Patents

Literature

163 results about "Underground gas storage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

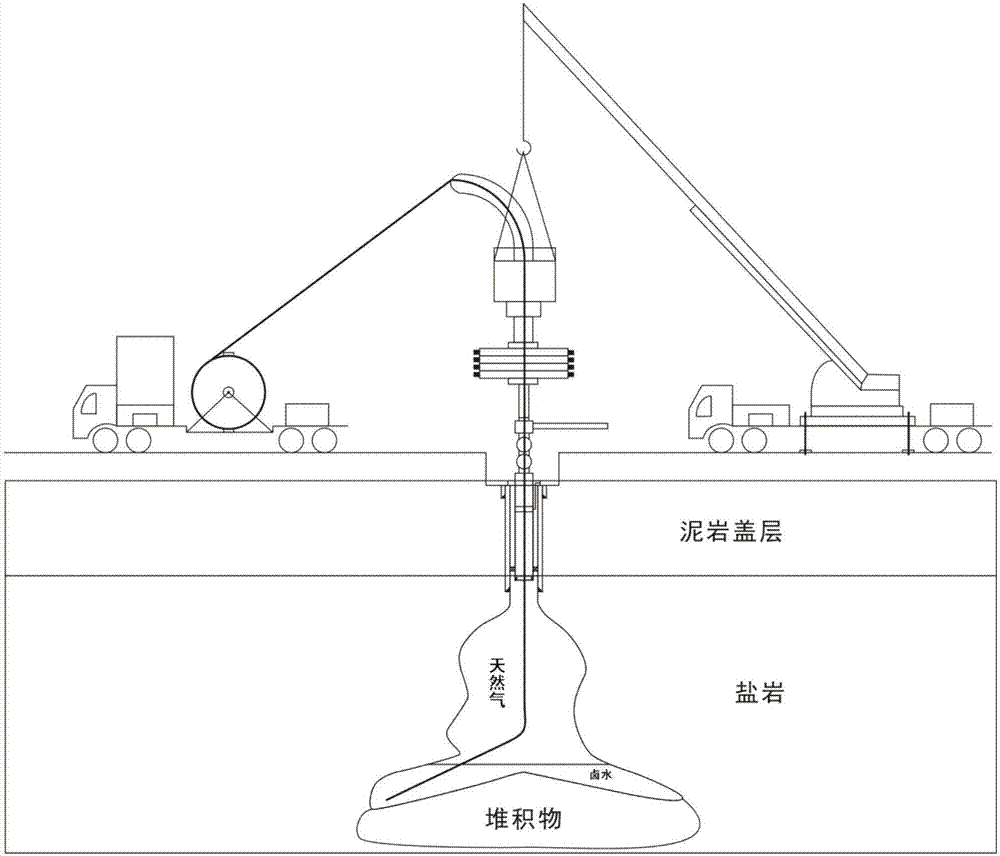

Construction method for rock salt cavity gas storage house

InactiveCN101315025APlay the role of isolating and protecting the top plateRegulate market supplyMining devicesFluid removalOil waterFresh water

The invention relates to a construction method for a gas storage reservoir in a rock salt cavity, belongs to the salt mine mining and the rock salt cavity utilization fields, and mainly used for the dissolution construction of an underground gas storage reservoir in a eutectic salt deposit. The construction method is characterized in that a method for down-flow type gas storage reservoir construction comprises the following steps: fresh water is infused into a salt deposit by a water injection pump and through a water injection pipe, the rock salt is dissolved from up to down, and at the same time, the natural gas is infused; the expenses for oil consumption of the original oil cushion method and the cost for brine purification treatment can be saved by using the method; and the method is more economical and more environment-friendly. The gas storage reservoir can be used from the beginning of construction; the single well oil cushion method with three to five years of construction cycle is not required for constructing the gas storage reservoir; the construction of the gas storage reservoir needs no cycle basically; the reservoir storage capacity is small in the beginning period; the gas storage reservoir can be used as a large gas storage reservoir in the middle and the late periods; the problems of long period for the construction of the gas storage reservoir by using the oil cushion method, difficult detection of the oil water interface, as well as other relative technical problems are thoroughly solved; and the construction method is an ideal method for rapid dissolution construction of the gas storage reservoir in the rock salt deposit.

Owner:TAIYUAN UNIV OF TECH

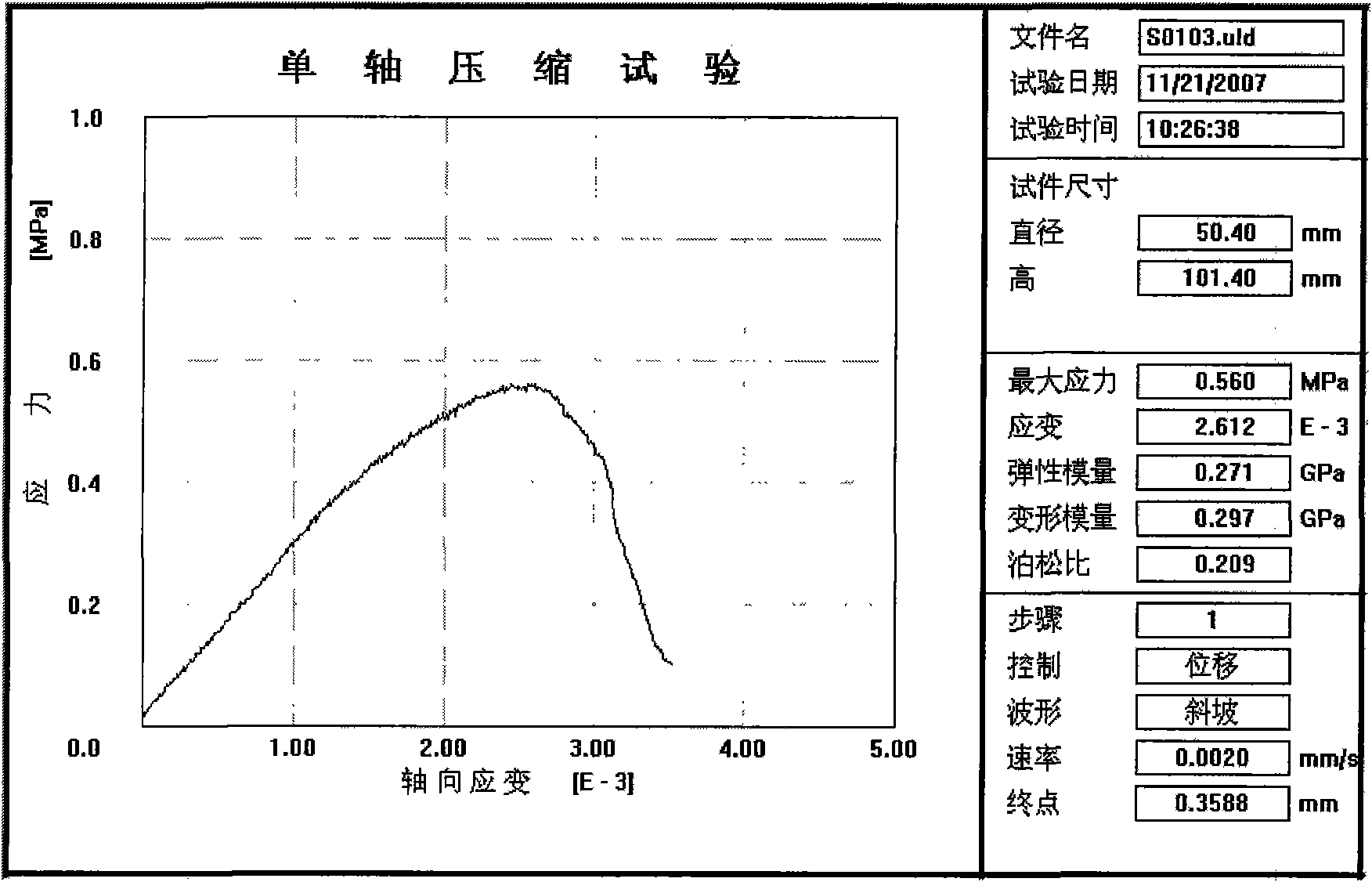

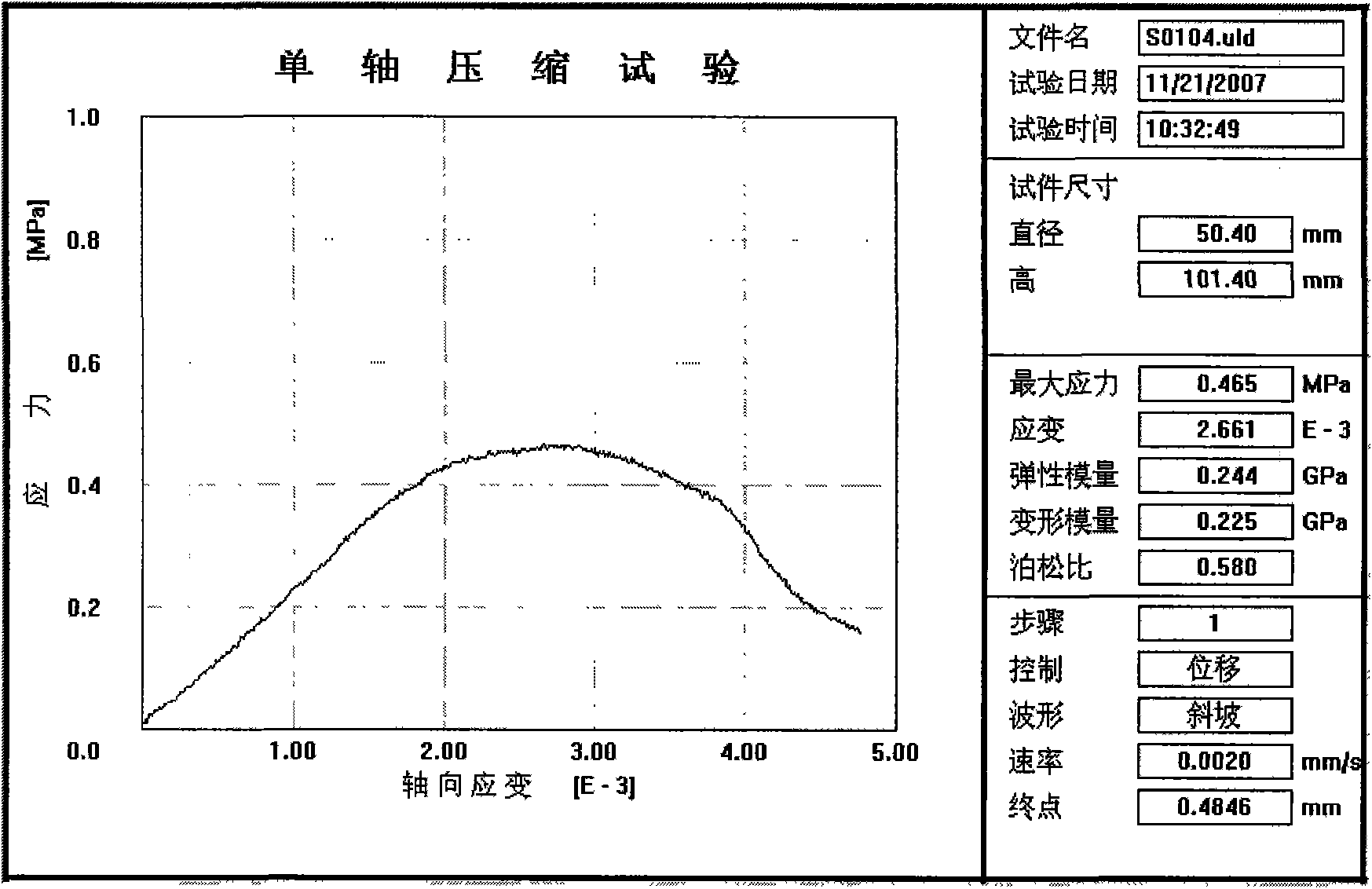

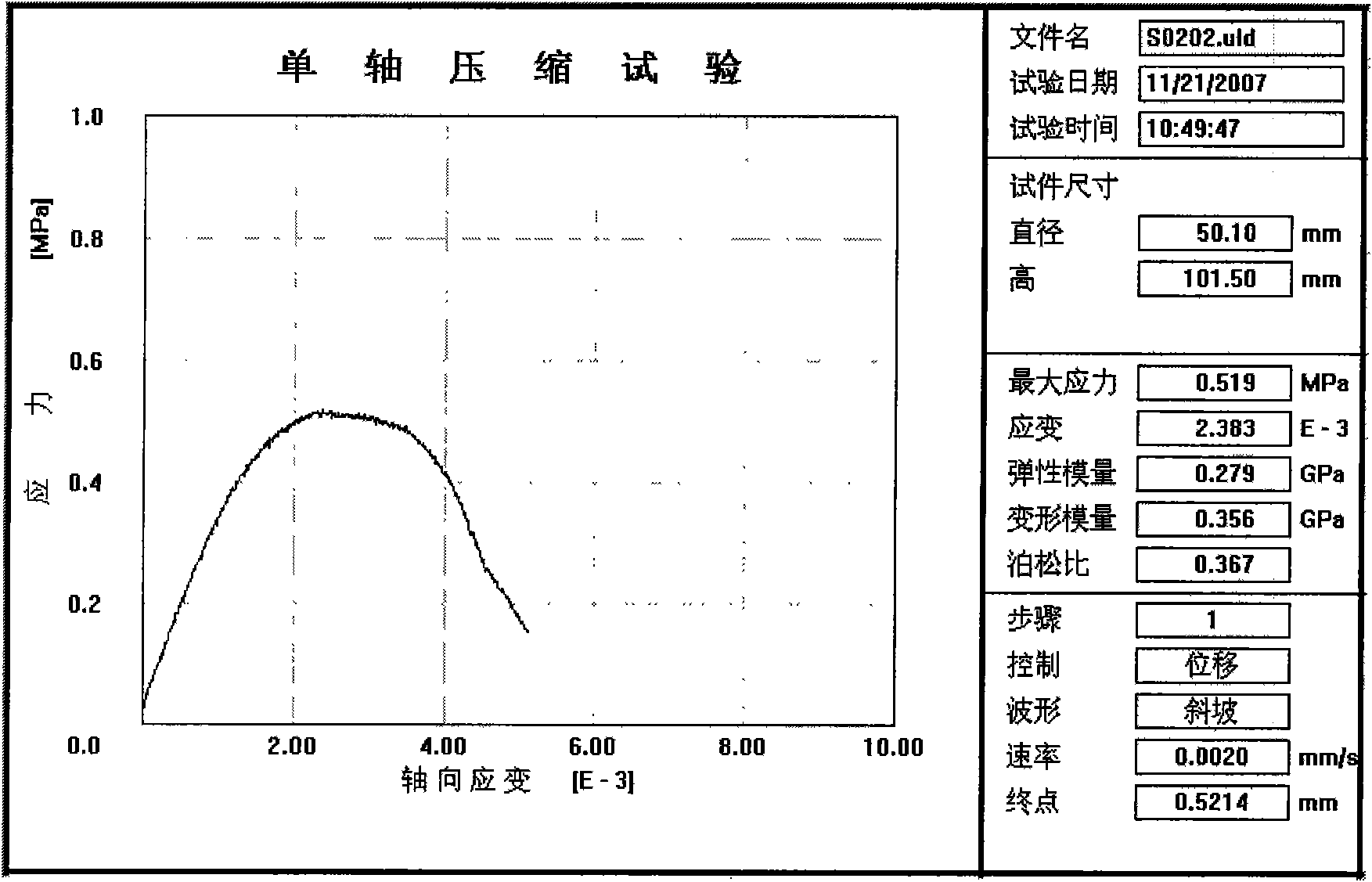

Softrock-like material and preparation method

InactiveCN101614629ALight weightLittle elasticityPreparing sample for investigationEarth material testingFilling materialsSlurry

The invention discloses a softrock-like material and a preparation method thereof. The softrock-like material is composed of filler, aggregate, cementitious materials, additives and water in certain proportion. The preparation method comprises the steps of: 1. weighing the raw materials; 2. loading and stirring: adding water in a stirrer, causing the barrel wall of the stirrer to be smooth, then starting the stirrer, and adding the filler, aggregate, cementitious materials and additives sequentially followed by continuous stirring; 3. adding water and stirring: adding water during stirring, setting the speed of the stirrer at high and continuing stirring; 4. shaking and forming: discharging the materials, pouring the slurry into a pre-manufactured die, vibrating with a vibrating rod, causing the slurry to be even, removing foam and finally scraping the surface of the model to be level; and 5. maintaining in a baking house: sending the manufactured die into the baking house for maintenance. The material has the characteristics of low volume-weight, low compression strength and elastic modulus, stable property, easy processing, low cost and no toxicity, and is suitable for geomechanics research on softrock exploration and stability of softrock underground gas storage cavity.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

