Patents

Literature

443 results about "Pouch cell" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cylindrical cells are used with spectrophotometers that have a larger, circular light beam. Each cell has an outside diameter of 22 mm and an inside diameter of 19 mm. Each package contains one cell and two windows. Cylindrical cells are used with spectrophotometers that have a larger, circular light beam.

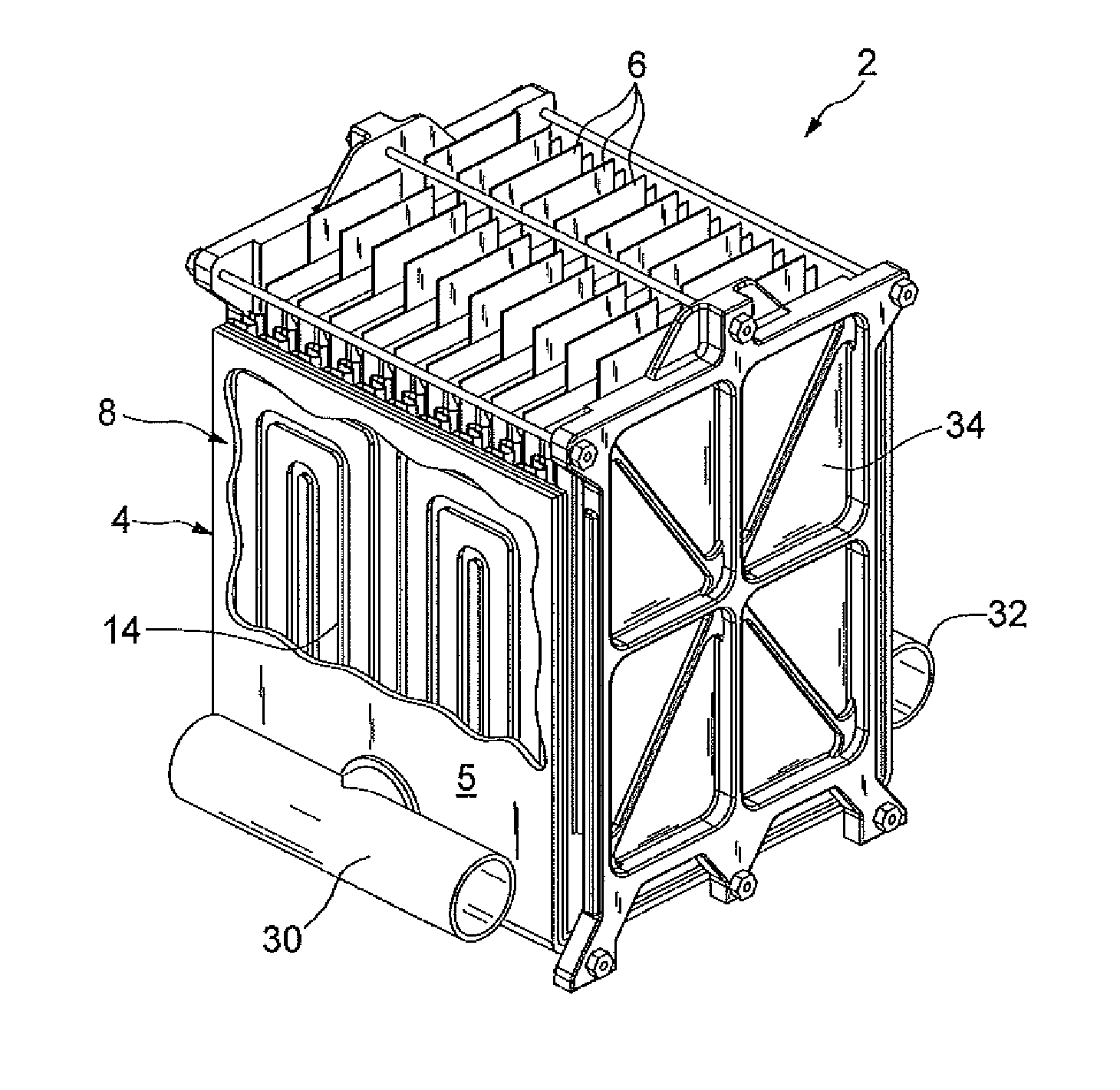

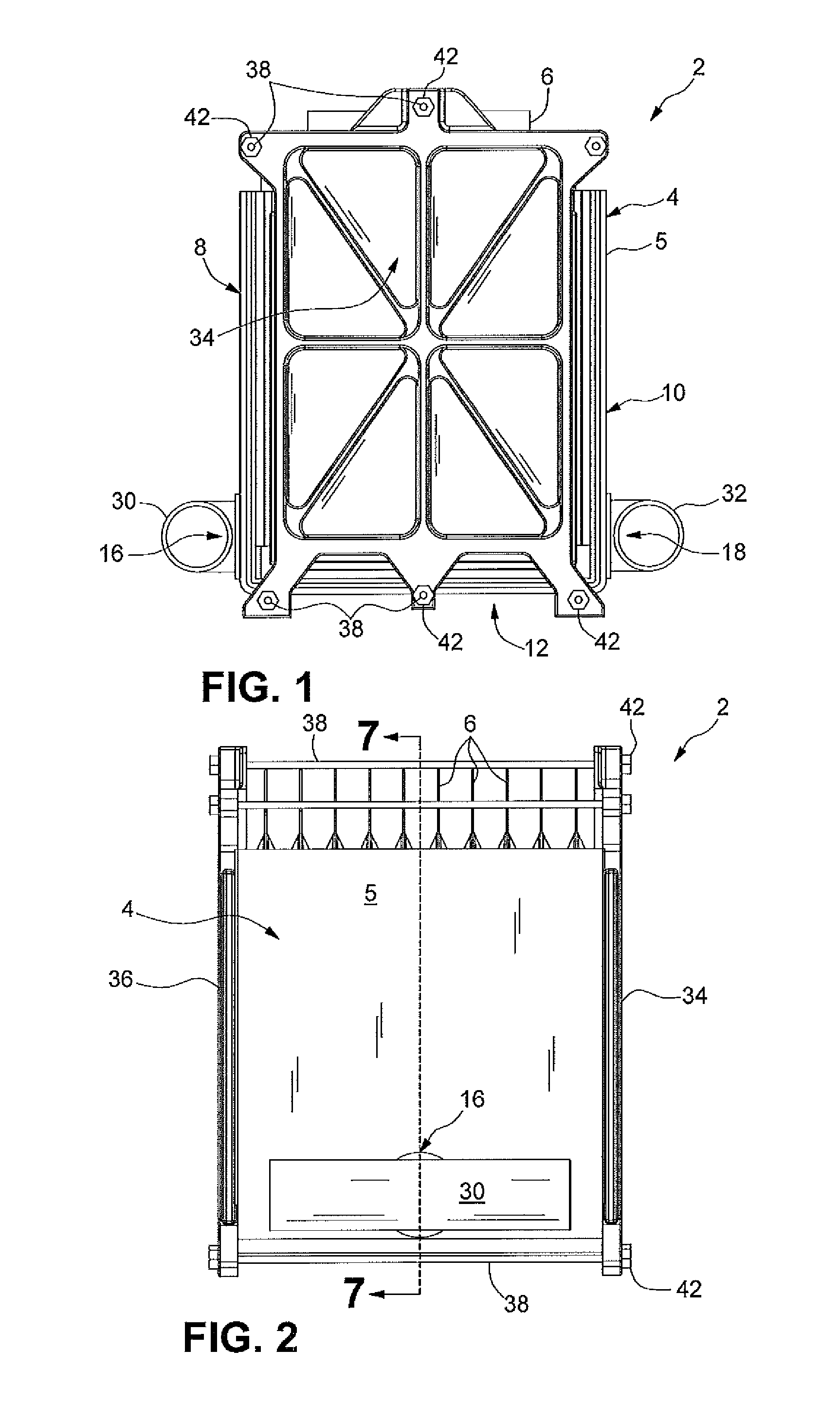

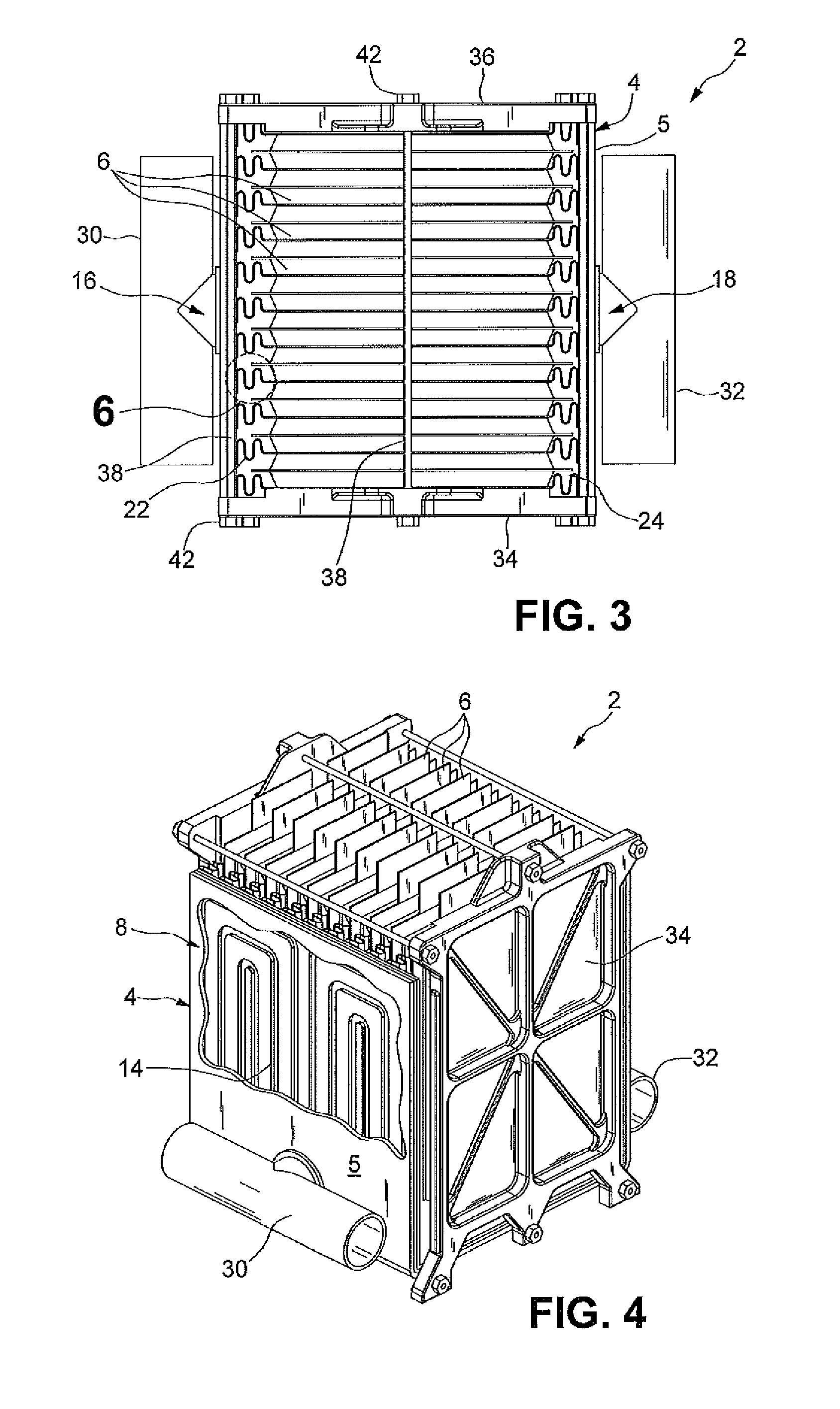

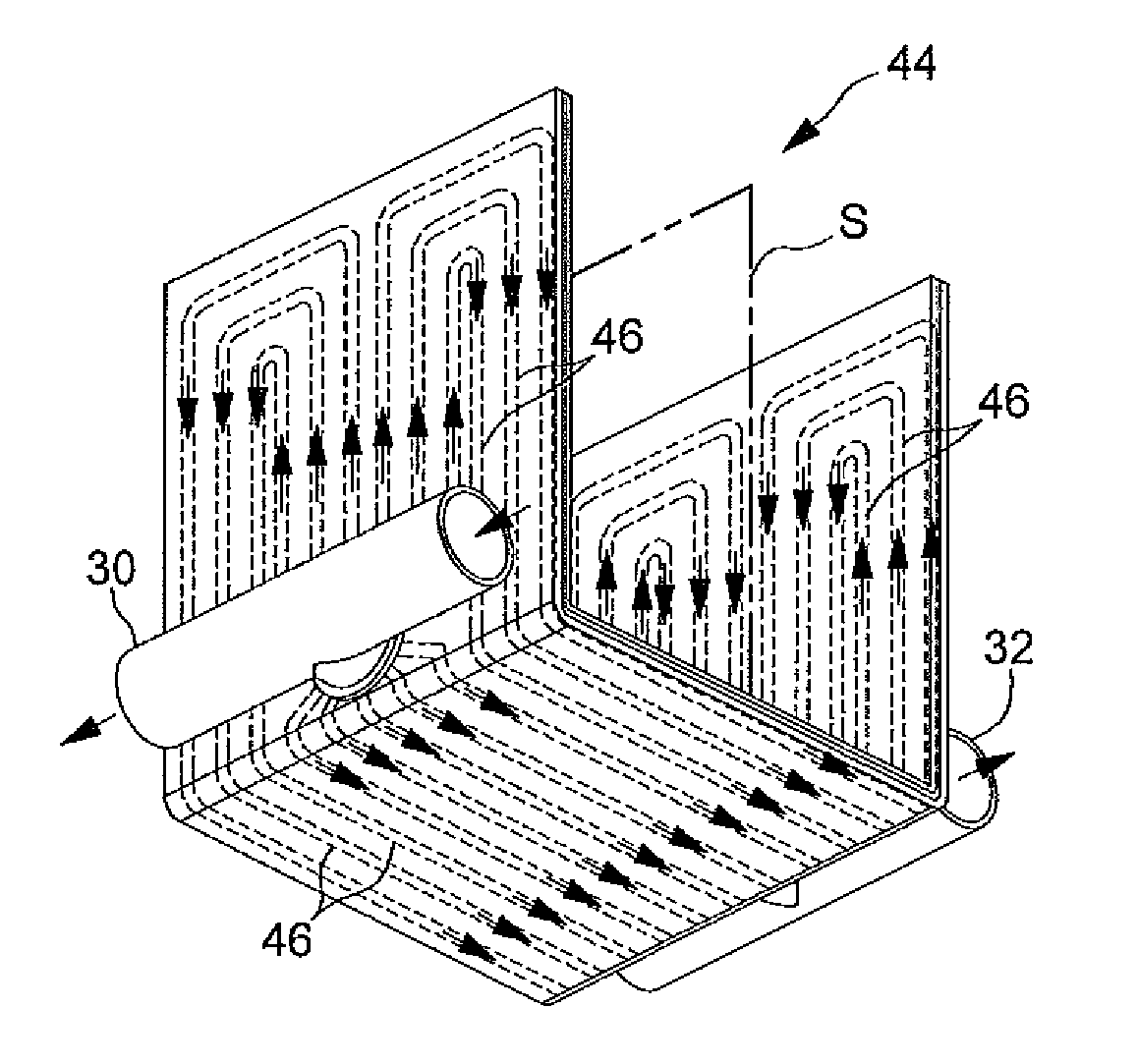

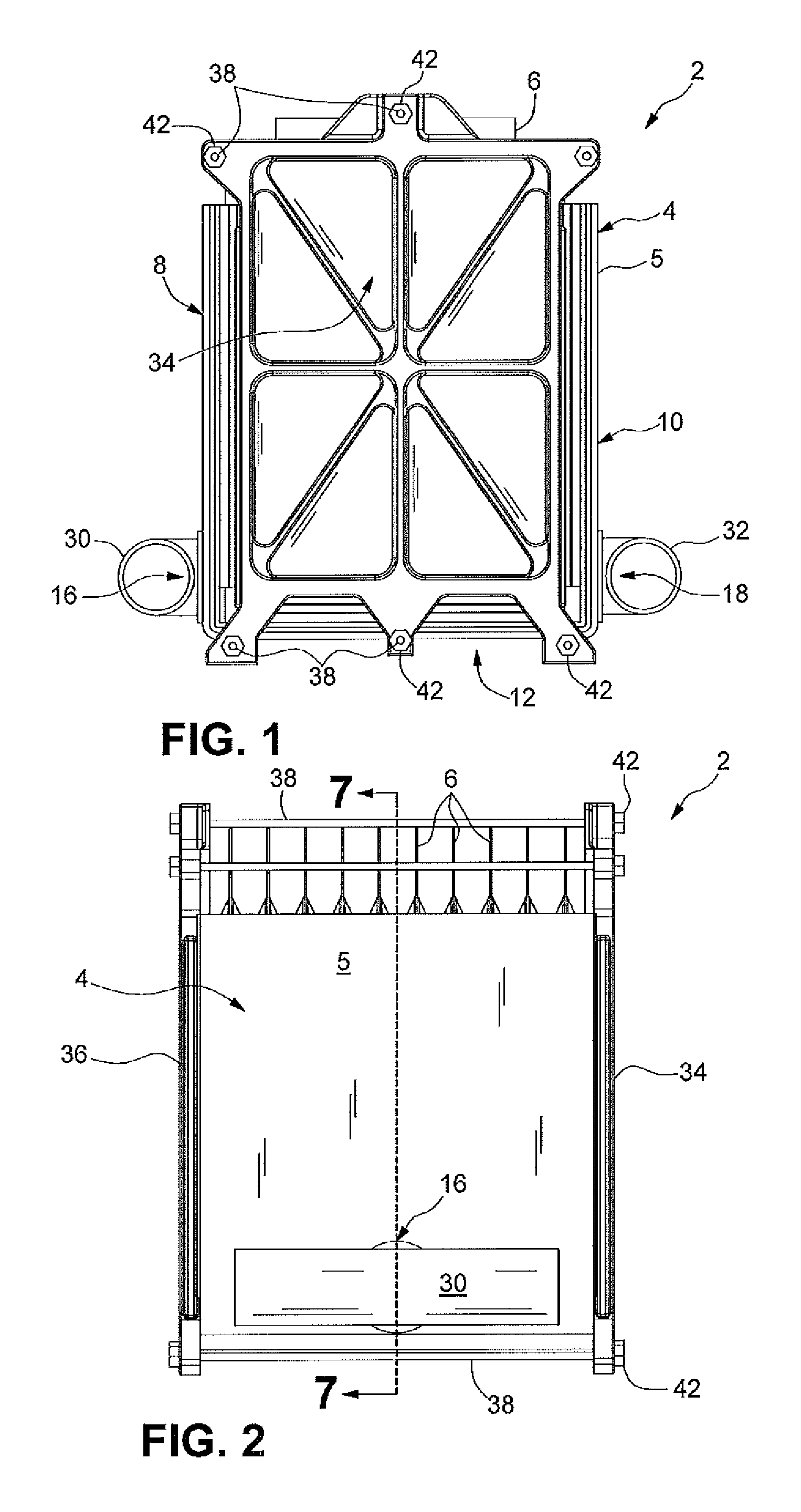

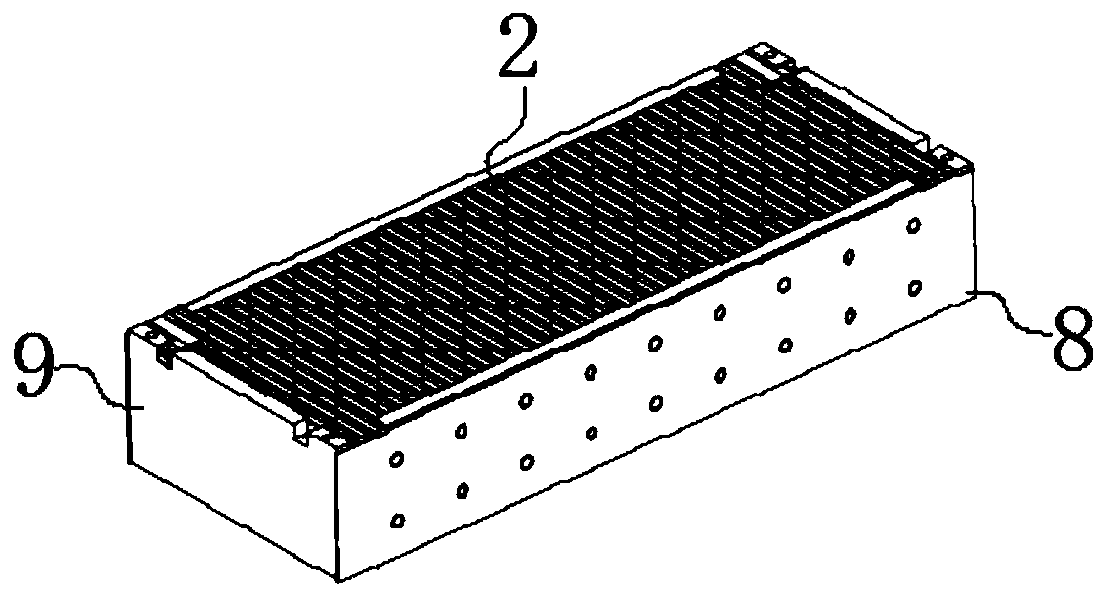

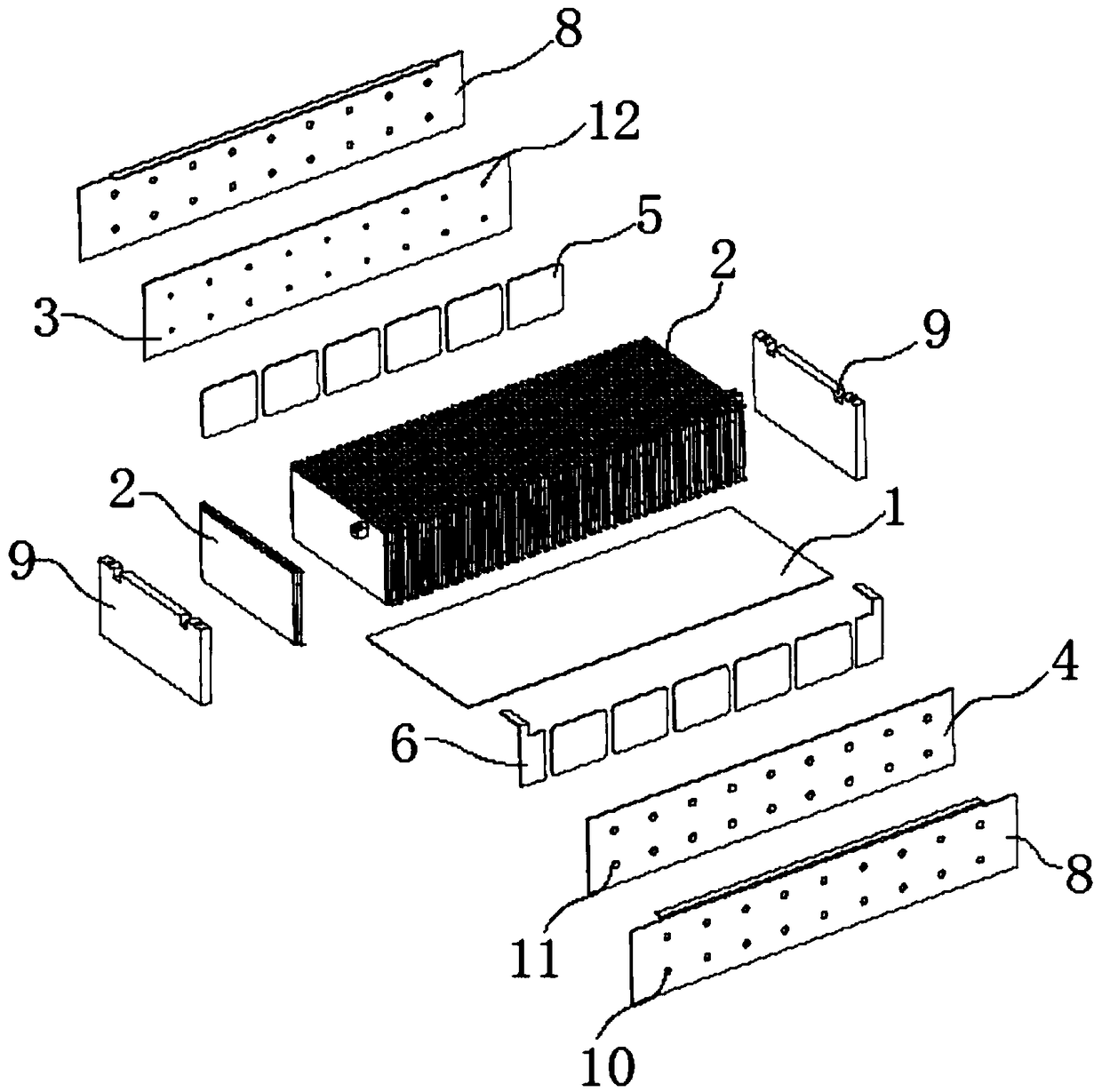

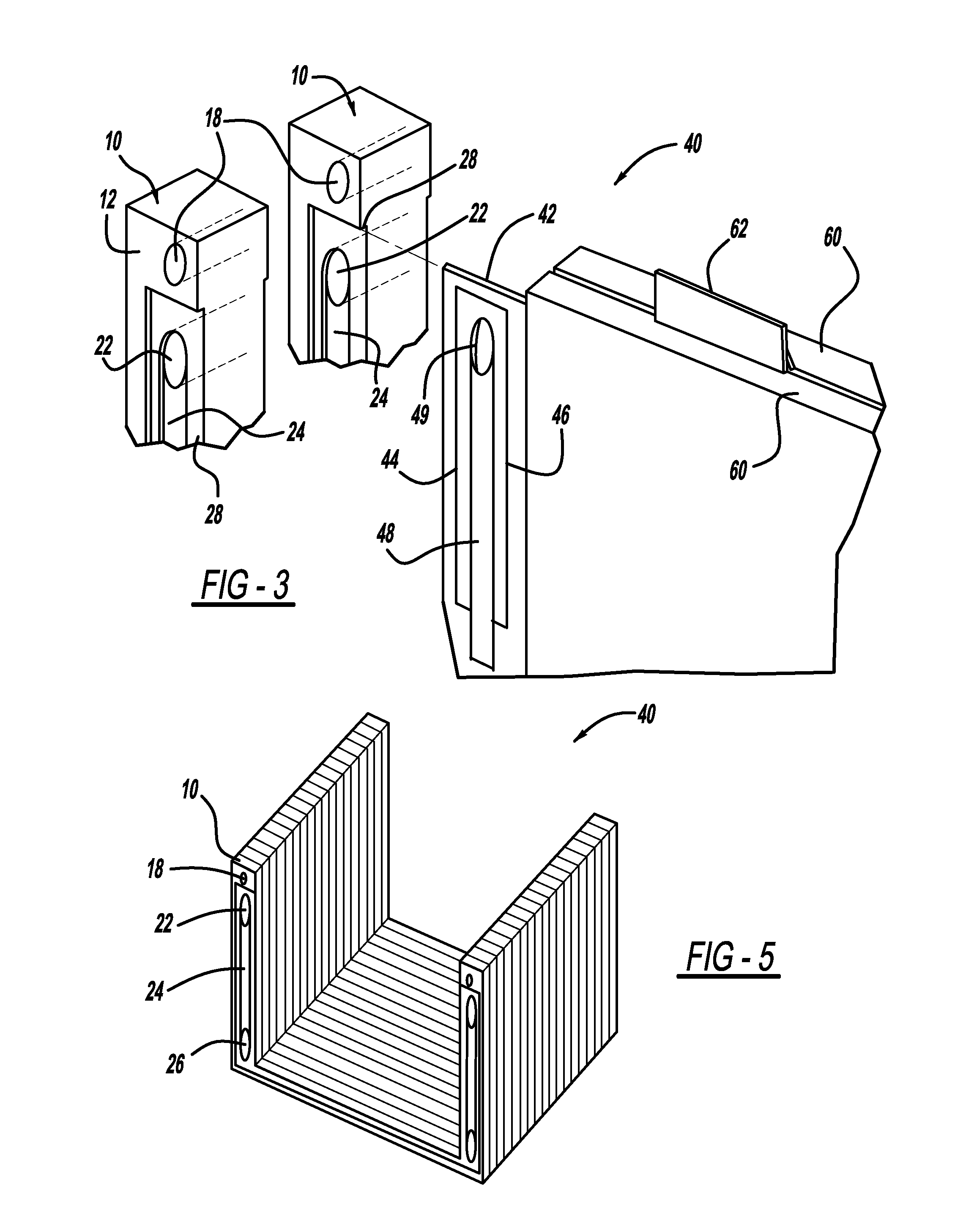

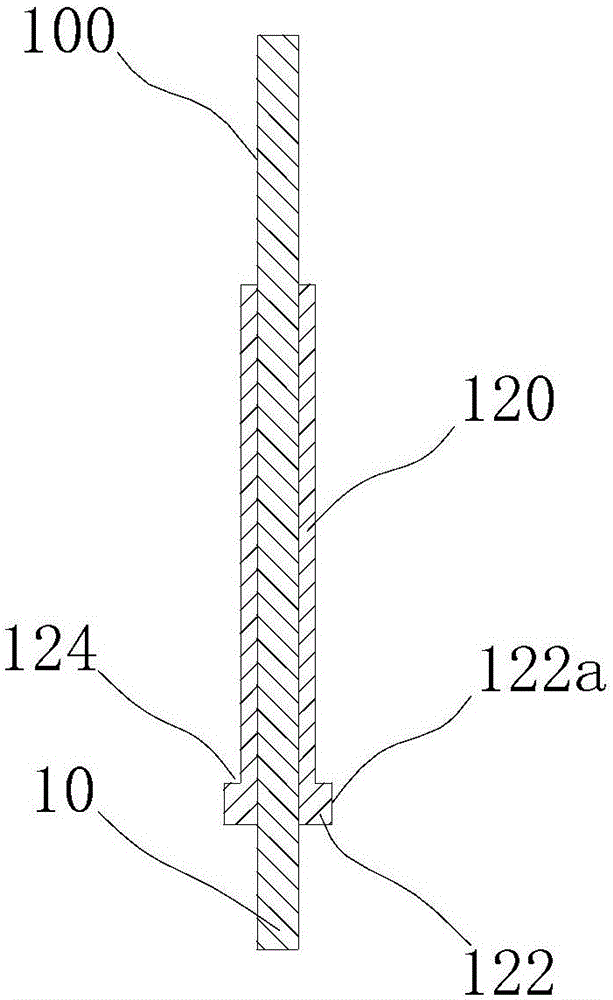

U-formed cooling plate with solid fins for lithium pouch cells

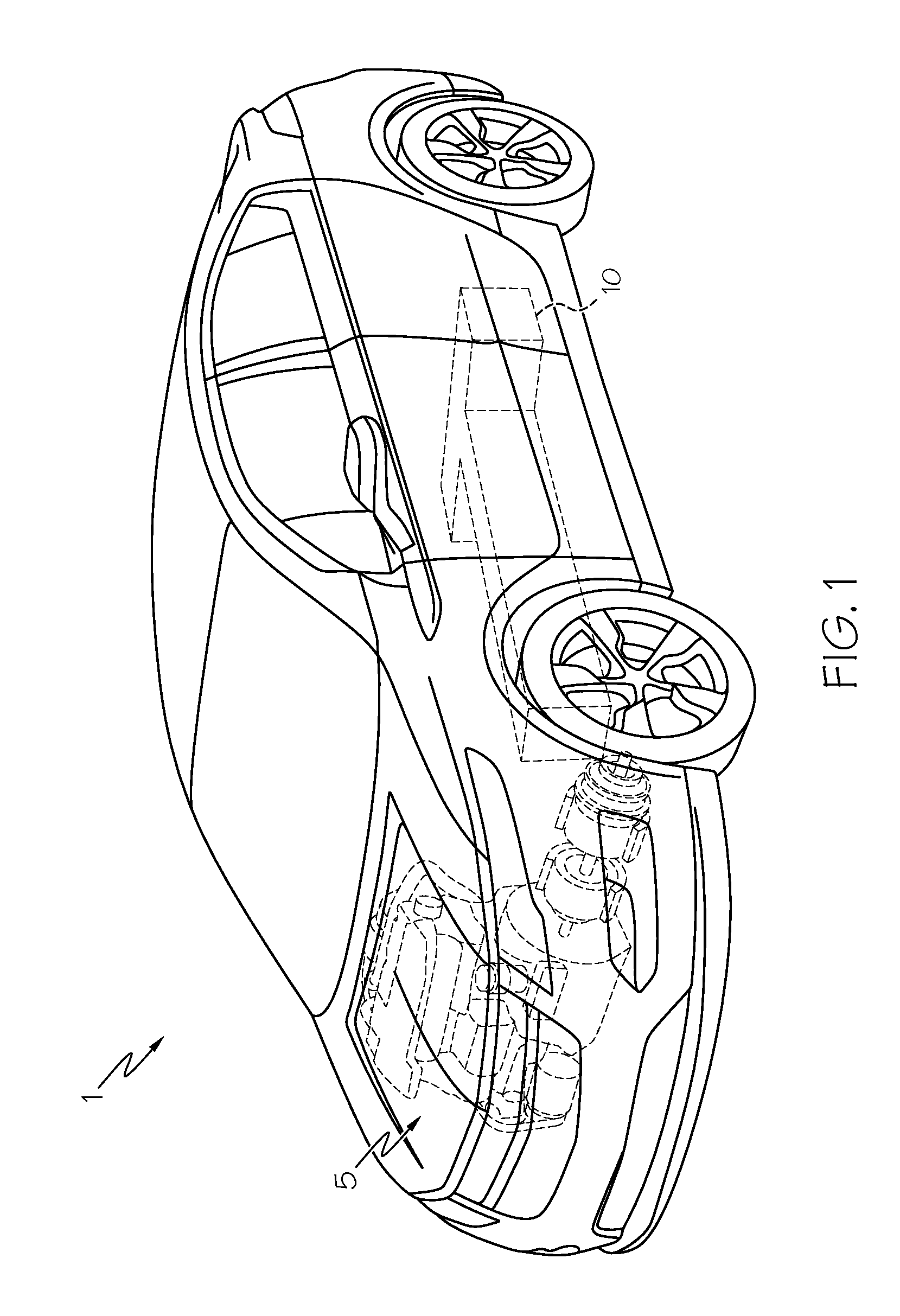

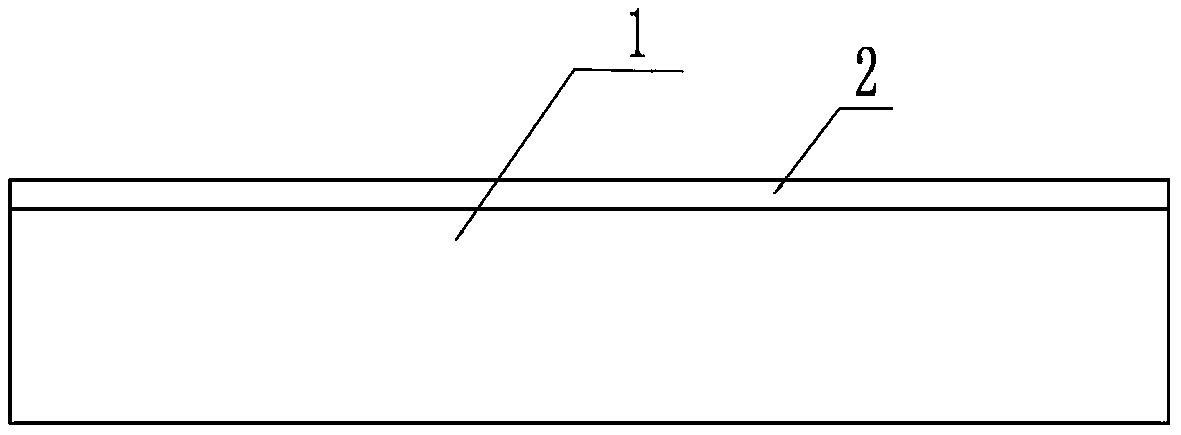

ActiveUS20110212355A1Minimize the number of componentsSimple manufacturing processCell temperature controlCell component detailsEngineeringPouch cell

