Patents

Literature

73results about How to "Meet capacity requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

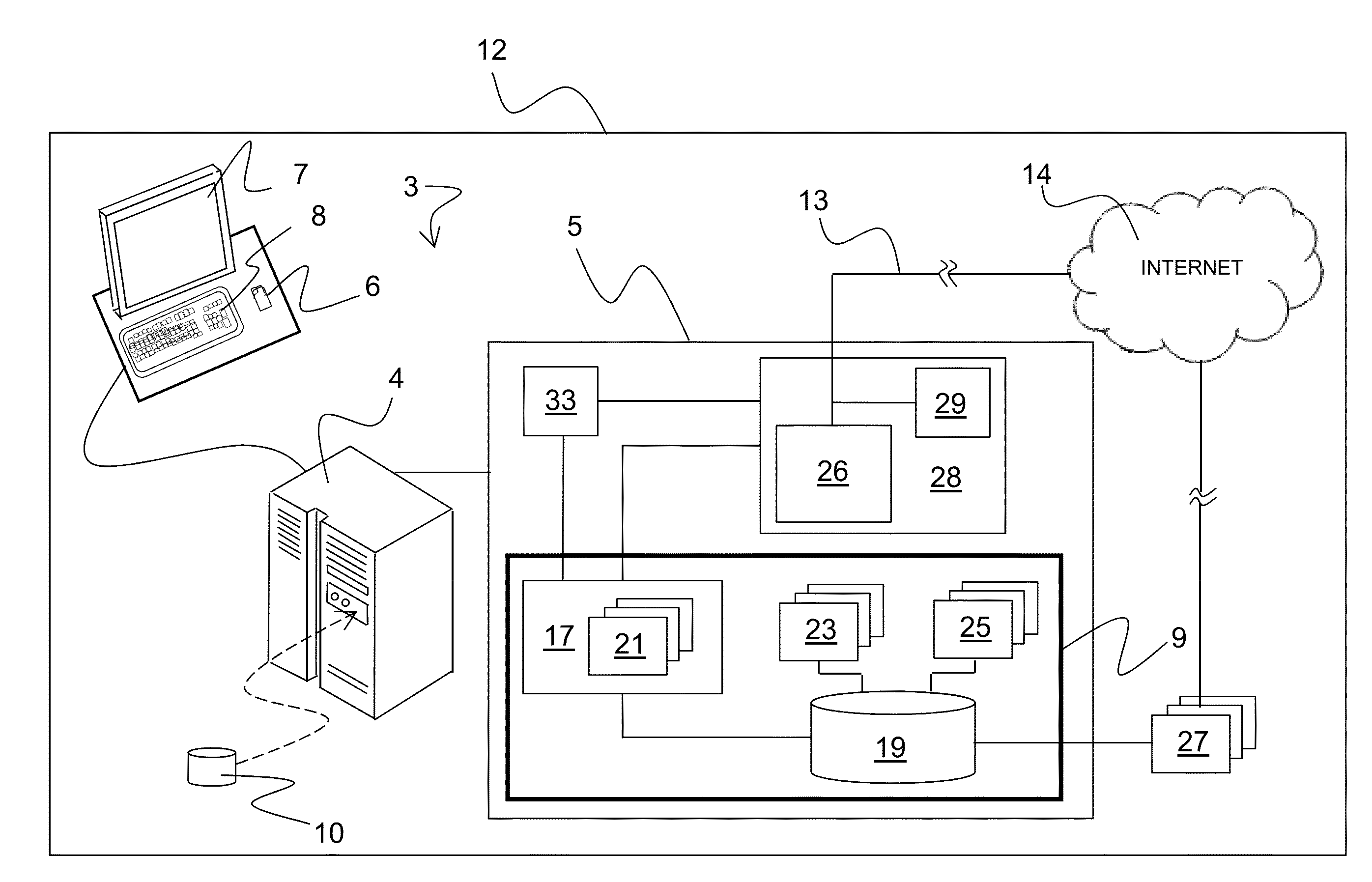

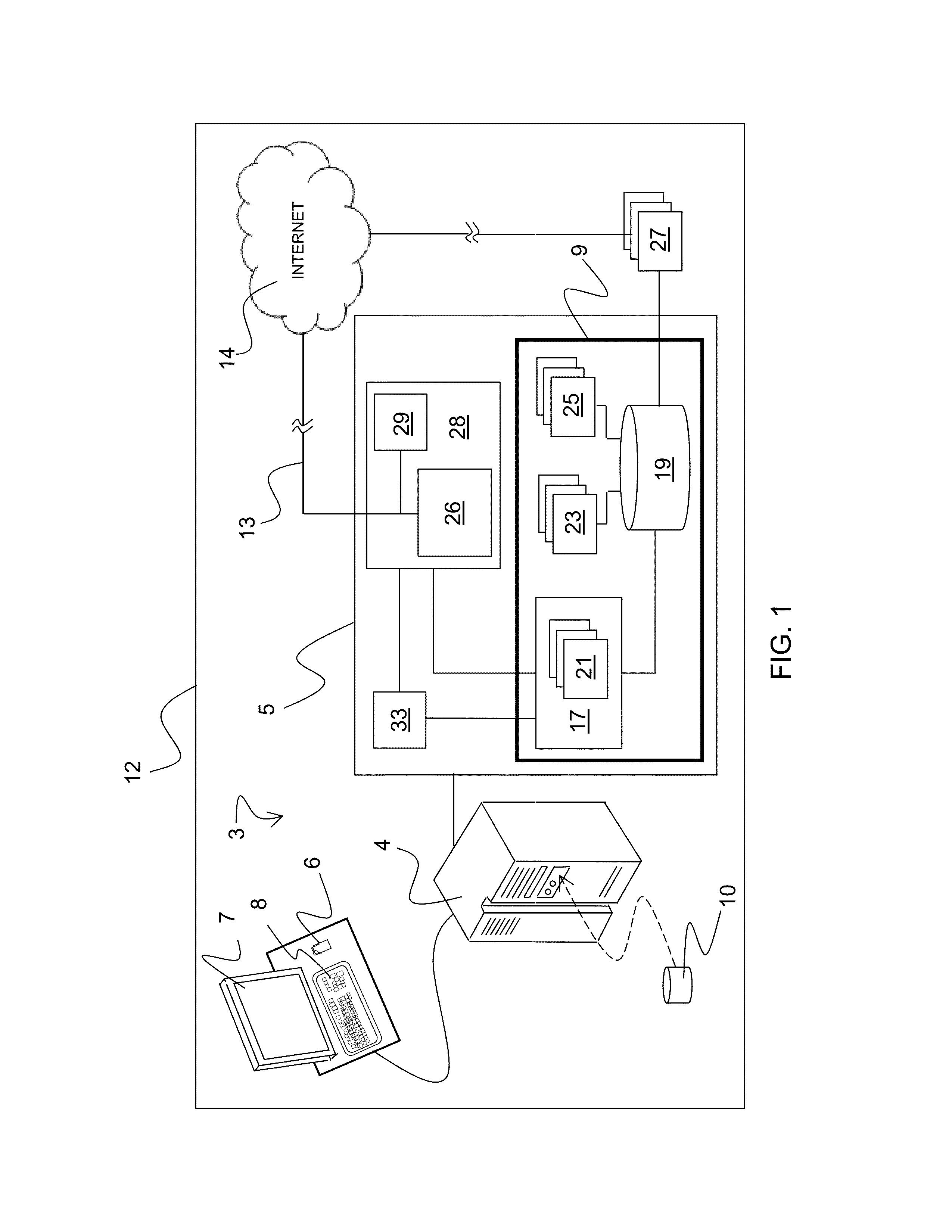

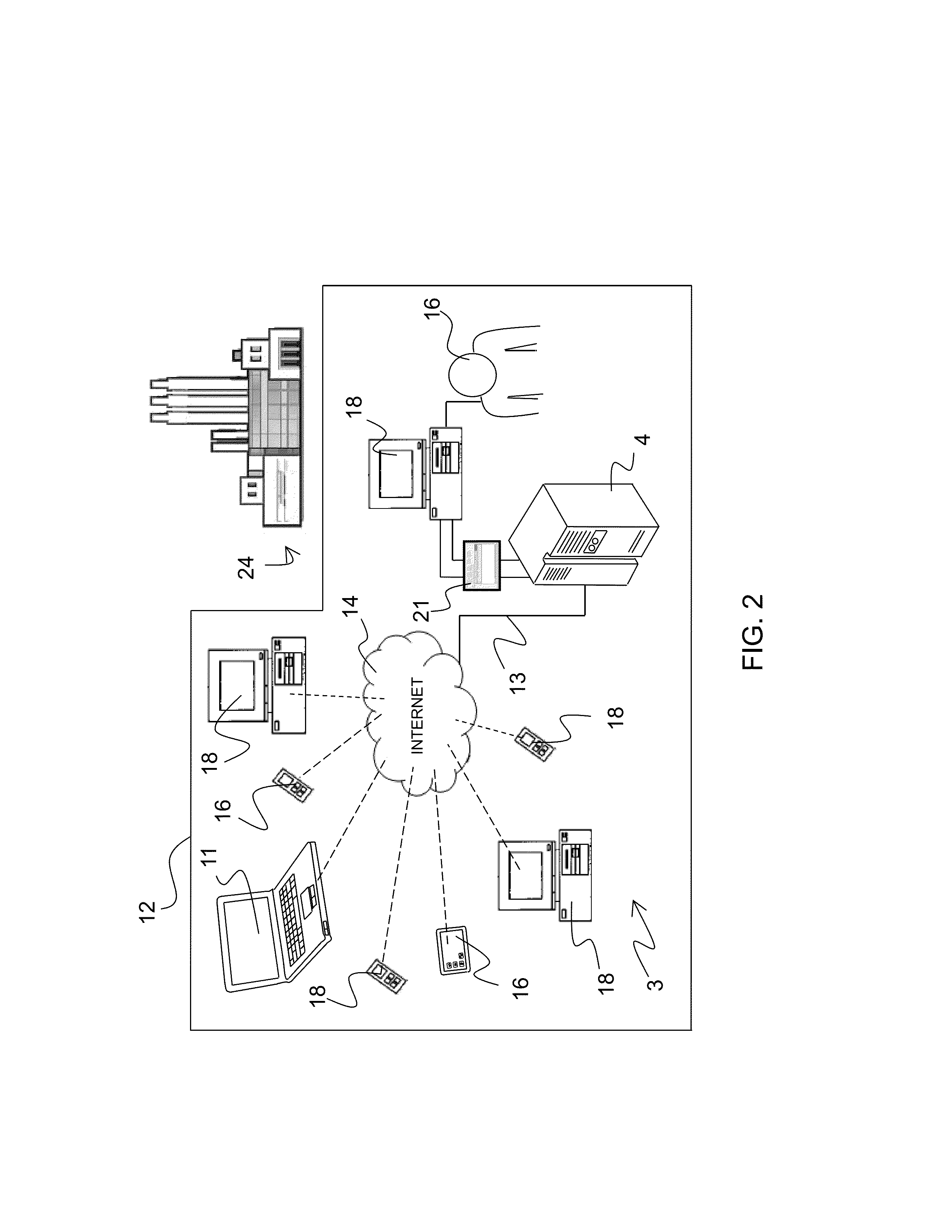

Method and apparatus for competitive solicitation and bidding

A method and apparatus for providing secure, online centralized control over a solicitation and bidding process and more particularly the method and apparatus for the procurement of services and commodities, such as for example, procuring electricity to meet capacity for an electric generating plant, the method and apparatus providing screening and rejection of unqualified applicants, transparency exceeding governmental guidelines, options to aggregate offers among bidders that meet criteria, and facilitate automated, real time bid evaluation and ranking.

Owner:ACCION GRP

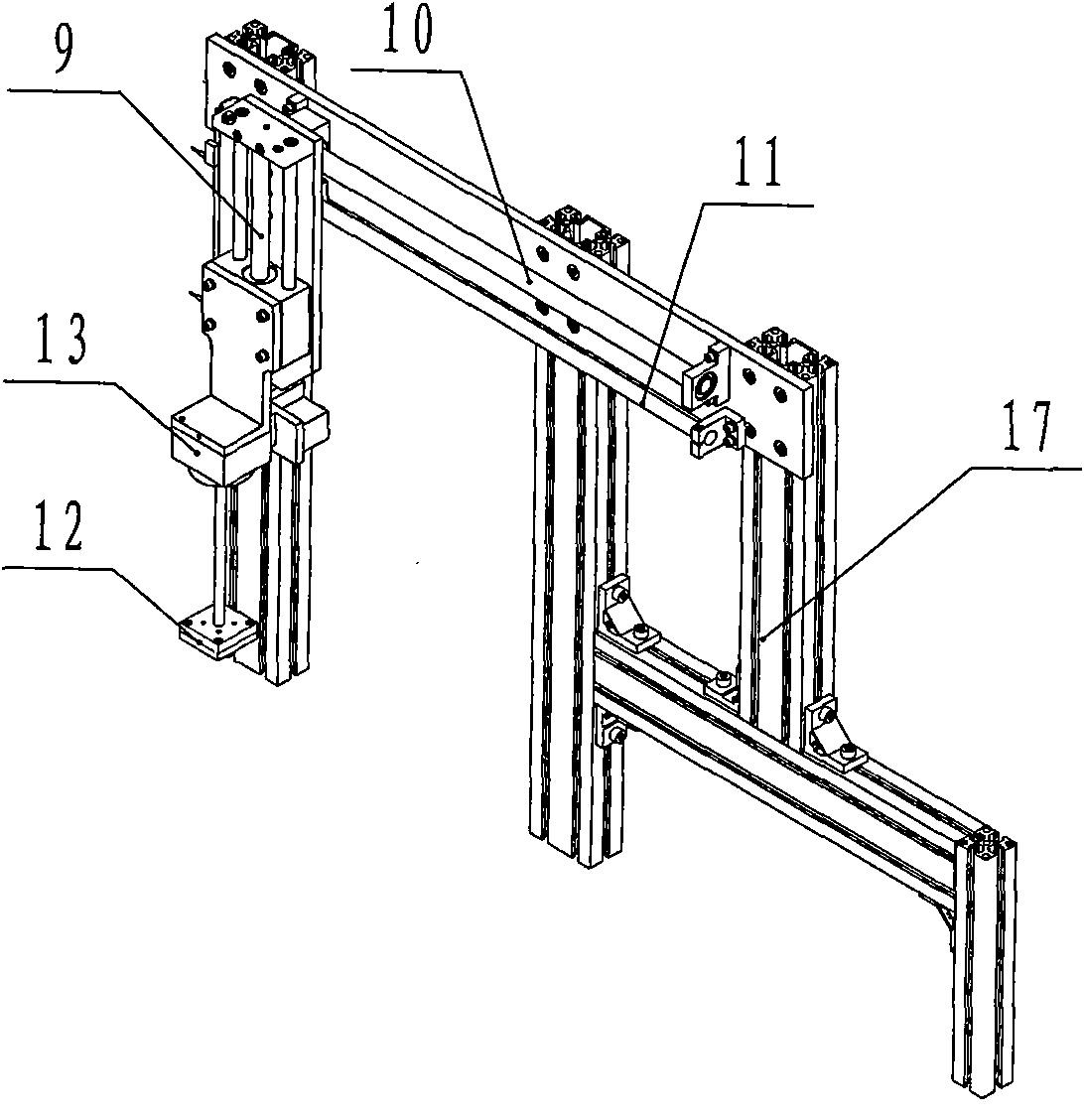

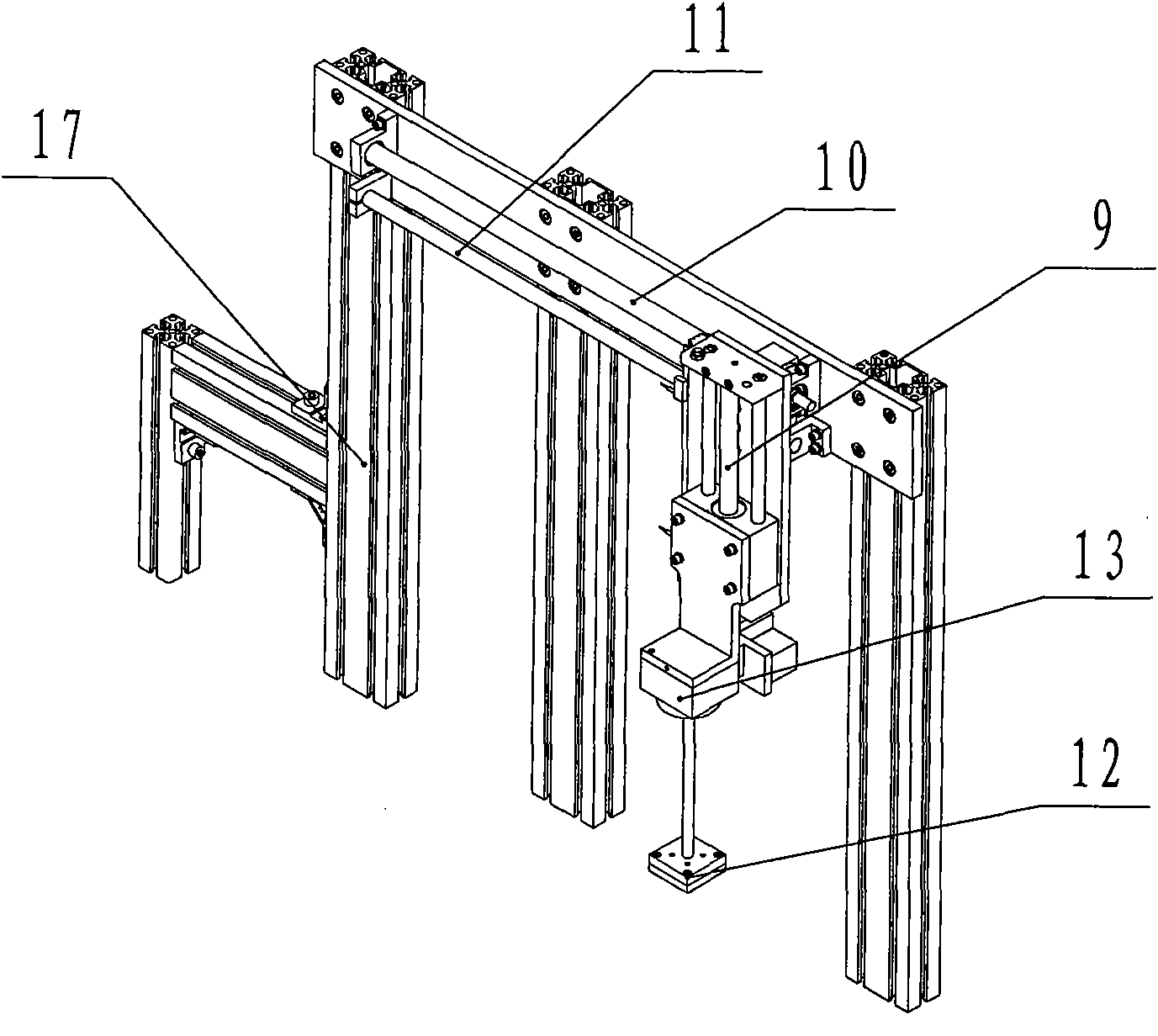

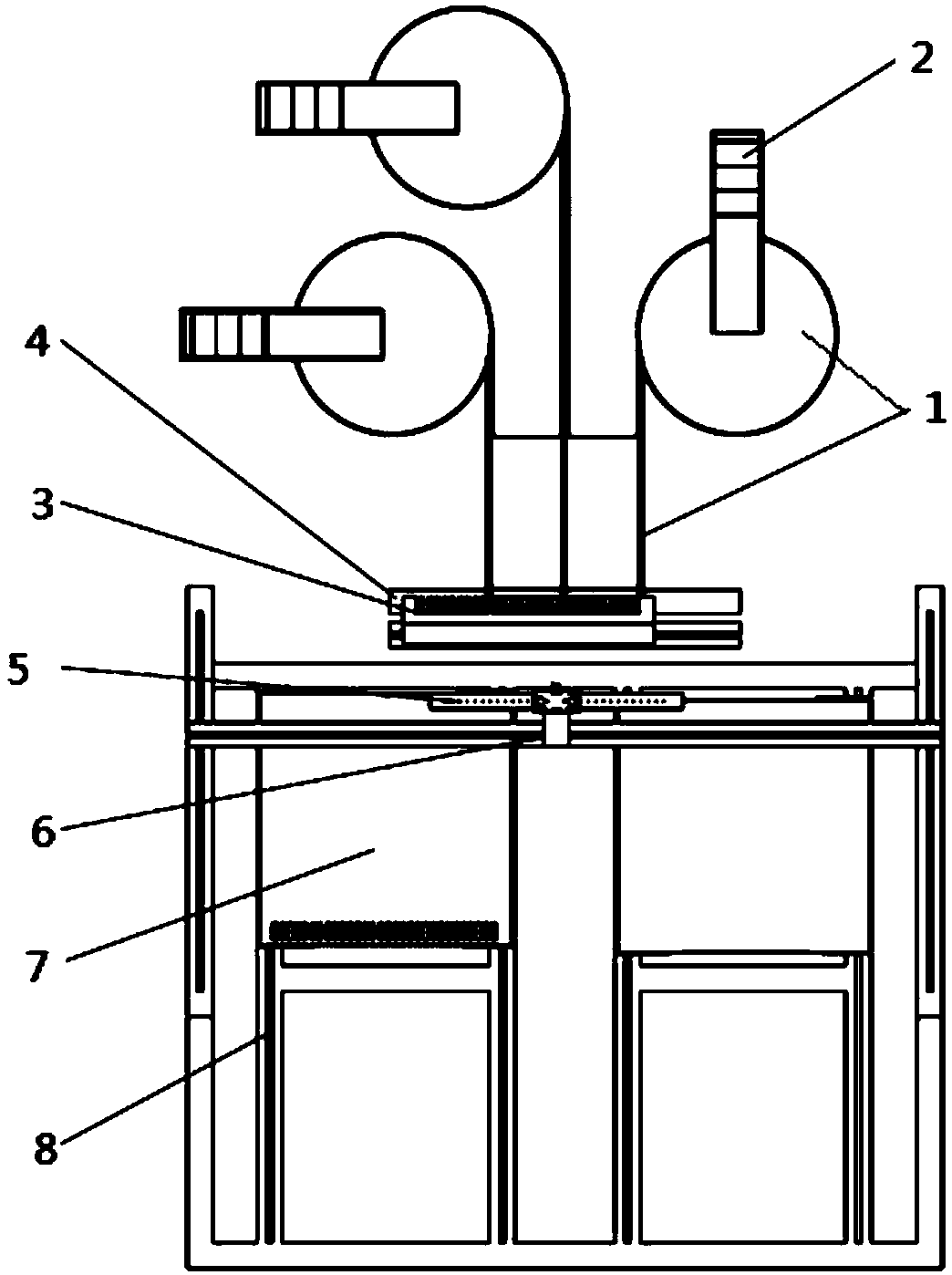

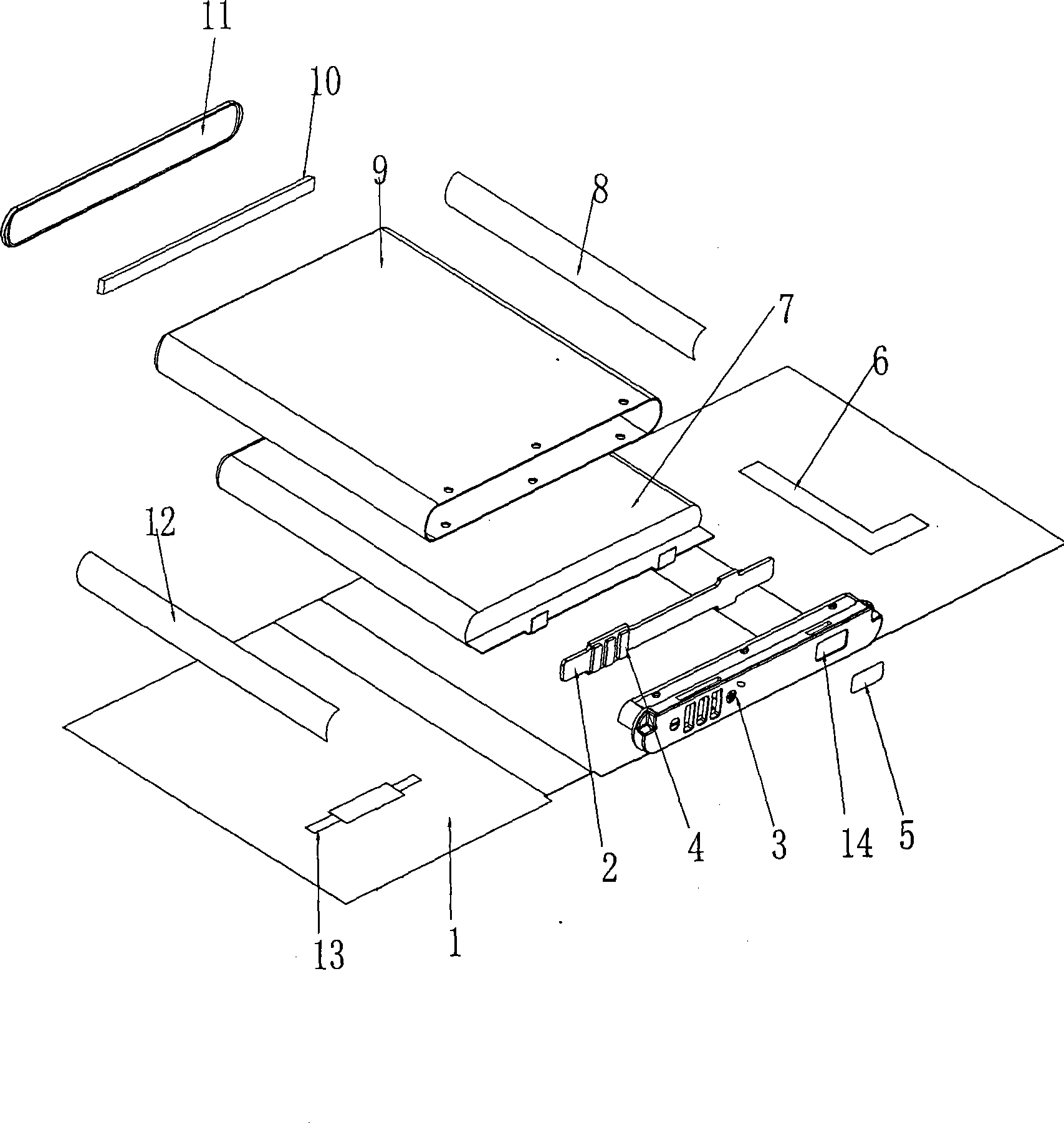

Electrode piece loading device for power lithium battery

The invention discloses an electrode piece loading device for a power lithium battery. The device solves the problem that an electrode piece loading device for the power lithium battery does not exist currently. The device comprises an anode and cathode piece shaping mechanism and an anode and cathode piece conveying mechanism. The anode and cathode piece shaping mechanism comprises a bracket and a loading platform respectively, wherein left and right rotary screw rods are arranged below the loading platform; bearing blocks are sleeved on two sides of each of the left and right rotary screw rods; the bearing block and four sides of the bottom of the loading platform are fixed; a long hole is reserved on the loading platform; a baffle plate passes through the long hole; and a nut is fixed on the baffle plate. The anode and cathode piece conveying mechanism comprises a pedestal and a push cylinder respectively, wherein the pedestal is respectively provided with a precision ball screw rod and a guide shaft; a sucking disc is fixed below the push cylinder; the push cylinder is sleeved on the guide shaft, and is in threaded connection with the precision ball screw rod. The positioning precision is greatly improved; the positioning time is shortened; the production efficiency is effectively improved; and the device has the advantages of simple structure, convenient operation and low cost.