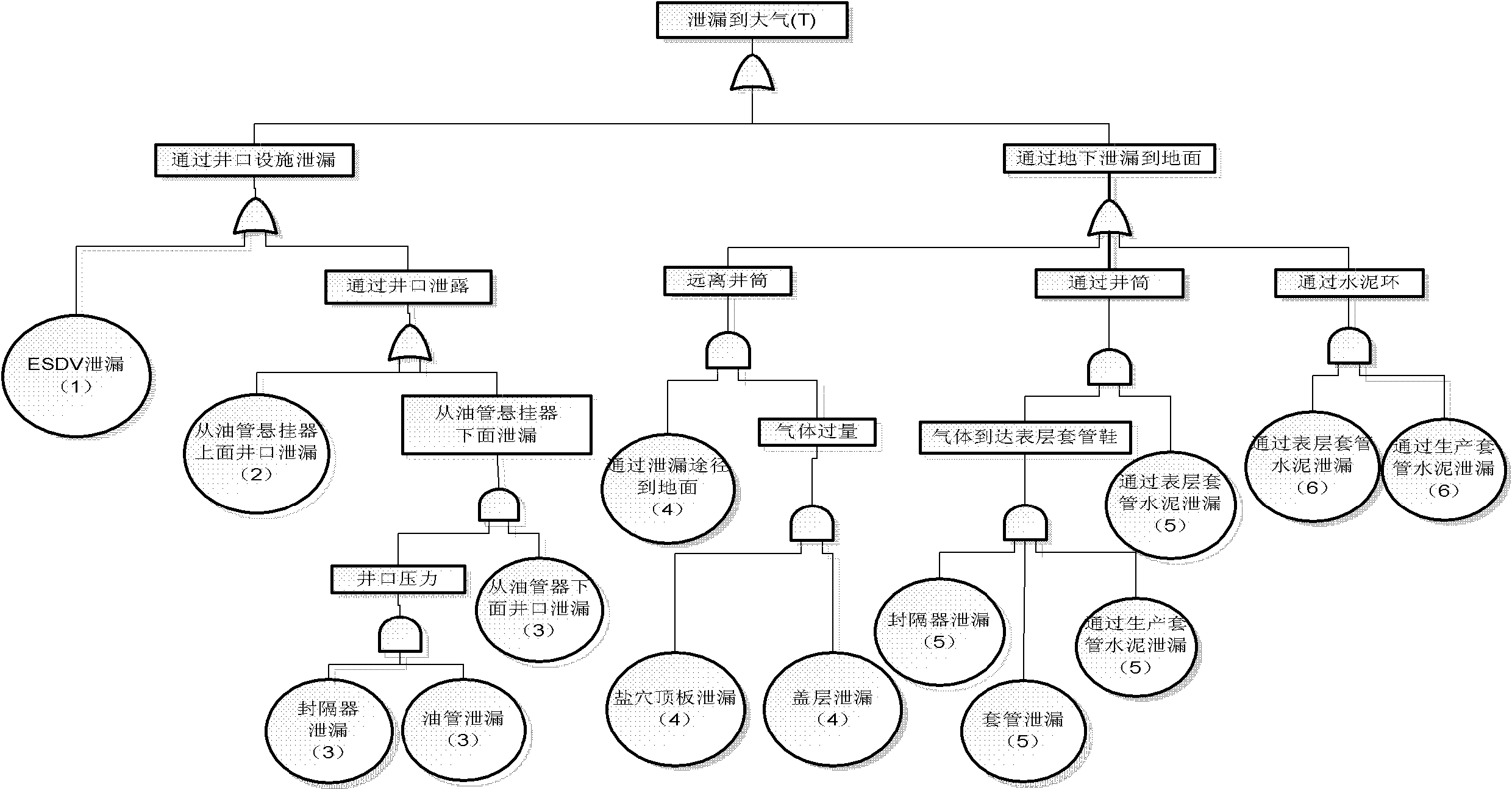

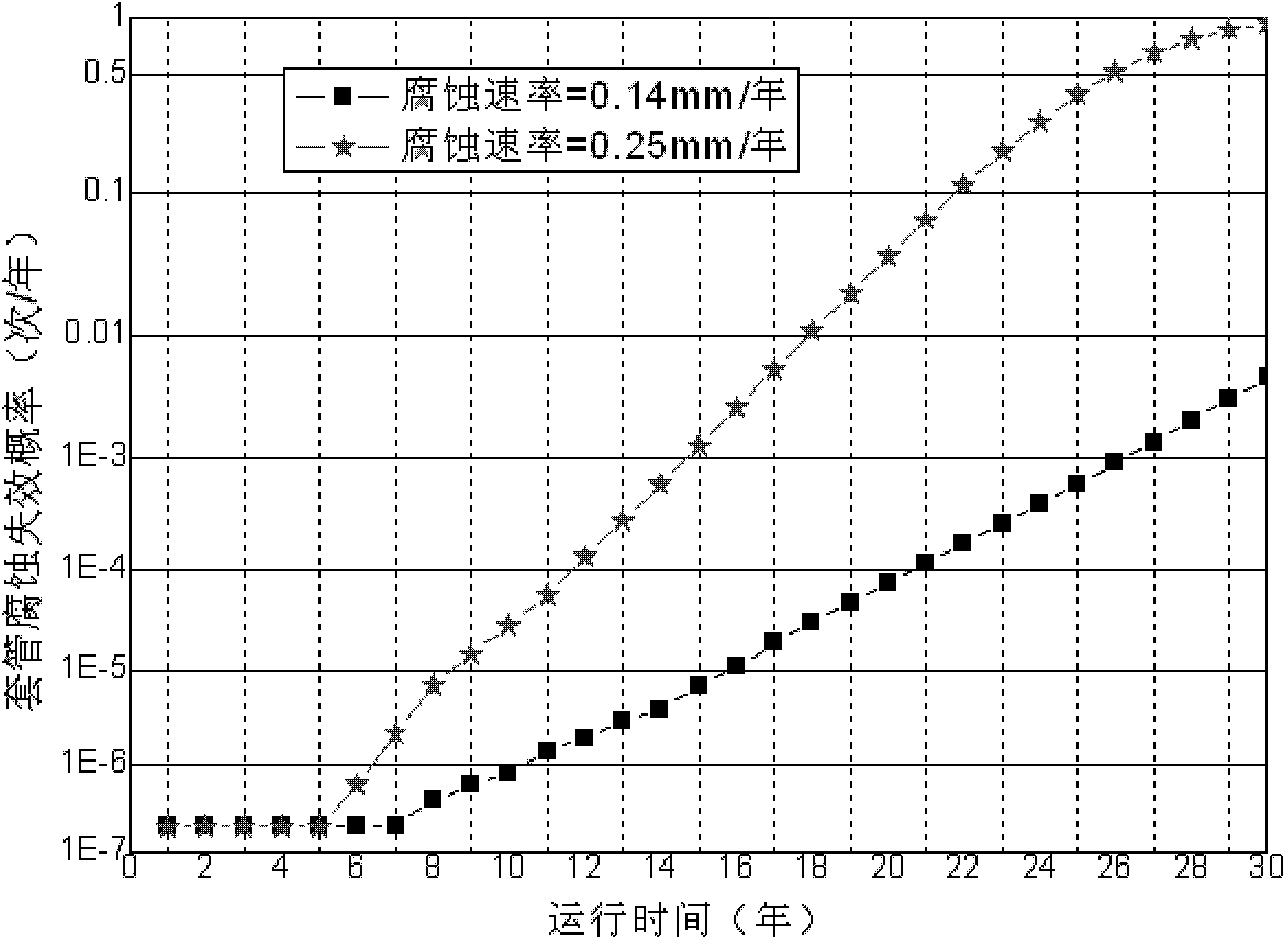

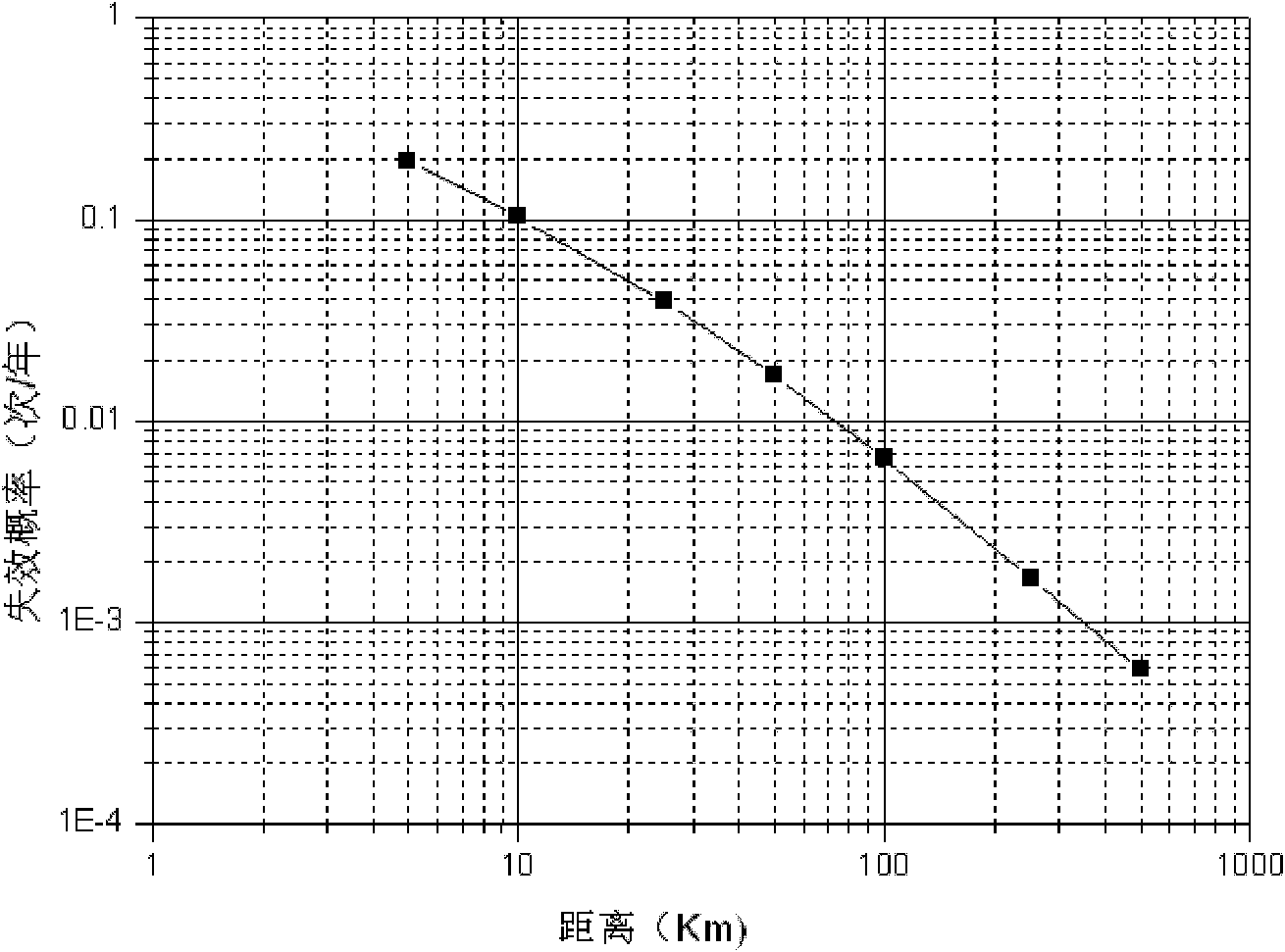

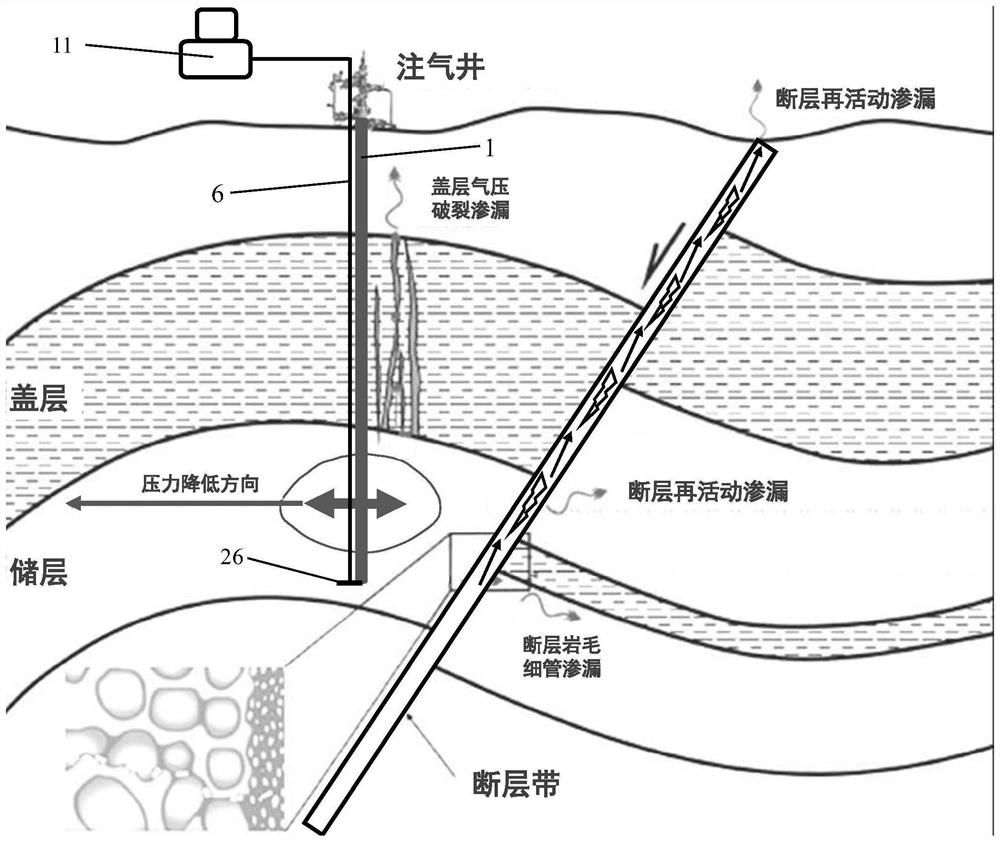

Determination method for risk of storage medium leakage of underground natural gas storage reservoir

ActiveCN102495935ASolve the key problem of failure probability calculationSpecial data processing applicationsNatural gas storageEngineering

The invention provides a determination method for risk of storage medium leakage of an underground natural gas storage reservoir. The method is used for determining the risk of storage medium leakage of the underground natural gas storage reservoir based on a fuzzy fault tree so as to judge the possibility of leakage failure of the underground natural gas storage reservoir. In the method, the fault tree for the storage medium leakage from a salt cavern underground natural gas storage reservoir to the outside atmospheric environment is established, the probability of basic event causing the storage medium leakage to the outside atmospheric environment is determined by a historical data statistical method and an established engineering evaluation model, influence of various risk factors on the probability of basic event is introduced into the calculation of the probability of basic event in the form of correction factors, and simultaneously, according to the principle of controlling the leakage mode by a main event, and the fault tree logic, the determination methods for the risk of small-leakage mode, big-leakage mode and cracking mode storage medium leakage of the salt cavern underground natural gas storage reservoirs are established.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

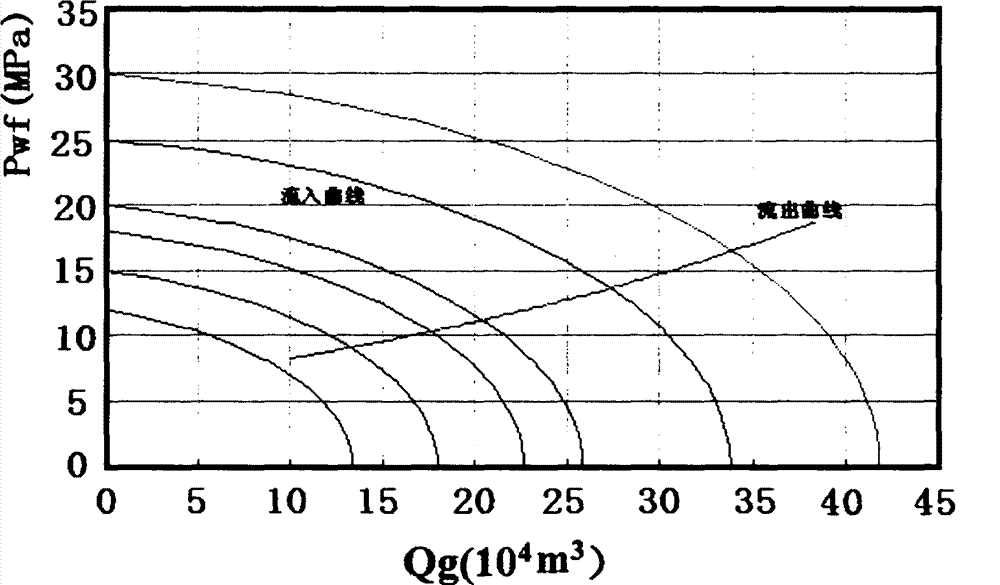

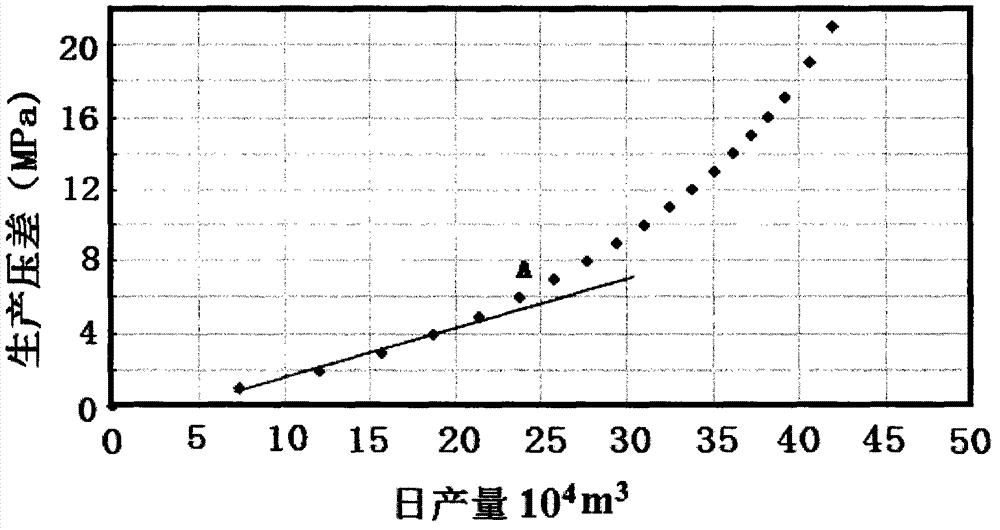

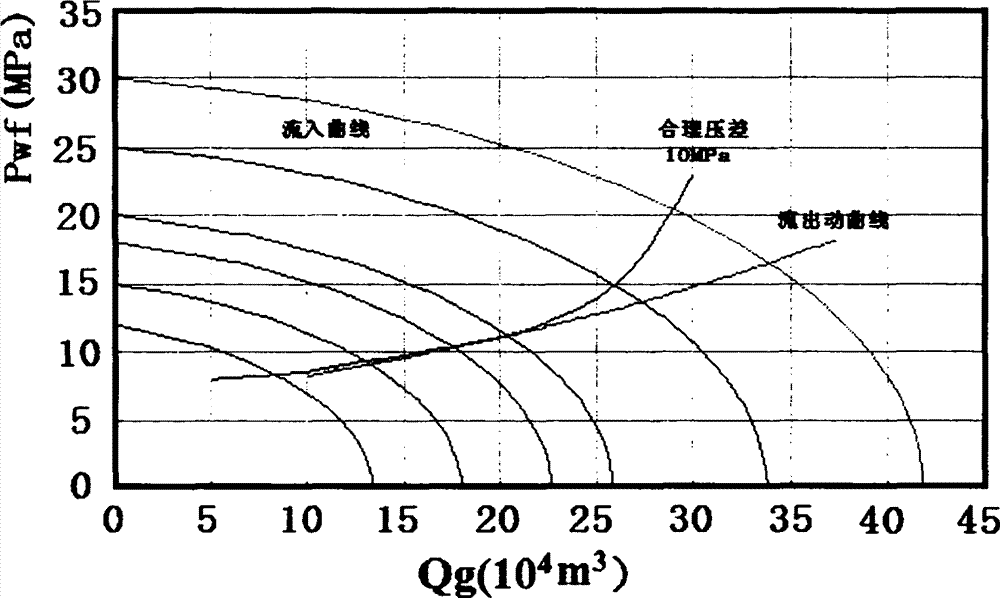

Correction method for reasonable productivity prediction of underground gas storage well

InactiveCN104847341AIn line with actual productionBorehole/well accessoriesPressure differenceCorrection method

The invention relates to a correction method for reasonable productivity prediction of an underground gas storage well. The method comprises the following steps that a gas well binomial productivity equation (inflow curves) represents the supply capacity of a stratum; the flowing capacity of an oil pipe under the condition of limited pipe diameter of the oil pipe is determined through the oil pipe flowing capacity (outflow curve); the maximum flowing capacity of a gas well under the condition of the oil pipe can be obtained through combined intersections of the curves; for the production capacity of the gas well, limits to reasonable production pressure differences also shall be taken into consideration besides the capacity of the intersections of the inflow curves and the outflow curve. According to the invention, the intersections of the inflow curves and the outflow curve are corrected through establishing reasonable production pressure differences of the gas well, and the reasonable productivity of the gas well is obtained after correction. The method is simple in calculation, conforms to the actual situation, and can further guide the design of the gas storage effectively.

Owner:DAGANG OIL FIELD OF CNPC

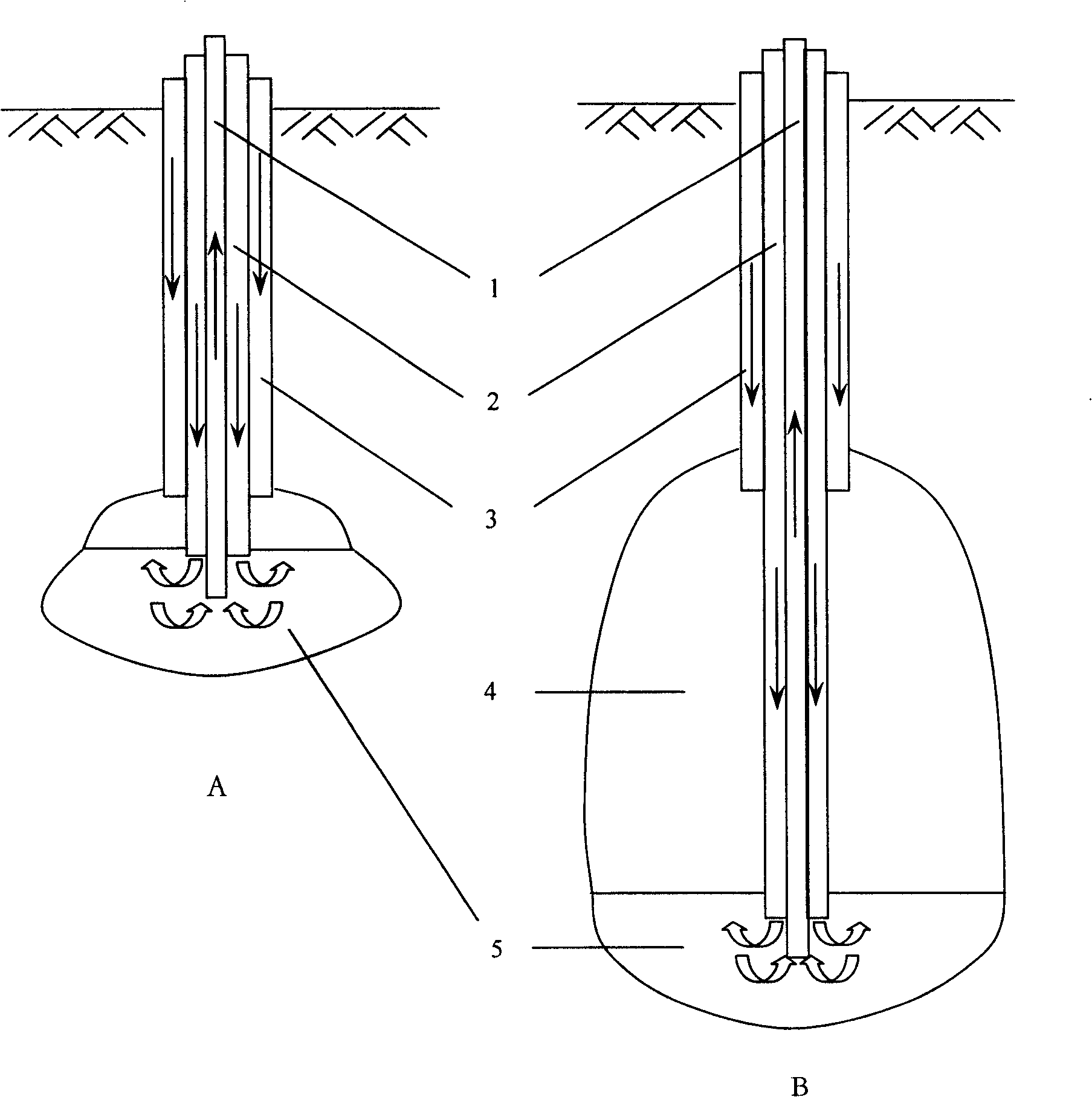

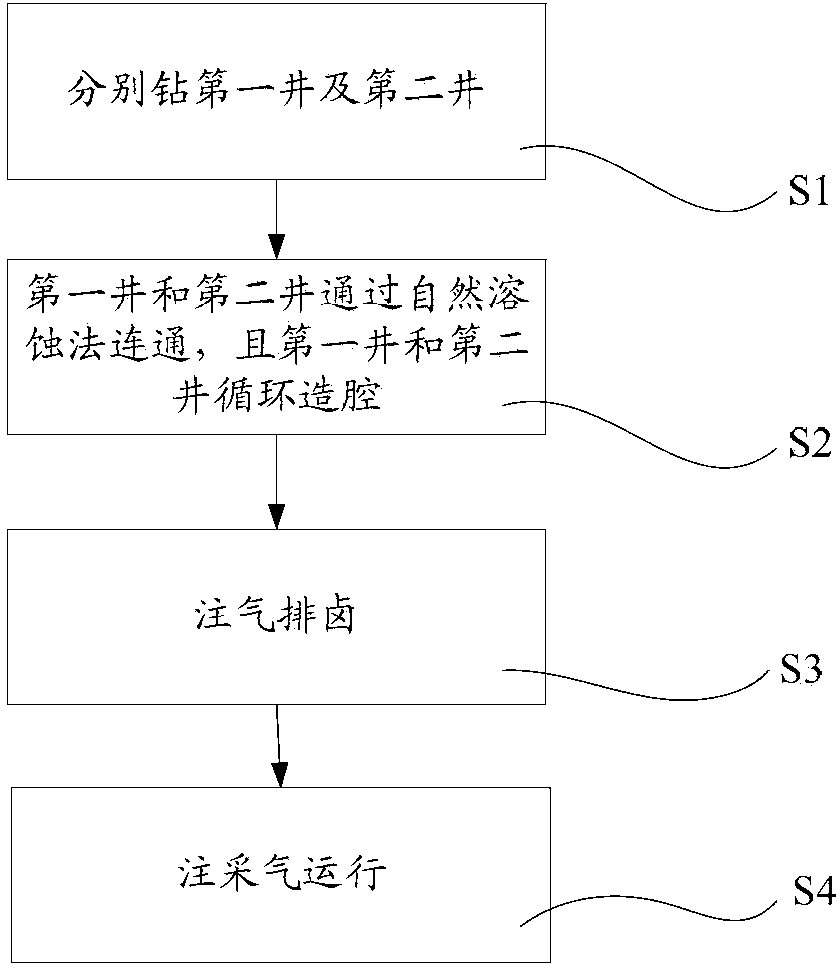

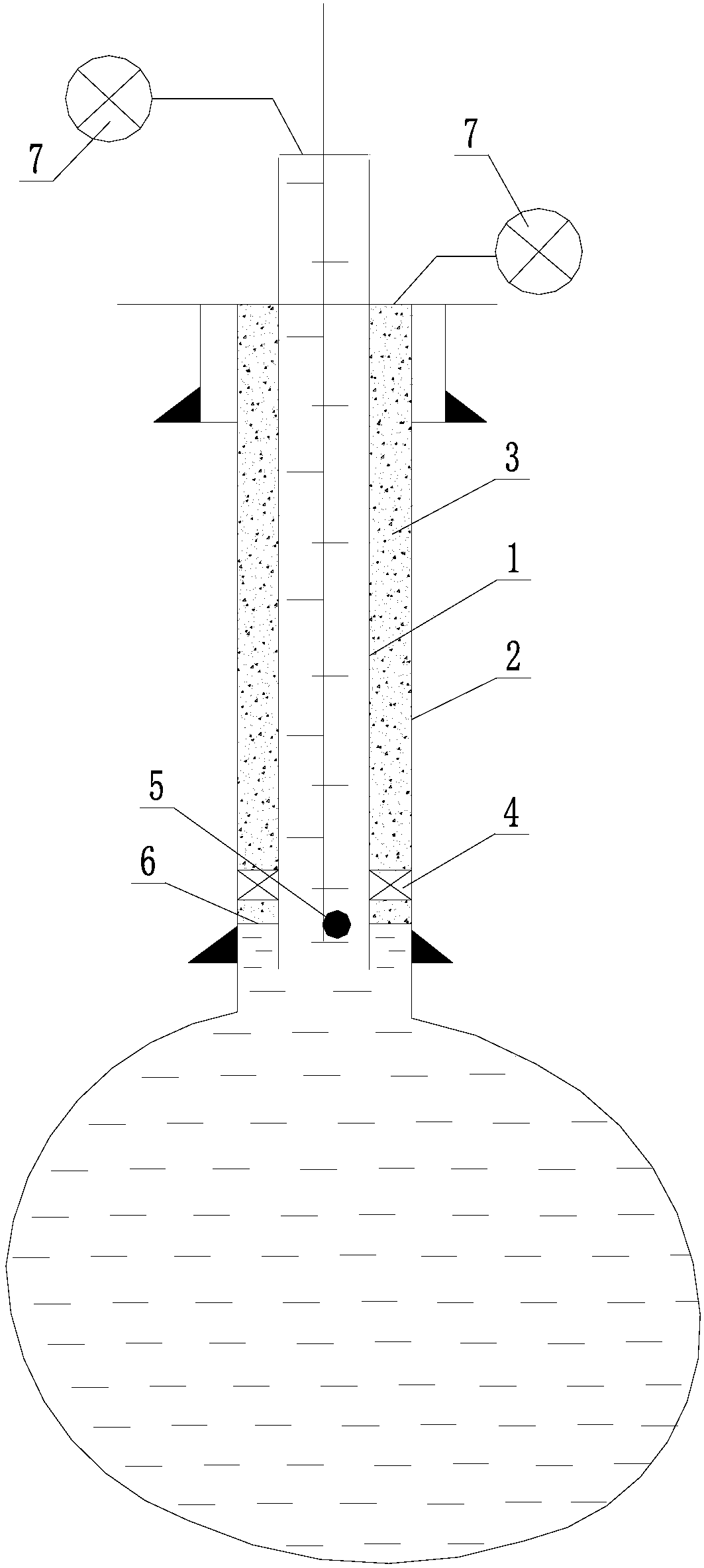

Salt-cavern gas storage twin-well building method

ActiveCN103850711AGuaranteed safe operationIncrease the volume of dissolutionMining devicesDissolutionConvection

The invention discloses a salt-cavern gas storage twin-well building method, and belongs to the technical field of technology for building salt-cavern gas storages. The salt-cavern gas storage twin-well building method comprises the steps of: first, respectively drilling a first well and a second well, wherein the distance between the center lines of the first and second wells is 15m-30m; second, communicating the first and second wells through a natural dissolution method, and circularly building cavities for the first and second wells; third, injecting gas into the first well, discharging brine water from the second well; fourth, performing gas injection and recovery to the first or second well, or simultaneously performing gas injection and recovery to the first and second wells. According to the salt-cavern gas storage twin-well building method, respectively through injecting water into the first well and discharging brine water from the second well, the water injection volume is increased, the cavity building speed is enhanced, and the storage building period is shortened; respectively performing solution mining to the cavities of first and second wells by a single well convection method, the storage is built by fully utilizing salt beds, the dissolution volume of the cavity is enlarged, the cavity form and stability are ensured, and thus the gas storage is ensured to operate safely.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Method for constructing underground gas storage by depleted oil-gas reservoir

InactiveCN103089306AImprove protectionReasonable distributionMining devicesWell drillingCorrosion prevention

A method for constructing an underground gas storage by a depleted oil-gas reservoir includes the steps: firstly, drilling a well; secondly, performing injection-production well completion interaction; thirdly, controlling injection-production well safety; fourthly, optimizing corrosion prevention; fifthly, monitoring formation parameters; sixthly, plugging an old well; and seventhly, expanding water drainage capacity. The method has the advantages that reservoir protection effects are obvious, matching technology is safe, environment-friendly and energy-saving, a well field and a wellhead are reasonably arranged, drilling speed is high, complex well drilling accidents are prevented, the requirements of an injection-production well on safety production and operation can be met, and the underground gas storage is large in storage volume, high in mobility and wide in peak-shaving range.

Owner:DAGANG OIL FIELD GRP

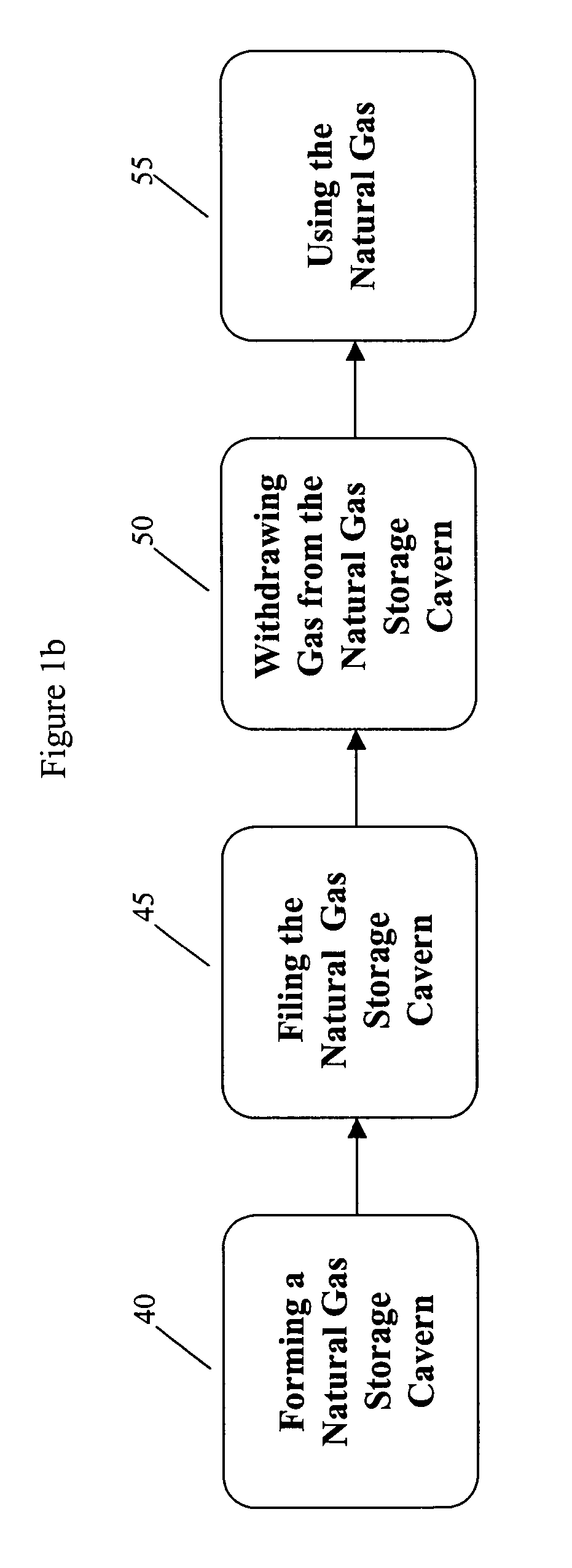

Underground gas storage with short term reversible flow operable for use in arbitrage/trading

A system and method are provided for short term trading in gas and / or gas derivatives. In a preferred embodiment, the system provides a plurality of shallow depth salt gas storage facilities. Each of the facilities is typically operated at pressures in a range close to the pipeline pressure, typically within a range of 20 to 80 bars. If trading results in a difference to be made up, then computers operating the facilities respond quickly to add or remove gas from the pipelines, as required, with a response time as low as two minutes to change the net direction of flow of gas into or out of the storage facilities.