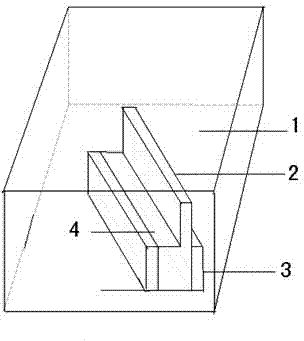

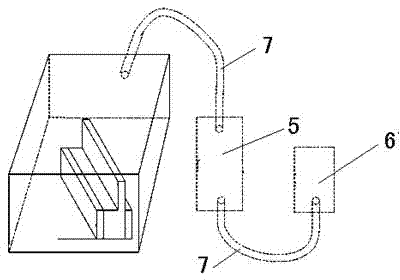

A cooling system for a battery pack module with a plurality of battery cells includes a cooling plate assembly having a first side wall and a second side wall spaced apart from one another. The first and second side walls are connected by a base wall. The first side wall, the second side wall and the base wall have at least one flow channel formed therein. The first side wall has an inlet in fluid communication with the flow channel. The second side wall has an outlet in fluid communication with the flow channel. The cooling plate assembly is configured to be placed in heat transfer communication with the battery cells disposed between the first and second side walls. The cooling plate assembly permits a coolant to flow into the inlet, through the at least one flow channel, and out of the outlet to regulate a temperature of the battery cells.

Owner:GM GLOBAL TECH OPERATIONS LLC

U-formed cooling plate with solid fins for lithium pouch cells

ActiveUS8383260B2Minimize the numberSimple manufacturing processCell temperature controlCell component detailsPouch cellBattery cell

Owner:GM GLOBAL TECH OPERATIONS LLC

Battery diaphragm with high-temperature-resistant metal-organic frame material coating, and preparation method and application thereof

ActiveCN109461873AAvoid direct contactAvoid short circuitFuel and primary cellsFuel and secondary cellsPorosityState of art

The invention discloses a battery diaphragm with high-temperature-resistant metal-organic frame material coating, and a preparation method and application thereof. The battery diaphragm takes a commercial diaphragm as the substrate, and the single surface or double surface is coated with the metal-organic frame material. Compared with the prior art, the battery diaphragm disclosed by the inventionhas the following advantages: the metal-organic frame material coating is high in porosity and large in specific area, and the electrolyte wetting property of the diaphragm can be improved; the metalorganic frame material coating can effectively improve the heat-insulating property of the diaphragm, and improve the safety performance of the battery in the high-temperature environment; the metal-organic frame material coating can effectively control the shuttle of the electrolyte ion, improve the ion transport number, restrain the bad and side effect, improve the battery capacity, and prolongthe circulating life; the uniform duct structure enables the lithium ions to be uniformly deposited / peeled, thereby fundamentally restraining the growth of the lithium dendrites; the battery diaphragm disclosed by the invention has good flexibility and mechanical performance, and can be used for assembling a practical soft-package battery.

Owner:NANJING UNIV

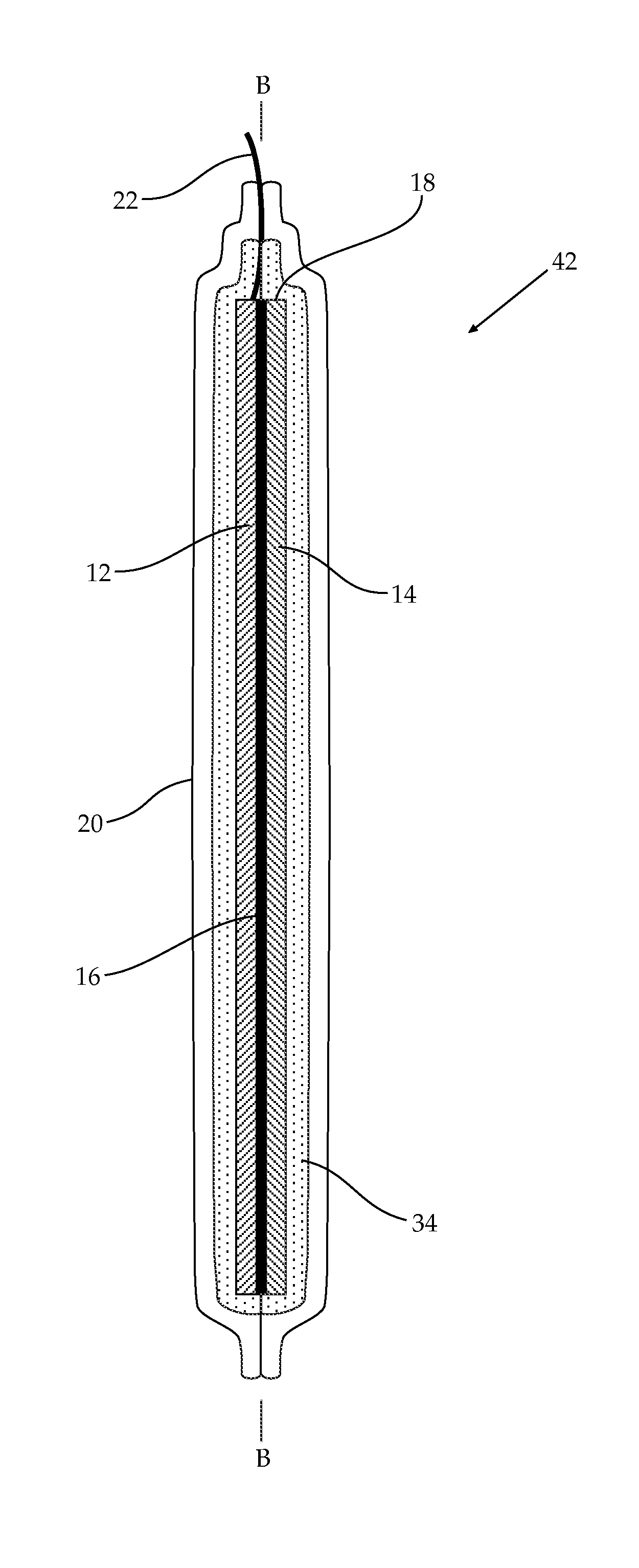

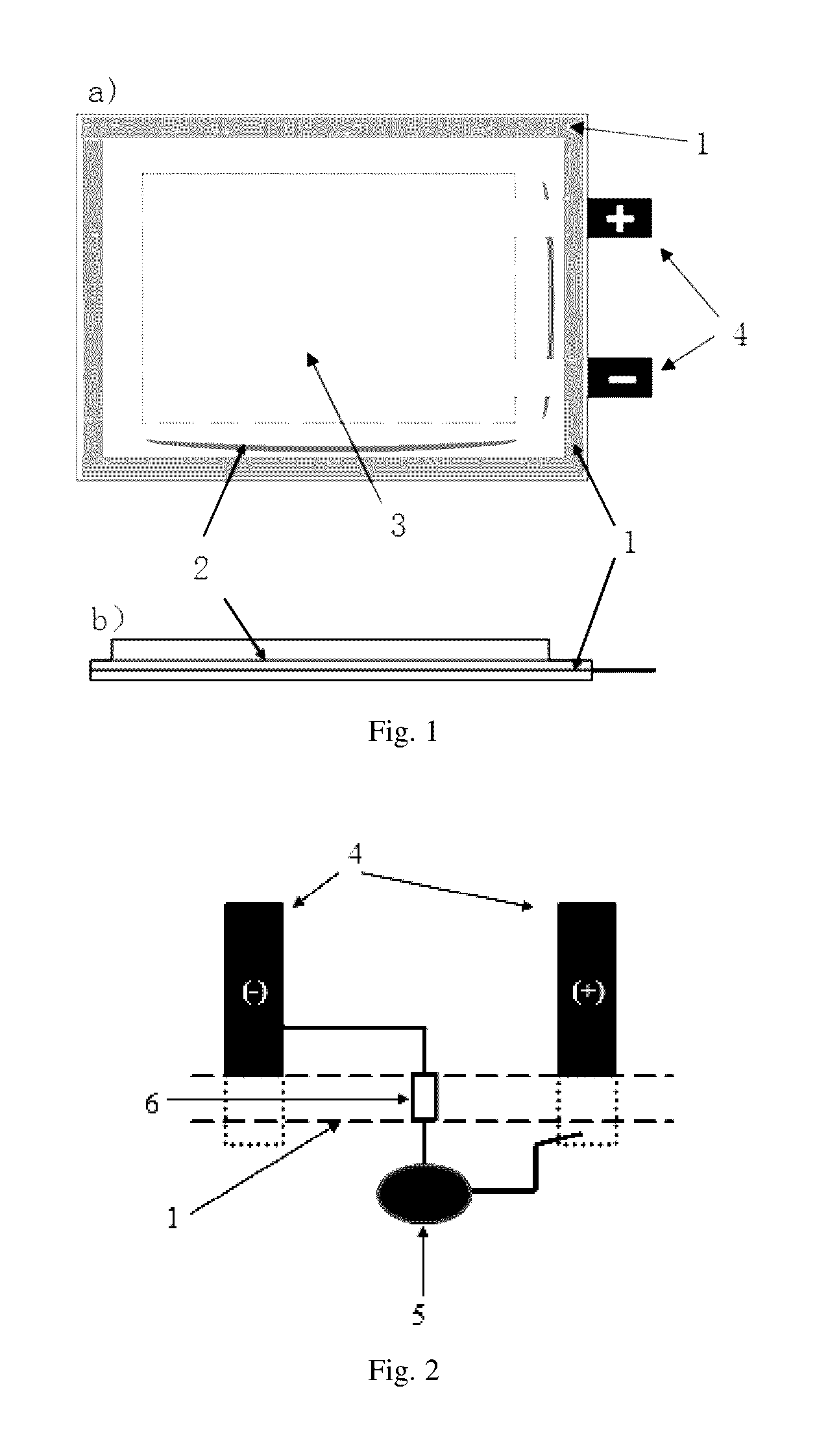

Pouch cell comprising an empty-volume defining component

Disclosed are pouch cells, for example lithium-ion pouch cells, where a portion of the inner volume of the pouch is substantially empty and there is subatmospheric pressure inside the pouch. In some embodiments gas released inside the pouch, for example during use of the cell, is accommodated in the substantially empty portion of the inner volume of the pouch, avoiding pouch bulging.

