Servo- pressing machine

A technology of servo presses and servo motors, which is applied in the field of presses, can solve problems such as difficulties in the development of large presses, and achieve the effects of fast processing speed, high control precision, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

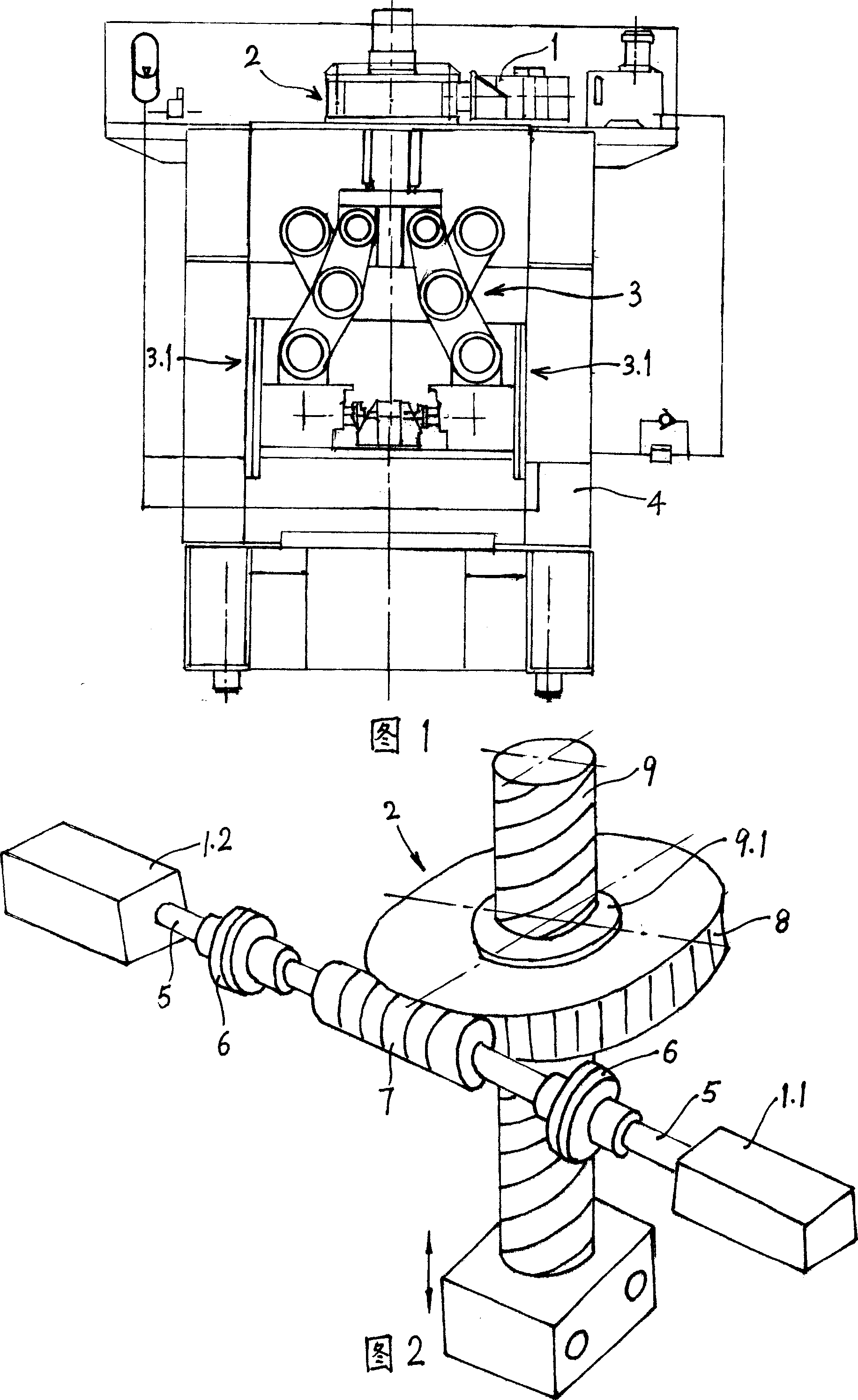