Owner:CANATXX ENERGY

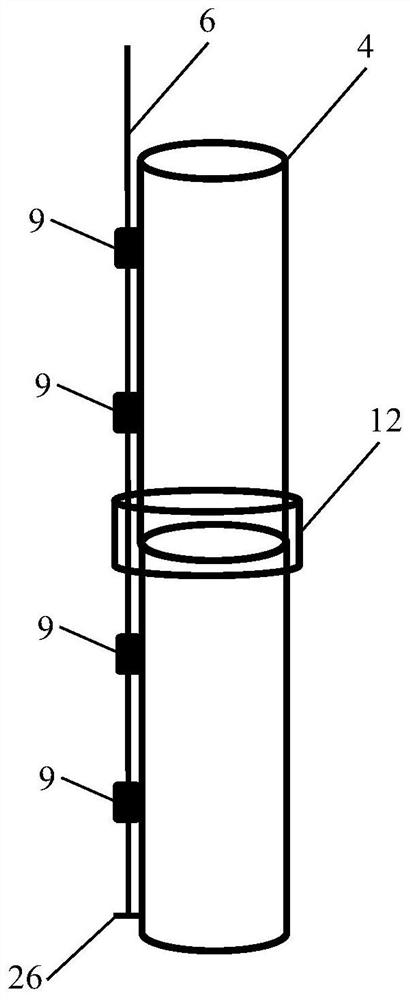

Coiled tubing tubular column device and brine discharging and capacity expanding method thereof for salt cavern underground gas storage reservoir

ActiveCN107152264AEffective flushIncrease gas storage volumeDrilling rodsGeothermal energy generationLine tubingCoiled tubing

The invention discloses a coiled tubing tubular column device and a brine discharging and capacity expanding method thereof for a salt cavern underground gas storage reservoir. The coiled tubing tubular column device comprises a coiled tubing, a tubing outside connector, a weighting pipe, a hydraulic safety joint and a rotary washing tool. The brine discharging and capacity expanding method comprises the following steps: firstly, screening a gas storage reservoir waiting for capacity expansion, and determining brine discharging capacity; secondly, installing a coiled tubing operation machine, ground corollary equipment and pipelines; thirdly, installing a well mouth well control device and the coiled tubing tubular column device, and testing sealing performance; fourthly, unloading the coiled tubing tubular column device, and injecting gas for brine discharge; fifthly, washing blocked dregs and discharging brine; and sixthly, taking out the coiled tubing tubular column device and a brine discharging tool. Brine discharge and capacity expansion are carried out by adopting the coiled tubing tubular column device, the coiled tubing can be arranged into a cavity bottom or the dregs, the blocked dregs can be effectively washed by using the rotary washing tool, a brine discharging passage can be formed again, and smaller than 20% of residual brine remaining at the bottom of the cavity incapable of being discharged in a traditional brine discharge pipe can be effectively discharged.

Owner:中国石油天然气股份有限公司西气东输管道分公司 +1

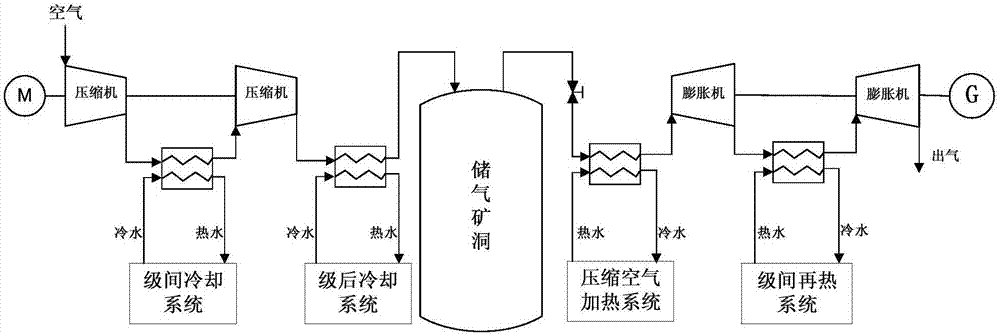

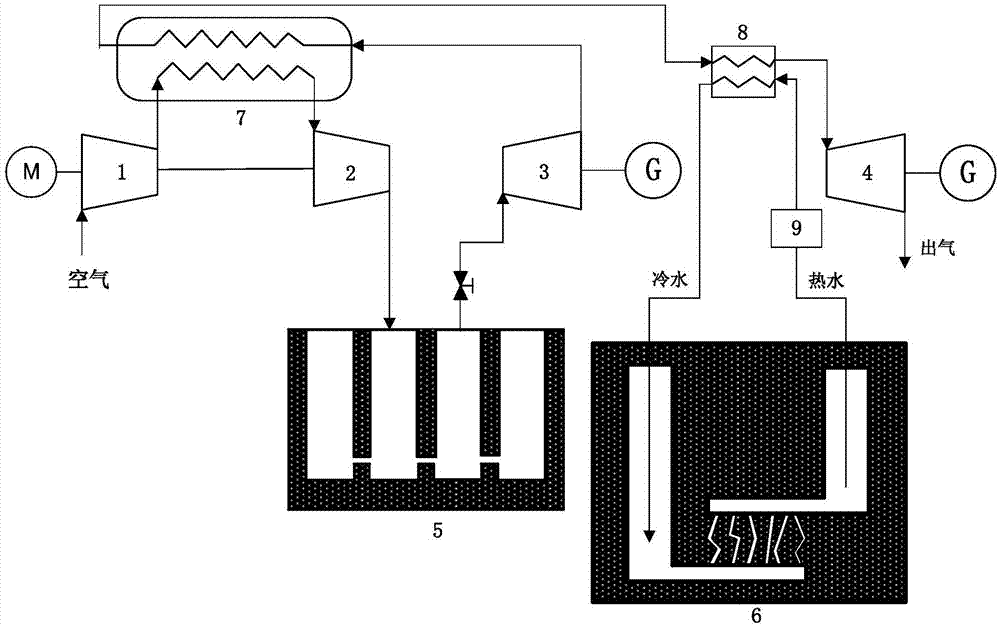

Gas storage and heat storage integrated hot dry rock reheating compressed air energy storage system

ActiveCN107461603AImprove efficiencyReduce irreversible lossOther heat production devicesGeothermal energy generationThermal energy storageCoupling

The invention relates to a gas storage and heat storage integrated hot dry rock reheating compressed air energy storage system. The gas storage and heat storage integrated hot dry rock reheating compressed air energy storage system comprises a plurality of compressors and a plurality of expansion units, wherein the compressors are connected with a motor through couplings; the adjacent compressors are connected with one another through heat accumulators; the last-stage compressor is connected with an inlet of an underground gas storage well group; an outlet of the underground gas storage well group is connected with the first expansion unit; the first expansion unit is connected with a gas flow inlet of a heat exchanger through a heat accumulator; a gas flow outlet of the heat exchanger is connected with the second expansion unit; a working medium inlet and a working medium outlet of the heat exchanger are connected with a hot dry rock heat collecting system through pipes to form a circulation loop; the heat exchanger and the hot dry rock heat collecting system form a reheating system; when the number of the expansion units is greater than 2, reheating systems are separately arranged among the adjacent expansion units behind the first expansion unit. Heat of interstage cooling of the compressors is recycled in a compression stage, air of interstage reheating is preheated in an energy releasing stage, heat loss of the system is reduced effectively, and the efficiency of the system is improved.

Owner:XI AN JIAOTONG UNIV

Old well plugging method for constructing underground gas storage by depleted oil-gas reservoir

InactiveCN103089195AGuaranteed movementPrevent gas blowingSealing/packingWell cementingHigh pressure

Disclosed is an old well plugging method for constructing an underground gas storage by a depleted oil-gas reservoir. In order to prevent natural gas injected into the gas storage from channeling to a position close to an old well borehole along a gas reservoir, or vertically migrating along a first interface and a second interface of an oil well cement ring or channeling into a shaft along a perforated hole and migrating towards a non-gas-storage layer and a wellhead, the gas reservoir is plugged by a high-pressure squeezing process, a multi-stage cement plug is driven into the shaft to plug the shaft, and the length of a continuous cement plug above a top boundary of the gas reservoir is larger than or equal to 300m. If the top of cement above the top boundary of the gas reservoir is larger than 200m and a continuous cement bond section below a cap rock of the top boundary of the gas reservoir is larger than 25m, the continuous cement plug can be directly injected in a sectioned manner. If the top of cement above the top boundary of the gas reservoir is smaller than 200m and the continuous cement bond section below the cap rock of the top boundary of the gas reservoir is smaller than 25m, the cap rock above the top boundary of the gas reservoir is forged and milled by a casing, the forging and milling length is larger than or equal to 30m, and the continuous cement plug is injected in a sectioned manner after forging and milling. The old well plugging method has the advantage that the natural gas entering the casing is effectively prevented from migrating towards the non-gas-storage layer and the wellhead.

Owner:DAGANG OIL FIELD GRP

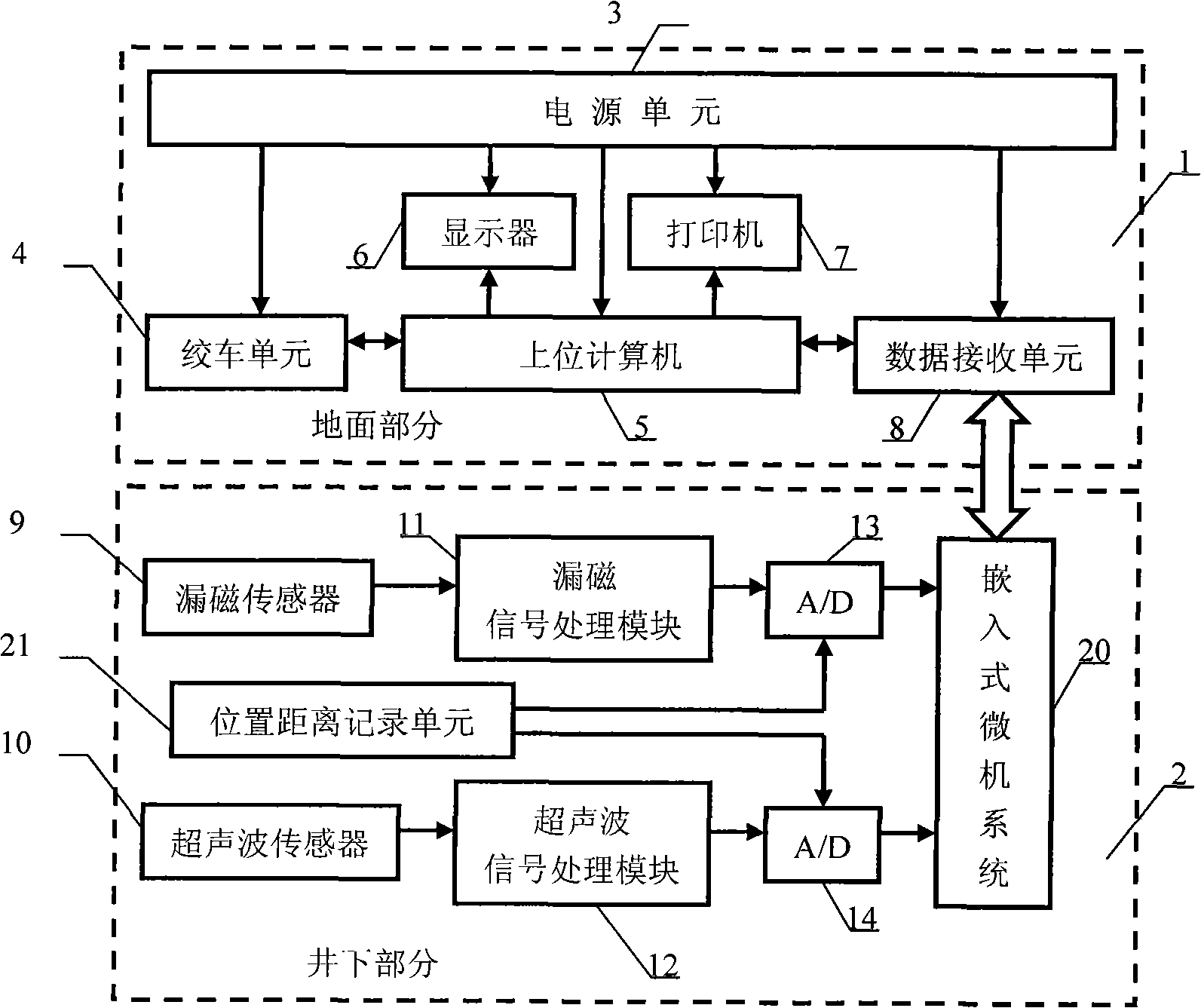

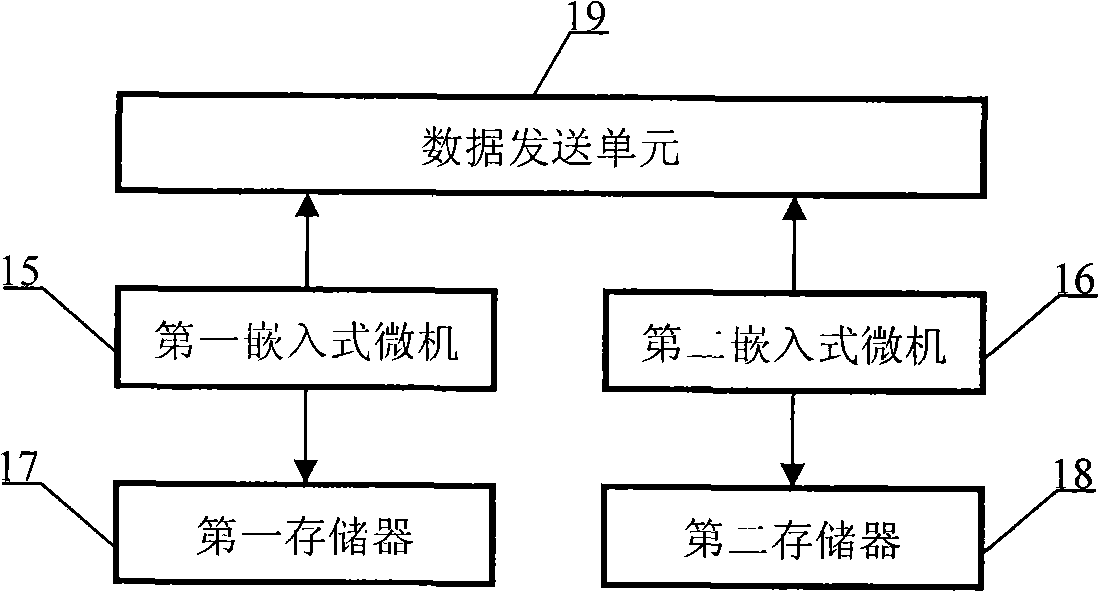

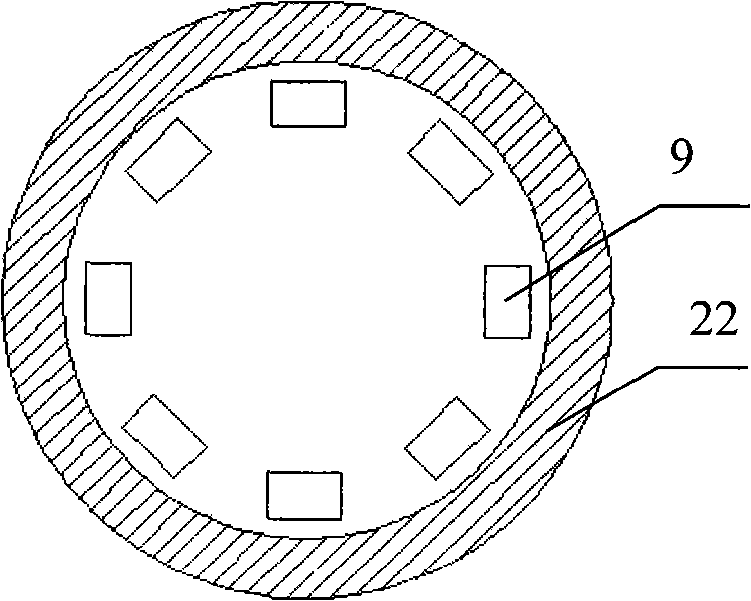

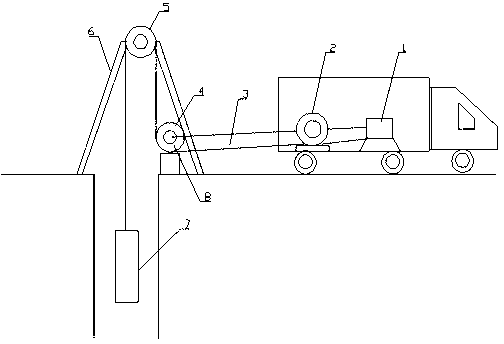

Device for detecting metal body of underground gas storage well

InactiveCN101358948AImprove reliabilityStrong field adaptabilityAnalysing solids using sonic/ultrasonic/infrasonic wavesContainer filling methodsDisplay deviceEngineering

The present invention relates to a metal shaft detection device of the underground gas storage well, and belongs to the technical field of security detection of the underground gas storage well. The detection device comprises a ground processing part and an underground detection part; wherein, the ground processing part mainly comprises a data receiving unit, a winch unit, a host computer and a display; the underground detection part comprises a magnetic flux leakage sensor, a magnetic flux leakage signal processing module, a first A / D conversion unit, an ultrasonic sensor, an ultrasonic signal processing module, and a second A / D conversion unit; the magnetic flux leakage sensor, the magnetic flux leakage signal processing module and the first A / D conversion unit are connected in sequence; the ultrasonic sensor, the ultrasonic signal processing module and the second A / D conversion unit are connected with each other; one end of the two A / D conversion units is connected with an embedded computer system, and the other end is connected with a position distance recording unit. The detection device integrates the characteristics of the magnetic flux leakage detection and the ultrasonic detection, can effectively detect the corrosion, fatigue crack and other phenomena of the metal shaft in use, and has the advantages of high reliability and strong on-site adaptability.