Owner:ETV ENERGY LTD

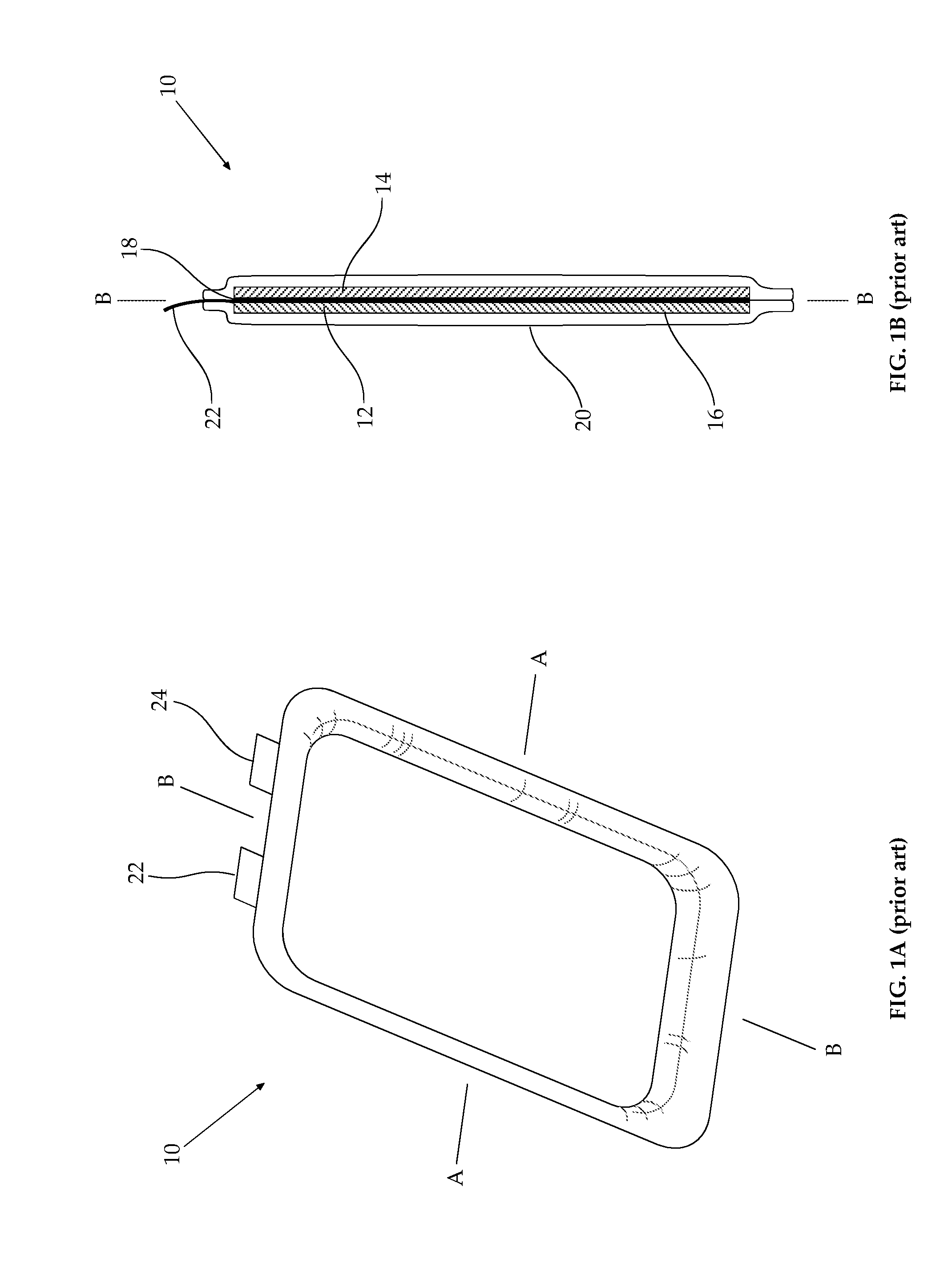

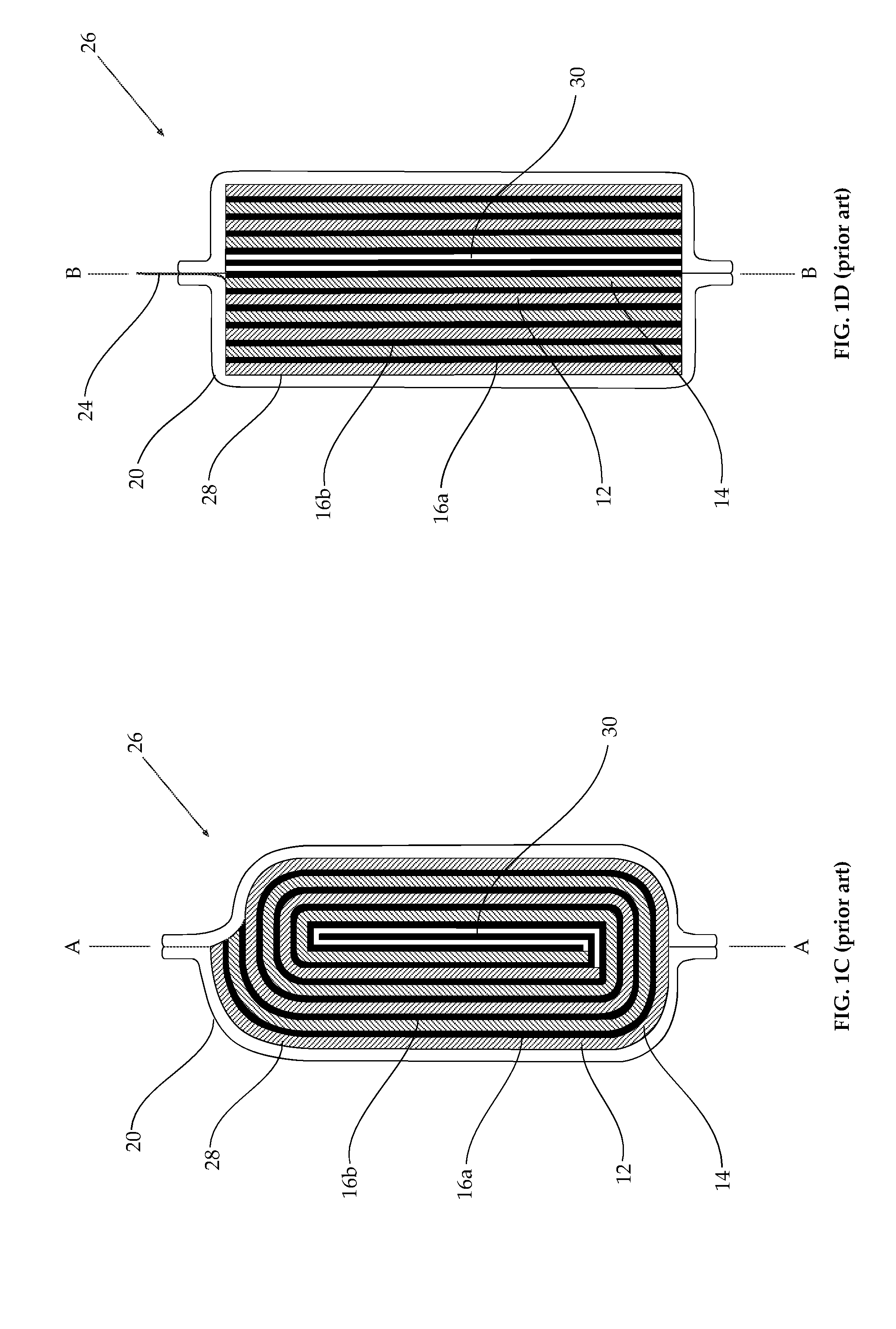

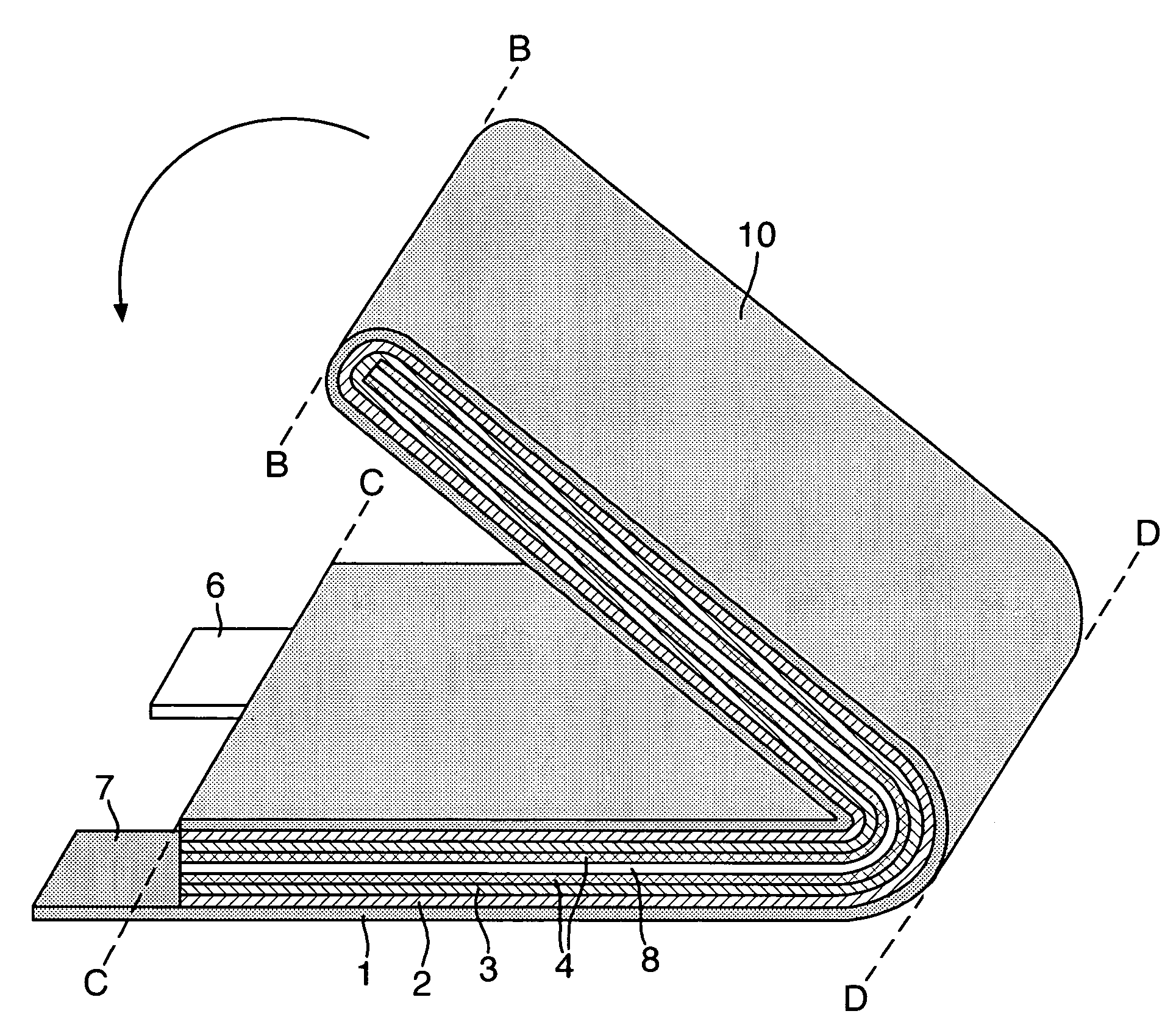

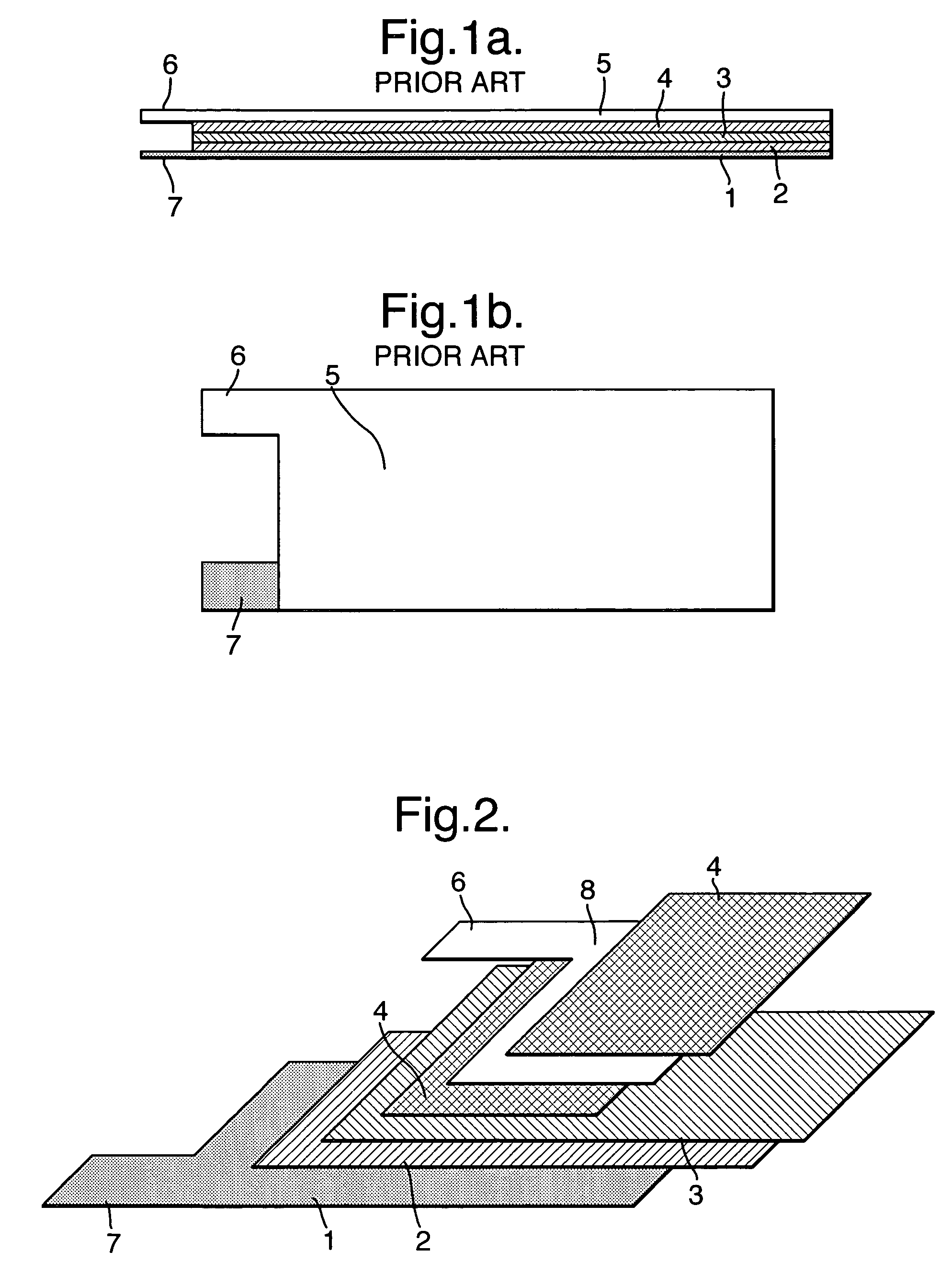

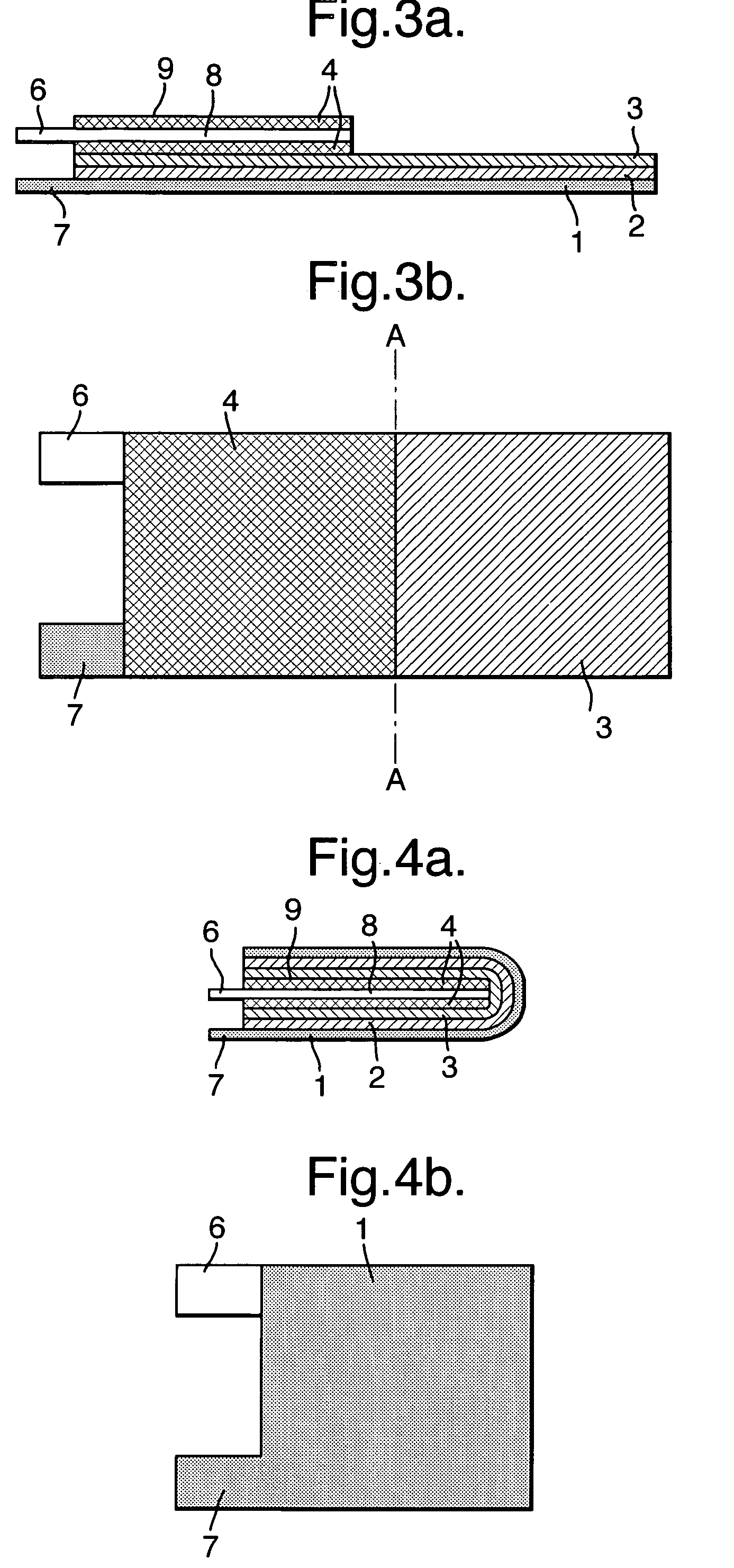

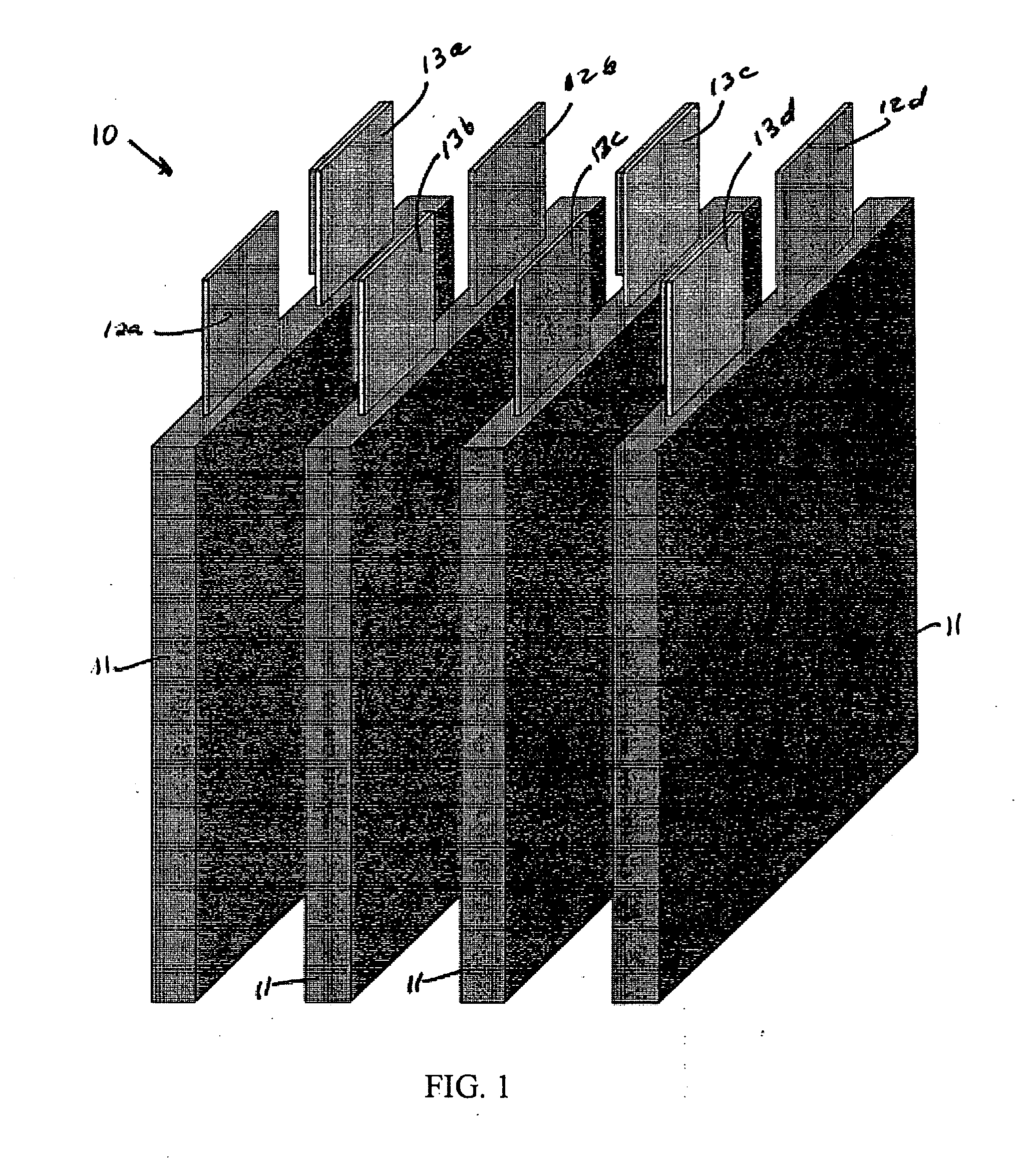

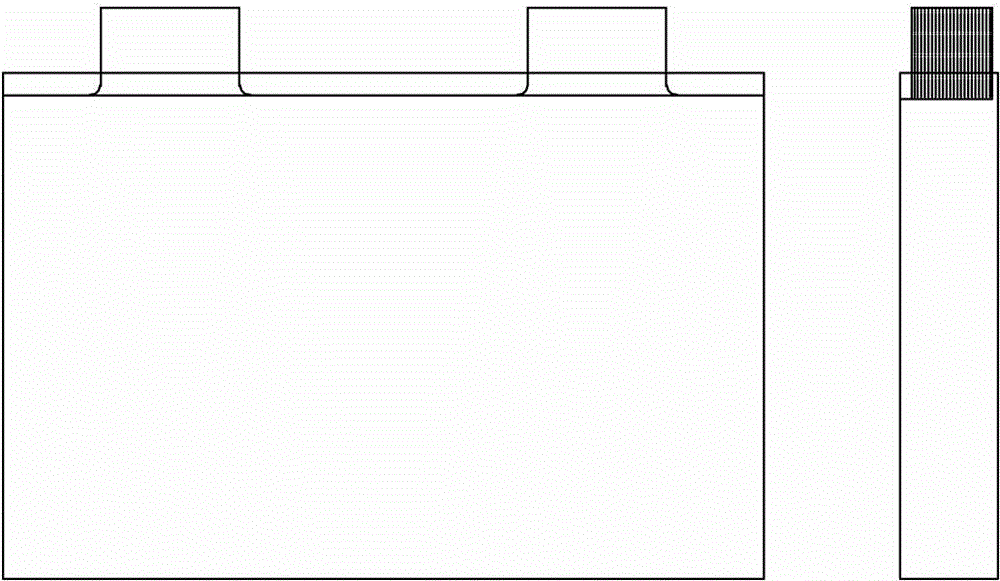

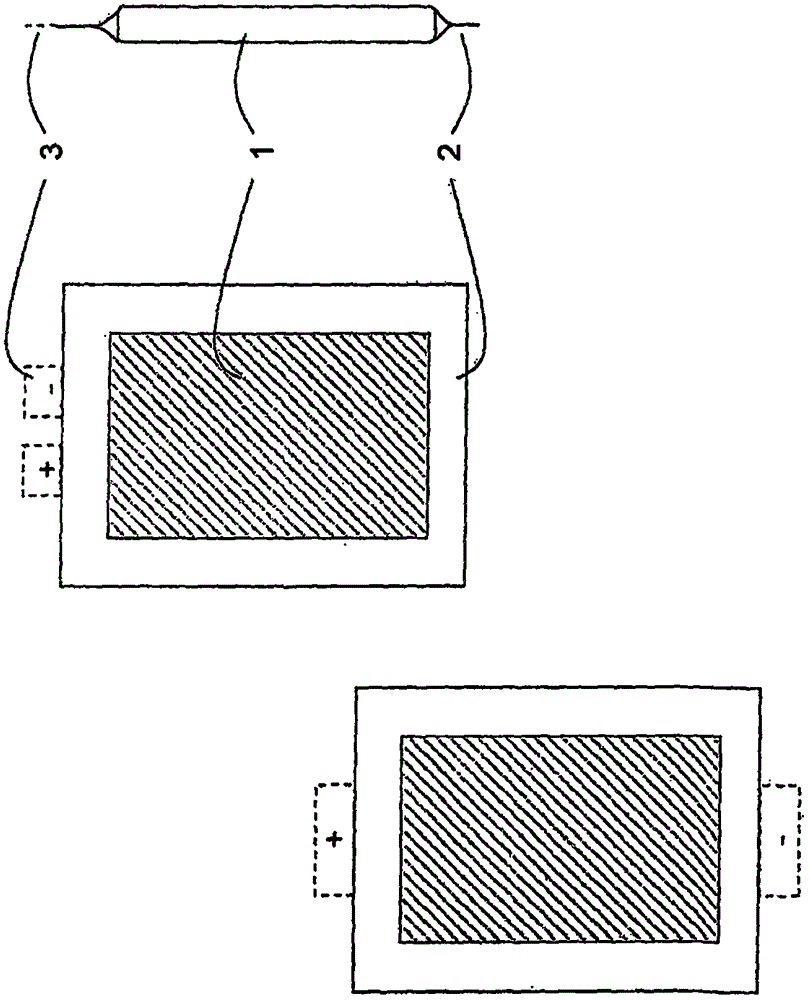

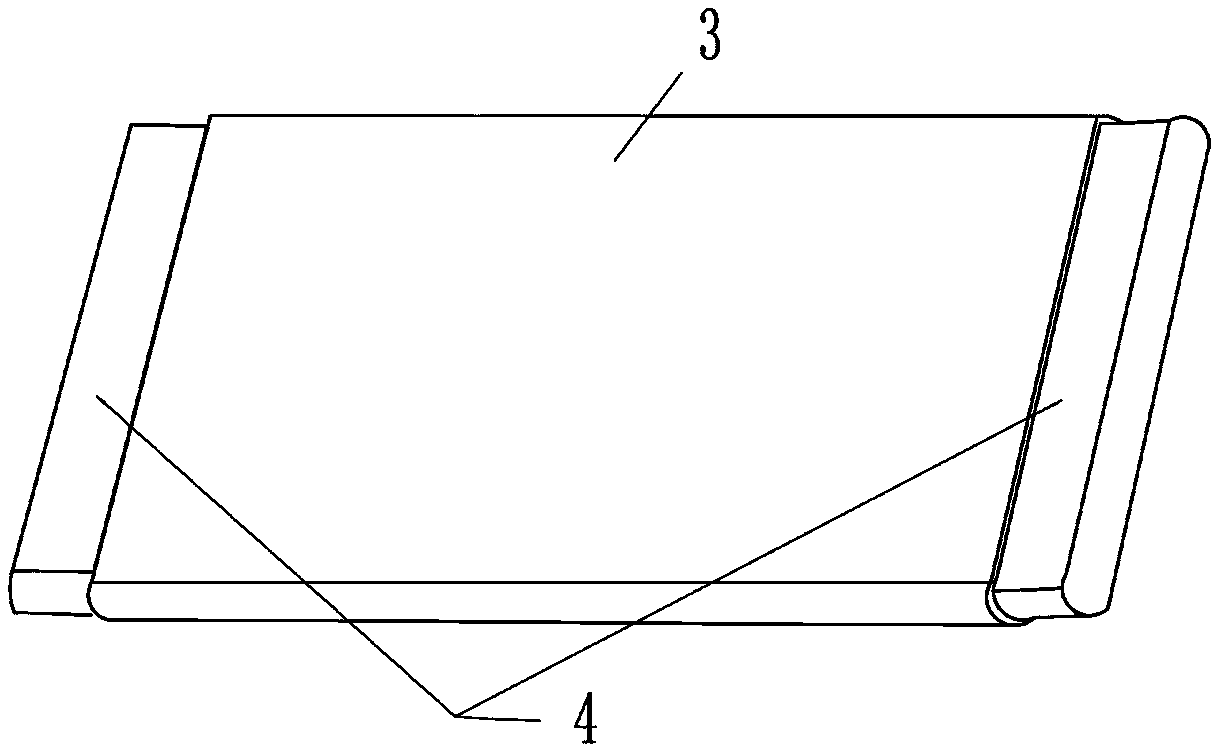

Pouch cell construction

ActiveUS7629077B2Increase energy densityReduce resistancePrimary cell maintainance/servicingFinal product manufactureEngineeringPouch cell

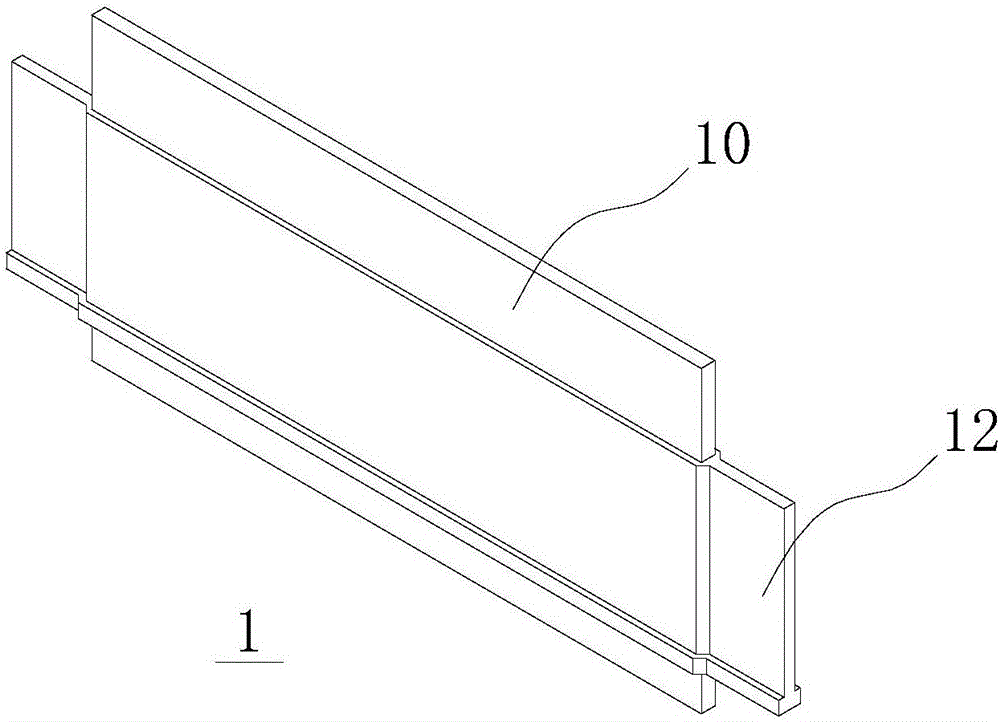

An electrode assembly is formed by respectively overlaying a sheet cathode 1, a sheet separator 3 and a double-sided sheet anode 8 to form a stacked structure 10, and subjecting the stacked structure to multiple folds, wherein the initial fold comprises folding the cathode in half around the double-sided anode so as to surround the respective upper and lower active anode surfaces thereof. The multiple folds may comprise one or more subsequent parallel folds made with the fold line D-D extending perpendicular to the original length of the stacked structure such that its overall length is halved at each fold. A pouch battery comprising said electrode assembly has improved safety and performance characteristics. The pouch battery construction has especial application to lithium primary batteries.

Owner:QINETIQ LTD

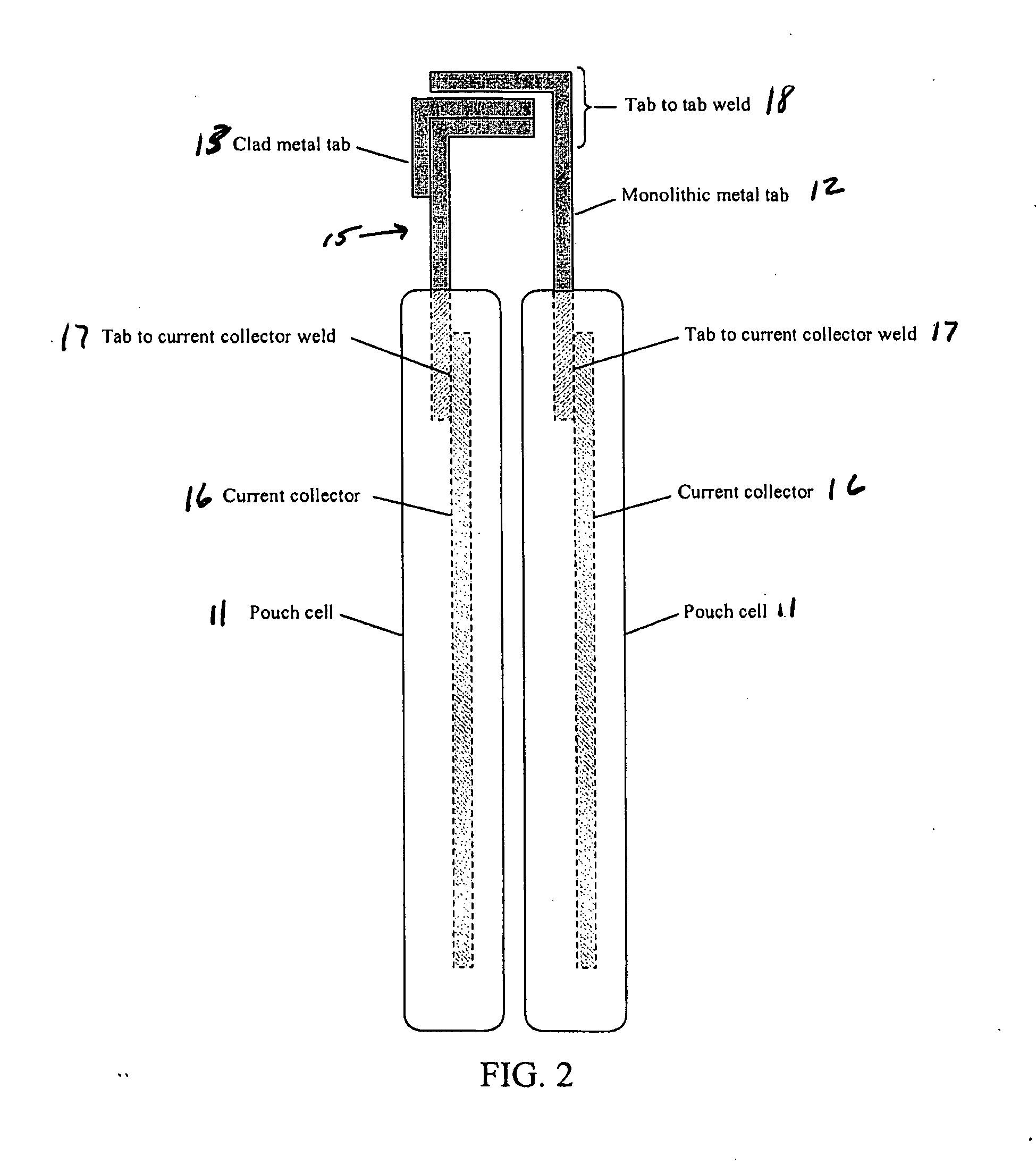

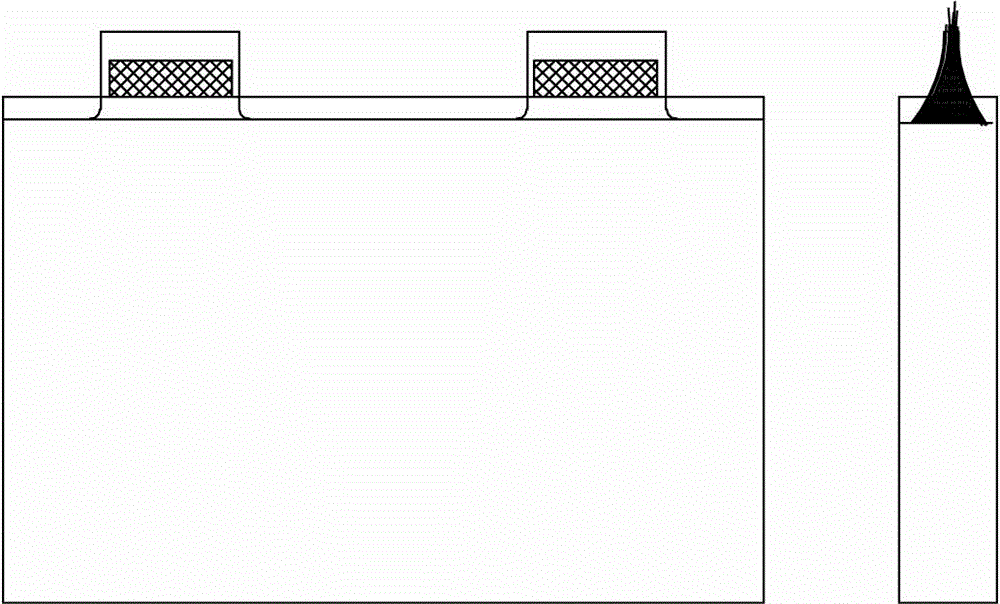

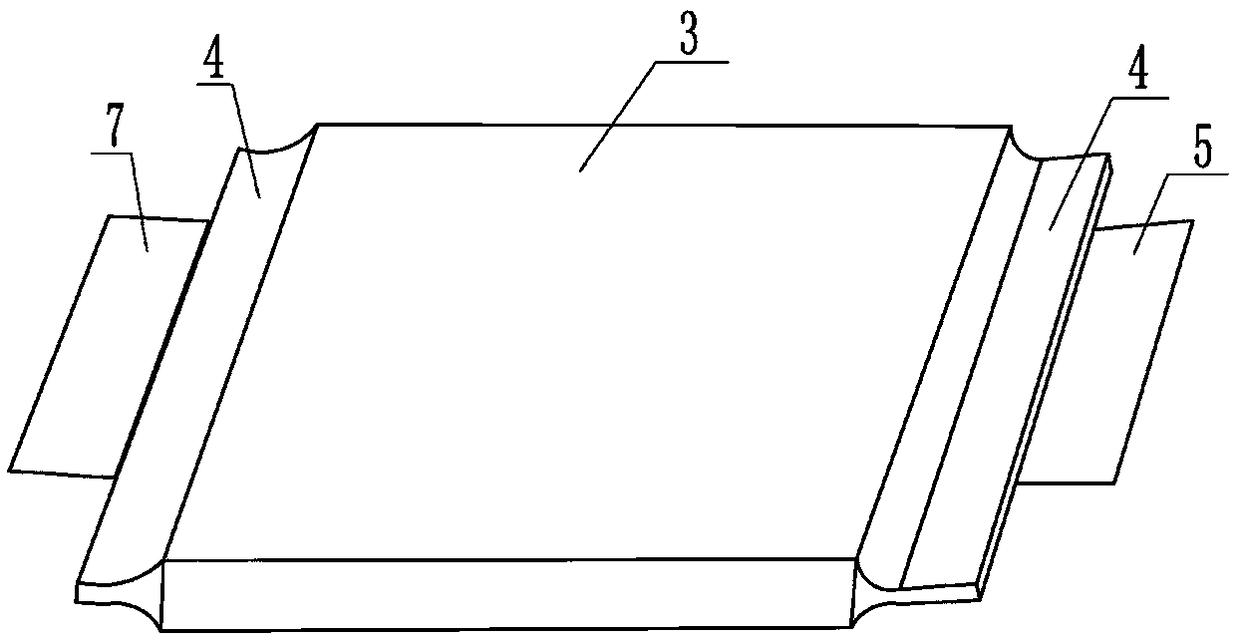

Battery Tabs and Method of Making the Same

InactiveUS20110274964A1Improve corrosion resistanceLess-robustPrimary cell to battery groupingCell electrodesMechanical millingEngineering

A terminal for a Li-ion battery cell utilizes a bimetallic strip formed from the materials used as the Li-ion cell current collectors, such as copper and aluminum. The bimetallic strip is to be used as, at least one, of the Li-ion pouch cell terminals. At least one portion of the bimetallic strip has one of the metallic components removed by such means as chemical or electrochemical etching, mechanical milling, skiving, or grinding, the remaining component being connected to the collector and the other end of the strip serving as the terminal.

Owner:EMS ENGINEERED MATERIALS SOLUTIONS LLC

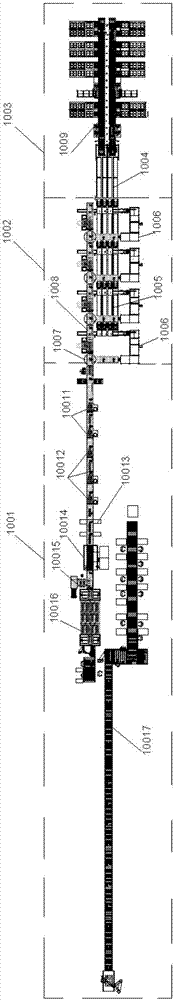

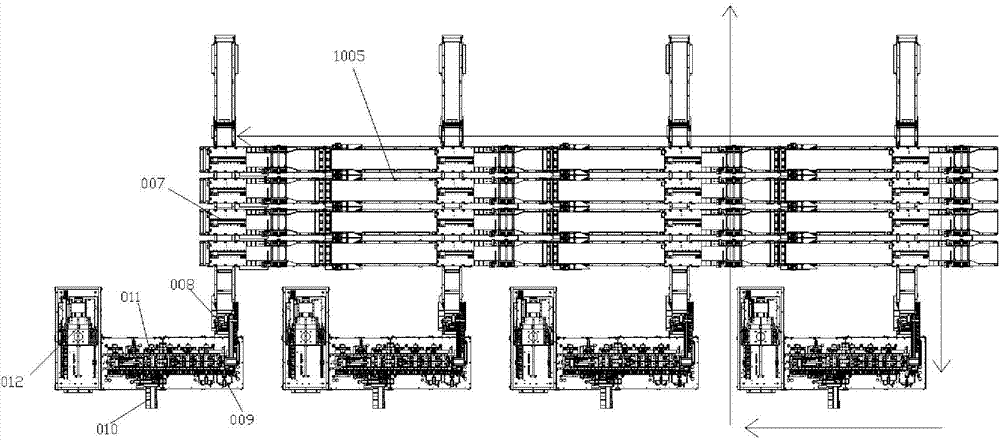

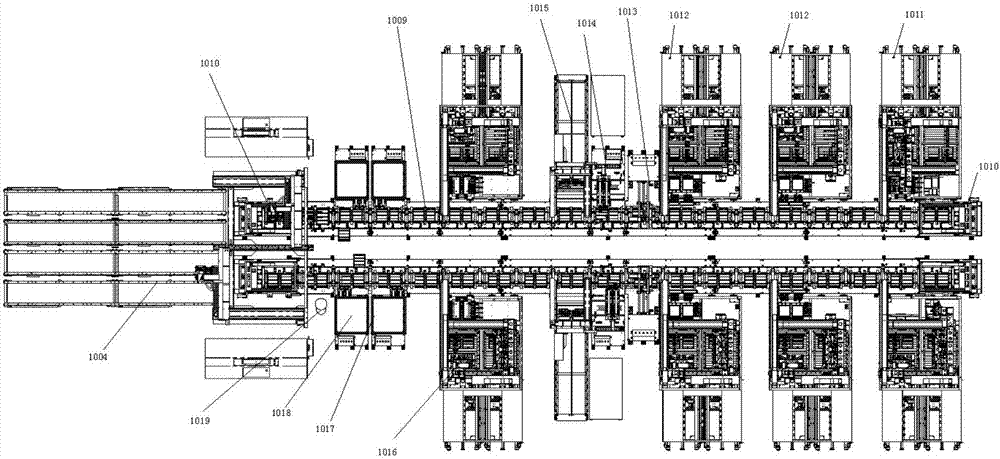

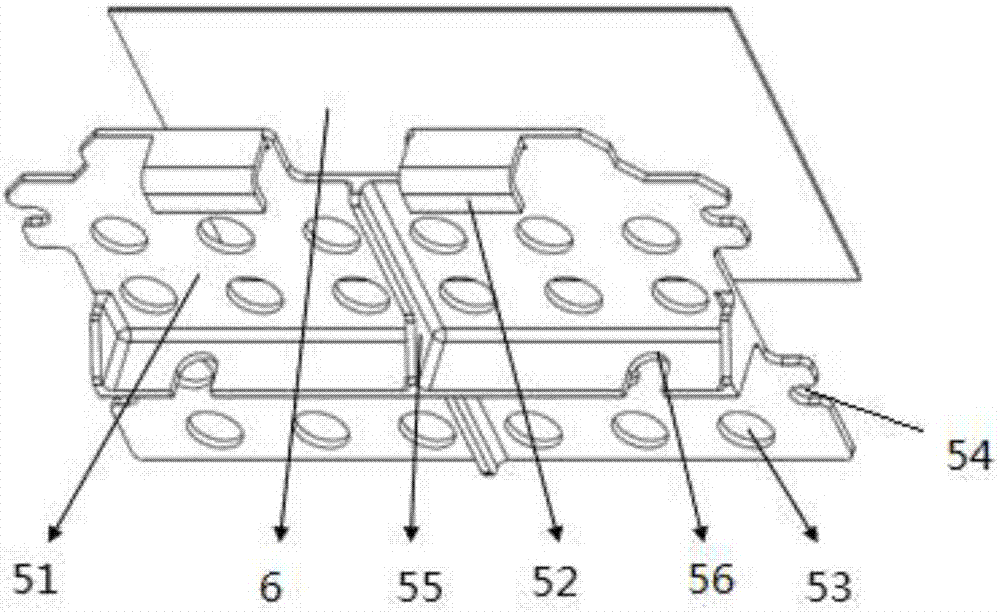

Soft packaging lithium battery PACK production line

PendingCN107171014AAvoid short circuitEasy to sortAssembling battery machinesFinal product manufacturePouch cellManufacturing line

The invention discloses a soft packaging lithium battery PACK production line, which comprises a soft packaging PACK classification cache section, a soft packaging PACK stacking section and a soft packaging PACK sorting section, wherein the discharging end of the soft packaging PACK classification cache section is connected with the soft packaging PACK stacking section; the other end of the soft packaging PACK stacking section is connected with the soft packaging PACK sorting section through four soft packaging battery conveying lines. The soft packaging PACK production line uses a pneumatic device for secondary positioning; the power is transmitted through a guide rail; the fast positioning of a work plate (dual-positioning) can be realized; the positioning is firm and reliable; the mounting and the dismounting are convenient and fast; a clamp block is durable; the positioning precision is high; the work efficiency is greatly improved; the soft packaging PACK sorting section uses two-chain conveyance and a dual-back-flow mode; the yield is doubled; the production efficiency is improved. The soft packaging PACK stacking section uses four-belt line conveyance and four-stacking-section operation; the efficiency is improved.

Owner:广东光博智能科技有限公司

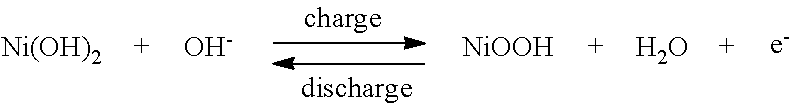

Alkaline and non-aqueous proton-conducting pouch-cell batteries

ActiveUS20160233461A1Easy to understandBatteries circuit arrangementsFinal product manufactureProtonEngineering

Provided are sealed pouch-cell batteries that are alkaline batteries or non-aqueous proton-conducing batteries. A pouch cell includes a flexible housing such as is used for pouch cell construction where the housing is in the form of a pouch, a cathode comprising a cathode active material suitable for use in an alkaline battery, an anode comprising an anode active material suitable for use in an alkaline battery, an electrolyte that is optionally an alkaline or proton-conducting electrolyte, and wherein the pouch does not include or require a safety vent or other gas absorbing or releasing system as the anode active material and the cathode active material do not increase the internal atmospheric pressure any more than 2 psig during cycling. The batteries provided function contrary to the art recognized belief that such battery systems were impossible due to unacceptable gas production during cycling.

