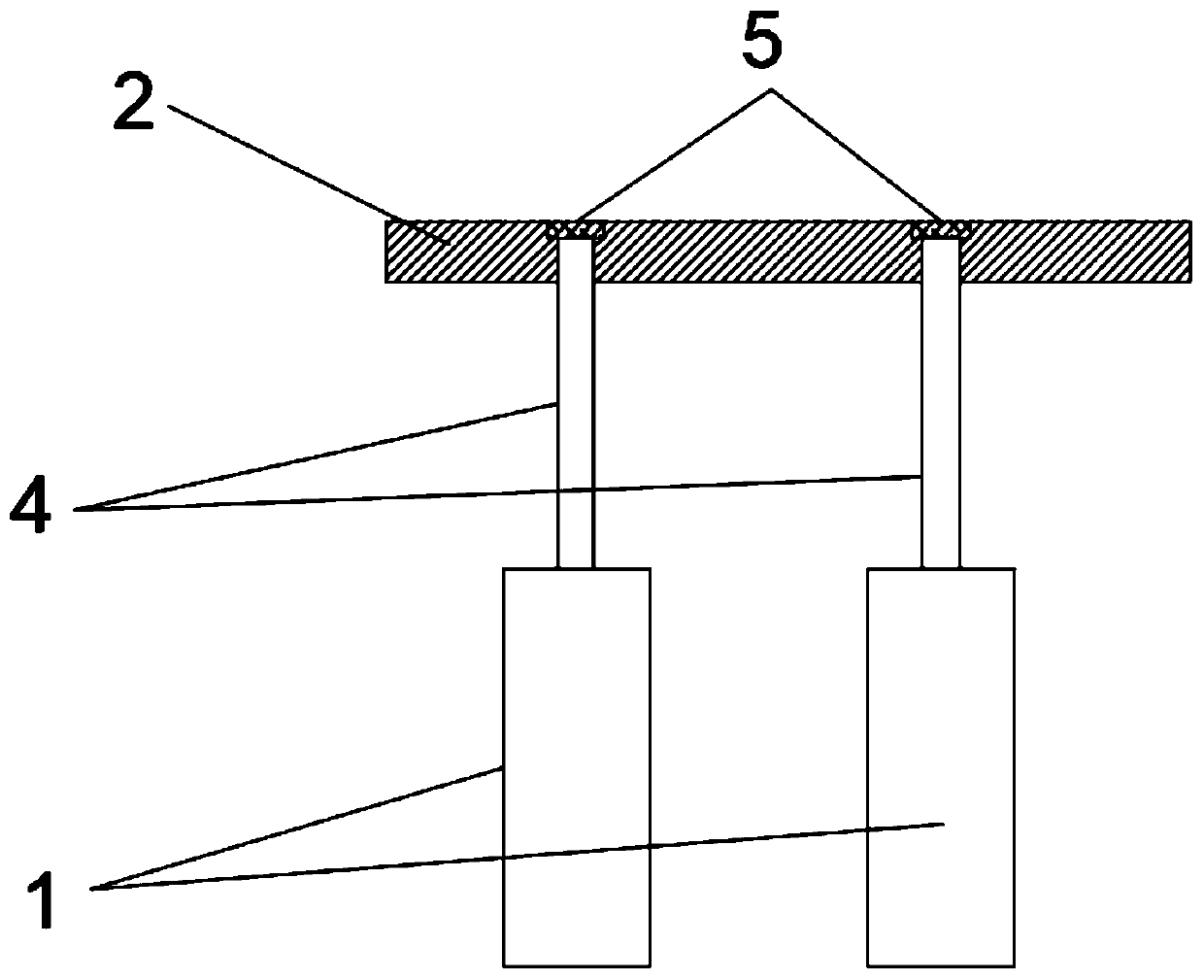

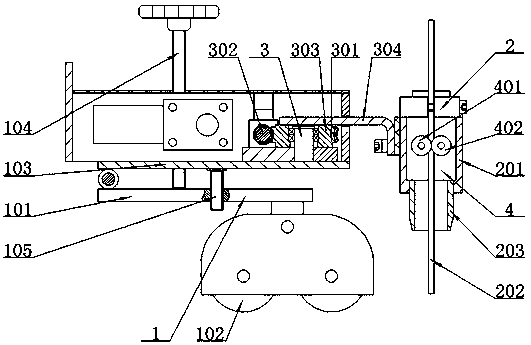

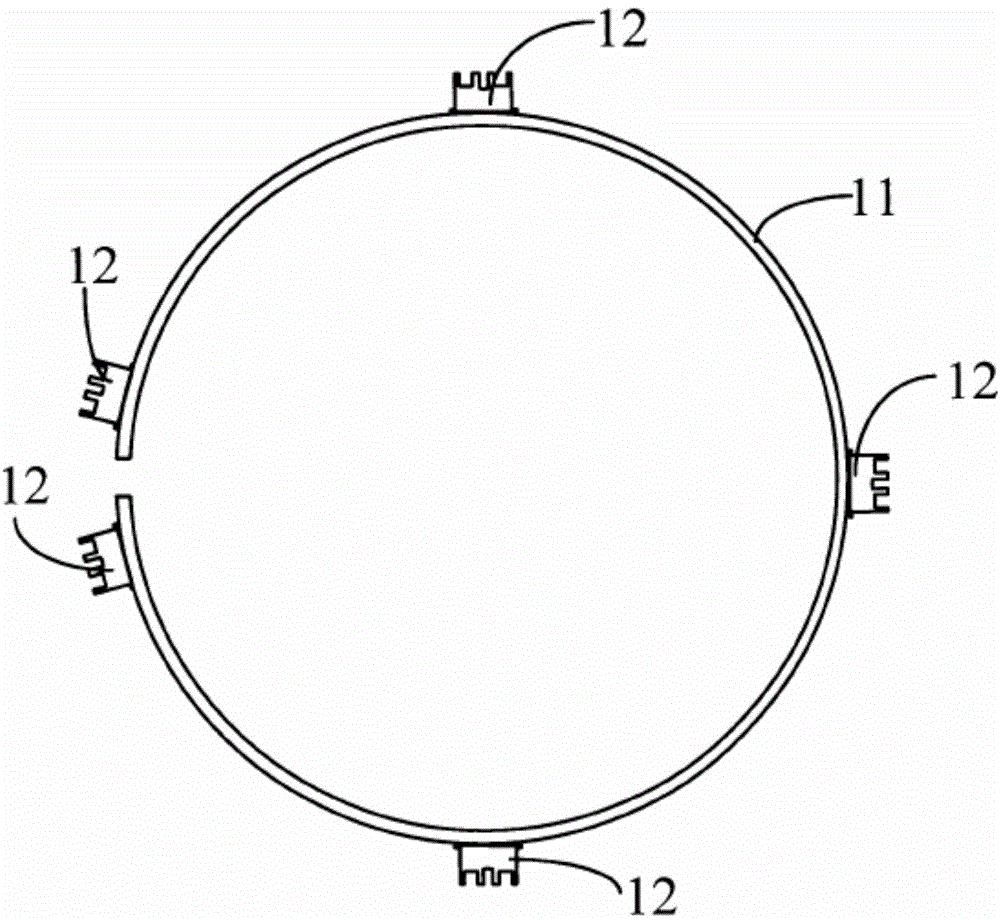

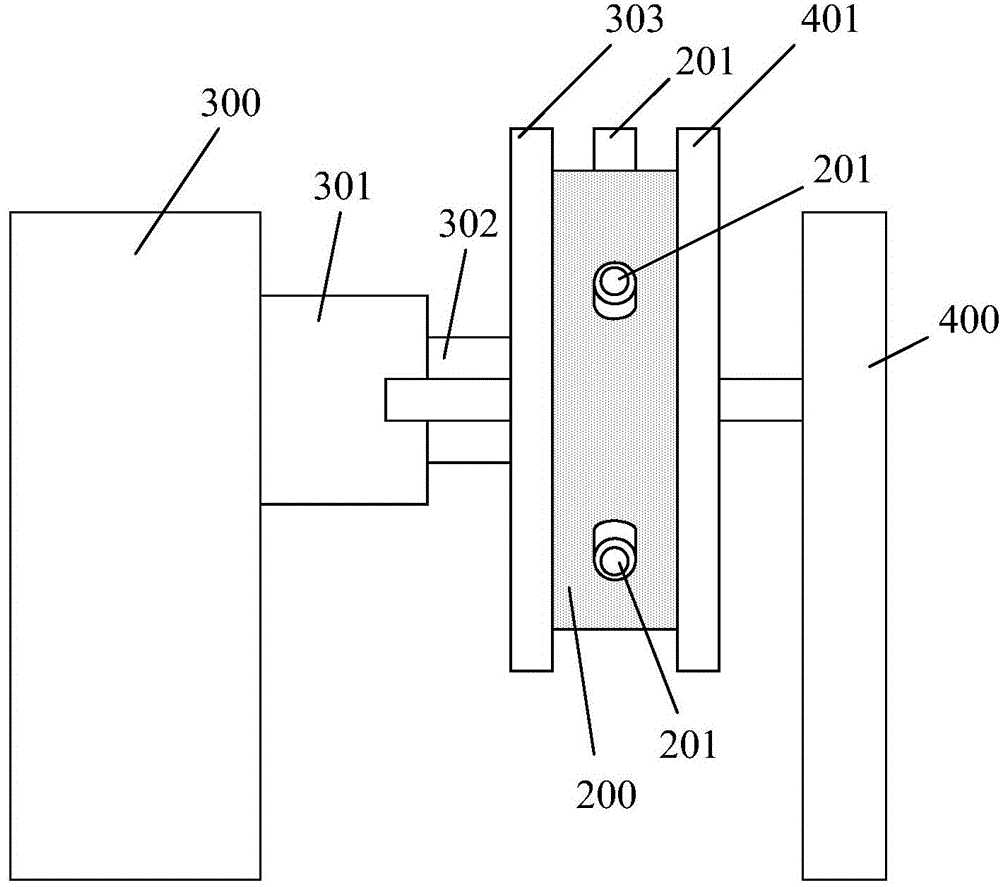

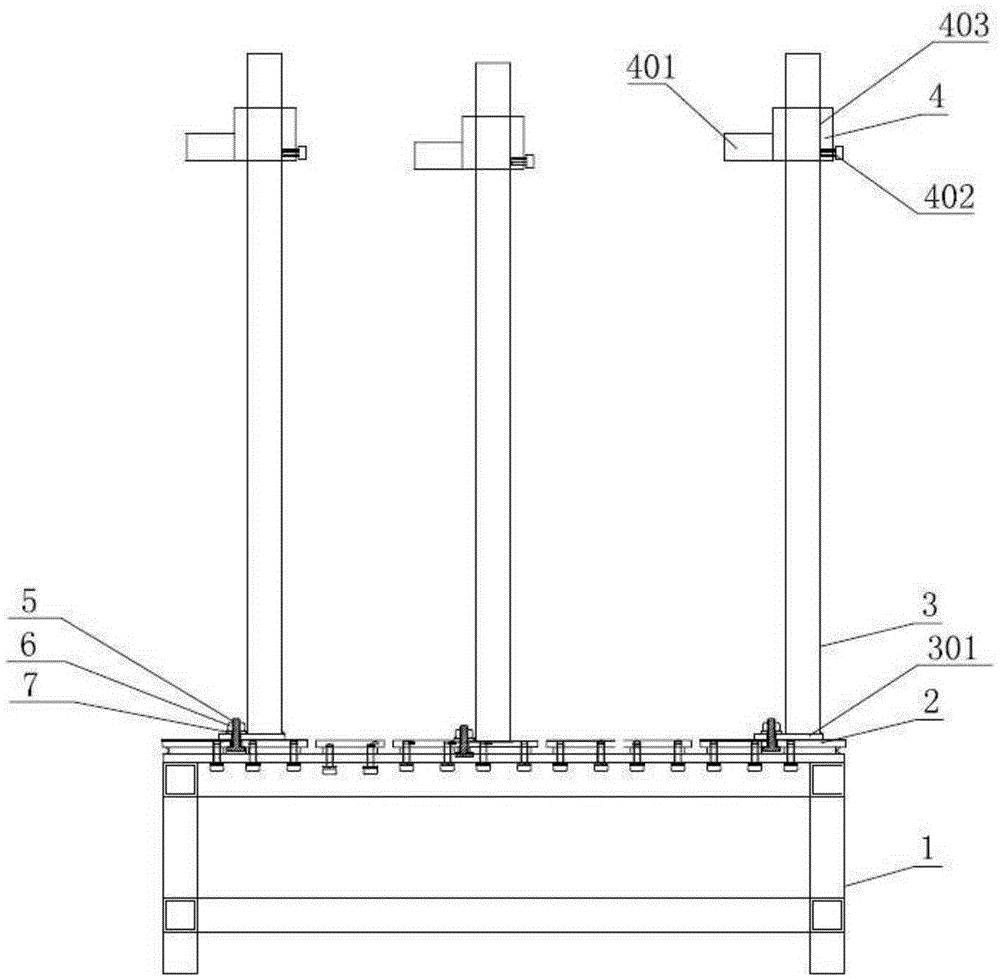

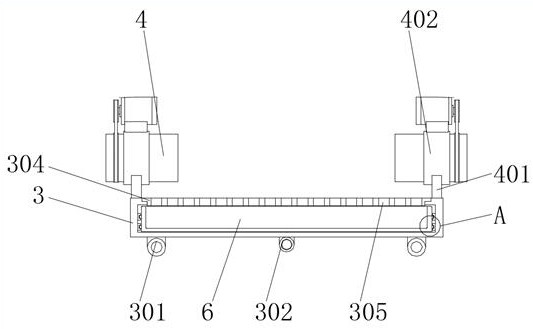

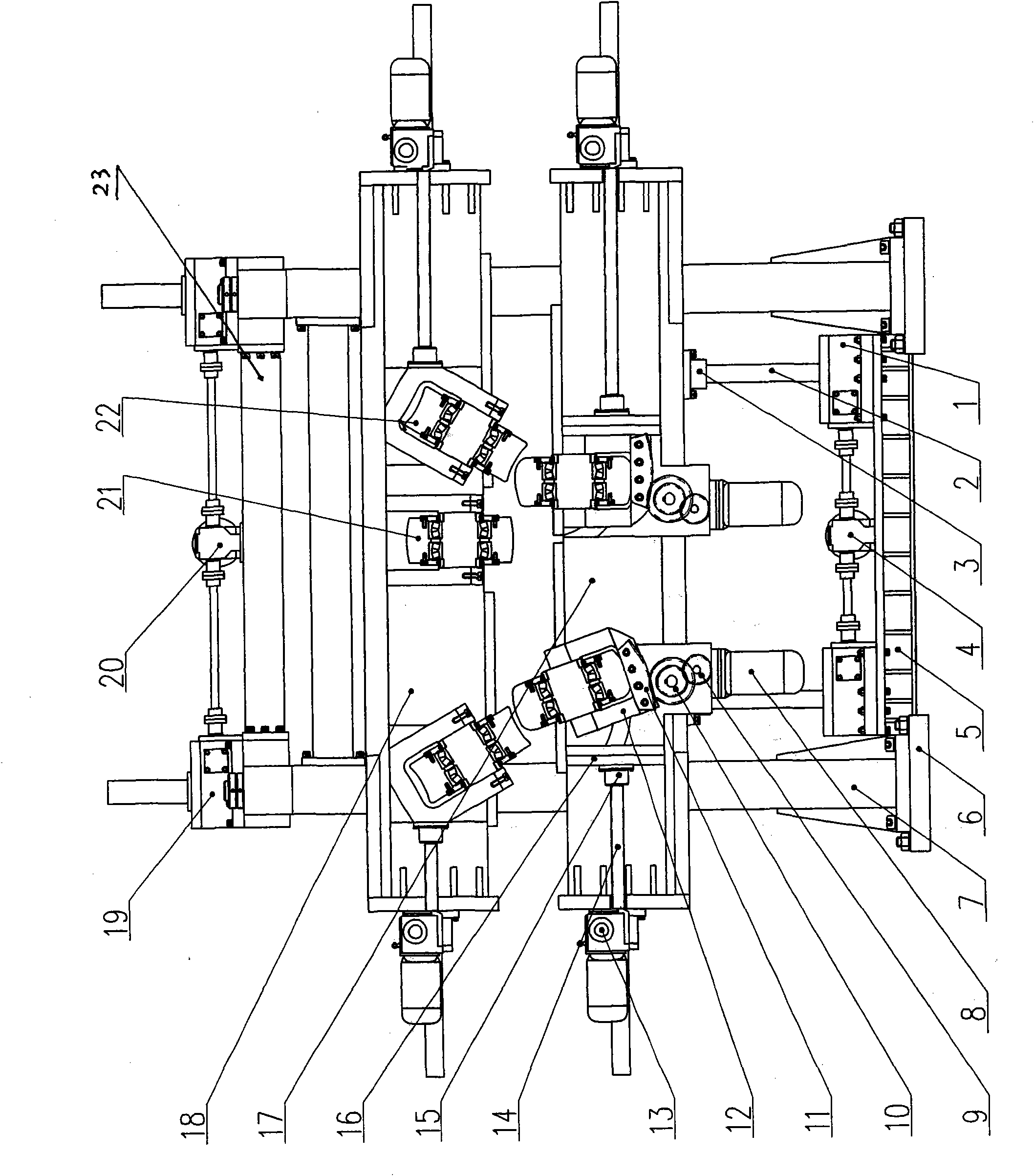

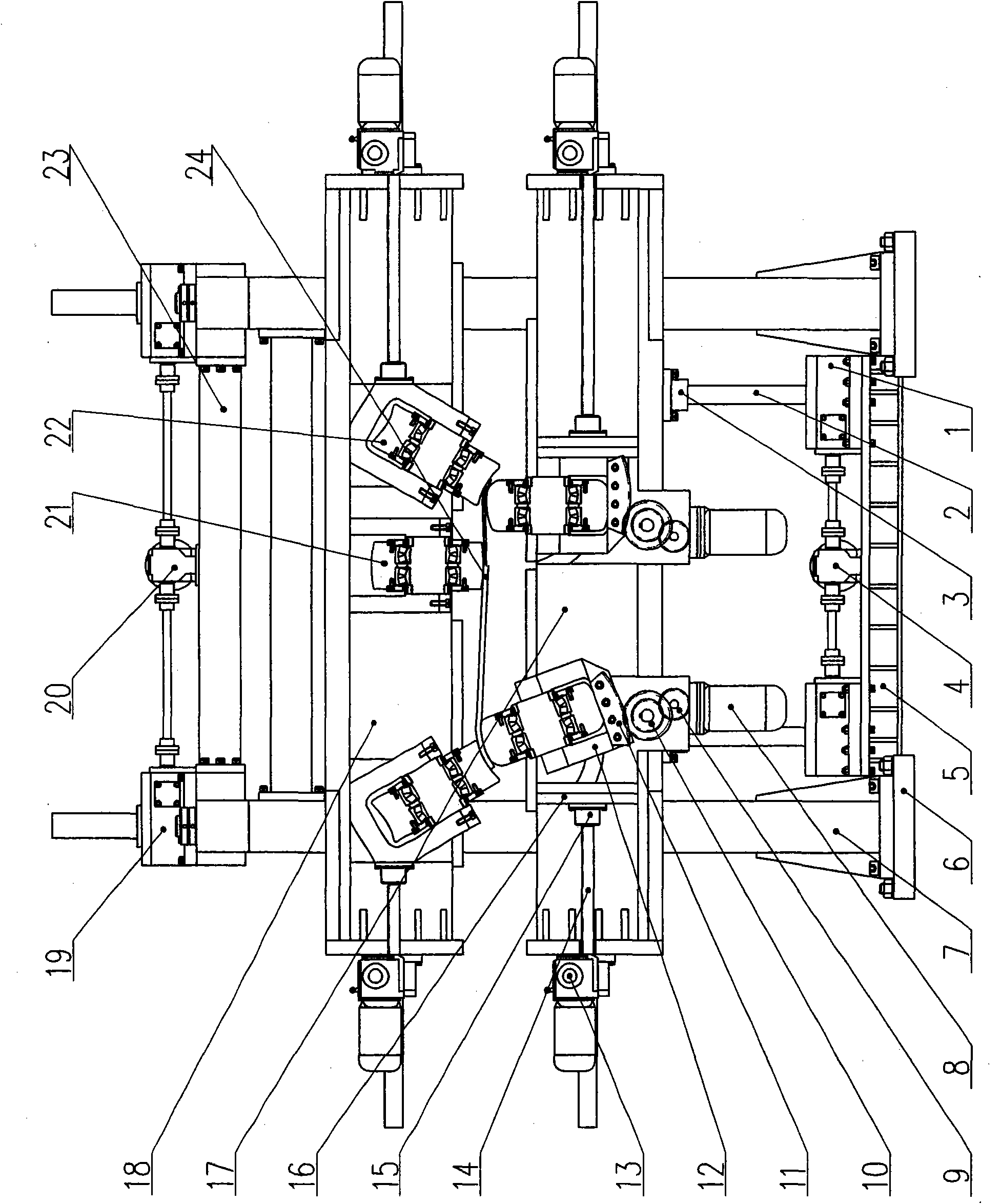

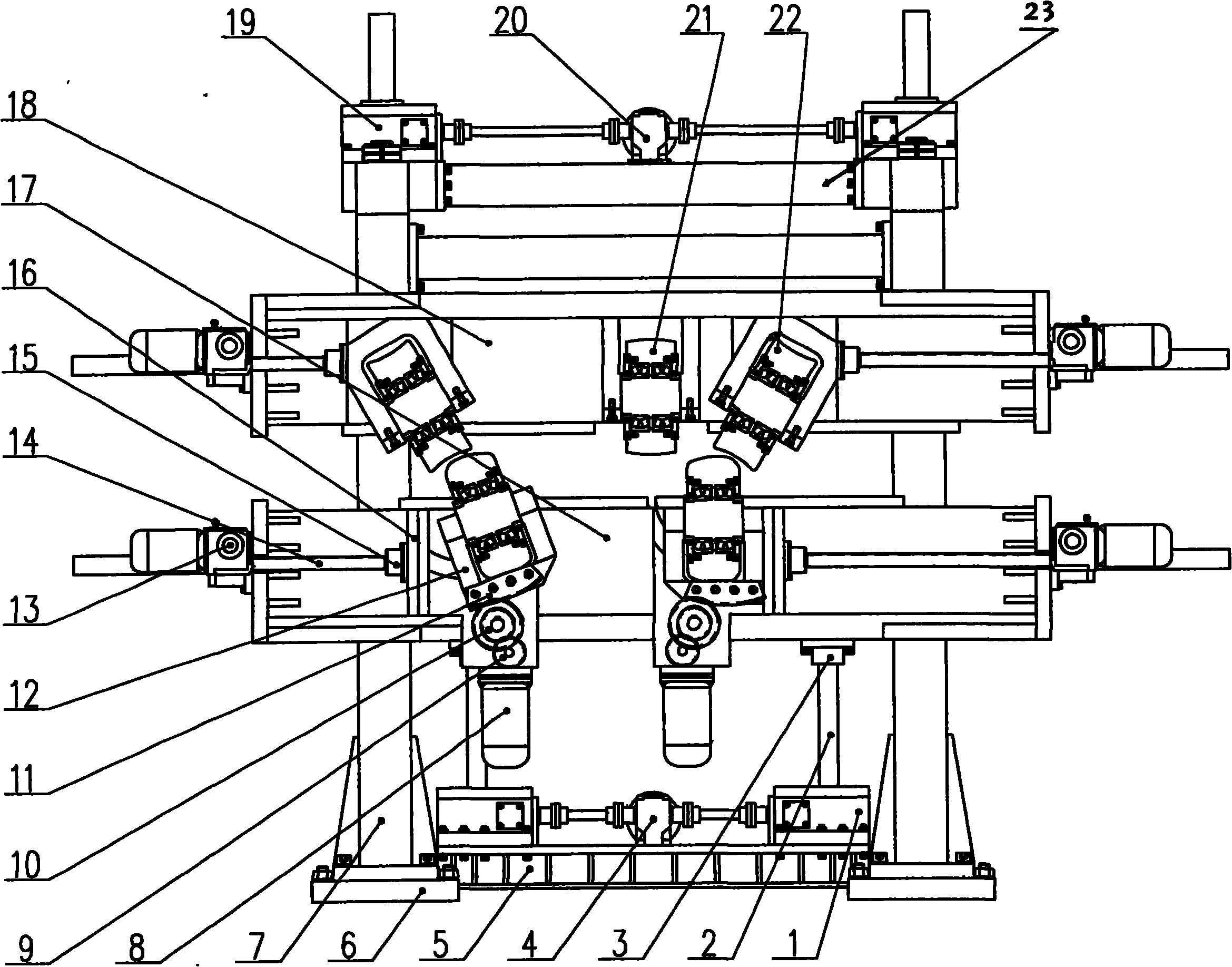

Automatic tailor-welding tool for reel sprinkler reel wing plate

InactiveCN105598626AGuarantee the quality of tailor weldingReduce the quality of tailor weldingWelding/cutting auxillary devicesAuxillary welding devicesCircular discProduction schedule

The invention discloses an automatic tailor-welding tool for a reel sprinkler reel wing plate. The automatic tailor-welding tool comprises a supporting underbed (1), turnover shafts (2), a workpiece supporting part (3), a welding mechanical arm (4) and an electric control device (5), wherein the supporting underbed is fixedly installed on the ground, the turnover shafts are installed on the inner side faces of the upper portion of the supporting underbed, and at least one turnover shaft is provided with a turnover driving device (21); the two ends of the workpiece supporting part are fixedly connected with the turnover shafts respectively, the workpiece supporting part comprises a workpiece supporting plate (31) of a flat plate structure, multiple pressing devices (32), multiple locating devices (33) and a hollow groove-type structure are arranged on the upper surface of the workpiece supporting plate, and the electric control device comprises an industrial control computer. The automatic tailor-welding tool for the reel sprinkler reel wing plate can achieve automatic operation, the influence on production schedule of reel wing plate by human factors is reduced, production efficiency is high, and meanwhile the tailor-welding quality of the reel wing plate can be ensured.

