Mould structure of horizontal rotary bottle blowing machine

A blow molding machine and mold technology, which is applied in the field of blow molding machines, can solve the problems that the horizontal rotary blow molding machine cannot arrange cooling water channels, etc., and achieve the effect of improving the cooling effect, increasing the contact area, and simplifying the design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

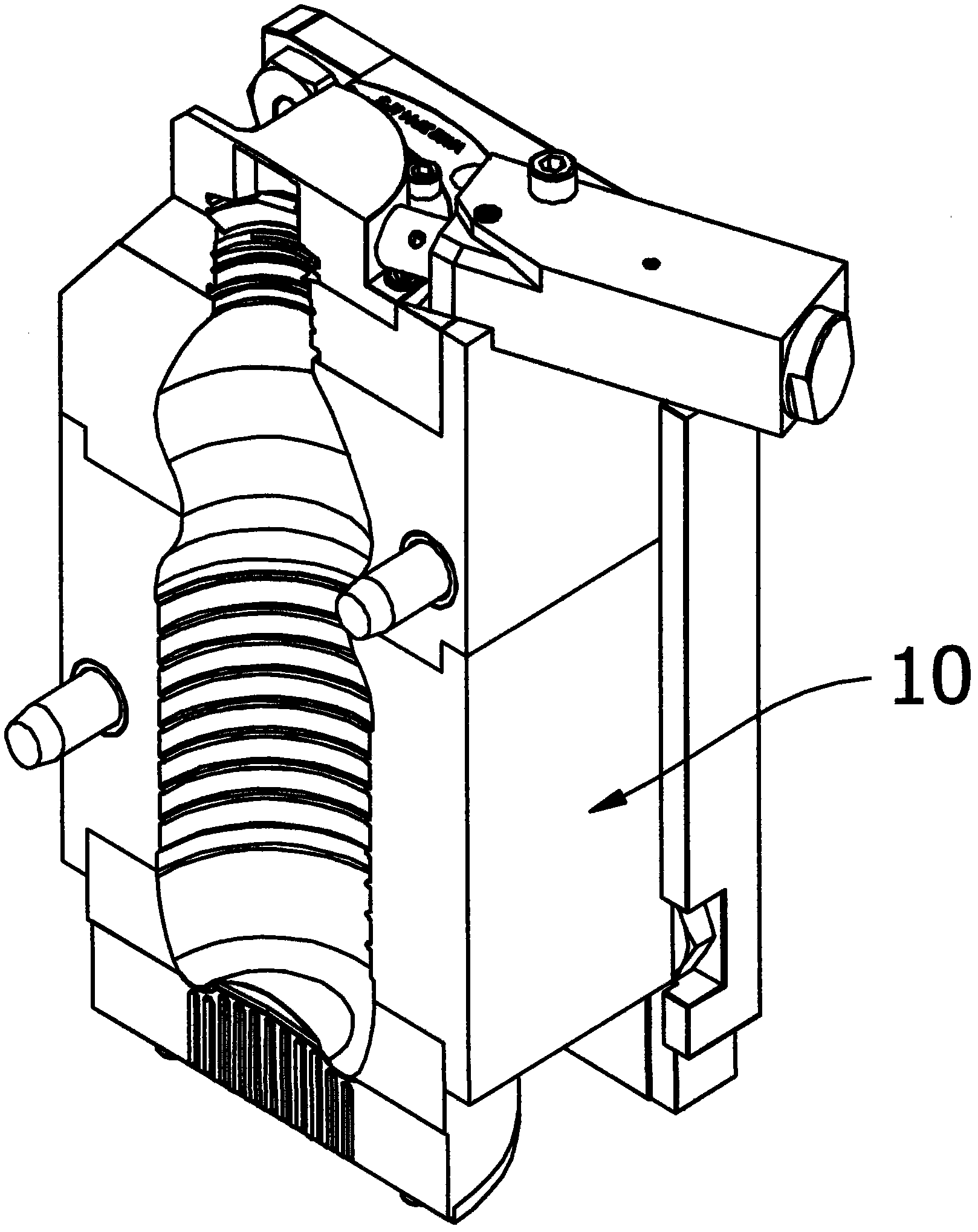

[0018] Such as figure 1 , Figure 4 As shown, a specific embodiment of the mold structure of the horizontal rotary blow molding machine of the present invention, the mold structure includes a left half mold 10 and a right half mold 20 .