Owner:OVONIC BATTERY CO INC

Soft cell module

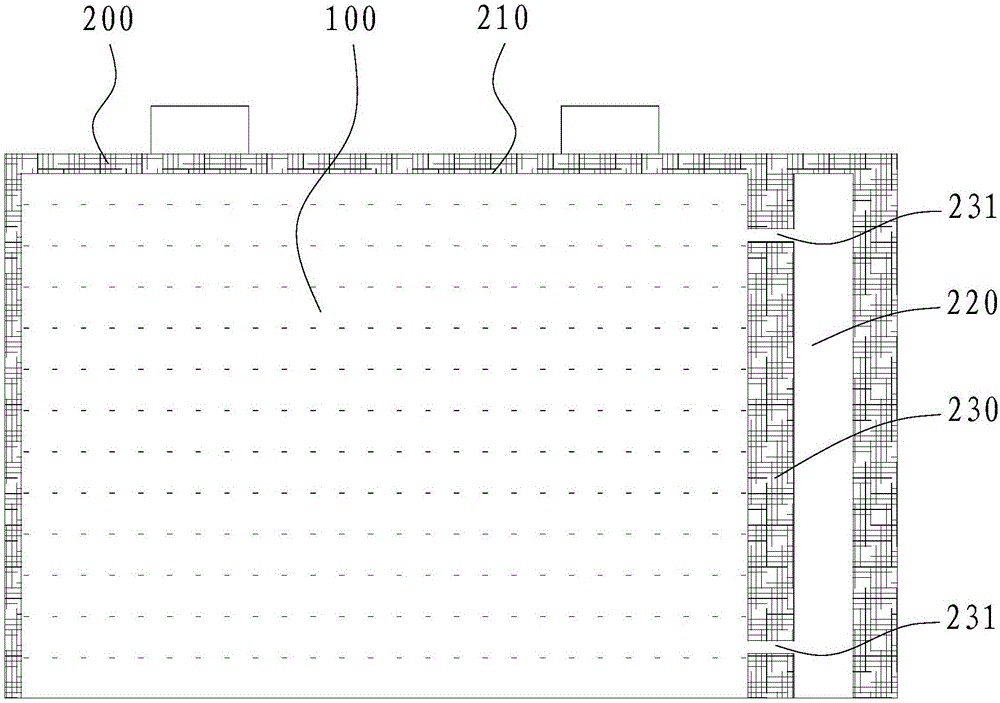

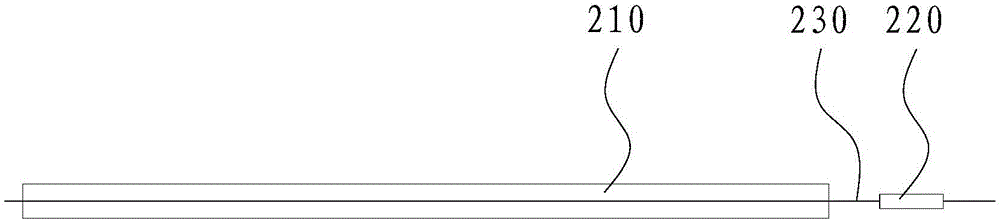

PendingCN109411667AReduce weightReduce the use temperatureSecondary cellsCell component detailsBusbarAdhesive

The invention discloses a soft cell module. The module comprises a bottom plate, a protecting frame assembly, at least two soft cores which are parallelly arranged, at least one first insulation panel, at least on second insulation panel, at least one first busbar which is used for leading out positive electrodes of each soft core and at least one second busbar which is used for leading out negative electrodes of each soft core. A first adhesive fills the gaps between the insulation panels and the busbars and the gaps between the busbars and the soft cores, the insulation panels and side plates are bonded through a second adhesive, outer frames and other structural components used for fixing in an existing cell module can be replaced with the first adhesive and the second adhesive, and therefore the weight of the soft cell module is greatly reduced while the structure of the cell module is ensured. The bottoms of the soft cores are connected with the bottom plate through a heat thermalconductive adhesive to achieve the uniform heat dissipation of the cores and the reduction of the using temperature of the cell module.

Owner:广州市垠瀚能源科技有限公司

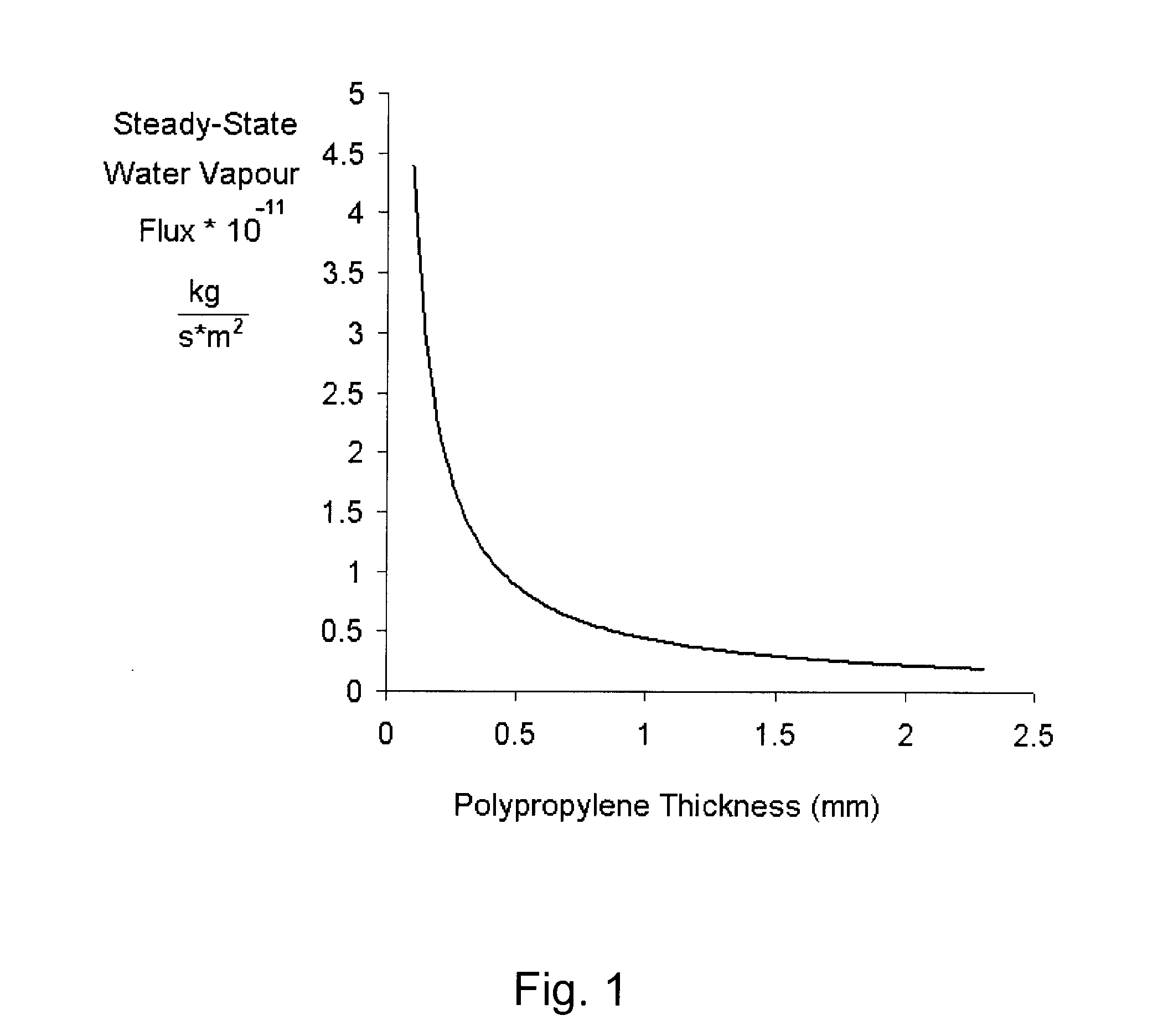

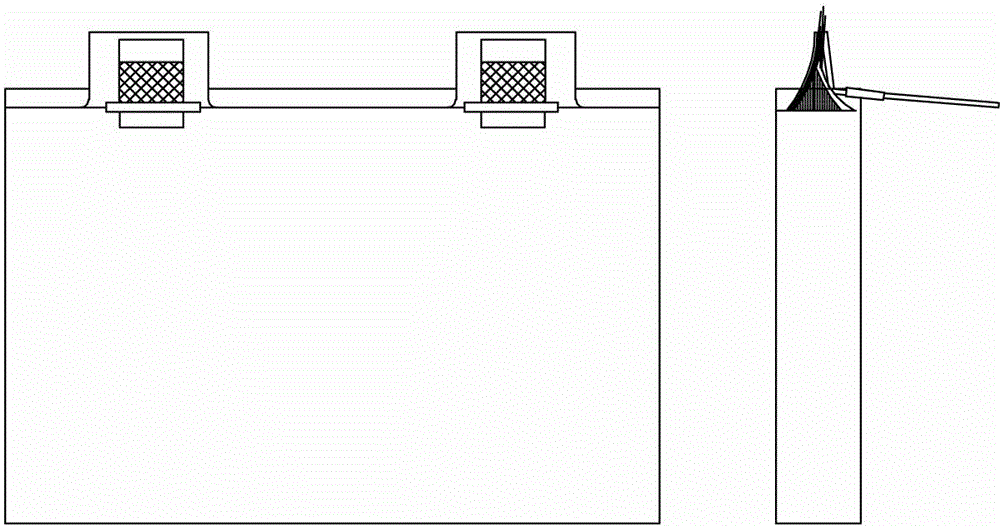

Barrier layer coatings for battery pouch cell seal

ActiveUS20160336552A1Improve hydrophobicityImprove surface roughnessFinal product manufactureJackets/cases materialsEngineeringPouch cell

A prismatic battery cell and a method of making such a cell. The cell includes one or more anode regions, one or more cathode regions, an electrolyte region to facilitate ion flow between the anode and cathode regions, electrically-conductive tabs attached to the corresponding anode and cathode regions, and a pouch-like containment formed around the regions. The containment is made up of a pair of facing substantially planar surfaces sealingly joined to one another. A barrier layer coating is made up of at least one low-permeability material and is placed over at least a portion of the cell edge that is defined by the joined surfaces such that the barrier layer coating blocks ambient gases or vapors from passing through the relatively gas-permeable heat seal region that is used to join the pouch surfaces. The barrier layer coating may also include one or more hydrophobic surface treatments or enhancements, including in one form an additional layer of surface treatments to funtionalize the surface and in another form by surface roughening.

Owner:GM GLOBAL TECH OPERATIONS LLC

Fabrication method of soft pack battery

ActiveCN109449474AImprove yieldAvoid damageFinal product manufactureSecondary cells manufactureEngineeringPlastic film

The invention relates to a fabrication method of a soft pack battery. The fabrication method comprises the following steps of 1) pasting two side thickness surfaces of a lamination battery cell with adhesive tapes; 2) performing top sealing on the top of the battery cell with a tab by an aluminum plastic film, performing side sealing on one of the side thickness surfaces of the battery cell, allowing the other side thickness surface of the battery cell to face an air bag mouth packaged by the aluminum plastic film, and locally packaging the aluminum plastic film at a downstream of an adhesivetape pasting position on the other side thickness surface along an air exhaust direction; and 3) performing liquid injection, primary sealing, formation, air pumping and secondary sealing after localpackage, thereby obtaining the soft pack battery. According to the fabrication method of the soft pack battery, provided by the invention, local package is performed on the aluminum plastic film aftertop sealing and side sealing of the battery cell, so that the adhesive tape is prevented from being directly sucked during the subsequent air pumping process, the stress to the adhesive tape during the air pumping process is reduced, and the pasting failure of the adhesive tape is prevented.

Owner:DO FLUORIDE NEW ENERGY TECHNOLOGY CO LTD

Pouch battery module

ActiveCN110289376ALarge thermal resistanceEnsure consistencySecondary cellsCell component detailsThermal insulationAdhesive

The invention relates to a pouch battery module comprising a module bottom plate and a battery unit, wherein the battery unit comprises two parallel pouch battery cells and a fixing bracket for fixing the pouch battery cells; a fireproof insulating thermal insulation layer is disposed between the two pouch battery cells; a heat-conducting aluminum plate is disposed on the outer side of the fixing bracket and is closely attached to the pouch battery cells; an outer side of the heat-conductive aluminum plate is covered with an insulating protective film; the module bottom plate is provided with a groove that is engaged with the fixing bracket and the heat-conducting aluminum plate; and the bottom of the heat-conducting aluminum plate is fixed to the module bottom plate by a thermal conductive adhesive. The pouch battery module can delay the process that the thermal runaway of a normal battery cell is triggered by the thermal runaway of an adjacent battery cell in the extreme case, and can quickly release the thermal runaway energy by a liquid cooling system in the extreme case, thereby effectively extending the overall thermal runaway time of the battery module and a battery system and ensuring the personal safety of passageers on an electric vehicle.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Soft-packed battery module and assembling method thereof

ActiveCN111341954AOvercoming the problems caused by expansionGuaranteed reliabilityFinal product manufactureCell lids/coversEngineeringStructural engineering

The invention discloses a soft-packed battery module and an assembling method thereof. The soft-packed battery module comprises a battery cell group, and left and right side plates, upper and lower cover plates and front and rear end covers which are arranged on the outer side of the battery cell group. The left and right side plates and the upper and lower cover plates or the left and right sideplates and the front and rear side plates are adjustably and detachably connected in a matched manner to tightly press the internal battery cell group, so that the left and right side plates are continuously restrained by the upper and lower cover plates or the left and right side plates to generate pressure for clamping battery cells so as to tightly press the battery cells, and the pressure is 5-300kPa. The left and right side plates, the upper and lower cover plates and the front and rear end covers are detachably connected to package the battery cells to form the soft-packed battery module. The battery cell group comprises foam, the left and right side plates are parallel to or consistent with the plane of the battery cells in direction, and the front and rear side plates are verticalto the left and right side plates and the horizontal plane. According to the battery module, the overall reliability is greatly improved, and the assembly efficiency of the battery module is high.

Owner:SUZHOU QINGTAO NEW ENERGY TECH CO LTD

Method for improving hardness and toughness of flexibly-packaged battery

InactiveCN102653656AHigh hardnessImprove toughnessFinal product manufactureElectrolyte accumulators manufactureManufacturing technologyKetone solvents

The invention discloses and provides a method capable of improving wrinkle-resistant capability of an ultrathin battery greatly. The method provided by the invention comprises the following steps: taking an alcohol or ketone matter as a solvent, adding one kind or multiple kinds of alcohol soluble or ketone soluble resin slowly into the solvent according to certain proportion at the normal temperature under the condition of high-speed stirring, wherein stirring times lasts for 15-60 minutes; adding a defoaming agent and a flatting agent to the mixed solution and stirring uniformly; adding alcohol or ketone solvent continuously so as to adjust the viscosity of the mixed solution, and stirring for 10-60 minutes, thus obtaining a resin solution; uniformly spraying the obtained resin solution between an ultrathin battery electrode plate and an aluminum plastic film by a spraying gun; and standing the ultrathin battery processed by the above steps at the normal temperature or standing and drying in an anaerobic sealed vacuum box at a high temperature, wherein the drying time depends on the thickness of the sprayed resin. The method capable of improving wrinkle-resistant capability of the ultrathin battery greatly provided by the invention can be widely applied to the field of manufacturing technology of lithium batteries.

Owner:珠海格力新能源科技有限公司

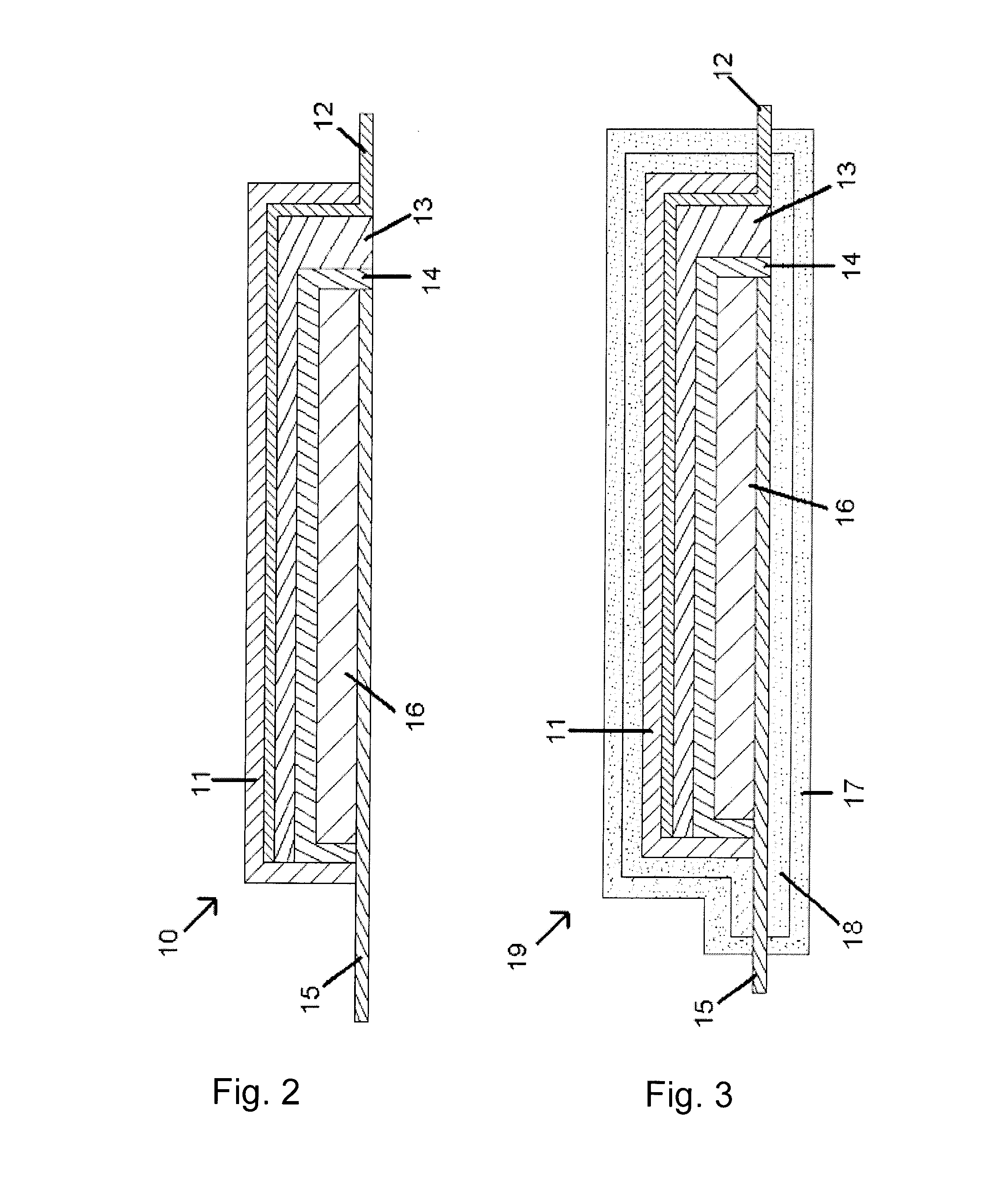

Thin film electrochemical cell with a polymer double seal

ActiveUS20140363721A1Increasing the thicknessBulky to transportCell temperature controlCell sealing materialsOptoelectronicsElectrochemical cell

A double-sealed thin film electrochemical pouch cell, comprising a cathode current collector, a cathode, an electrolyte, an anode, and an anode current collector, which is double-sealed by a first inner laminate layer forming a primary seal covered by a second outer polymer layer forming a secondary seal. The second outer polymer layer comprises embedded particles to increase the thermal conductivity of the second outer polymer layer.

