Soft-packaged battery module fixing structure

A fixed structure and battery module technology, applied to battery pack parts, structural parts, circuits, etc., can solve problems such as unfavorable batch production, low group efficiency, and complex grouping of pouch battery packs, and achieve easy production line Large-scale production, convenient application, simple and reliable fixed structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing:

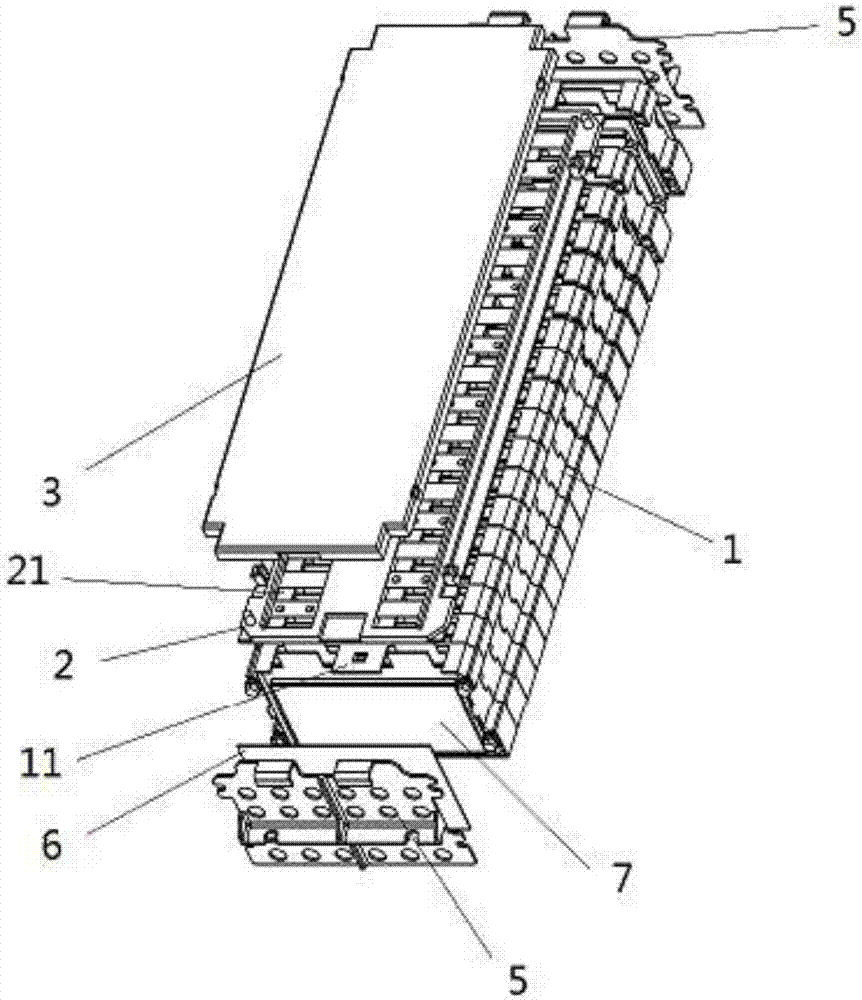

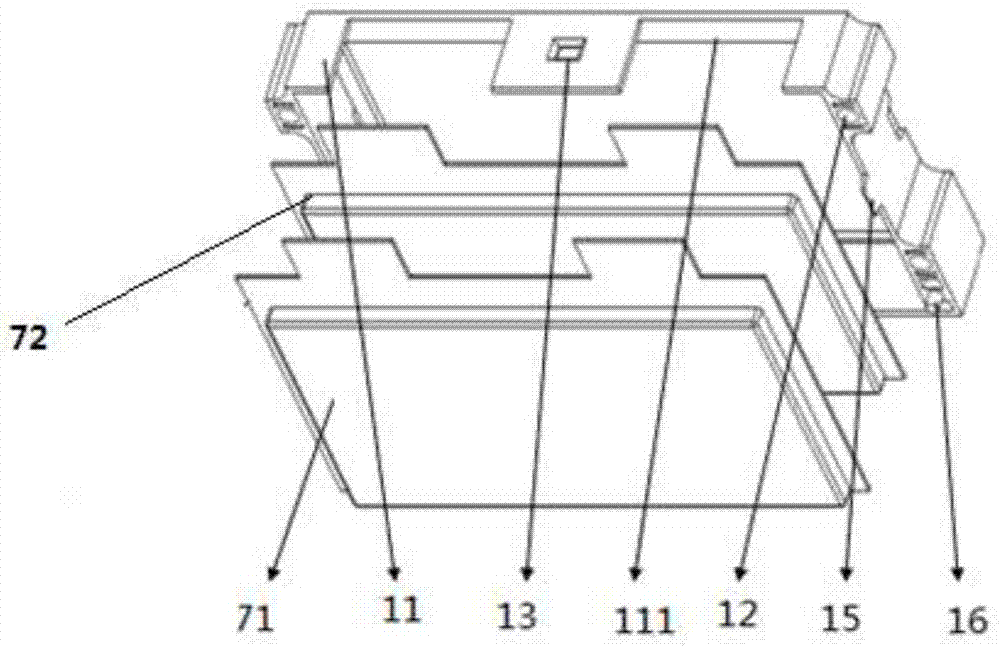

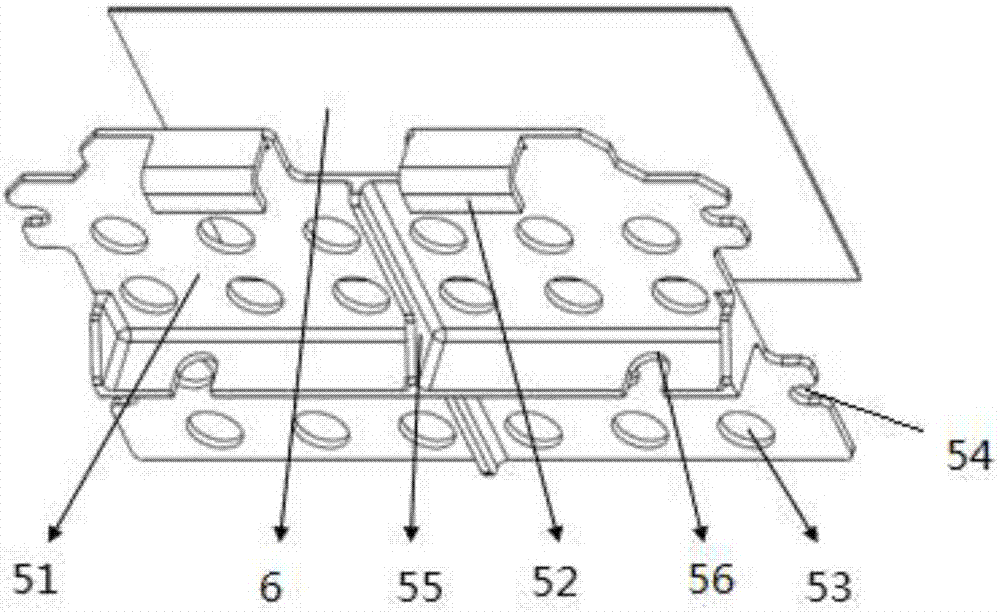

[0019] like figure 1 As shown, the soft-pack battery module fixing structure of this embodiment includes a battery module unit 1 and a cell assembly 7 disposed in the battery module unit 1, and the upper end of the battery module unit 1 is sequentially provided with snap-fit The cover plate 2 and the top cover 3 of the battery module unit 1 are provided with side pressure plates 5 connected and fixed with the battery module unit 1 through screw rods 4 at the left and right ends of the battery module unit 1. The strip-shaped holes 21 protrude from the battery lugs, and a heat insulating sheet 6 is provided between the side pressure plate 5 and the battery module unit 1 . The cell assembly 7 includes a plurality of pouch cells 71 stacked in sequence, and adjacent pouch cells 71 are separated from each other by a heat insulating layer 72 .

[0020] like figure 2 As shown, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com