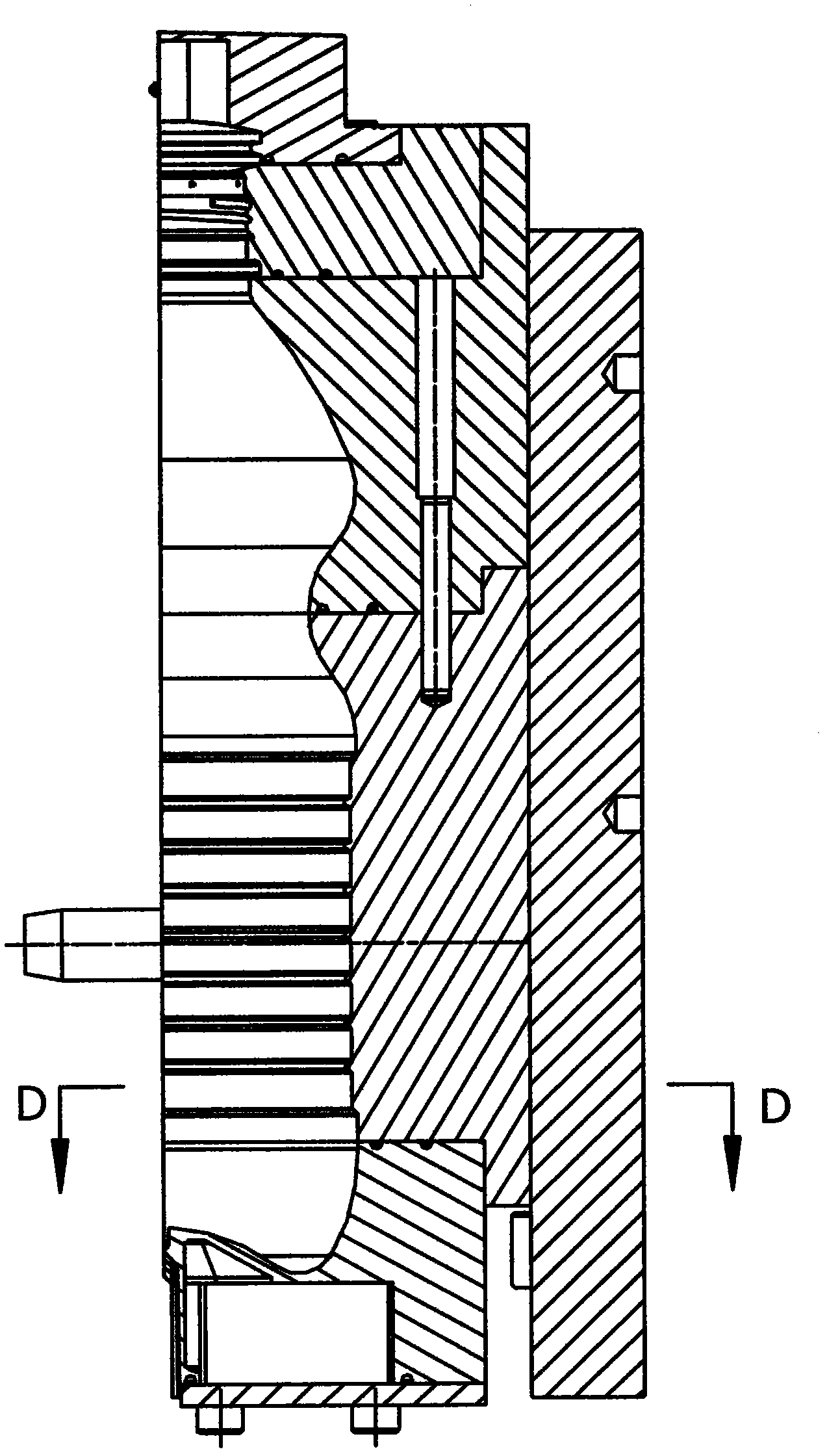

[0019] Such as figure 2 , Figure 5 As shown, each of the left half-mold 10 and the right half-mold 20 at least includes a bottle cavity and a cooling water circuit arranged around the bottle cavity. Left half mold 10 is made up of left upper half mold and left lower half mold, and right half mold 20 is made up of right upper half mold and right lower half mold.