Owner:JIANGSU HUAYUAN IRRIGATION & DRAINAGE

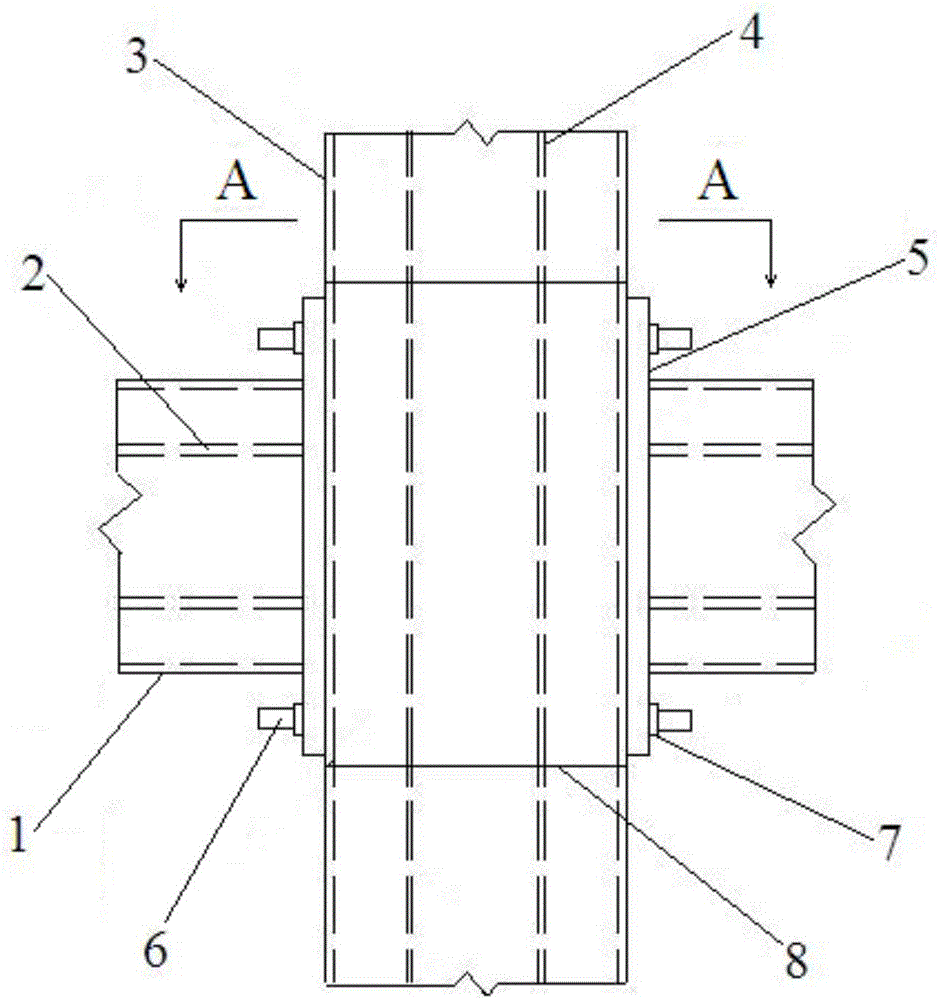

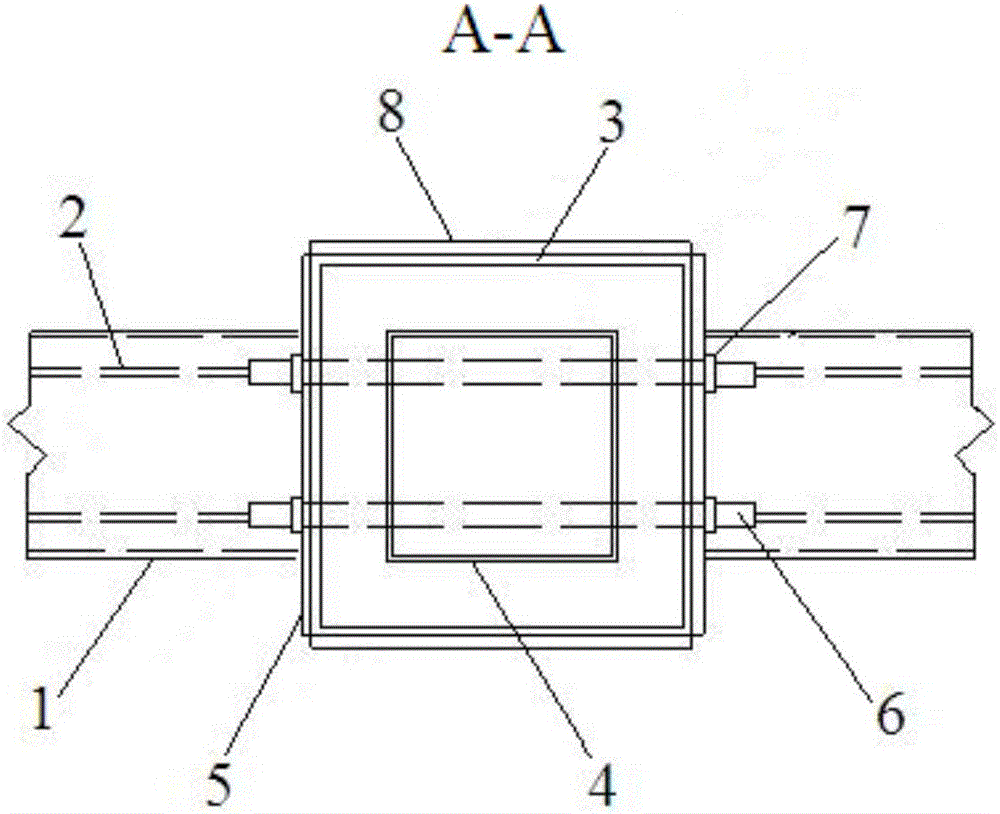

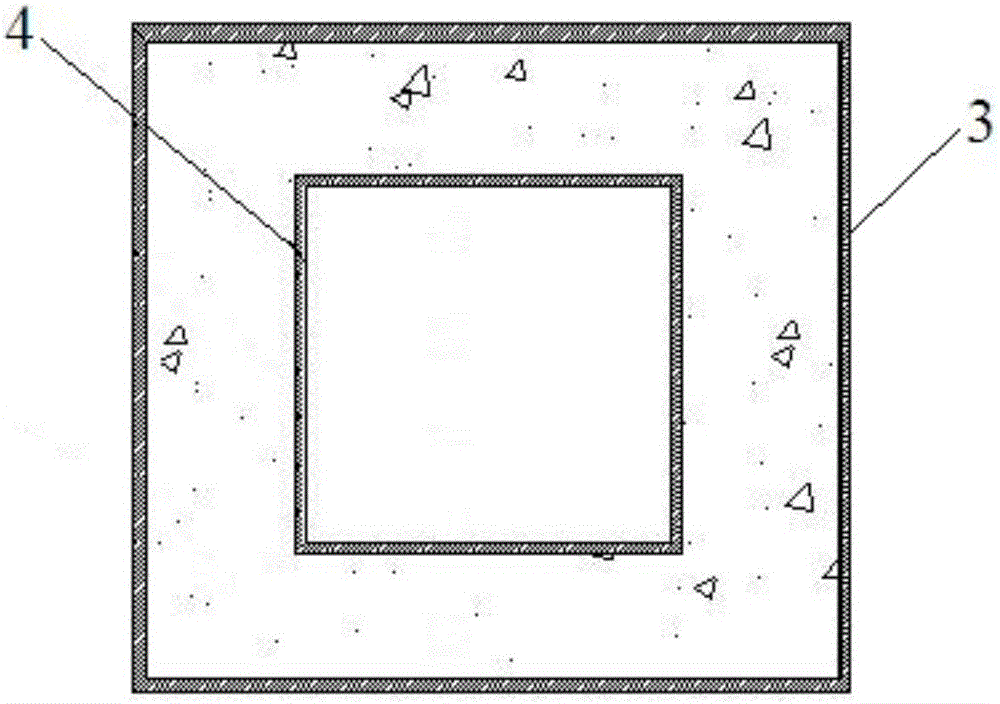

High-strength concrete-filled steel tube column-beam joint structure and construction method thereof

InactiveCN106836491AFirmly connectedIncreased torsional strengthBuilding constructionsHigh strength concreteUltimate tensile strength

The invention discloses a high-strength concrete-filled steel tube column-beam joint structure and a construction method thereof. The high-strength concrete-filled steel tube column-beam joint structure comprises a tube column and a tube beam, wherein a first column square steel tube and a second column square steel tube are arranged on the outer side wall and inner side wall of the tube column, and the part between the first column square steel tube and the second column square steel tube is filled with concrete; a first beam rectangle steel tube and a second beam rectangle steel tube are arranged on the outer side wall and inner side wall of the tube beam separately, the part between the first beam rectangle steel tube and the second beam rectangle steel tube is filled with concrete, and beam end plates are welded at two ends of the tube beam; two beam end plates on the tube beam are fixedly connected to the left side and right side of the tube column through nuts and bolts; reinforced steel plates are arranged at the front side and back side of the tube column separately; and two edges of the reinforced steel plates are welded with the edges of the two beam end plates separately. According to the high-strength concrete-filled steel tube column-beam joint structure, the torsion strength and connection strength of the connection joint of the tube column and the tube beam are improved separately. The construction method of the high-strength concrete-filled steel tube column-beam joint structure is used for building the high-strength concrete-filled steel tube column-beam joint structure.