Owner:TAIYUAN FENGHUA INFORMATION EQUIP

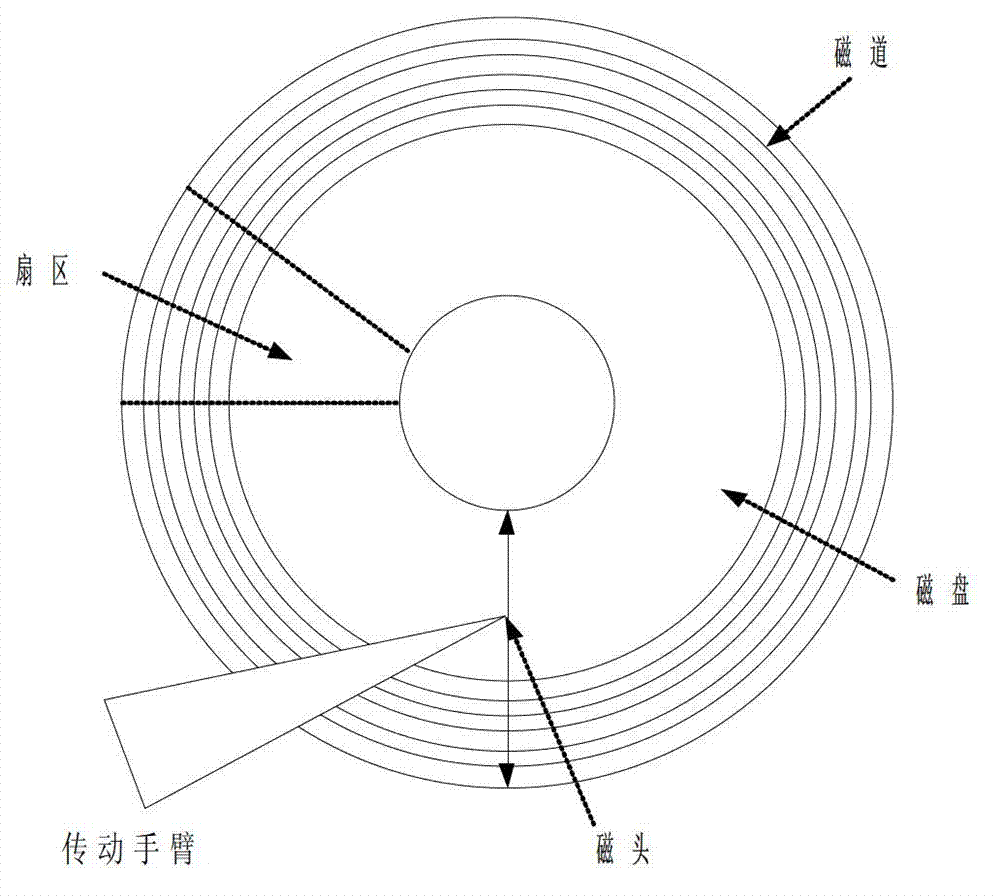

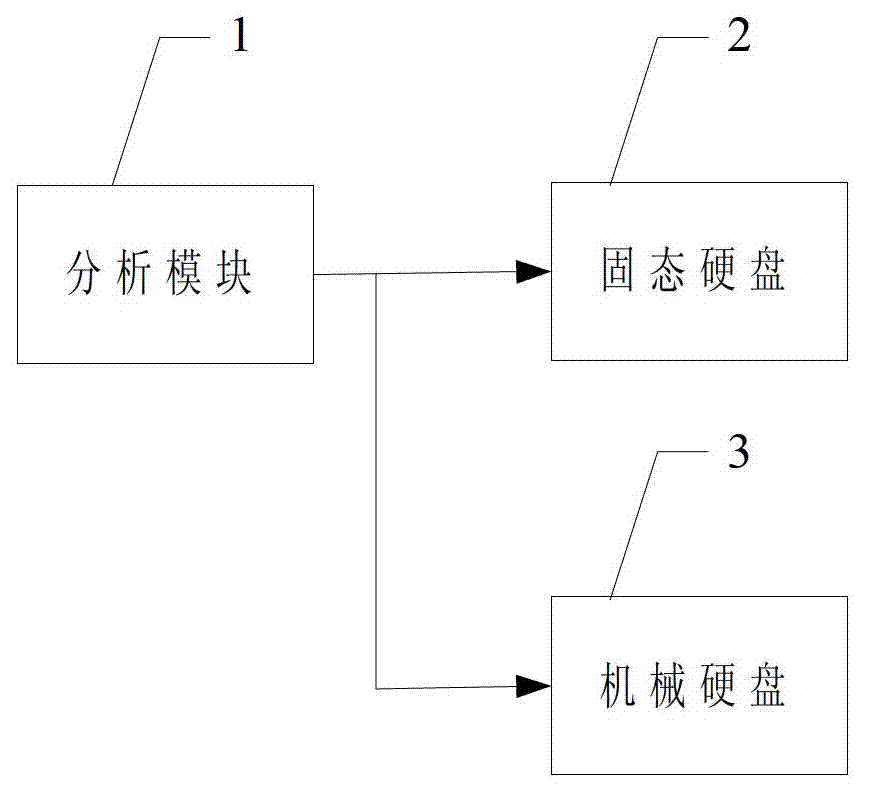

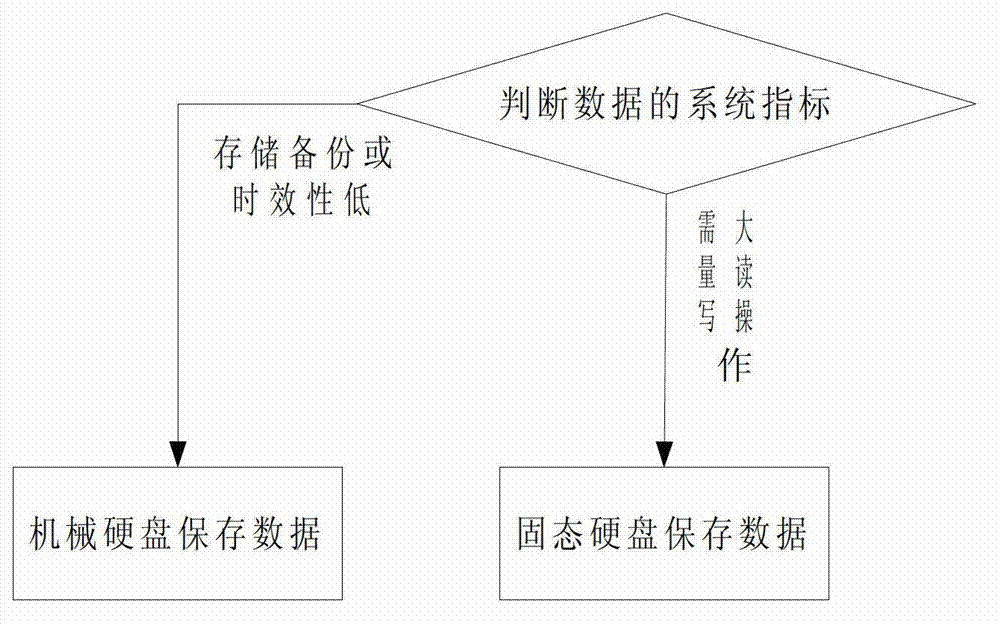

Storage system and method for concentration type system

InactiveCN103076993AReduce dependenceCost-effectiveInput/output to record carriersRequirements analysisSolid-state drive

The invention relates to a storage system and method for a concentration type system. The storage system for the concentration type system comprises a requirement analysis module, a solid hard disc and a mechanical hard disc; wherein the requirement analysis module is used for analyzing the system index of data needed to be stored in the system and respectively sending the data into the solid hard disc and the mechanical hard disc for storage; the solid hard disc is used for storing data needed to be subjected to a large amount of reading and writing operation and frequent implementation of input and output operation; and the mechanical hard disc is used for storing backups or data with low time validity and limited random input and output. According to the storage system, the mechanic hard disc and the solid hard disc are used for layering storage, the characteristic of high I / O (input / output) of the solid hard disc can be maximally utilized; the dependence on a storage network is reduced, a local hard disc can be directly used for carrying out processing and backup of tickets, and the cost performance of a storage scheme is greatly improved; and the cost of construction and maintenance is lowered.

Owner:北京思特奇信息技术股份有限公司

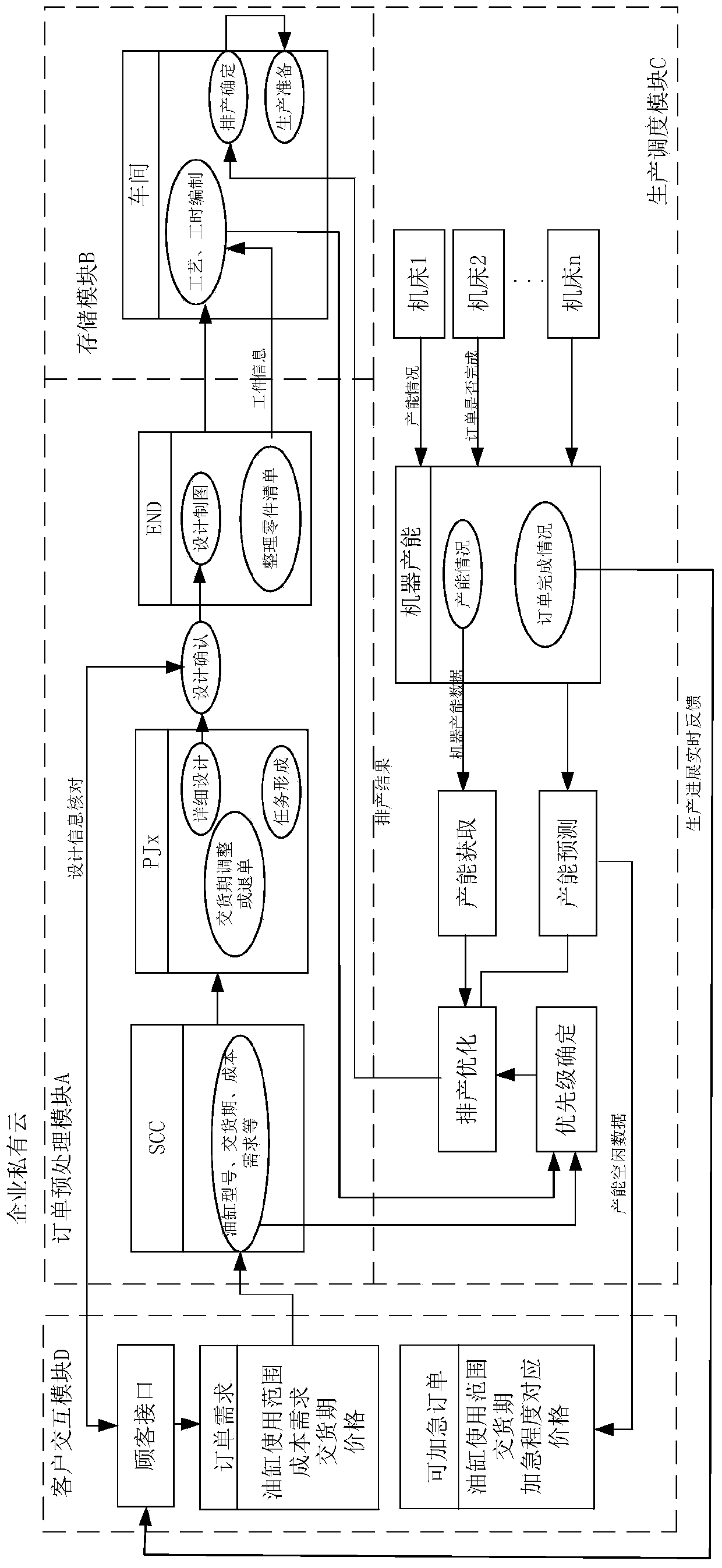

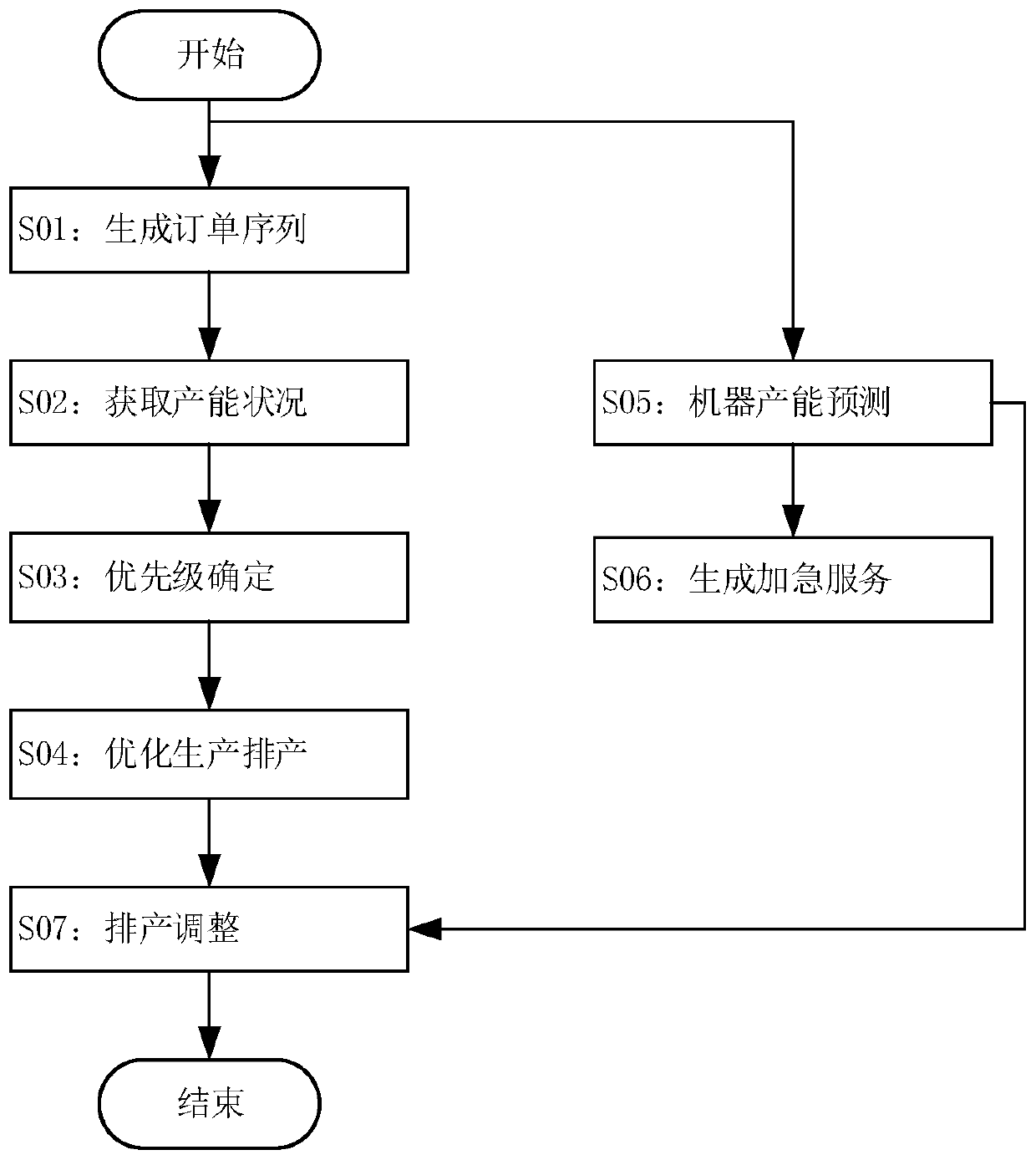

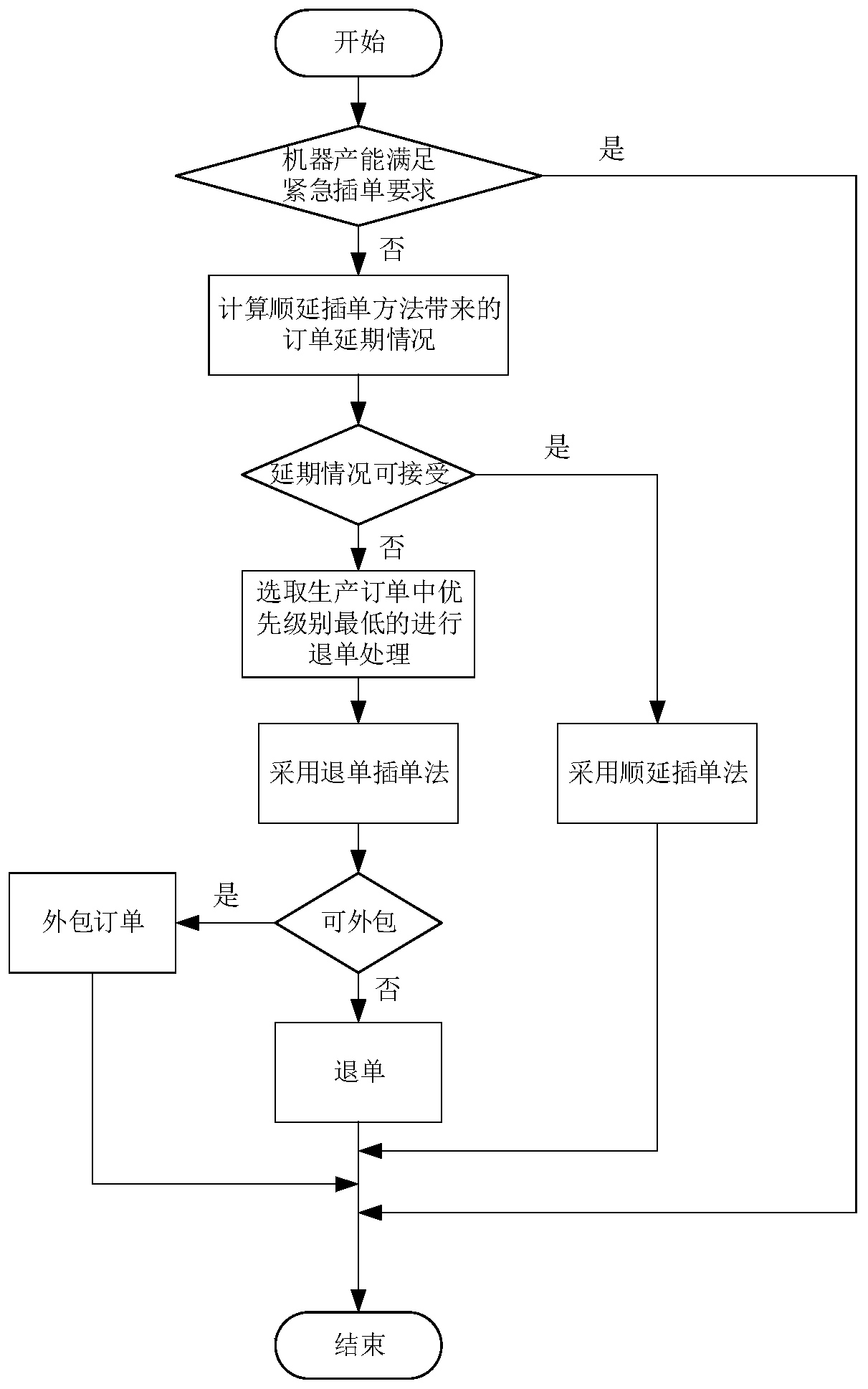

Oil cylinder product production scheduling optimization device for complex customization demands of customers

ActiveCN111191846ADistribute quicklyAllocation is accurateForecastingBuying/selling/leasing transactionsCustomer requirementsProcess engineering

The invention relates to an oil cylinder production scheduling optimization device for complex customization demands of customers, which comprises an order preprocessing module, a production scheduling module, an information storage module and a customer interaction module, wherein the order preprocessing module is used for processing customer demands to obtain a production task package; the production scheduling module is used for obtaining an optimal production scheduling plan of the current production task package according to the machine capacity condition, and the production tasks comprise an order insertion task and an unexecuted waiting task; the information storage module is used for storing the production task package and the optimal production scheduling plan; and the customer interaction module is used for realizing communication with a client. Compared with the prior art, the device has the advantages of improving the utilization rate and production efficiency of processingequipment and the like.

Owner:TONGJI UNIV

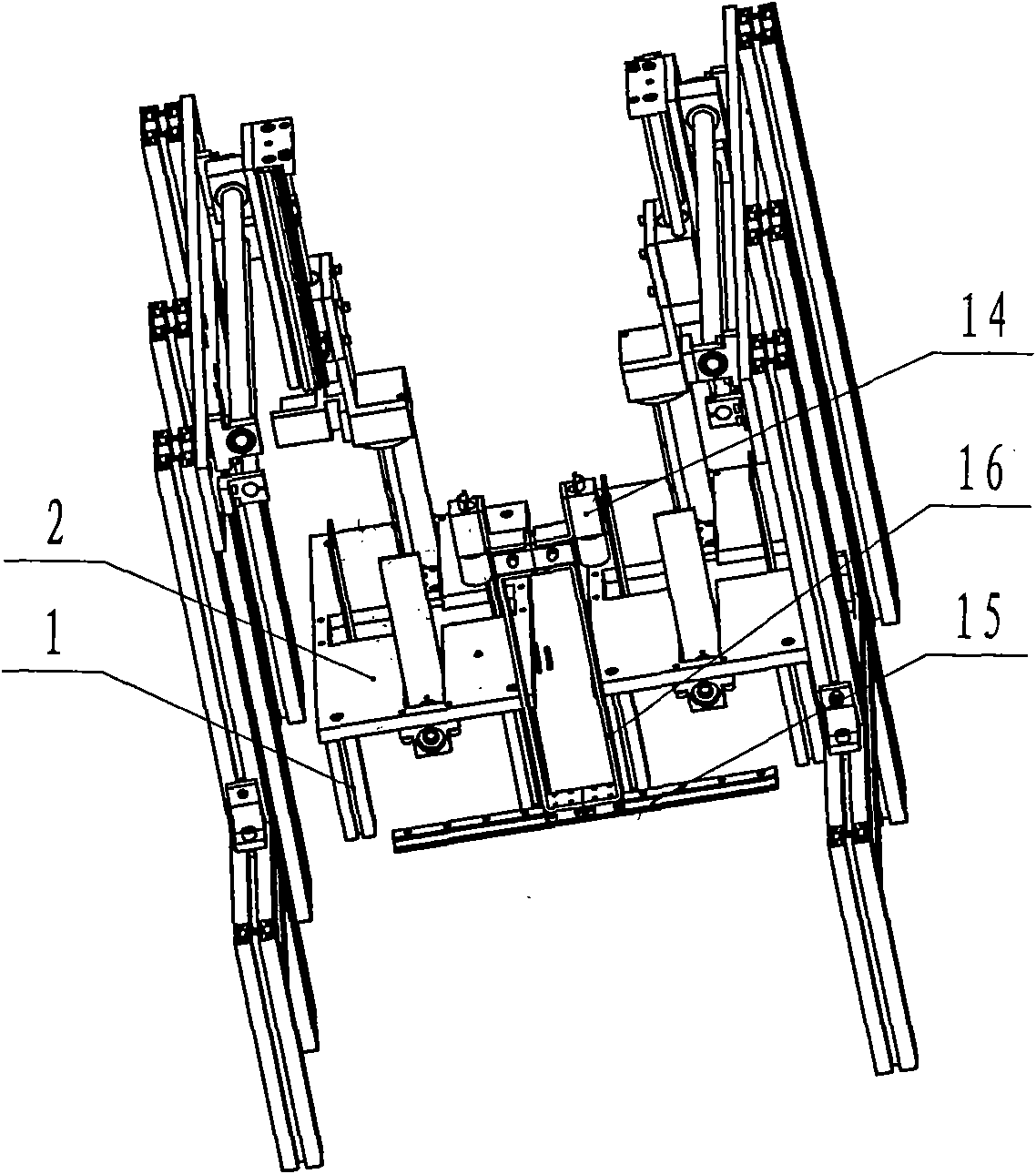

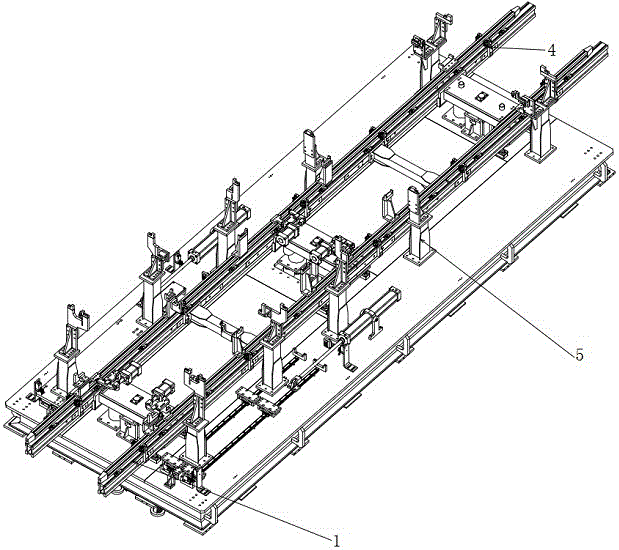

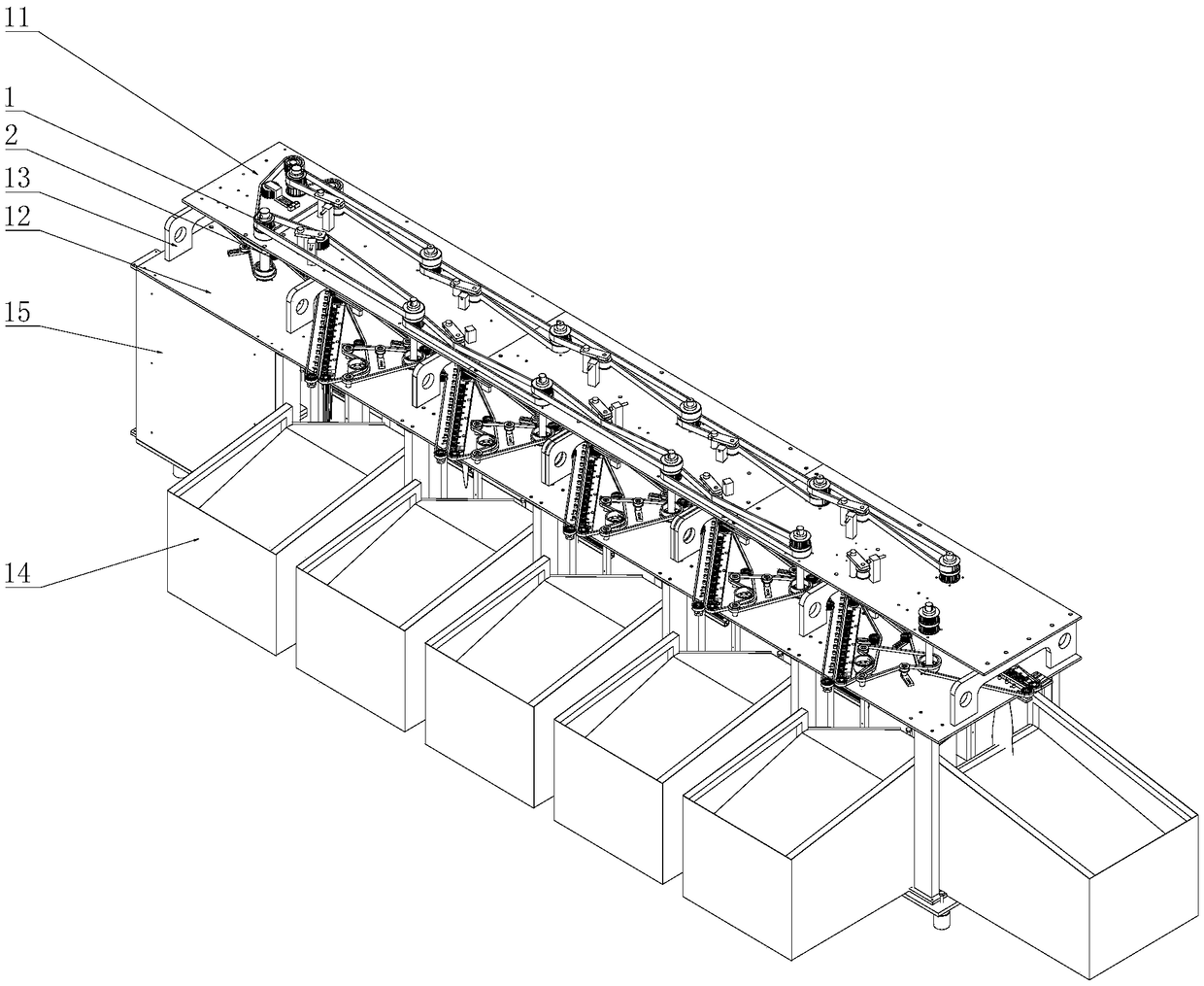

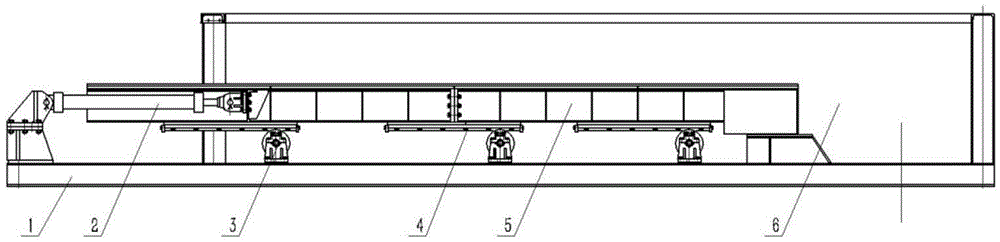

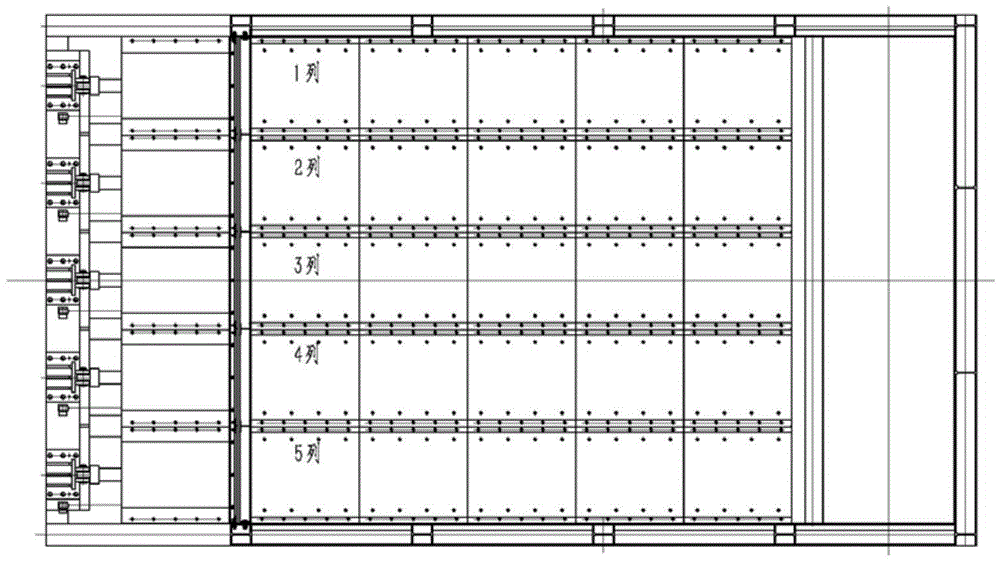

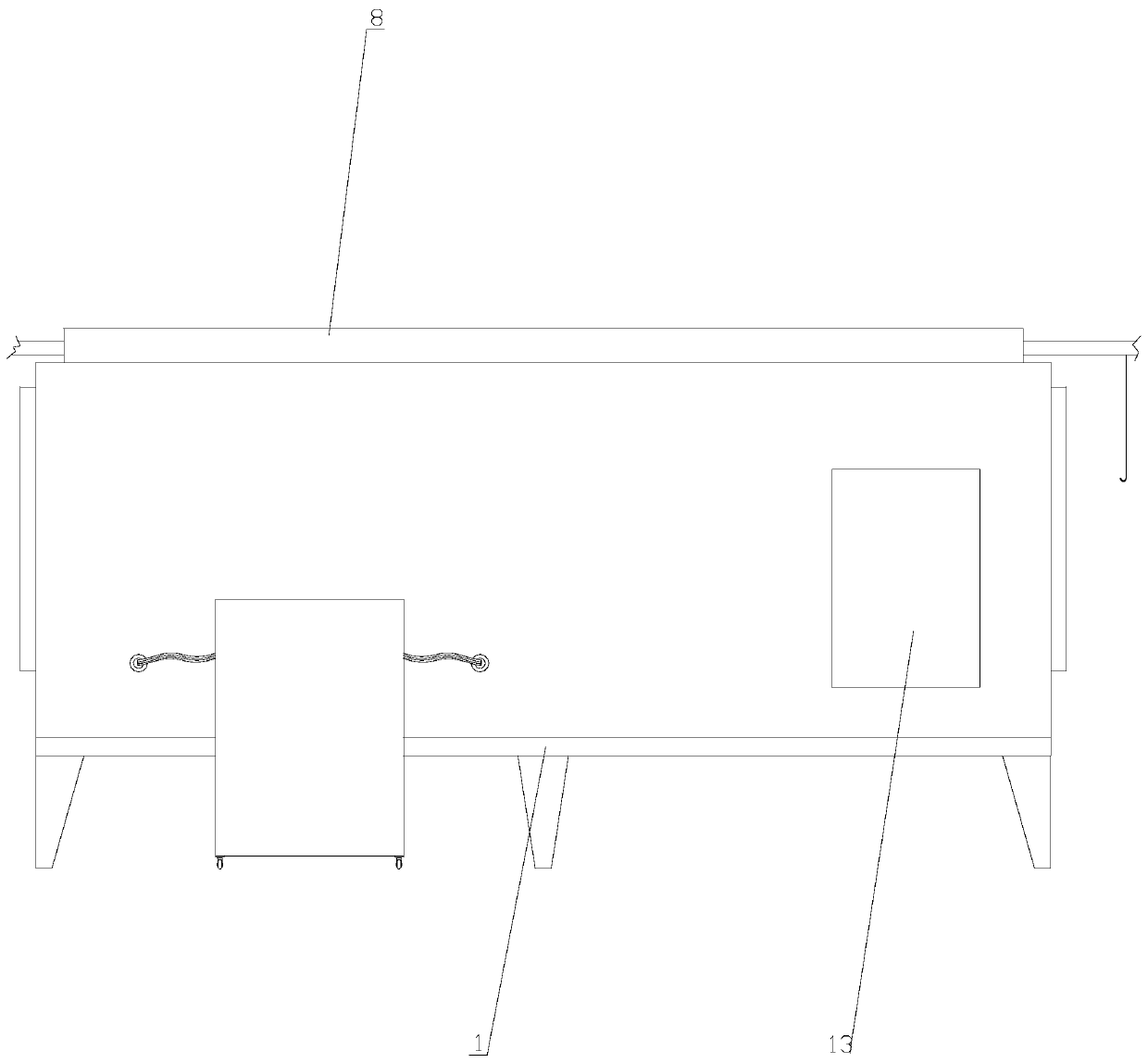

Manual stepping type car body main welding line skid conveying system

InactiveCN106219178ASolve the uniqueness defectAvoid irreplaceabilityMechanical conveyorsEngineeringElectric control

The invention discloses a manual stepping type car body main welding line skid conveying system. The manual stepping type car body main welding line skid conveying system comprises a conveying split sliding rail. A roller bed split skid is installed on a conveying jacking structure. Pneumatic jacking devices are arranged under the conveying sliding rail. A roller bed is provided with the manual stepping hand-push split type roller bed skid. An electronic control unit controls the pneumatic jacking devices to conduct automatic jacking, so that the skid is automatically conveyed. According to the manual stepping type car body main welding line skid conveying system, a set of independent jacking sliding mechanism is adopted, system production synchronization is ensured, the split type skid can overcome the defect that the structure is unique, the conveying method is flexibly adjusted, and the capacity requirements are met; compatible using among welding stations can be achieved, the cost is reduced, the situation that the parts cannot be replaced after being abraded is also avoided, and finally only one set of electronic control unit needs to be added to automatically convey the skid; and integrated planning and step-by-step construction implementation are conducted, thus, the various capacity requirements can be met, the investment cost is reduced, the conveying method is flexibly adjusted, and the technology structure during early-stage investment can be fully applied and upgraded in the later period.

