Method and device for sizing and sawing large-sized profiles

A fixed-length sawing and large-size technology, which is applied in the field of large-size profile sawing and equipment, can solve problems such as unrealizable, achieve the effects of small space occupation, investment saving, and production capacity requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

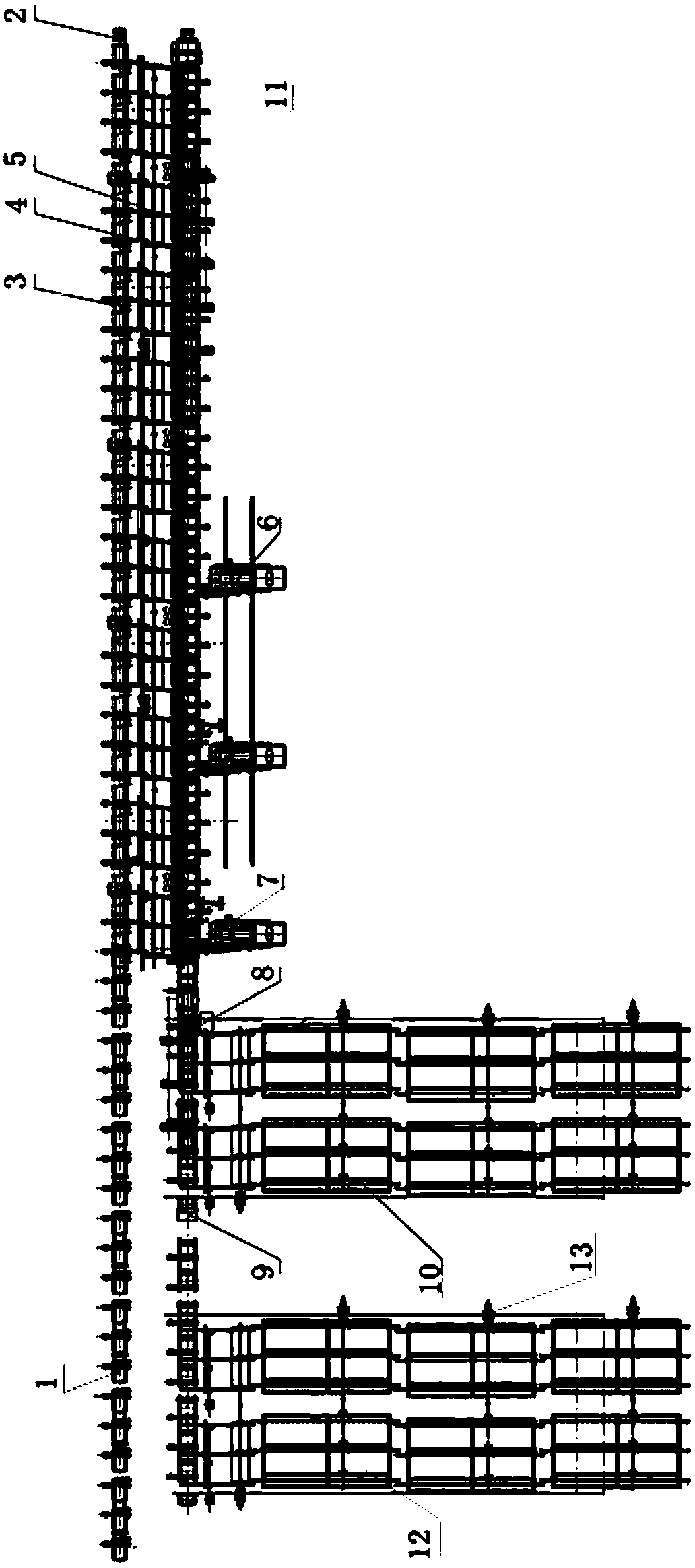

Image

Examples

Embodiment

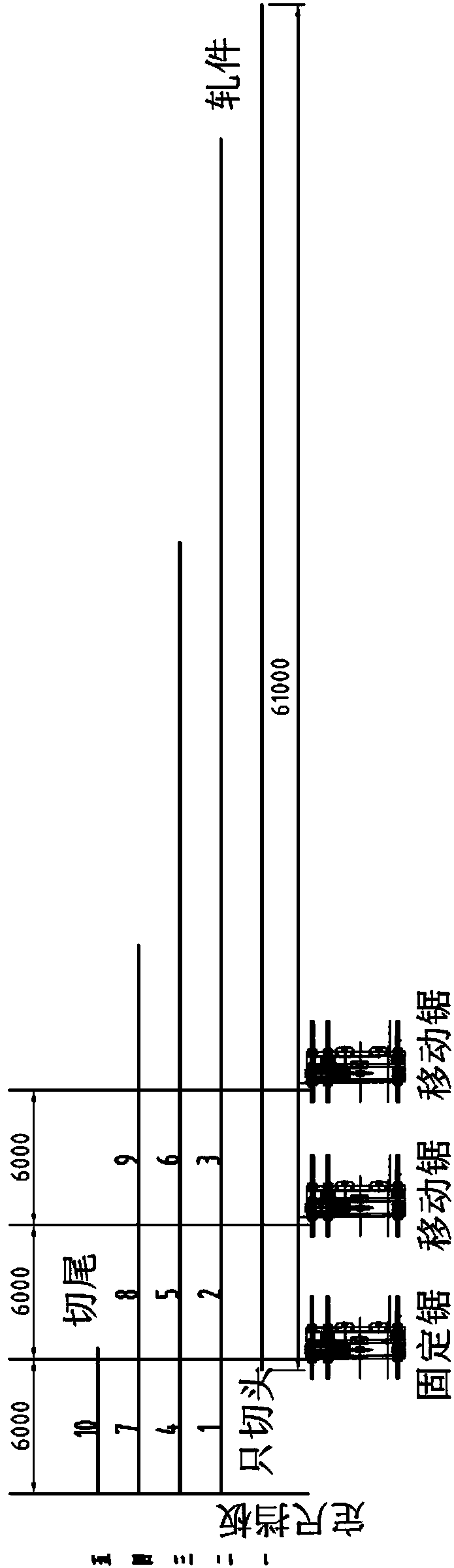

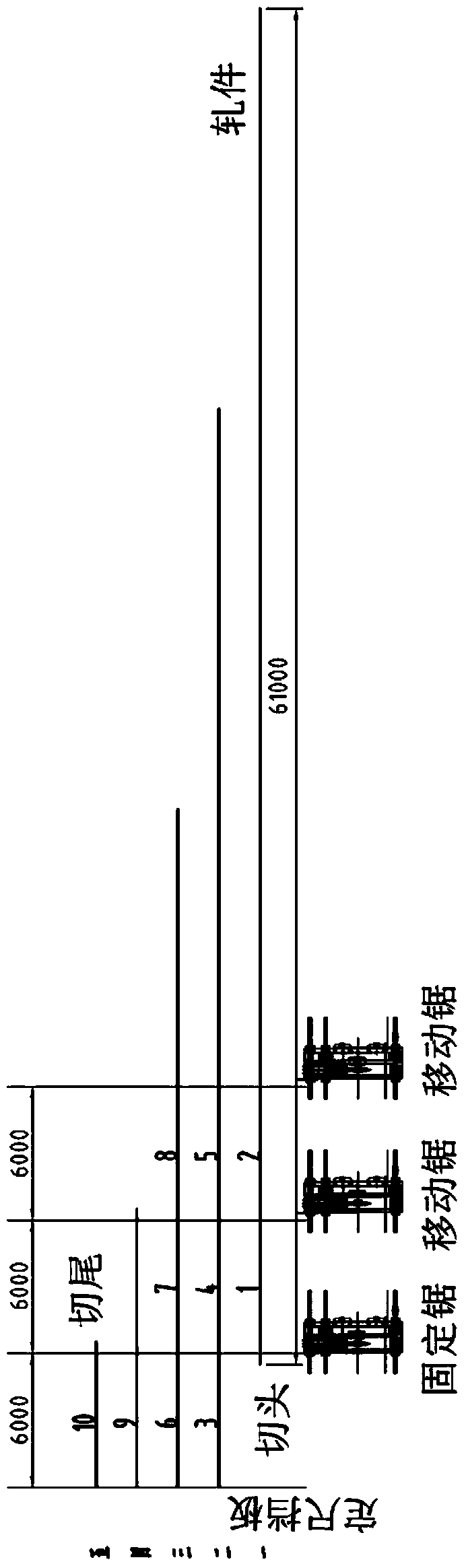

[0025] The rolled piece is 61m long, has a fixed-length range of 6m, and saw five times.

[0026] Such as figure 2 As shown, the sawing plan one: 61m long rolled piece is placed on the sawing roller table, the first saw, the fixed sawing head, two mobile saws cut to a fixed length of 6m respectively, and cut out 2 finished profiles, the second saw The fixed saw, two mobile saws and a sizing machine cooperate to cut 3 finished profiles with a fixed length of 6m, the third saw, the fixed saw, two mobile saws and a sizing machine cooperate to cut 3 finished products with a fixed length of 6m The profile, the fourth saw, is combined with a fixed saw and a sizing machine to cut out a finished profile with a fixed length of 6m, and the fifth saw cuts out a finished profile with a fixed length of 6m from the fixed saw cutting tail. Each time the finished profile is sawed, the first and second collection stands are mounted, and the cut head and tail are collected in the chute below the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com