Owner:CHANGAN UNIV

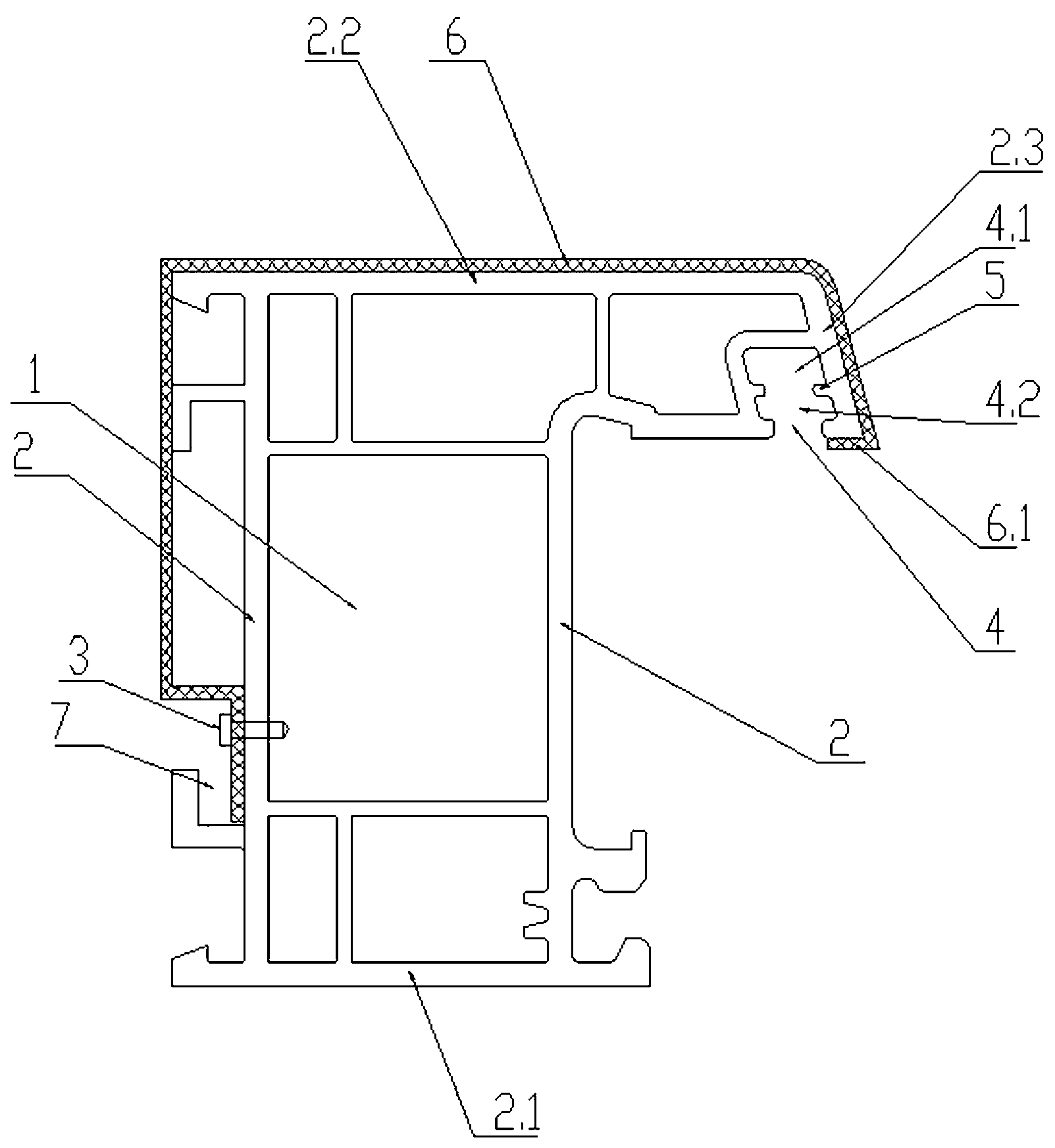

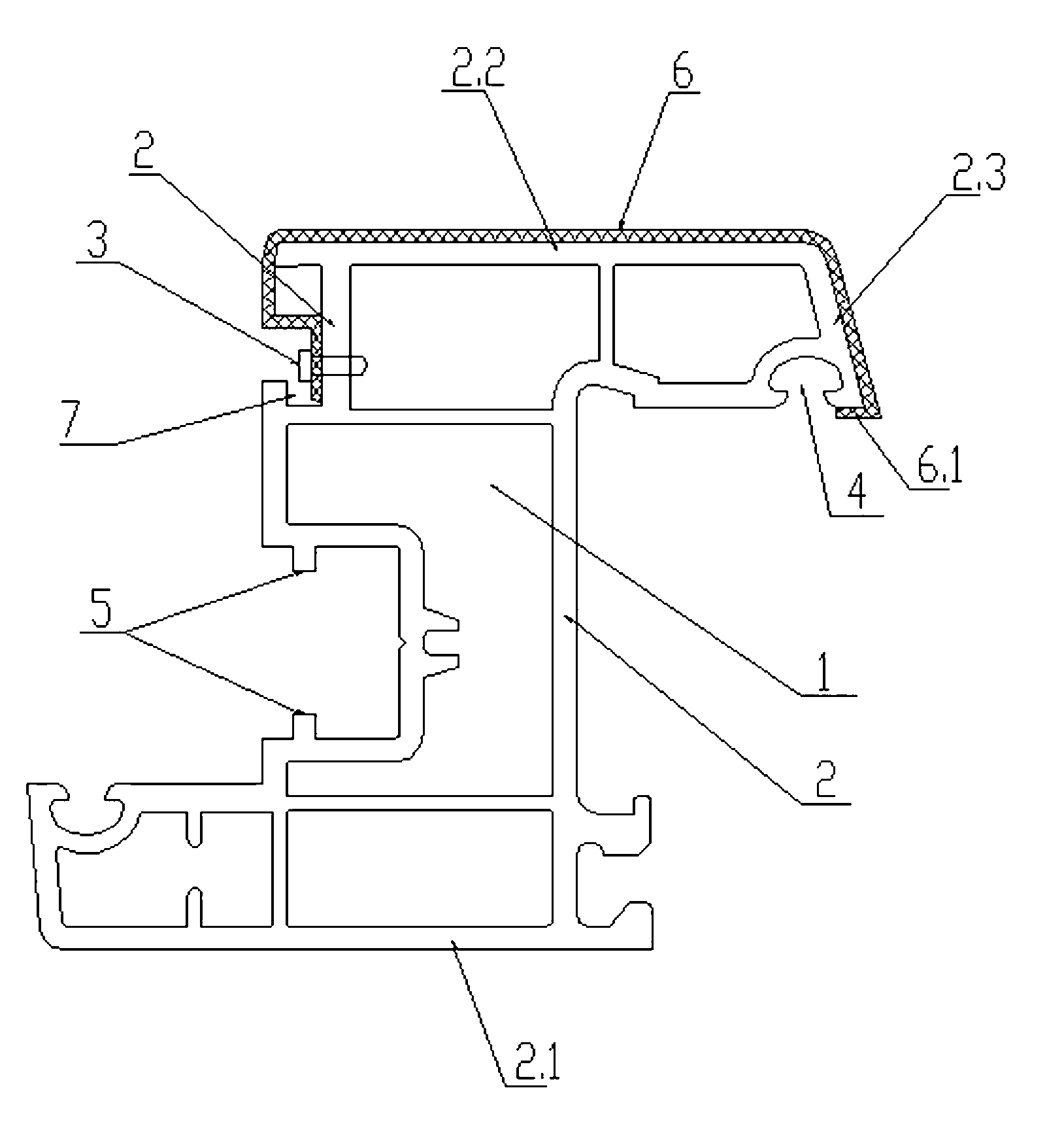

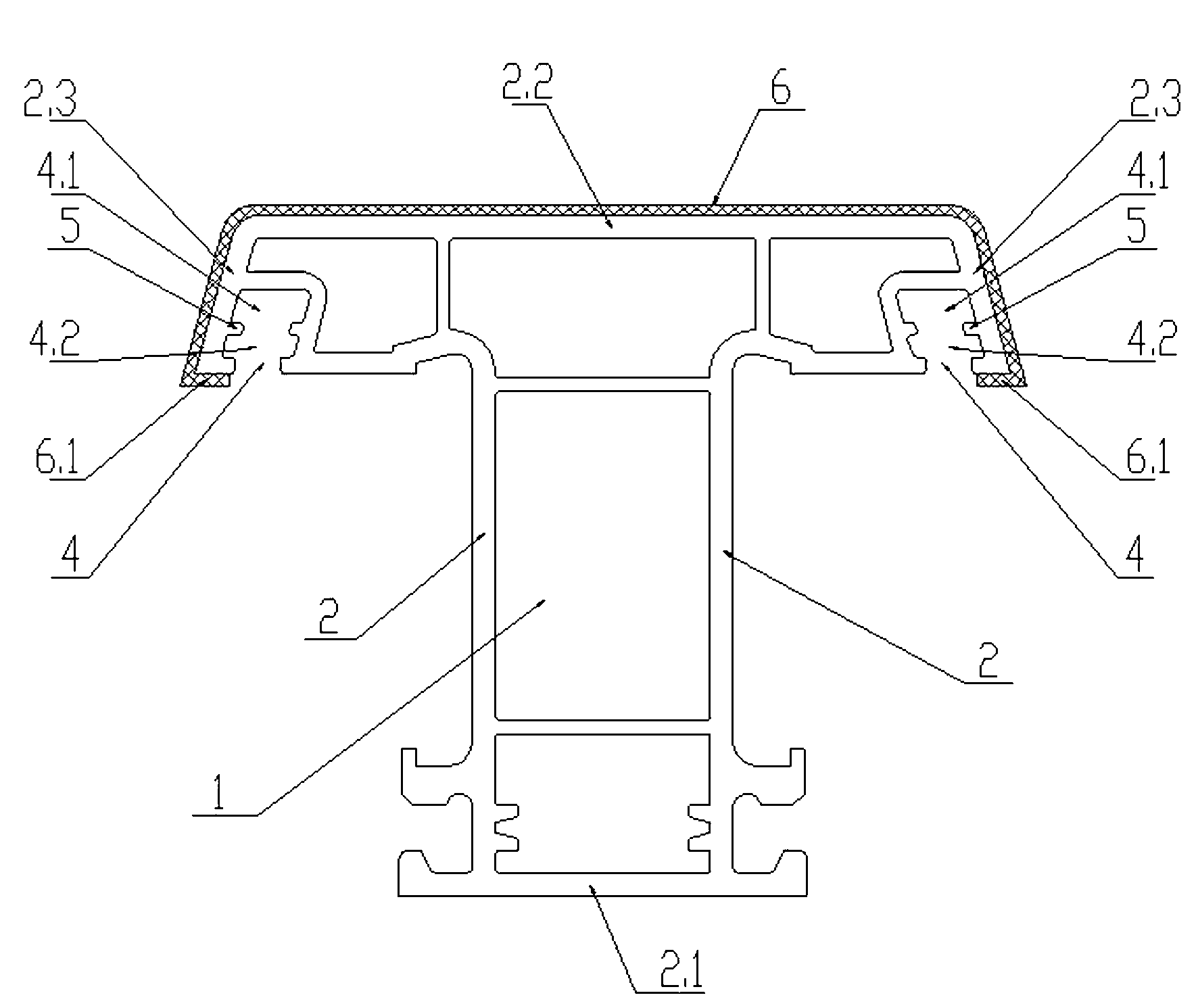

Plastic steel profile and production technology

ActiveCN103277015AHigh strengthImprove wind pressure resistanceWindow/door framesWing framesLoad resistanceEngineering

The invention provides a plastic steel profile which comprises a plastic steel profile body. An outer visual surface, an inner visual surface and two connecting plates for connecting the inner visual surface with the outer visual surface are arranged on the body, and a metal plate is arranged on the outer visual surface. A production technology of the plastic steel profile includes the steps: machining the plastic steel profile; cutting the plastic steel profile; assembling the plastic steel profile; welding the plastic steel profile; and mounting the metal plate on the plastic steel profile body after the plastic steel profile is welded. The plastic steel bridge cutoff door and window profile can be produced and has the advantage that the profile is high in ageing resistance and not easy to deform and droop and has wind load resistance.

Owner:山东玉景智能家居有限公司

Chemical nickel-phosphorus-plated alloy solution and method for applying the same to printed wiring board to deposit nickel-phosphorus alloy

InactiveCN105828533AStabilized phosphorus contentStable crystalline formLiquid/solution decomposition chemical coatingConductive pattern reinforcementBisulfideThiazole

The invention relates to the technical field of printed wiring board chemical nickel-phosphorus-plated alloys, particularly to a chemical nickel-phosphorus-plated alloy solution and a method for applying the same to a printed wiring board to deposit a nickel-phosphorus alloy. The chemical nickel-phosphorus-plated alloy solution includes organic disulphides and polysulfides and inorganic polysulfides, and specifically contains but is not limited alkyl disulphides and derivatives thereof, thiuram and derivatives thereof, thiazole and derivatives thereof, and thiourea and derivatives thereof. The content of a sulfide accelerator in a chemical nickel plating solution is 0.05 to 50 ppm, can satisfy an actual production nickel depositing rate requirement, can prevent the nickel-phosphorus alloy deposited on a copper-based circuit from diffusion plating or skip plating, and can still keep nickel-phosphorus alloy deposition activity after aging of a bath solution.

Owner:GUANGDONG LEAR ELECTROCHEM LTD

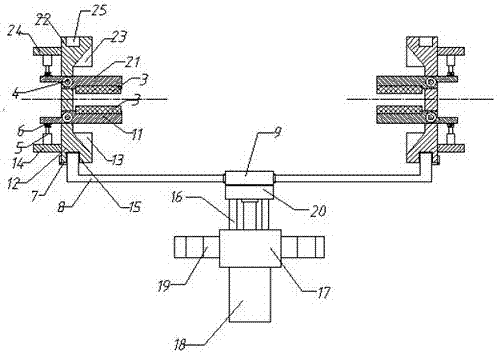

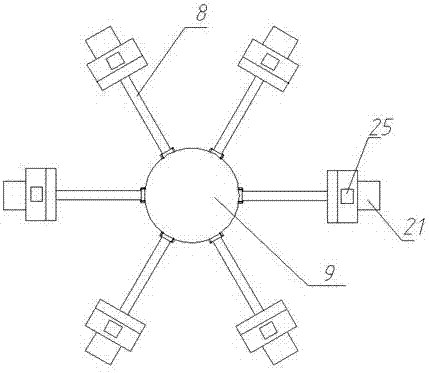

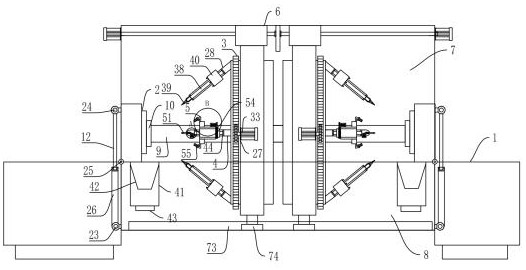

Cooler welding device and using method thereof

PendingCN114131276AEasy to weldGuaranteed weldingWelding/cutting auxillary devicesAuxillary welding devicesReciprocating motionEngineering