Owner:HUAZHONG UNIV OF SCI & TECH

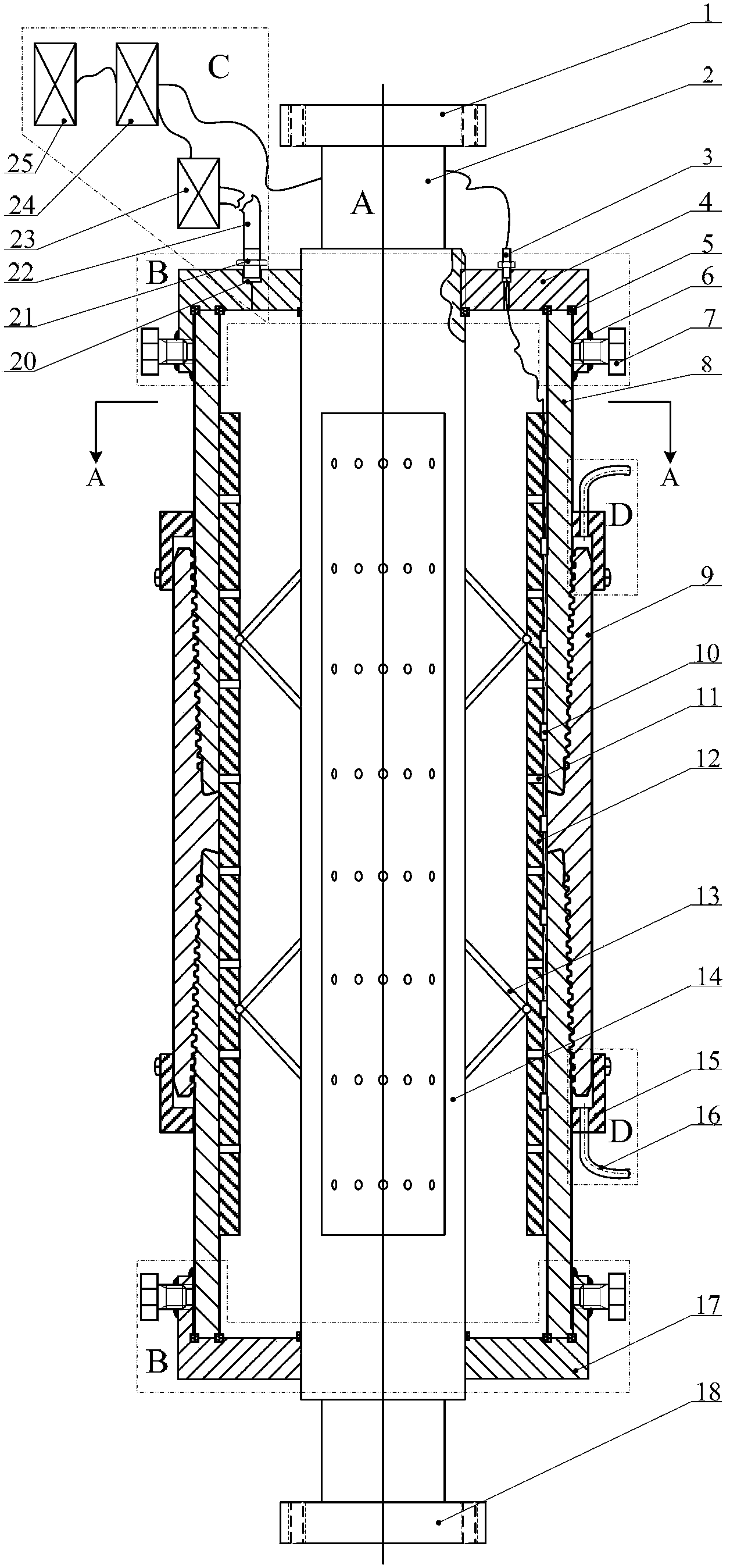

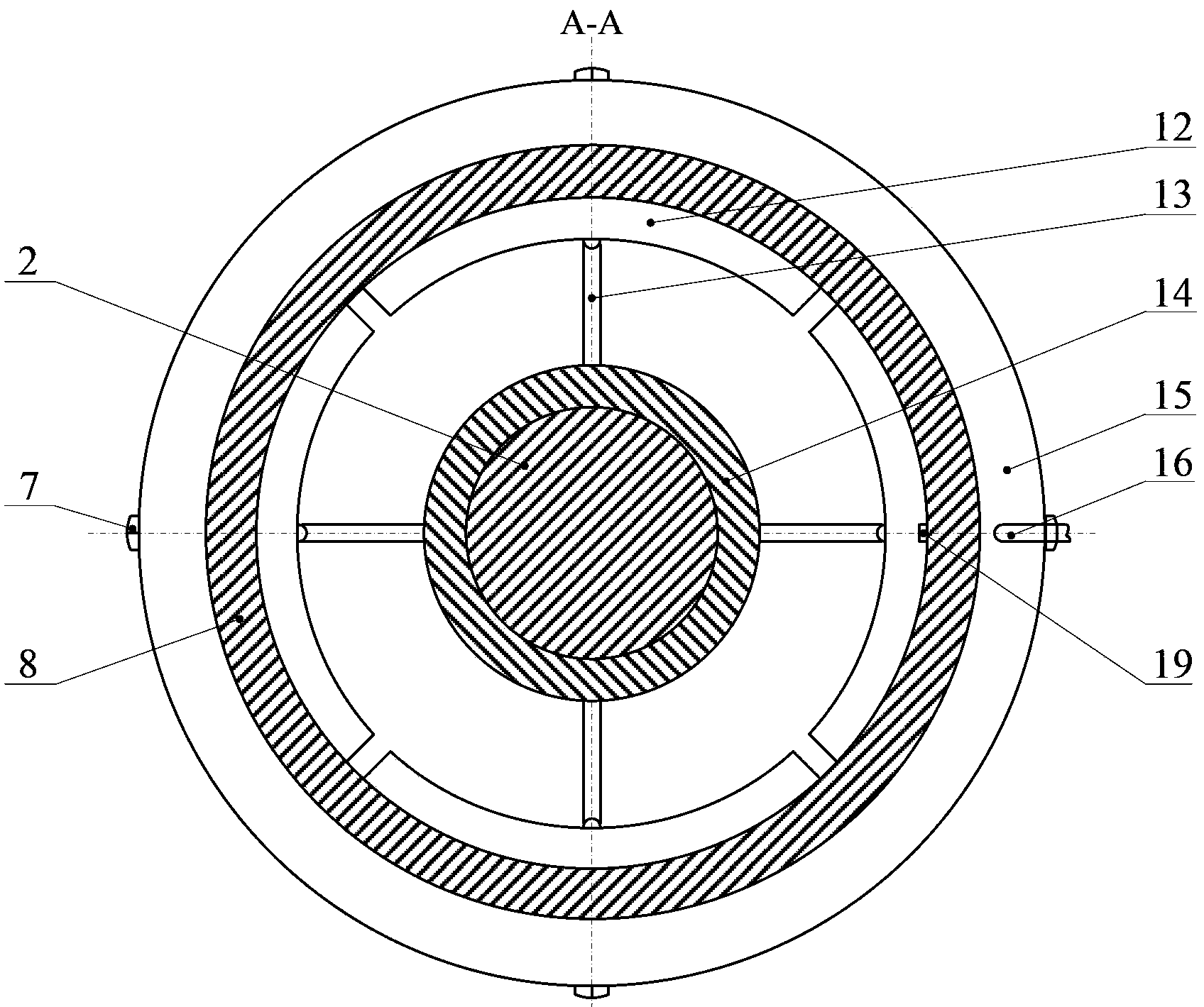

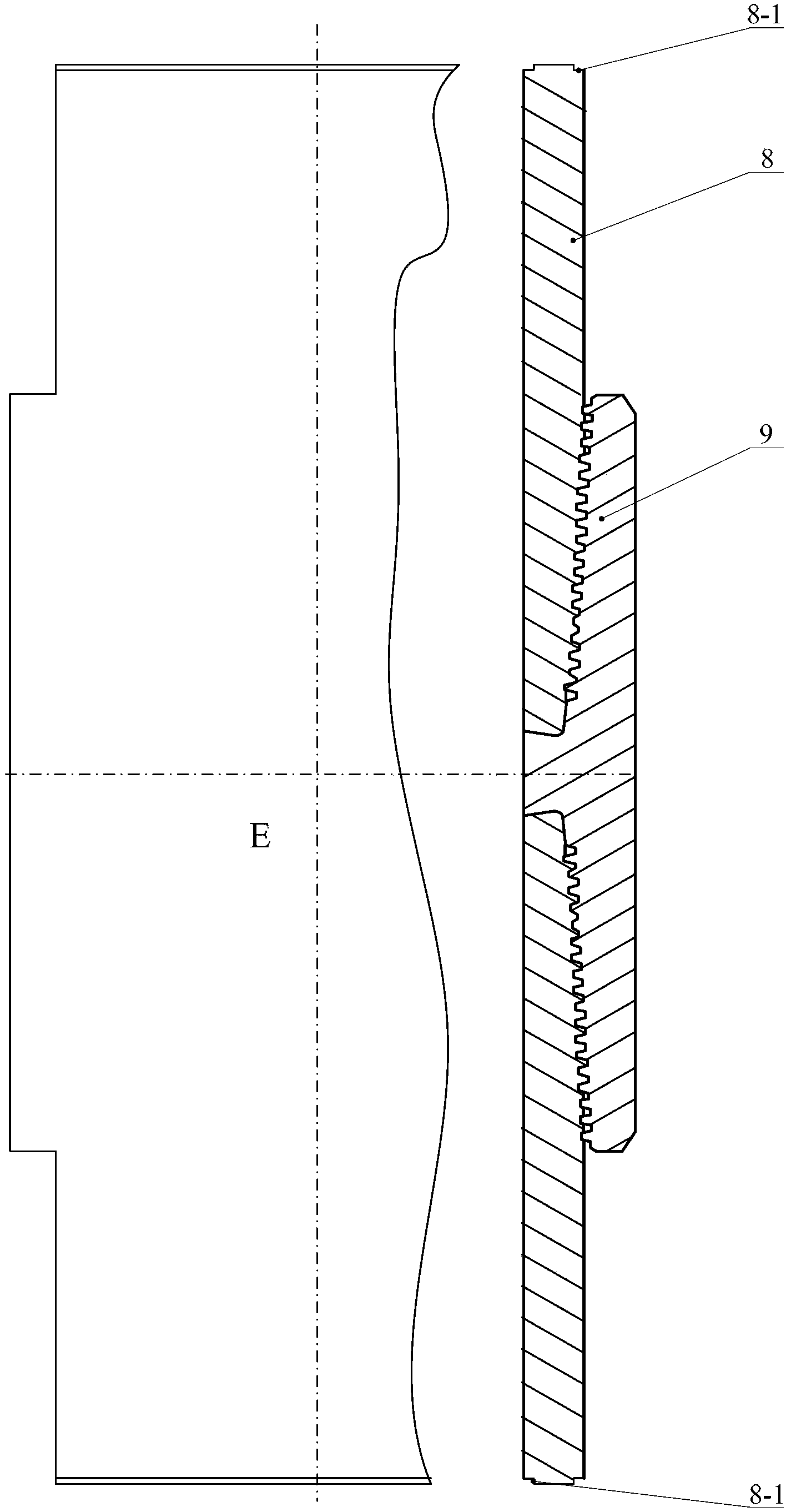

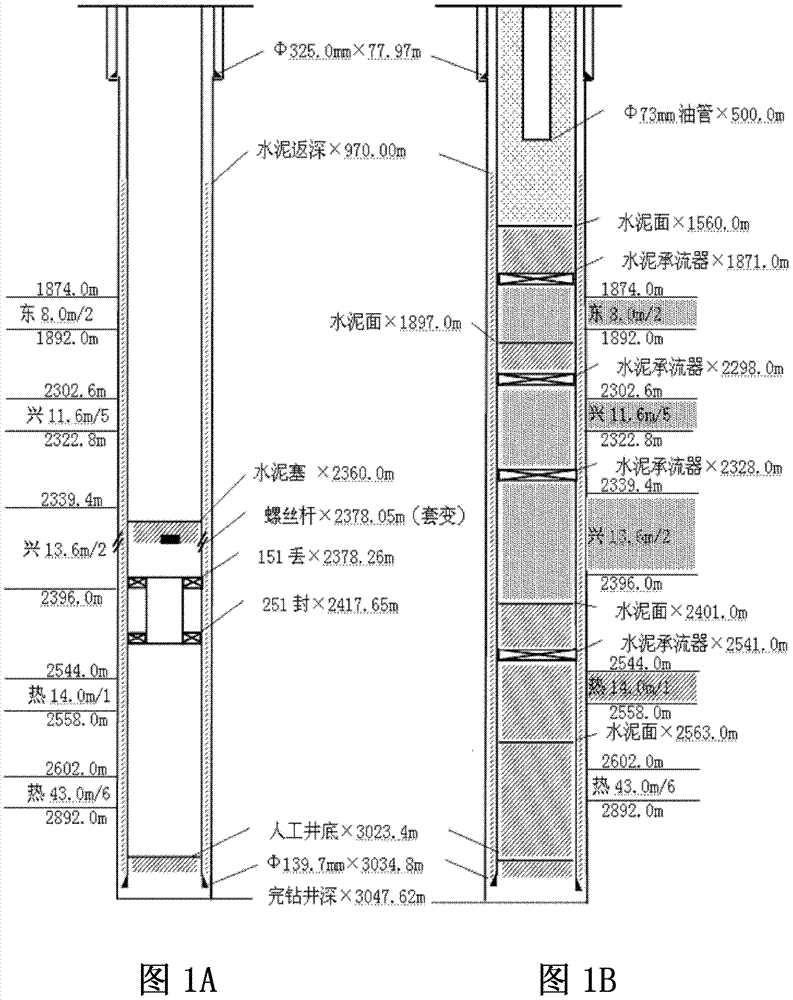

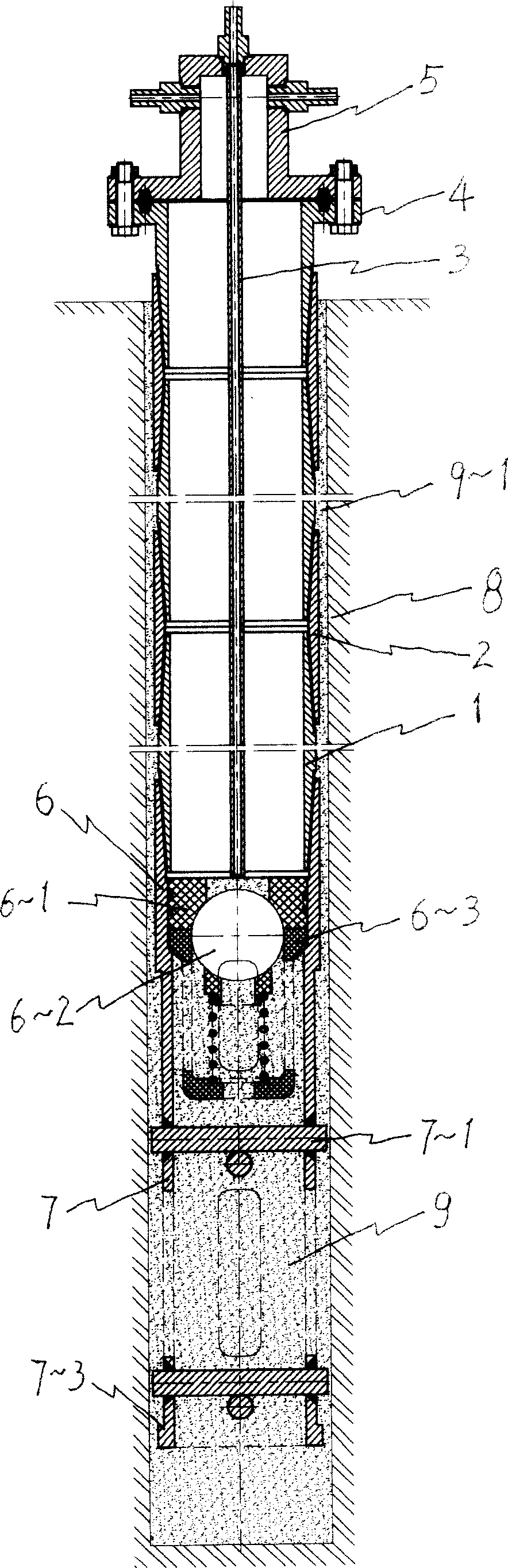

Internal-pressure fatigue test device for well-completion pipe string of underground gas storage reservoir and test method thereof

ActiveCN103852225AEnsure safetyPrevent leakageMeasurement of fluid loss/gain rateMaterial strength using repeated/pulsating forcesInternal pressurePressure transmission

The invention discloses an internal-pressure fatigue test device for a well-completion pipe string of an underground gas storage reservoir and a test method thereof and belongs to the technical field of petroleum drilling well completion. The test device includes a pressure transmission mechanism, enclosed cavity mechanisms, a control system, leakage detection systems and a pipe string sample. The pressure transmission mechanism passes through an internal cavity of the pipe string sample from top to bottom. The upper and lower ends of the pipe string sample are packaged through the enclosed cavity mechanisms. The enclosed cavity mechanisms are connected with the control system. The leakage detection system is installed on the pipe string sample. Therefore, a test device of a simulating gas storage reservoir well-completion pipe string in a gas injection and gas production process is formed so that radial pressure change data of the well-completion pipe string are obtained. The internal-pressure fatigue test device for the well-completion pipe string of the underground gas storage reservoir and the test method thereof are capable of detecting the sealing performance and fatigue strength of well-completion pipe string joints under a plurality of changes of an internal pressure through use of a fatigue test machine so as to obtain the radial pressure change data and thus a design basis is provided to oil-field work personnel and operating parameters of the gas storage reservoir are optimized.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Method for plugging old underground gas storage well

ActiveCN103244071APrevent gas blowingMeet the requirements of normal production operationSealing/packingWell cementingMaterial Perforation

The invention discloses a method for plugging an old underground gas storage well. The method comprises the steps of utilizing a cement bearing device and adopting padding mixed with superfine cement to plug a jetted air reservoir target layer in an extruding mode and reserving a cement plug; utilizing the cement bearing device and adopting padding mixed with superfine cement to plug perforated well sections under the jetted air reservoir target layer in the extruding mode and reserving a cement plug; utilizing the cement bearing device and adopting padding mixed with superfine cement to plug perforated well sections above the jetted air reservoir target layer in the extruding mode and reserving a superfine cement plug; selecting superfine sections with high superfine permeability to solve the problem that the well cementation quality of well sections above the target layer is disqualified, and arranging cement partition plates after perforation so as to prevent gas channeling outside tubes; plugging the target layer and other perforated well sections and waiting on cement setting under pressure by utilizing the cement bearing device; and arranging a whole cement plug and reserving cement faces to be 300m higher than the perforated well sections. The method for plugging the old underground gas storage well can effectively save plugging materials and improve the plugging effect.

Owner:PETROCHINA CO LTD

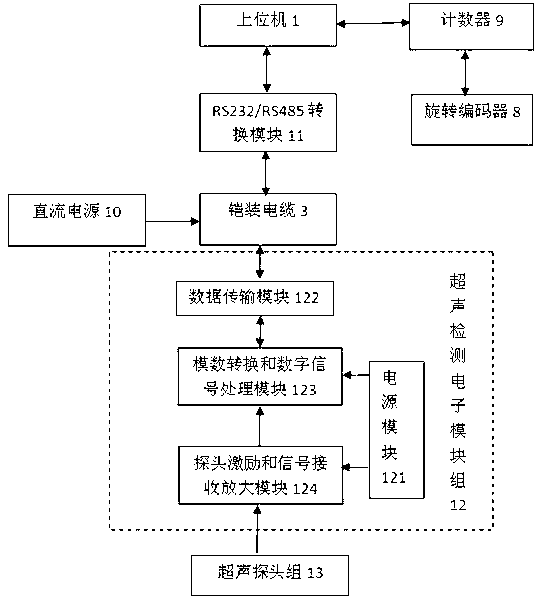

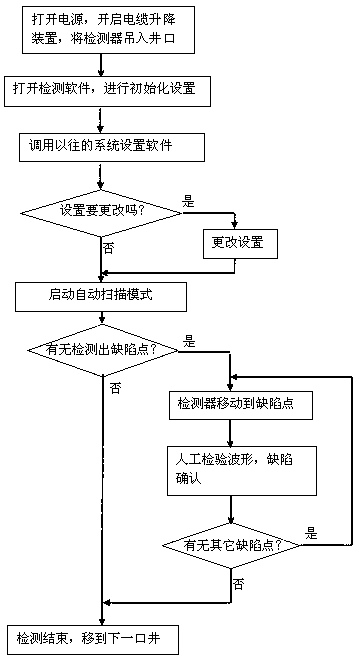

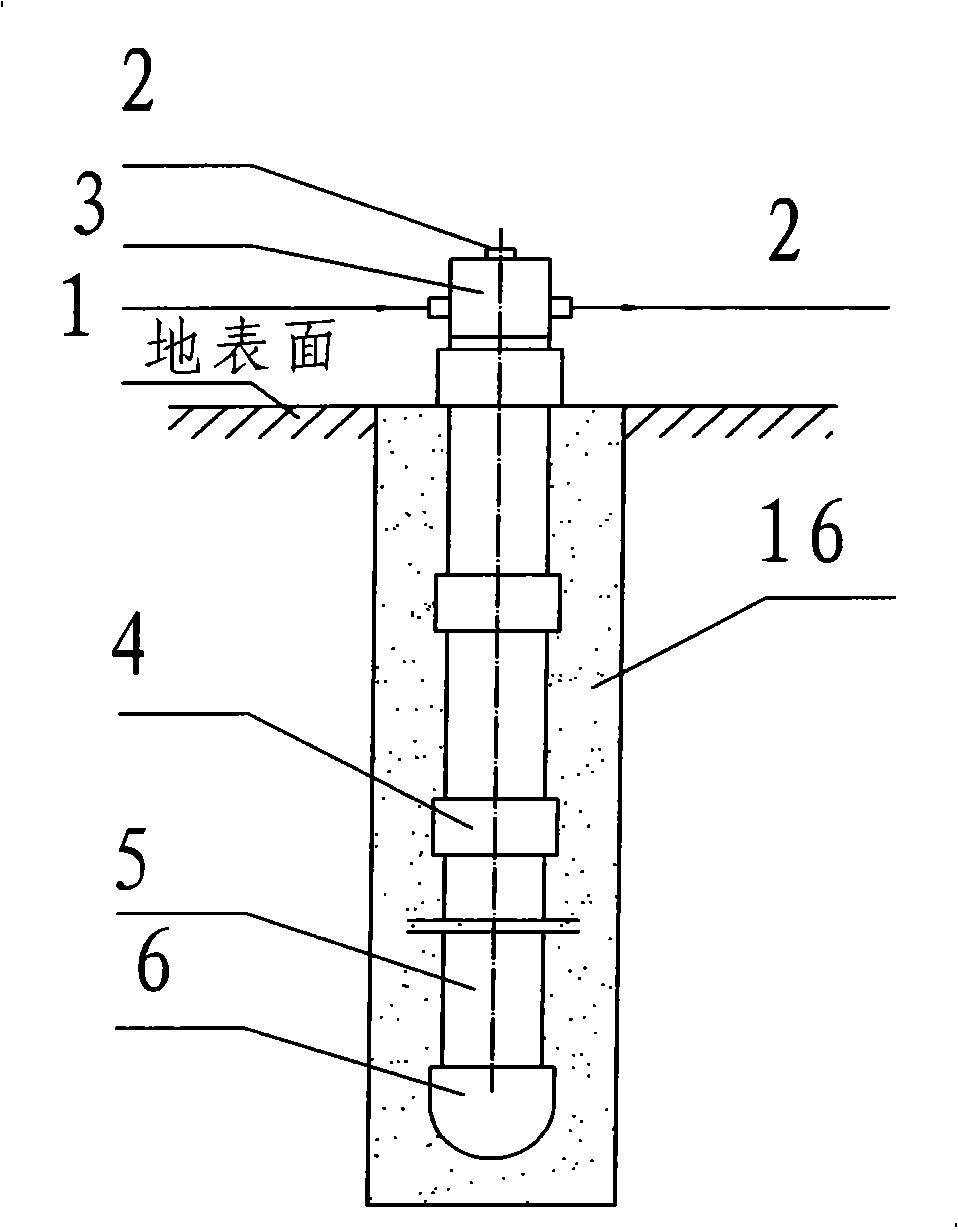

Underground gas storage well wall automation comprehensive detection system and detection method

ActiveCN103134855AComprehensive detectionGuaranteed operational safetyAnalysing solids using sonic/ultrasonic/infrasonic wavesStructural engineeringProcess engineering

The invention relates to an underground gas storage well wall automation comprehensive detection system and a detection method. The system comprises an upper computer, a position measuring device, a cable lifting device, a direct current power supply and an underground movable detector, wherein the upper computer is placed on a well, and the movable detector is communicated with a device on the well through an armor cable and obtains power. Occupied space of the cable is saved, field operation is convenient, a wall thickness corrosion probe group and a flaw detection probe group are arranged inside the movable detector, detection for the wall thickness corrosion and flaws can be achieved simultaneously, and detection for the gas storage well is complete. Meanwhile, an underground device of the system integrates encouraging, receiving, amplification and signal processing and transmission functions, therefore ultrasonic signals does not need to be transmitted to the ground to be processed for a long distance, fidelity and the signal to noise ratio of the signals are greatly improved, and detection results are accurate.

Owner:山东省特种设备检验研究院鲁特检验检测有限公司 +1

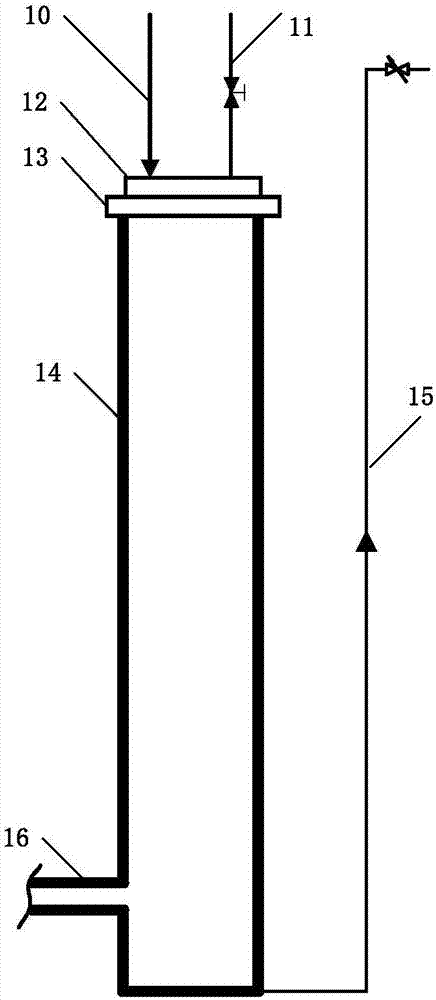

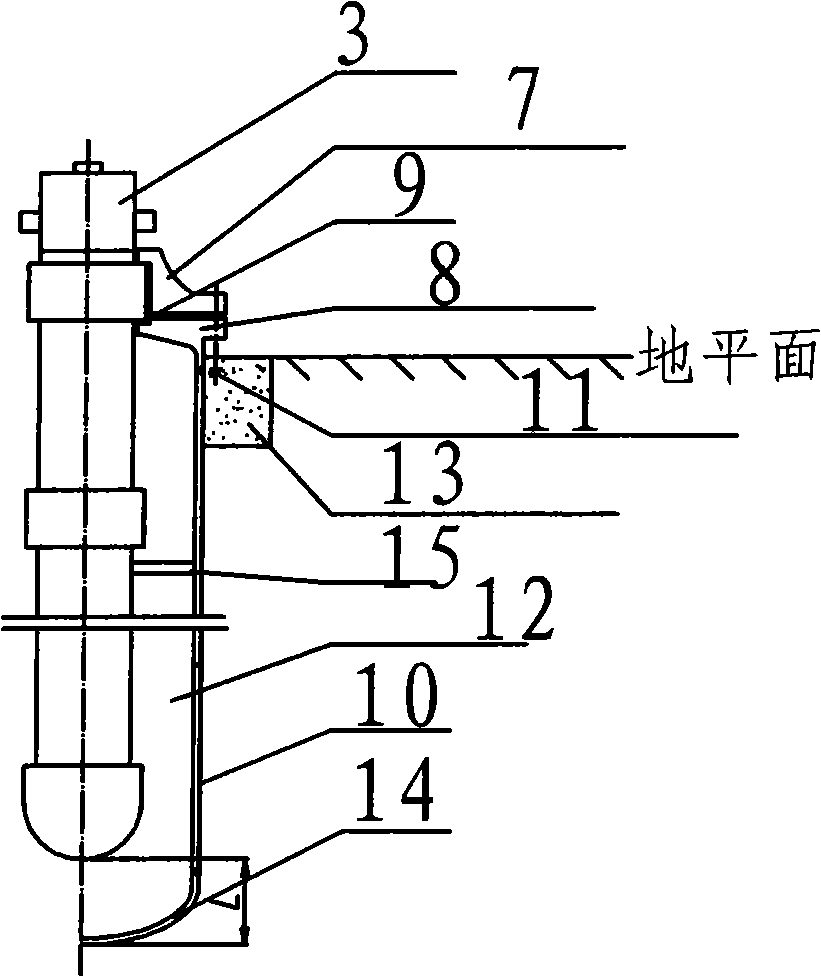

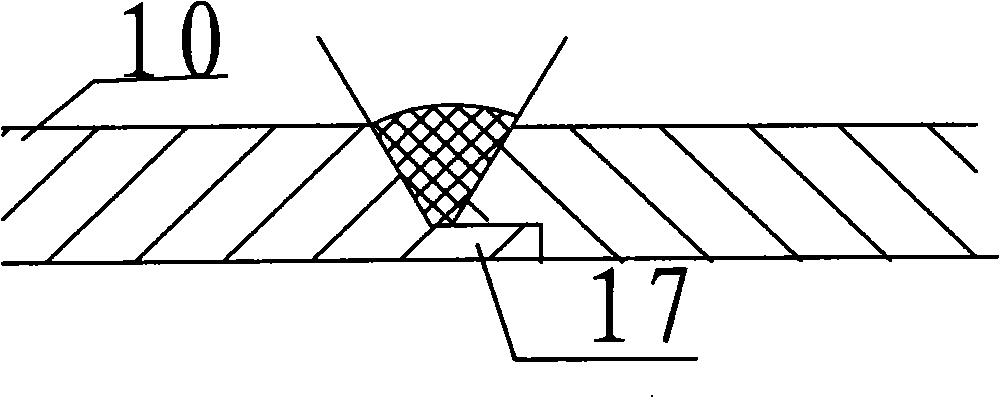

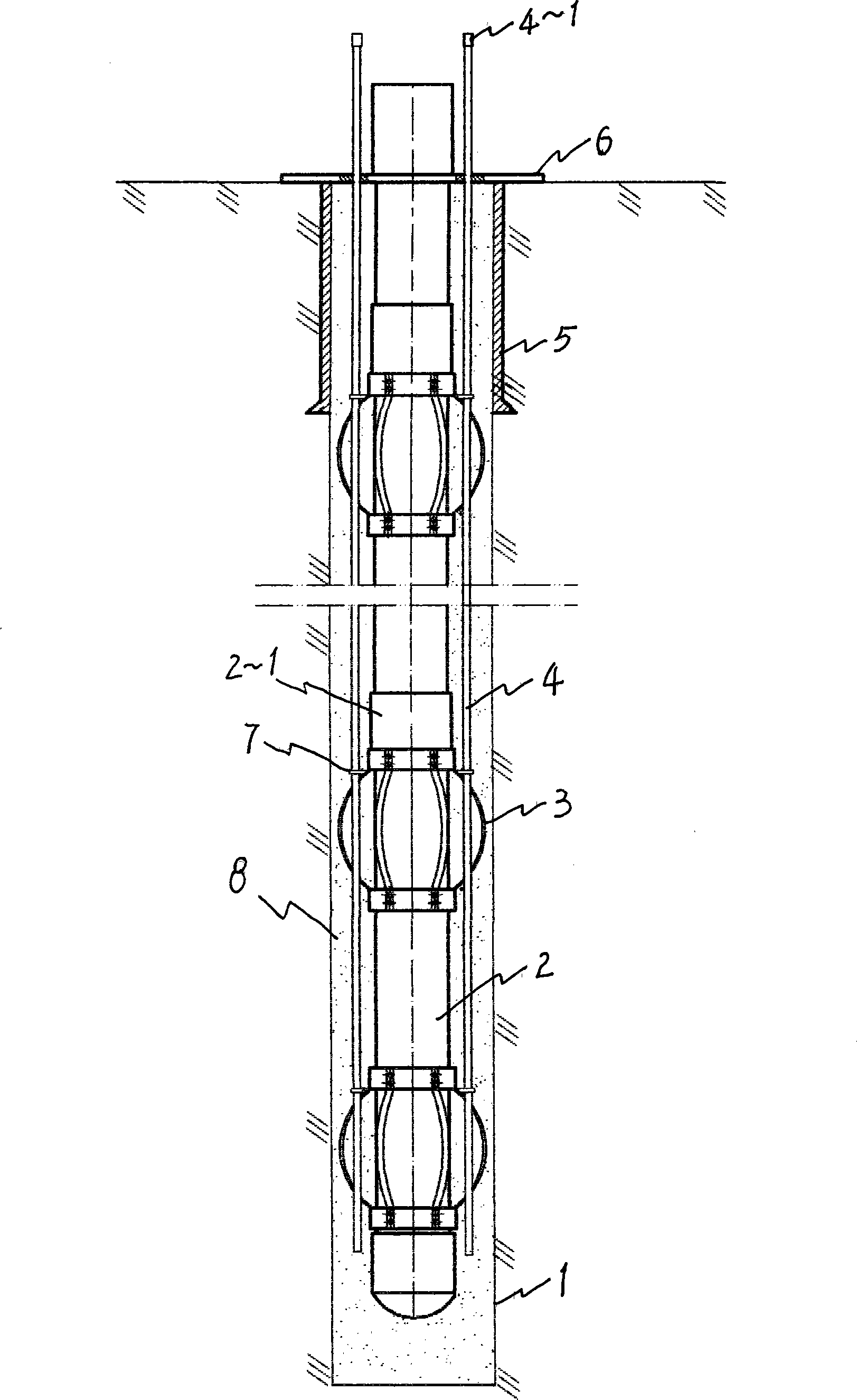

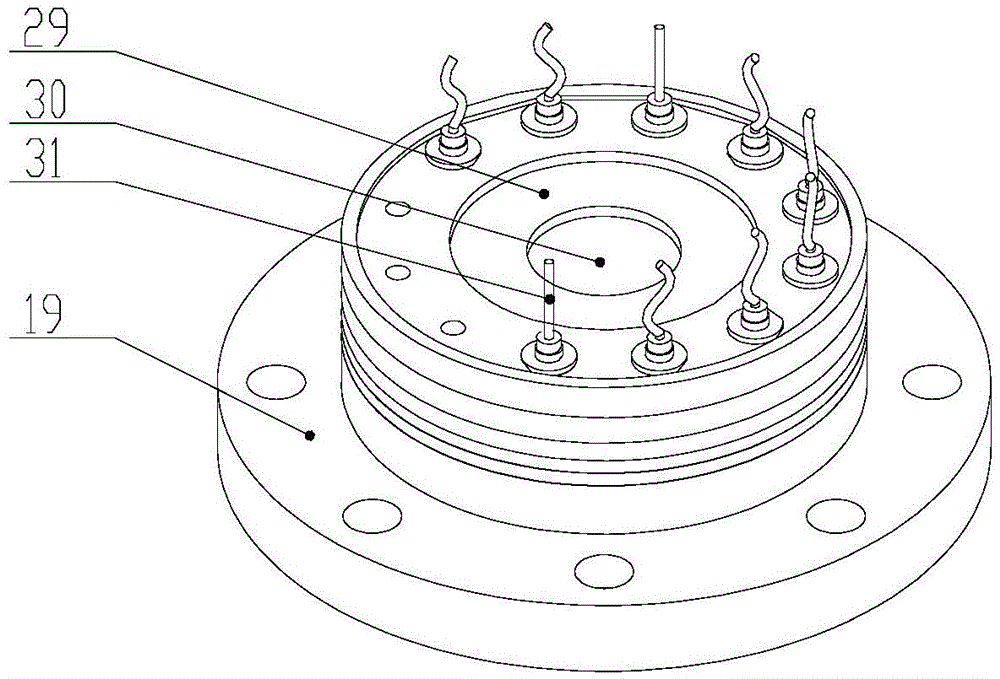

Double-wall sleeve suspension type high-pressure gas underground storing well installation method and structure thereof