Owner:HIGER

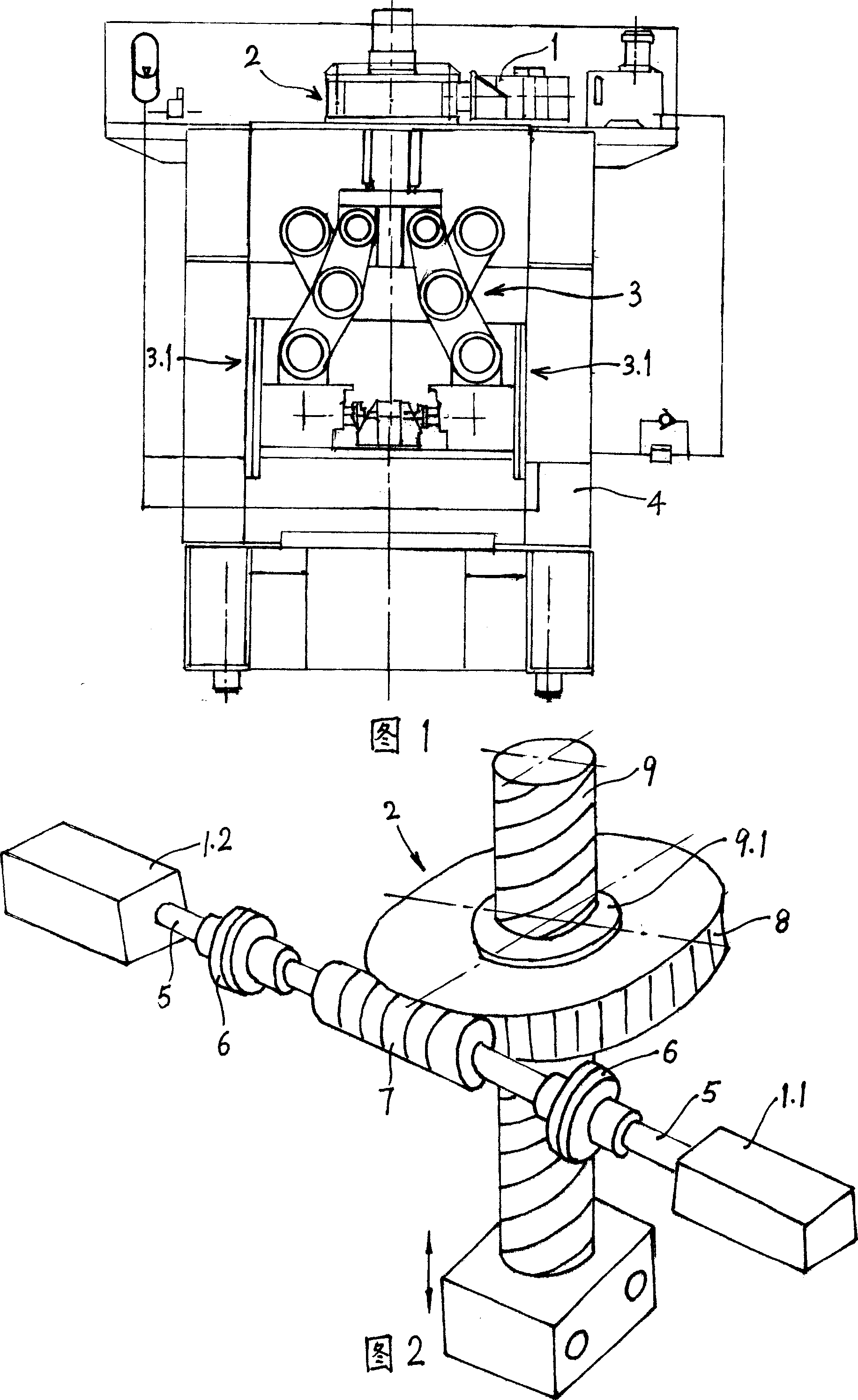

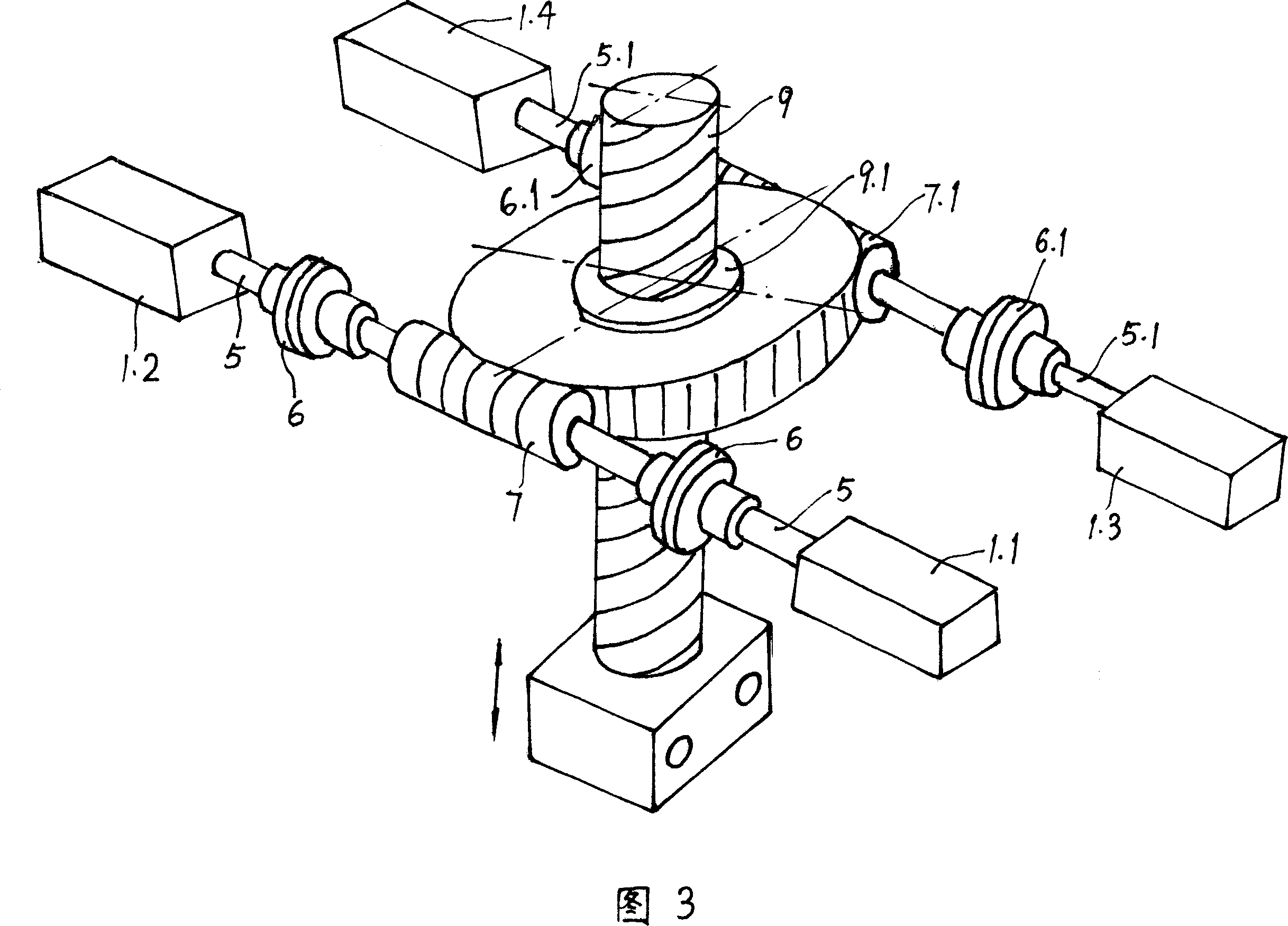

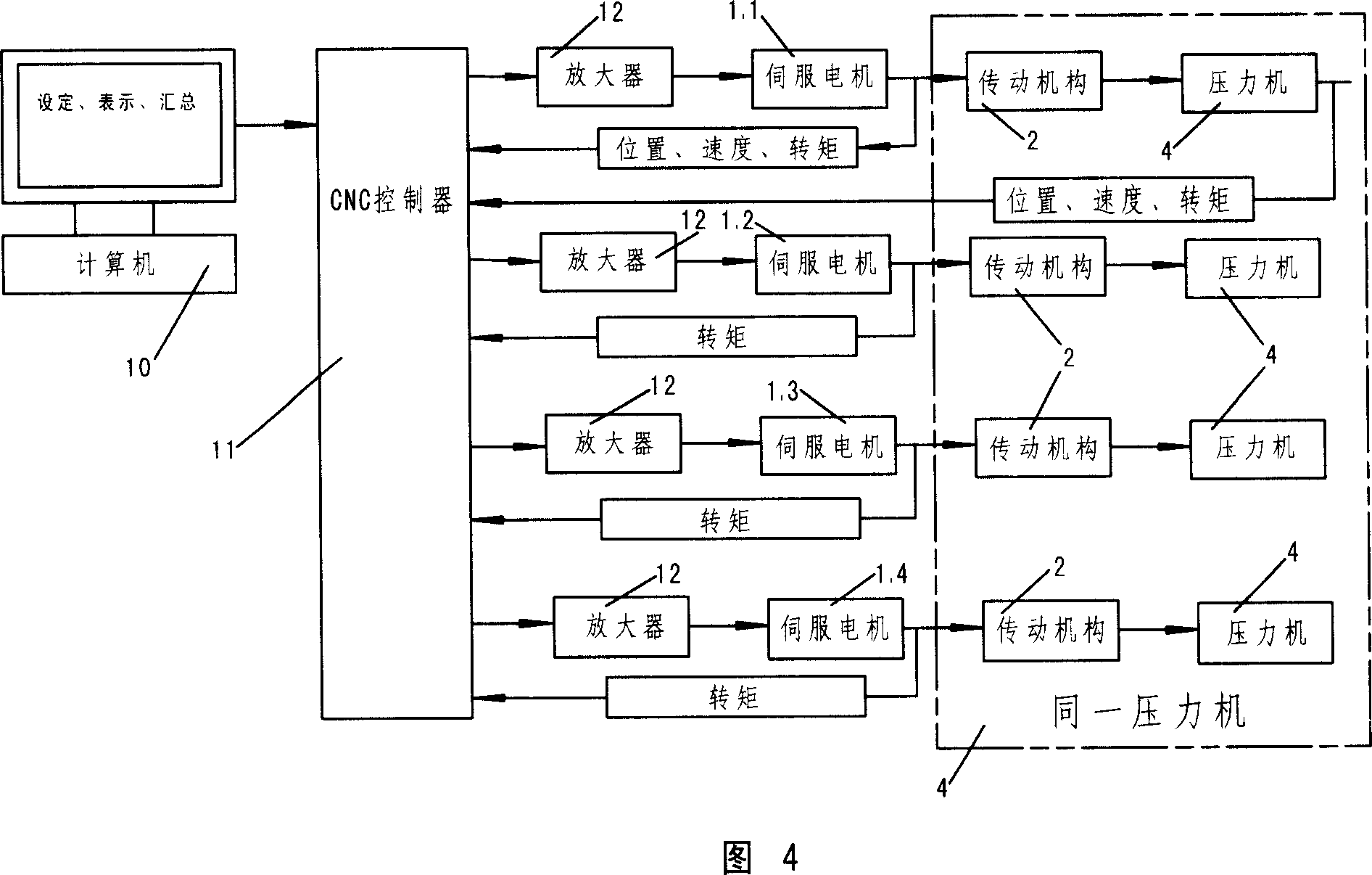

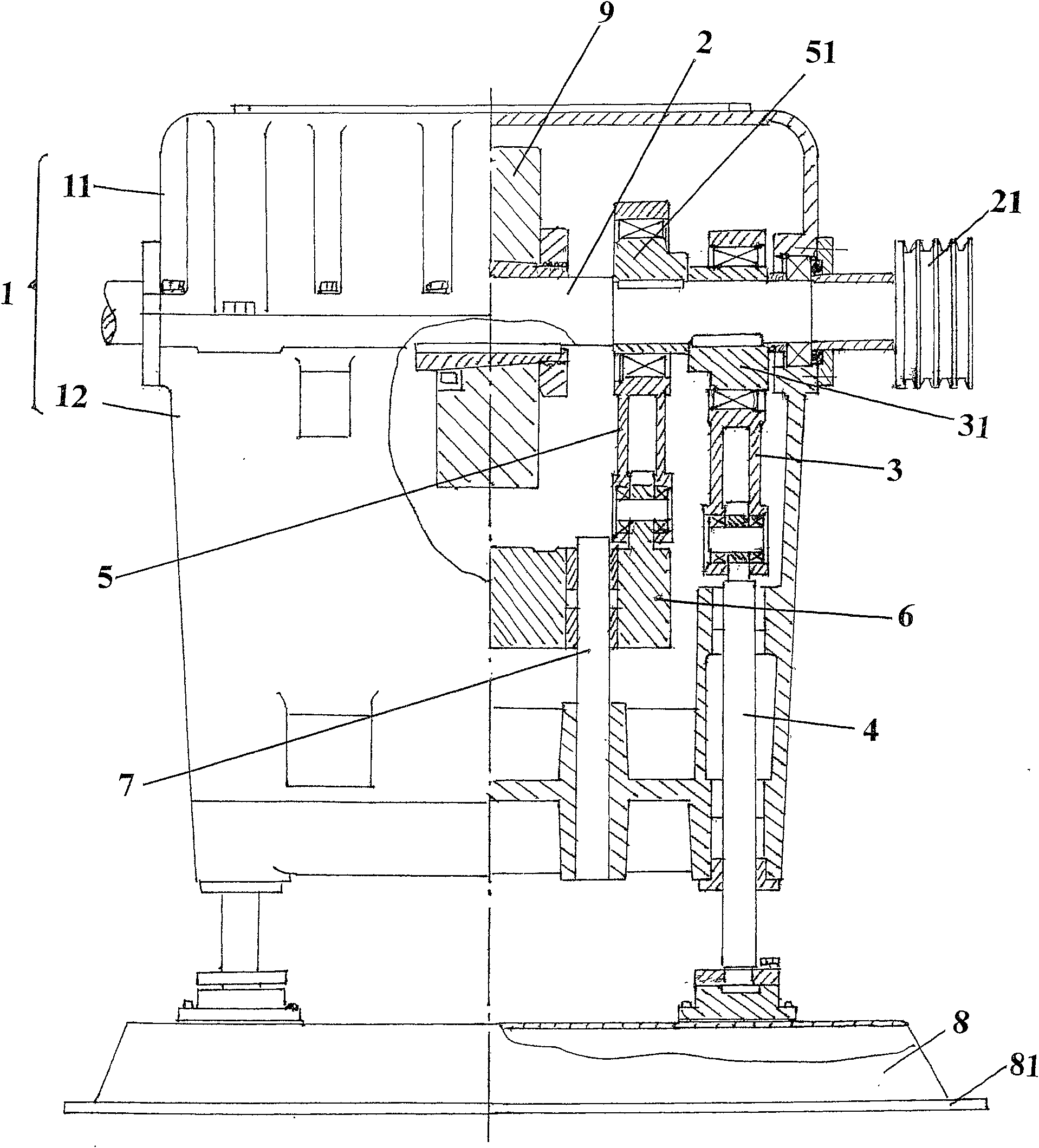

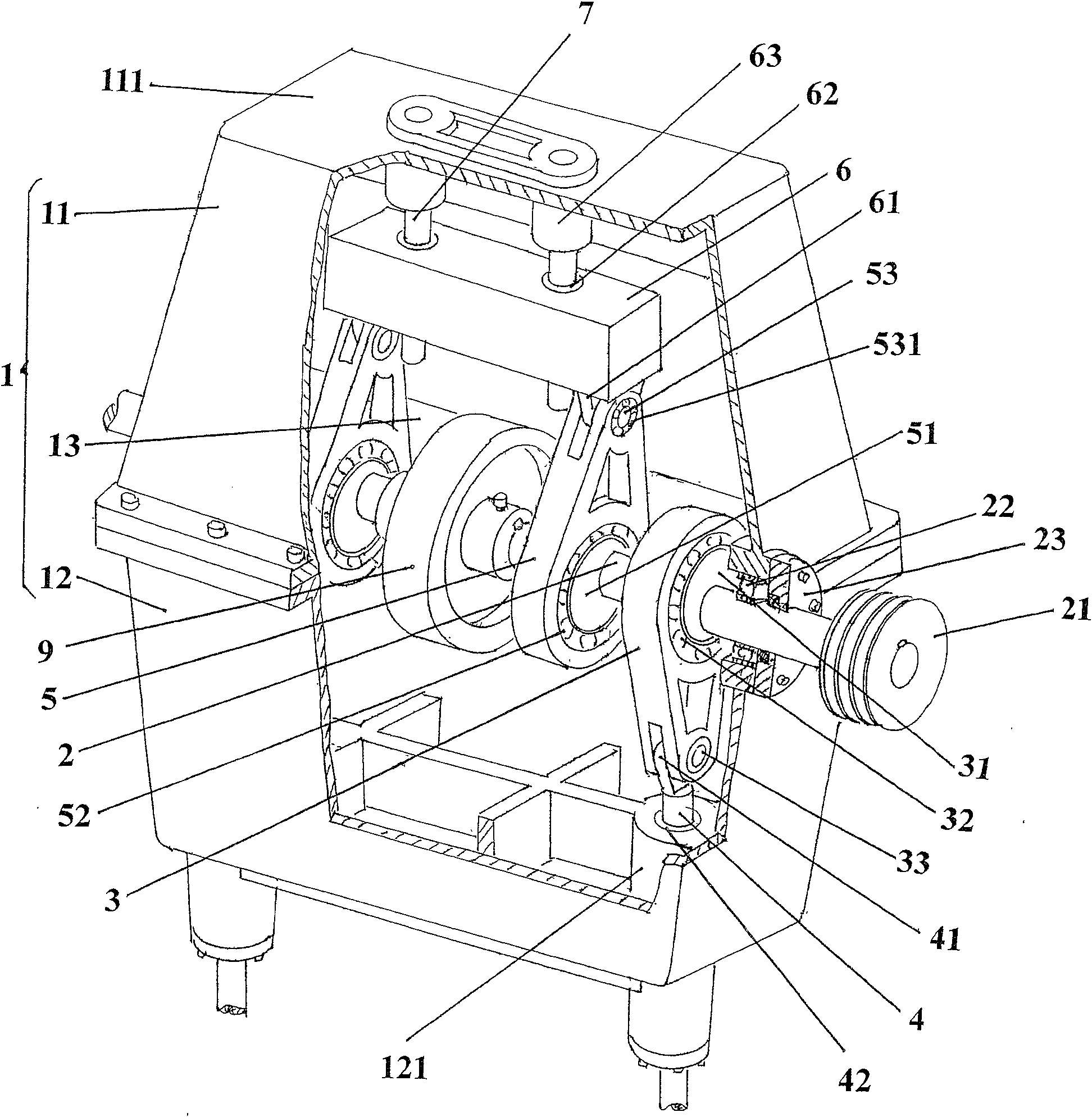

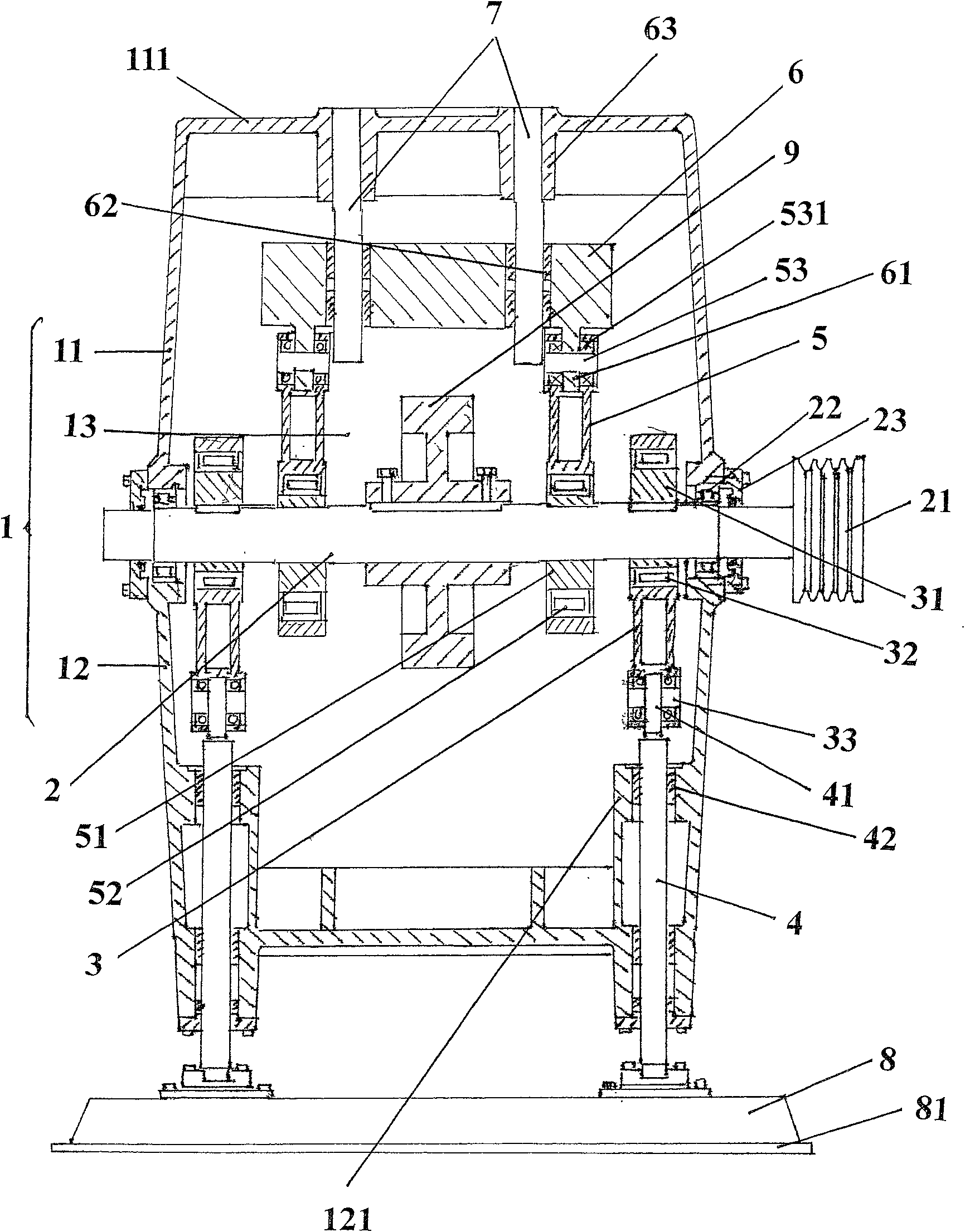

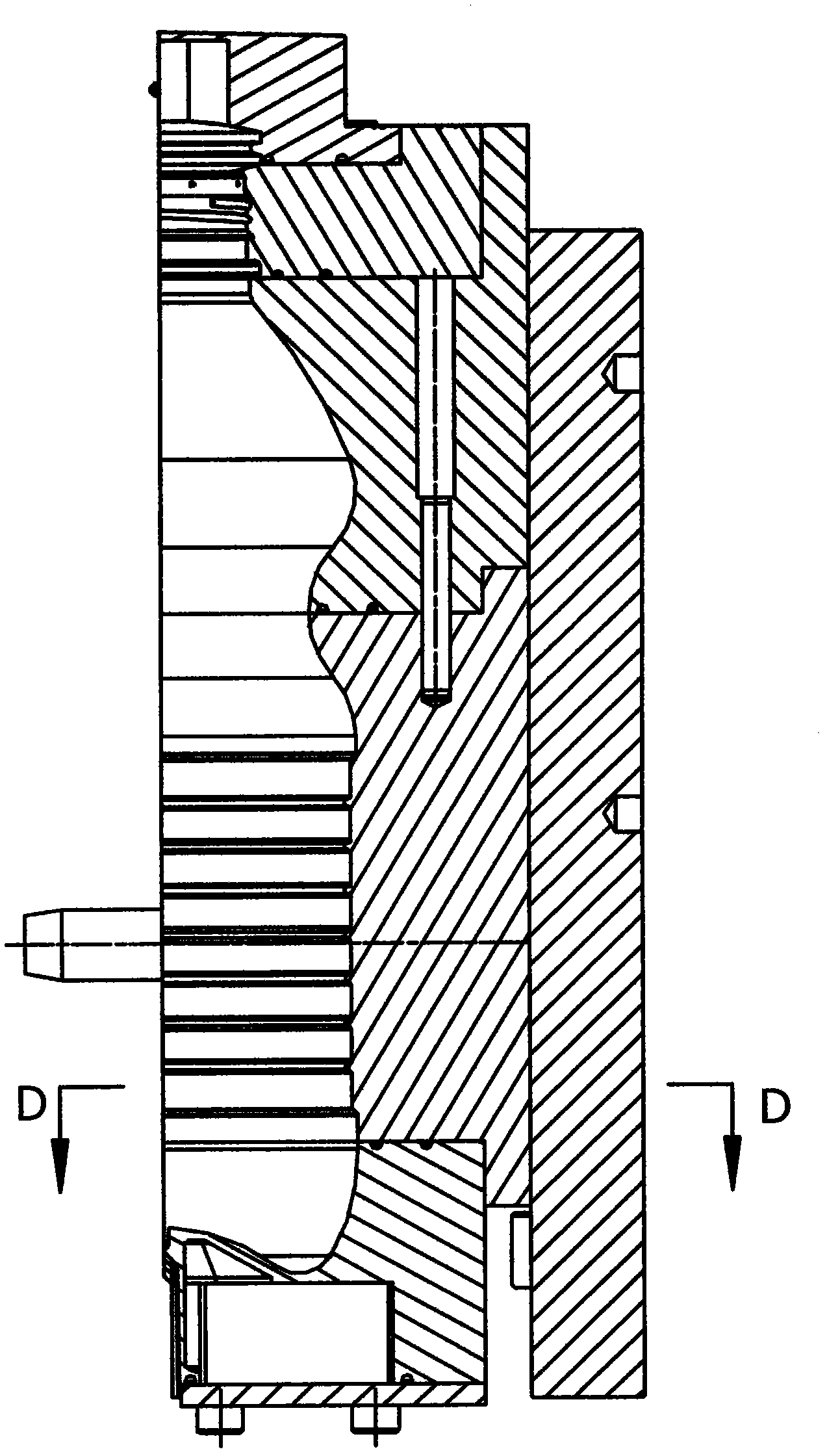

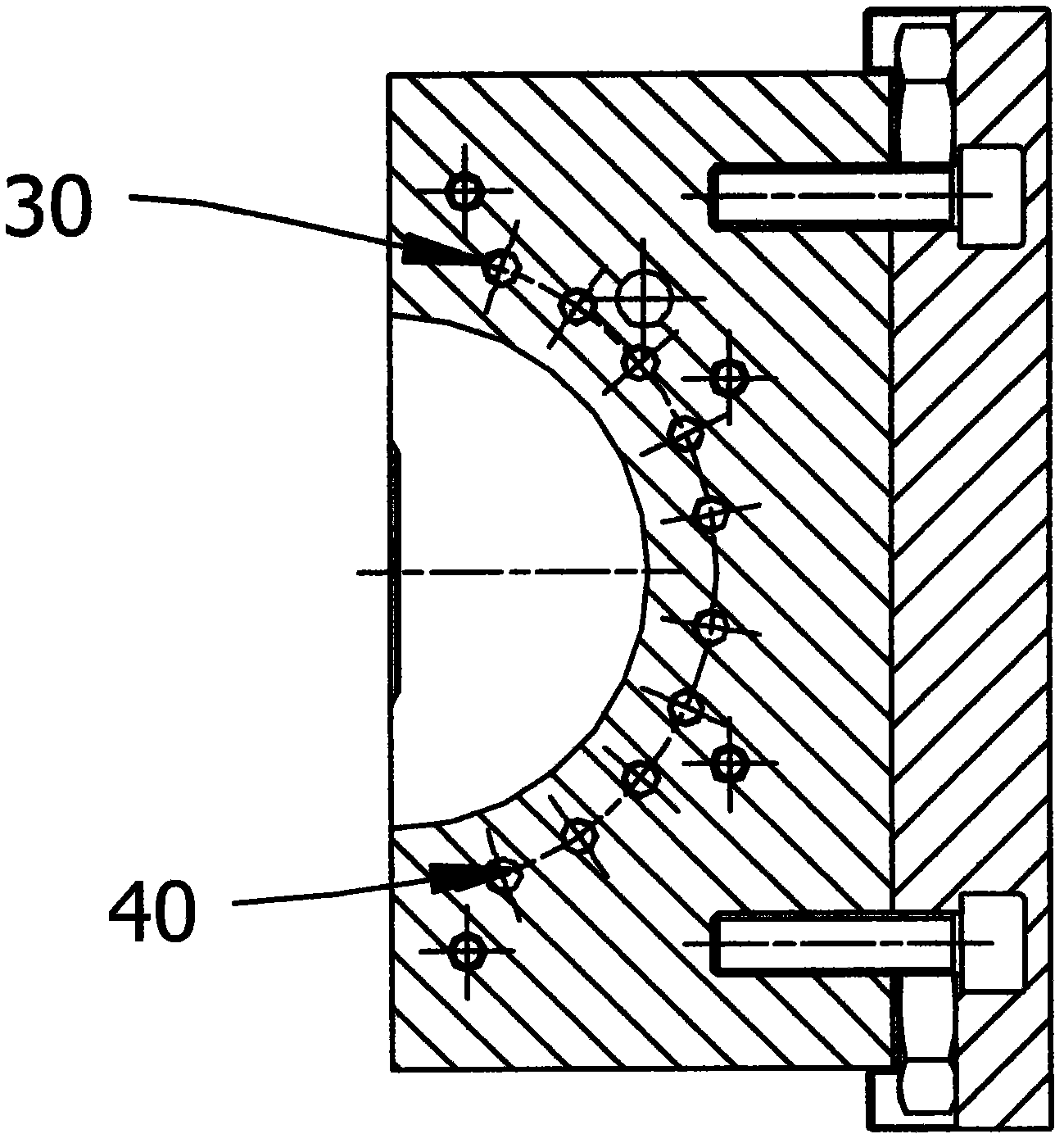

Servo- pressing machine

An actuator press comprises a generator, an operation device and a gear train between the generator and the operation device, which is characterized in that: the invention is provided with the actuator generator which inputs a torque for the gear train and is provided with the actuator generator which inputs a place and speed torque. The advantages of the invention are that: 1. the invention can meet the capacity requirement of the giant press when the actuator generator is used as the drive source; 2. the strength of the ball screw can be effectively increased and the service life is lengthened; 3. the invention is of high control precision, quick processing speed and high reliability.