The invention belongs to the technical field of cooler machining, and particularly relates to a cooler welding device which comprises a workbench, the top of the workbench is connected with a fixing frame, the inner top wall of the fixing frame is provided with a welding mechanism used for making linear reciprocating motion on the horizontal plane of a workpiece, and a clamping mechanism used for positioning the workpiece is arranged below the welding mechanism. The four corners of the workpiece are positioned in the positioning grooves through the clamping mechanism, then the clamping mechanism is matched with the adjusting mechanism to do vertical upward lifting motion or overturning motion, when the clamping mechanism does vertical upward lifting motion through the adjusting mechanism, welding of the workpiece positioned in the clamping mechanism is mainly facilitated, and the welding efficiency is improved. When the clamping mechanism conducts overturning motion, the clamping mechanism can adjust the rotating angle of a first servo motor to be 180 degrees every time through debugging of the first servo motor in the adjusting mechanism, it is guaranteed that the horizontal plane of a workpiece positioned in the clamping mechanism is 180 degrees every time the workpiece rotates, and it is guaranteed that the front face and the back face of the workpiece positioned in the clamping mechanism can be welded.

Owner:南通万马液压机械有限公司

Electrode structure of spiral-wound electrode battery and manufacturing method of structure

InactiveCN110380106AGuaranteed weldingPrevent looseningFinal product manufactureCylindrical casing cells/batterySpiral woundEngineering

The invention provides an electrode structure of a spiral-wound electrode battery and a manufacturing method of the structure. The structure comprises a lower casing and an upper cover of a stainlesssteel material, a winding core and an electrode isolation assembly wound around the winding core are fixed in the inner middle portions of the lower casing and the upper cover, and the periphery of the electrode isolation assembly includes an anode tab and a cathode tap extending to upper and lower portions of the electrode isolation assembly respectively; the anode tab made of aluminum is connected with a positive plate; the cathode tab made of nickel is connected with a negative plate; and the external surface in the upper end surface of the anode tab is connected with a nickel plate, and the nickel plate is welded to the lower surface of the upper cover. Thus, tab welding is ensured, loosening is prevented, and the safety is improved.

Owner:ZHANGZHOU WANBAO ENERGY TECH CO LTD

Combined forging die and manufacturing method thereof

InactiveCN102000759AGuaranteed weldingEasy to weldFurnace typesForging/hammering/pressing machinesEngineeringForging

The invention relates to a combined forging die and a manufacturing method thereof. The forging die comprises a die head and a die body, wherein the outer edge of the lower end face of the die head is fixedly connected with the outer edge of the upper end face of the die body in a welded way. The invention has the following advantages that the defect that an integral forging die cannot be used repeatedly can be effectively overcome; the cost of die manufacturing is reduced; the forging die can be changed just by separately detaching the worn die head or die body, without changing the whole forging die, thereby meeting the requirement of energy saving and emission reduction; processing difficulty is lower, processing time is short, the overall utilization of the forging die is improved; the service life of the forging die is prolonged; and therefore, the production efficiency is improved further.