Owner:ELECTROVAYA

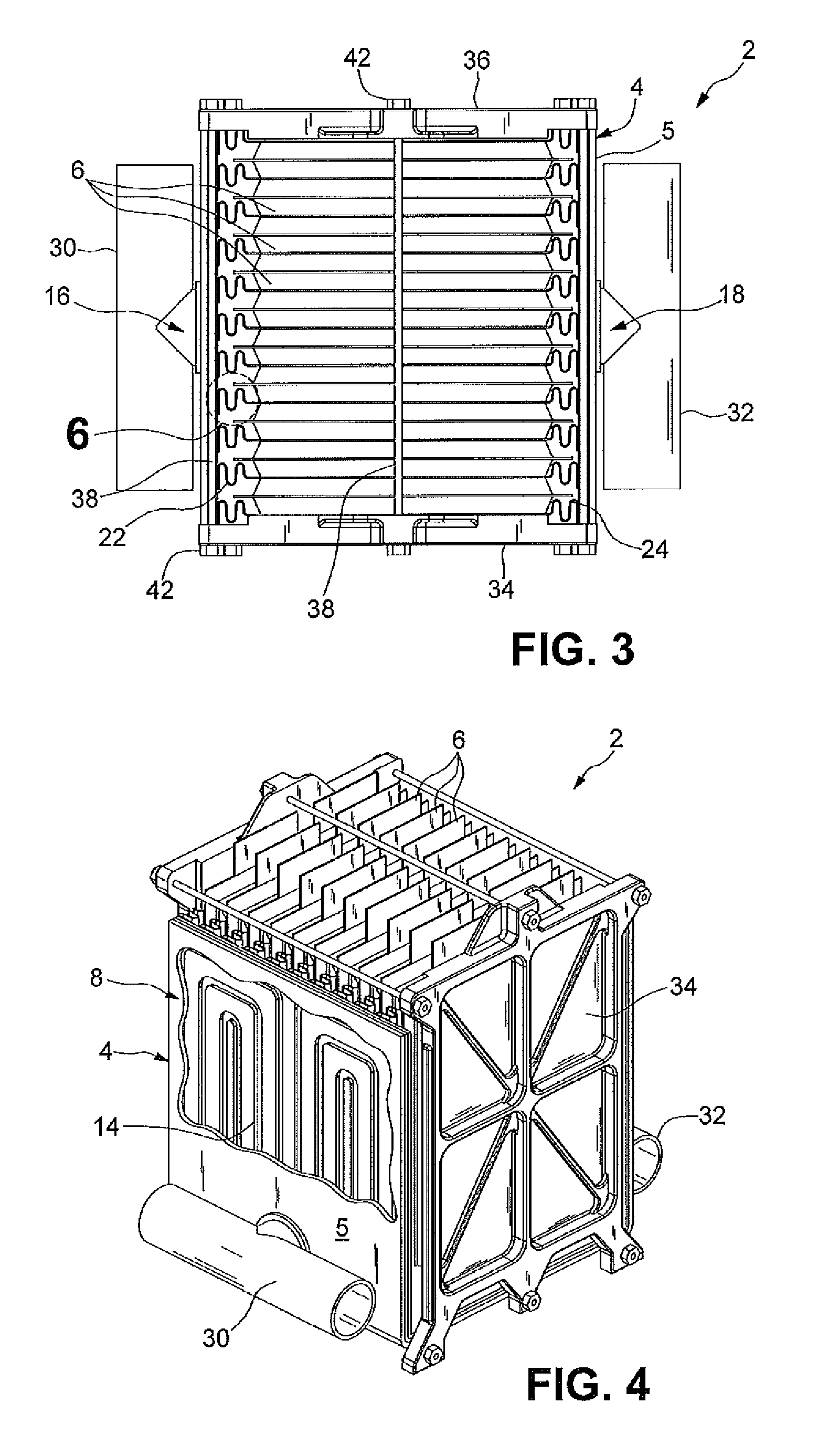

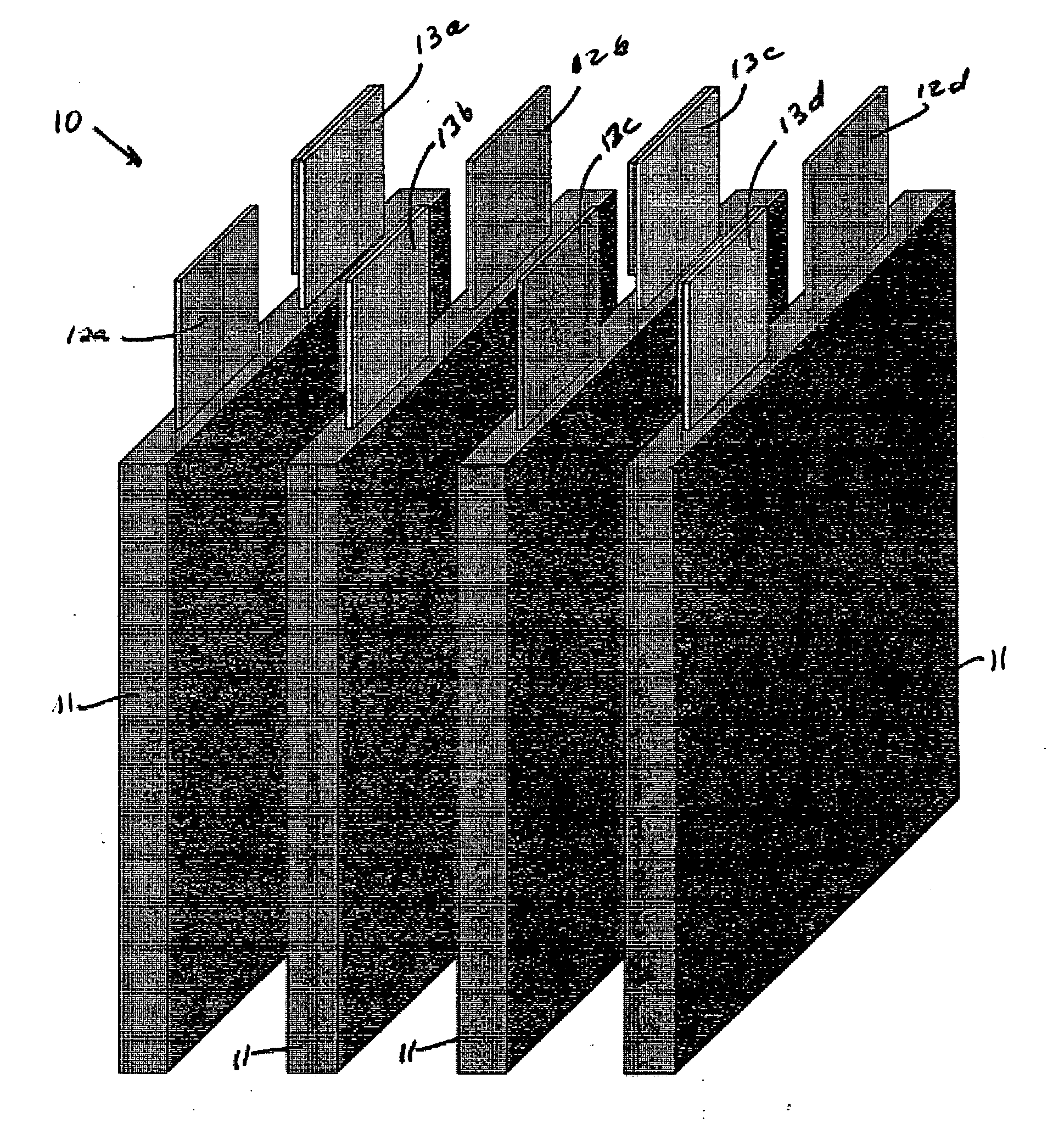

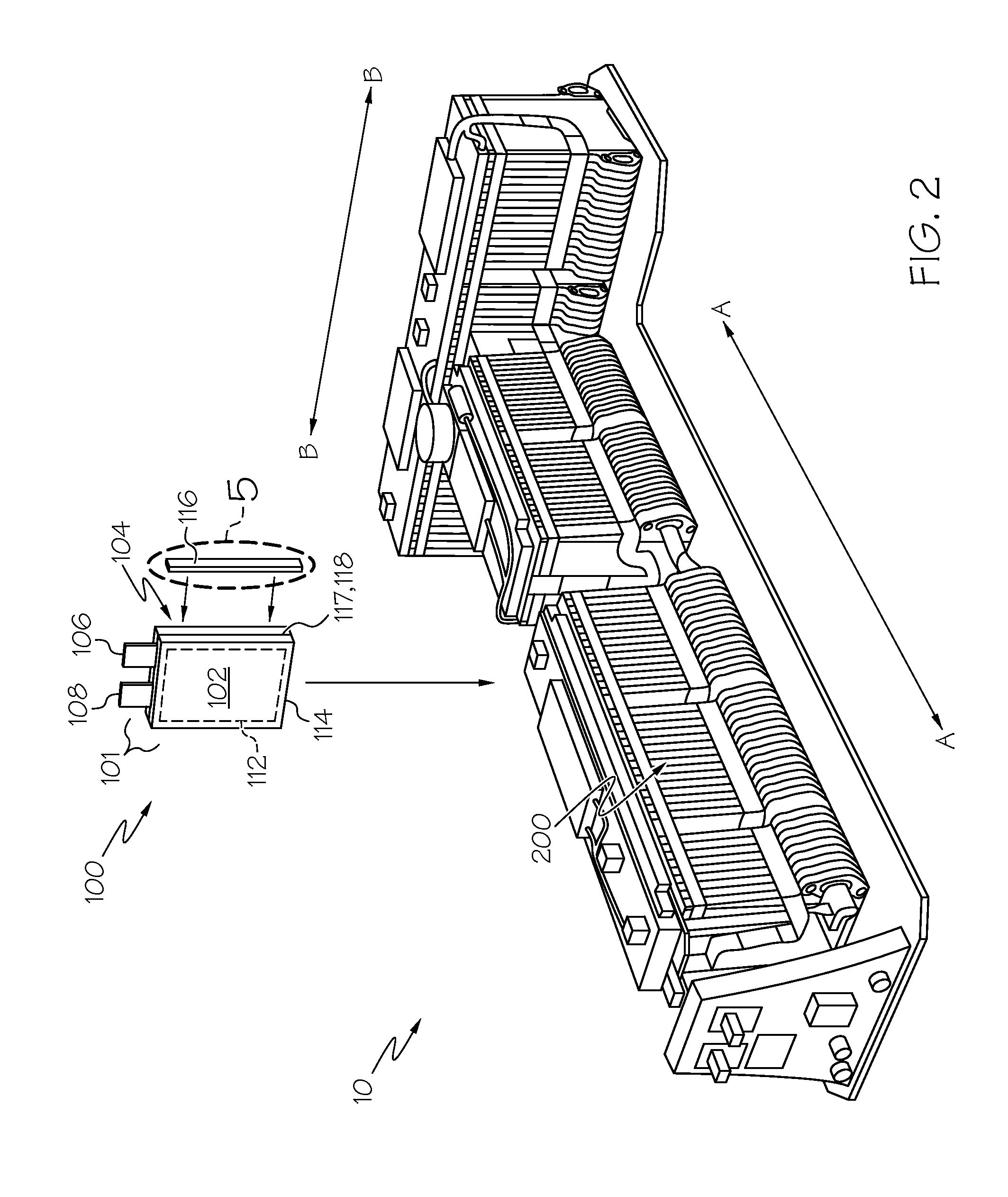

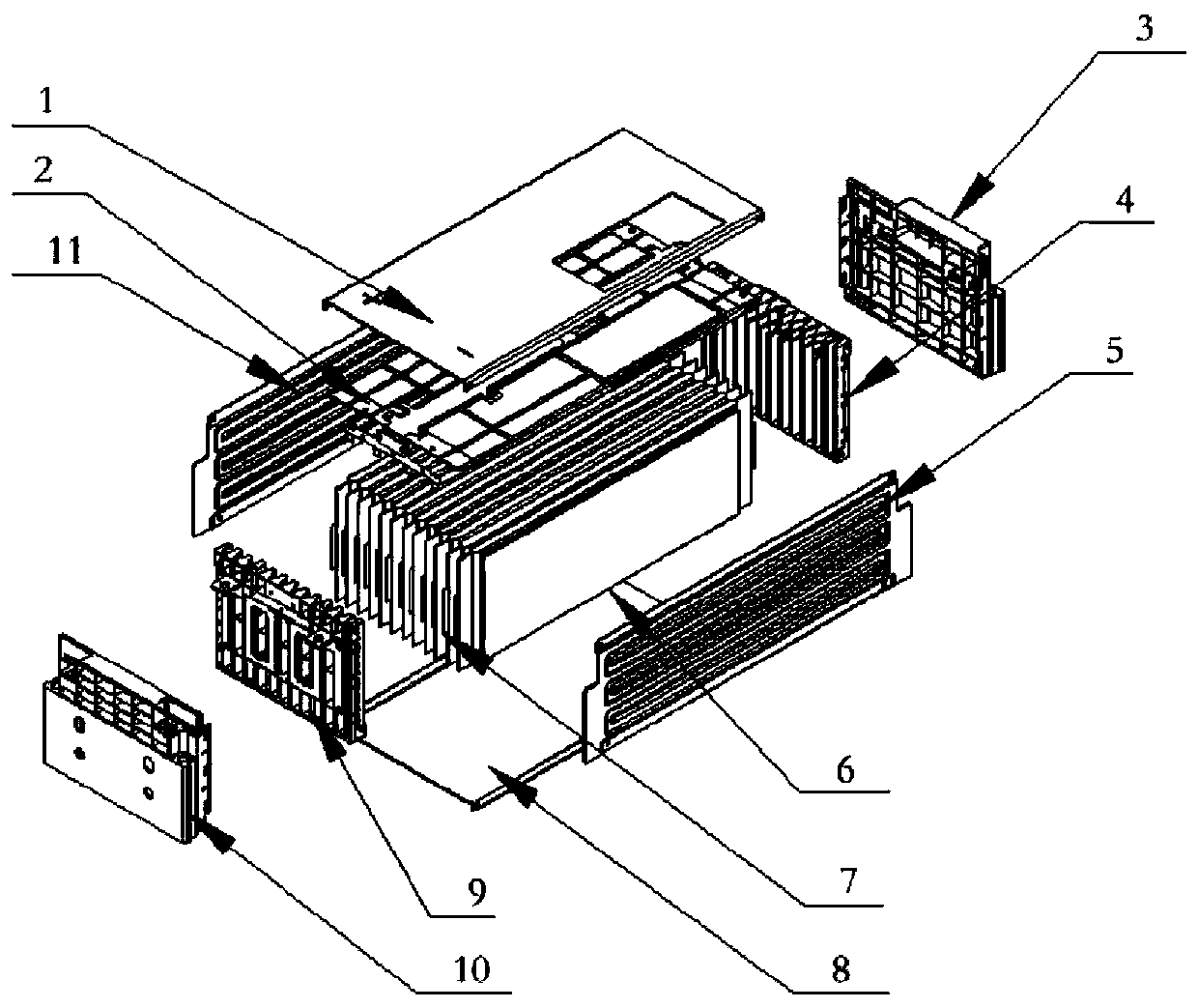

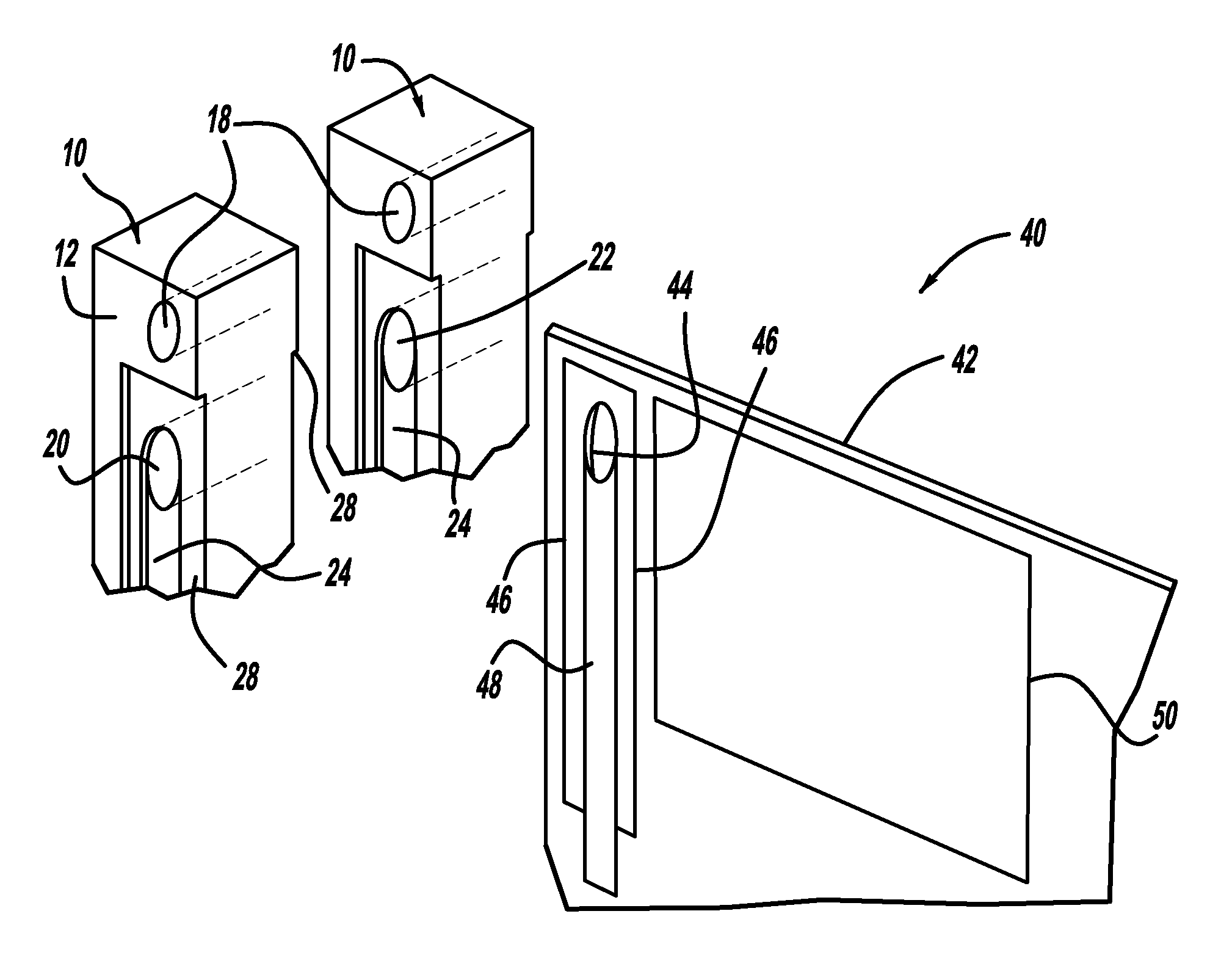

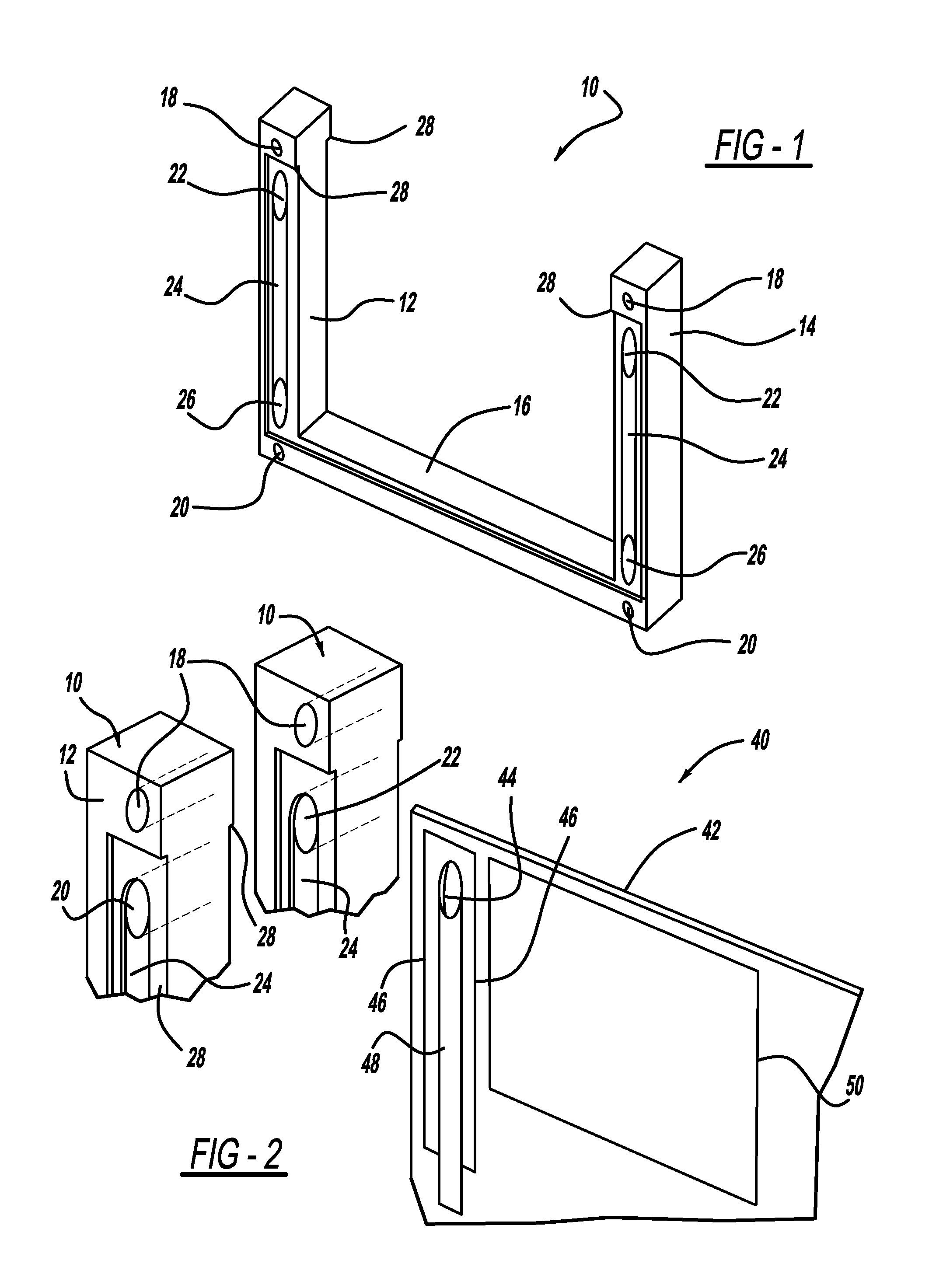

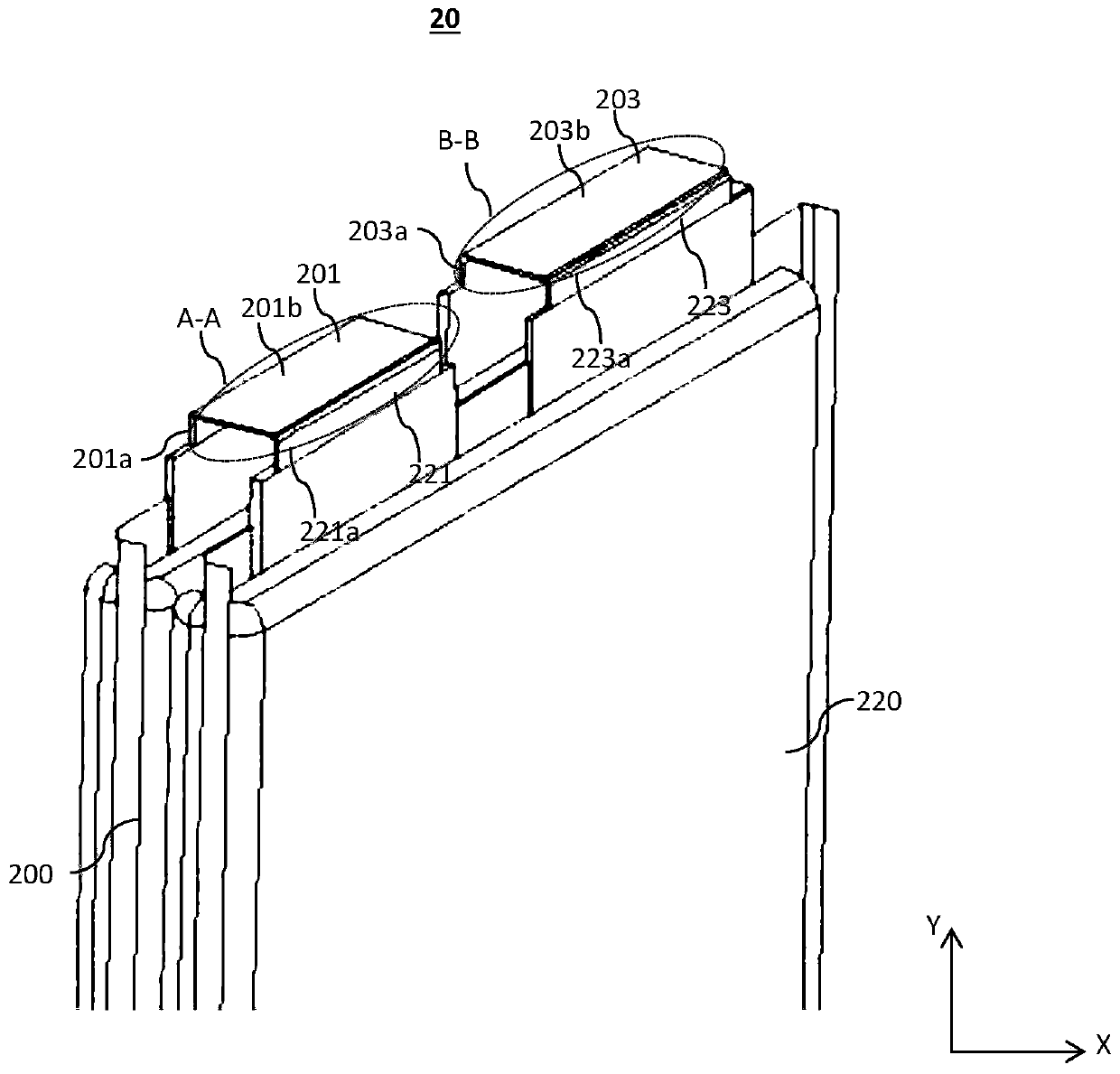

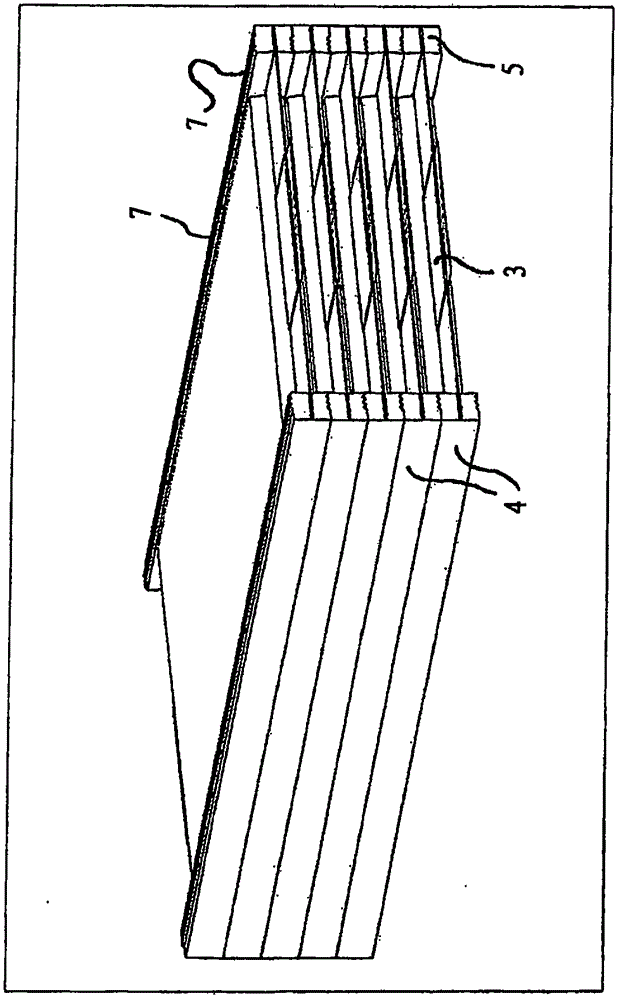

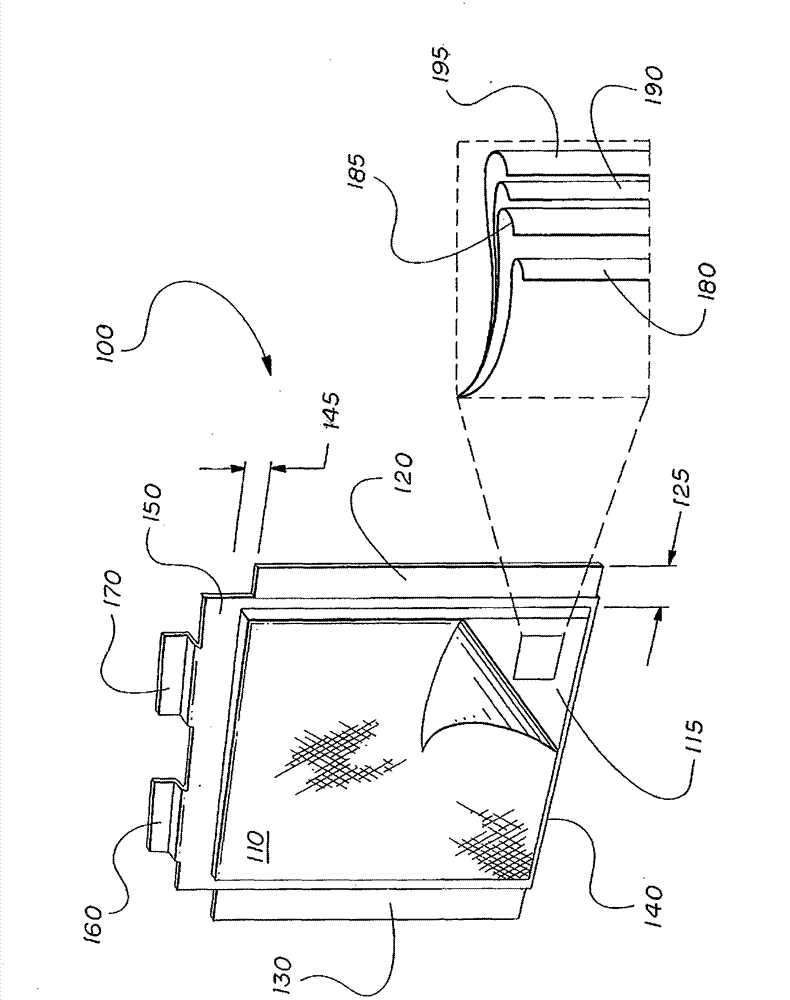

Modular plate carrier concept for mounting and embedded cooling of pouch cell battery assemblies

ActiveUS20120040225A1Final product manufactureSmall-sized cells cases/jacketsComputer moduleEngineering

A modular assembly for housing battery cells. The modular assembly includes a plurality of U-shaped members having cooling fluid channels, where the U-shaped members are mounted together in a stacked manner. Each cooling fluid channel includes an inlet and outlet orifice, where the orifices in the stacked U-shaped members align with each other. The modular assembly also includes a plurality of thermally conductive carrier plates, where a battery cell is mounted to and between opposing carrier plates. Side edges of the carrier plates are mounted in opposing retention slots in opposing U-shaped members where a cooling fluid channel in the U-shaped member is provided within the retention slot so that a cooling fluid flowing through the cooling fluid channel and the U-shaped members contacts the carrier plates and draws heat therefrom.

Owner:GM GLOBAL TECH OPERATIONS LLC

Soft packed battery tab welding method

The invention discloses a soft packed battery tab welding method and provides a soft packed battery tab welding manner, which can improve the energy density of a soft packed battery and improve the manufacturing efficiency of the soft packed batteries. The method comprises the following steps: firstly, carrying out ultrasonic pre-welding to an incoming battery cell; bending an adhesive tab welding end for 90 degrees, and then ultrasonically welding the adhesive tab welding end to an exposed battery cell foil material pre-welded in the step a; cutting adhesive tabs and the battery cell foil material together; finally, bending a welding zone to a side surface of the battery cell for 90 degrees so as to enable the adhesive tabs to be parallel to the battery cell, and keeping the two adhesive tabs to be parallel. According to the tab welding method, the adhesive tabs are bent and deformed in advance, then welding and cutting are performed, the automation is easy to realize, foil material is prevented from being broken by tearing, the process is reasonable, and high-energy density and high production efficiency are achieved.

Owner:SHANDONG GOLDENCELL ELECTRONICS TECH

Method for verifying package reliability of soft-package battery

InactiveCN105591160AComprehensive and specific testHave pursuasive powerFinal product manufactureElectrolyte accumulators manufactureLiquid statePlastic film

A method for verifying package reliability of a soft-package battery comprises steps as follows: firstly, an aluminum-plastic film material is cut and then folded, one side is packaged by adhesive tab pieces, the other side is subjected to direct side seal, then a certain amount of electrolyte is injected, high-temperature placement is performed after packaging, liquid-state heat seal is performed close to the folded part, high-temperature placement is performed again, finally, package tension is detected by a detection piece with the width being 15 mm plus / minus 1 mm, and a battery package is judged to be qualified when the tension is larger than or equal to 34.5 N. The matching feasibility of aluminum-plastic films with tab materials, technologies and equipment can be characterized quickly, directly and actually with the method.