Owner:网野(武汉)高科技有限公司

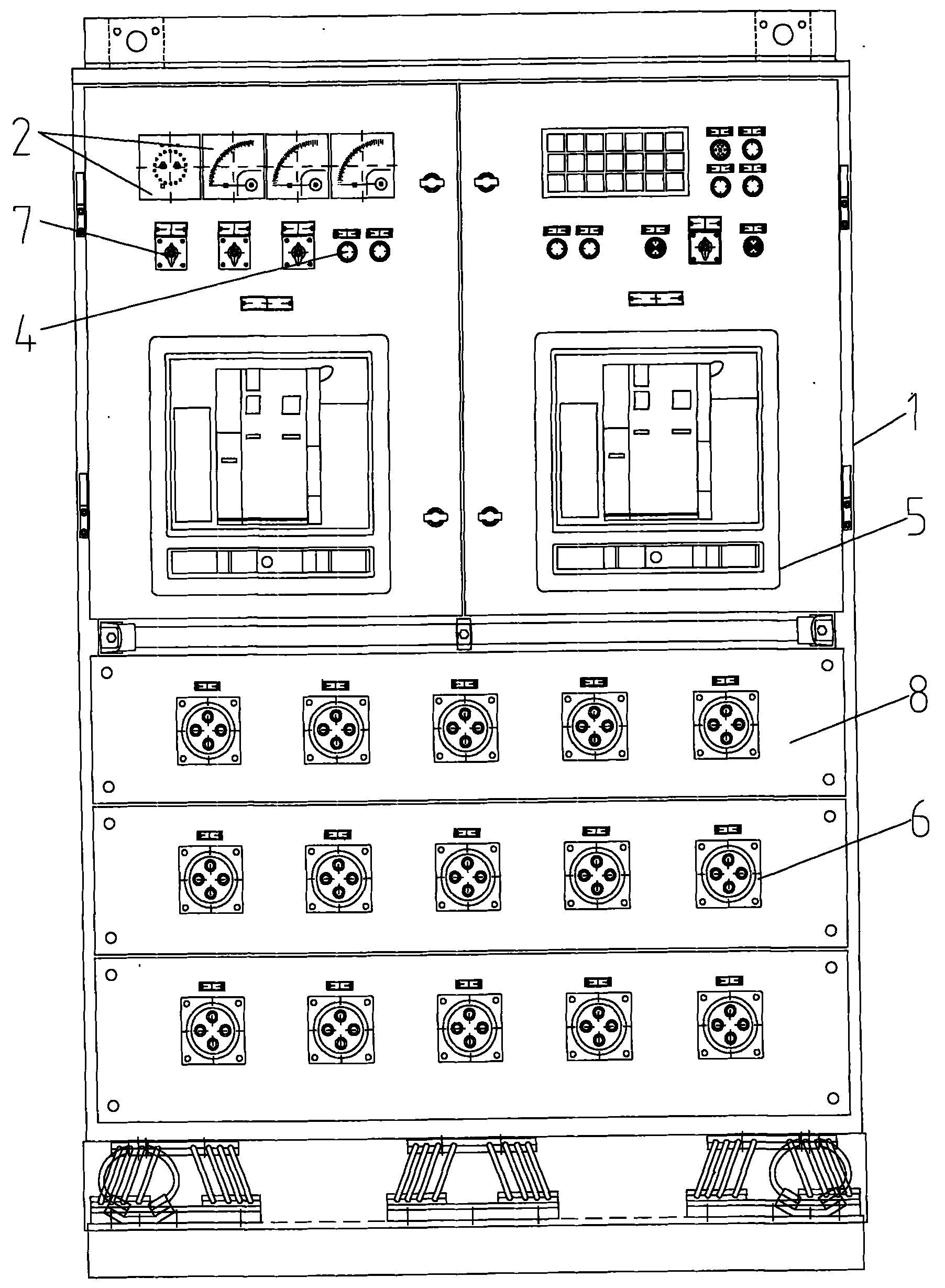

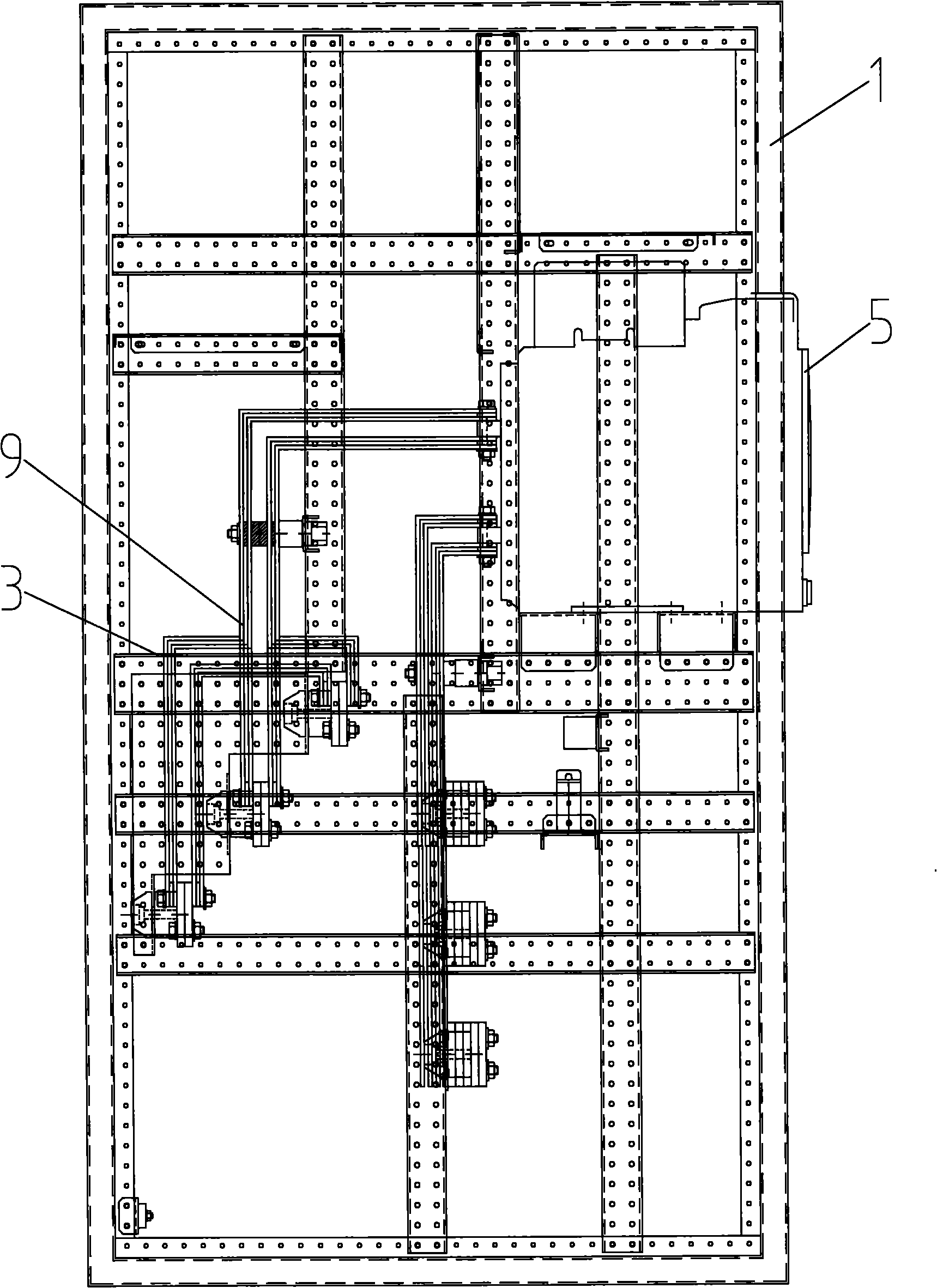

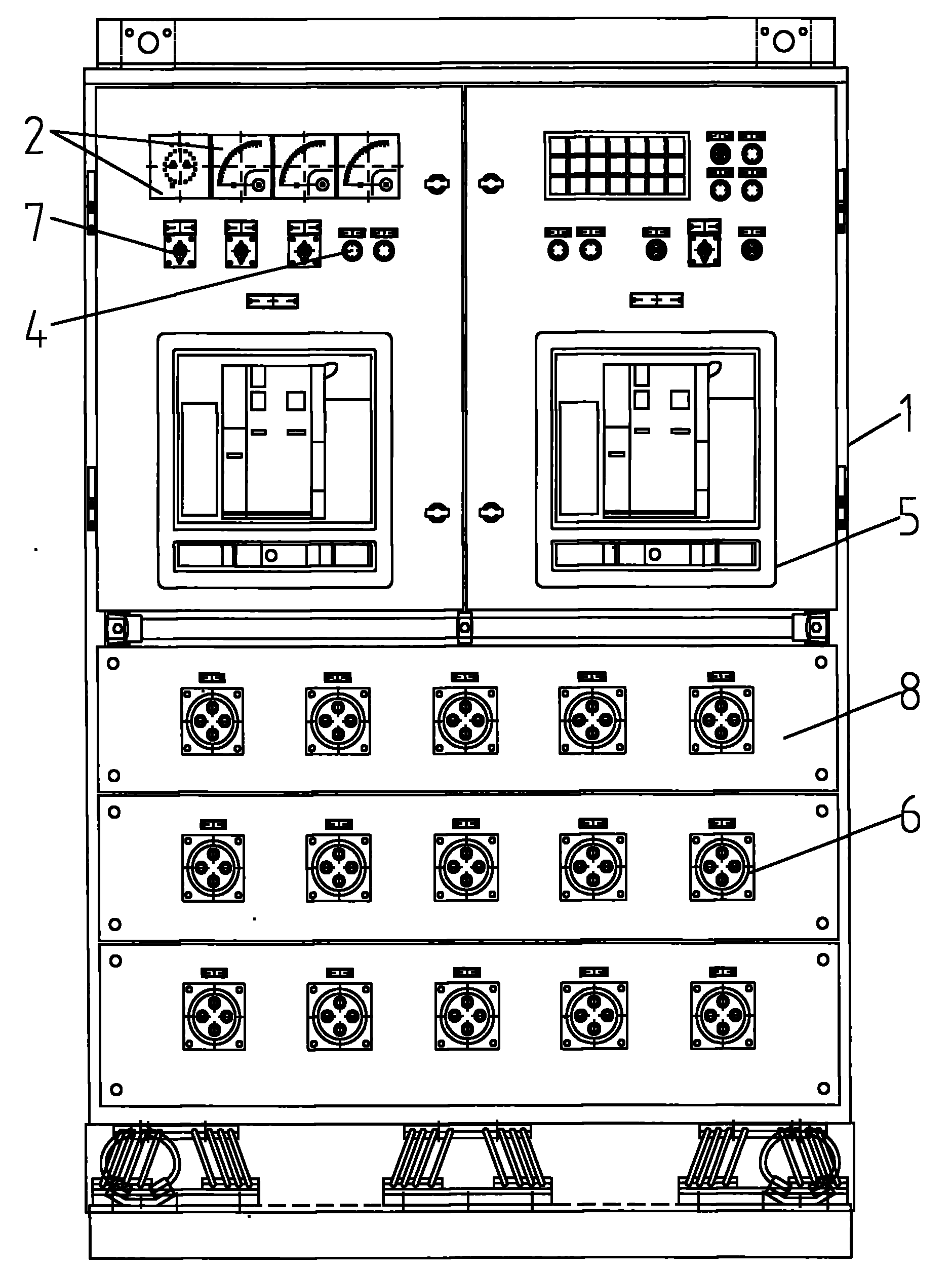

Shore connection box

InactiveCN101982913AMeet capacity requirementsImprove protectionSubstation/switching arrangement boards/panels/desksSwitch operated by excess currentsElectricityPower station

The invention discloses a shore connection box, comprising a box body, instrumentations, an internal installation board, display parts, circuit protecting parts, circuit input or output equipment and control parts, wherein the circuit input or output equipment is the large current socket, which is installed on socket installation boards; and the socket installation boards are fixed on the frame of the box body. The shore connection box has the following advantages: the shore connection box can bear high power, realize interchange of ship power and shore power; after being subject to phase sequence adjustment, the main power from the power stations on the ships or shores is supplied to the opposite load; and power and short circuit, phase loss, overload and inverse phase sequence protecting and alarming functions are provided to the load through connection of heavy-current breakers and the large current sockets.

Owner:镇江船舶电器有限责任公司

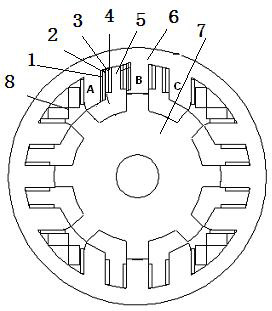

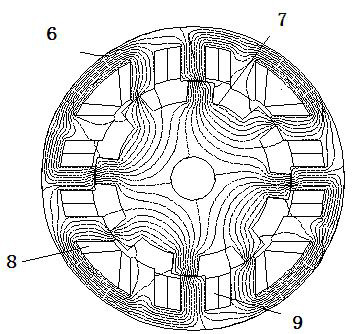

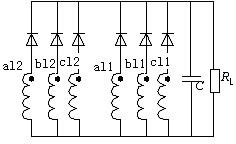

Multi-winding double-salient-pole generator and output transformation and control device

InactiveCN102497038AIncrease output capacityImprove reliabilityMagnetic circuit stationary partsStructural associationLow voltageIntermediate frequency

The invention discloses a multi-winding double-salient-pole generator and an output transformation and control device, and particularly relates to an aviation generator. A three-phase 12 / 8 pole single-winding double-salient-pole generator is adopted, and four sets of armature windings with three phases of A, B and C are wound on a stator slot together; and (al1, bl1, cl1) and (al2, bl2, cl2) form two sets of low-voltage three-phase windings, and (ah1, bh1, ch1) and (ah2, bh2, ch2) form two sets of high-voltage three-phase windings, wherein (al1, al2, ah1 and ah2), (bl1, bl2, bh1 and bh2), and (cl1, cl2, ch1 and ch2) are placed in the same slot respectively, and each set of the windings and a power conversion device of each set of the windings form an independent generation channel. By using the multi-winding double-salient-pole generator and the output transformation and control device disclosed by the invention, 28.5V, 28.5V / 57V, 0-70V, 115V / 200V and 400Hz intermediate frequency communications, and the output of a 270V high-voltage direct current power supply are realized.

Owner:中国人民解放军徐州空军学院

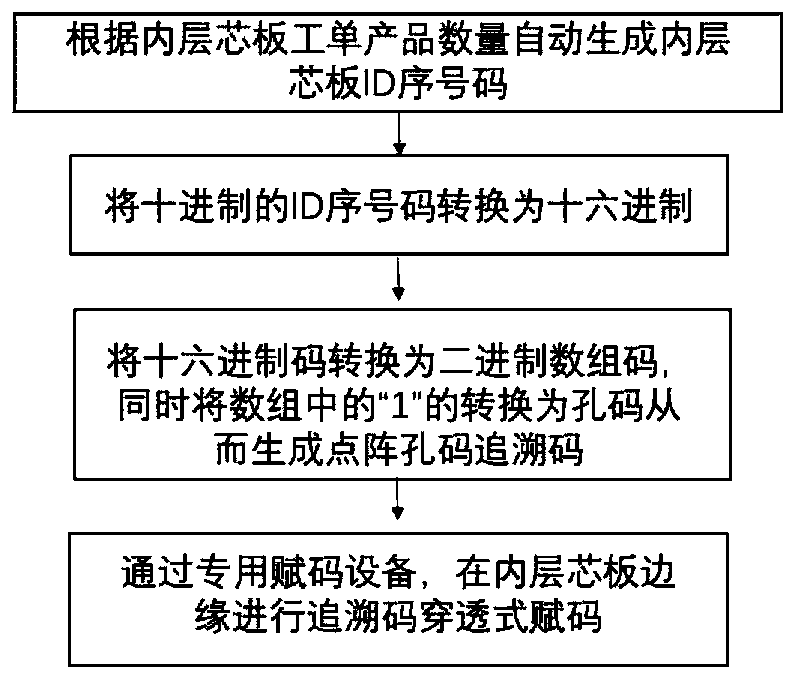

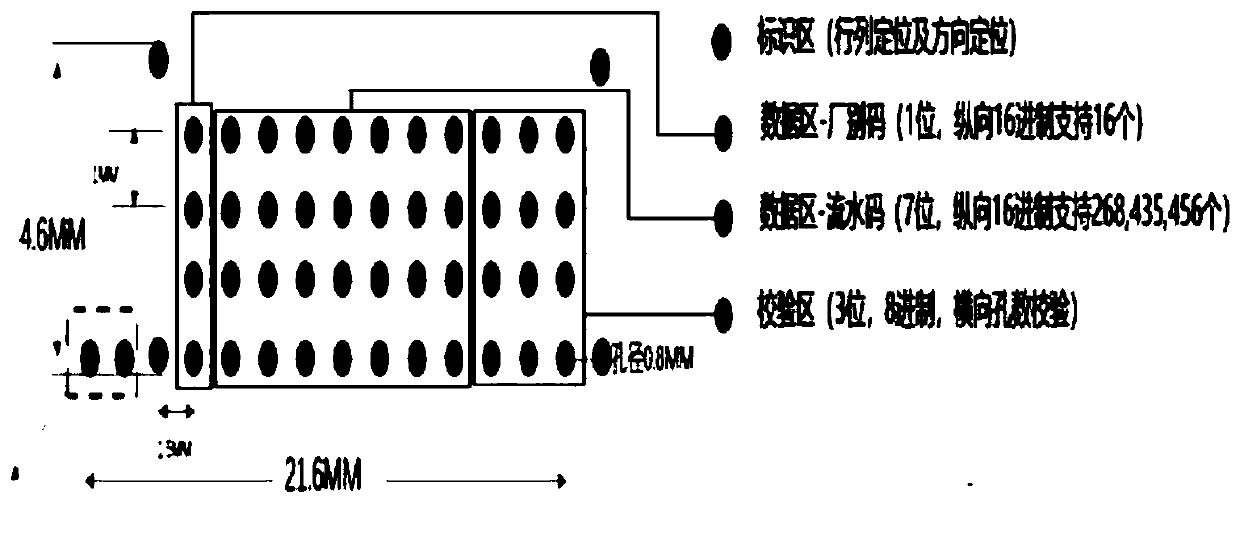

Method for realizing full-process tracing of PCB product manufacturing based on hexadecimal lattice hole codes

InactiveCN110991588APenetratingWill not affect the recognition ratePrinted circuit aspectsInspection/indentification of circuitsDot matrixParallel computing

The invention discloses a method for realizing the full-process tracing of PCB product manufacturing based on hexadecimal lattice hole codes. The method comprises the following steps that: S1, the sequence code of an inner-layer core board is generated, transcoding is performed, a lattice code is generated, and code assignment is performed; S2, the association of the inner-layer core board with anouter-layer board and the sequence code production of the outer-layer board are performed, the inner-layer core board is associated with an outer-layer board, specifically, inner-layer core board tracing codes are identified and analyzed through a photoelectric analysis module in an overlapping and pre-arranging process, inner-layer core board ID sequence numbers are associated according to a product process, and a new outer-layer board ID sequence number is automatically generated according to groups; S3, the transcoding of the outer-layer board is performed, a dot matrix code is generated,and code assignment is performed; S4, tracing code reading is performed; and S5, a tracing system is established. Therefore, the association of the IDs of the inner-layer core board and the outer-layer core board is realized, and the full-process tracing of a PCB from the inner layer to the outer layer is realized.

Owner:南京品微智能科技有限公司

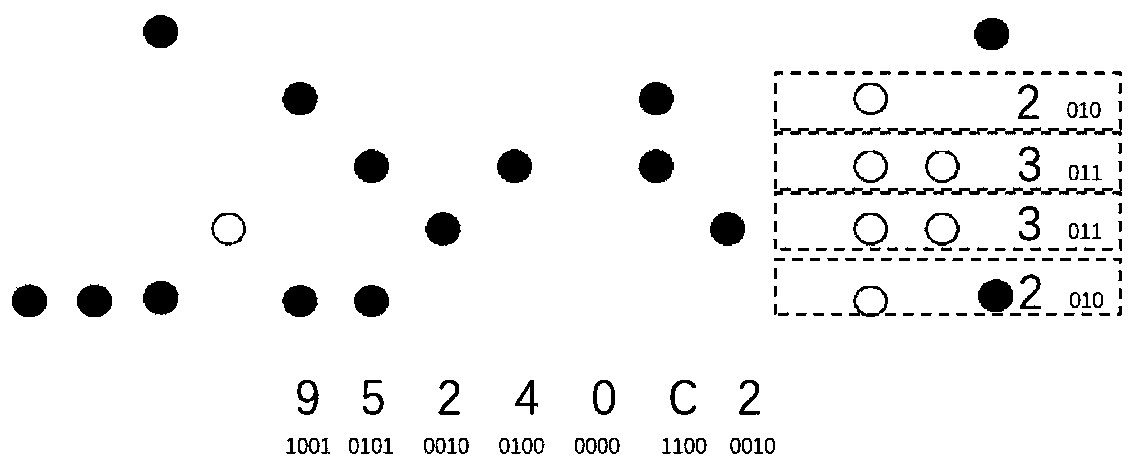

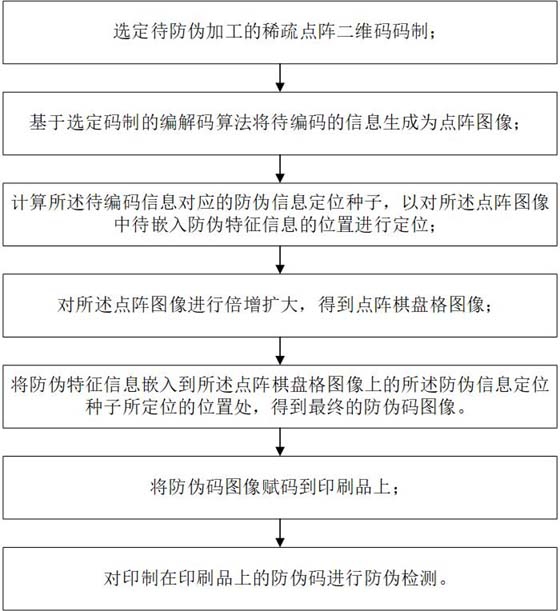

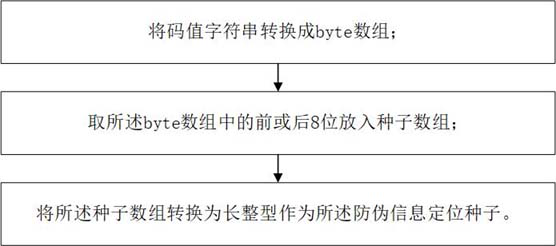

Anti-counterfeiting method based on sparse dot matrix codes

ActiveCN113313225AScan code detection size is smallLow print quality requirementsCommerceRecord carriers used with machinesDot matrixAlgorithm

The invention discloses an anti-counterfeiting method based on sparse dot matrix codes. The method comprises the following steps: selecting a sparse dot matrix two-dimensional code system to be subjected to anti-counterfeiting processing; generating the information to be coded into a dot matrix image based on a coding and decoding algorithm of a selected code system; calculating an anti-counterfeiting information positioning seed corresponding to the to-be-coded information so as to fix the position where the anti-counterfeiting feature information is to be embedded in the dot matrix image; multiplying and enlarging the dot matrix image to obtain a dot matrix checkerboard image; embedding the anti-counterfeiting feature information into the position positioned by the anti-counterfeiting information positioning seed on the dot matrix checkerboard image to obtain a final anti-counterfeiting code image; tagging the anti-counterfeiting code image to a printed matter; and carrying out anti-counterfeiting detection on the anti-counterfeiting code printed on the printed matter. The anti-counterfeiting code image generated based on the anti-counterfeiting method provided by the invention has the advantages of being high in concealment, strong in anti-copying capability, low in cost of tagging consumables and suitable for surface printing of various materials such as software packages, hard packages, plastics, ceramic tiles and metal.

