Lighting device and vehicle lamp

A lighting device and a technology for installing grooves, which are applied in the field of lighting, can solve problems such as the influence of lighting light distribution of automobile lights, poor structural stability of light guide elements, etc., and achieve the effects of simple and reliable fixed structure, avoiding sliding, and facilitating processing and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

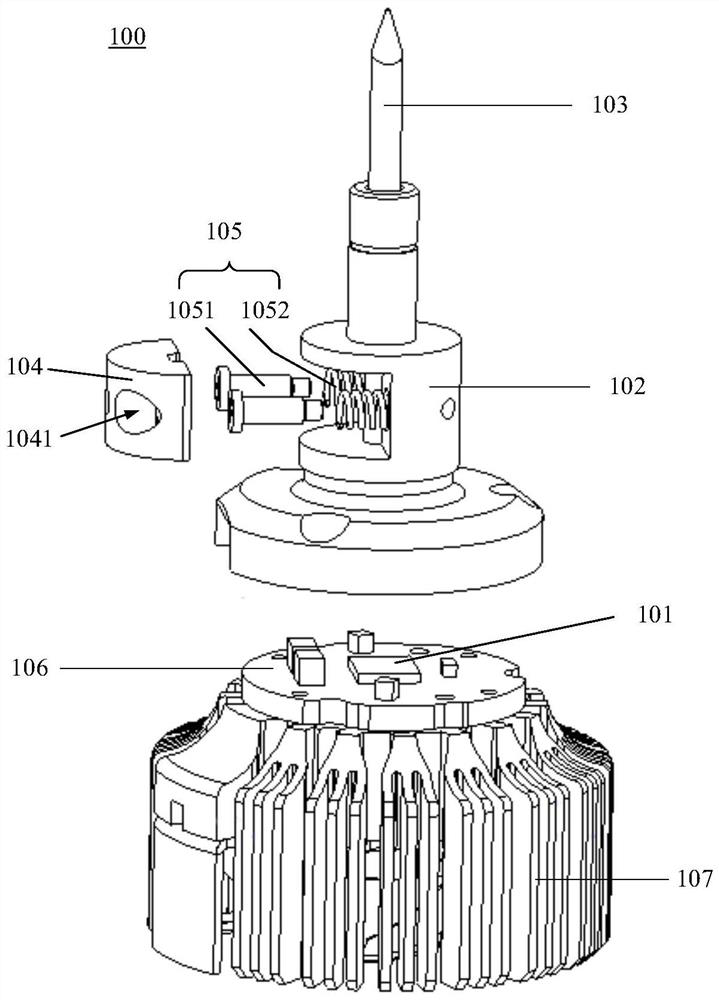

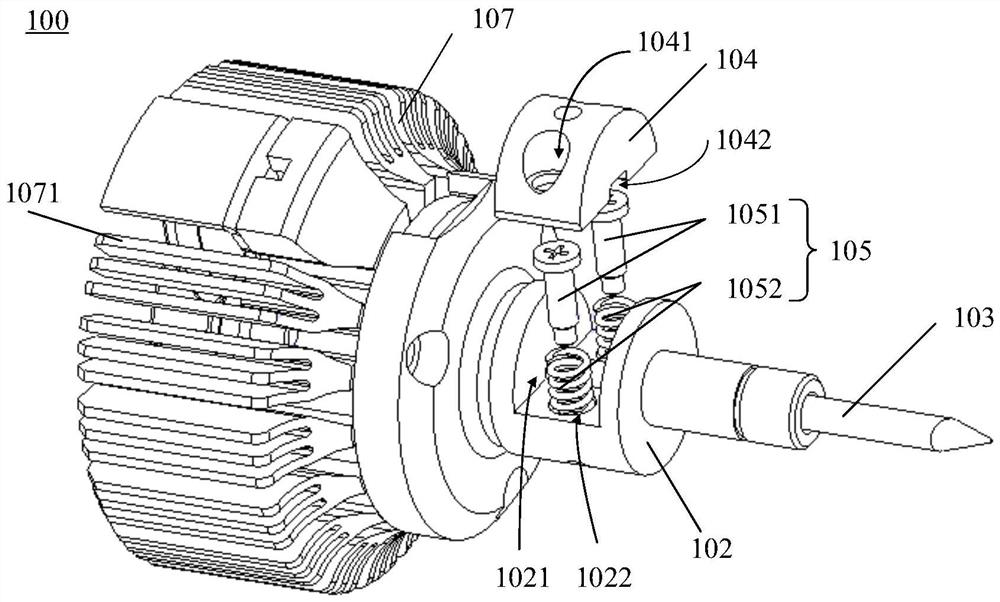

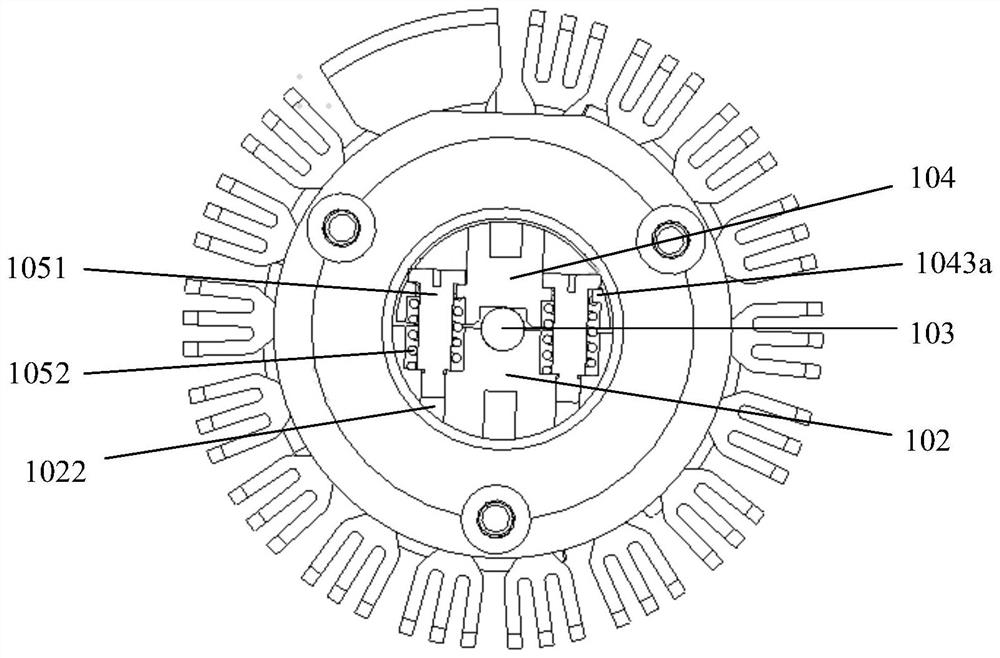

[0033] See figure 1 and figure 2 , figure 1 and figure 2 It is a schematic structural diagram of the lighting device 100 provided by Embodiment 1 of the present invention. The lighting device 100 includes a light emitting device 101 , a housing 102 , a light guide rod 103 , a fixing piece 104 , and an elastic component 105 .

[0034] The housing 102 is provided with a mounting hole and a mounting groove 1021 communicating with the mounting hole. The light guide rod 103 is inserted in the mounting hole. One end of the light guide rod 103 is the light incident surface, and the other end is the light exit surface. The light-emitting device 101 is opposite, and the light emitted by the light-emitting device 101 enters the light guide rod 103 through the light-incident surface, and exits from the light-exit surface; The component 105 is connected, and the elastic component 105 is elastically deformed so that the fixing member 104 fixes the light guide rod.

[0035] Compared w...

Embodiment 2

