Battery cell tab connecting structure, soft package battery, electric equipment, electric vehicle and power station

A technology for connecting structures and electrical equipment, applied in secondary batteries, structural parts, battery pack parts, etc., can solve the problems of detecting welding quality, reducing the flow area of busbars, easy separation, etc. The effect of avoiding virtual welding and facilitating the detection of welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

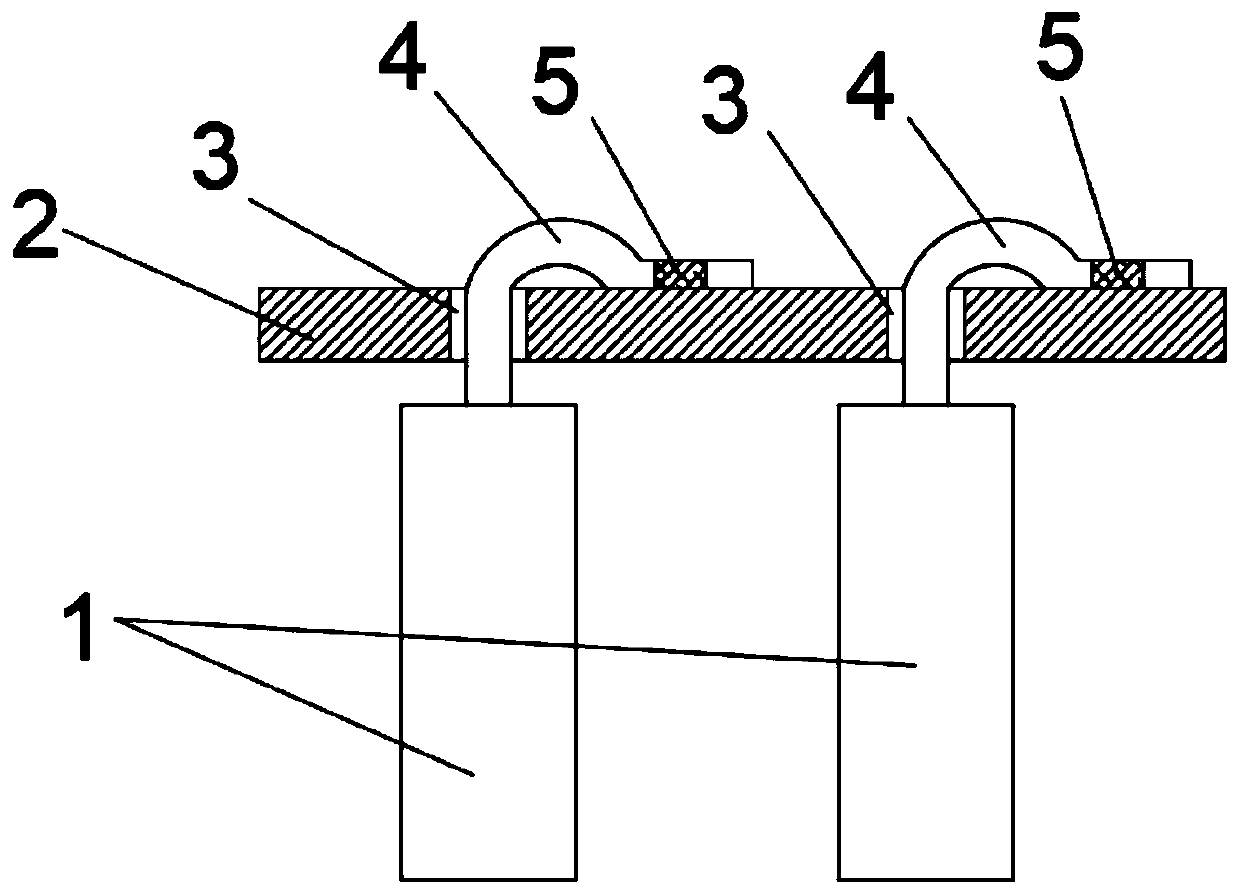

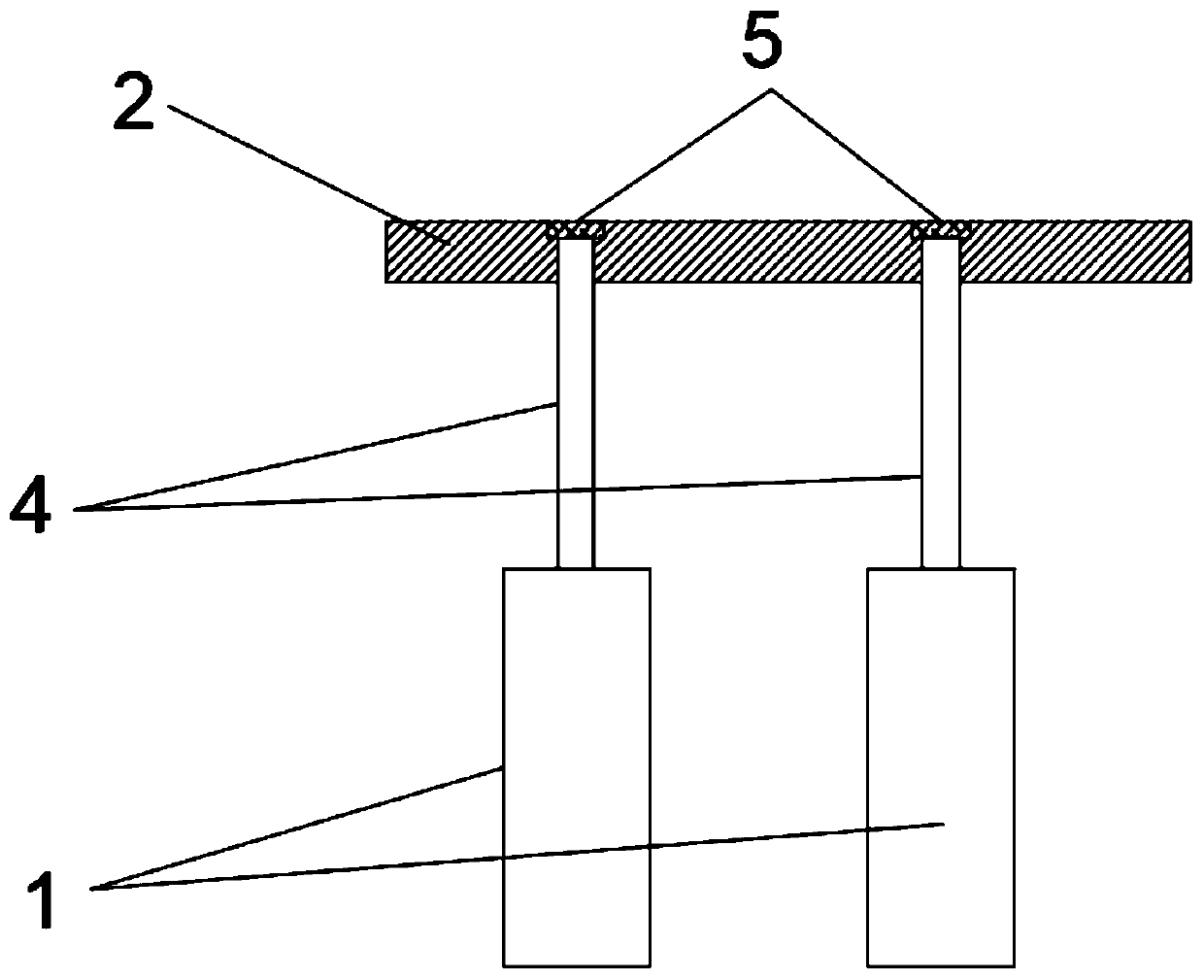

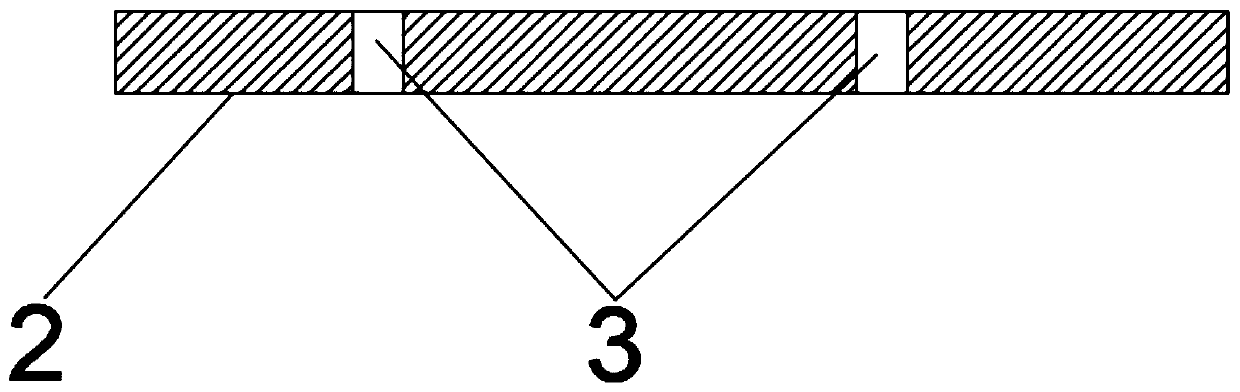

[0030] Such as Figure 1-Figure 4 As shown, the embodiment of the battery lug connection structure disclosed in the present invention includes a tab 4 and a bus bar 2. The bus bar 2 has a through hole 3 adapted to the tab 4, and the through hole 3 corresponds to the tab 4. Setting, one end of the tab 4 is connected to the cell 1, the other end of the tab 4 is inserted into the corresponding through hole 3 on the bus bar 2, the tab 4 is not bent, and the tab 4 and the bus bar 2 are at the through hole 3 Joined by laser welding.

[0031] The end of the tab 4 away from the cell 1 is flush with the side of the bus bar 2 away from the cell 1, and the end of the tab 4 away from the cell 1 and the side of the bus bar 2 away from the cell 1 are at the corresponding throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com