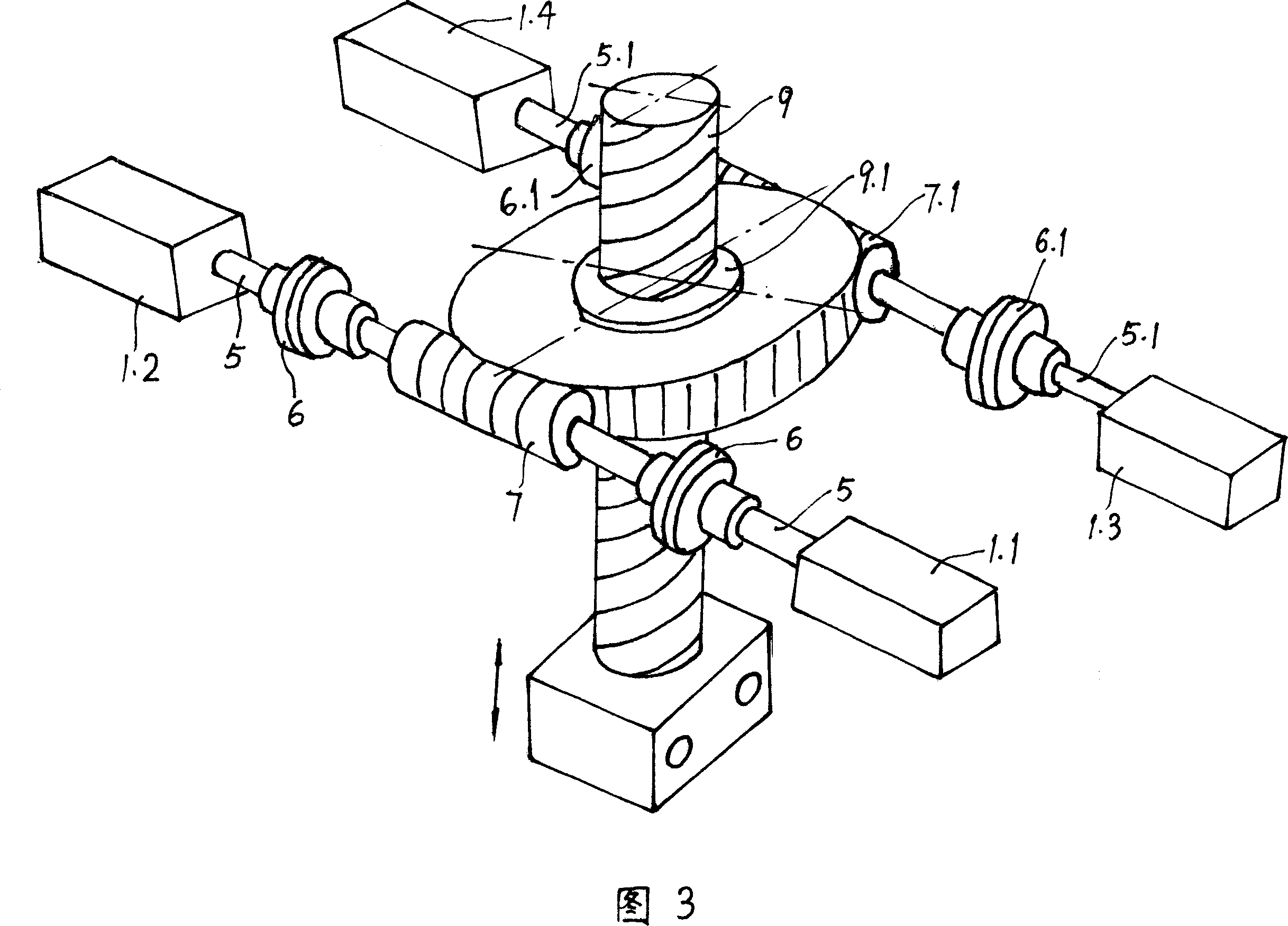

[0014] Referring to Figures 1 to 4, the servo press according to the present invention includes: a motor, an actuator 3 and a transmission mechanism 2 connected between the two, and is characterized in that it has a servo motor 1.2 for inputting torque to the transmission mechanism 2 , 1.3, 1.4 and servo motor 1.1 for input position and speed torque.