Owner:SHANDONG GOLDENCELL ELECTRONICS TECH

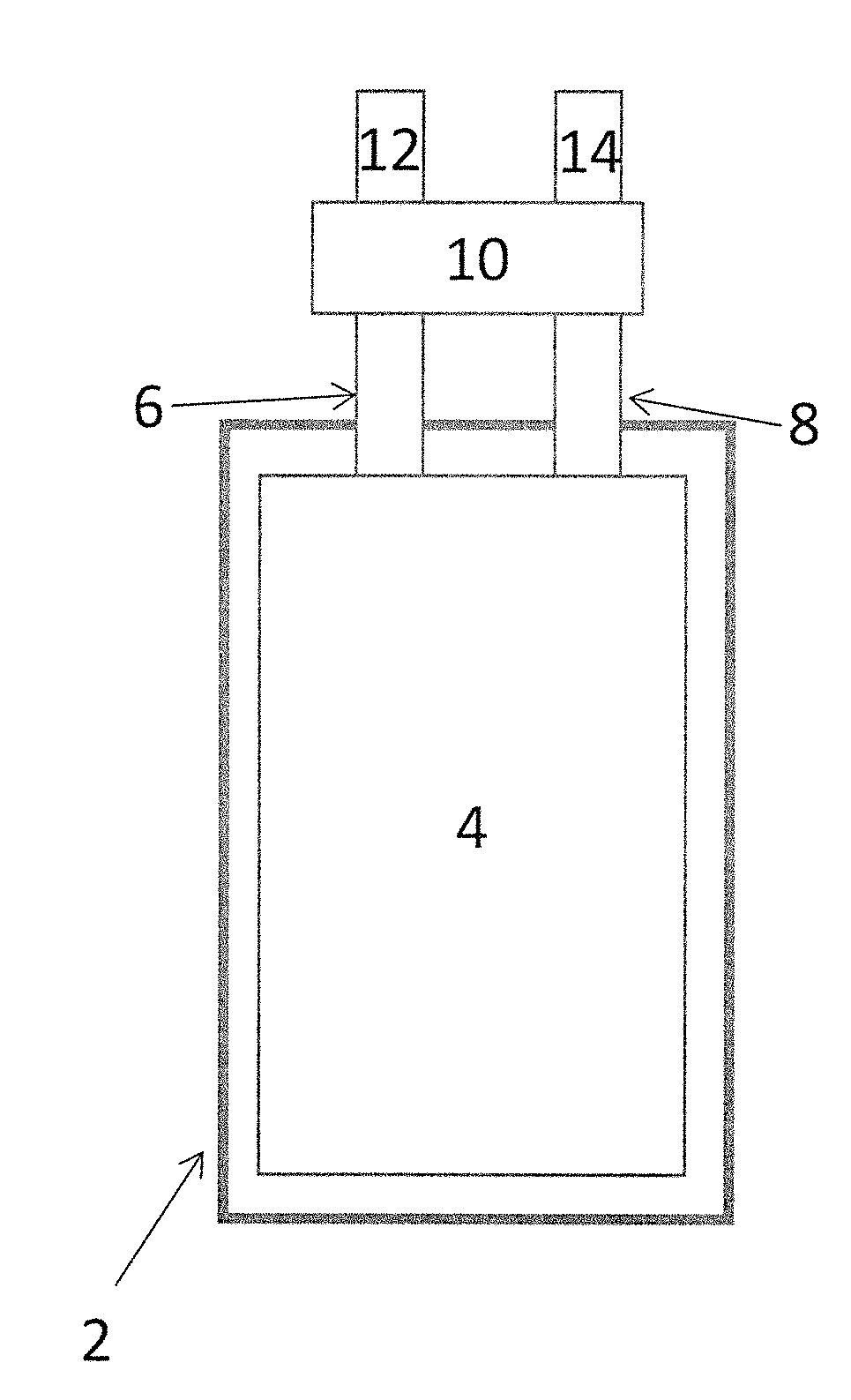

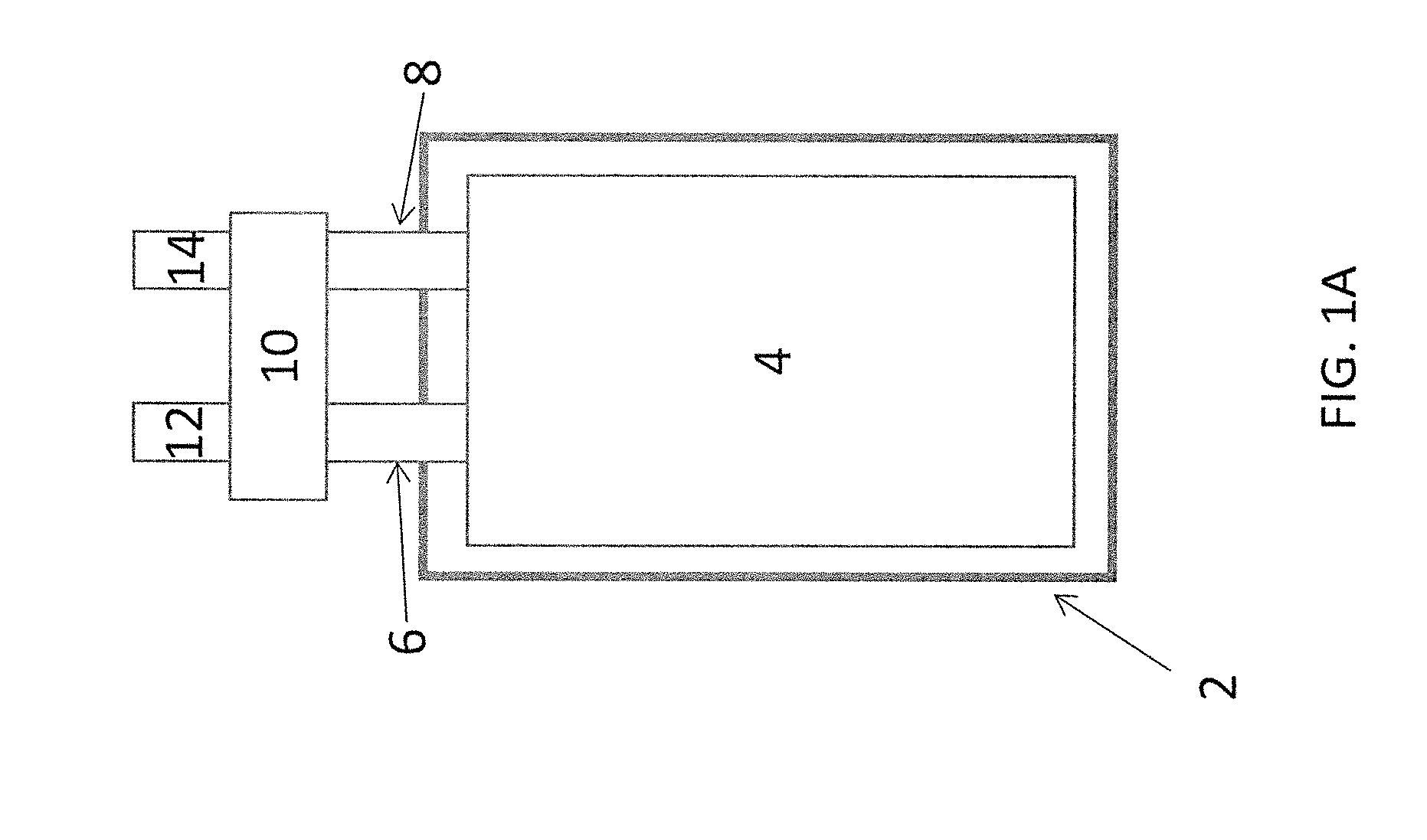

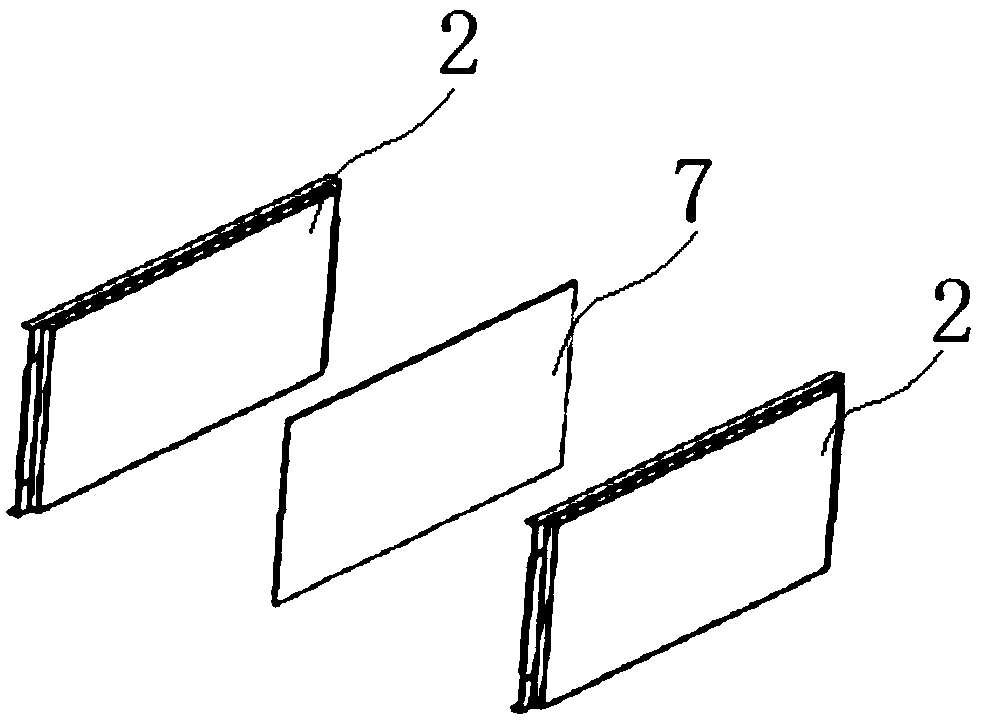

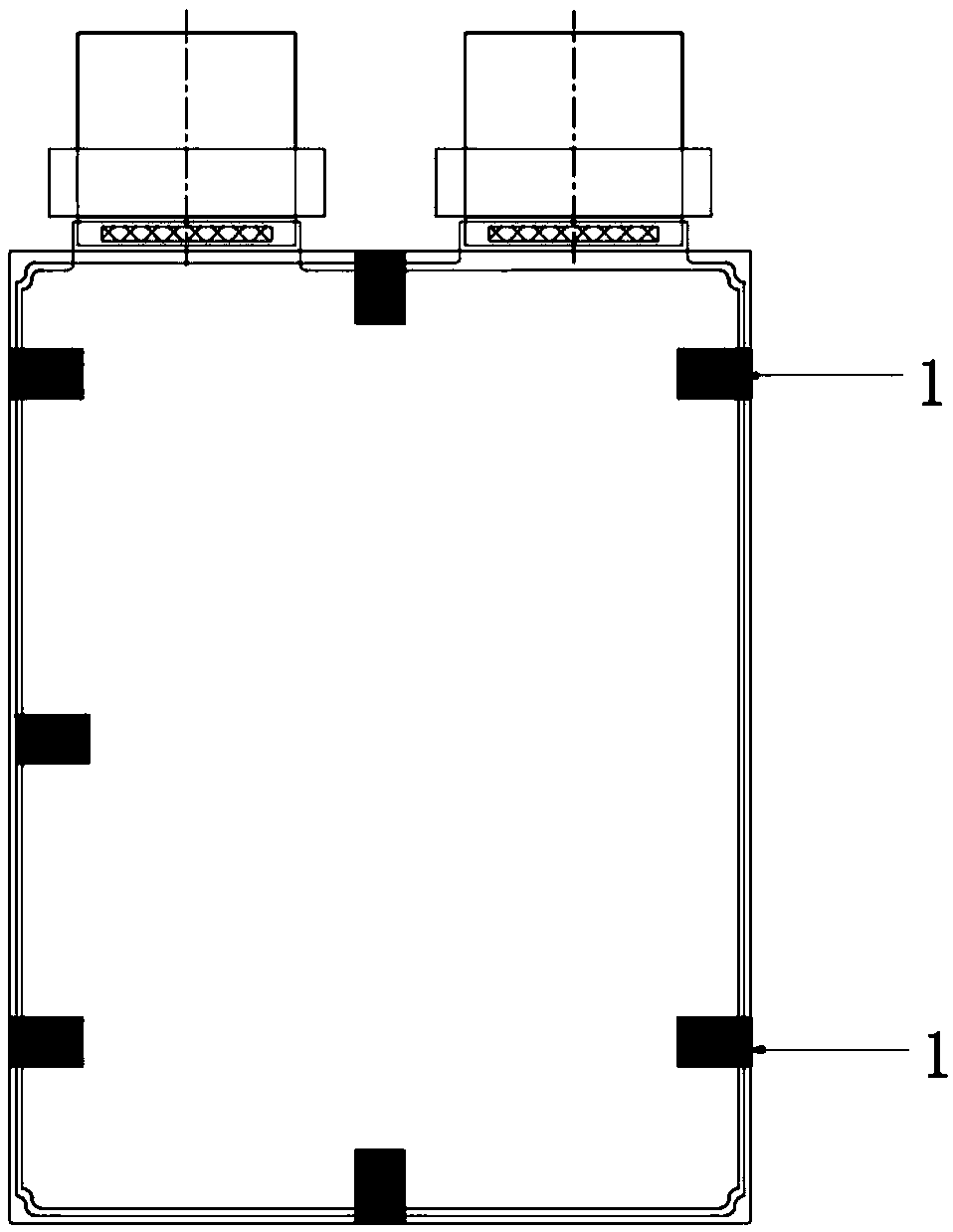

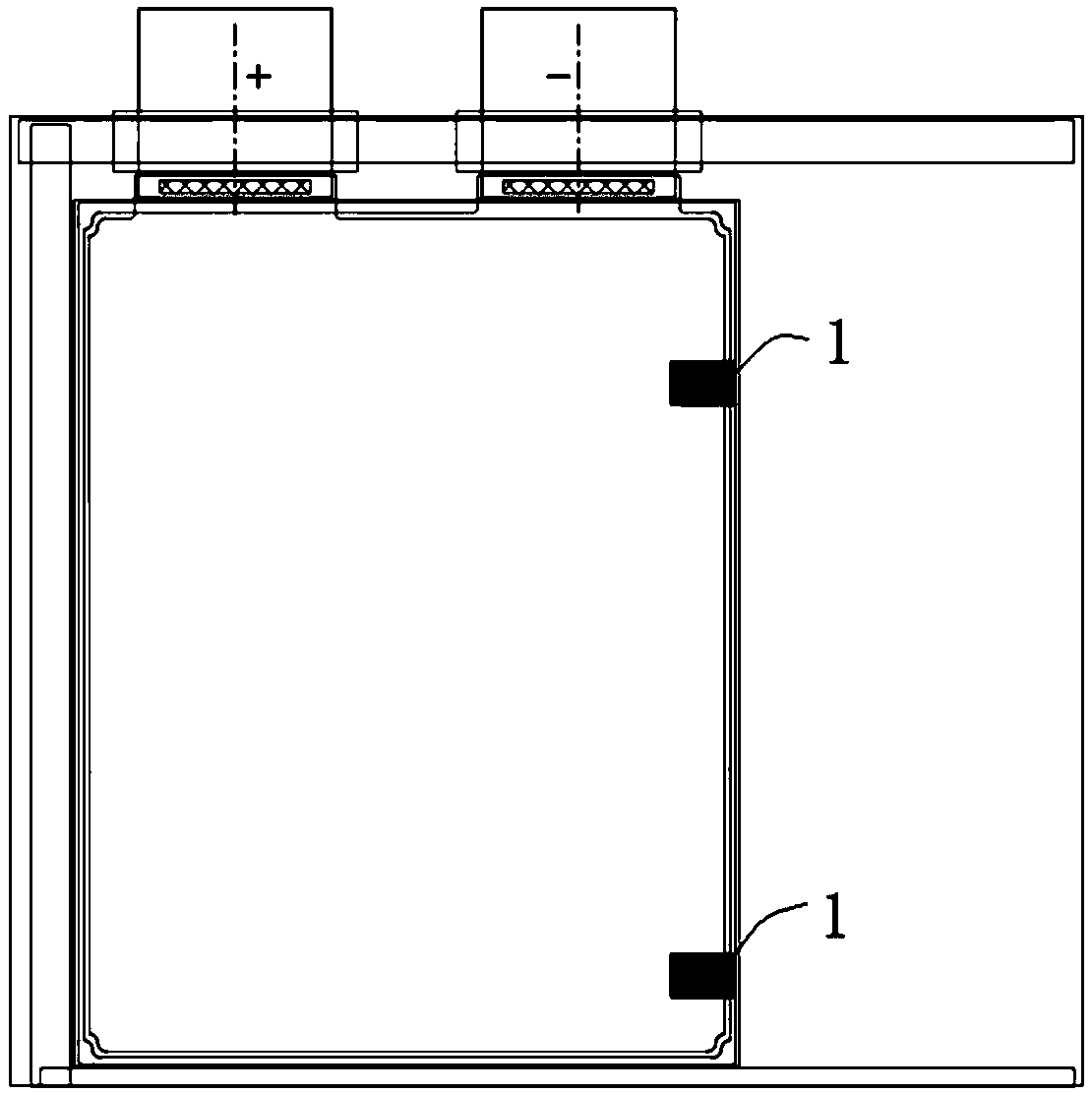

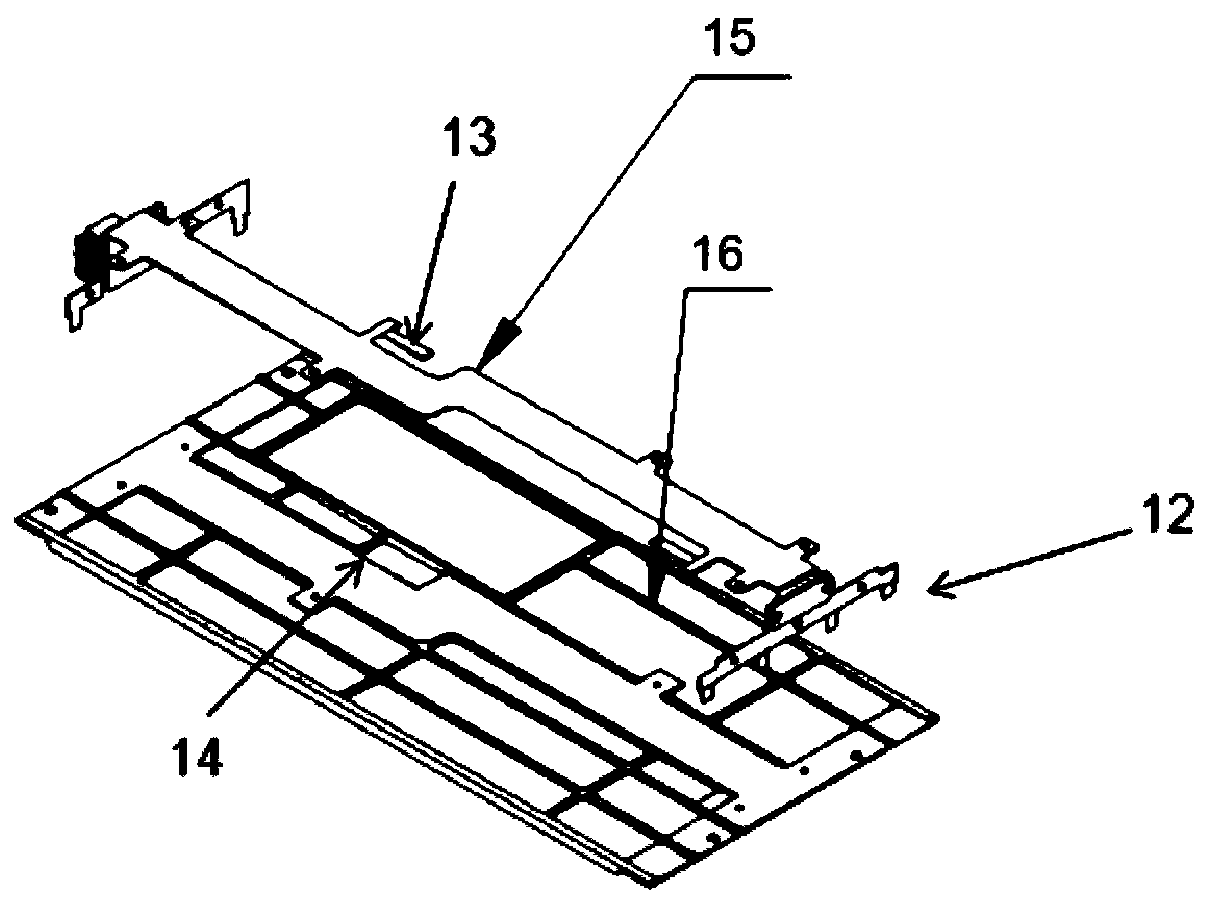

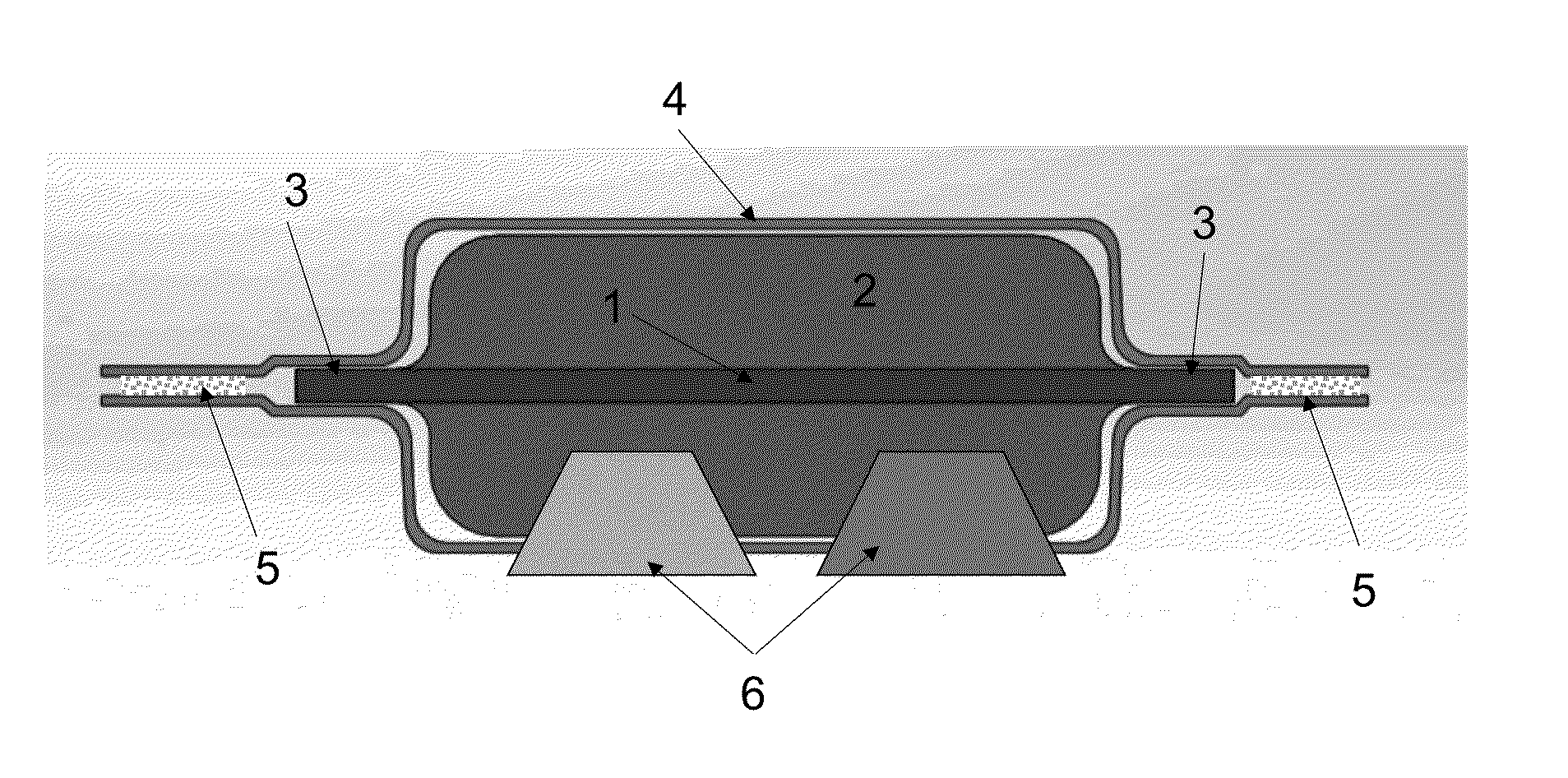

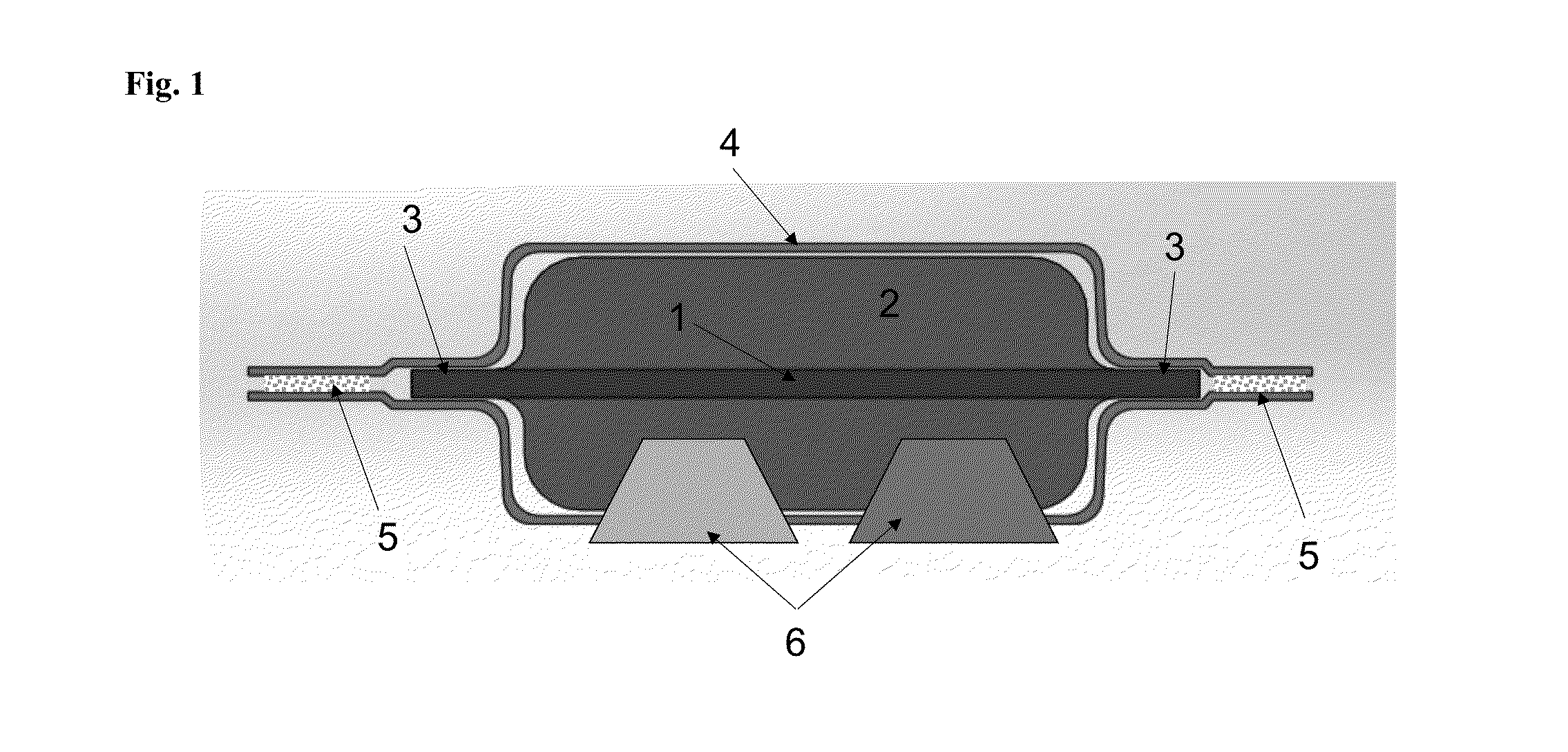

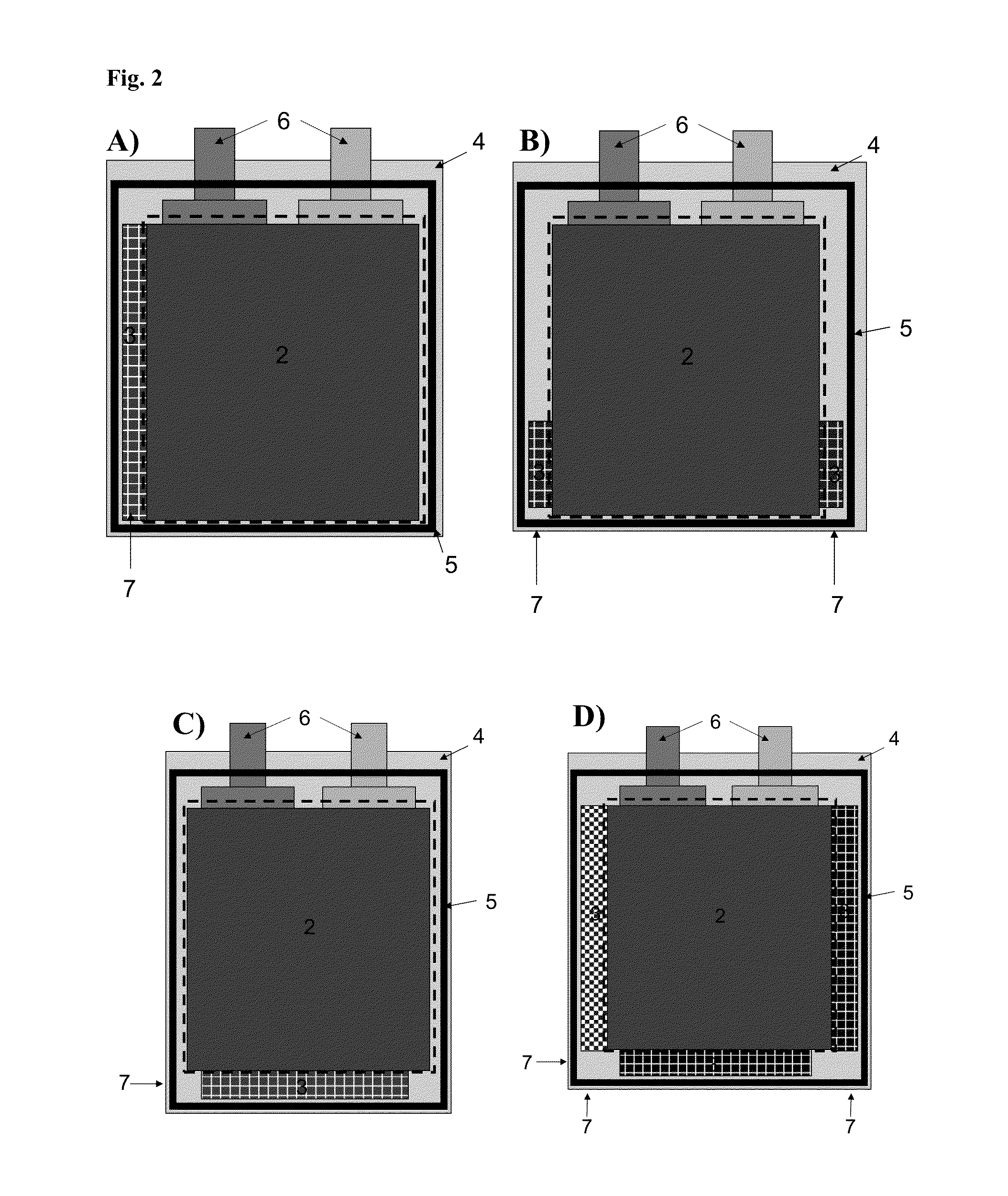

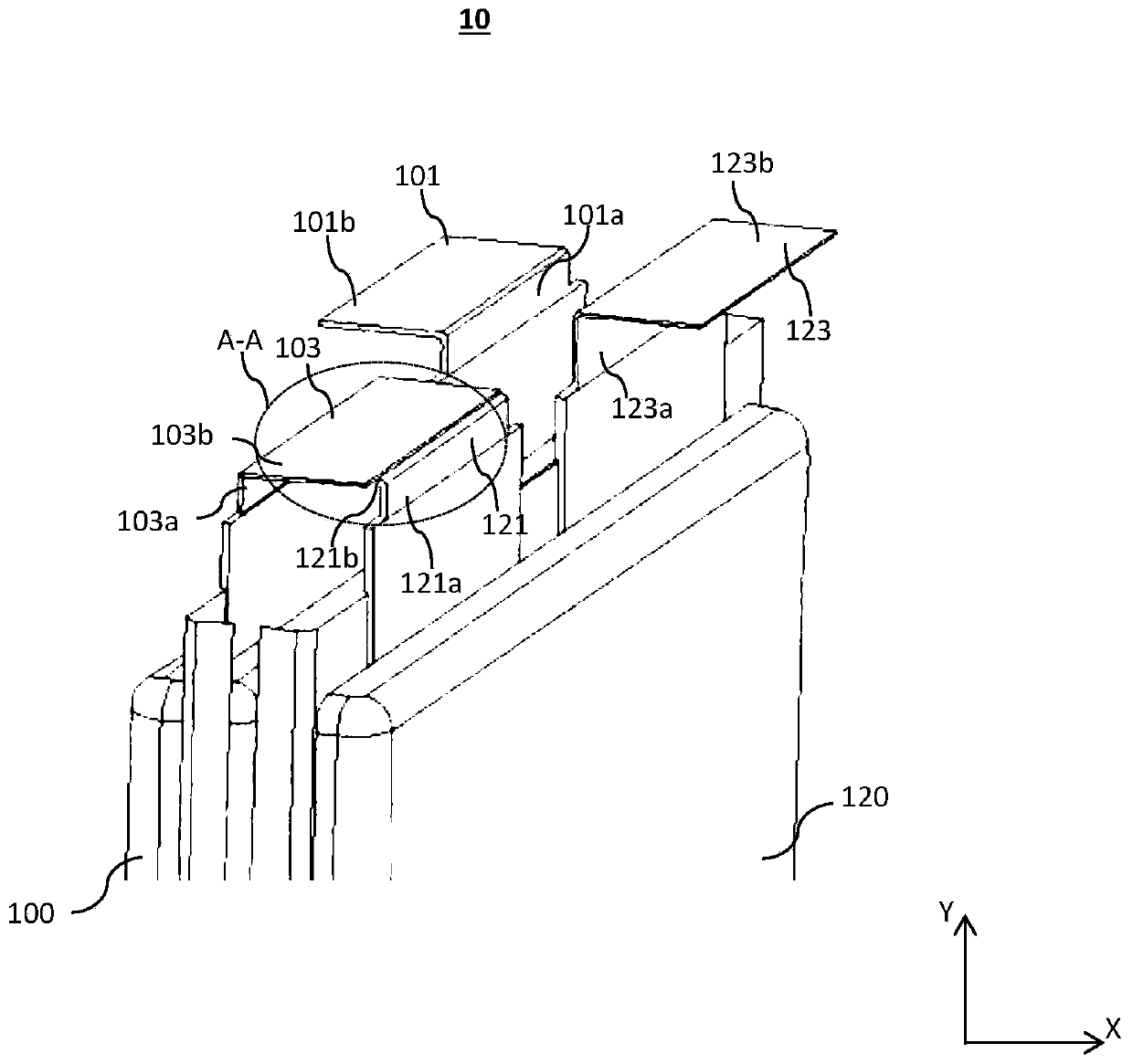

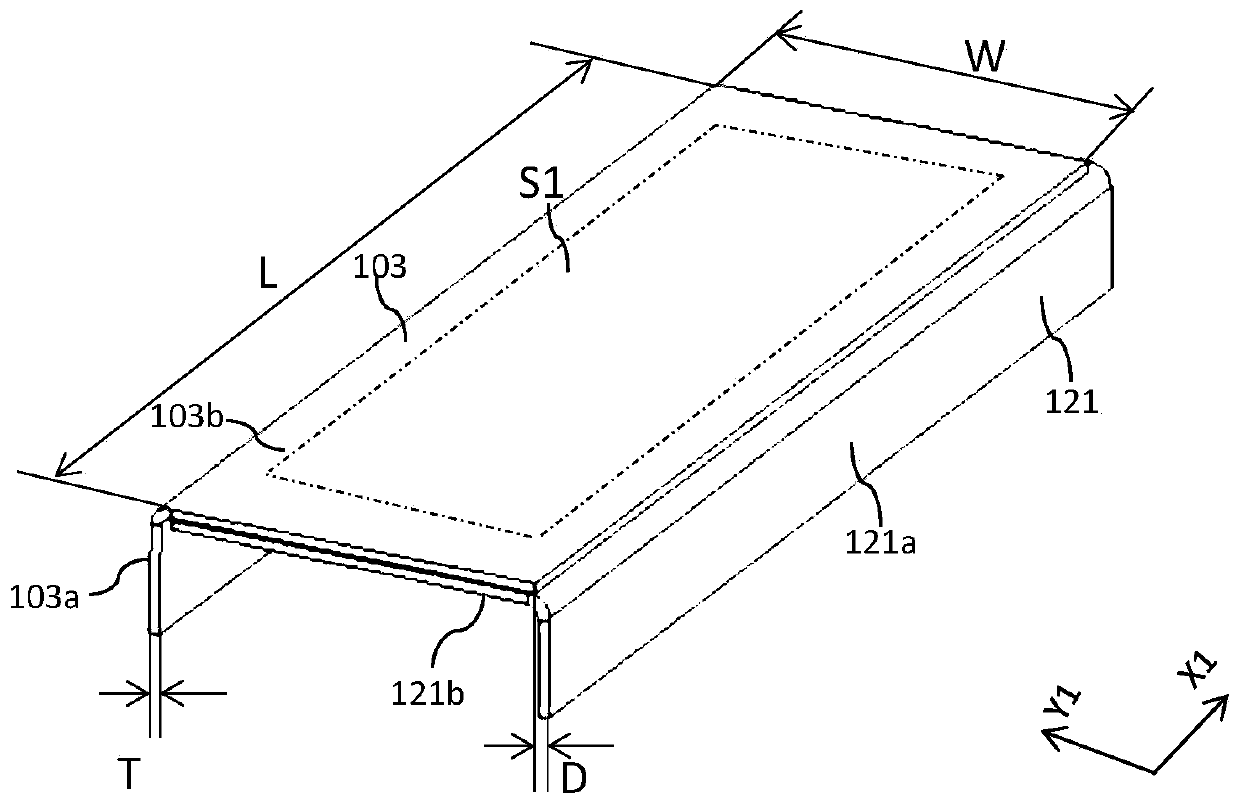

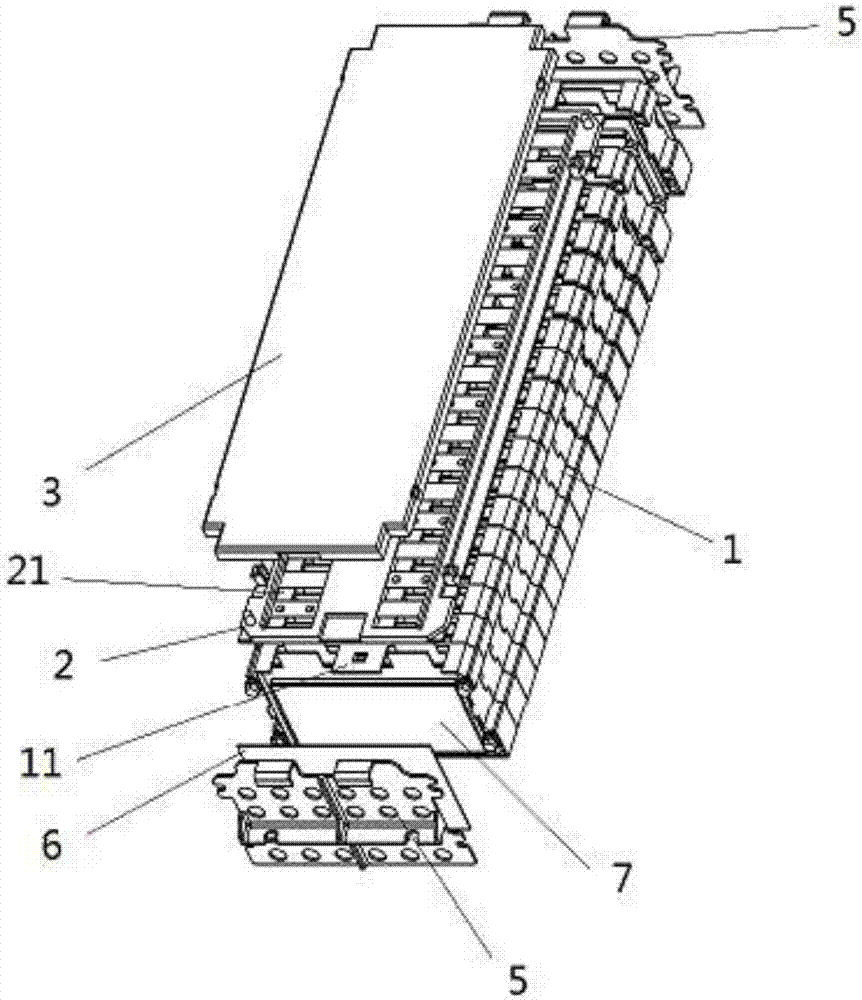

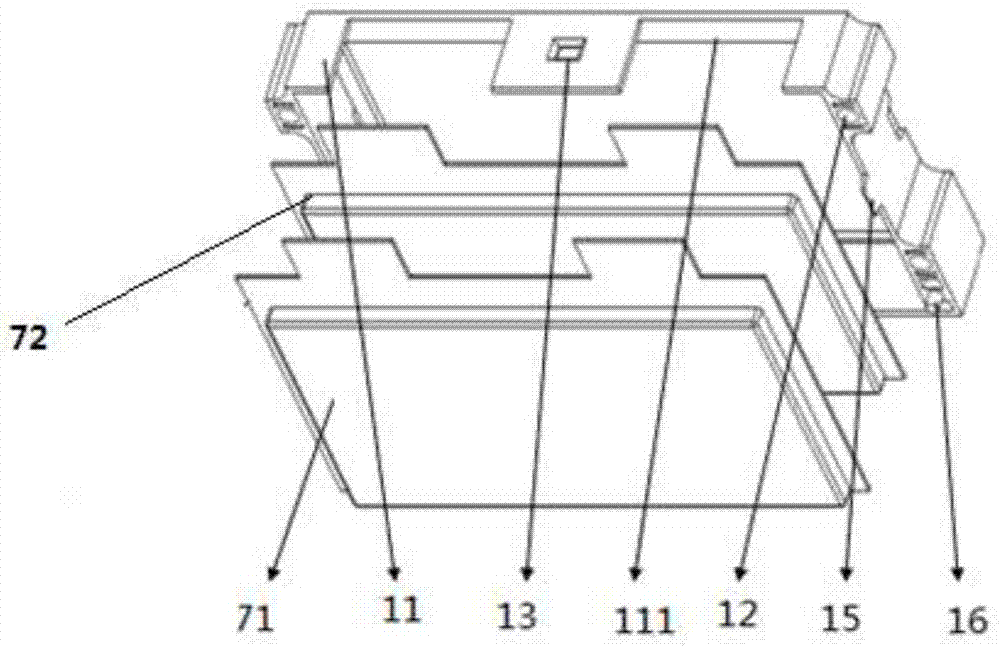

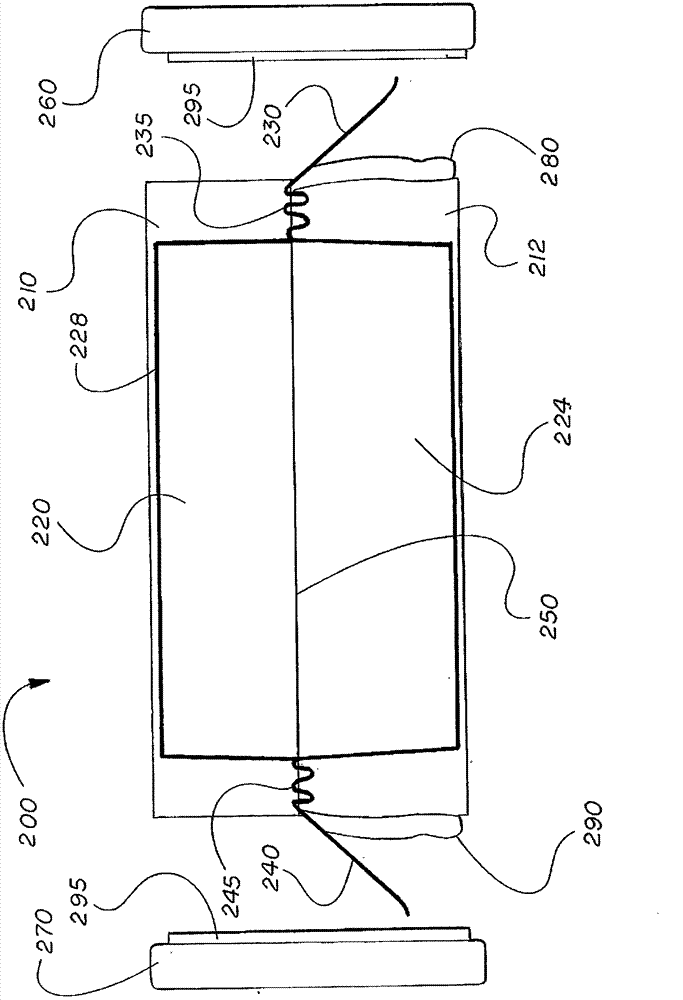

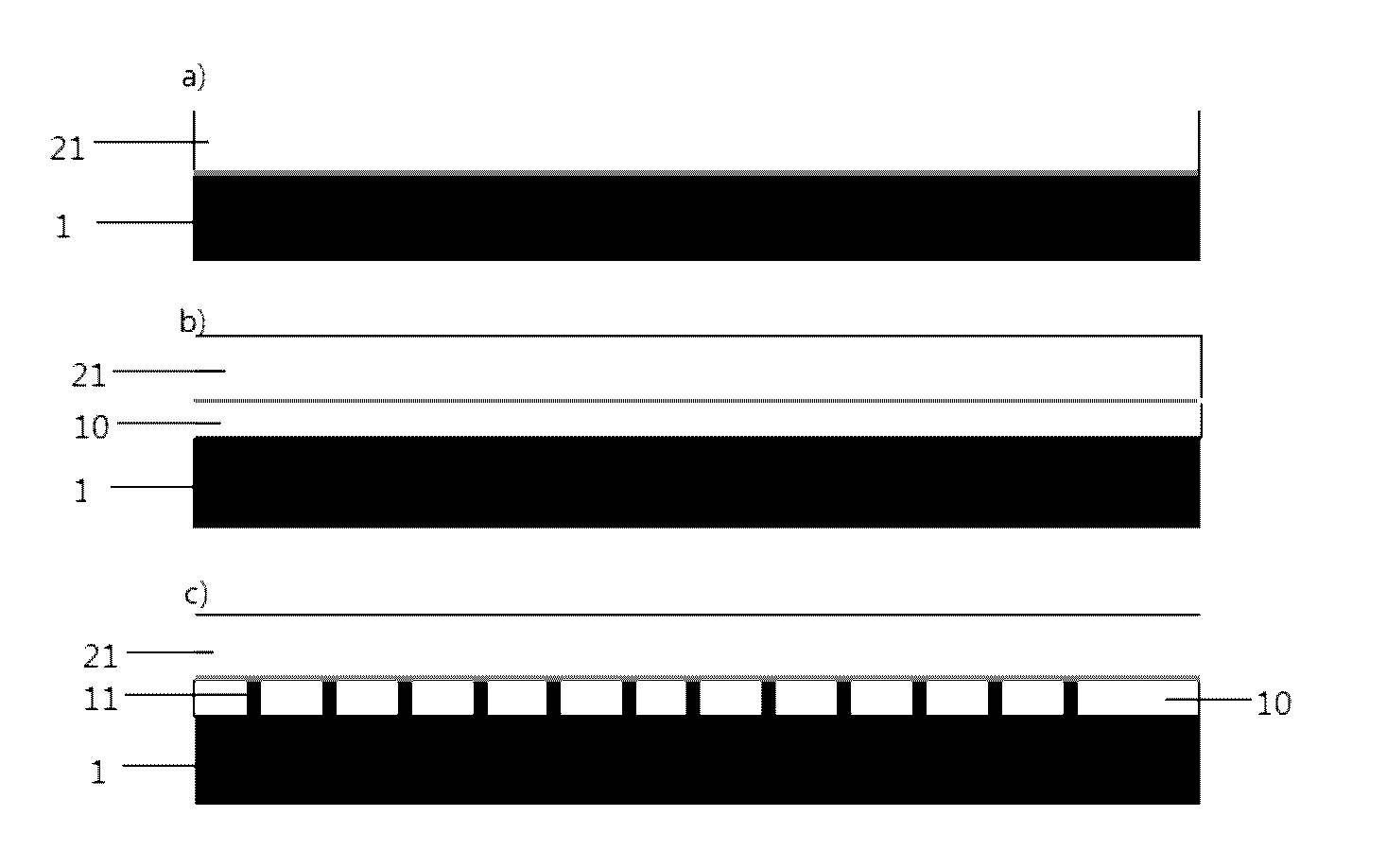

Li-ion pouch cell and a cell module

ActiveUS20140205882A1Improve abilitiesMinimize the differenceFinal product manufactureCell temperature controlPouch cellThermal conductivity

The present invention provides a Li-ion pouch cell wherein the Li-ion pouch cells comprise a sealed enclosure, electrode stack and thermally conductive elements, wherein the electrode stack and the thermally conductive elements are in the sealed enclosure, the thermally conductive elements include extensions which extend beyond the electrode stack, the sealed enclosure has thermal conductivity, the thermally conductive elements provide a thermally conductive pathway connecting the electrode stack and the sealed enclosure by way of the extension. The present invention also provides a cell module comprising the Li-ion pouch cells. The Li-ion pouch cell and the cell module according to the present application could minimize differences in cell temperature, monitor internal cell temperature, cool the cell rapidly, increase cell and module safety, allowing for minimal impact on cell energy density, performance or life and difficulty of manufacturing.

Owner:FARASIS ENERGY

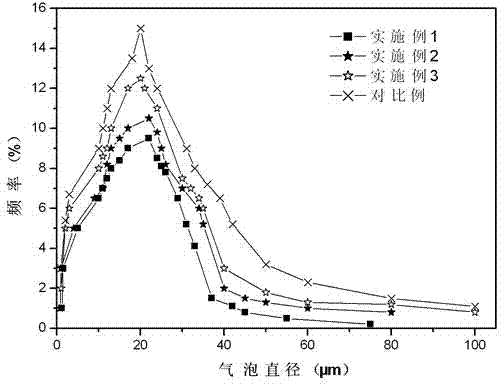

Packaging method of soft-packaged lithium ion battery

InactiveCN104766997AImprove pass rateImprove qualityFinal product manufactureElectrolyte accumulators manufactureTest batteryPhysical chemistry

A packaging method of soft-packaged lithium ion battery comprises following steps: (1) fixing a to-be-test battery; (2) heating the to-be-test battery apparatus; (3) punching the to-be-test battery and exhausting gas from the to-be-test battery and (4) packaging the to-be-test battery. In the invention, by means of addition of a vacuum buffer control apparatus, vacuumizing time and vacuumizing degree can be accurately controlled, thereby increasing the qualification rate and the quality of the battery during the packaging process. Meanwhile, by means of a step-type sine vacuumizing method, not only is electrolyte free from being leaked outwardly but also the micro bubble content in the soft-packaged battery can be further reduced and the battery packaging quality can be improved due to the bubble distribution characteristics of the soft-packaged lithium ion battery during the vacuumizing process.

Owner:JIANGSU LENENG BATTERY INC

Pole lug packing structure and soft-packing battery

ActiveCN106252578ALow side resistanceImprove stress concentrationCell component detailsStress concentrationEngineering

The invention relates to the field of energy storage devices and particularly relates to a pole lug packing structure and a soft-packing battery. The pole lug packing structure comprises a pole lug piece and two pole lug rubber layers, wherein the pole lug piece comprises two main planes, the two pole lug rubber layers extend along the width direction and are symmetrically adhered to the two main planes, the two ends of the two pole lug rubber layers are adhered together, each of the pole lug rubber layers comprises an area A and an area B along the length direction, wherein the areas A are closer to the outer side than the areas B, and the areas B exceed the areas A along the direction vertical to the main planes, so that grooves are formed between the areas A and the areas B. The soft-packing battery comprises a packing bag and a pole lug packing structure, the pole lug piece passes through the edge of the packing bag, the inner side of the pole lug piece is positioned inside the packing bag, the outer side of the pole lug piece is positioned outside the packing bag, the edge of the packing bag is connected with the areas A and the areas B through heat sealing to form a sealing structure, wherein the compression of the areas A is larger than that of the areas B. The soft-packing battery provided by the embodiment can be used for effectively improving the problem of stress concentration so as to inhibit the over-low side resistance.