ActiveCN101403317AAvoid going up the wellPrevent sinkingMining devicesStorage devicesDouble wallNitrogen gas

The invention discloses an installation method of a double-walled sleeve suspended type high pressure gas underground gas storage well, and a structure thereof, wherein, the method comprises the following steps: well drilling is carried out; an outer mineshaft body is welded and sunk into the drilled well, the upmost end of the outer mineshaft body is connected with a lower-side heteromorphic equipment flange with a groove in a welding way; cement is injected to form a well cementation layer and a groundwork layer, and the groundwork layer is pre-embedded with a plurality of anchor bolts; the anchor bolts are connected and fixed with the lower-side heteromorphic equipment flange; an internal mineshaft is installed in the outer mineshaft body; two split heteromorphic equipment flanges are compressed on the upper end face of the upmost section hoop, and then the split heteromorphic equipment flanges are clamped with the lower-side heteromorphic equipment flange by bolts; and nitrogen is introduced between the internal mineshaft and the outer mineshaft body. By adopting the device and the well cementation method, the stored gas can be prevented from leaping to the outside of the well, sinking and leakage, and the gas storage well can bear the corrosion of the outer wall of the mineshaft, thus guaranteeing the axial elongation of the gas storage well when bearing pressure.

Owner:TIANJIN SPECIAL EQUIP INSPECTION INST

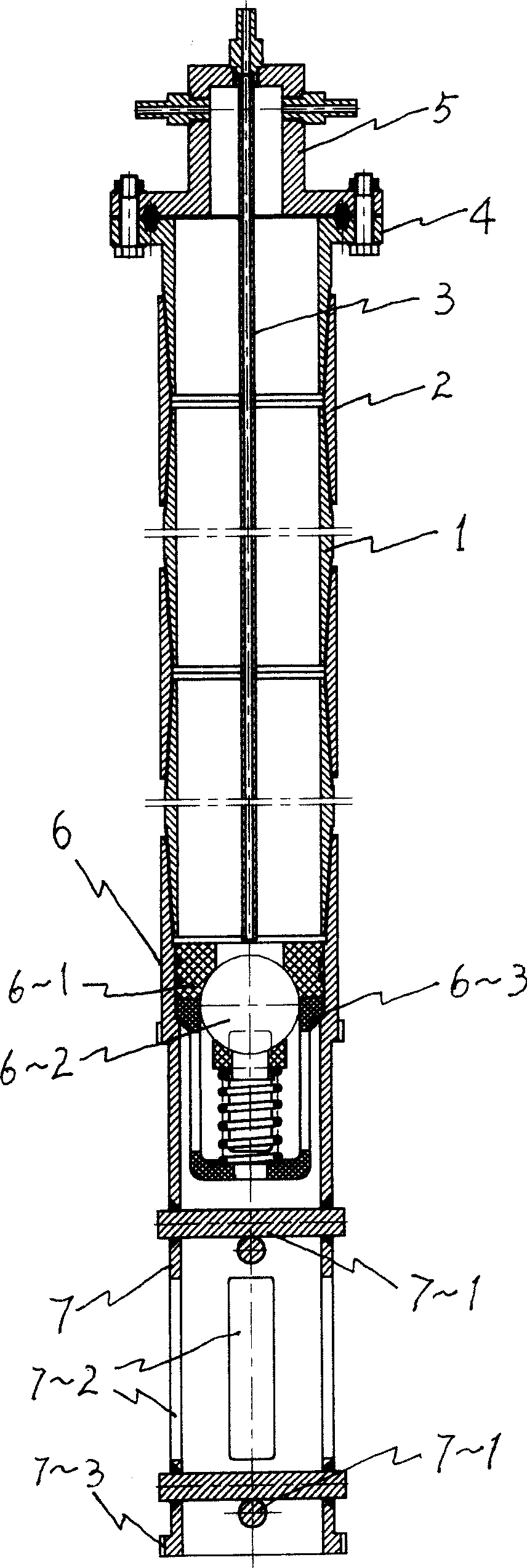

A fixation method for underground gas storage well bore

InactiveCN1837672AFirmly condensedAvoid pollutionContainer filling methodsContainer discharging methodsFixation methodPollution

The invention relates to a method for fixing underground gas storage well cylinder, which comprises a well cylinder whose bottom has a one-way valve and a fixing bracket inside the basic well; a irrigating device for mounting insertion tube and modulating the cement via the cement pump, insertion tube, and one-way valve to fill cement into the cylinder and the well wall; then removing the irrigating device; and waiting the cement be solidified. The invention can avoid pollution on the inner chamber of well cylinder, to eliminate the washing process. And it can improve the safety and service life of well cylinder.

Owner:自贡力源科技有限公司

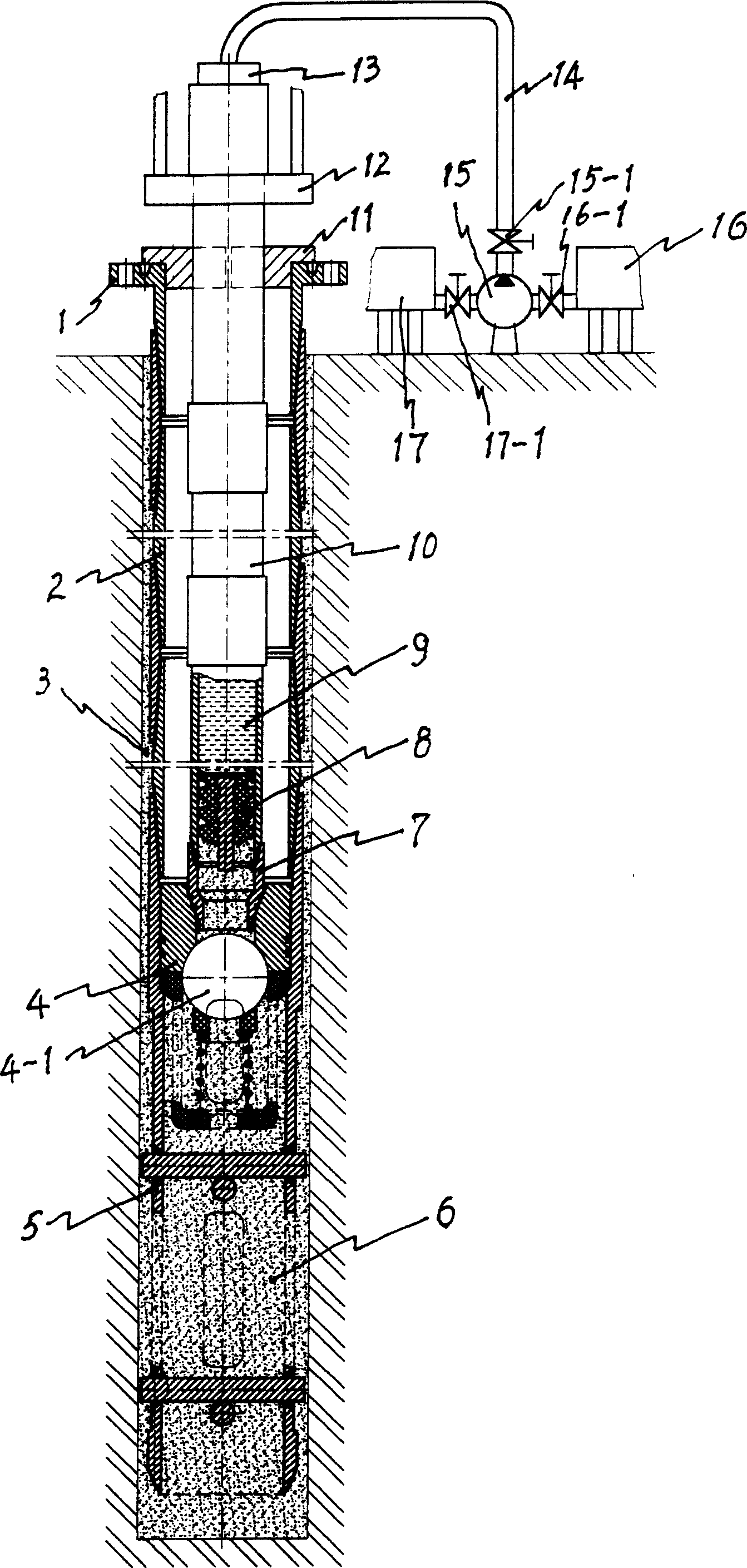

Underground gas storage well shaft and its fixing method

InactiveCN1952466AReasonable structural designEasy grouting and fixingContainer filling methodsPressure vesselsCement slurryHigh pressure

The invention relates to a mine shaft of high-pressure gas underground storage well and the fixed method. The mine shaft comprises shaft body, connecting sleeve, four-way control head, one-way sealing head and foundation fixed bracket on the bottom, and drainage pipe. The fixed method comprises drilling base well, setting shaft body, producing cement slurry, cement slurry perfusion along inner cavity of mine shaft and one-way valve, installing drainage pipe and four-way control head. Because of one-way valve applied as bottom sealing head of mine shaft, base fixed bracket added, and cement slurry perfusion improved, it is provided with reasonable structure design, convenient and stable operation for perfusion, fixed connection between the mine shaft and well wall, good safety, convenient repair and maintenance, and longer service life so on. Inconvenient assembling and fixing well shaft, small attachment force with cement, bad stability of perfusion fixing technology, uneasy operation, mine shaft rotating or moving in working and bad safety are conquered.

Owner:自贡力源科技有限公司

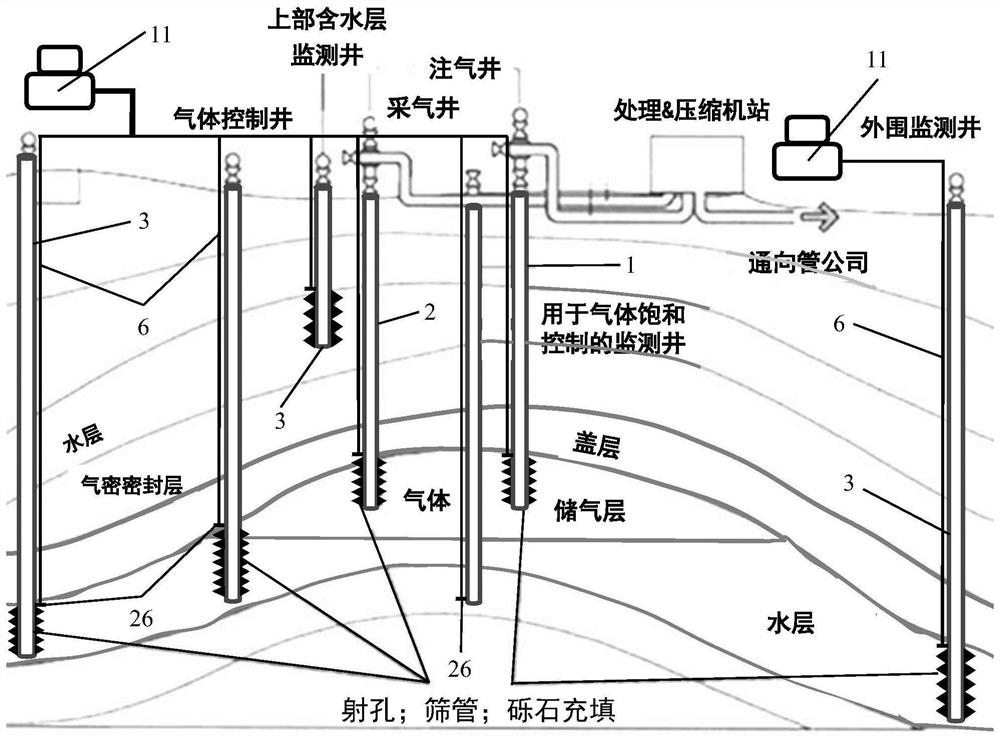

Underground gas storage safe operation monitoring system and monitoring method

The invention provides an underground gas storage safe operation monitoring system and monitoring method. The underground gas storage safe operation monitoring system comprises armored optical cables,quasi-distributed optical fiber pressure sensors and underground three-component detector arrays, wherein the armored optical cables and the quasi-distributed optical fiber pressure sensors are distributed inside and outside all gas injection wells, gas production wells and monitoring well sleeves and outside in-well gas injection and production pipes, and the underground three-component detectorarrays are partially distributed in a monitoring well. The measurement armored optical cables, the quasi-distributed optical fiber pressure sensors and a composite modulation and demodulation instrument placed near a wellhead are fixed to the outer side of the metal sleeve. According to the underground gas storage safe operation monitoring system, real-time on-line monitoring of changes of noise,temperature, pressure, stress / strain and distribution characteristics of microseism events in all wells is comprehensively and fully utilized, intelligent comprehensive analysis and evaluation are carried out on all parameters and information monitored in real time on line, grading classification is carried out on various risks or accidents influencing safe and stable operation of the gas storage, early warning signals and information of accident risks are issued in time, and long-term stable and safe operation of the gas storage is ensured.

Owner:BGP OF CHINA NAT GASOLINEEUM CORP +1

High pressure underground gas well shaft fixing method

The invention belongs to a method for fixing a high pressure underground gas storage well casing. The method comprises the following steps: a well casing with a centralizer and a plurality of grout pipes are sunk into a basic well; the grout pipes simultaneously inject grout into the basic well at different pressure within the pressure range from 3MPa to 10MPa until the grout overflows. As the centralizer is added on the shell of the well casing and a plurality of pipes are adopted to inject grout at different pressure at the same time, the well casing can be ensured to be arranged at the central position of the basic well while grout of different pressure is injected into the well at the same time. The grout is stirred under the action of the pressure difference; and the injection and filling effect is effectively promoted. The invention has the characteristics of that the installation and fixation method is reliable, the well casing and the wall of the basic well are connected firmly with excellent entirety, the well casing does not loose when in use, the use security of the gas storage well is effectively improved, the performance life is long, etc. The invention overwhelms the defects of the grouting fixation process in the background technology, such as poor reliability and security, likelihood of loosing when in use, etc.