Owner:北京微点科学技术有限公司

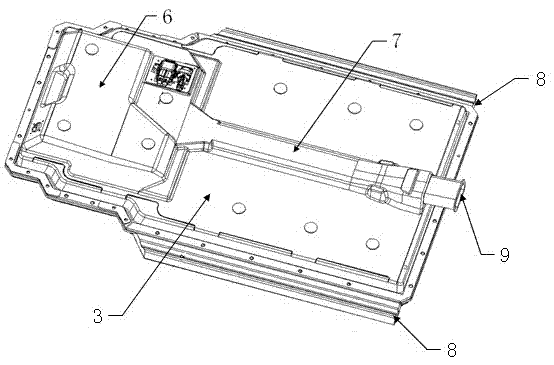

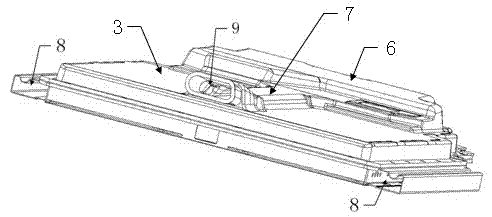

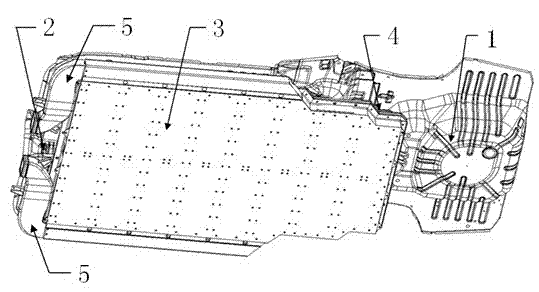

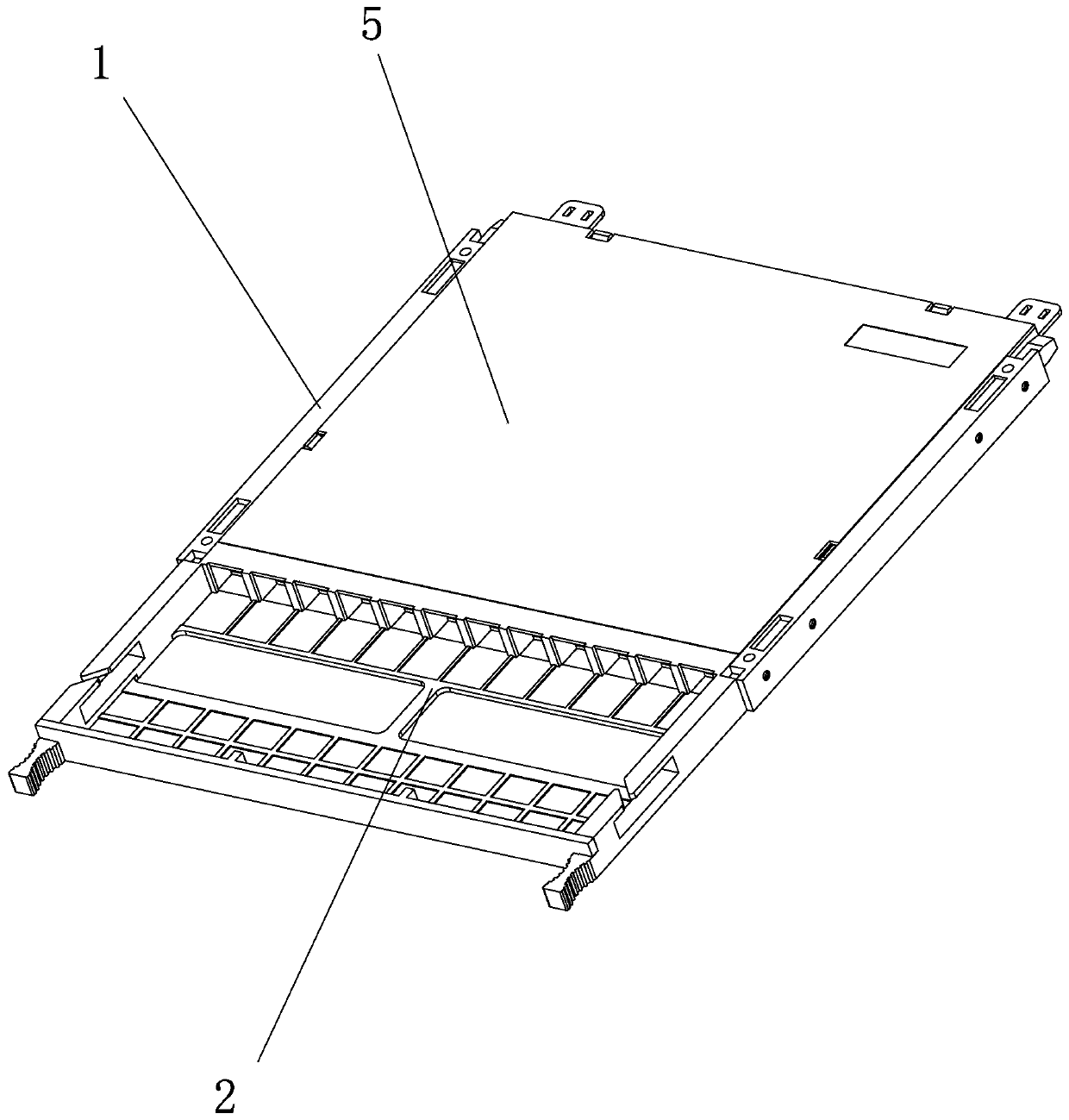

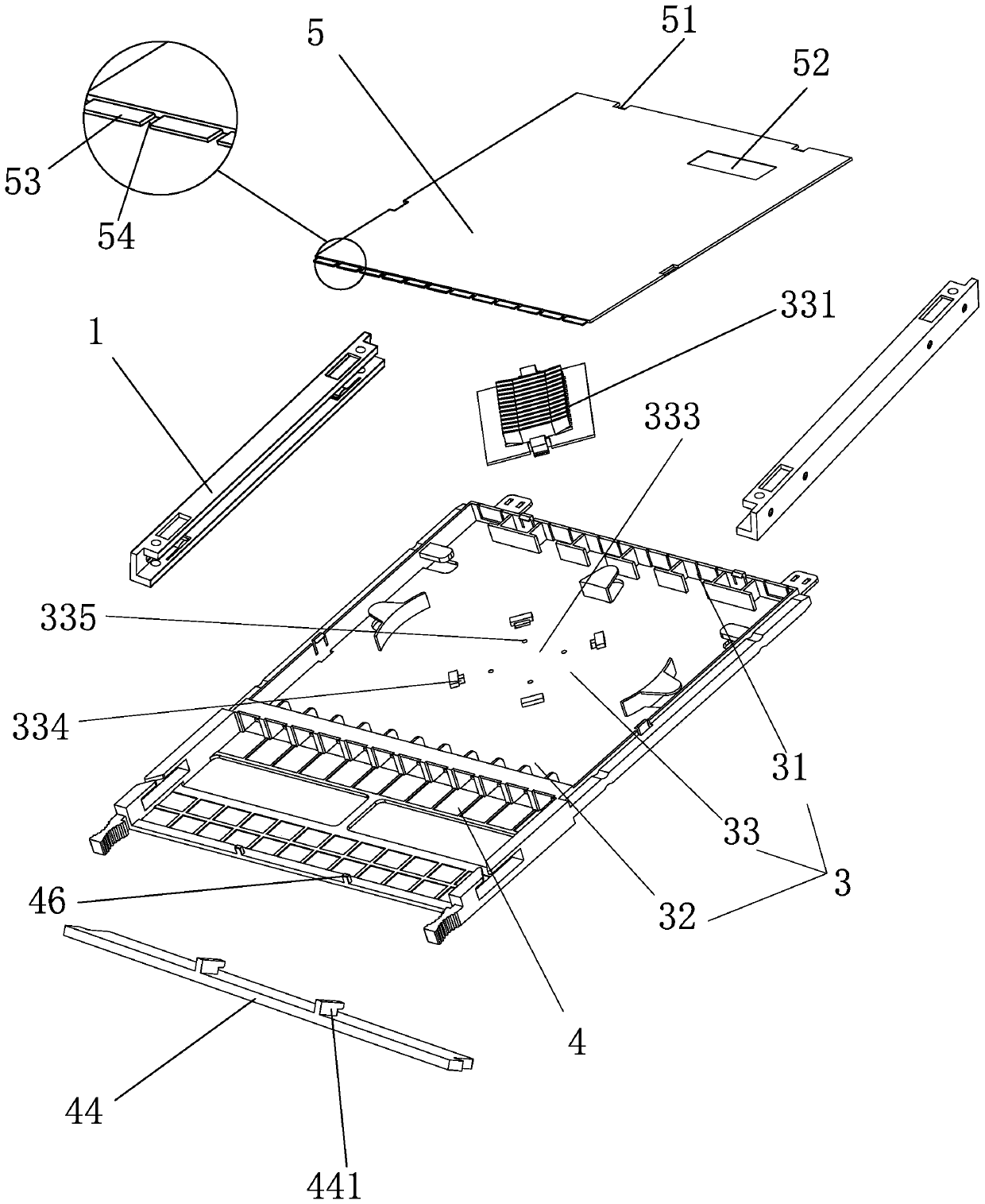

Matching structure of electric car battery pack and car body

InactiveCN102390246AMeet capacity requirementsEfficient use ofElectric propulsion mountingSecondary cellsElectrical batteryAutomotive battery

The invention discloses a matching structure of an electric car battery pack and a car body, which is characterized in that: the battery pack is arranged on a central position below a car body floor, the front end of the battery pack is arranged right below an instrument console, and the rear end of the battery pack is close to a trunk; a front projection on the front part of the upper surface of the battery pack corresponds to the lower surface of an middle passage on the car body floor, and a rear projection on the rear part of the upper surface of the battery pack corresponds to the lower surface of a rear seat position; and the battery pack is connected with the car body floor through bolts. The upper surface of the battery pack is provided with an air inlet pipe, and two side surface of the battery pack are respectively provided with an exhaustion pipe. Due to the adoption of the matching structure, a low-temperature heating function and a high-temperature heat radiation function of the battery pack can be realized; the battery pack effectively utilizes the space on the lower part of the floor and is completely bonded with the car body, so the load of a front axle and a rear axle of the car can be uniformly distributed; and the requirements that the capacity design of the battery pack is maximized and the car body modification is minimized can be satisfied, and the matching structure also has the advantages of convenience in installation and disassembling and the like.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD +1

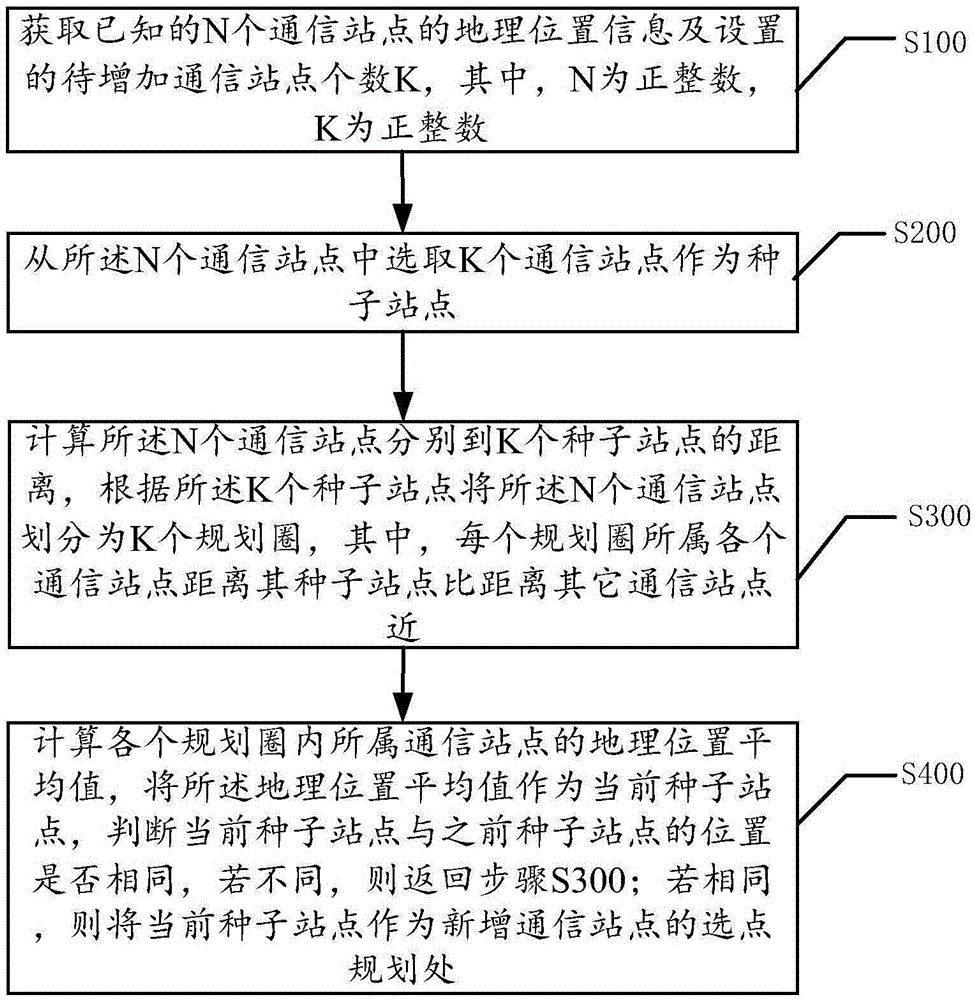

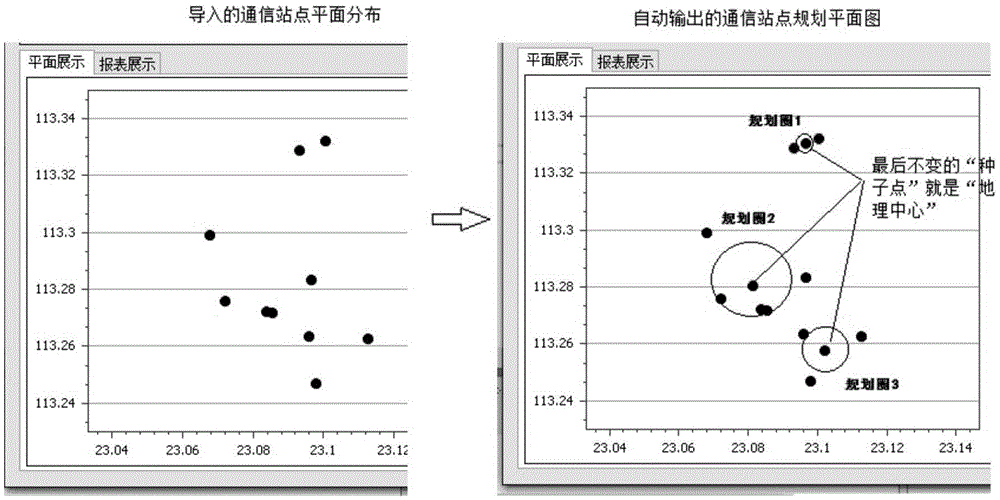

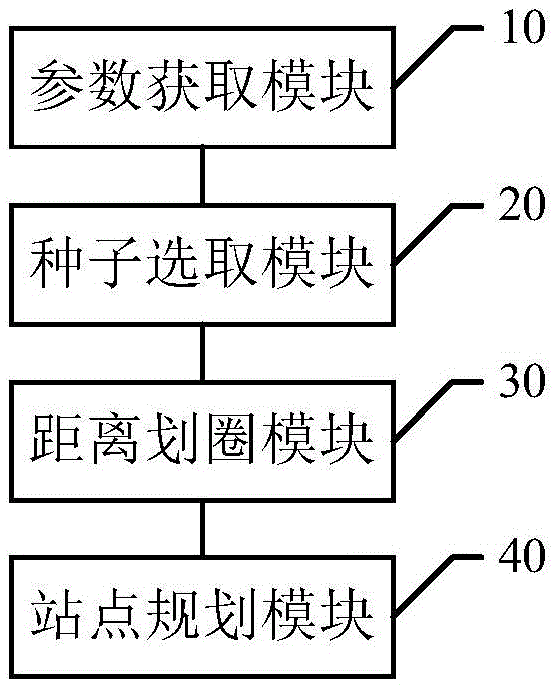

Mobile communication site planning method and system

ActiveCN105682104ASolve the problem of low work efficiency and difficulty in obtaining the least cost planning solutionMeet coverageNetwork planningGeographic siteSite planning

The invention discloses a mobile communication site planning method and system. The mobile communication site planning method comprises the steps: acquiring geographic position information of known N communication sites and a set to-be-added communication site number K; selecting K communication sites as seed sites from the N communication sites; computing a distance between each N communication site and each K seed site, and dividing the N communication sites into K planning circles according to the K seed sites, wherein in each planning circle, each affiliated communication site is closer to a corresponding seed site than other communication sites; computing a geographic position mean value of the affiliated communication sites in each planning circle, utilizing the geographic position mean value as a current seed site till the position of the seed site does not change, and utilizing the current seed site as a site planning position of a newly added communication site. According to the mobile communication site planning method and system, an optimum site position is selected to establish a new site, and the fewest sites can be utilized, so that costs are reduced.

Owner:广州银禾网络通信有限公司

Tray placing equipment before spraying of neodymium iron boron products

The invention discloses tray placing equipment before spraying of neodymium iron boron products. The tray placing equipment comprises a conveying device for conveying the neodymium iron boron productsto an arranging device, the arranging device for arranging the neodymium iron boron products, and a tray placing device for placing the arranged neodymium iron boron products into trays through a three-axle manipulator. The tray placing equipment has the following beneficial effects: the action of tidily placing the neodymium iron boron products on the trays is finished by the machine; the traysfully filled with the neodymium iron boron products are only manually taken out; and empty trays are placed on, so that labors are reduced, ahead tray placement by workers is not needed, and the working efficiency can be improved.

Owner:廊坊京磁精密材料有限公司

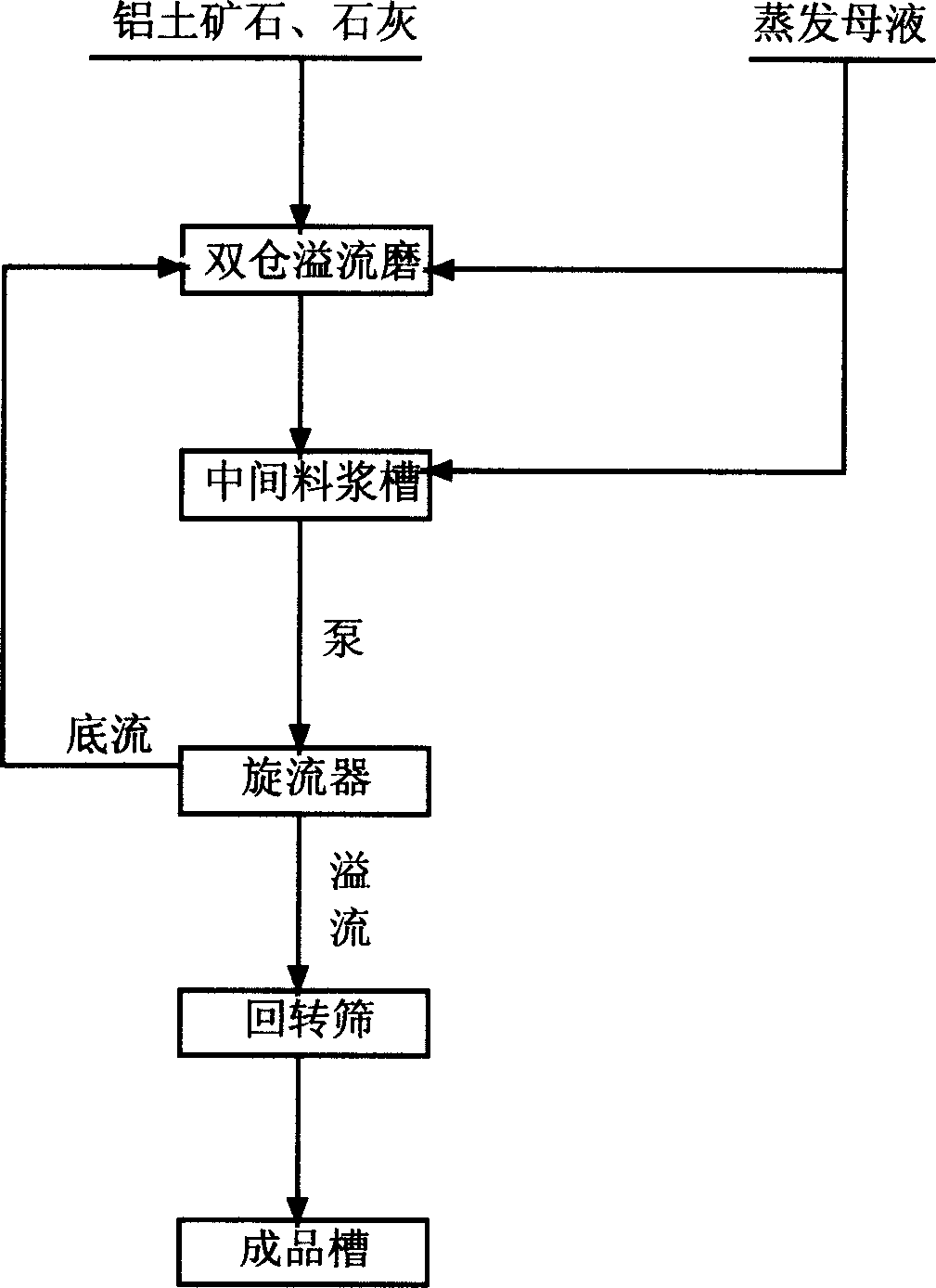

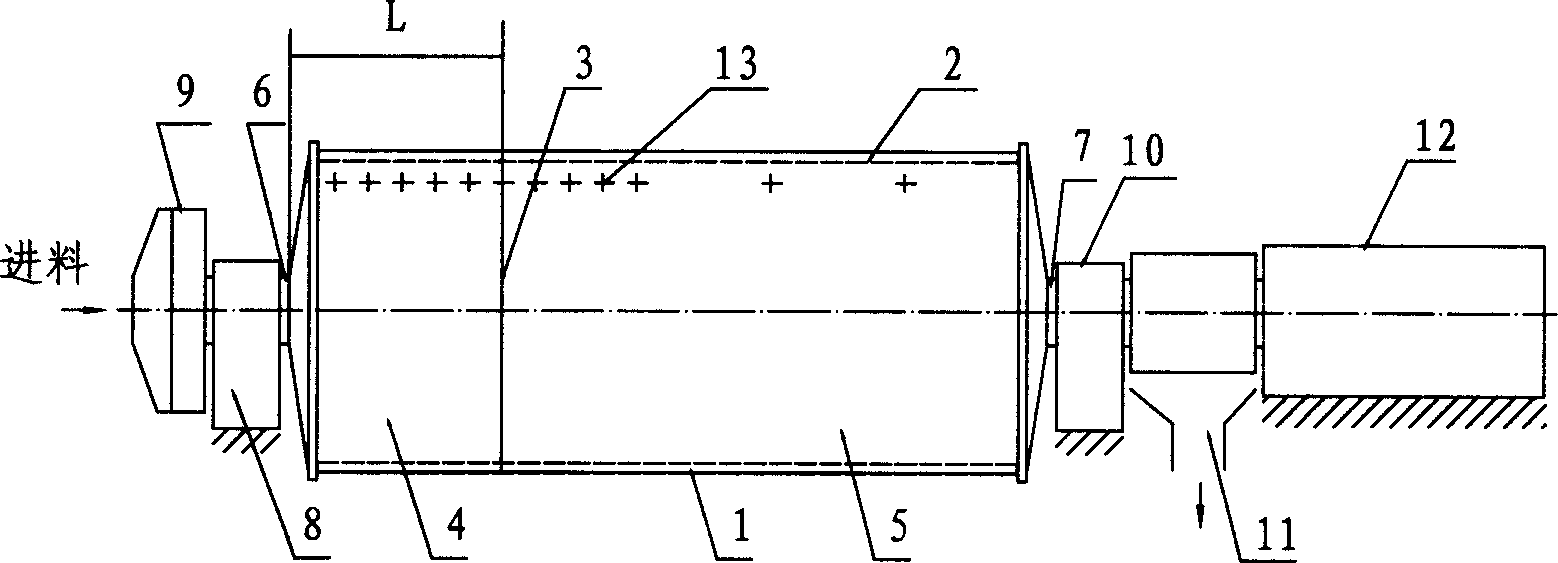

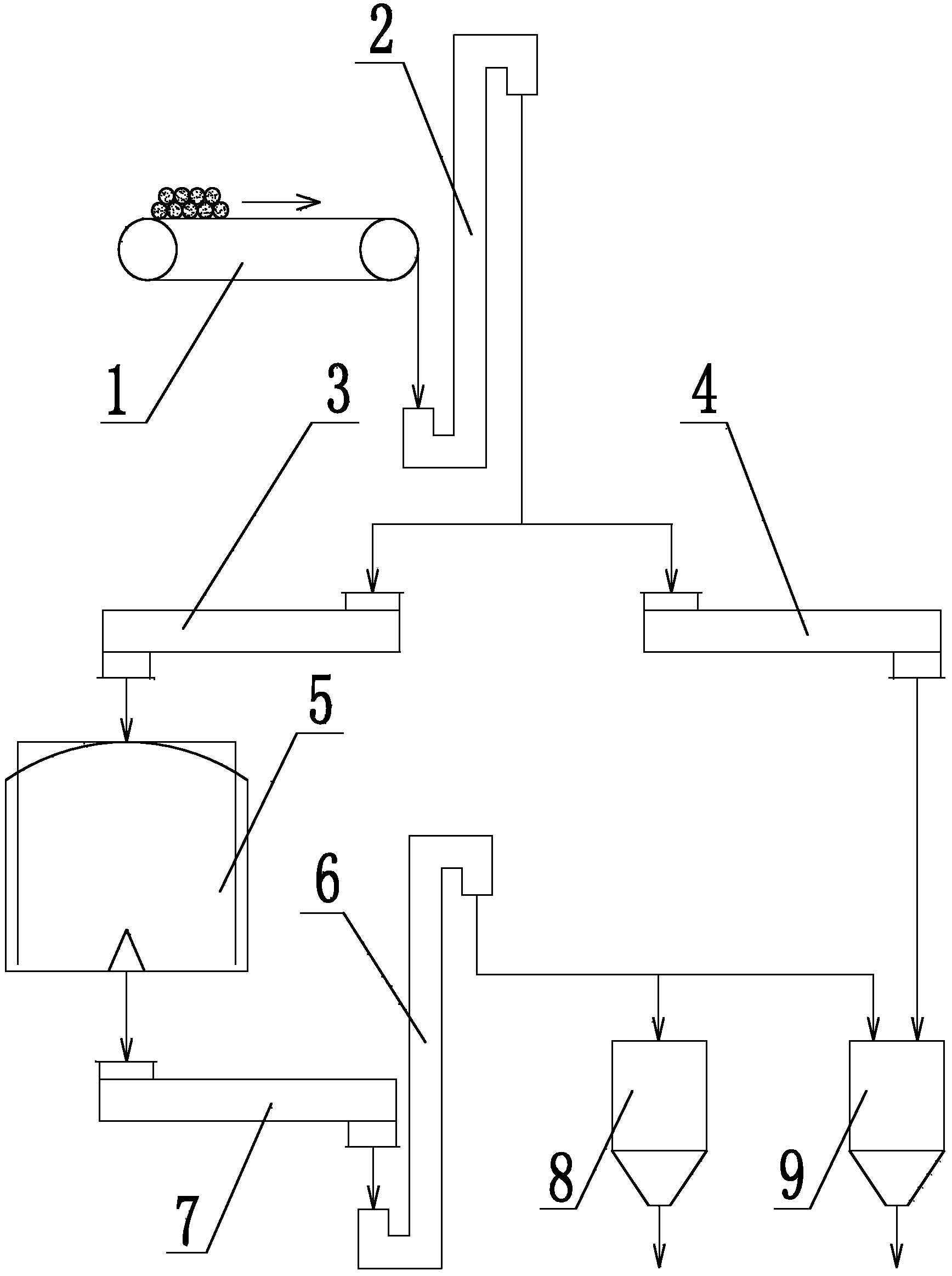

Bauxite grinding technology and apparatus thereof

The bauxite grinding process includes the following steps: feeding bauxite ore, lime and evaporation mother liquor into two-bin overflow grinding mill, breaking, coarse grinding, fine grinding, overflow discharging the ground ore slurry and feeding the ore slurry into intermediate slurry groove, then pumping the ore slurry into cyclone separator, sorting, discharging coarse granules slurry out from bottom outlet of cyclone separator and back returning the coarse granules slurry into two-bin overflow grinding mill and further grinding, screening fine granules slurry and feeding the fine granules slurry into finished product groove to make storage.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

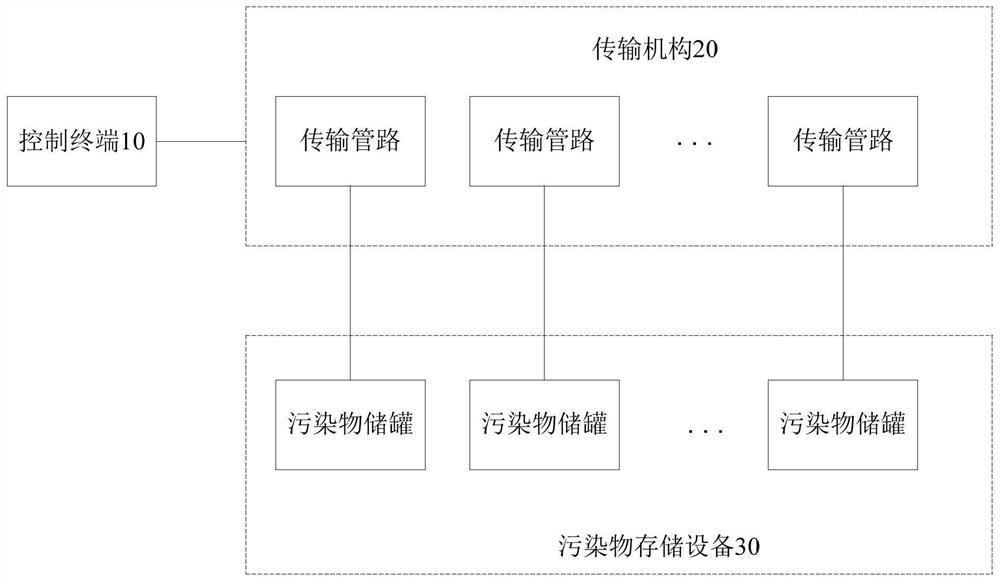

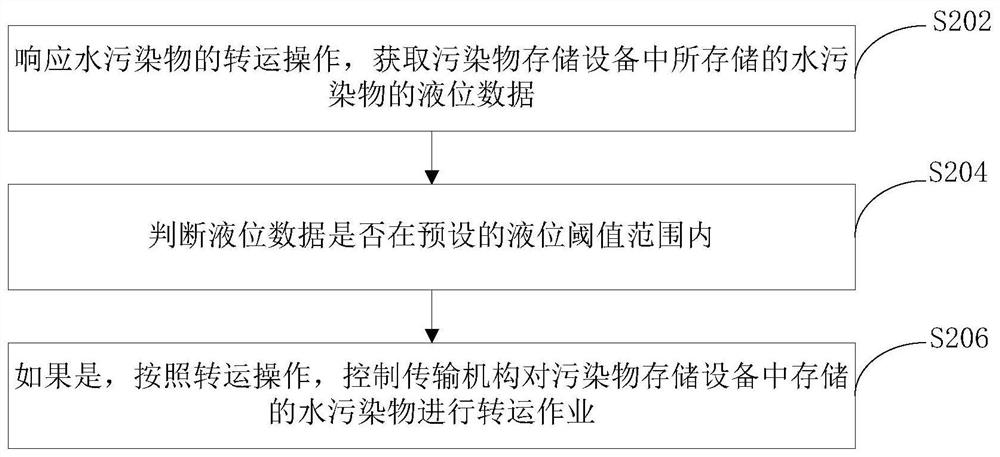

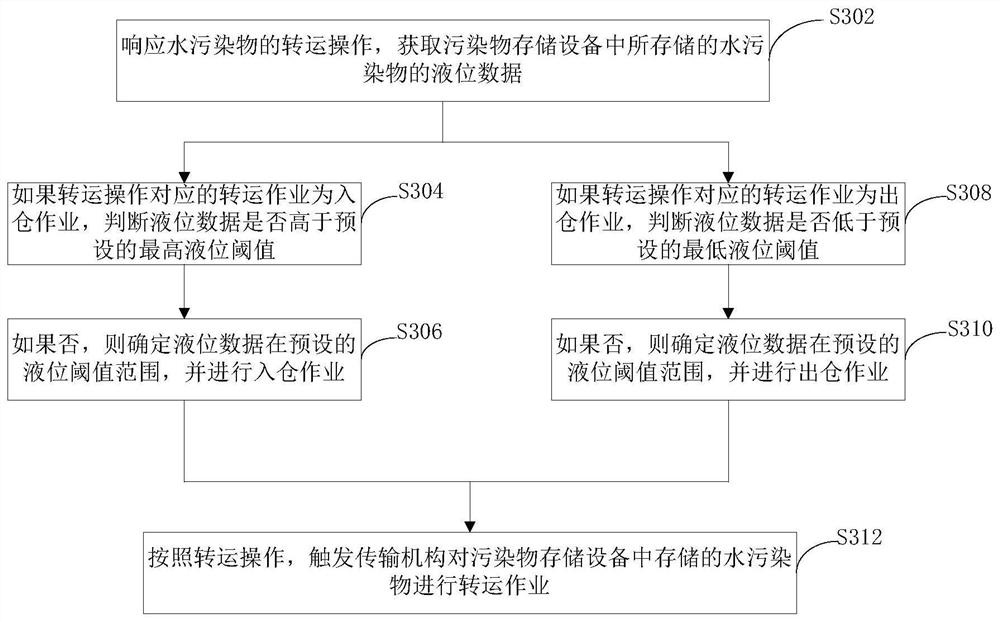

Water pollutant collection control method and intelligent marine cloud bin device

InactiveCN112982345AConvenient for centralized processingImprove transport efficiencyWater cleaningWaterborne vesselsEnvironmental engineeringTransfer operation

The invention provides a water pollutant collection control method and an intelligent marine cloud bin device, and relates to the technical field of ship water pollutant transfer. The method comprises the steps that transfer operation of water pollutants is responded, and liquid level data of the water pollutants stored in pollutant storage equipment is acquired; whether the liquid level data is within a preset liquid level threshold range is judged; and if yes, a transmission mechanism is controlled to perform transfer operation on the water pollutants stored in the pollutant storage equipment according to the transfer operation. According to the water pollutant collection control method and the intelligent marine cloud bin device, the liquid level data is fully considered in the water pollutant transfer process, and transfer of the water pollutants can be realized according to the liquid level data so that the transfer process of the water pollutants is enabled to fully meet the capacity requirement of the intelligent marine cloud bin device, centralized processing of the water pollutants is facilitated and the transfer efficiency of the water pollutants can also be enhanced.