Owner:CONTEMPORARY AMPEREX TECH CO

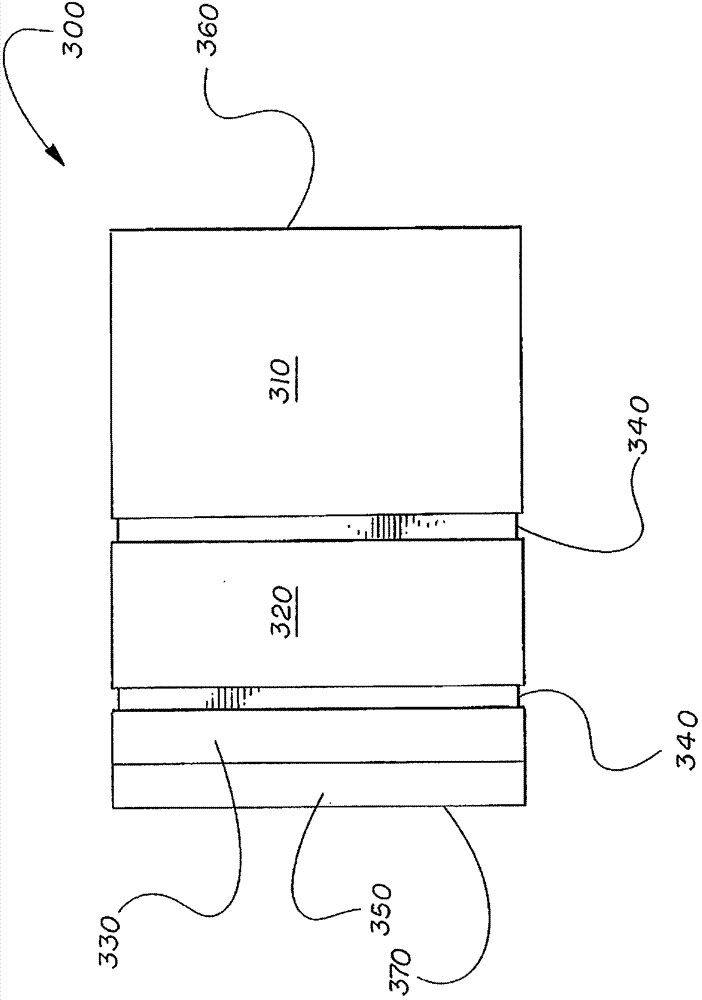

Battery component and electrochemical device

PendingCN110518183AImprove mechanical propertiesImprove the environmentSecondary cellsCell component detailsMechanical resistanceEngineering

The embodiment of the invention relates to a battery component and an electrochemical device. The battery component provided by one embodiment of the invention comprises a first end; a first cell; a second battery cell stacked with the first battery cell, wherein each of the first battery cell and the second battery cell comprises a first tab and a second tab, one of the first tab and the second tab of the first battery cell is configured to be electrically connected with one of the first tab and the second tab of the second battery cell to form a first series tab component, or the first tab and the second tab of the first battery cell are configured to be electrically connected with the first tab and the second tab of the second battery cell respectively to form a first parallel tab component; and a first insulator which at least covers the first end and is positioned in a gap of the first series tab component or the first parallel tab component at the first end. According to the battery component and the electrochemical device provided by the embodiment of the invention, the connection between the soft package battery and the outside can be achieved through a simple structure, and meanwhile, the battery component has the good mechanical resistance and environmental resistance.

Owner:DONGGUAN POWERAMP TECH LTD

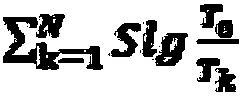

Method for measuring gas volume in battery, device and application thereof

ActiveCN109655127AMaterial analysis using sonic/ultrasonic/infrasonic wavesVolume measurement apparatus/methodsLithiumTest battery

The invention discloses a method for measuring gas volume in a battery, a device and application thereof, wherein the method, the device and the application thereof belong to the field of lithium ionbattery testing. The battery is a rectangular hard-housing battery or a rectangular soft packaging battery. The largest-areas surface of the battery is called as a battery plane. Along the battery plane, the battery is divided into n areas of which the areas are A respectively. A transmission ultrasonic signal strength without a gas gap is recorded as T0, and a transmission ultrasonic signal strength of an i-th area of a to-be-tested battery with unknown inner gas volume Vi is recorded as Ti. The value of lg(T0 / Ti) is calculated. A local gas volume Vi of each area in the battery plane is obtained according to a proportional relation between the local gas volume Vi and lg(T0 / T) of the battery in the i-th area which is penetrated by ultrasonic sound. Then all Vis are added for obtaining thetotal inner gas volume V of the battery. The method and the device have advantages of no loss, quantifiability and imageability.

Owner:无锡领声科技有限公司

Soft-packaged battery module fixing structure

PendingCN107195832AThe fixed structure is simple and reliableIncrease energy densityCell component detailsPower batteryHigh energy

The invention relates to a soft-packaged battery module fixing structure. The soft-packaged battery module fixing structure comprises a battery module unit and an electric core component arranged in the battery module unit; a cover plate and a top cover which are clamped and matched with the battery module unit are sequentially arranged at the upper end of the battery module unit; the left and right end of the battery module unit are provided with side pressing plates which are in screw connection with the battery module unit; the cover plate is provided with multiple strip-shaped holes which stretch out of battery polar lugs; and heat isolating sheets are arranged between the side pressing plates and the battery module unit. The soft-packaged battery module fixing structure can be combined and superposed arbitrarily to form soft-packaged battery modules with different numbers of serial and parallel connection so as to meet voltage and capacity requirements of a power battery system. Meanwhile, the soft-packaged battery module fixing structure can make a full use of the advantage of high energy density of the soft-packaged battery, the designed soft-packaged battery module fixing structure gives full consideration to the light-weight requirement, improves the energy density of the battery module and accordingly greatly improves the energy density of the system.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