Owner:SICHUAN PETROLEUM & NATURAL GAS SCI & TECH CORP

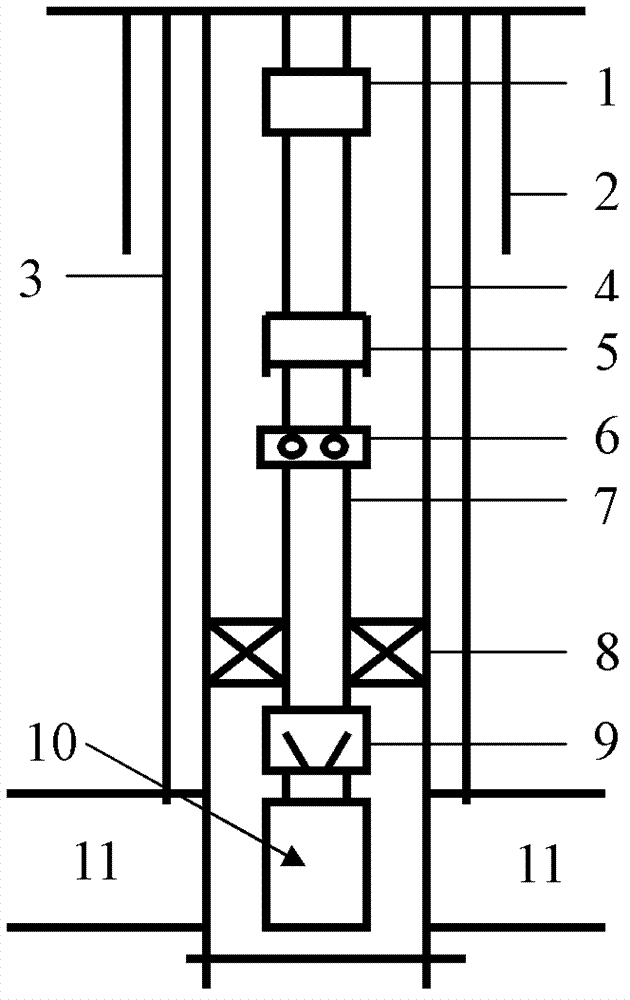

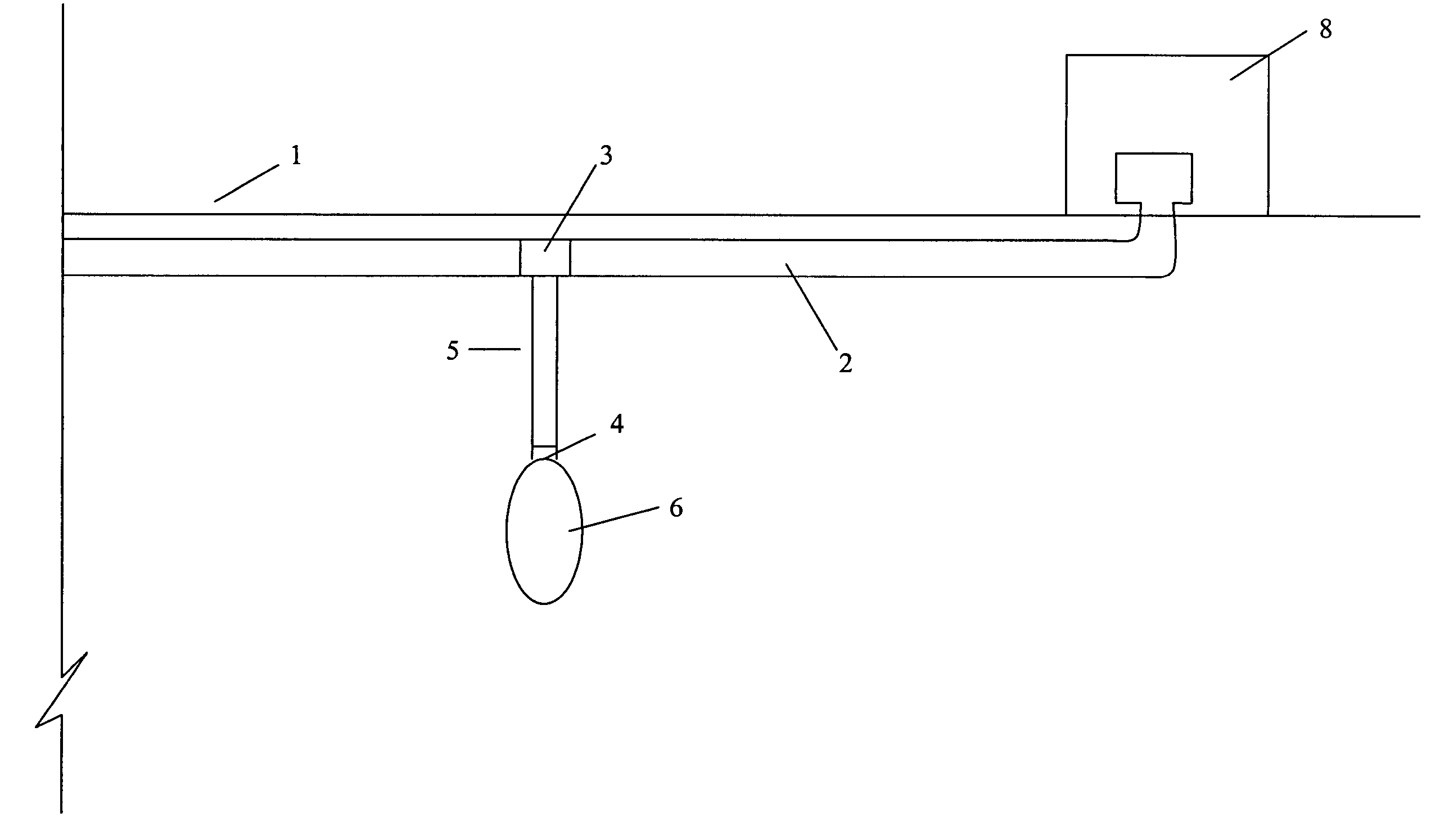

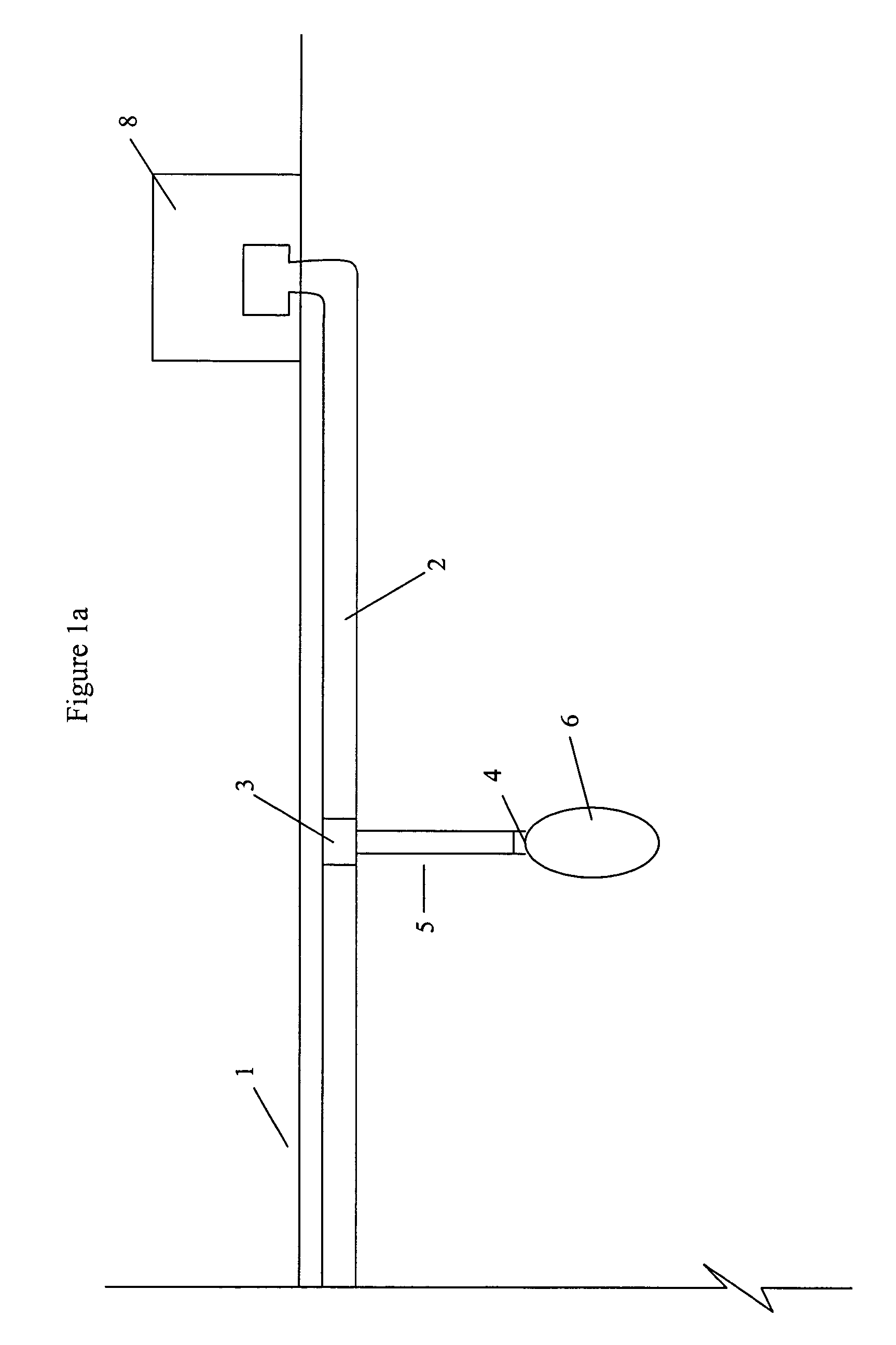

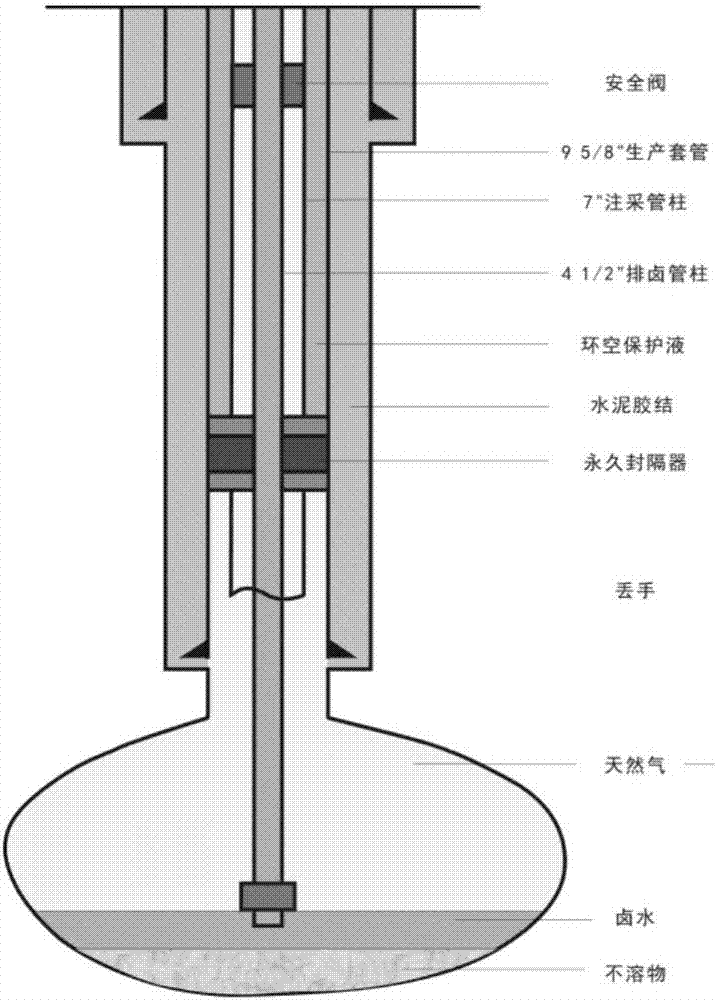

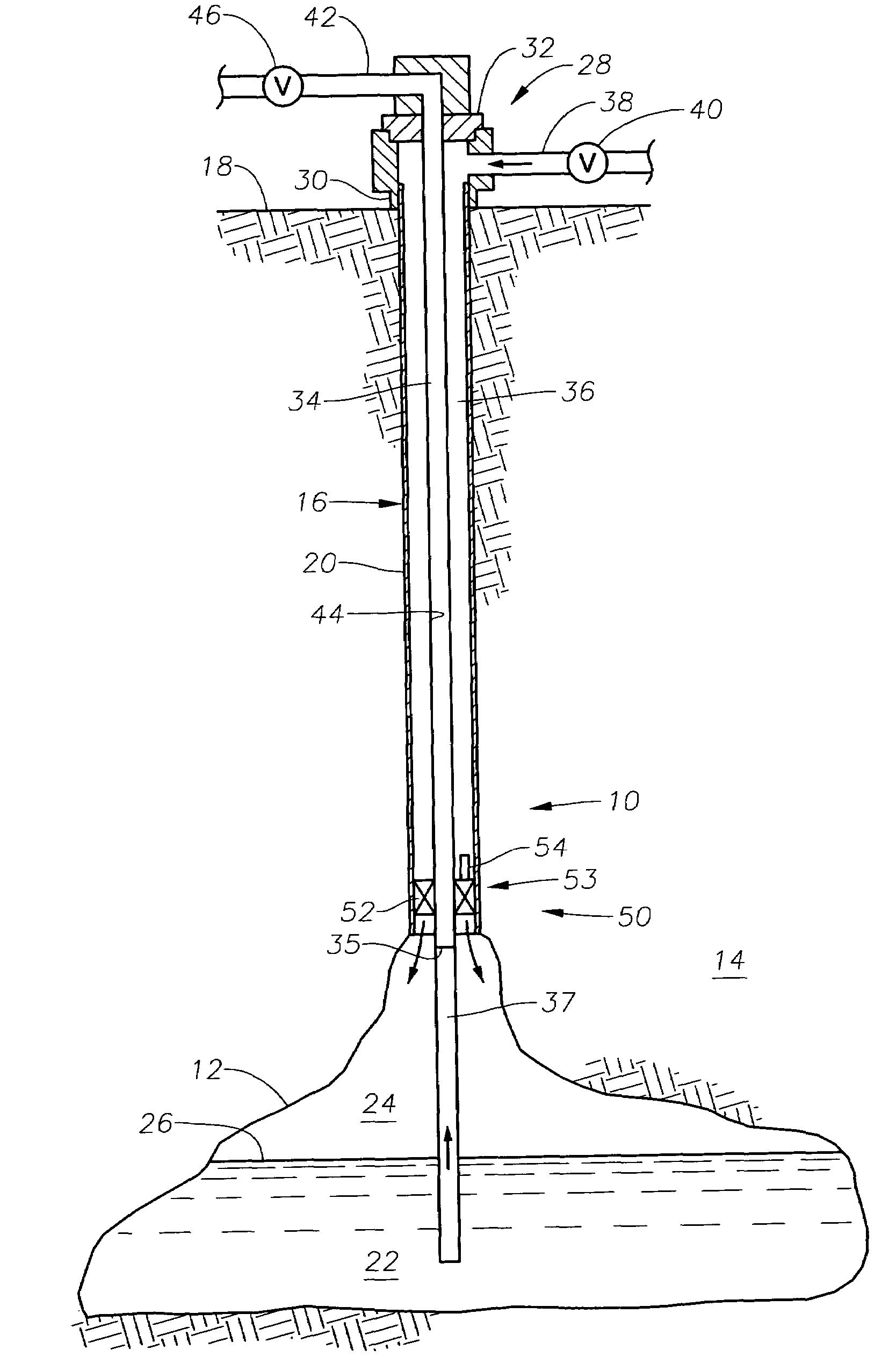

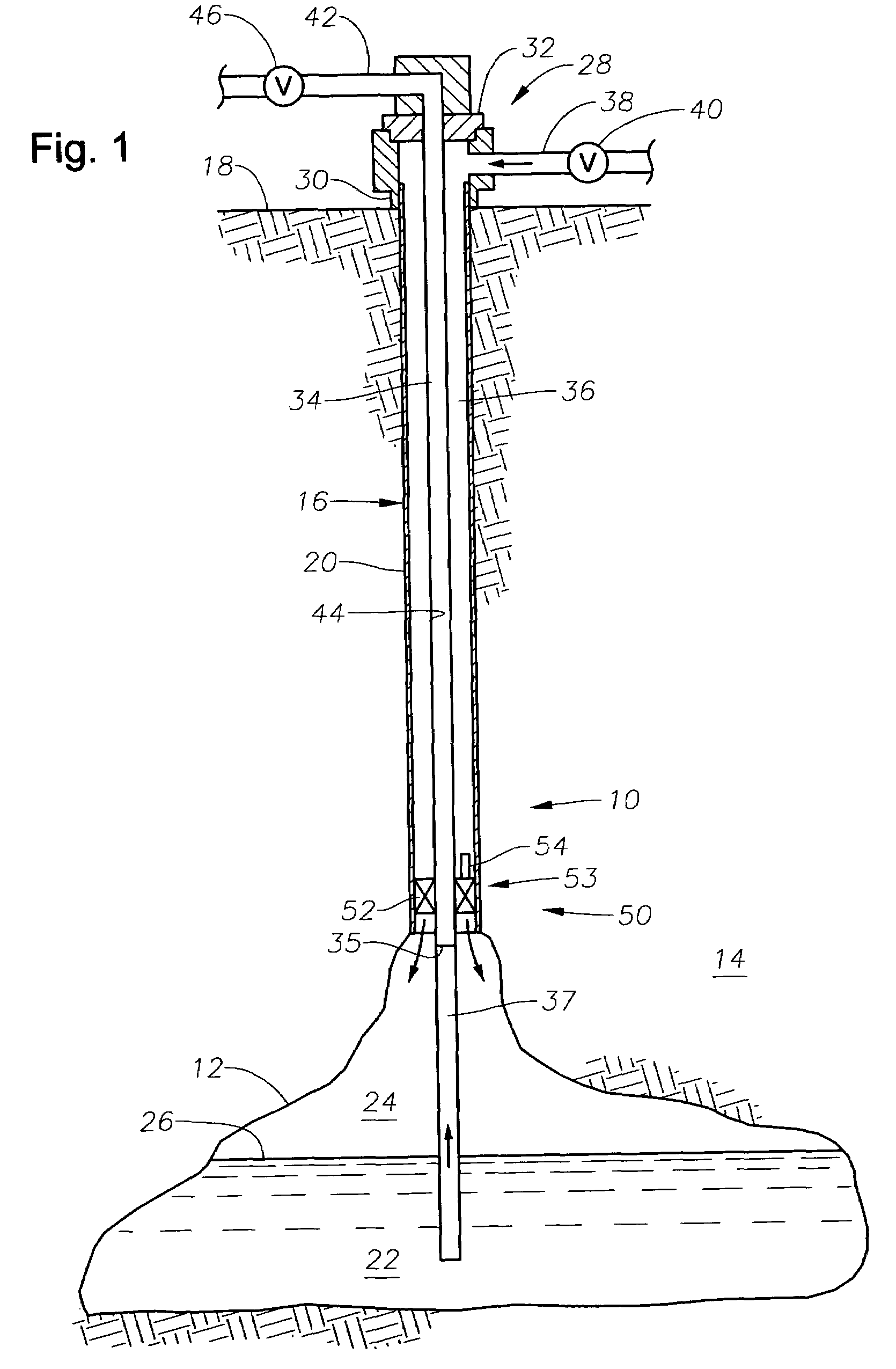

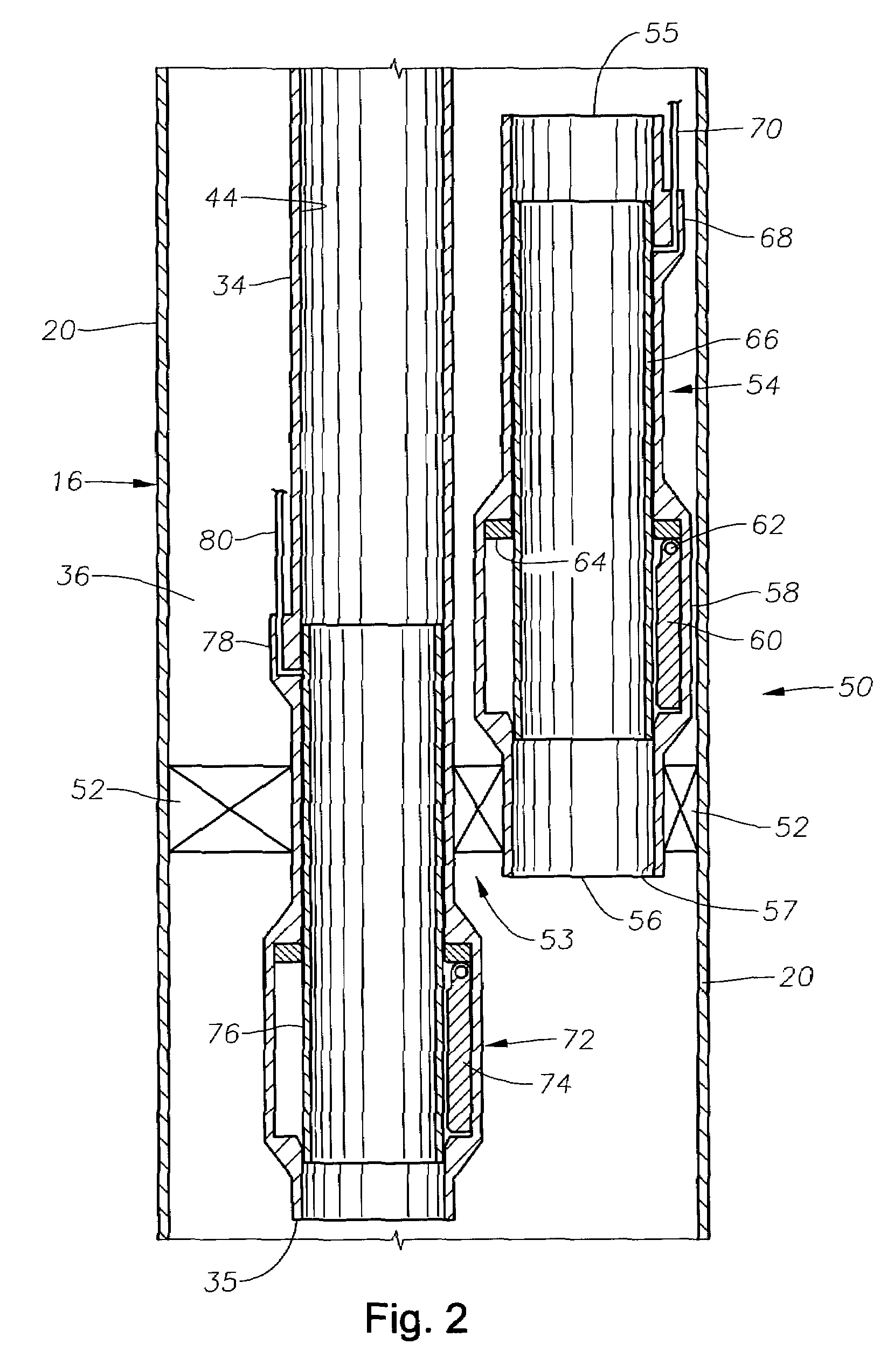

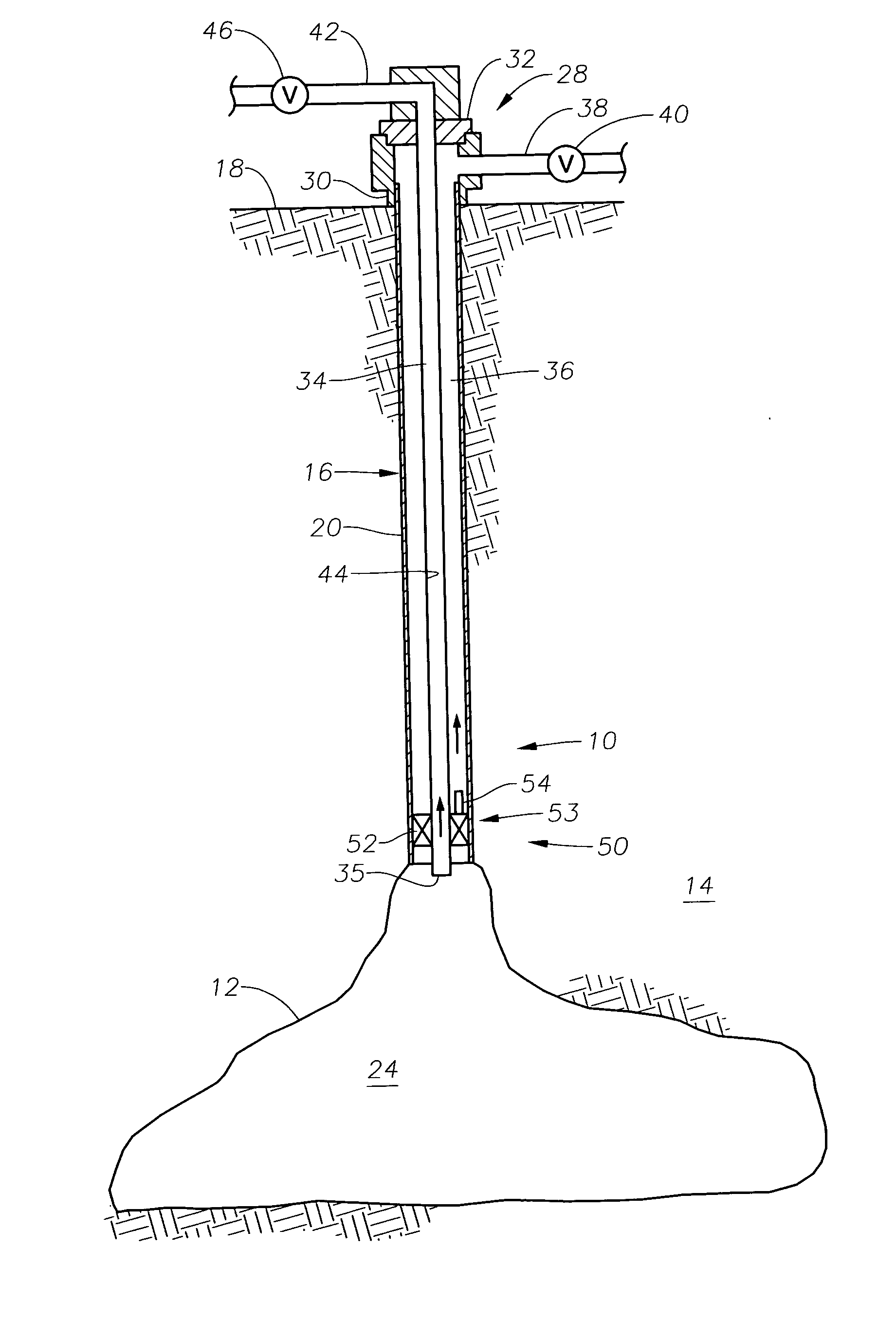

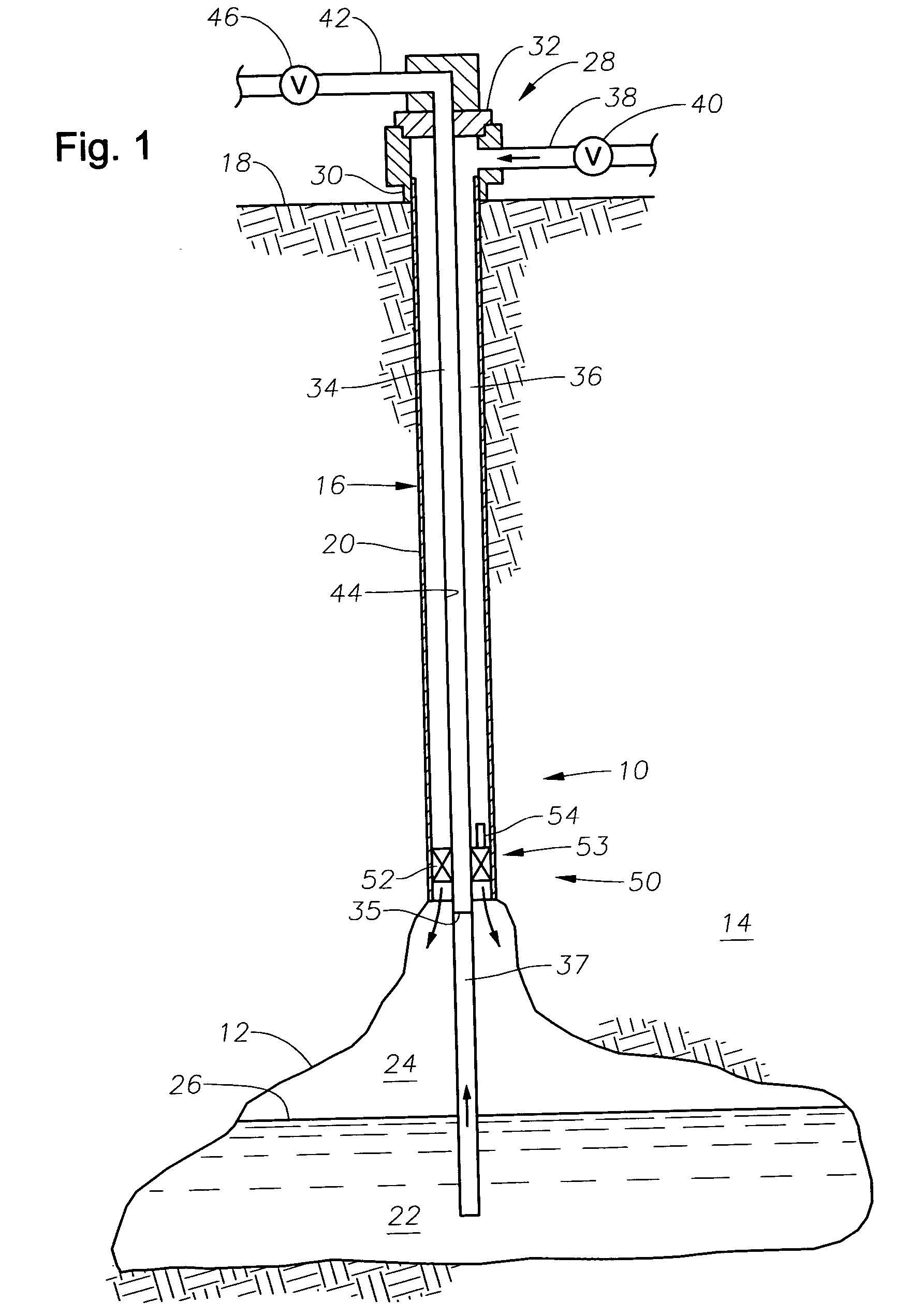

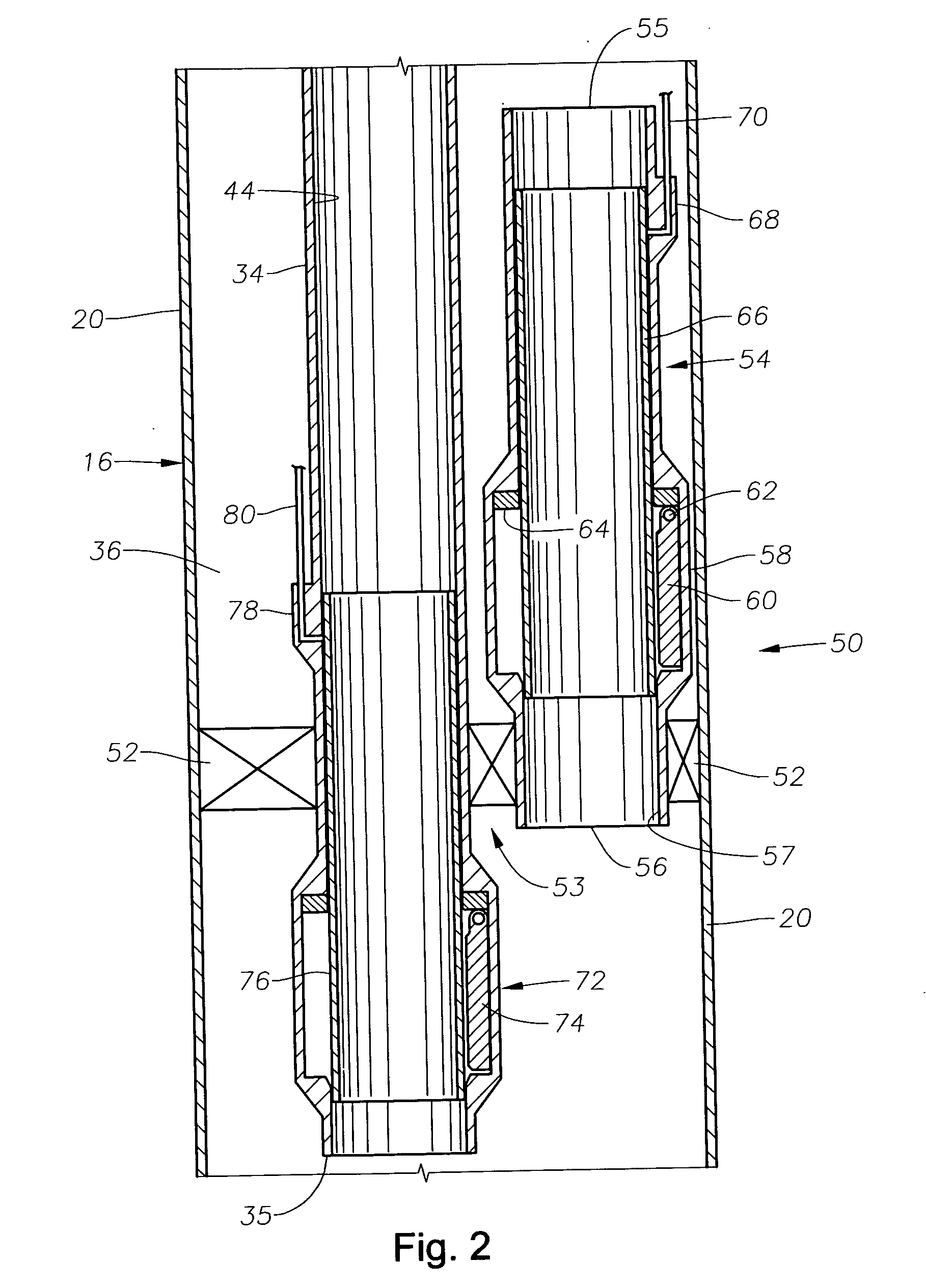

Annular safety and flow control system for underground gas storage

ActiveUS7258508B2Easy constructionIncrease chanceMining devicesFluid removalControl systemEngineering

A gas storage well with a tubing string that is disposed within a wellbore communicating an underground storage cavern with the surface. A surface controlled subsurface safety and flow control system is provided within the wellbore so that all flow into or out of the well can be shut down rapidly in the event of an emergency. The safety and flow control system features a dual opening-style packer element that provides an annulus seal between the surrounding casing and the tubing string and between the casing and a pup joint that is located within the annulus. Both the tubing string and the pup joint contain surface controlled subsurface safety valves that are capable of quickly shutting off flow through both the flowbore and the annulus. Each valve can be opened or closed independently of the other.