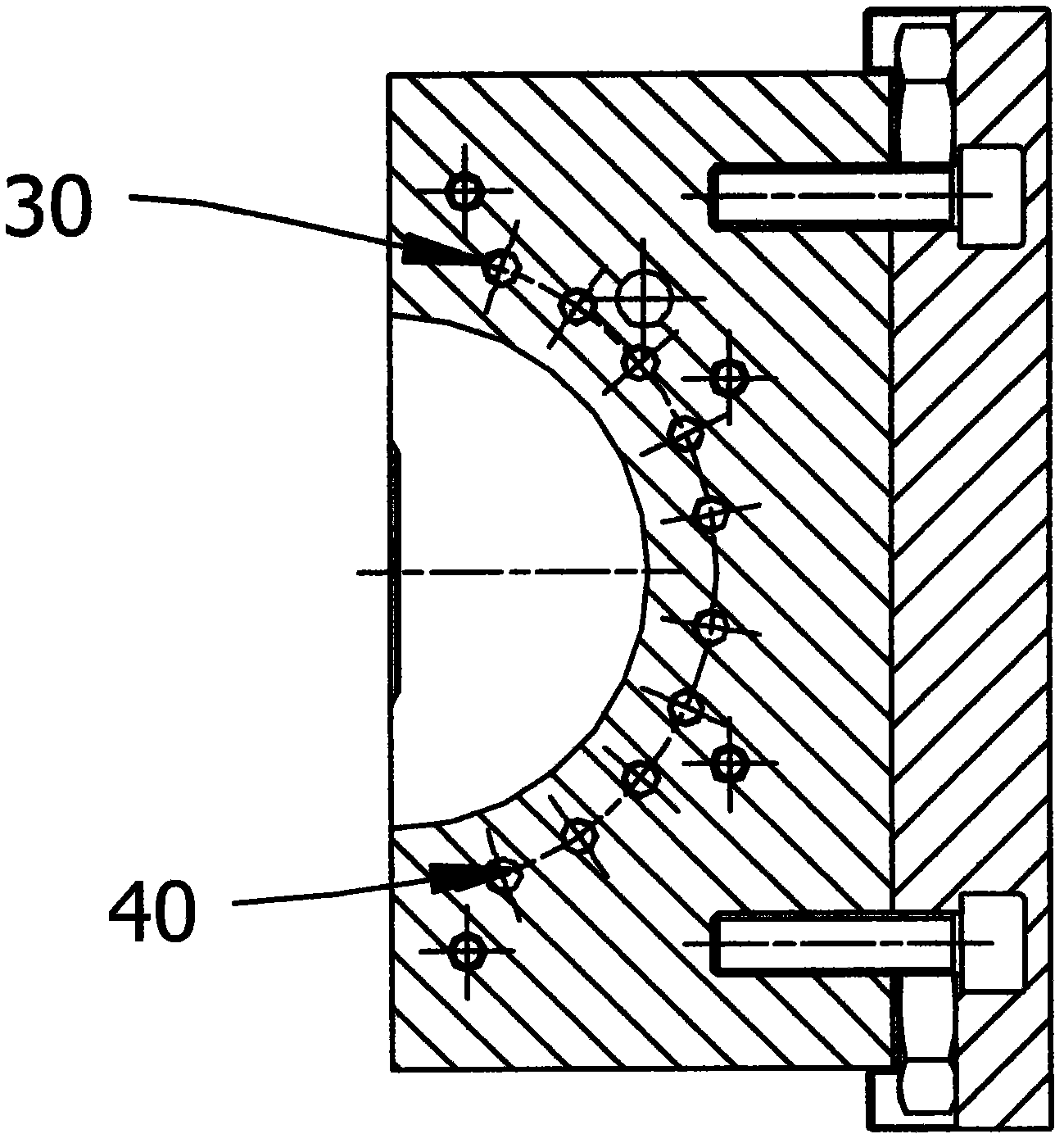

[0020] Such as image 3 As shown, the cooling water circuit includes a water inlet 30 and a water outlet 40; as Image 6 As shown, the cooling water circuit includes a water inlet 50 and a water outlet 60 . The cooling water circuit is close to the cavity wall of the bottle cavity. The cooling waterway is a continuous waterway. The cooling water path is bent and arranged ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com