Owner:SHANDONG DONGYI MACHINERY MFG

Production method for ceramic aluminum-clad plate and ceramic aluminum-clad plate obtained by method

The invention provides a preparation method of ceramic aluminum-clad plate, the method comprising the following steps: S1, rolling pretreatment: metal aluminum plate A and metal aluminum plate B are subjected to compound pretreatment by rolling method to obtain metal composite aluminum plate C; S2 . Brazing connection: put the metal aluminum plate A of the metal composite aluminum plate C towards the ceramic plate, stack it on the ceramic plate, put the two together into a vacuum brazing furnace for brazing to obtain a ceramic aluminum-clad substrate; wherein, The melting point of the metal aluminum plate A is lower than the melting point of the metal aluminum plate B by at least 50°C. The ceramic aluminum-clad plate prepared by the preparation method provided by the invention has good interface continuity and high peel strength, which can reach more than 180 N / cm.

Owner:BYD CO LTD

Automobile machining board laser welding robot

ActiveCN110238518ARealize three-axis movementHigh degree of automationLaser beam welding apparatusFixed frameEngineering

The invention belongs to the technical field of panel welding instruments, and particularly discloses an automobile machining board laser welding robot. A workbench is included. A containing frame is placed on the workbench and internally provided with a plurality of support rods. The support rods are fixedly connected with the two opposite sides of the containing frame. A welding mechanism, an overturning mechanism and a pressing mechanism are arranged on the workbench. The welding mechanism comprises a fixing frame, a lifting assembly and a welding head. The welding head is fixed to the lifting assembly, the lifting assembly is used for driving the welding head to move towards the Z axis, and the fixing frame is provided with a first drive unit driving the lifting assembly to move towards the X axis, and a second drive unit driving the lifting assembly to move towards the Y axis. The overturning mechanism comprises a clamping claw and a rotation assembly, wherein the clamping claw is used for clamping the containing frame, the rotation assembly is located on one side of the fixing frame, the clamping claw is fixedly connected with the rotation assembly, and the rotation assembly is used for driving the clamping claw to overturn. The pressing mechanism is used for pressing a workpiece. The automobile machining board laser welding robot can automatically overturn the workpiece, and accordingly double-face welding can be conducted on the workpiece.

Owner:昆山高科创志机器人自动化有限公司

Abrasion resistant steel and low-carbon steel dissimilar metal submerged-arc welding technology

ActiveCN104625358AWeld without cracksHigh weld strengthArc welding apparatusCarbon steelDissimilar metal

The invention relates to an abrasion resistant steel and low-carbon steel dissimilar metal submerged-arc welding technology and belongs to the technical field of dissimilar metal welding technologies. According to the technology, by the adjustment and controlling to welding positions, welding parameters, interlayer-temperature and the like, when the high-carbon and high-manganese abrasion resistant steel is welded with the low-carbon steel dissimilar metal, the purposes of preheating before welding and slow cooling after welding are achieved, so that no cracks occur in welding seams after welding is completed, the welding seams do not crack after being heated again through a heating furnace, and it is guaranteed that rolling goes on smoothly. Compared with a traditional abrasion resistant steel and low-carbon steel dissimilar metal welding technology, the abrasion resistant steel and the low-carbon steel dissimilar metal submerged-arc welding technology has no special requirements for raw materials and equipment, so that the manufacturing cost is lowered.

Owner:云南昆钢新型复合材料开发有限公司

Battery cell tab connecting structure, soft package battery, electric equipment, electric vehicle and power station

PendingCN111293270AEasy to detectNo resilienceSecondary cellsCell component detailsPower stationBusbar

The invention discloses a battery cell tab connecting structure which comprises tabs and busbars. Through holes matching the tabs are formed in the busbars; the through holes correspond to the tabs; one end of each tab is connected with a battery cell, and the other end of the tab is inserted into the corresponding through hole in a busbar; the tabs and the busbars are connected through laser welding at the through holes. The invention further provides a soft package battery which comprises the battery cell tab connection structure, electric equipment, an electric vehicle and a power station. According to the battery cell tab connecting structure, the soft package battery, the electric equipment, the electric vehicle and the power station, which are provided by the invention, the busbarover-current area is not occupied; the busbars and the tabs are firmly welded; pseudo soldering can be avoided; and the welding quality is convenient to detect.

Owner:四川国创成电池材料有限公司

High-elongation high-strength hot-dip galvanized steel sheet and production method thereof

PendingCN113512679AGuaranteed weldingGuaranteed forming effectHot-dipping/immersion processesFurnace typesChemical compositionSteel plates

The invention belongs to the technical field of steel smelting, and particularly relates to a high-elongation high-strength hot-dip galvanized steel sheet and a production method thereof. The technical purpose of the invention is to provide the high-elongation high-strength hot-dip galvanized steel sheet and the production method thereof. The high-elongation high-strength hot-dip galvanized steel sheet provided by the invention comprises the following chemical components in percentages by weight: 0.03-0.10% of C, 0.20-0.60% of Si, 1.20-2.00% of Mn, 0.015-0.070% of Als, less than or equal to 0.020% of P, less than or equal to 0.010% of S, less than or equal to 0.006% of N and the balance of Fe and inevitable impurities. The production method comprises the following steps: smelting, hot rolling, acid rolling, annealing and hot-dip galvanizing. The hot-dip galvanized steel prepared by the method has high strength, high elongation and obvious economic benefit.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

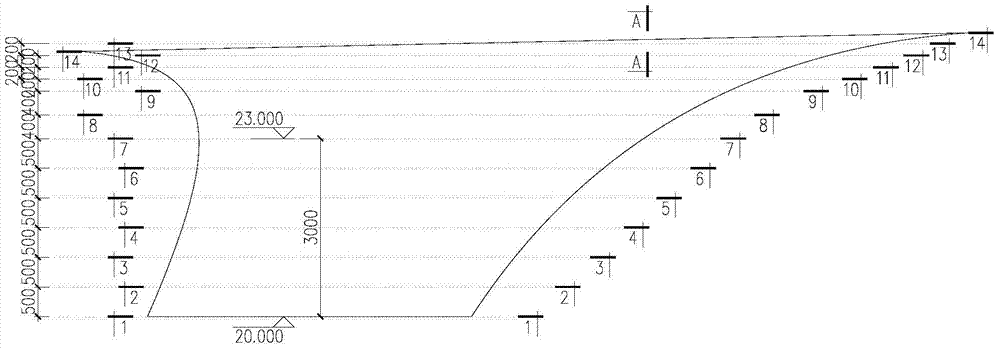

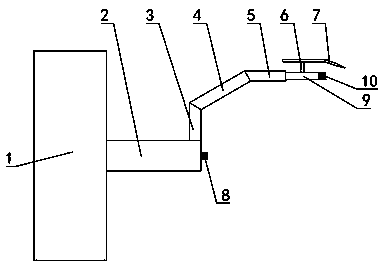

Lamp pole longitudinal joint welding mechanism

The invention relates to a lamp pole longitudinal joint welding mechanism comprising a guide mechanism located in a to-be-welded lamp pole, and a welding joint mechanism connected to the guide mechanism. The guide mechanism comprises a plate. A guide wheel walking in a welding joint is connected to the bottom face of the plate. A connecting plate is hinged to the top face. A stud is in screw connection with the connecting plate. The lower end of the stud abuts against the upper surface of the plate and is used for adjusting the included angle between the plate and the connecting plate. The connecting plate is connected with the welding joint mechanism through a welding swing mechanism. Due to the fact that the guide wheel is matched with the welding joint, the effect that the welding jointmechanism conducts welding effectively along the welding joint is ensured while the guide wheel combs the welding joint. In addition, due to existing of the welding swing mechanism, the effect that awelding wire of the welding joint mechanism is welded in a zigzag shape in the welding joint is ensured, and thus the quality of the welded gap is ensured.

Owner:JIANGSU TEWEI MACHINE TOOL MFG

A kind of production method of zn/cu-ag/cu-au composite coated steel strip for photoelectric material

ActiveCN105063620BReduce glossPrecise and controllable thicknessSuperimposed coating processLoss rateHydrogen

A production method of a Zn / Cu-Ag / Cu-Au composite coating steel band for a photoelectric material comprises the following steps: using a 08Al cold-rolled steel sheet as a raw material and carrying out cold rolling; after conventional degreasing, carrying out uncoiling, splitting and deburring; hot-dipping Zn; thermally spraying Cu-Ag; carrying out primary annealing at a pure nitrogen protective atmosphere; thermally spraying Cu-Au; carrying out secondary annealing at a pure nitrogen protective atmosphere; and air-cooling to a room temperature and coiling. The tensile strength is 250-300MPa, and the elongation percent is 42-48%. One Zn / Cu-Ag / Cu-Au composite coating is generated on the surface. After the Zn / Cu-Ag / Cu-Au composite coating steel band is placed under an indoor conventional atmospheric condition for 960 days, the gloss loss rate of the coating is not larger than 0.3%, and the surface corroded area is not larger than 0.3%. The product has excellent electricity and heat conductivity. After the Zn / Cu-Ag / Cu-Au composite coating steel band is kept at 300-350 DEG C for 960 days, the surface oxidized area is not larger than 0.2%, and the hardness variation rate is not larger than 0.2%. The product also has excellent welding and machining performance.

