Method for verifying package reliability of soft-package battery

A soft pack battery, reliability technology, applied in secondary batteries, climate sustainability, non-aqueous electrolyte batteries, etc., can solve the large difference in composite technology and material properties, can not explain the packaging effect, can not characterize the soft pack Lithium-ion battery packaging life and other issues, to achieve the effect of intuitive testing and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

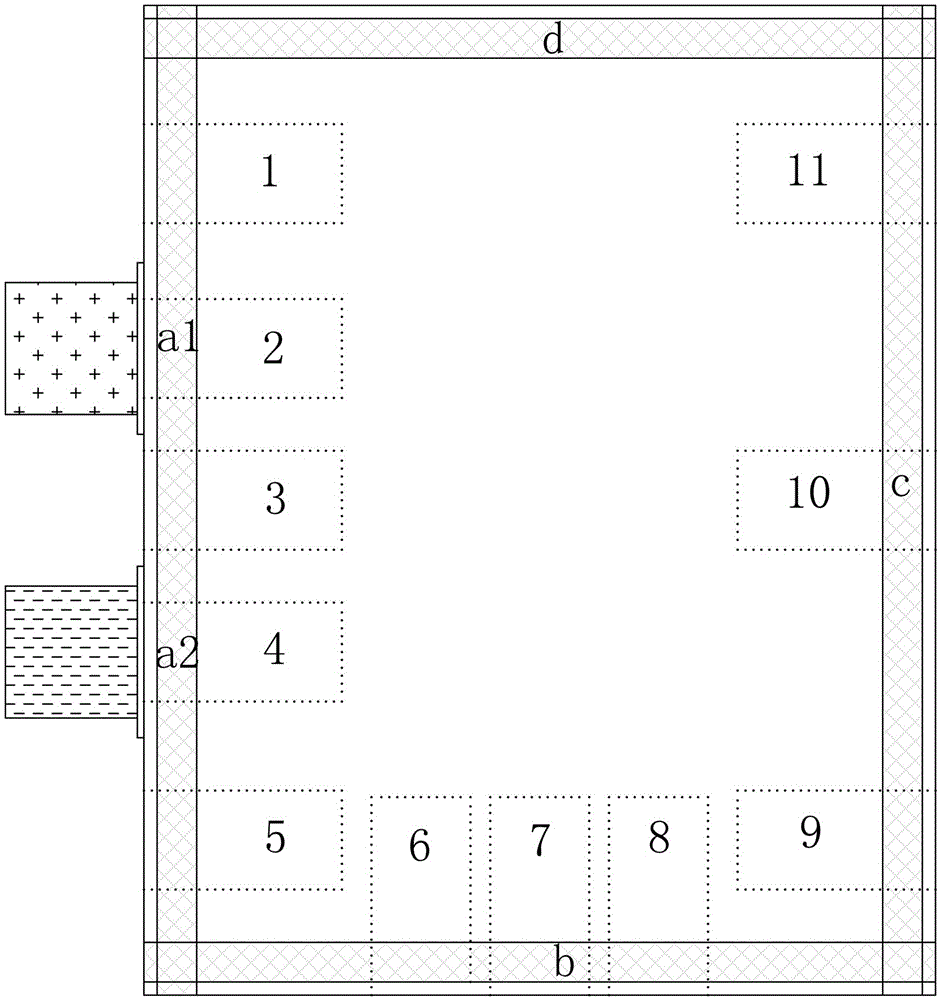

[0024] like figure 1 As shown, first cut the Japanese DNPD-ND408 aluminum-plastic film material to a size of (120±1)*(300±1) mm, and then fold the cut aluminum-plastic film in half into (120±1)*(150± 1) mm size. At the same time, prepare tabs with glue, the specification of the positive tab is (Al) 0.2*20*9(3)*38, the specification of the negative tab is (Ni) 0.2*20*9(3)*38, the positive and negative tabs are Wrap the short end of the tab tab with high-temperature tape, fix it on one side of the aluminum-plastic film, and heat seal it with a top-sealing device. The joint between the top seal and the positive tab tab is marked as a 1 , the connection part between the top seal and the negative tab is marked as a 2 , heat sealing temperature 180 ℃, pressure 0.3Mpa, time 6S, seal width 6.0 ± 0.5mm. The other side of the aluminum-plastic film is heat-sealed with a side sealer, the heat-sealed part is marked as b, the heat-seal temperature is 180°C, the pressure is 0.3Mpa, the ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com