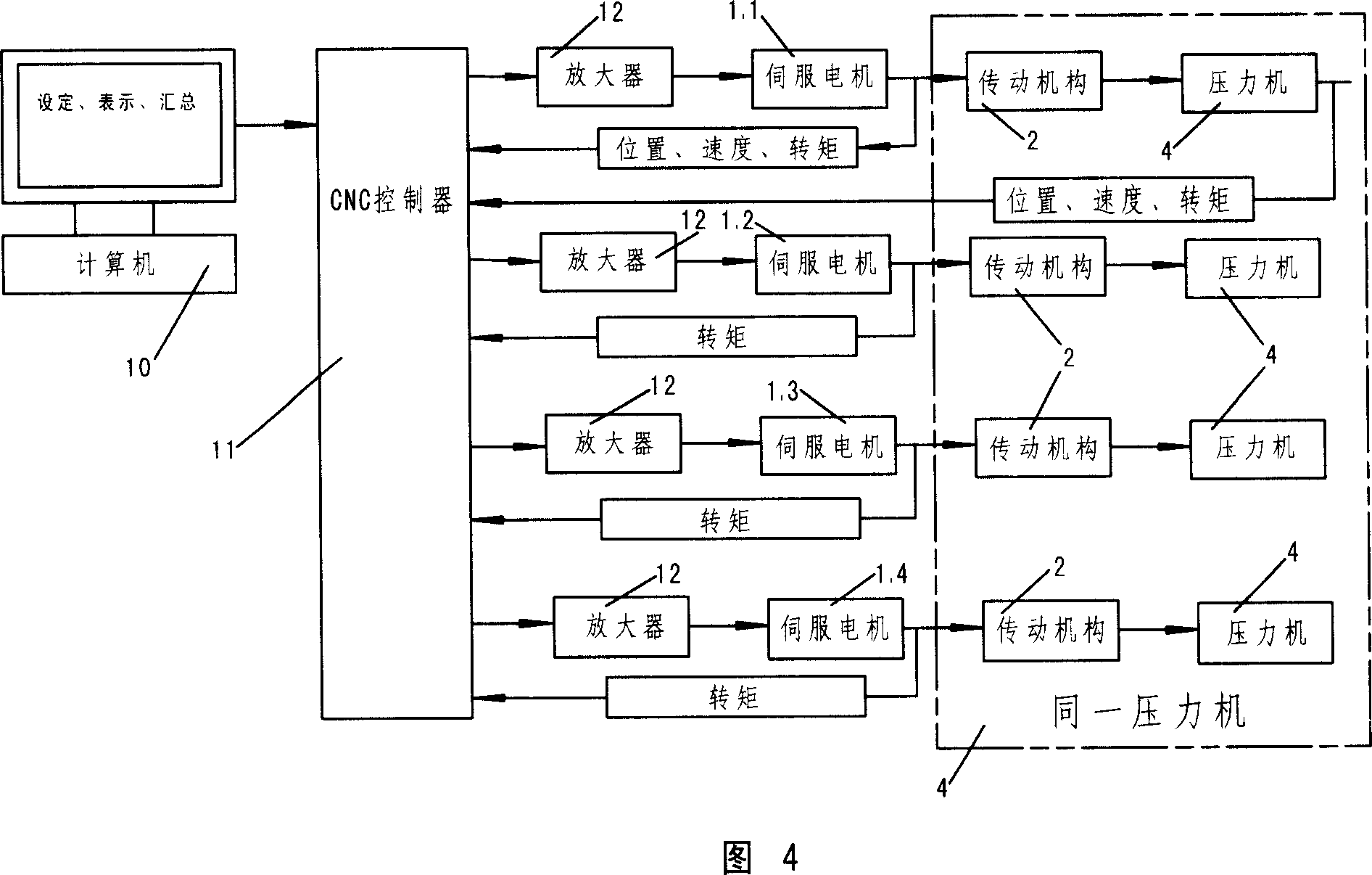

[0015] Referring to Fig. 4, the output signal sent by the computer 10 through the CNC controller 11 is amplified by the amplifier 12 to drive the servo motor 1 to run, and each servo motor 1.1, 1.2, 1.3, 1.4 feeds back the torque signal to the CNC control while outputting the torque device 11, wherein the servo motor 1.1 outputting position and speed torque should also feed back the position and speed signals to the CNC controller 11 at the same time, and at the same time, the press 4 feeds back the final position, speed and torque signals of the operation to CNC controller 11. In this way, it will be able to effectively avoid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com