Automatic intelligent double cross limiting range combustion control method for heating furnace

A heating furnace and double-cross technology, applied in the field of heating furnace combustion control, can solve the problems such as temperature control response time and control accuracy that cannot be changed, and achieve the effects of solving control accuracy problems, stabilizing furnace pressure, and reducing oxidation burning loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

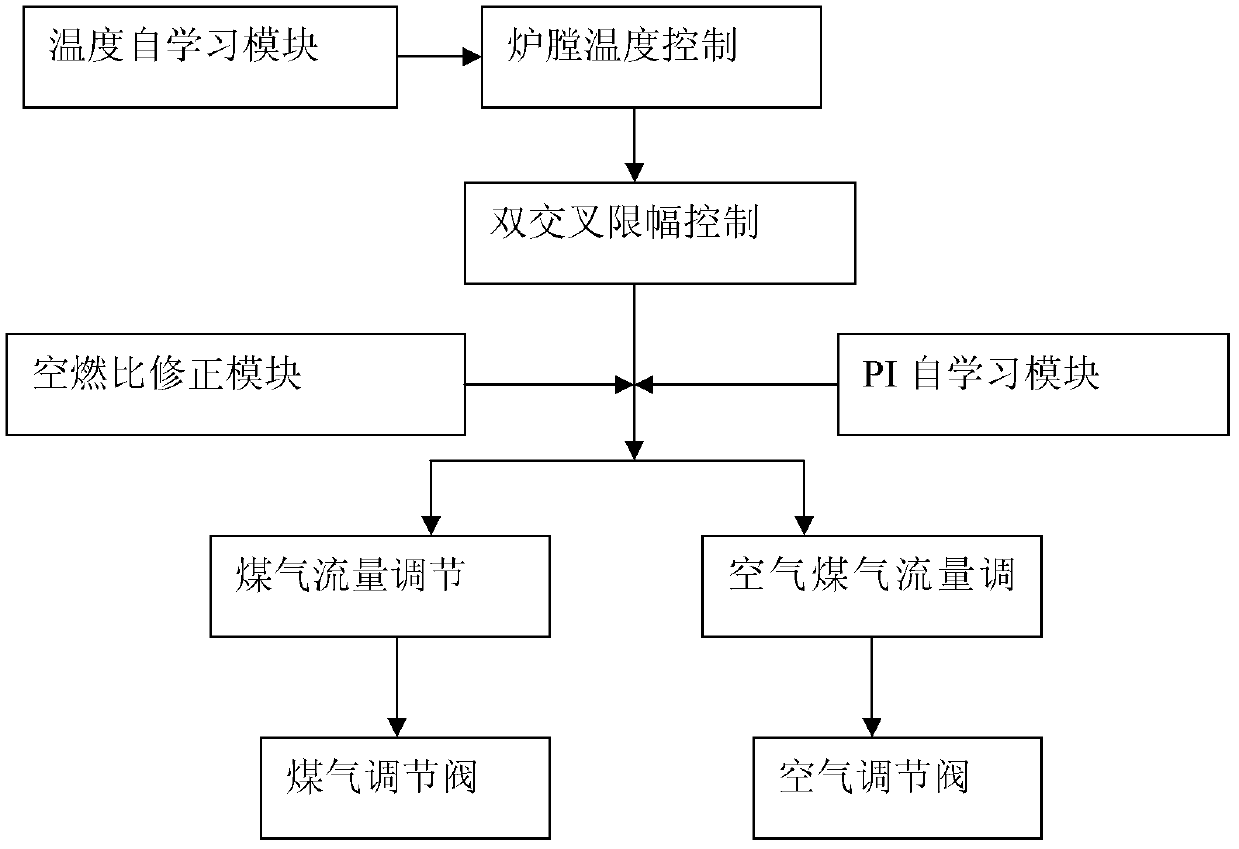

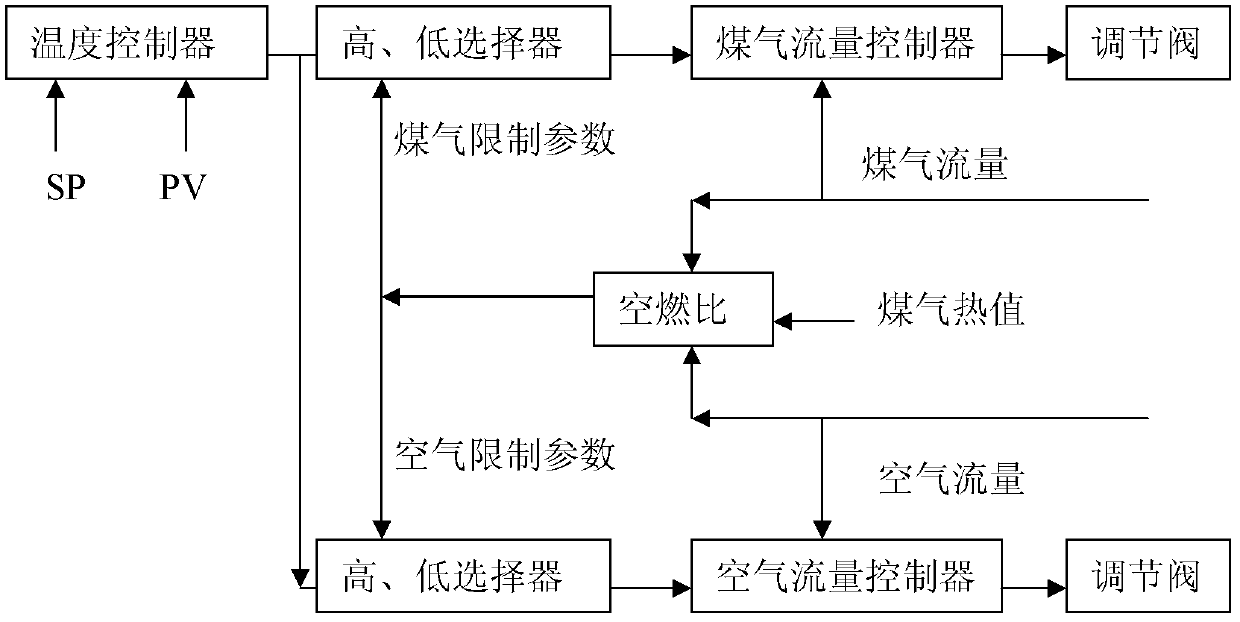

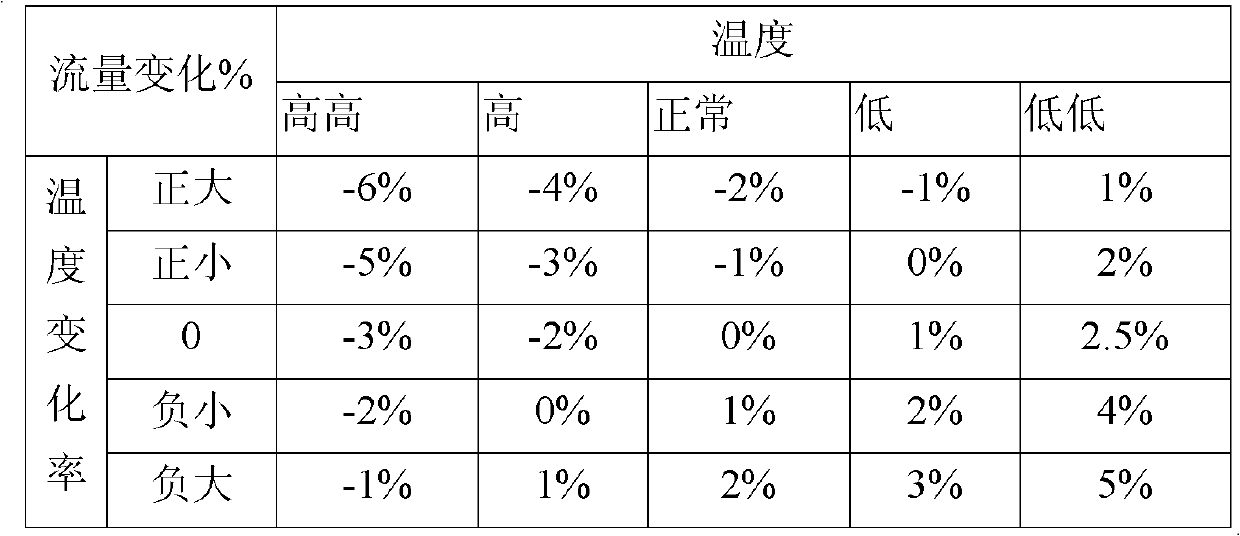

[0046] A set of automatic control method applied to the combustion process of heating furnace proposed by the present invention adopts a double-crossing limit control method combining air-fuel ratio self-correction, temperature self-learning, PI parameter self-learning and fuzzy control. The following is a specific The heating furnace is the whole process of automatic combustion control for the embodiment in detail. The heating furnace selected in this embodiment is a 2160 heat exchange, stepping, and mixed gas heating type heating furnace. The furnace uses high coke mixed gas as fuel, its normal calorific value: 9630kj / m3, and the reference ratio is 2.33:1 (air volume: gas volume). The heating furnace is divided into 6 heating sections, that is, the upper heating section, the lower heating section, the upper heating section, the lower heating section, the upper soaking section and the lower soaking section. The structural block diagram of the entire control method is as foll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com