Owner:BAKER HUGHES INC

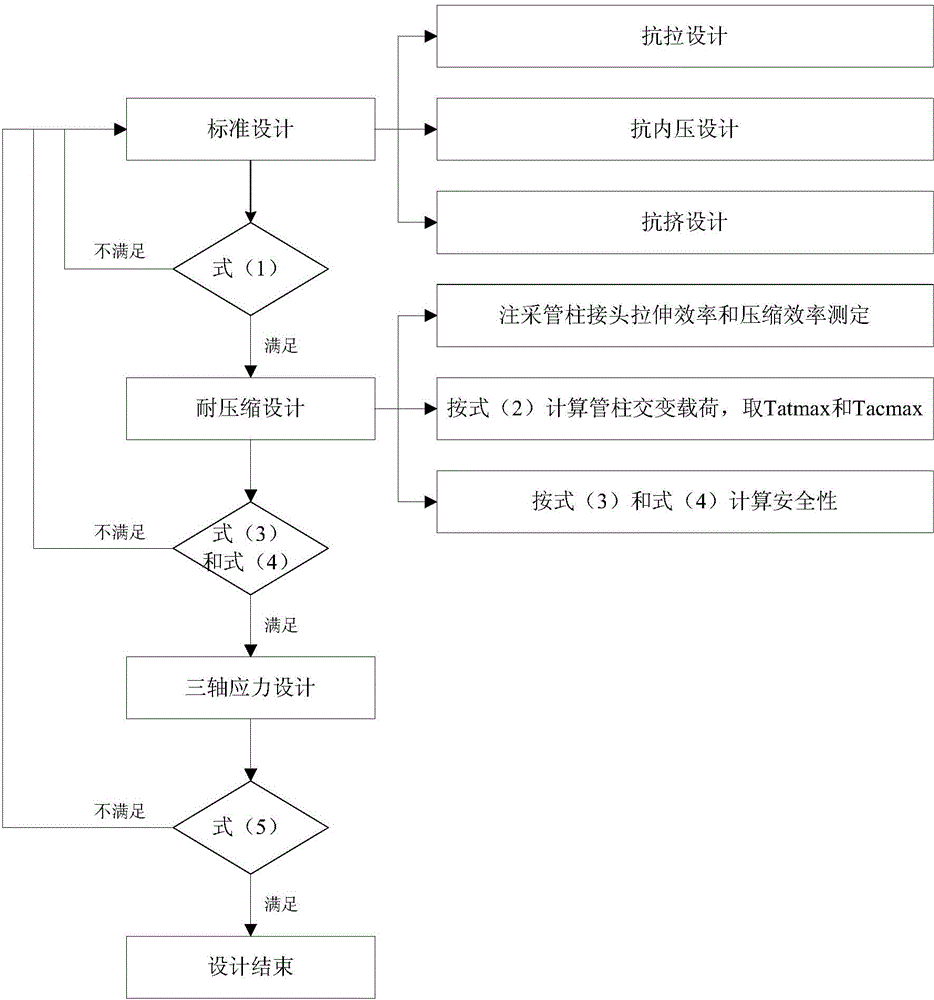

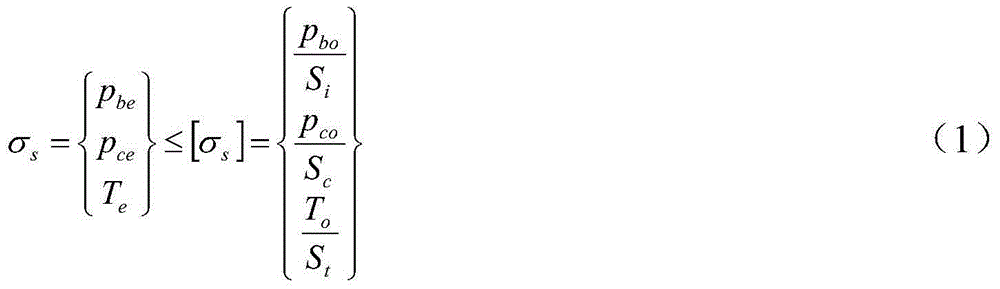

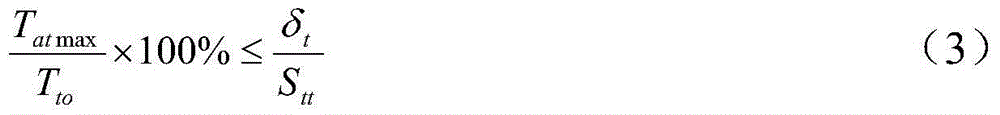

Underground natural gas storage injection-production pipe column designing method

ActiveCN104373053AImprove sealingMeet the job compression loadDrilling rodsInformaticsFriction effectNatural gas storage

The invention belongs to the technical field of well drilling and discloses an underground natural gas storage injection-production pipe column designing method. By comprehensively considering the influence on a pipe column from self weight of a pipe body, the temperature effect, the pressure effect and the friction effect generated by fluid flowing, on the basis of design of an existing pipe column, compression loads are considered and matched with the compression efficiency of a pipe column connector to design an underground natural gas storage injection-production pipe column, it is ensured that the compression efficiency of a connector of the designed pipe column meets the operation compression load and sealing requirements, and meanwhile as the triaxial stress of the pipe column is considered for design, the overall structural intensity of the injection-production pipe column can meet the operation load requirement. The underground natural gas storage injection-production pipe column designing method not only can meet the airtightness under stretching loads, but also can meet the airtightness of the pipe column after stretching and compression loads interchange, improve the sealing performance of the pipe column under the interchanged loads and ensure long-term safety operation of the injection-production pipe column.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

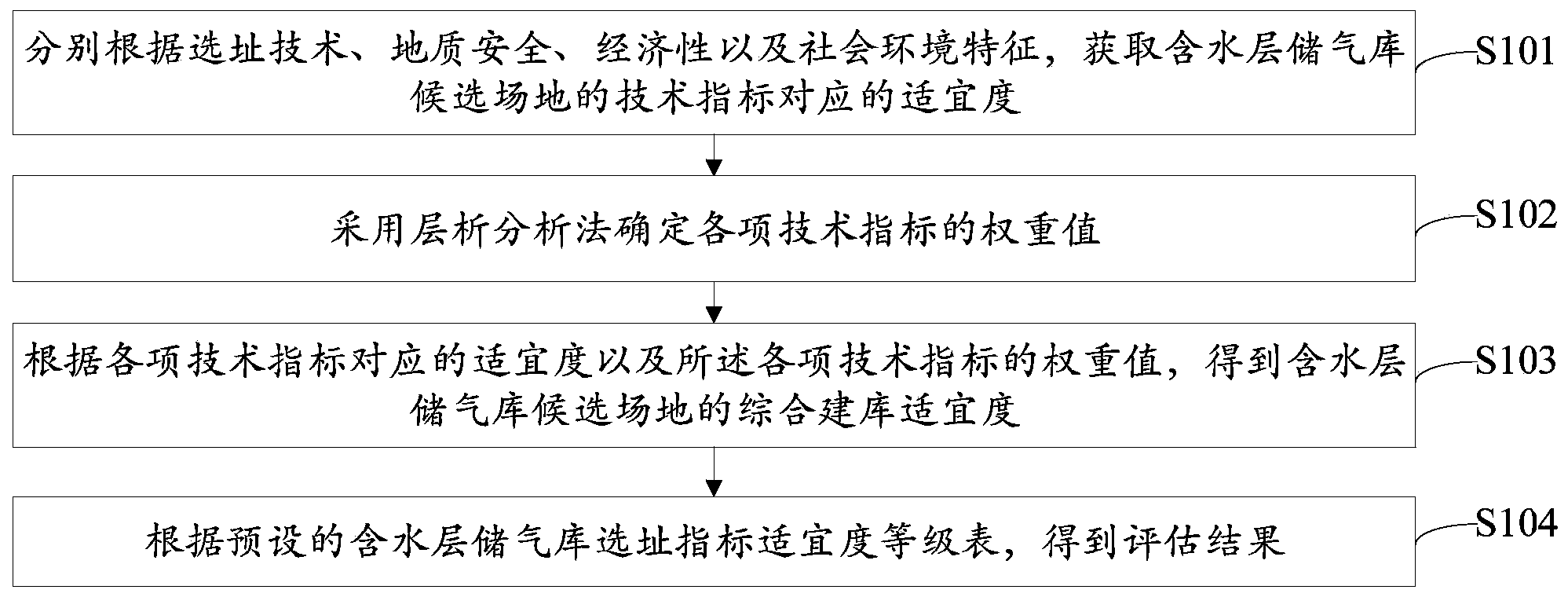

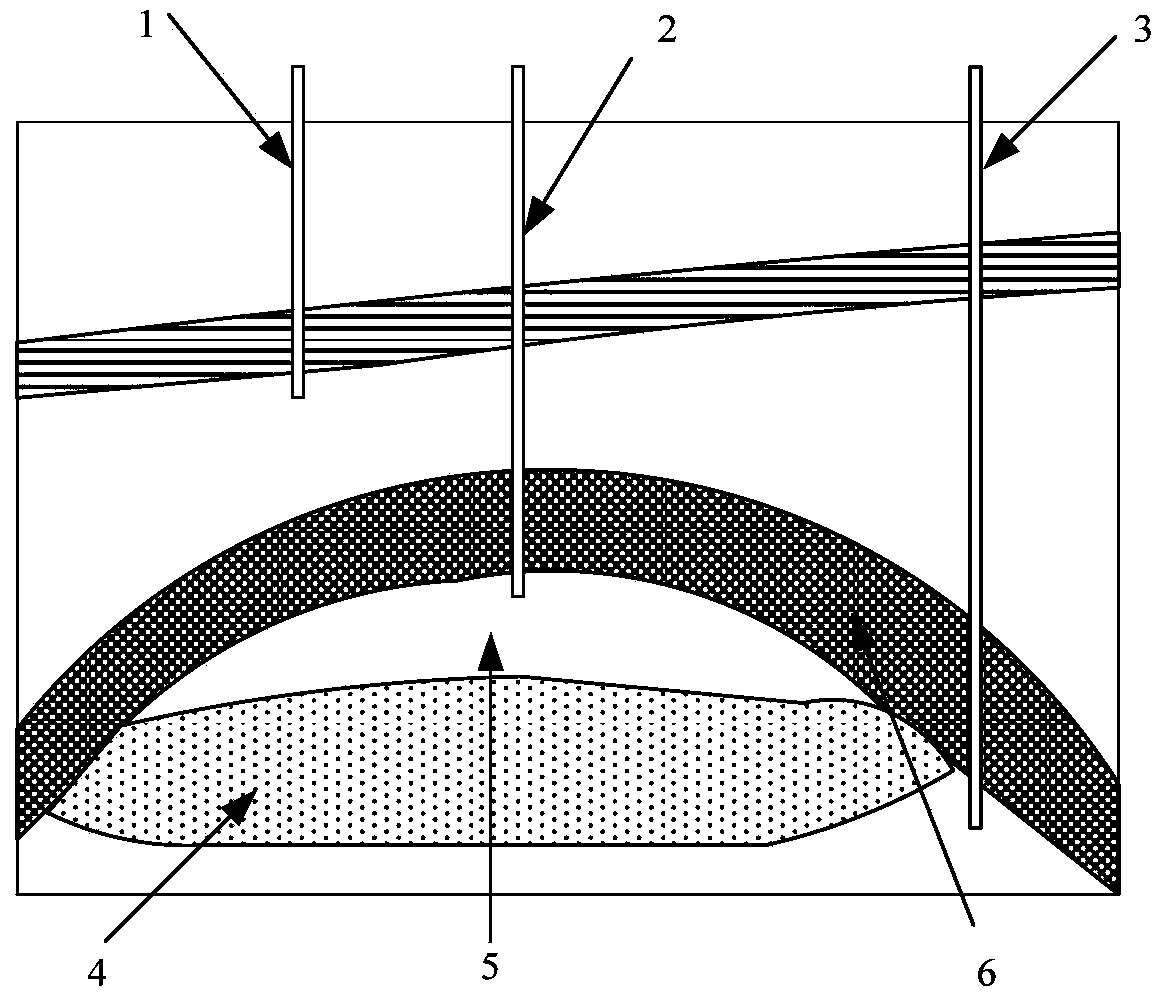

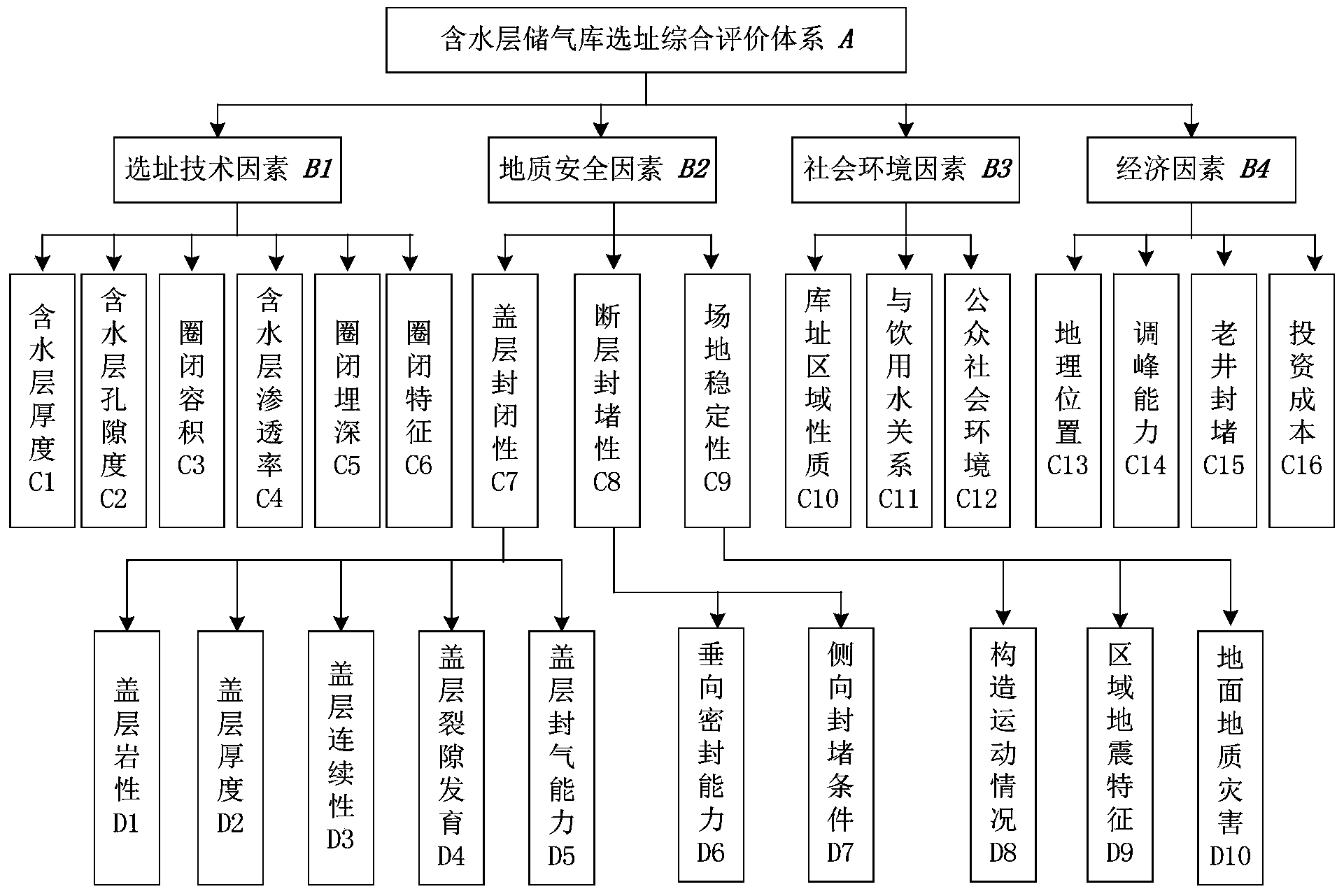

Site selection assessment method for water-bearing stratum underground gas storage

InactiveCN104240153ASite selection evaluation is scientific and effectiveObvious measurabilityData processing applicationsSite selectionComputer science

The invention discloses a site selection assessment method for a water-bearing stratum underground gas storage and belongs to the technical field of natural gas resource exploration and development. The method comprises the steps that suitability degrees corresponding to technical indexes of candidate sites of the water-bearing stratum gas storage are obtained according to the site selection technology, the geology safety, the economy and the social environment characteristic; an analytic hierarchy process is adopted for determining weight values of all the technical indexes; according to the suitability degrees corresponding to all the technical indexes and the weight values of all the technical indexes, the comprehensive storage construction suitability degree of each candidate site of the water-bearing stratum gas storage is obtained; the assessment result is obtained according to a preset classification list of the suitability degrees of the site selection indexes of the water-bearing stratum gas storage. According to the method, the technical principle, the determining method and steps of the site selection of the water-bearing stratum underground gas storage are defined, the measurability is high, and the scientific and reasonable technical method is provided for exploration and construction of the water-bearing stratum gas storage.

Owner:PETROCHINA CO LTD

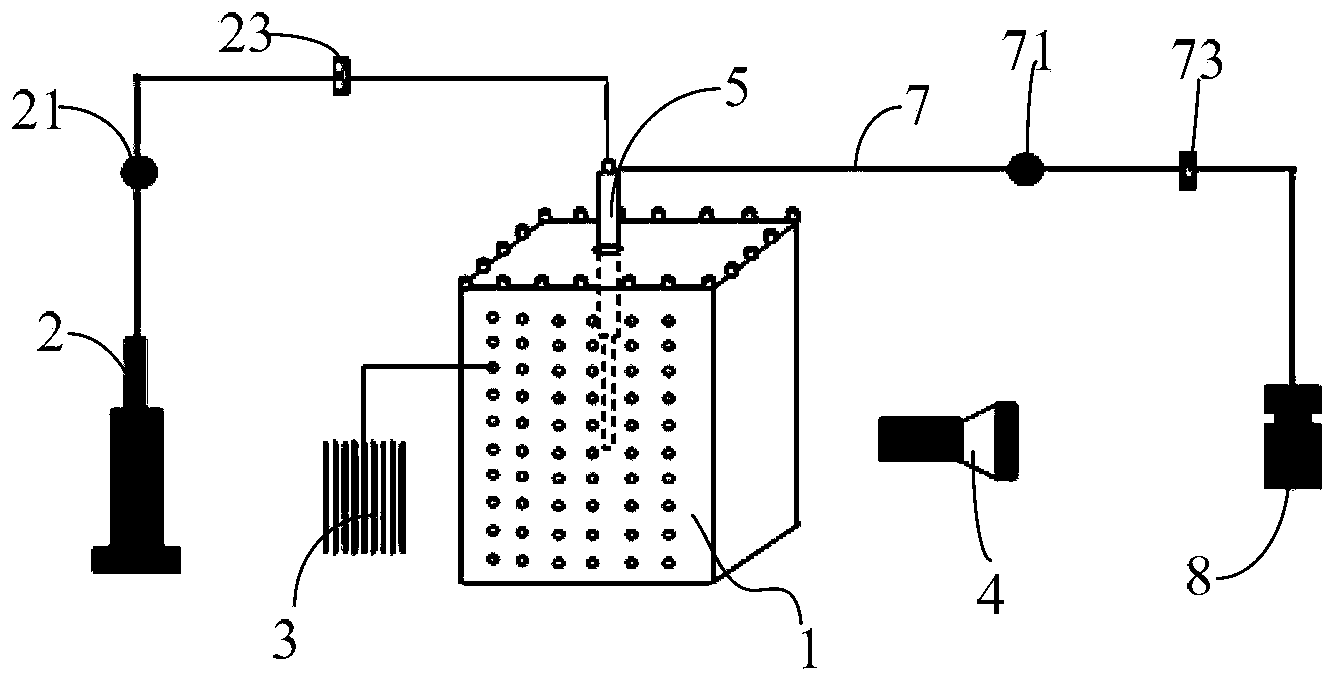

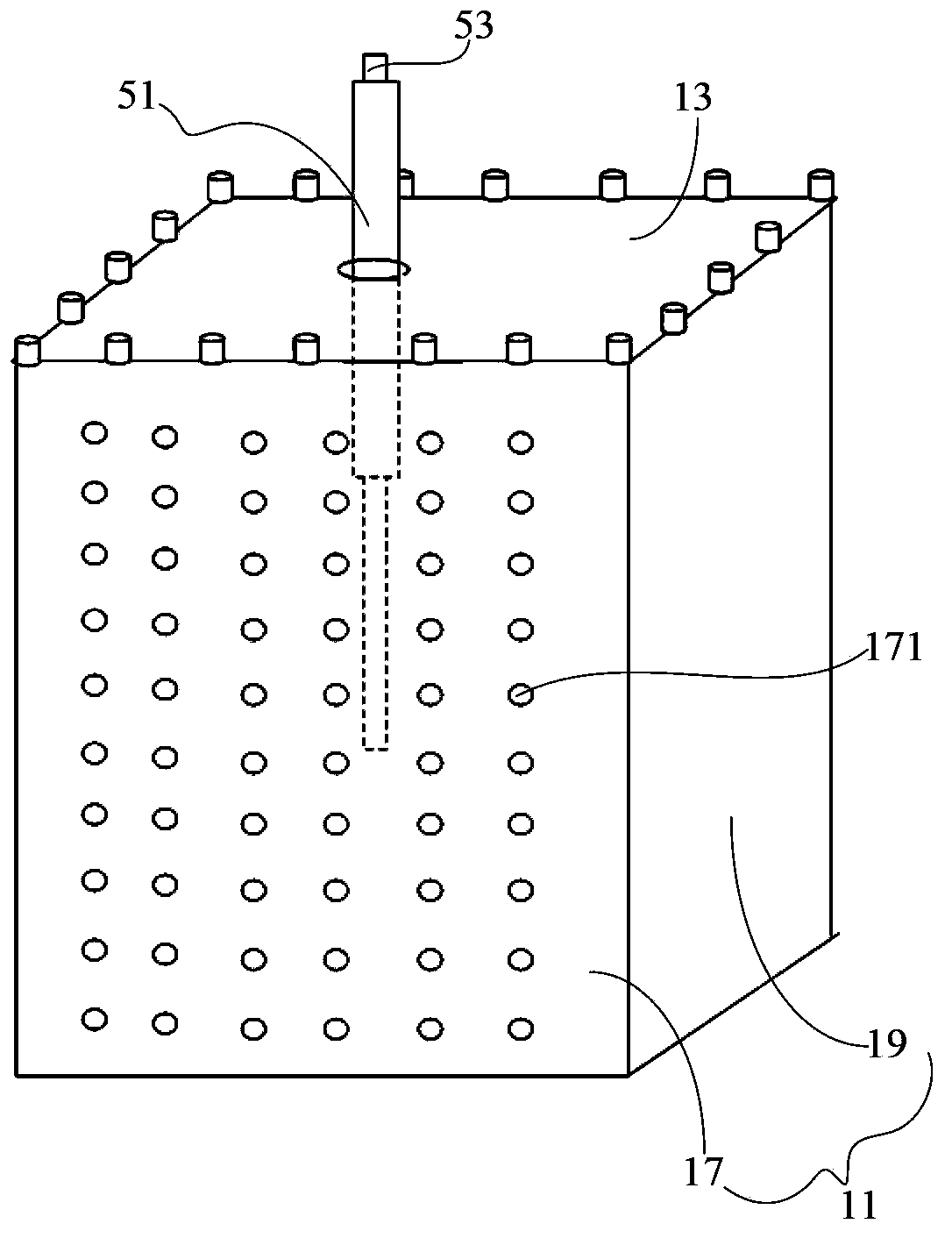

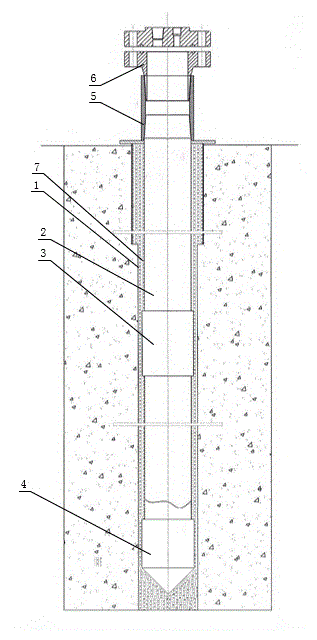

Physical simulation apparatus and method of convection and diffusion of salt-cavern gas storage cavity

The invention, which belongs to the technical field of establishment of an underground salt cavern gas storage, discloses a physical simulation apparatus and method of convection and diffusion of a salt-cavern gas storage cavity. The physical simulation apparatus comprises a simulation box, a displacement pump, a discharge pipe, a conductivity meter, a shooting device opposite to the simulation box, a cavity construction tubular column and a computer. The displacement pump and the discharge pipe are connected to the cavity construction tubular column; a first flowmeter is connected between the displacement pump and the simulation box; a second flowmeter is also arranged at the discharge pipe; and the shooting device, the first flowmeter, and the second flowmeter are connected to the computer by an operable way. According to the invention, simulation of various working conditions is carried out in the simulation box; fresh water is injected into the displacement pump and the discharge pipe discharges brine to make convection and diffusion phenomena, thereby reflecting the working condition and environment of the cavity construction process of the salt cavern gas storage actually. Therefore, the method and process parameters that are obtained based on the simulation apparatus and method and are used for accelerating a rock salt cavity construction speed become true and accurate, thereby improving the cavity construction speed and the cavity shape controlling beneficially.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