Owner:ZHEJIANG VISIONBLUE TECH CO LTD

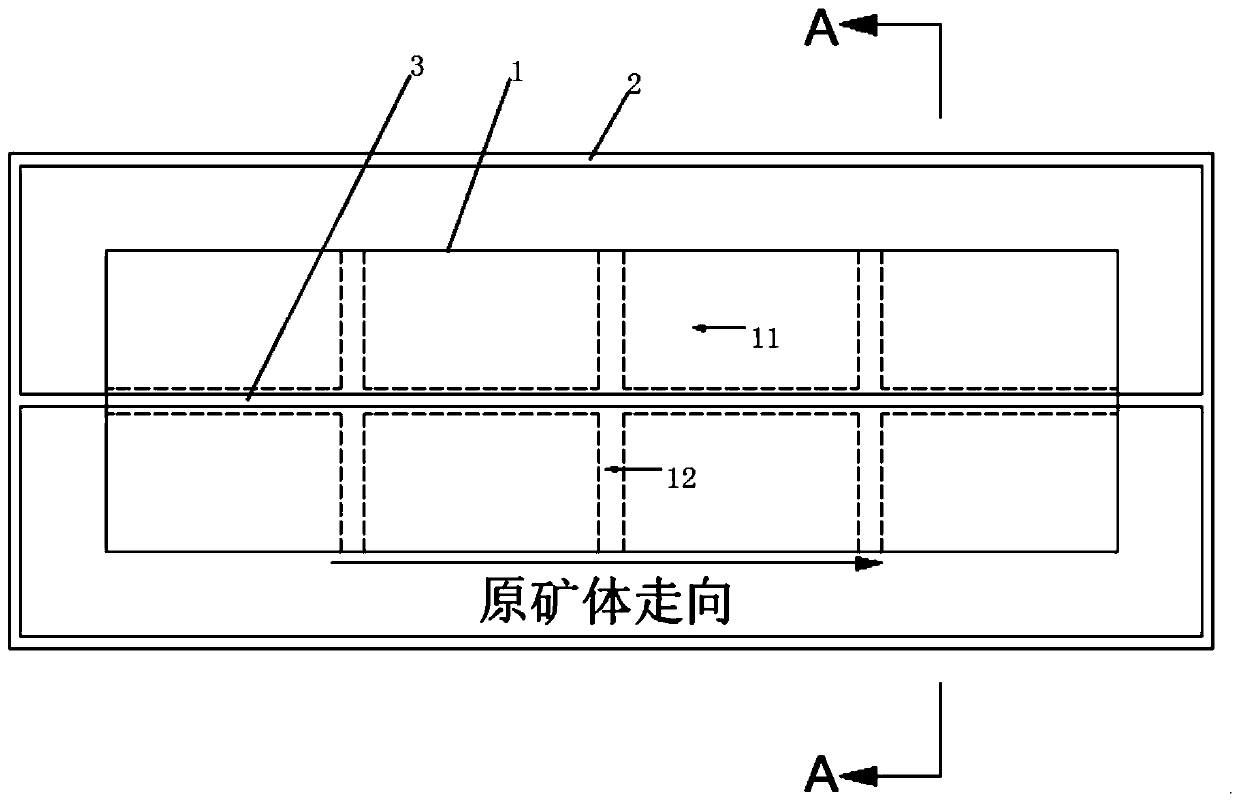

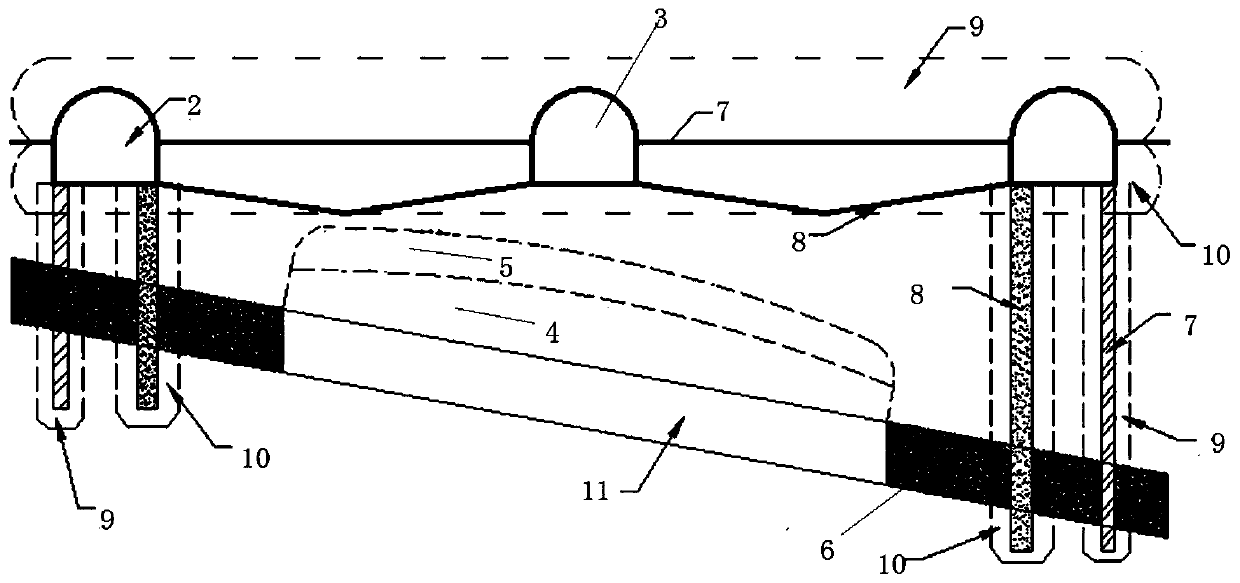

Heavy curtain and water curtain combined goaf gas storage cave depot designing method

ActiveCN111535863AMeet capacity requirementsSave moneyMining devicesUnderground chambersMining engineeringNatural gas storage

The invention provides a heavy curtain and water curtain combined goaf gas storage cave depot designing method. The heavy curtain and water curtain combined goaf gas storage cave depot designing method comprises the following steps that S1, an underground gas storage depot area for storing natural gas is designated according to the mining data and geological survey data of a mine; S2, multiple roadways are arranged above the underground gas storage depot area; and S3, multiple grouting holes and multiple water curtain holes are drilled in the roadways towards surrounding rock, water and groutare injected into the surrounding rock through the water curtain holes and the grouting holes to form a water curtain and a heavy curtain, and the underground gas storage depot area is sealed. According to the heavy curtain and water curtain combined goaf gas storage cave depot designing method, heavy curtain and water curtain systems are built, grouting is carried out to reinforce the surroundingrock, and holes and cracks are filled to reduce the seepage flow and seepage pressure; and the water curtain system is formed by the water curtain holes, the natural gas storage area is reinforced and sealed, natural gas is prevented from diffusing and leaking around, and the underground gas storages safety of the mine is ensured.

Owner:NORTHEASTERN UNIV

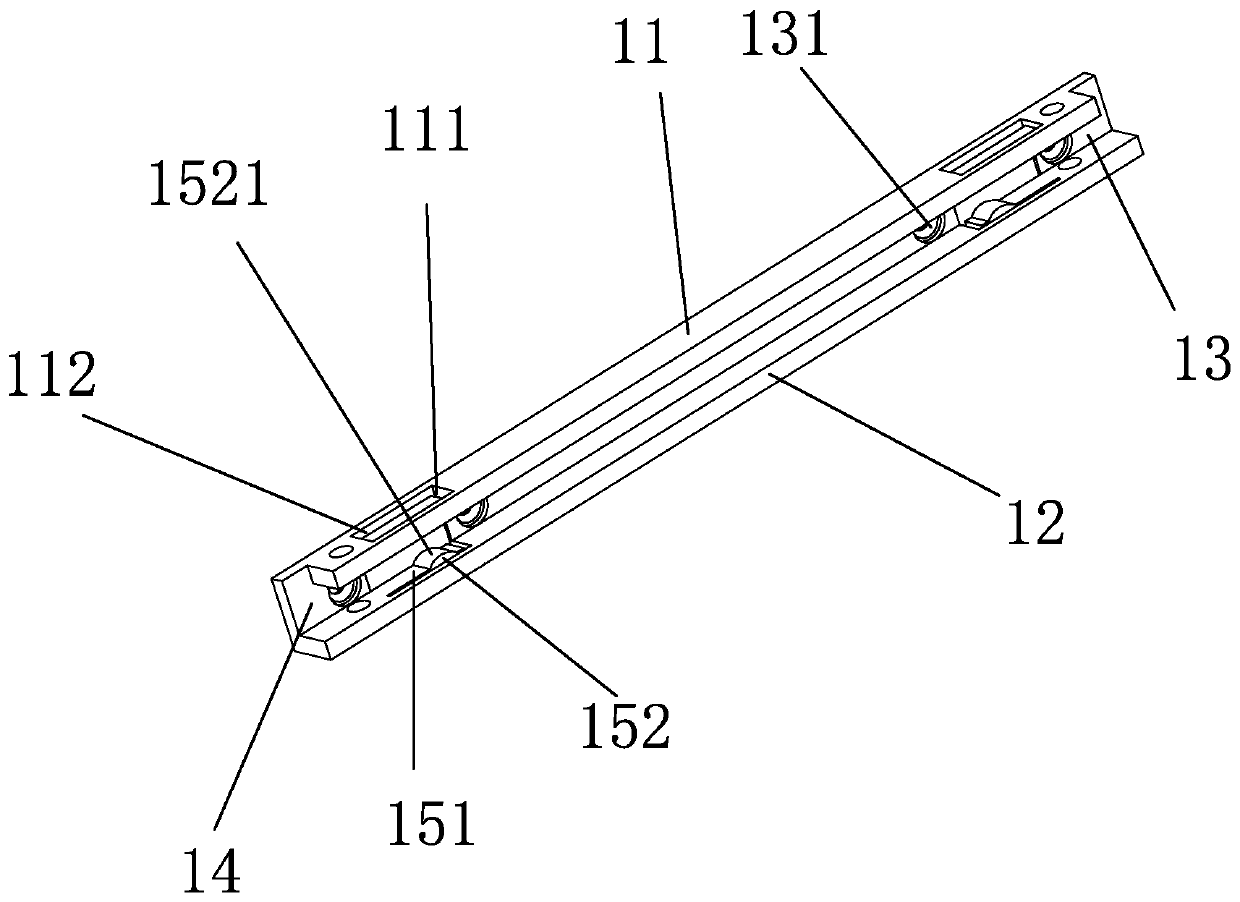

High-density optical fiber distribution tray

PendingCN111142202AReduce volumeThinCoupling light guidesFibre mechanical structuresPhysicsElectrical and Electronics engineering

The invention discloses a high-density optical fiber distribution tray. The optical fiber distribution tray comprises a tray body, the tray body is provided with a distribution area, a terminal area and a detachable cover body clamped with the distribution area, the distribution area is provided with an input end installation area, an output end installation area and a fiber storage area, the terminal area is arranged on the side face of the output end installation area, and the fiber storage area is provided with a welding clamping base which can be installed in multiple directions and is detachable. The high-density optical fiber distribution tray provided by the invention is small in size, thin in thickness, high in adapter density and reasonable in distribution and wiring, Meanwhile, different welding clamping bases can be dismounted or replaced, so that conversion of multiple modules between input and output is realized. The disc body can be dragged in the sliding rail by pullingthe handle, and the baffle can be dismounted or mounted as required, so that installation and maintenance of a distribution optical cable or a connection optical cable are facilitated. The optical fiber distribution tray is compact in structure, convenient to install and low in duty ratio, and miniaturization and high density of the optical fiber distribution tray are achieved.

Owner:惠州市飞博康实业有限公司

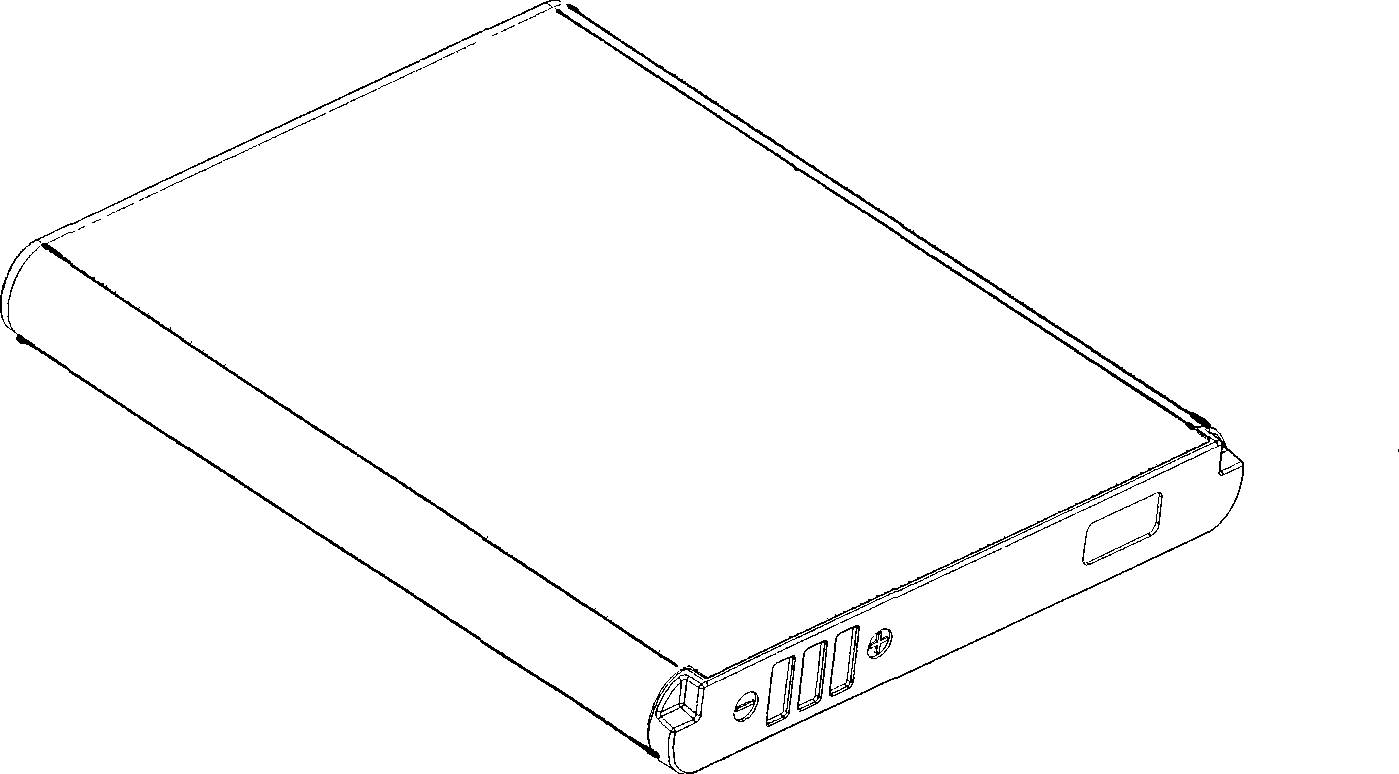

Polymer battery encapsulation method

InactiveCN101533926AIncrease capacityCapacity is easy to guaranteeFinal product manufactureOrganic electrolyte cellsEngineeringBattery cell

A polymer battery encapsulation method, including steps below: setting a PCM board on the upper bottom of a battery cell, to connect the PCM board and the battery cell electrically; clamping the PCM board on a front gluey shell; encapsulating the battery cell with the PCM board and the front glued shell into an aluminium shell; setting a bottom cover on the bottom of the aluminium shell; encapsulating the surface of the outer side of the aluminium shell with label paper. The invention is advanced with simple encapsulation, high productivity effect; the polymer battery cell is safe, secure and reliable in properties, with an appearance satisfied by the clients with high level requirements, with light weight and large upside potential of capacity, and low cost.

Owner:SUNWODA ELECTRONICS

Binning device used after tobacco leaf sorting

The invention relates to a binning device, in particular to a binning device used after tobacco leaf sorting. In order to solve the problem of excessive cylinder stroke and loud sound of the binning mechanism in the existing tobacco leaf binning device, the invention provides the binning device used after the tobacco leaf sorting. The binning device comprises a power mechanism and at least one binning station; the binning station comprises a transmission mechanism, a conveying mechanism and a binning mechanism, wherein the power mechanism drives the transmission mechanism to move, the transmission mechanism and the conveying mechanism are in a co-movement relation, and the binning mechanism performs the binning process on tobacco leaves transported by the conveying mechanism. By adopting the binning device, the cylinder movement stroke is reduced, and the speed of the binning is improved, so that the 10 pieces / s production capacity requirement of equipment is satisfied; a limiting buffer design can effectively reduce the impact and reduce the noise of the impact when binning; whole screws are fixed by adopting an anti-loose design, thereby meeting the frequent movement of the mechanism; and the binning device also has the characteristics of durability, stability and firmness.

Owner:BEIJING FOCUSIGHT TECH

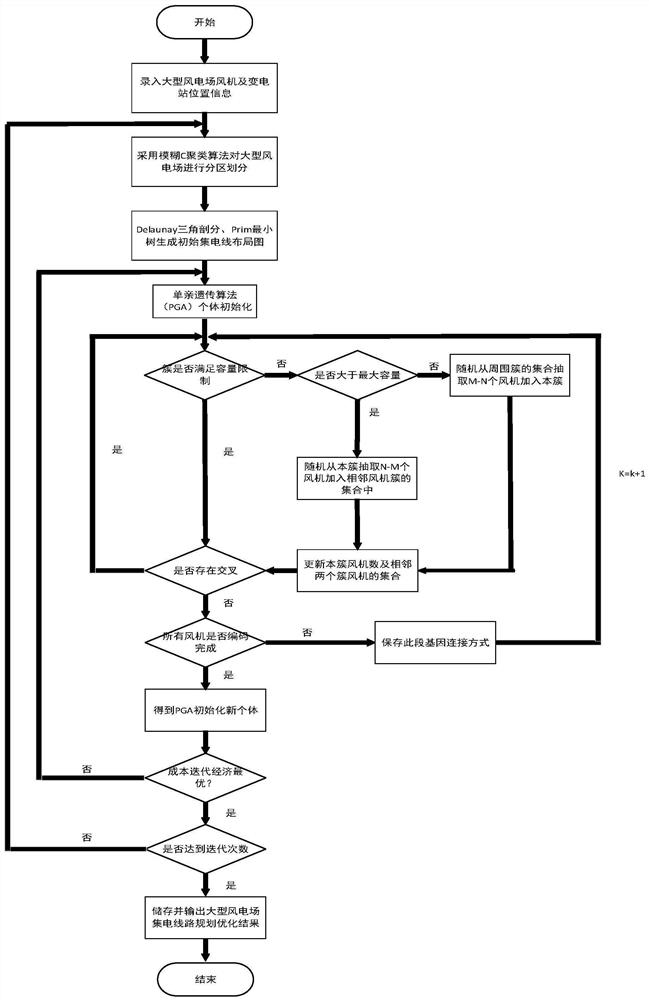

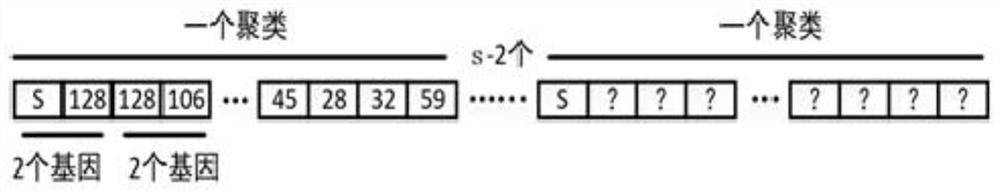

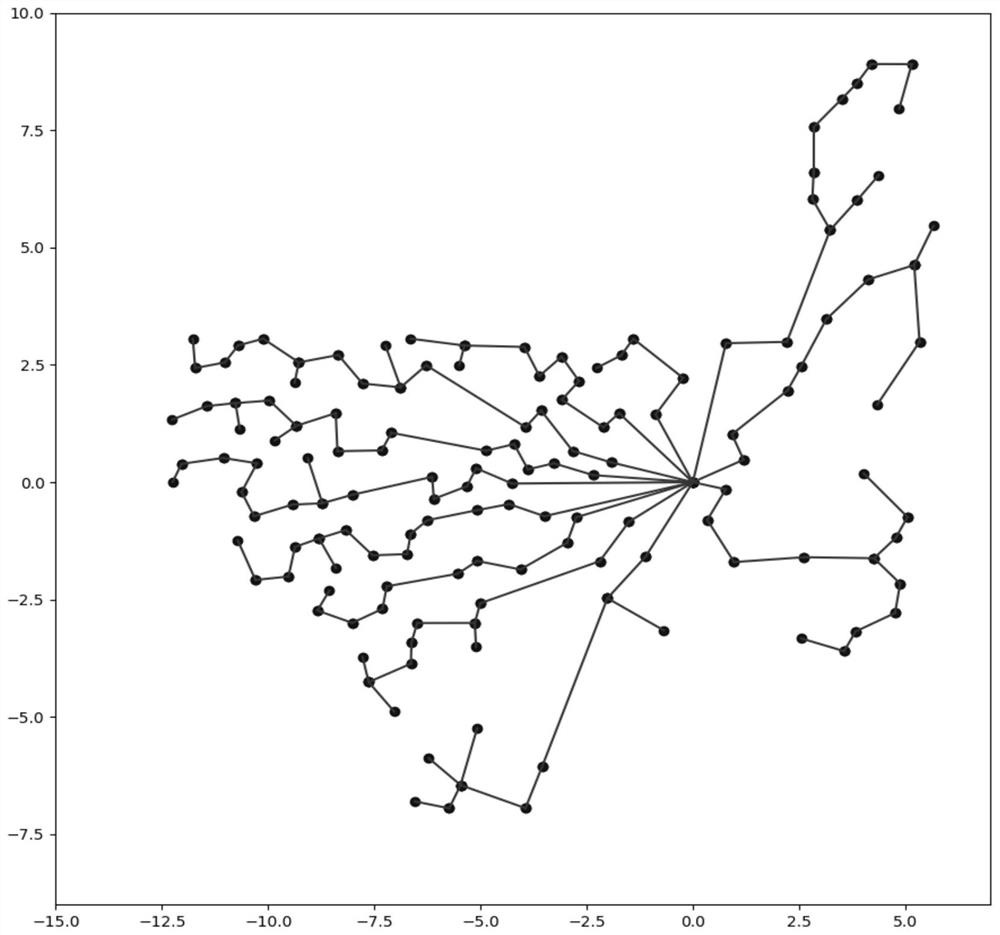

Control method and system for current collection lines of wind power base, storage medium and computing equipment

ActiveCN112072695AImprove layout economySave time and costSingle network parallel feeding arrangementsForecastingGenetics algorithmsEngineering

The invention discloses a control method and system for current collection lines of a wind power base, a storage medium and computing equipment. The method comprises the following steps: carrying outthe clustering on the whole wind power base based on the change of a fan distance generation mode through fuzzy C clustering, i.e., an FCM algorithm; acquiring a minimum spanning tree under a specified cluster number condition by using a Delaunay triangulation algorithm and a Prim algorithm so as to obtain the shortest-global-distance layout mode of the current collection lines of the wind power base under the condition; and finally, dynamically adjusting the number of the fans in each cluster and the connection modes of the current collection lines among the fans in the clusters by combininga PGA (Personal Genetic Algorithm) and comprehensively considering various engineering actual limiting conditions of the planning layout of the current collection lines of the wind power base so as toenable the planning layout of the current collection lines of the wind power base to be optimal, thereby obtaining a global optimal current collection line layout map. The method can effectively solve the problems that current large-scale wind power base current collection line layout mostly depends on manual planning, time is long, and high economy cannot be realized.

Owner:GUANGDONG MINGYANG WIND POWER IND GRP CO LTD

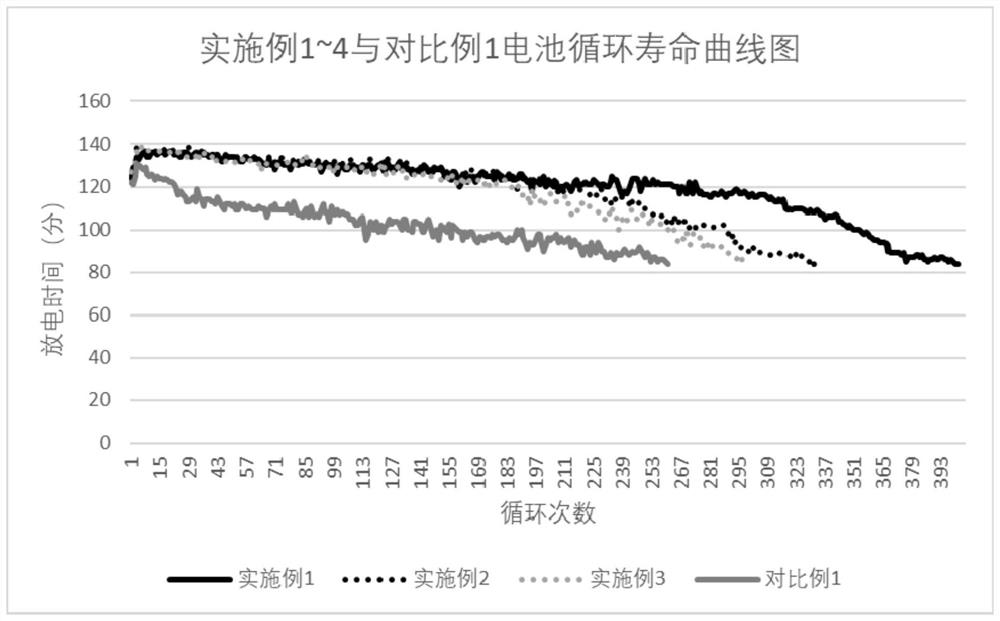

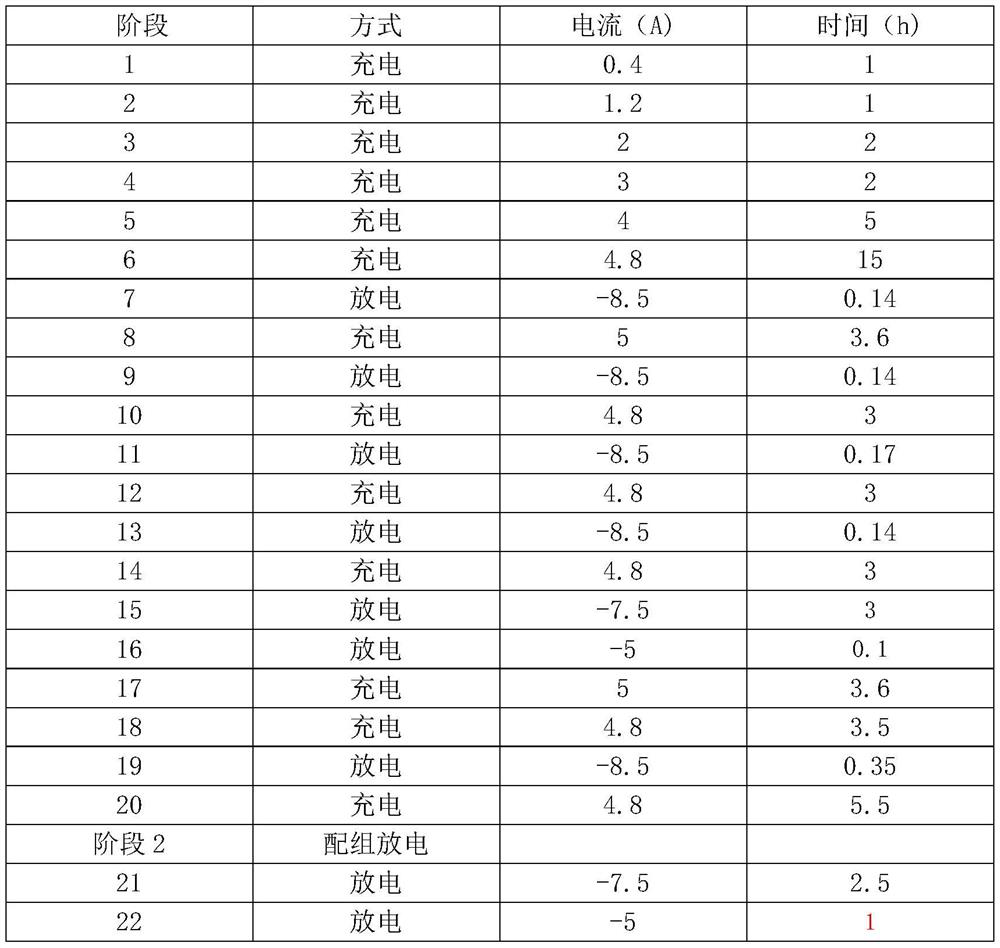

Manufacturing method of lead-acid storage battery

InactiveCN111916849AGuaranteed lifeMeet capacity requirementsFinal product manufactureCell component detailsProcess engineeringBattery cell

The invention relates to a manufacturing method of a storage battery, and the method comprises the following steps: 1, adding a first density sulfuric acid solution with the density of 1.04 g / cm <3>-1.28 g / cm <3> into a lead-acid storage battery; 2, performing electrifying for complete formation; 3, adding a second density sulfuric acid solution into the formed battery, and carrying out the blending, wherein the density of the second density sulfuric acid solution is 1.25-1.6 g / cm <3>, and the density of the second density sulfuric acid solution is greater than the density of the first densitysulfuric acid solution. According to the manufacturing method of the storage battery, not only is the service life of the battery ensured, but also the capacity requirement can be met; in addition, the formation efficiency can be improved, the energy is saved, and greater convenience is provided for producing batteries with different capacities.