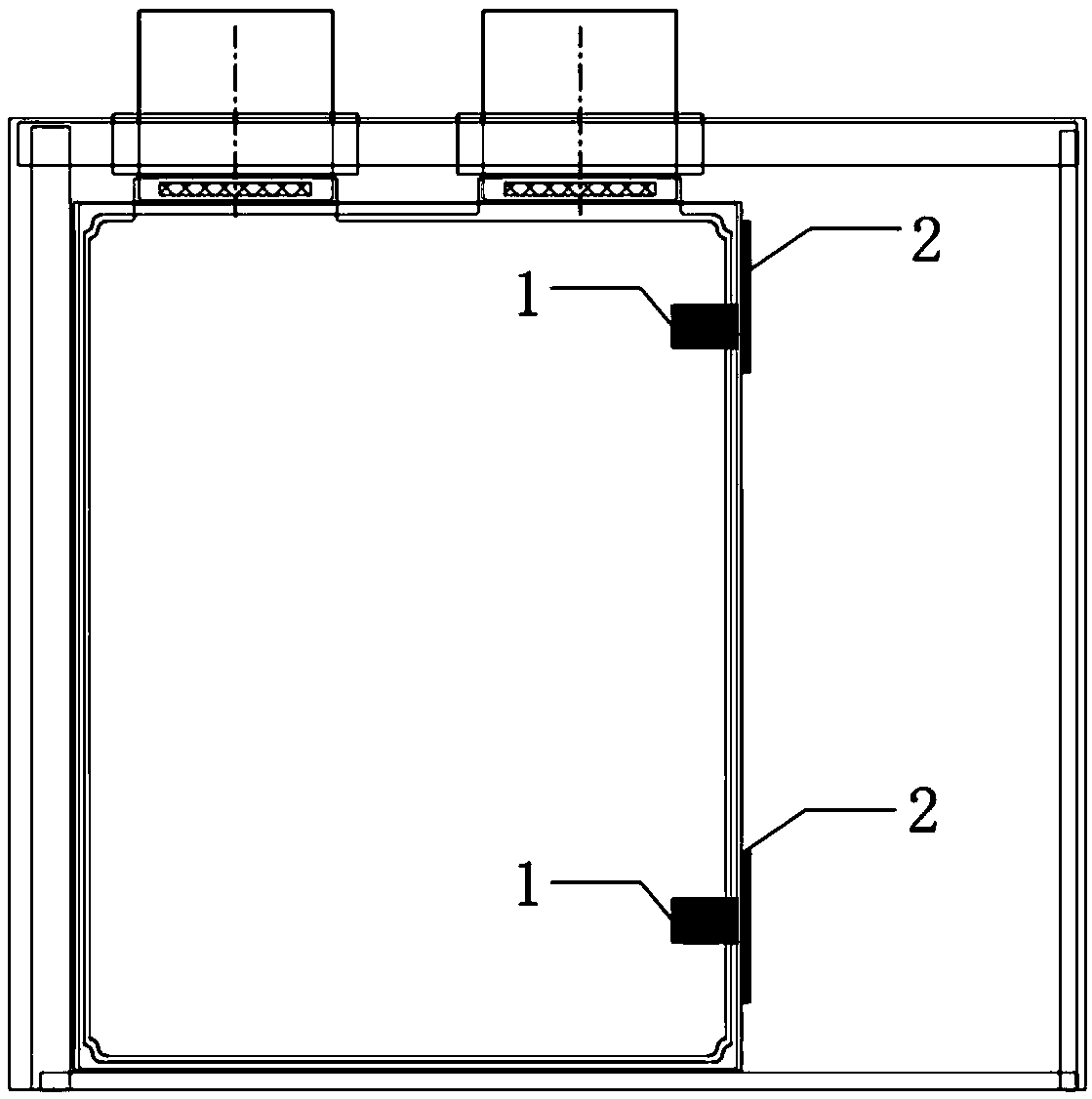

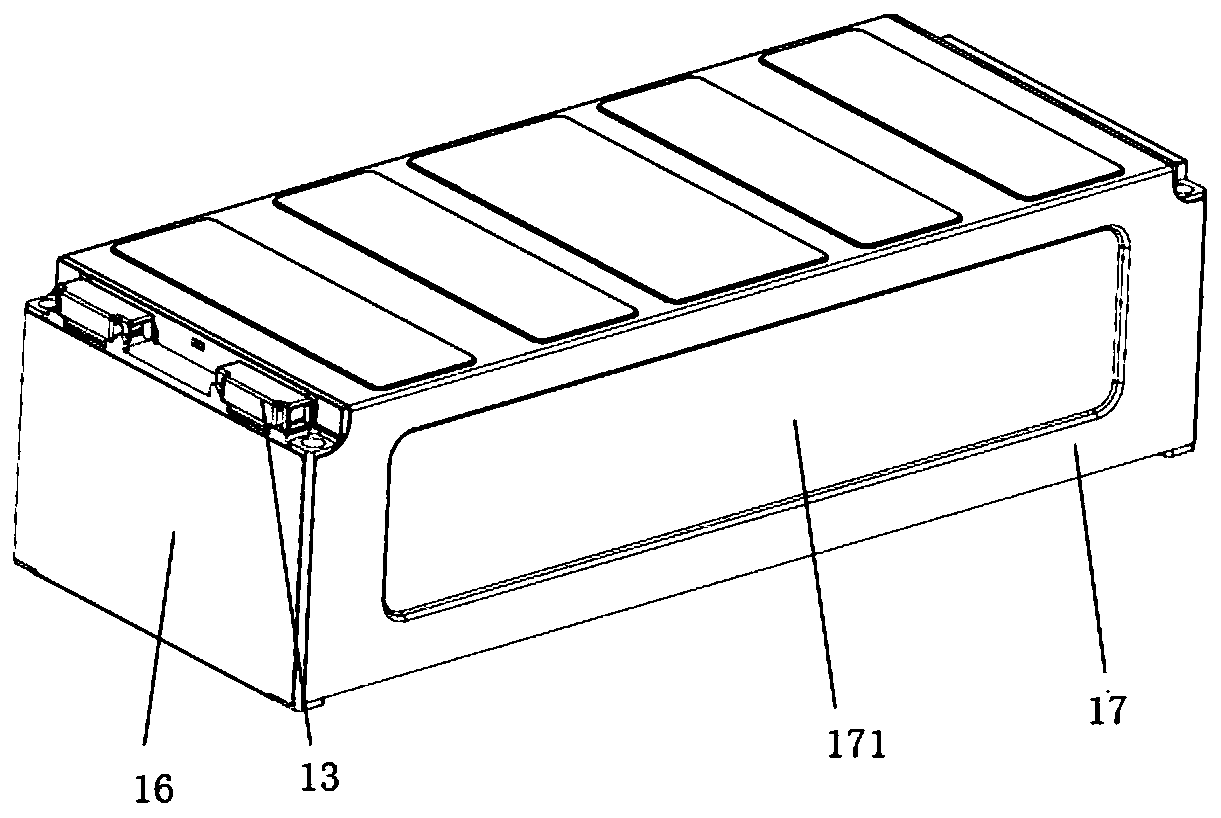

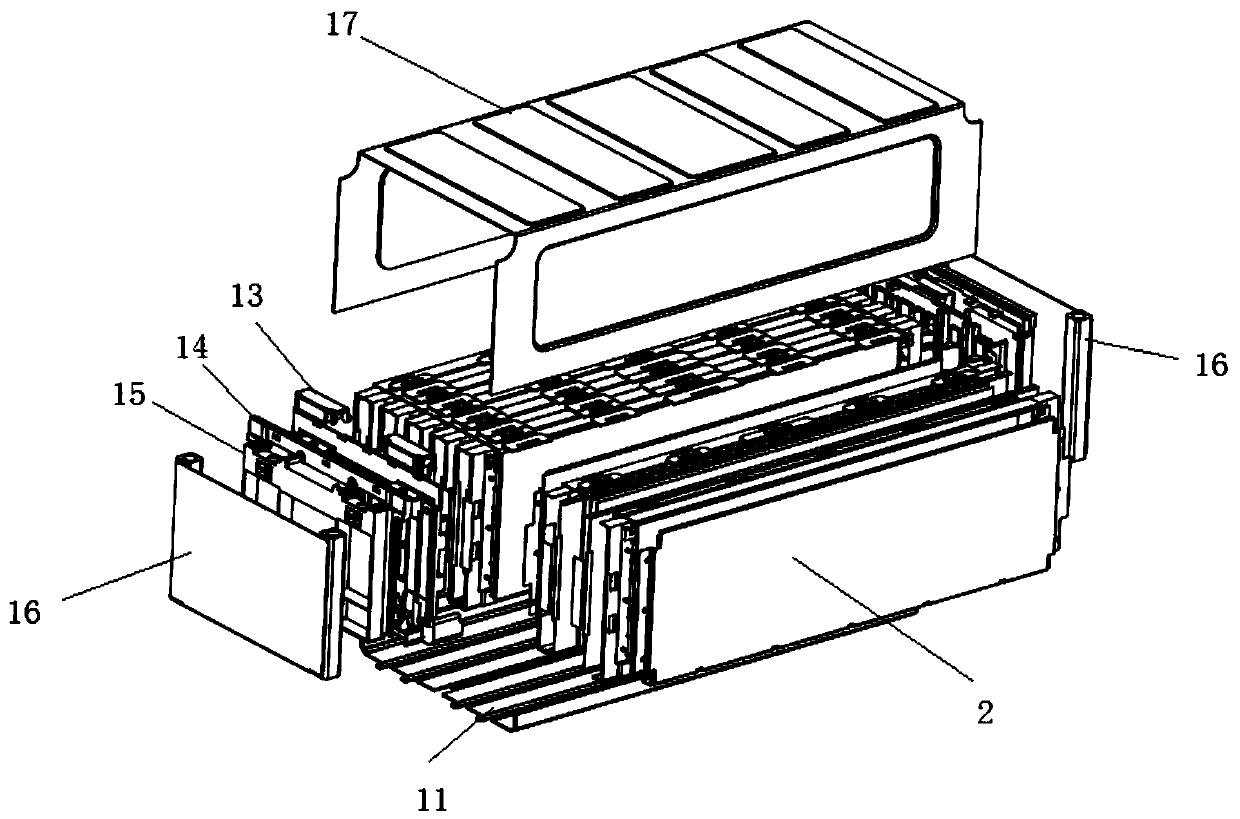

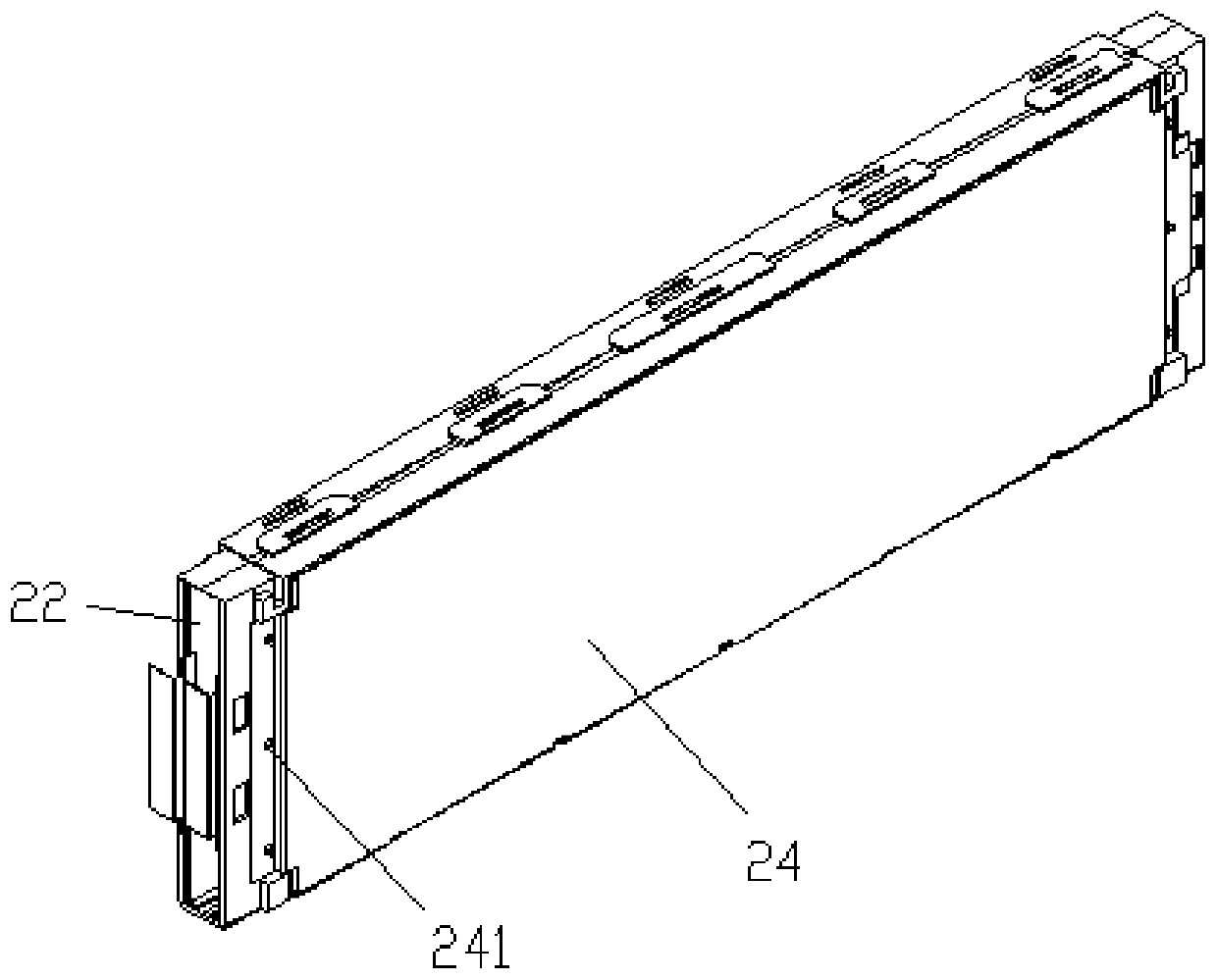

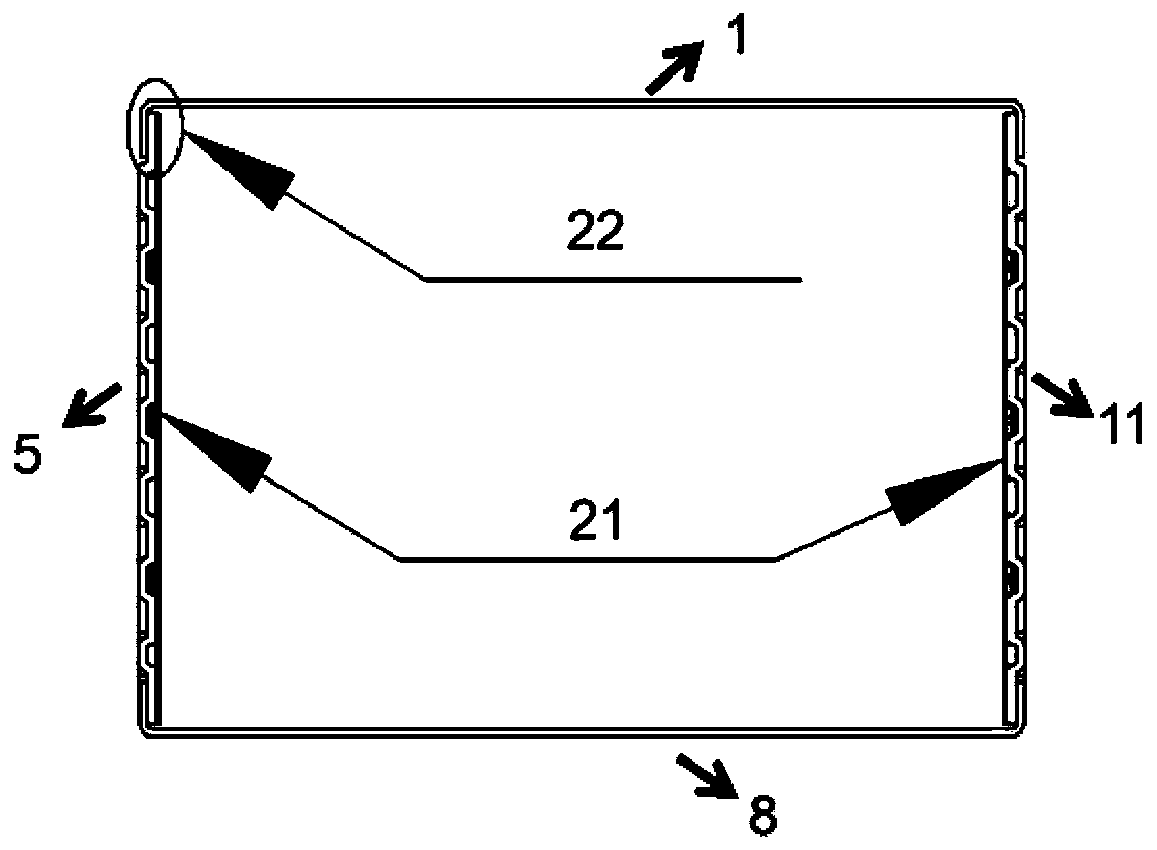

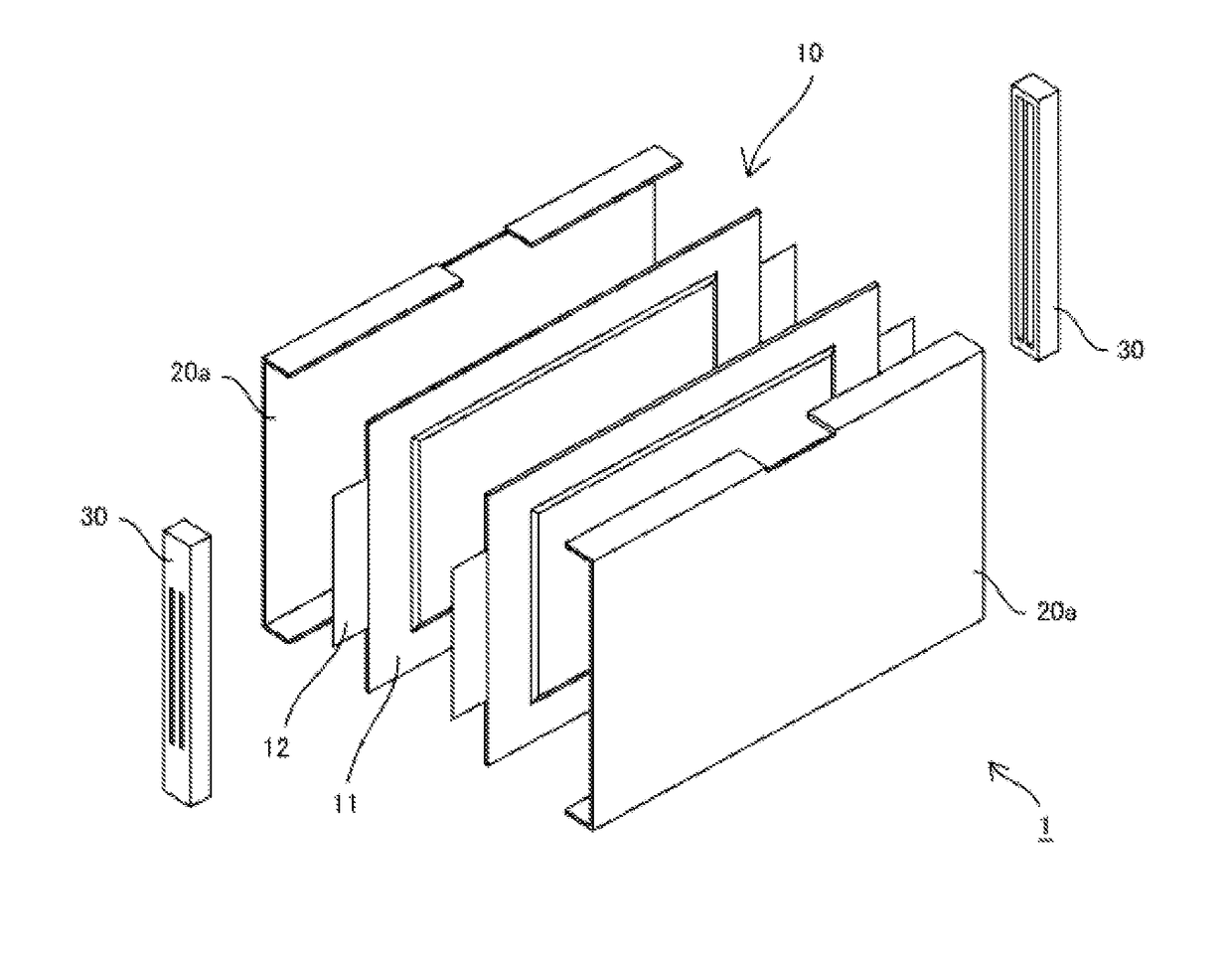

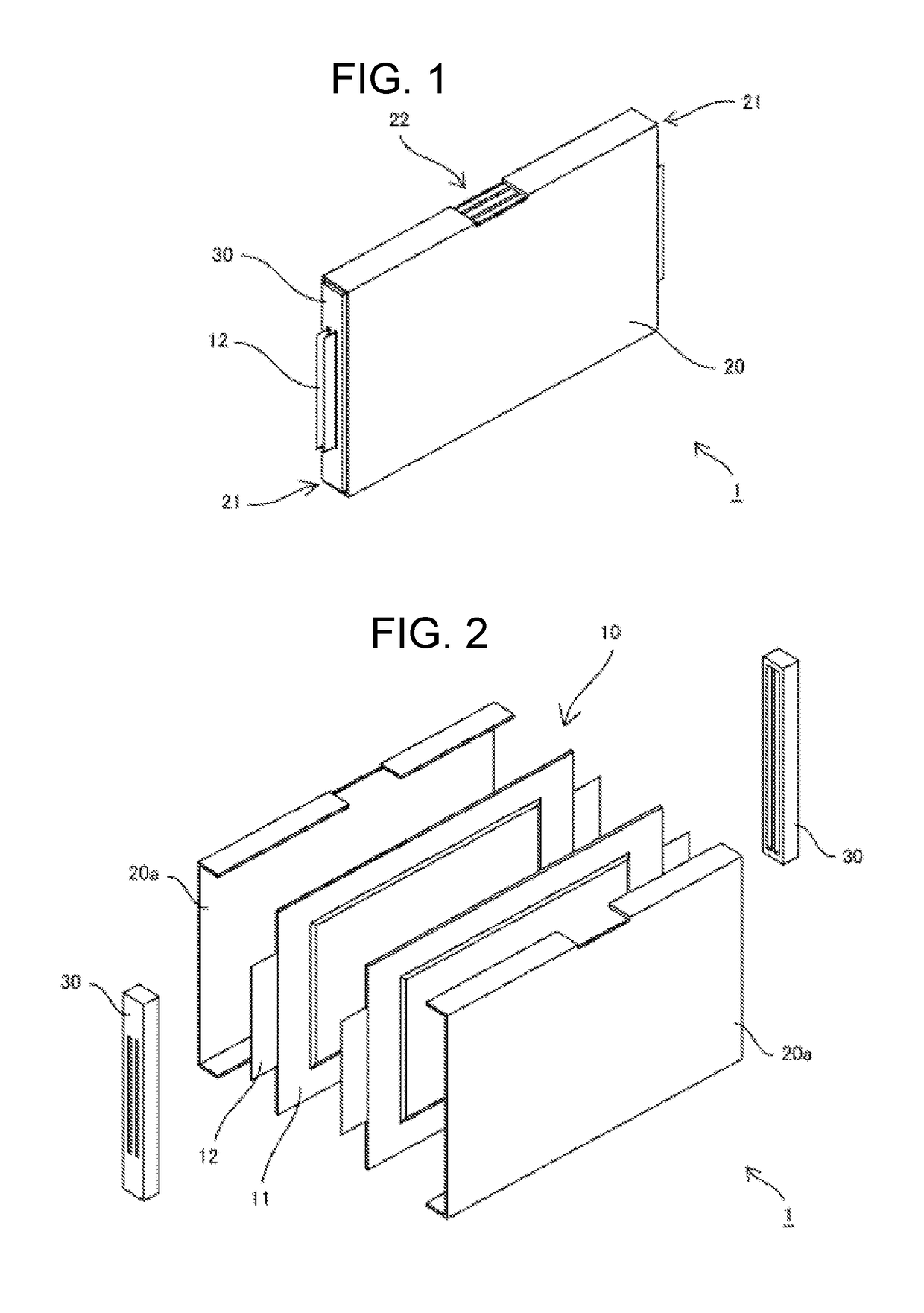

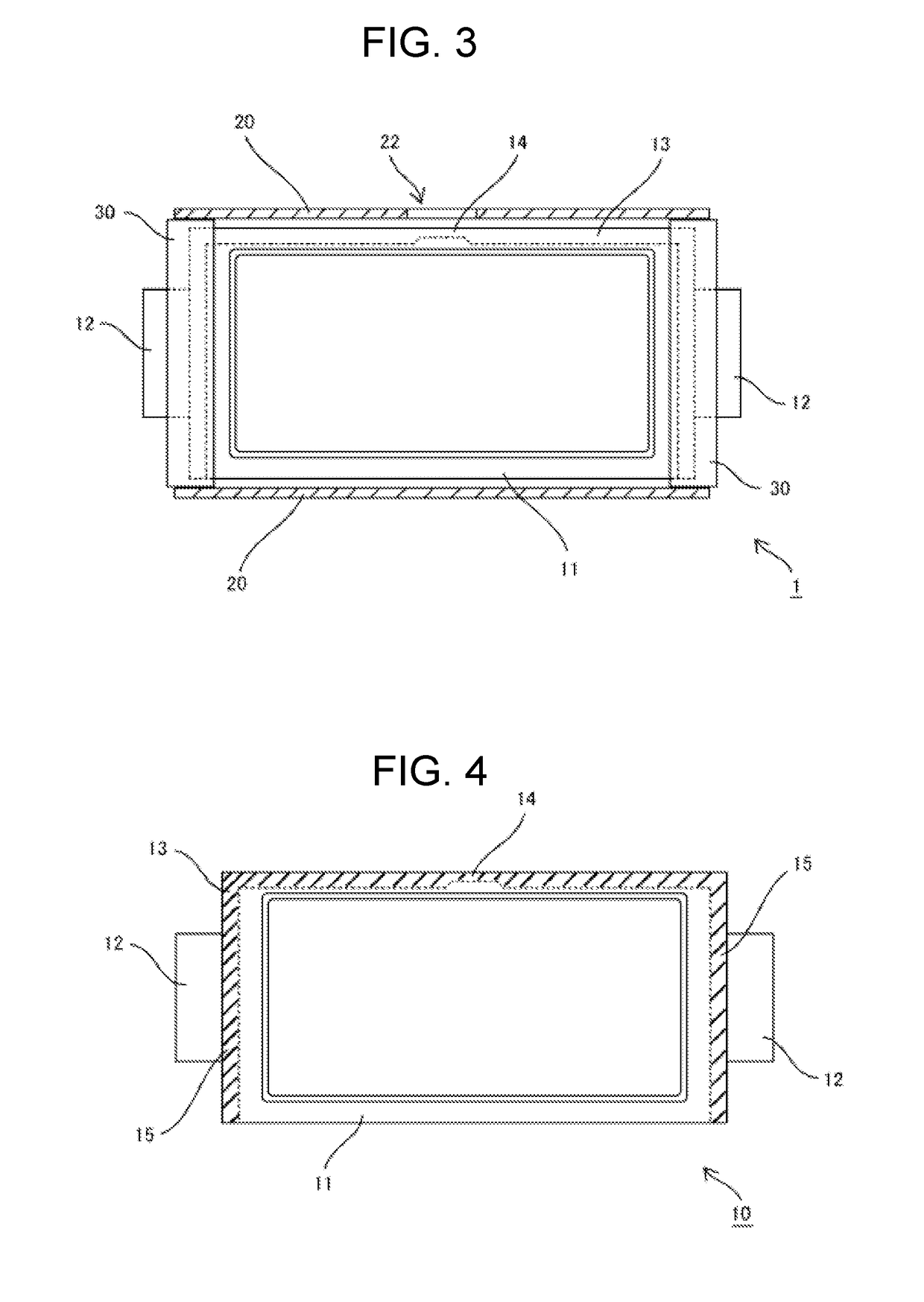

Power source device

In order to allow gas discharged from a pouch cell to be guided to a predetermined position, a power source device includes one or a plurality of pouch cells (10) having laminated film outer casing (11), and a housing member (20) enclosing the one or multiple pouch cells (10). The one or plurality of pouch cells (10) each includes thermally welded portion (13) formed by thermally welding the laminated film, and gas discharge portion (14) provided in at least a part of thermally welded portion (13). Housing member (20) includes exhaust port (22) communicating with gas discharge portion (14) of one or a plurality of pouch cells (10).

Owner:SANYO ELECTRIC CO LTD

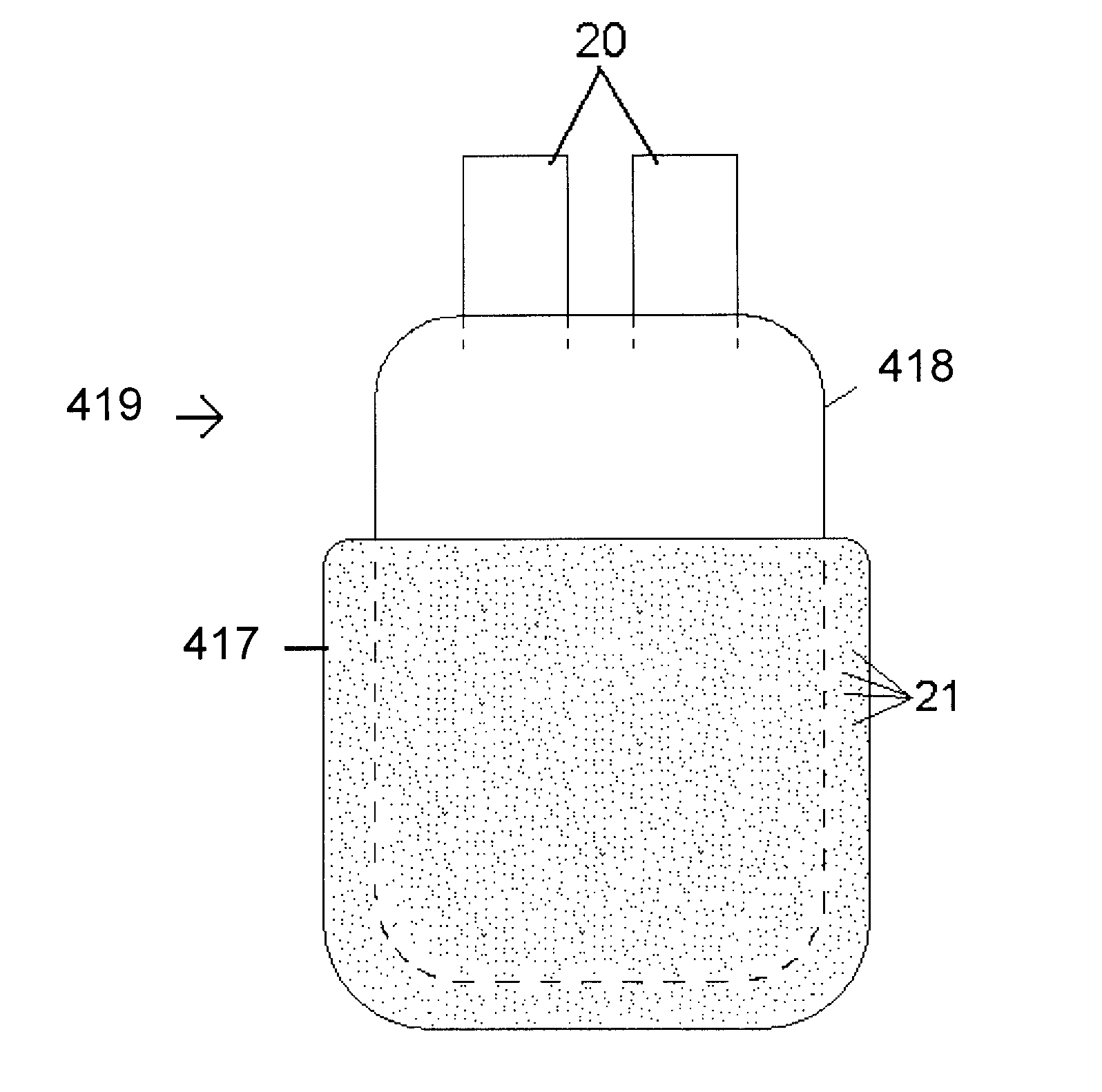

Pouch battery

PendingCN106486629AImprove flatulenceImprove securitySecondary cellsCell component detailsChemical reactionEngineering

The invention provides a pouch battery, comprising a cell and a packing film covering the cell; the packing film is provided with a battery chamber for receiving the cell and at least one gas receiver; the battery chamber is communicated with the air receivers through gas holes. When the cell produces gas inside due to abnormal chemical reactions, the gas may pass through the gas holes into the gas receivers; bulging of the pouch battery due to overcharge, overdischarge, high temperature and the like can be effectively improved, and battery safety and longer cycle life are provided for the battery.

Owner:HEBEI YINLONG NEW ENERGY

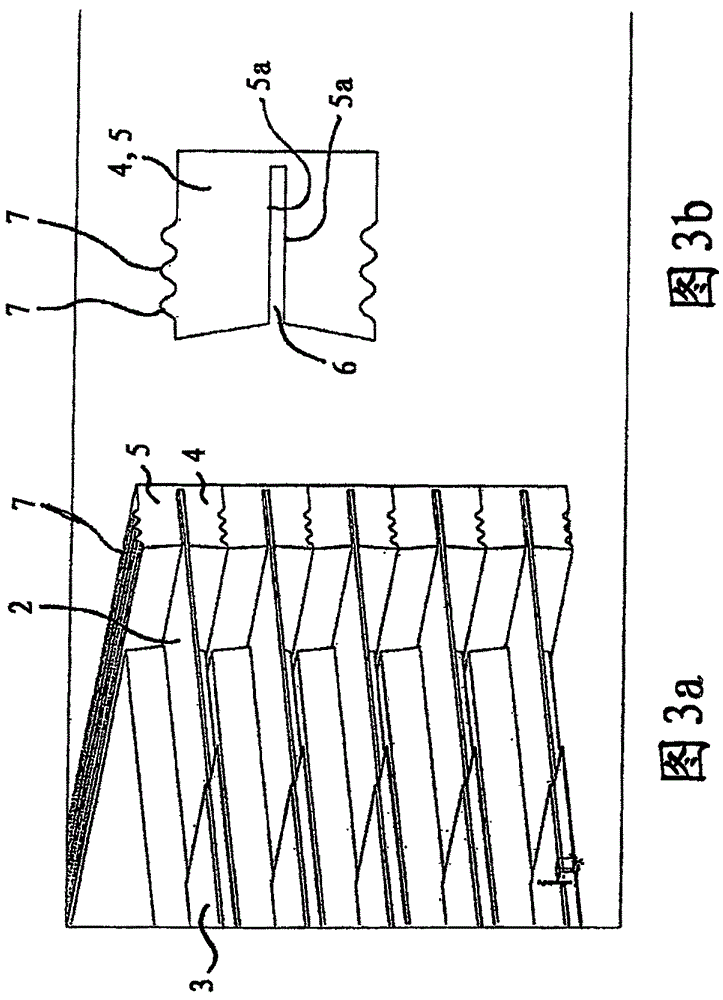

Receiving element for pouch cells

InactiveCN106384795AEasy to processNo penetrationFinal product manufactureBattery isolationEngineeringMechanical engineering

The invention relates to a receiving element (4) for mounting pouch cells, has a base body. The receiving element comprises a base body (5). With respect to an object of receiving the pouch cells securely and cost-effectively in a frame or housing, the receiving element is characterized in that the base body (5) is formed as a profile having a contact surface (5a) for contact against a sealing seam (2) of a pouch cell.

Owner:CARL FREUDENBERG KG

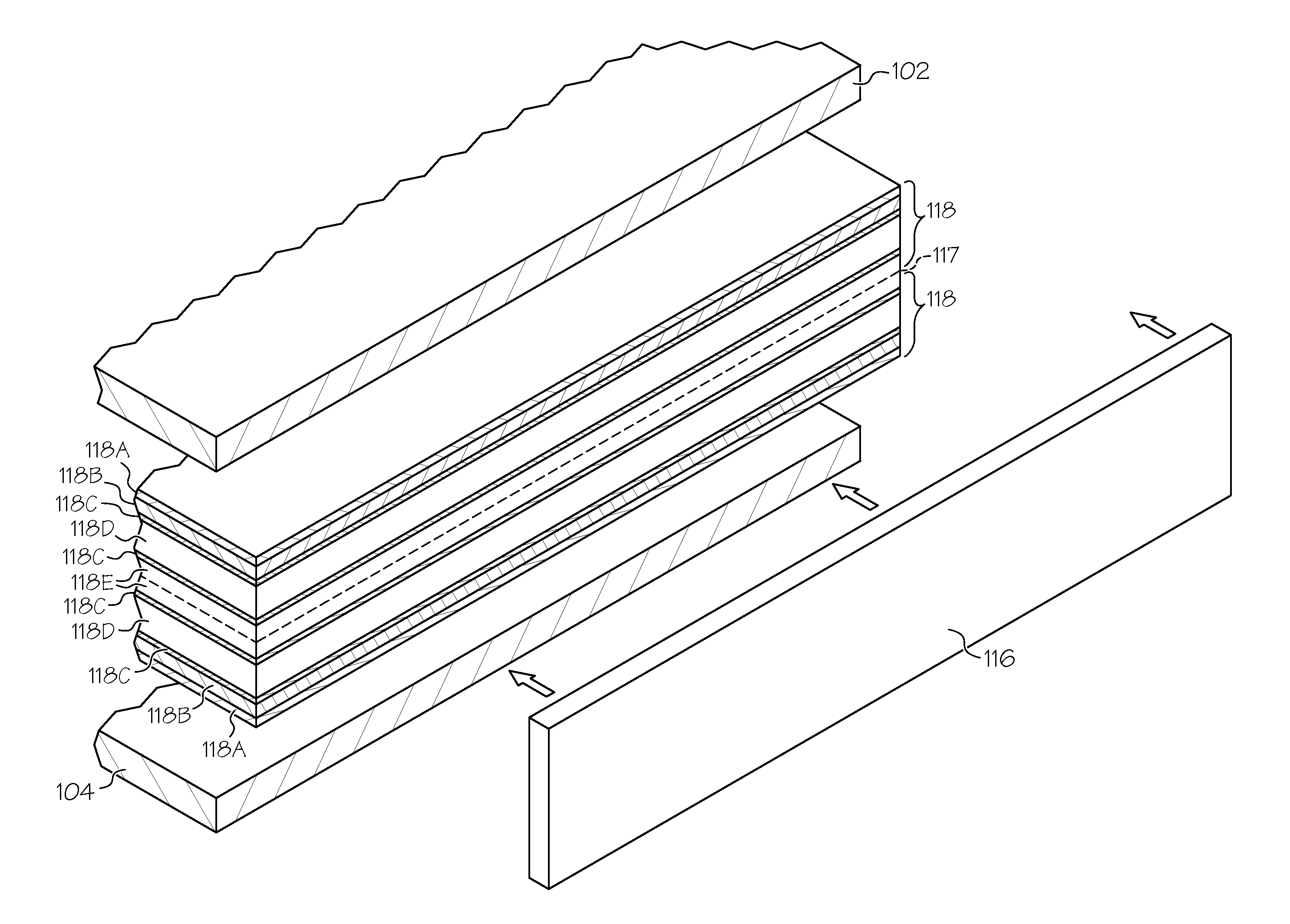

System and method for conducting battery heat using pouch cells

The present disclosure relates to apparatuses for conducting battery heat comprising an active material positioned between a first cover portion and second cover portion, each portion comprising a thermal conductive material and protection material connected to the thermal conductive material. Also included are systems for conducting heat includes a plurality of pouch cells each comprising an active material positioned between a first cover portion and second cover portion and a plurality of frames, at least one frame positioned between each of the plurality of pouch cells. Finally included are methods, for assembling a pouch cell structure for use in conducting battery heat, comprising constructing a pouch cell assembly by alternating a sequence of pouch cells and frames; positioning a first contact edge of each of pouch cell proximal to a first heat sink and a second contact edge of each pouch cells proximal to a second heat sink opposite the first contact edge; and connecting the first heat sink to the first contact edge of each of the plurality of pouch cells and connecting the second heat sink to the second contact edge of each of the plurality of pouch cells.

Owner:GM GLOBAL TECH OPERATIONS LLC

Large soft pack lithium ion battery and preparation method thereof

PendingCN108336286AImprove stabilityImprove securityFinal product manufactureSmall-sized cells cases/jacketsEngineeringLithium-ion battery

The invention discloses a large soft pack lithium ion battery and a preparation method thereof. The preparation method comprises the steps of providing at least one full-plate lug wound core, whereinthe plate lug welding areas of the full-plate lug wound core are correspondingly provided with insulating gaskets, so that the overall thickness of the plate lug welding areas is identical to the mainbody thickness of the full-plate lug wound core. By means of the insulating gaskets in the plate lug welding area, the preparation method of the large soft pack lithium ion battery overcomes unevenness of recesses and avoids self discharge and short circuit due to excessive compression of encapsulated positive and negative plates, thereby improving the stability and safety of the large soft packlithium ion battery. Meanwhile, the preparation method of the large soft pack lithium ion battery can avoid displacement and short circuit of bent plate lugs relative to positive and negative plate coatings nearby the plate lug welding area during a grouping process to improve the grouping reliability. Besides, the large soft pack lithium ion battery processed through the insulating gaskets is flat in core winding, attractive in appearance and low in cost. The preparation method of the large soft pack lithium ion battery is particularly applicable to preparing relatively thick large soft packbatteries and ensures a battery thickness upper to greater than 10.0 mm.

Owner:GREE ELECTRIC APPLIANCES INC

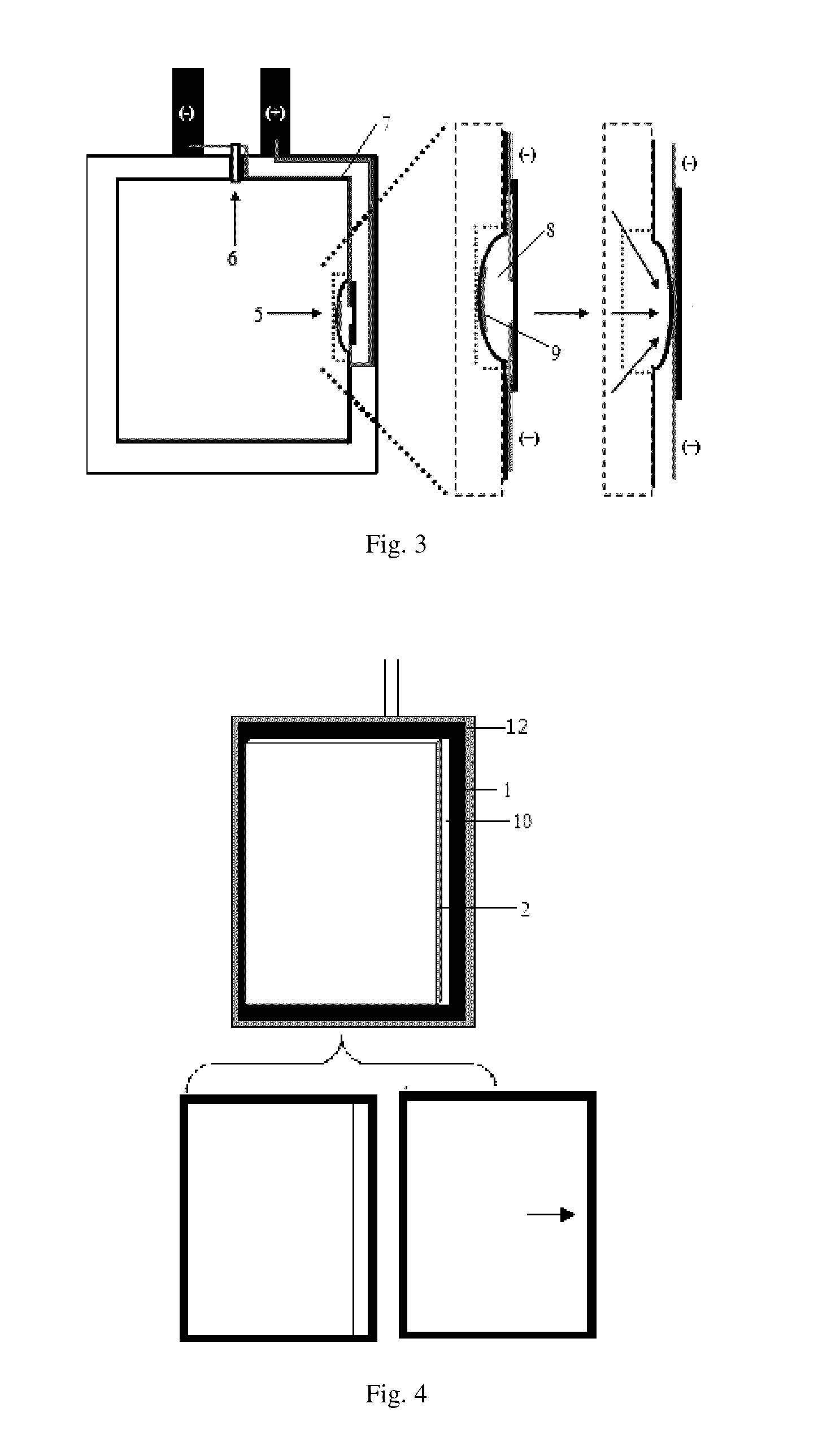

Pouch cell

ActiveUS20160344004A1No impact on seal integrityEasy to manufactureCells structural combinationCell component detailsCell handlingEngineering

The present invention relates to the field of battery cells, particularly to a pouch cell comprising a packaging seal, a heating element and a fault switch, wherein the fault switch will activate the heating element to generate heat to make the packaging seal delaminate when the inner space of the pouch cell reaches a predetermined pressure, such that the pouch cell vents. The mechanism and components of these venting concepts can be designed to be fully compatible with existing manufacturing methods and typical cell handling situations. The most favorable configuration has both vent device components outside the cell, with nothing passing through or even into the seal. Such a configuration has the advantage of having no impact on the seal integrity relative to a conventional pouch cell, is easy to manufacture, and has improved safety.

Owner:FARASIS ENERGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com