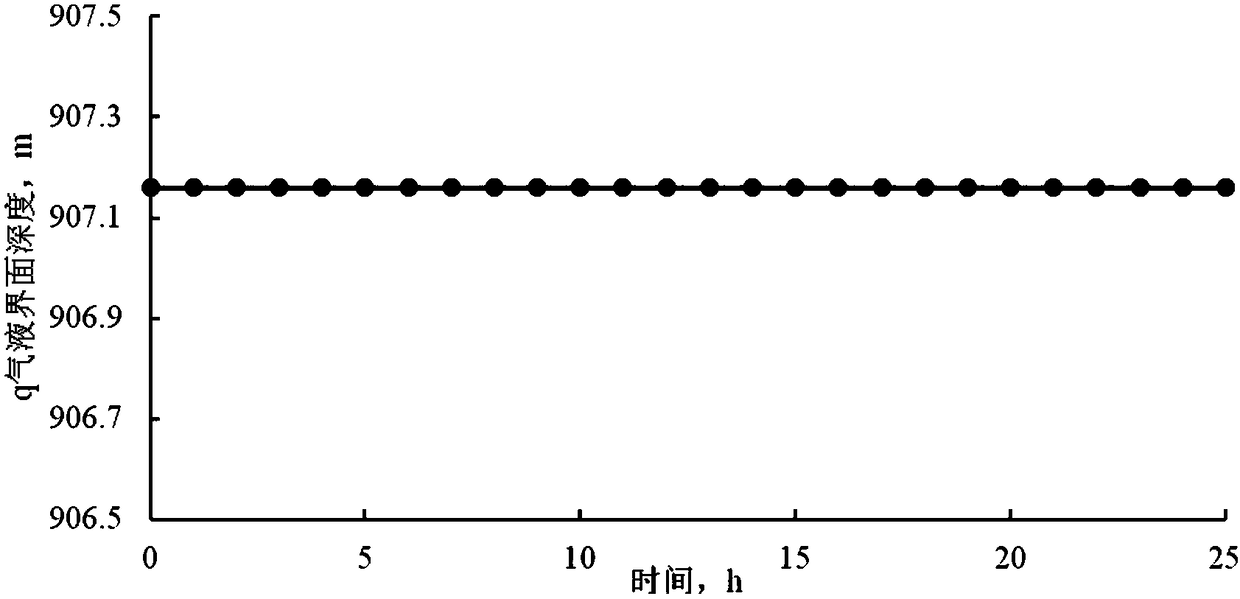

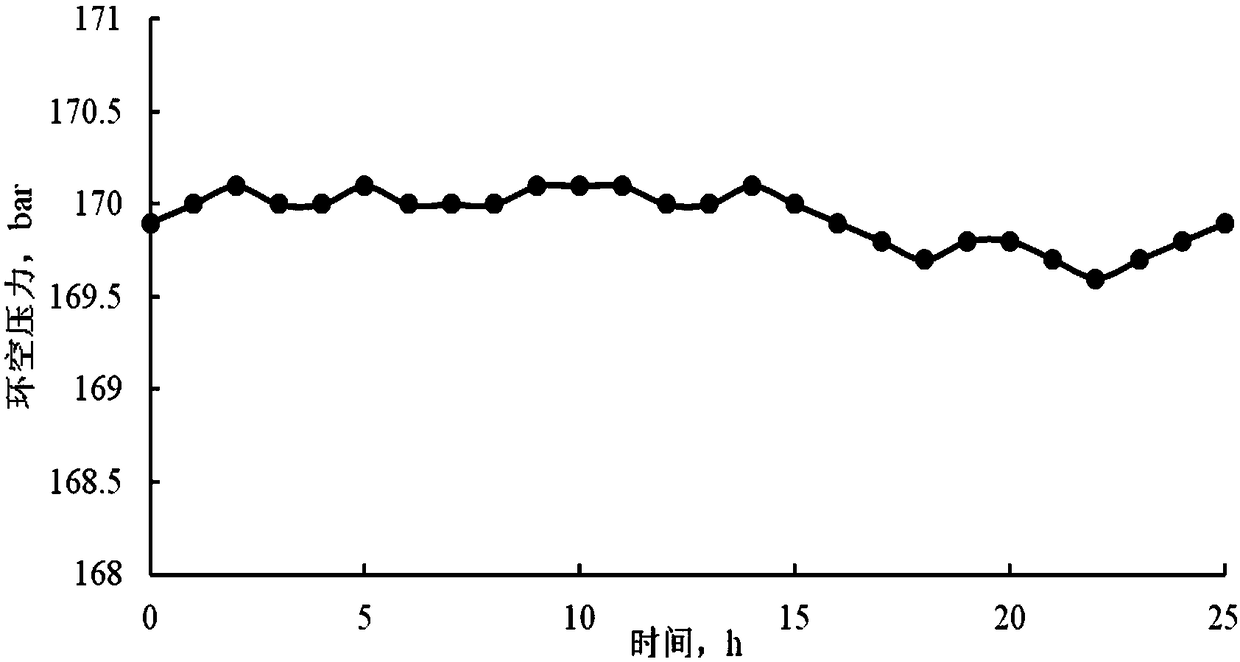

Method for detecting setting effect of packer in salt-cavern gas storage

ActiveCN108225687AComprehensive testing factorsLow priceMeasurement of fluid loss/gain rateNitrogenNitrogen gas

The invention relates to a method for detecting a setting effect of a packer in a salt-cavern gas storage. The method comprises the following steps: 1) washing a well after tripping in an injection-production casing; 2) injecting nitrogen into an annulus between the injection-production casing and a production casing, pressurizing brine in the annulus to below a packer setting position; 3) after setting the packer, continuing to inject nitrogen into the annulus to pressurize so that an annulus pressure of the packer at least is 1.1 times greater than an upper limit pressure of the salt-caverngas storage; 4) tripping in a gas-liquid interface inspection device in the injection-production casing, and detecting a gas-liquid interface below the packer between the injection-production casing and the production casing; 5) detecting and recording the depth of the gas-liquid interface, the wellhead pressure of the injection-production casing and the annulus pressure; and 6) judging the setting effect of the packer according to change situations of the gas-liquid interface below the packer, the wellhead pressure of the injection-production casing and the annulus wellhead pressure. The method is strong in practicability, simple to operate, high in airtightness detection precision, and helpful for effectively verifying the setting effect of the packer, so as to prolong the life of the salt-cavern underground gas storage and ensure safe and effective operation of the same.

Owner:CHINASALT JINTAN

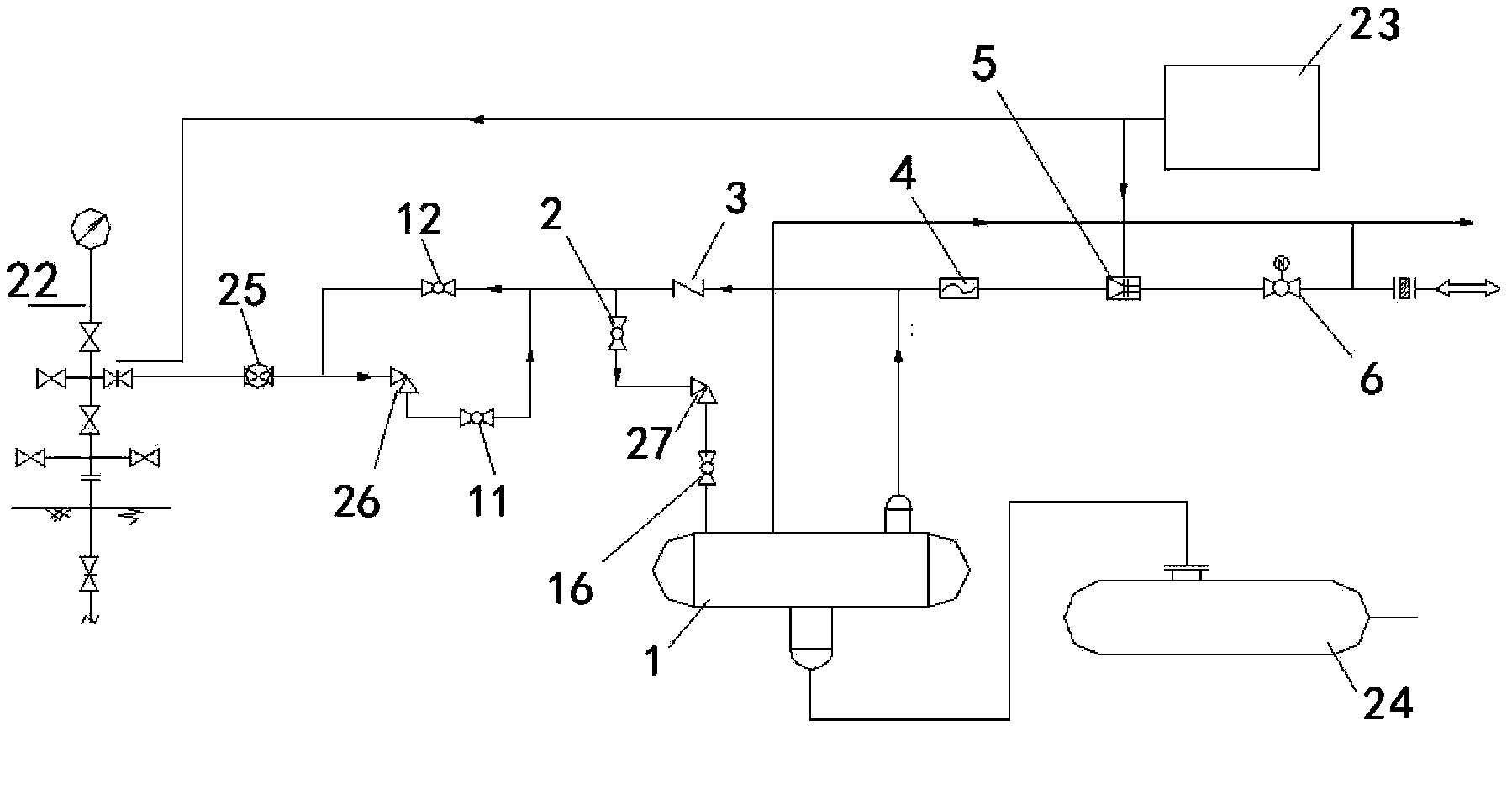

Underground gas storage reservoir simulating experimental device and experimental method

InactiveCN105784939AIntuitive observation of seepage phenomenonObserve seepage phenomenonAnalysing gaseous mixturesDiffusionExperimental methods

The invention discloses an underground gas storage reservoir simulating experimental device and an experimental method, aiming to solve the technical problem that a traditional gas storage reservoir simulating experimental device is incapable of well analyzing running and gas mixing mechanisms of a gas storage reservoir. The underground gas storage reservoir simulating experimental device comprises a gas container, a gas booster pump, a visualized sandstone pore model and a separator, wherein the gas container is connected with the gas booster pump through a pipeline, the visualized sandstone pore model is arranged in a calorstat and is connected with the gas booster pump through a pipeline, a camera is arranged above the visualized sandstone pore model, and the separator is connected with the visualized sandstone pore model through a pipeline. The underground gas storage reservoir simulating experimental device combining data monitoring results of the camera and a computer is capable of observing related percolation phenomena visually, analyzing displacement and mixing mechanisms during all processes effectively and computing fractal dimensions and diffusion coefficients of pore media accurately by simulating gas storage reservoir building, injection production and gas mixing processes.

Owner:SOUTHWEST PETROLEUM UNIV

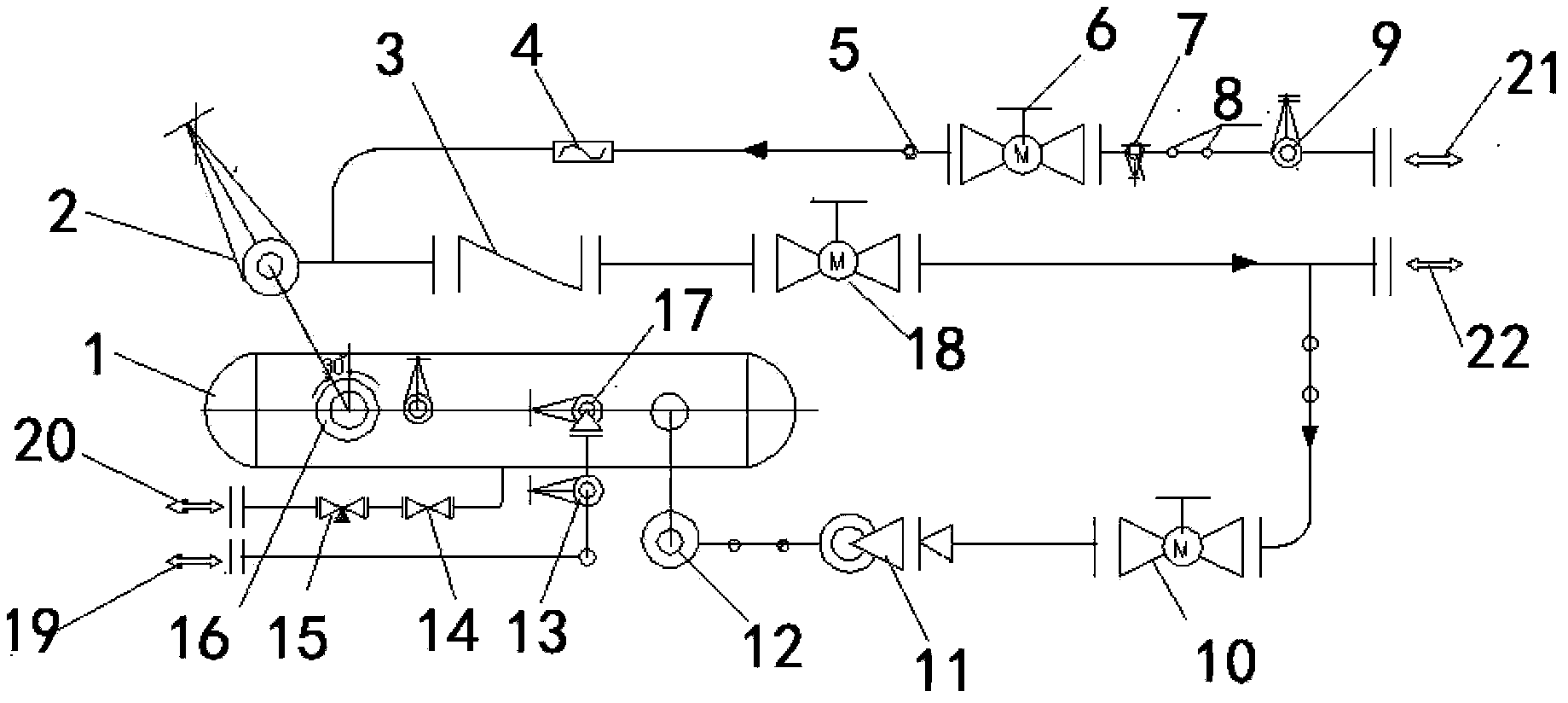

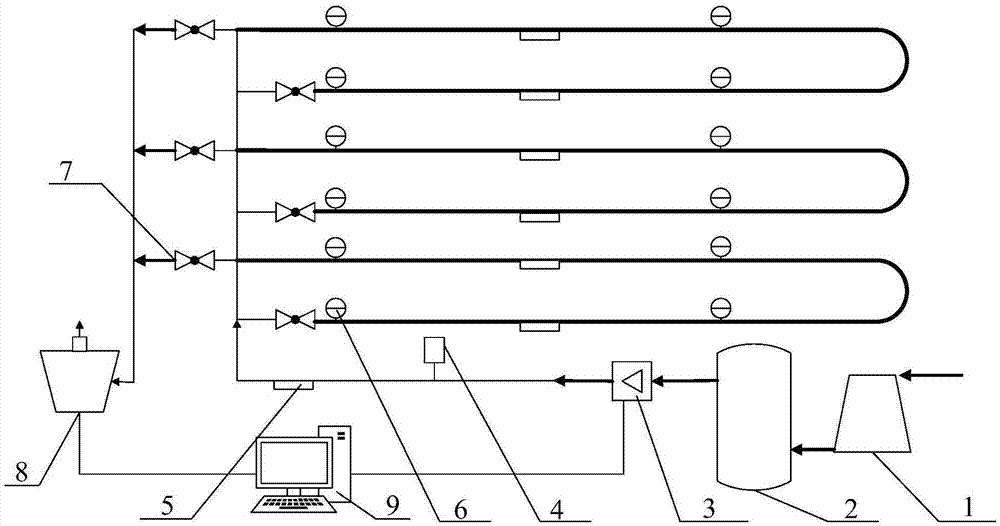

Gathering and transportation skid-mounted device for gas injection and production of salt cavern gas storage and process method

The invention discloses a gathering and transportation skid-mounted device for gas injection and production of a salt cavern gas storage and a process method and belongs to the technical field of gas injection and production in a well field. A horizontal gravity type separator is connected with electric ball valves, a plug valve, a manual ball valve and a safety valve; the other end of a first electric ball valve is connected with an angle throttle valve; the other end of the angle throttle valve is connected with a second electric ball valve, and the other end of the second electric ball valve is connected with a wellhead; the other end of the manual ball valve is connected with an axial-flow check valve and an ultrasonic flowmeter, the other end of the axial-flow check valve is connected with a third electric ball valve, and the other end of the third electric ball valve is connected with the wellhead; an emptying valve is connected with an instrument joint and a fourth electric ball valve, the other end of the fourth electric ball valve is connected with a methanol injection port, and the other end of the methanol injection port is connected with the other end of the ultrasonic flowmeter; the other end of the plug valve is connected with a normal pressure blowdown drum; a methanol dosing device is connected with the methanol injection port. According to the gathering and transportation skid-mounted device and the process method, the injection and production efficiency of the gas storage is improved and the safety and the reliability of equipment in the gas storage are improved.

Owner:PETROCHINA CO LTD

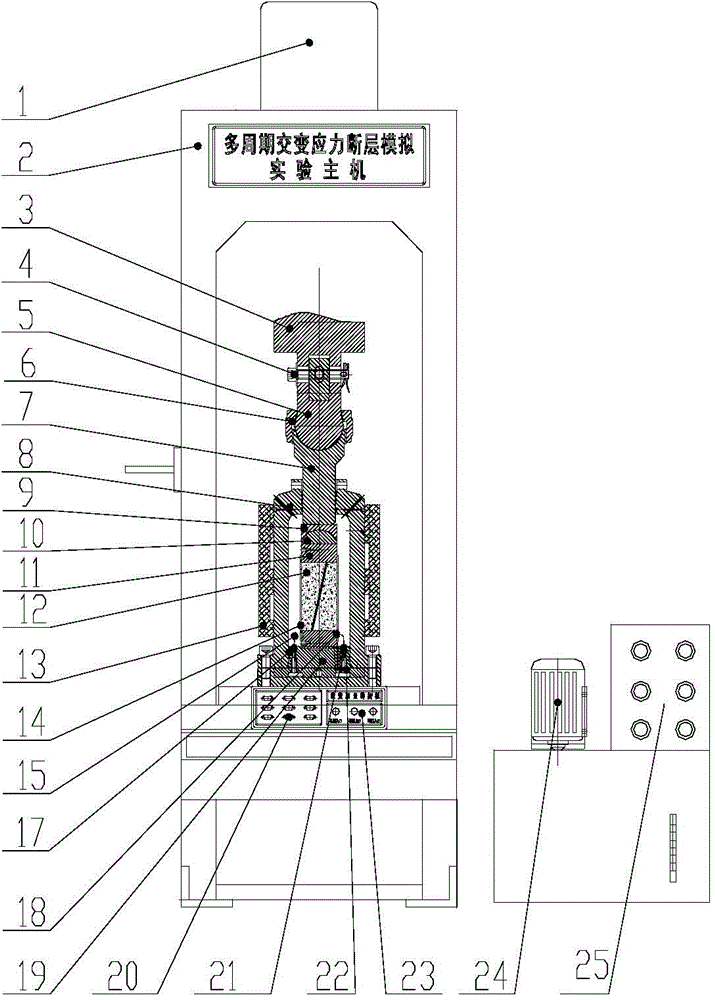

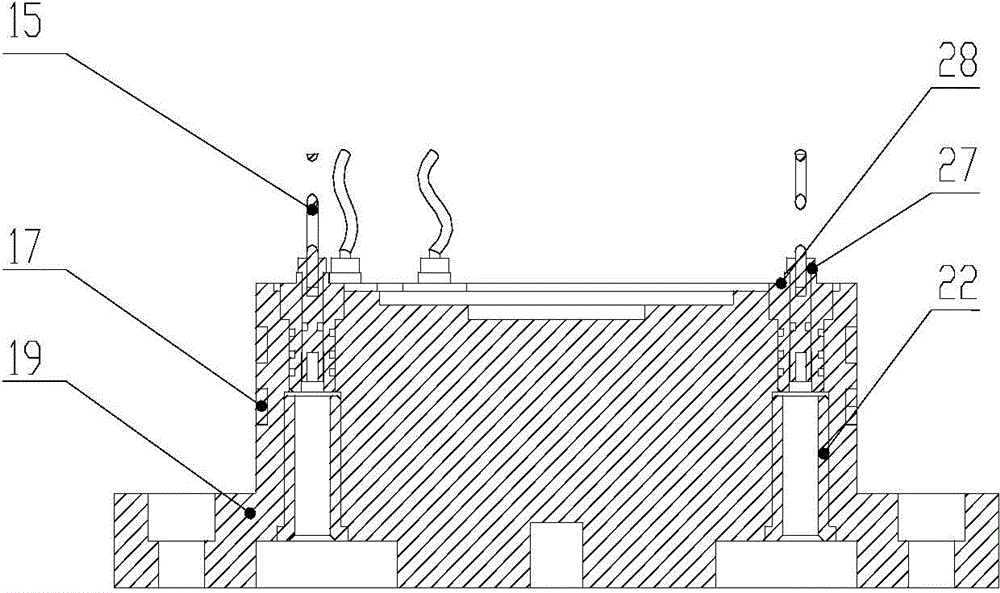

Simulation experiment device for fault with multi-period alternating stress

InactiveCN104792970APredict tightnessWithdrawing sample devicesPreparing sample for investigationStress conditionsData acquisition

The invention relates to a simulation experiment device for a fault with multi-period alternating stress, and mainly solves a problem of low possibility of judging fault sealing property of an existing underground gas storage. The simulation experiment device is characterized by comprising a core preparation system, a vacuumizing assembly, a host model system, a data collection and analysis system and a pressure injection system. The device can not only test sealing property parameters of a fault sample of the storage but also realize simulation of a stress state and the like of the sample of the storage under a multi-period alternating stress condition for real-time continuous monitoring, and further can perform comprehensive evaluation on sealing conditions of the fault of the storage under the multi-period alternating stress operation condition in combination with other geological conditions (such as lithologic characters, fault fillers, fault parameters and the like) of the storage.

Owner:LANGFANG BRANCH INST OF RES INST OF GASOLINEEUM EXPLORATION & DEV OF PETROCHINA

Method for manufacturing underground gas storage device for storing special gas

ActiveCN104609088AOvercoming technical difficulties that cannot be applied to storage of said specialty gasesGuaranteed cleaning passivation effectMetallic material coating processesStorage devicesGas passingAlloy

The invention discloses a method for manufacturing an underground gas storage device for storing special gas. The method includes the following steps that S1, materials are selected, and it is guaranteed that material components of a low-alloy structure steel assembly of the underground gas storage device meet the requirement; S2, degreasing and passivating are conducted on the underground gas storage device; S3, examination and acceptance inspection are conducted; S4, the low-alloy structure steel assembly of the underground gas storage device is assembled, a pipe opening is sealed, the sealed pipe is placed downwards into an uncased hole well, well cementation is conducted, and a well opening device is mounted. The method has the advantages that special gas such as hydrogen, oxygen, helium or industrial exhaust gas are stored through an underground gas storage well, a prepared acid cleaning agent, a degreasing agent, passivator and a circulating degreasing agent are adopted, the cleaning and passivation effects of the underground gas storage device are guaranteed, and the applicability and stability of the device for storing the special gas are guaranteed.

Owner:自贡华气科技股份有限公司

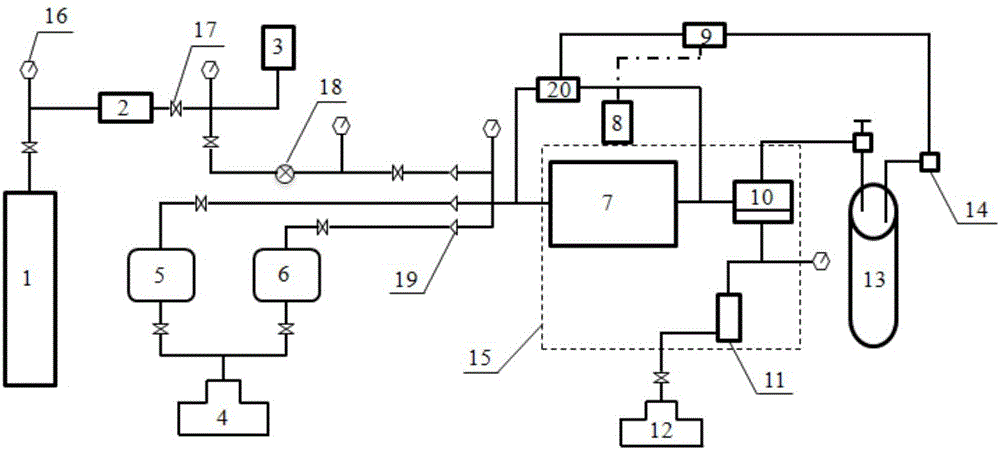

Device for measuring frictional resistance coefficient of gas in underground gas storage well and monitoring vibration of tubular column

The invention relates to the field of development of horizontal wells of underground gas storage wells, and particularly relates to a device for measuring the frictional resistance coefficient of gas in the underground gas storage well and monitoring the vibration of a tubular column. A system comprises four parts of a gas control unit, a pipeline testing unit, a vibration device unit and an acquisition control unit, wherein the gas control unit comprises a screw compressor, a buffer tank and a gas mass flow controller, the buffer tank is connected between the screw compressor and the gas mass flow controller; the pipeline testing unit comprises a simulating pipeline and a sensor; and the vibration device unit comprises a vibration sensor group and an upper computer, and a vibration sensor comprises an acceleration sensor. The acquisition control unit is realized by connecting a computer with a test device in series. The frictional resistance coefficient of the gas in the tubular column of the underground gas storage well is measured, the vibration performances of the tubular column under the working conditions of injection and extraction are monitored, and the structure integrity of the tubular column of the underground gas storage well and the safety of the whole well are guaranteed.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Annular safety and flow control system for underground gas storage

ActiveUS20060204337A1Easy constructionIncrease chanceMining devicesFluid removalControl systemEngineering

A gas storage well is provided with a tubing string that is disposed within a wellbore communicating an underground storage cavern with the surface. A surface controlled subsurface safety and flow control system is provided within the wellbore so that all flow into or out of the well can be shut down rapidly in the event of an emergency. The safety and flow control system features a dual opening-style packer element that provides an annulus seal between the surrounding casing and the tubing string and between the casing and a pup joint that is located within the annulus. Both the tubing string and the pup joint contain surface controlled subsurface safety valves that are capable of quickly shutting off flow through both the flowbore and the annulus. Each valve can be opened or closed independently of the other.

Owner:BAKER HUGHES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com