Manual stepping type car body main welding line skid conveying system

A conveying system, step-by-step technology, used in conveyors, mechanical conveyors, transportation and packaging, etc., can solve the problem of high investment costs, and achieve the effects of flexible control, cost reduction, and product diversification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

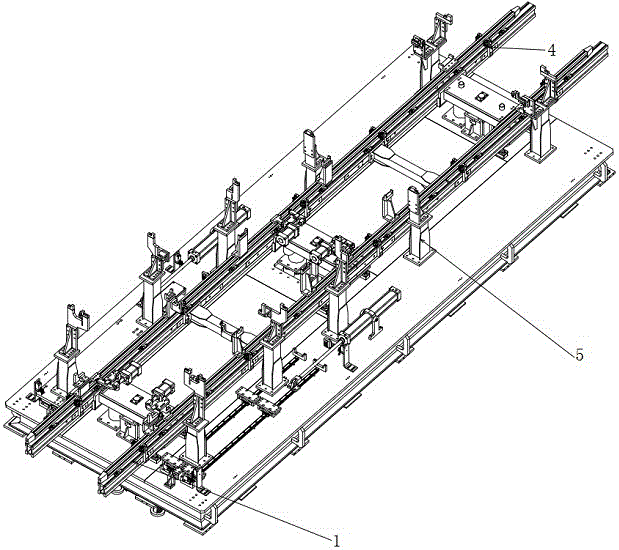

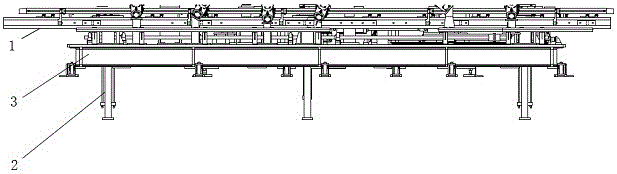

[0016] like figure 1 and 2 As shown, a manual step-by-step car body main welding wire skid conveying system disclosed in the present invention includes a conveying slide rail 1, a rolling bed is installed on the conveying slide rail, and a pneumatic jacking device is arranged under the conveying slide rail 2. The roller bed is equipped with a manual stepping and hand-push split roller bed skid 3, and also includes a set of electric control unit, which controls the automatic lifting of the pneumatic jacking device 2 to realize automatic conveying of the skid.

[0017] There are ten welding stations 5 on the main welding line of the vehicle body, including a reserved station and an off-line station. A limiting device 4 is installed on the conveying slide rail to lock the skid body in place. The invention adopts a set of independent jacking and sliding mechanism to ensure the synchronous production of the system. The split skid can solve the unique defect of the structure, flex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com