Soft packaging lithium battery PACK production line

A soft-pack lithium battery and production line technology, which is applied to lithium batteries, primary batteries, and battery assembly machines, etc., can solve the problems of low qualification rate, large floor space, and high labor cost of soft-pack lithium batteries, so as to improve the qualification rate and Stability, improved sorting, protection from damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be further described below according to the accompanying drawings and specific embodiments, but the embodiments of the present invention are not limited thereto.

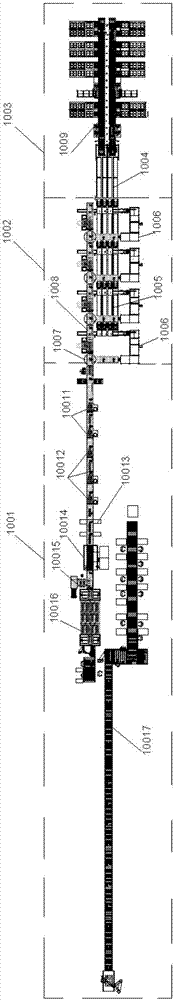

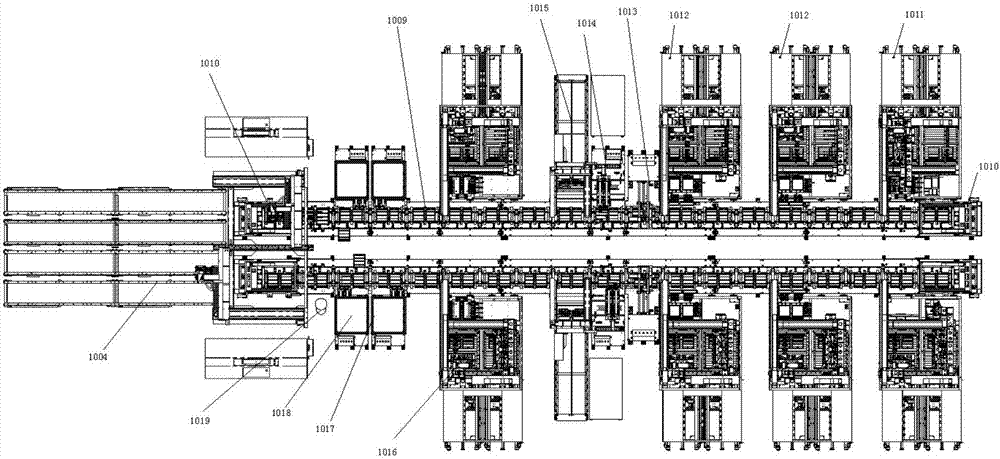

[0053] Such as figure 1 , figure 2 with image 3 As shown, a soft pack lithium battery PACK production line includes a soft pack pack classification cache section 1001, a soft pack pack stacking section 1002 and a soft pack pack sorting section 1003, and the discharge end of the soft pack pack sorting buffer section 1001 is connected to the soft pack PACK stacking section 1002, the other end of the soft pack PACK stacking section 1002 is connected to the soft pack PACK sorting section 1003 through four soft pack battery transmission lines 1004;

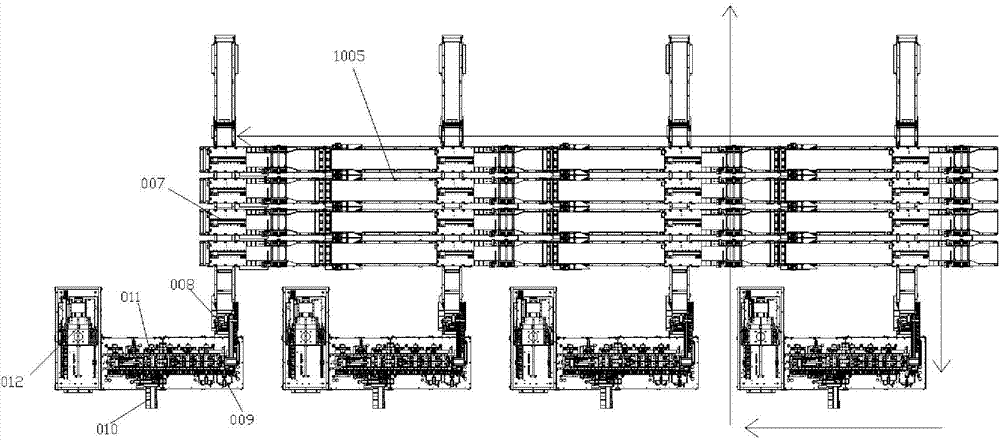

[0054] The soft pack PACK stacking section 1002 includes four belt conveyor lines 1005, and each belt conveyor line 1005 is connected to a soft pack battery conveyor line 1004, and each belt conveyor line 1005 is equipped with a set of s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com