[0052] Please refer to Figure 7 and Figure 8 , Figure 7 It is a schematic structural diagram of the lighting device 200 provided by Embodiment 2 of the present invention, Figure 8 It is a schematic diagram of the fixing structure of the light guide rod 103 of the lighting device 200 in the second embodiment of the present invention. The components in this embodiment that are the same as those in Embodiment 1 are denoted by the same serial numbers. The difference between this embodiment and Embodiment 1 is that the mounting groove 2021 on the housing 202 is a threaded hole, the fixing piece 204 is in the shape of a sheet, which is made of rigid metal material, and can be placed in the mounting groove 2021, and the connecting piece 2051 As a stud matching the mounting groove 2021, the connecting piece 2051 is threadedly connected to the mounting groove 2021, so that the connecting piece 2051 is fixed on the housing 202, the elastic piece 2052 is arranged between the conne...

Embodiment 3

[0056] Please refer to Figure 9 and Figure 10 , Figure 9 It is a schematic structural diagram of the lighting device 300 provided by Embodiment 3 of the present invention, Figure 10 It is a schematic diagram of the fixing structure of the light guide rod 103 of the lighting device 300 in the second embodiment of the present invention. The components in this embodiment that are the same as those in Embodiment 1 are denoted by the same serial numbers. The difference between this embodiment and Embodiment 1 is that the installation groove 3021 on the housing 302 is a threaded hole, the fixing piece 304 is in the shape of a sheet, which is made of rigid metal material and can be placed in the threaded hole, and the connecting piece 3051 is The stud matching the threaded hole, the connecting piece 3051 is threadedly connected with the mounting groove 3021 , so that the connecting piece 3051 is fixed on the housing 302 , and the elastic piece 3052 is a spring, which is arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com