Owner:CHAOWEI POWER CO LTD

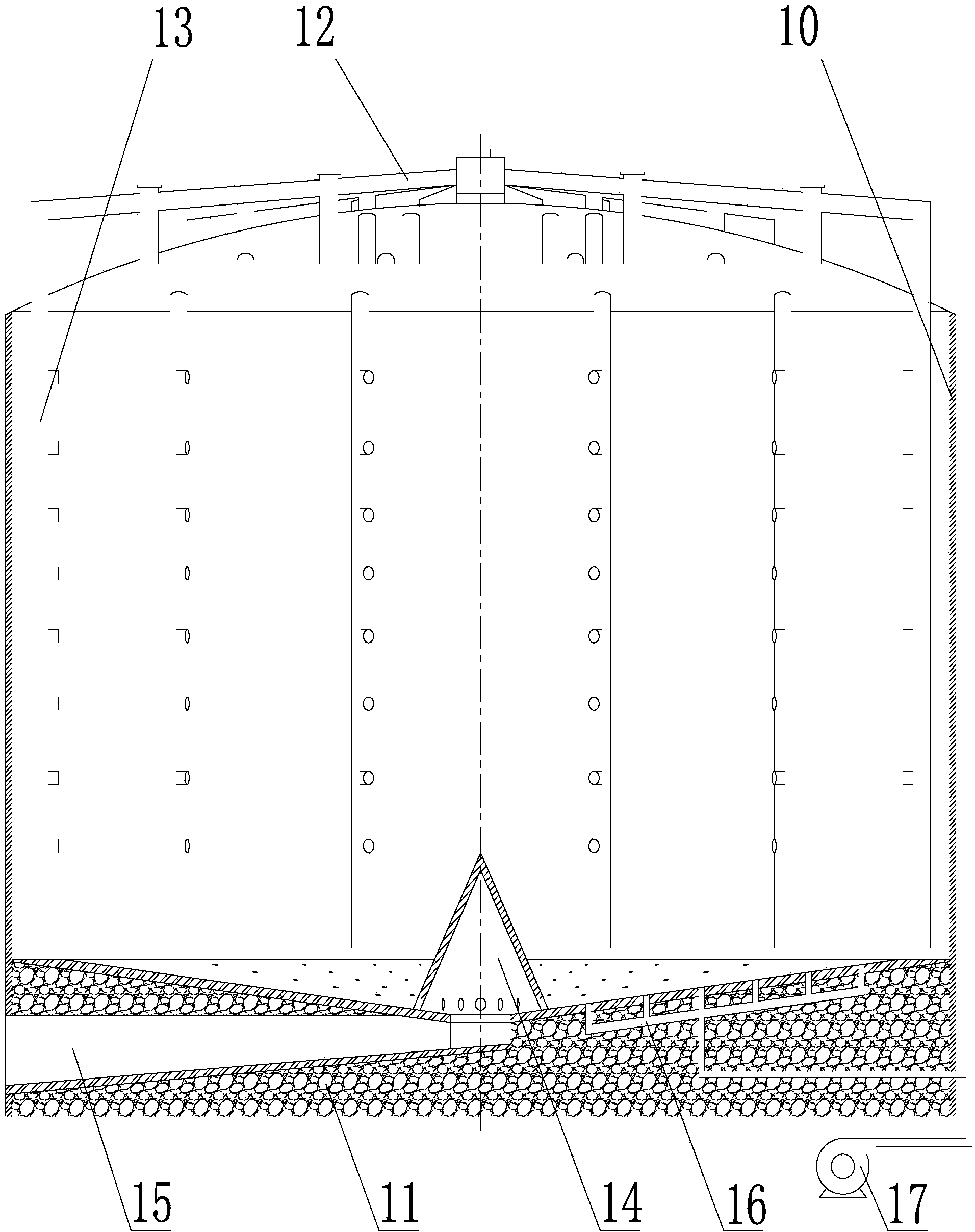

Efficient solid material reservoir bottom comb type material pusher

ActiveCN104555483AIncrease productionSimple structureLoading/unloadingReciprocating motionEngineering

The invention relates to an efficient solid material reservoir bottom comb type material pusher. The efficient solid material reservoir bottom comb type material pusher comprises a fixed base, a shell and a horizontal comb bed, wherein the shell is installed on the fixed base, the front end of the shell is provided with a material inlet, and the tail end of the shell is provided with a discharging opening; the comb bed comprises a plurality of independently moving push plates, wherein each push plate is respectively connected with a driving device; the driving devices drive the push plates to carry out reciprocating motion; two adjacent push plates adopt a movement mode of consistent front lines and staggered rear lines, and the speed of the front line of each push plate is slower than the speed of the rear line of each push plate; a plurality of carrier rollers and guide rails are installed between the push plates and the fixed base. According to the efficient comb type material pusher, the inertia of materials is fully utilized, a purpose of reservoir bottom unloading is achieved according to speed change between the front line and the rear line of each push plate, and the yield of the comb type material pusher is further improved due to cohesion among solid bulk materials. The efficient comb type material pusher has the advantages of simple integral structure, few parts, low production and manufacture difficulty, low repairing cost and safety and reliability in operation.

Owner:HUAXIN EQUIP MFG +2

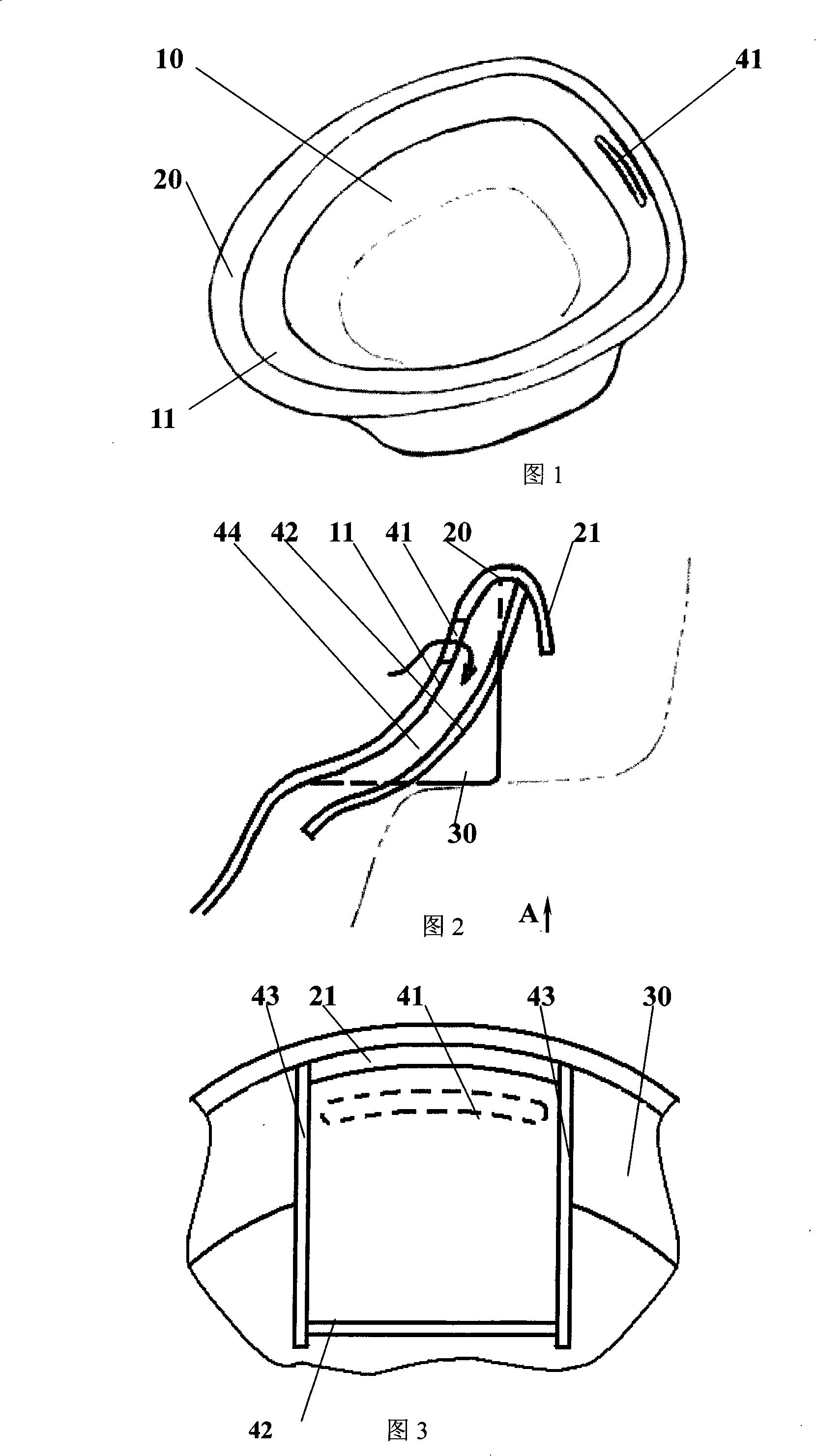

Bidet with hollow cross section support structure adapted for closet

The invention discloses a hip bath tub which is matched with a toilet bowl and has a hollow section supporting structure. The hip bath tub comprises a tub body which is composed of a tub wall and a tub edge, and the upper opening of the tub wall is in an outward diverging disk shape; a supporting structure used for widening the tub edge and heightening the tub body is arranged at the lower part of the tub edge, the supporting structure adopts a hollow section supporting structure which is formed by adopting the gas-assisted injection molding technology and bent along the lower end of the tub edge, and the bent profile of the hollow section supporting structure is basically identical with the shape of the upper edge of the matched toilet bowl; an overflow structure is arranged in the position of the tub edge positioned at the rear part of the tub body, and the overflow structure comprises an overflow opening arranged in the position of the tub edge and a flow guiding structure communicated with the overflow opening; a flow guiding structure installation space, the width of which is identical with that of the flow guiding structure, is arranged on the hollow section supporting structure. The hip bath tub adopts the gas-assisted injection molding technology, the supporting structure is arranged at the lower end of the tub edge, thereby not only the volume of the tub body is increased, but also the supporting stability of the tub body is enhanced, and the raw materials are also saved.

Owner:徐克林

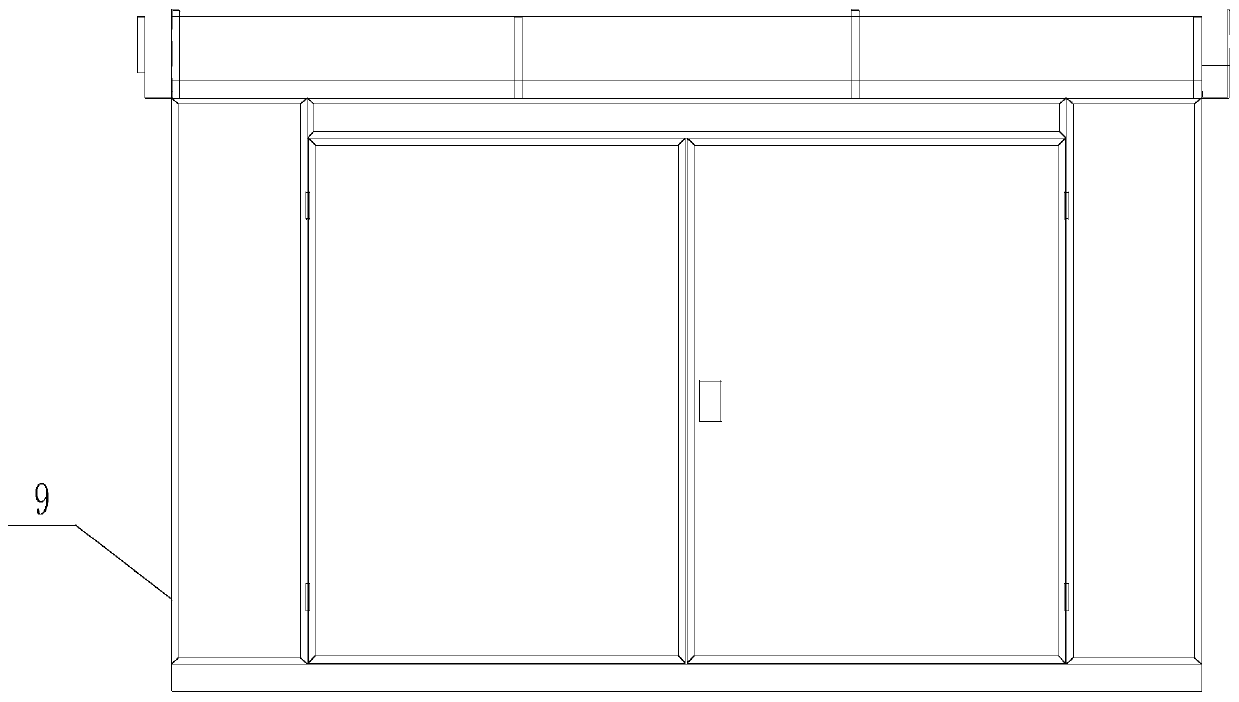

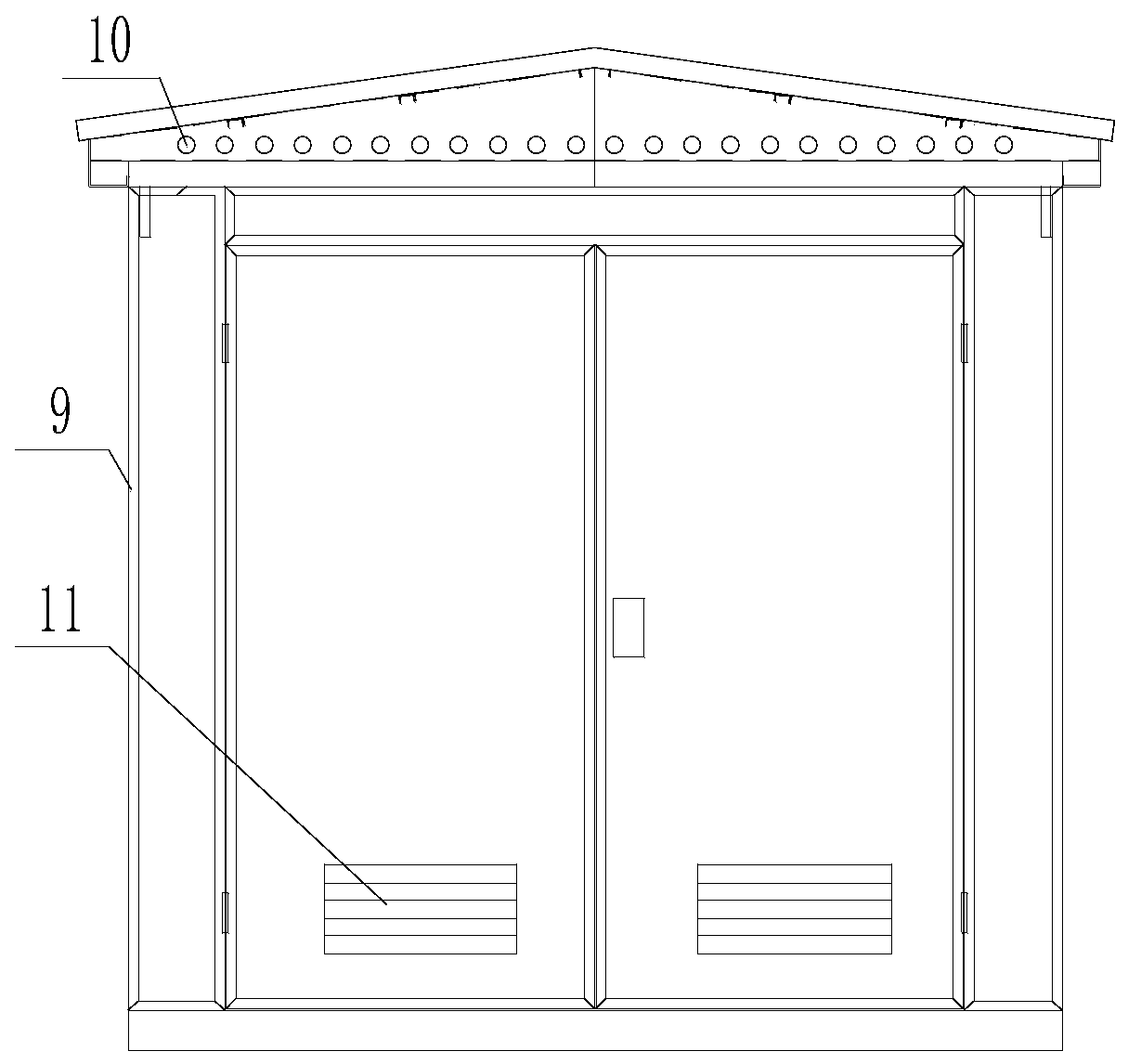

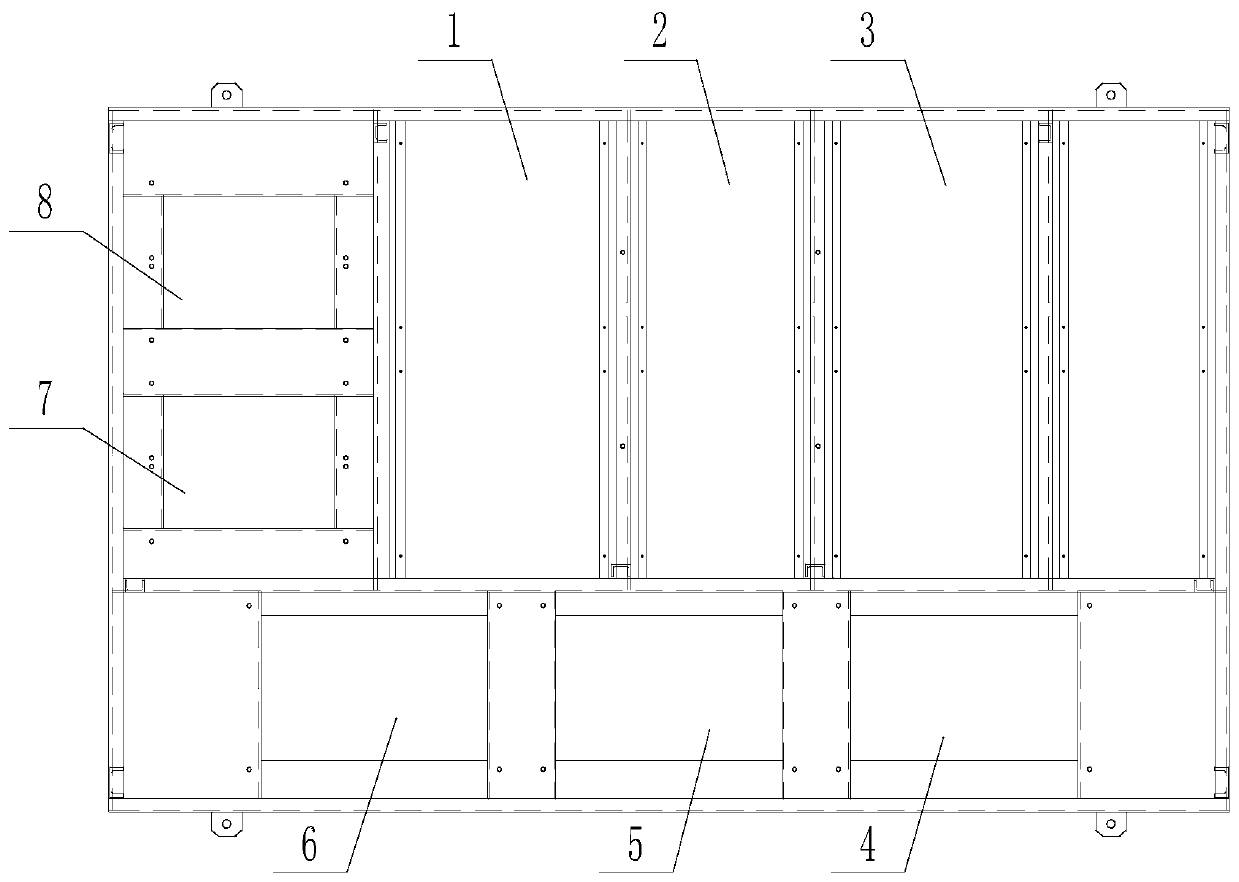

Outdoor power transformation box

InactiveCN110212427AMeet capacity requirementsReduce construction costsSupervisory desks/panelsSubstation/switching arrangement detailsMicrocontrollerCommunications system

The invention discloses an outdoor power transformation box, and belongs to the technical field of power transformation boxes. The outdoor power transformation box mainly comprises a box body; a transformer, a low-voltage cabinet, a high-voltage cabinet, a wire outlet cabinet, a capacitor cabinet, a wire inlet cabinet and a monitoring system are arranged in the box body; the transformer, the low-voltage cabinet, the high-voltage cabinet, the wire outlet cabinet, the capacitor cabinet and the wire inlet cabinet are connected with the monitoring system; the monitoring system comprises a microcontroller, a GPRS module, a ferroelectric memory, a switching value input and output module, an analog transmitting output module, a metering chip, a temperature and humidity sensor; and the GPRS module, the ferroelectric memory, the switching value input and output module, the analog transmitting output module, the metering chip and the temperature and humidity sensor are connected with the microcontroller. The monitoring system is additionally arranged; and communication system signals can reach all monitoring terminals through GPRS communication, so that the real-time performance of the monitoring system is improved, and the cost is reduced. The outdoor power transformation box is mainly used for converting a voltage and a current of electric energy.

Owner:STATE GRID SHANDONG ELECTRIC POWER +1

Crankcase structure for needling machine

The crankcase for needle punching machine as one non-woven fabric making machine has the structure including one case, one main shaft with ends on the case, one pair of first link rods, and one pair of second link rods located in the first pair of link rods, one pair of guide rods, one pair of push rods, and one flywheel on the main shaft. It features one balance weight over the main shaft to slip fit the guide rods. The crankcase in the improved structure can raise the needle punching speed of the needle punching machine for high output.

Owner:常熟市伟成非织造成套设备有限公司

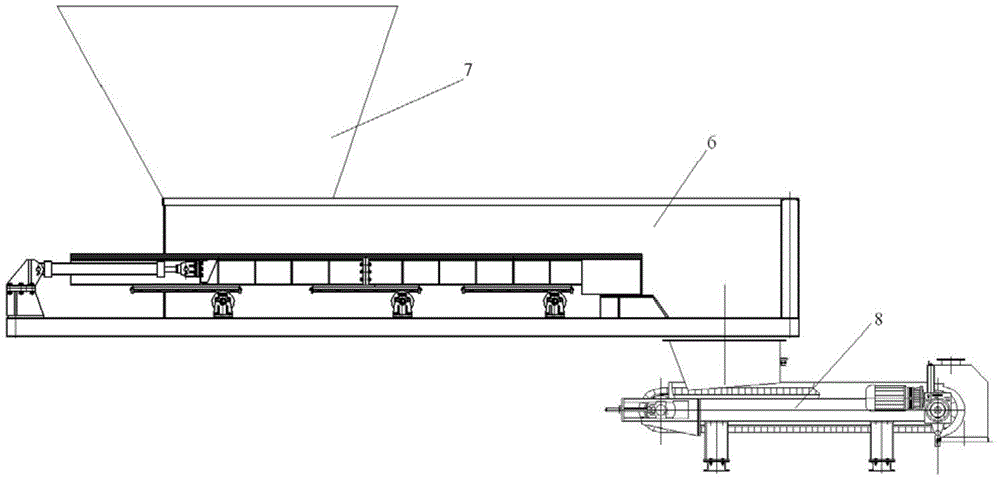

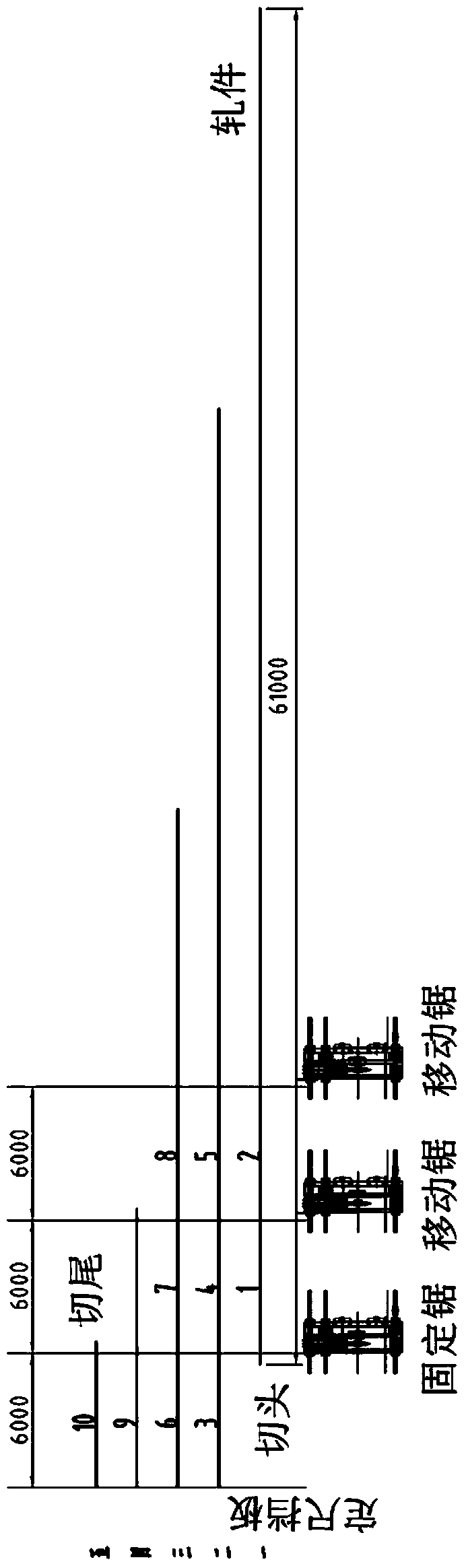

Aluminum oxide warehousing system and conveying and storing method thereof

ActiveCN103640818ALarge diameterLow costLarge containersLoading/unloadingSmall footprintFunnel shape

The invention relates to an aluminum oxide warehousing system and a conveying and storing method of the aluminum oxide warehousing system, and belongs to the technical field of aluminum oxide warehousing. The aluminum oxide warehousing system comprises a material warehousing part and a material conveying part. A radial structure is adopted for a warehouse top feeding pipe of the material warehousing part, the warehouse bottom is in a funnel shape, a vertical feeding pipe in a warehouse is added in the warehouse, so that aluminum oxide in the warehouse diffuses to the periphery after falling off, the dissociation phenomenon caused by uneven feeding is effectively reduced, the phenomenon of uneven stress on a warehouse body caused by uneven stack of the aluminum oxide is eliminated, and stability of the warehouse body is improved; an air supply channel is added in the warehouse bottom and can provide disturbing force for the static aluminum oxide at the bottom in the air supplying process, so that the aluminum oxide flows out of the warehouse rapidly and the problem of dead mass areas is solved. According to the material conveying part, the material conveying distance is shortened, and conveying flexibility is increased; the diameter of the warehouse body is larger, the warehousing capacity reaches 3-5 million tons, overall occupied area of the warehouse system is small, warehouse manufacturing cost is reduced substantially, and therefore the requirement of the aluminum oxide production capacity can be met completely.