Owner:武汉钢铁有限公司

Welding method for focusing ring assembly

InactiveCN105436687ASimple welding processIncrease success rateElectron beam welding apparatusEngineeringMechanical engineering

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

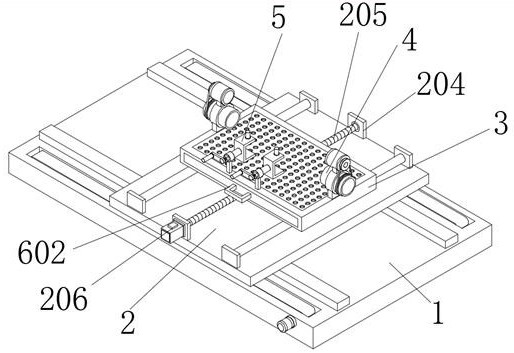

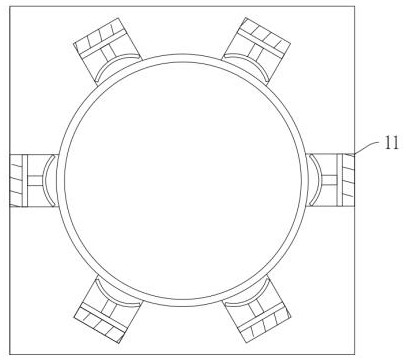

Welding method of tube plate for tube plate heat exchanger

ActiveCN110421283ARealize automatic identificationAvoid deformationWelding/cutting auxillary devicesAuxillary welding devicesPlate heat exchangerEngineering

The invention discloses a welding method of tube plate for tube plate heat exchanger and belongs to the technical field of automatic welding. The welding method is characterized in that the welding method comprises the following steps that 1, the welding point of the tube plate heat exchanger and the central position of tube plate welding point are identified; 2, the number of tube plates s and the number of welding layers n are calculated; 3, according to the number of tube plates s, the number of welding layers n and the central coordinate of the welding point of tube plates, a control device formulates the welding plan on the basis of the principle of from the outside to the inside and principle that the mechanical arm drives the welding gun to rotate 90 degrees after each welding; 4, the welding gun (7) can be moved to the welding spot; 5 the second CCD camera (10) identifies and processes the image information of the current welding point, and then obtains the coordinates and radius of a center of the corresponding single tube plate circle; 6, the welding gun (7) welds the tube plate according to the welding plan; and 7, the welding gun (7) welds the not welded tube plates. The welding method of tube plate for tube plate heat exchanger realizes automatic welding, reduces welding heat stress and ensures good sealing property of welding.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

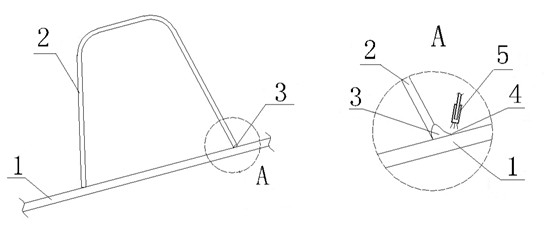

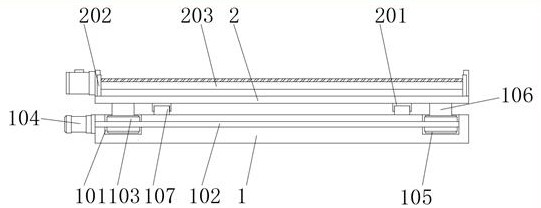

Locating welding tool for spiral guide rail

InactiveCN105345349AAdjust the lift angleGuaranteed weldingRailsWelding/cutting auxillary devicesButt weldingEngineering

The invention relates to a locating welding tool for a spiral guide rail. The locating welding tool comprises a tool rack. A plurality of tool plates are fixedly connected to the surface of the tool rack. A plurality of stand column mounting plates are fixedly connected to the surfaces of the tool plates. Each stand column mounting plate is connected with a longitudinally-arranged stand column. Shelves are movably arranged on the stand columns. The locating welding tool is simple in structure and convenient to use; the stand columns and the stand column mounting plates on the tool rack can shift in the linear direction, the shelves on the stand columns can vertically shift in the stand columns, and therefore the aim of adjusting the center distance of the guide rail and the lifting angle of the guide rail is achieved; the center distance between different guide rails is achieved; welding of gear racks and the guide rails is guaranteed; smooth butt welding of the left and right guide rails and the spiral guide rail is achieved; the requirements of drawings are met; and production efficiency is greatly improved.

Owner:SYMAX ELEVATOR CHINA

Welding operation table with welding position capable of being adjusted in real time for machining mechanical mold parts

PendingCN114453815AAvoid offsetGuaranteed stabilityWelding/cutting auxillary devicesAuxillary welding devicesDrive wheelTransmission belt

The invention discloses a mechanical mold part machining welding operation table capable of adjusting the welding position in real time, which comprises a base, two groups of adjusting grooves are formed in the inner side of the base, a transmission rod is mounted on the inner side of the base in a penetrating manner, the transmission rod penetrates through the interiors of the two groups of adjusting grooves, and two groups of transmission rollers are mounted on the outer side of the transmission rod. The transmission roller is located on the inner side of the adjusting groove, and a conveying belt is movably installed on the outer side of the transmission roller. The movable inner pipe is installed, a motor is controlled to operate to drive a driving wheel at the output end to rotate, the driving wheel rotates to drive a transmission belt on the outer side to rotate, the transmission belt rotates to drive a driven wheel on the inner side to rotate, and the driven wheel rotates to drive the movable inner pipe on the inner side to rotate on the inner side of a fixed outer ring; the movable inner pipe rotates to drive the adjusting rod and the clamping plate on the inner side to rotate, the clamping plate rotates to drive the tubular workpiece on the inner side to rotate, the device can conveniently and automatically adjust the angle of a welding seam during welding, and the workpiece is comprehensively welded.

Owner:YELLOW RIVER CONSERVANCY TECHN INST

Machining device for production of sprinkling irrigation device

ActiveCN113560781AGuaranteed weldingIncrease productivitySpraying apparatusWelding/cutting auxillary devicesSlag (welding)Agricultural engineering

The invention discloses a machining device for production of a sprinkling irrigation device. The machining device comprises a pre-welding main body, a self-service fixing device, a segmentation type circulating welding device, a flexible impact type welding slag removing device, an embedded periodic paint spraying device and a circulating welding moving device. The invention belongs to the technical field of machining for production of the sprinkling irrigation device, and specifically relates to the machining device for production of the sprinkling irrigation device. An embedment principle (one object is embedded into a second object and then the two objects are embedded into a third object or a certain object penetrates through a cavity of another object) is creatively applied to the technical field of machining for production of the sprinkling irrigation device, and the embedded periodic paint spraying device with the embedded structure is creatively designed. While machining of multiple working procedures is conducted, it can be ensured that excessive space is not occupied, and the technical problem that the machining device needs multiple procedures and cannot have multiple procedures is solved.

Owner:JIANGSU KEXIANG PUMP CO LTD

Machine set for producing medium-caliber straight-seam double-sided submerged-arc welding steel pipe and forming method of steel pipe

InactiveCN101844163ASmall resilienceAdjustable amount of deformationArc welding apparatusEngineeringReducer

The invention relates to a machine set for preliminarily forming and processing a steel pipe and a forming method, which is designed for solving the problems that the pipe body is easy to form a peach-shaped tip when the homogeneous machine set is formed and the like. The machine set comprises a lower crossbeam, a base and a frame, wherein a worm gear reduction box is arranged at two ends of the lower crossbeam; the worm gear reduction box is connected with a worm gear speed reducer by a coupling connecting rod; a lower box and an upper box are arranged on the frame; a propulsion connecting assembly is arranged under the lower box; the propulsion connecting assembly is connected with the worm gear reduction box by a connecting guide screw; a lower roller seat is arranged on the lower box and connected with a connecting plate; the lower roller seat is equipped with a swing connecting gear, a bull gear and a pinion, and the pinion is connected with the worm gear speed reducer; the worm gear speed reducer is arranged at two ends of the lower box; the worm gear speed reducer is connected with the propulsion connecting assembly by the guide screw; and an upper structure such as the upper box and the like is basically the same as a lower structure such as the lower box and the like. The machine set has the advantages of downward close-mouth of the steel pipe and no peach-shaped tip. The invention regards to the machine set for producing the medium-caliber straight-seam double-sided submerged-arc welding steel pipe and the forming method of the steel pipe.

Owner:赵春友

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com