Owner:NORTHEASTERN UNIV ENG & RES INST CO LTD

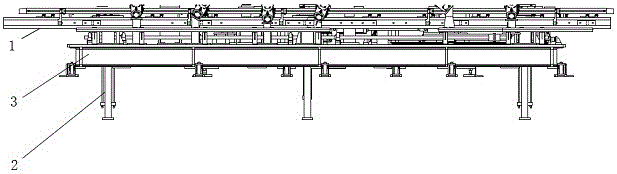

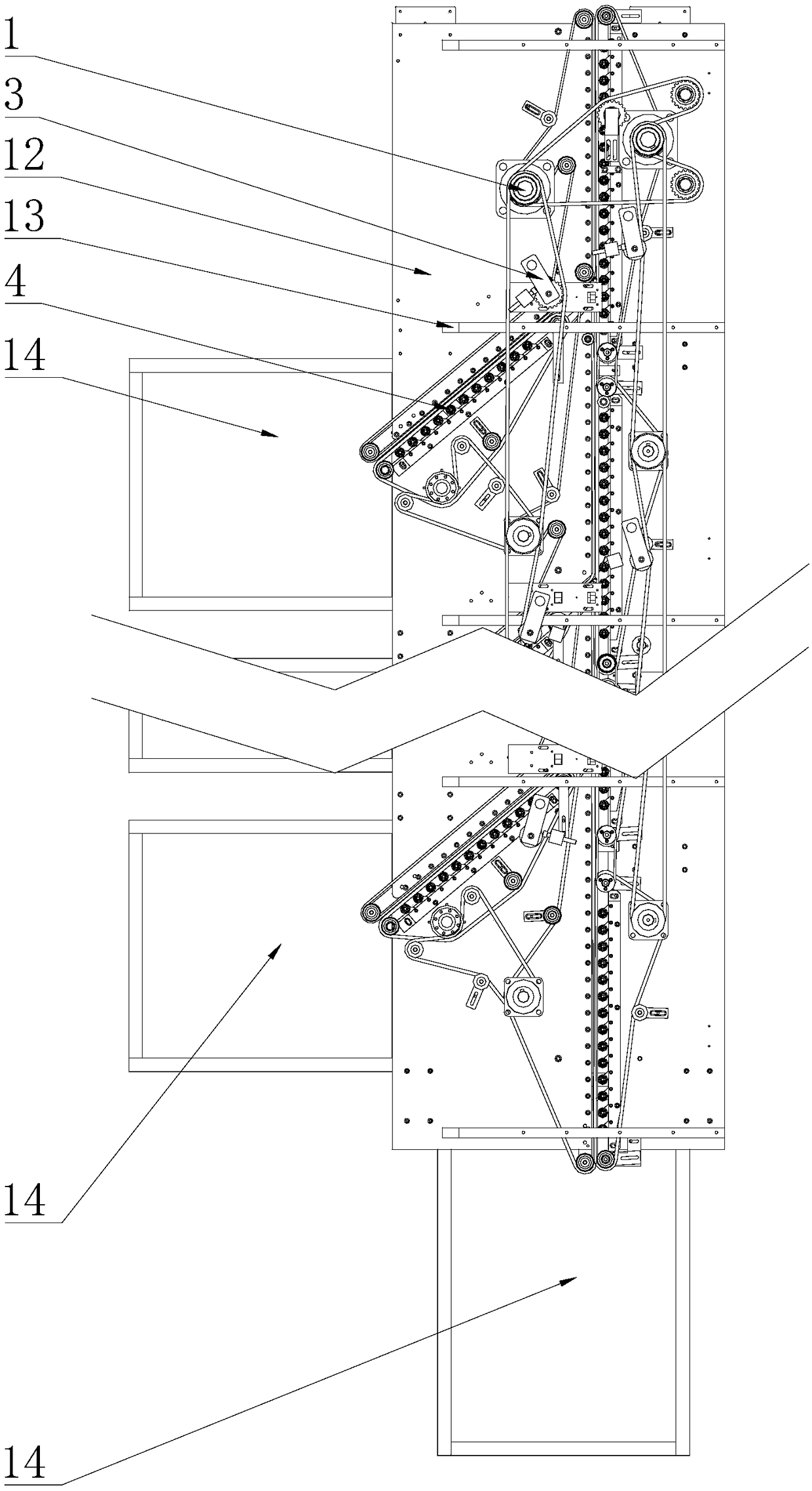

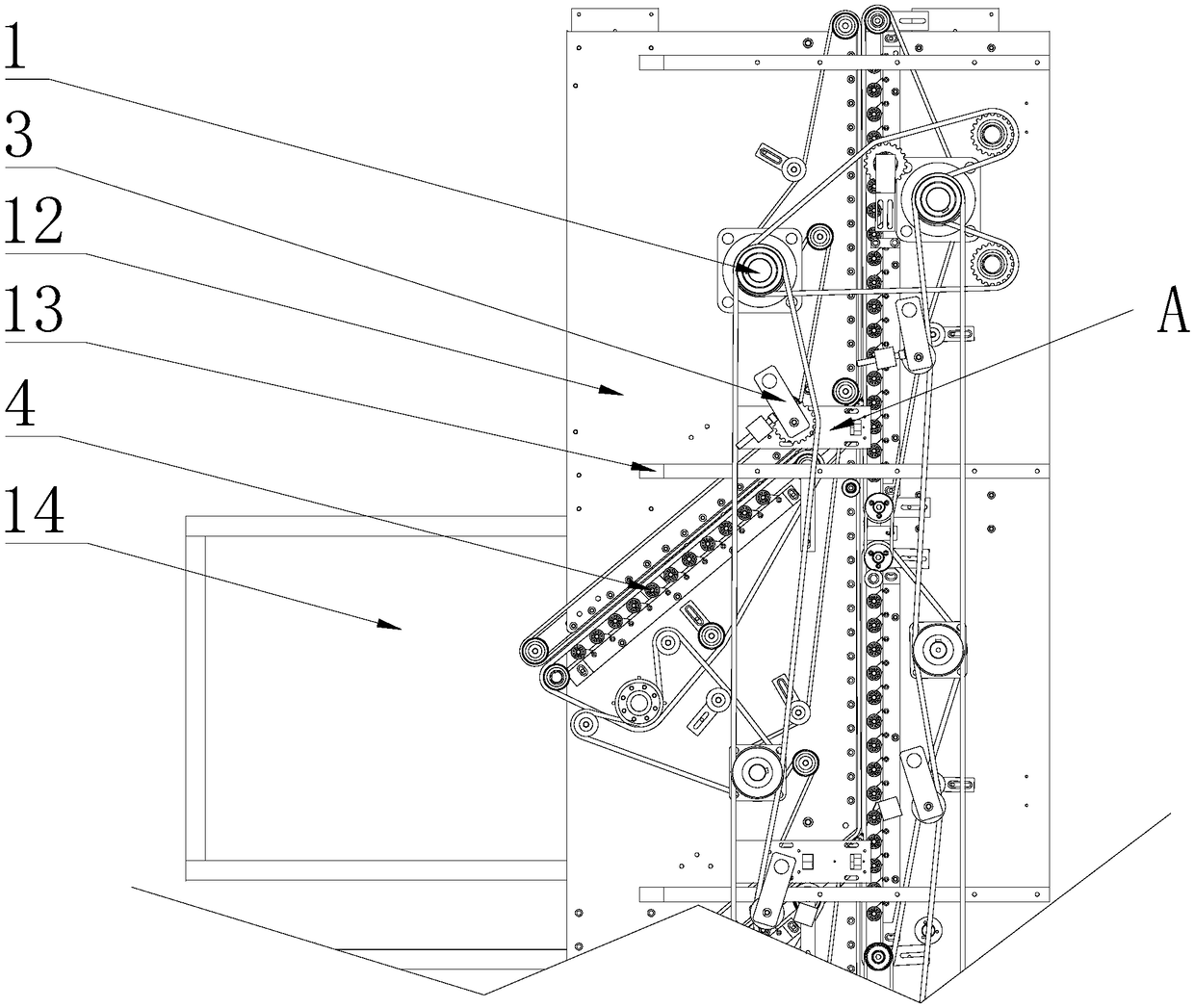

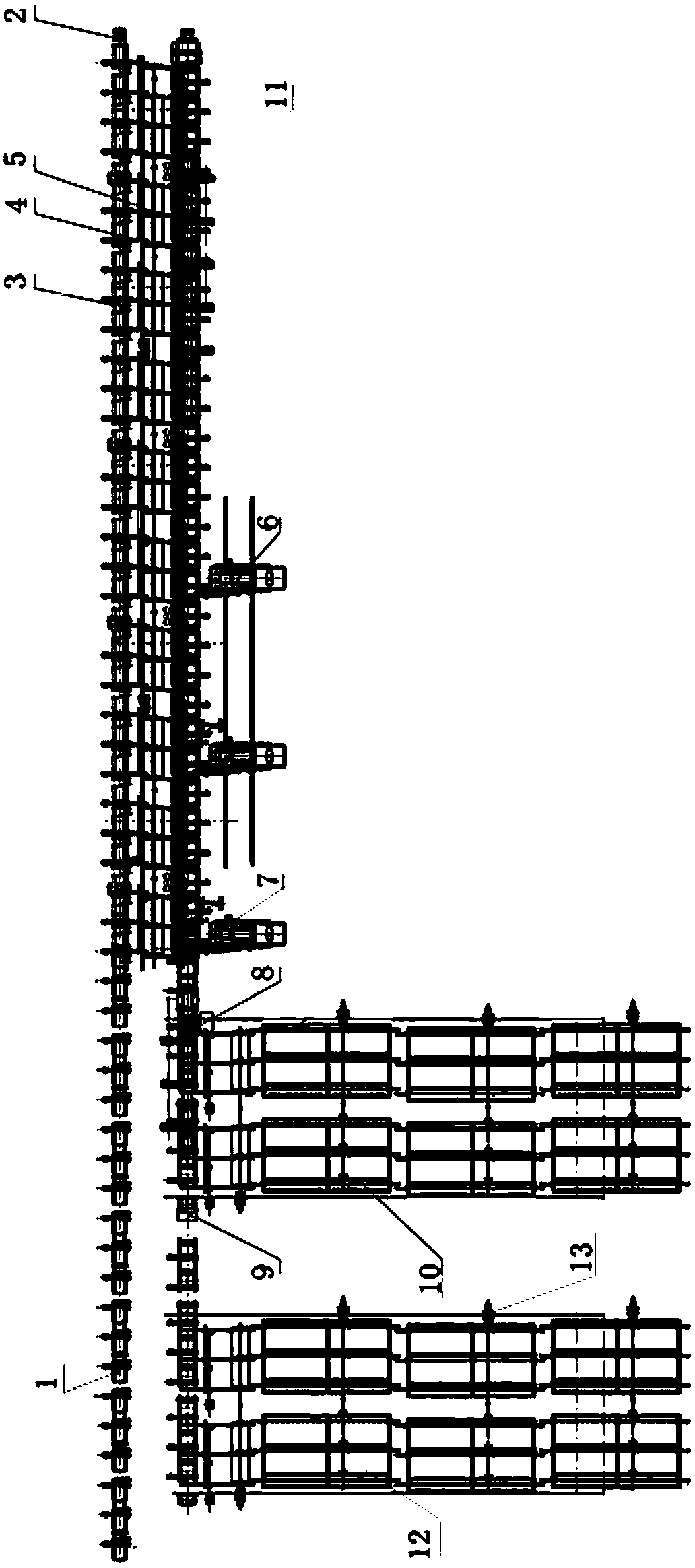

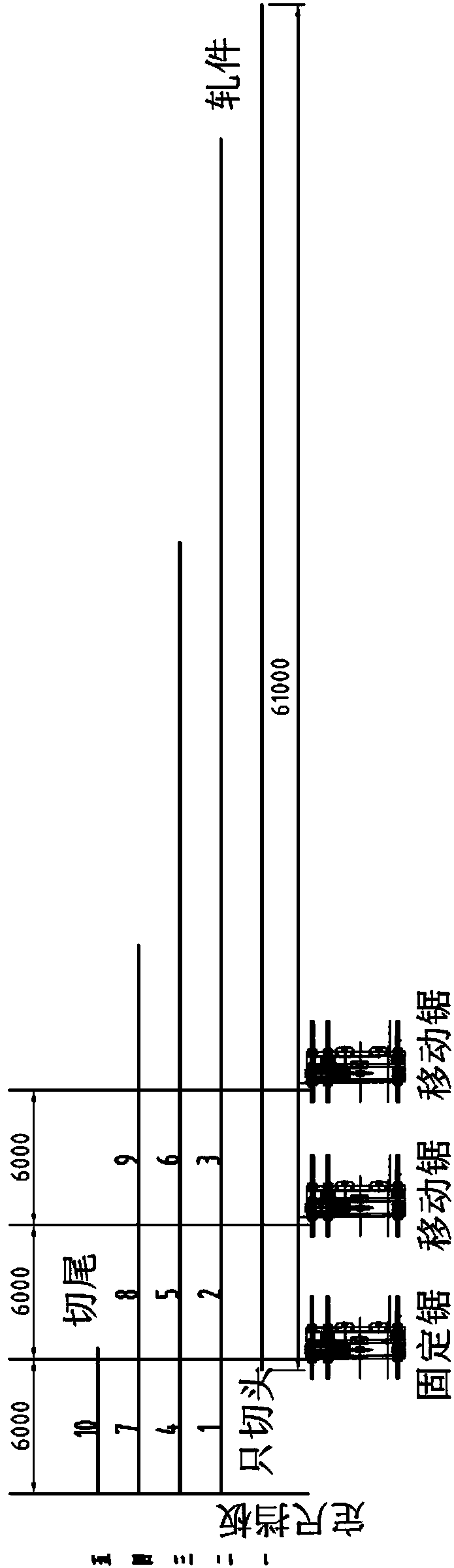

Method and device for sizing and sawing large-sized profiles

ActiveCN104384606AMeet the rolling rhythmMeet capacity requirementsMetal sawing devicesMetal sawing accessoriesEngineeringMechanical engineering

The invention relates to a method and a device for sizing and sawing large-sized profiles. The method for sizing and sawing the large-sized profiles comprises the following steps: transmitting supplied profiles from a grouping rack input roller channel to a sawing rail parallel to the grouping rack input roller channel, and sawing the supplied profiles by cooperation of a fixed saw, a movable saw and a sizing machine. The device for sizing and sawing the large-sized profiles comprises the grouping rack input roller channel and the sawing rail parallel to the grouping rack input roller channel, wherein the fixed saw and the movable saw are arranged on the outer side of the sawing rail; the sizing machine is arranged on the sawing rail; a first collection rack and a second collection rack are arranged on the outer side of the tail of the sawing rail; a lifting baffle is arranged between the first collection rack and the second connection rack; the first collection rack and the second collection rack are respectively formed by an aggregate lifting chain, an aggregate fixing chain and an aggregate trolley; steel overturning trolleys are arranged on the outer sides of the first collection rack and the second collection rack. By virtue of the method and the device for sizing and sawing the large-sized profiles, the rolling rhythm and the capacity requirements can be met; the occupied space is small; the investment is reduced.

Owner:鞍钢集团工程技术有限公司

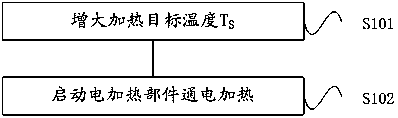

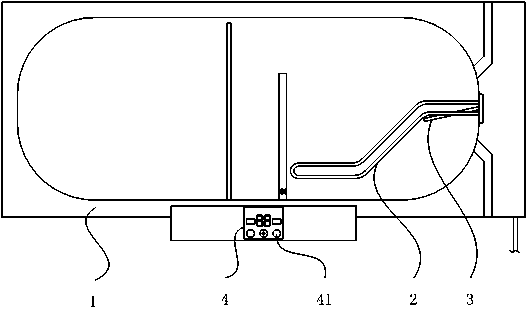

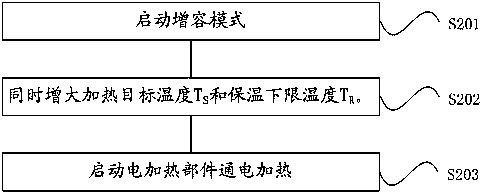

Control method of electric water heater

The invention discloses a control method of an electric water heater. The control method of the electric water heater comprises the steps of after a capacity increasing mode is started, increasing theheating target temperature TS, and staring an electric heating component of the electric water heater for electrifying and heating, wherein the increased heating target temperature TS is greater thanthe temperature TU set by a user. In the capacity increasing mode, the heating target temperature is increased to enable the heating target temperature to be higher than the temperature set by the user, so that even after the water in the electric water heater reaches the temperature set by the user, the electric water heater continues to be electrified for heating to continue heating the water in a heat preservation water tank, and the heat preservation water tank stores hot water with higher temperature so as to meet the requirement of the user for the hot water and achieve the capacity increasing function; and the capacity increasing requirement is met without additionally increasing the volume or arranging a heating device, so that the manufacturing cost of the electric water heater is effectively reduced.

Owner:QINGDAO ECONOMIC & TECHN DEV ZONE HAIER WATER HEATER +1

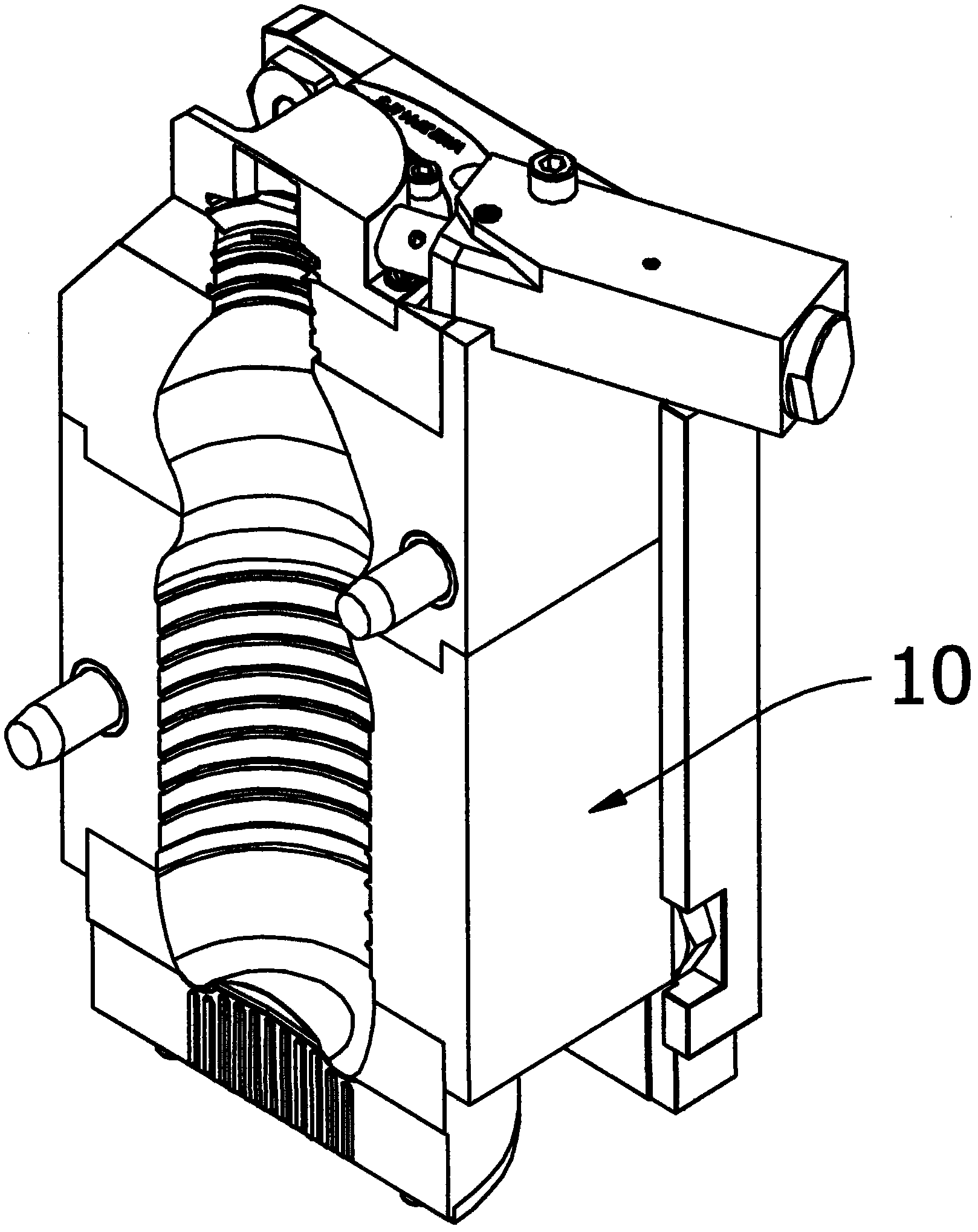

Mould structure of horizontal rotary bottle blowing machine

The invention discloses a mould structure of a horizontal rotary bottle blowing machine. The mould structure comprises a left half model and a right half model; and the left half model and the right half model at least respectively comprise a bottle cavity and a cooling water path arranged around the bottle cavity. In the mould structure of the horizontal rotary bottle blowing machine disclosed by the invention, the cooling water path of the left half model is separated from the cooling water path of the right half model, so that the horizontal rotary bottle blowing machine is possible to be used. The bending structure of the cooling water path ensures that the contact area of the cooling water path and the bottle cavity is greatly increased, and the cooling effect is greatly improved. The cooling water path is one continuous water path, so the designs of a water inlet pipe and a water outlet pipe are greatly simplified. By virtue of the design of the cooling water path, products are cooled fast in a mold cavity, so that the horizontal rotary bottle blowing machine can blow out acceptable product bottles to meet the production capacity requirements of equipment.

Owner:天良智能设备(上海)股份有限公司

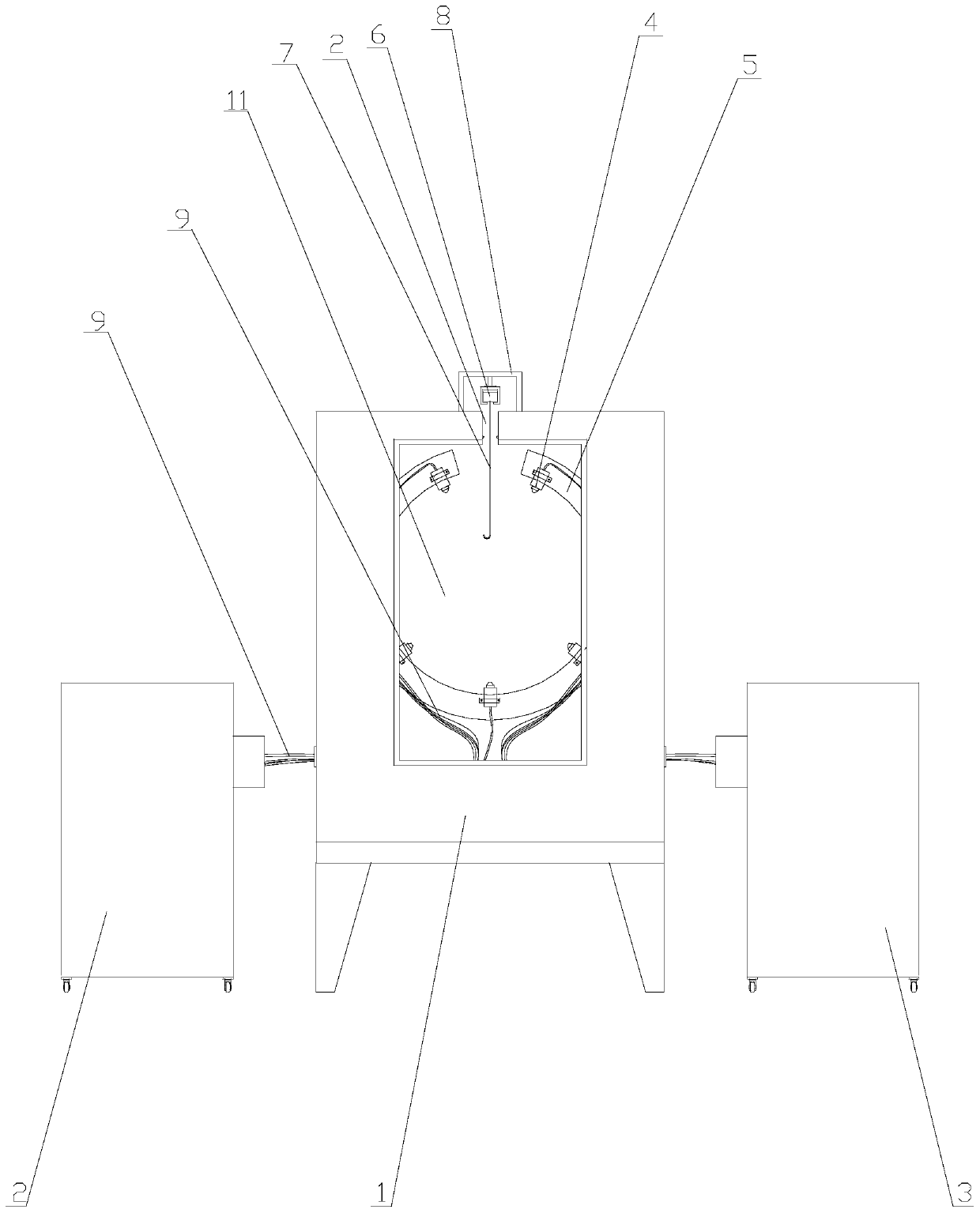

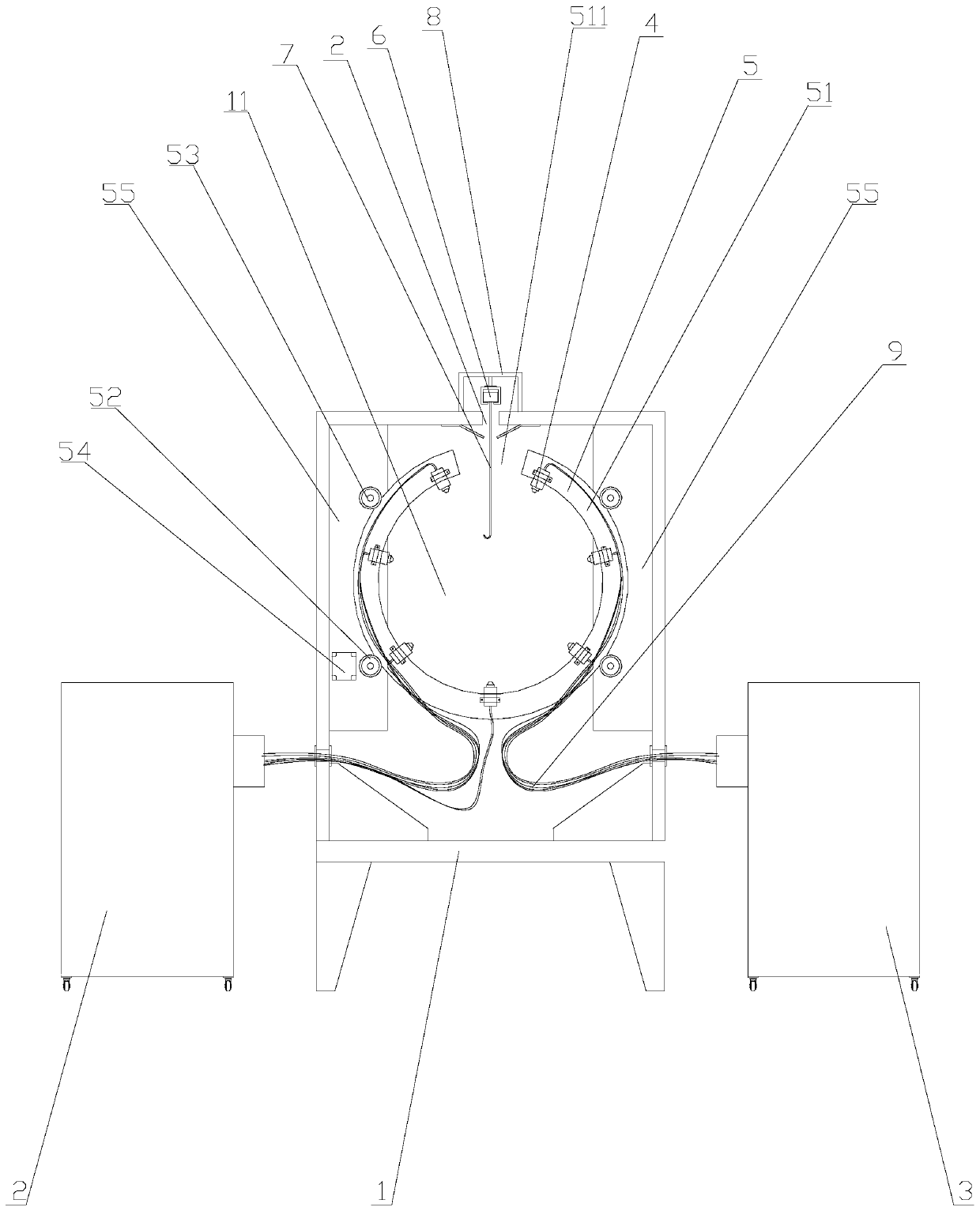

Automatic powder spraying device high in spraying efficiency

PendingCN111570155AImprove spraying efficiencyImprove spray qualityMovable spraying apparatusSpray boothsManufacturing engineeringMetallurgy

The invention discloses an automatic powder spraying device high in spraying efficiency. The automatic powder spraying device comprises a powder spraying box, a first powder box, a second powder box,a plurality of static powder spraying guns, powder spraying gun swing devices, a conveying rail, a plurality of spraying part hooks, a conveying rail protection shell and a powder conveying hose. A spraying cavity is formed in the powder spraying box. According to the automatic powder spraying device high in spraying efficiency, the powder spraying gun swing devices are arranged, the powder spraying guns are arranged on the powder spraying gun swing devices, the powder spraying gun swing devices can drive the powder spraying guns to do reciprocating rotating spraying around the surface of a workpiece, and the workpiece powder spraying efficiency and the spraying quality can be improved; and spraying is more even, even spraying can be carried out on the upper face and the lower face of theworkpiece, and powder waste is reduced; two lines are arranged back to back through a powder spraying room, part of drying ovens are public, and by means of the multi-layer layout design that the workpiece is hung on the bottom floor for spraying and pretreatment and drying are carried out on the second floor, the space is saved to the maximum extent, and the requirement of the production capacityis met; and the two lines share part of facilities, and energy consumption and the labor cost are reduced.

Owner:浙江好仕莱家居用品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com