Softrock-like material and preparation method

A technology of similar materials and soft rocks, applied in the field of model test similar materials, can solve the problems of low bulk density, poor plastic deformation ability of materials, low elastic strength ratio, etc., and achieve strong plastic deformation ability, good material uniformity, and stable mechanical properties reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

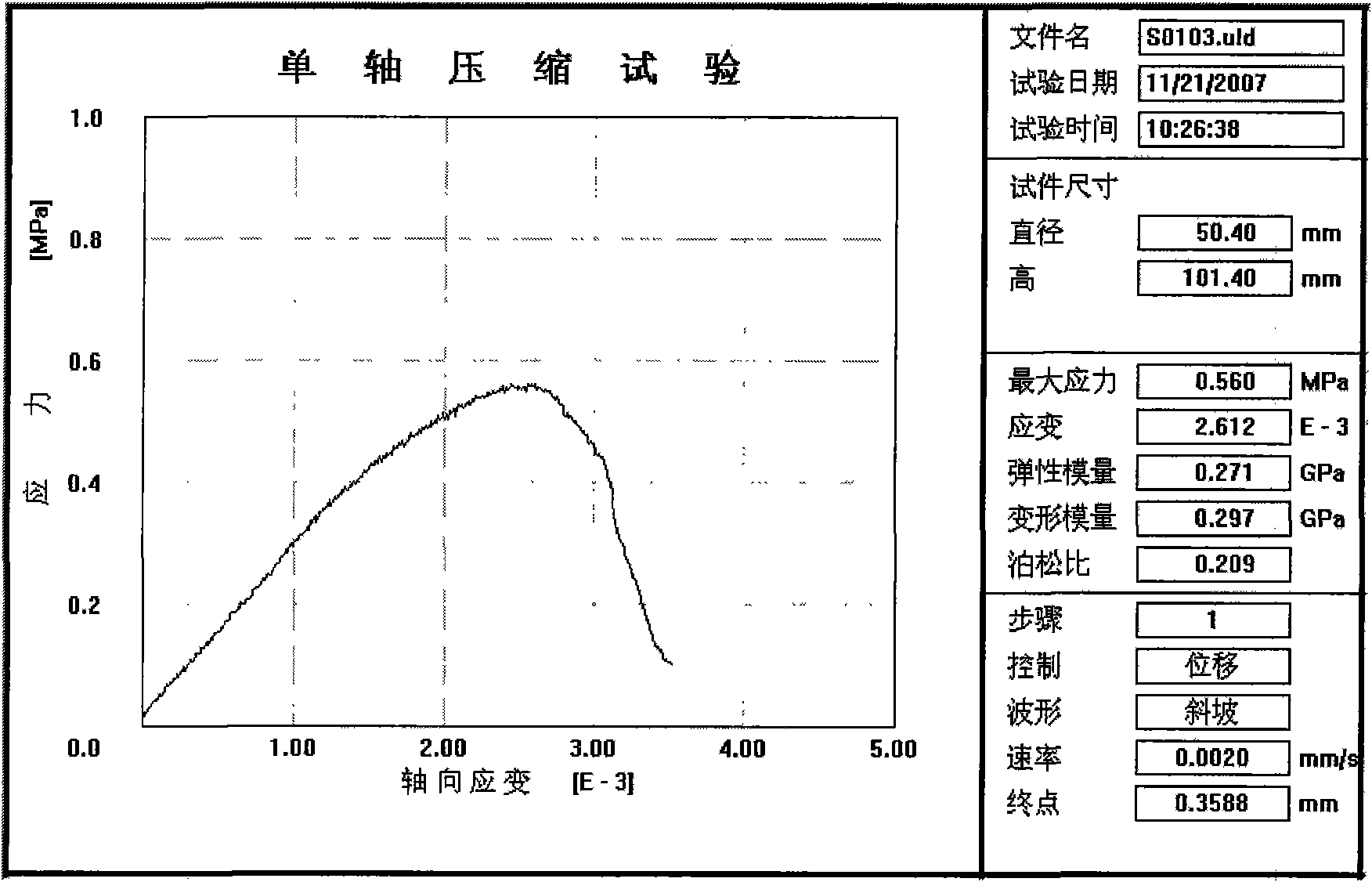

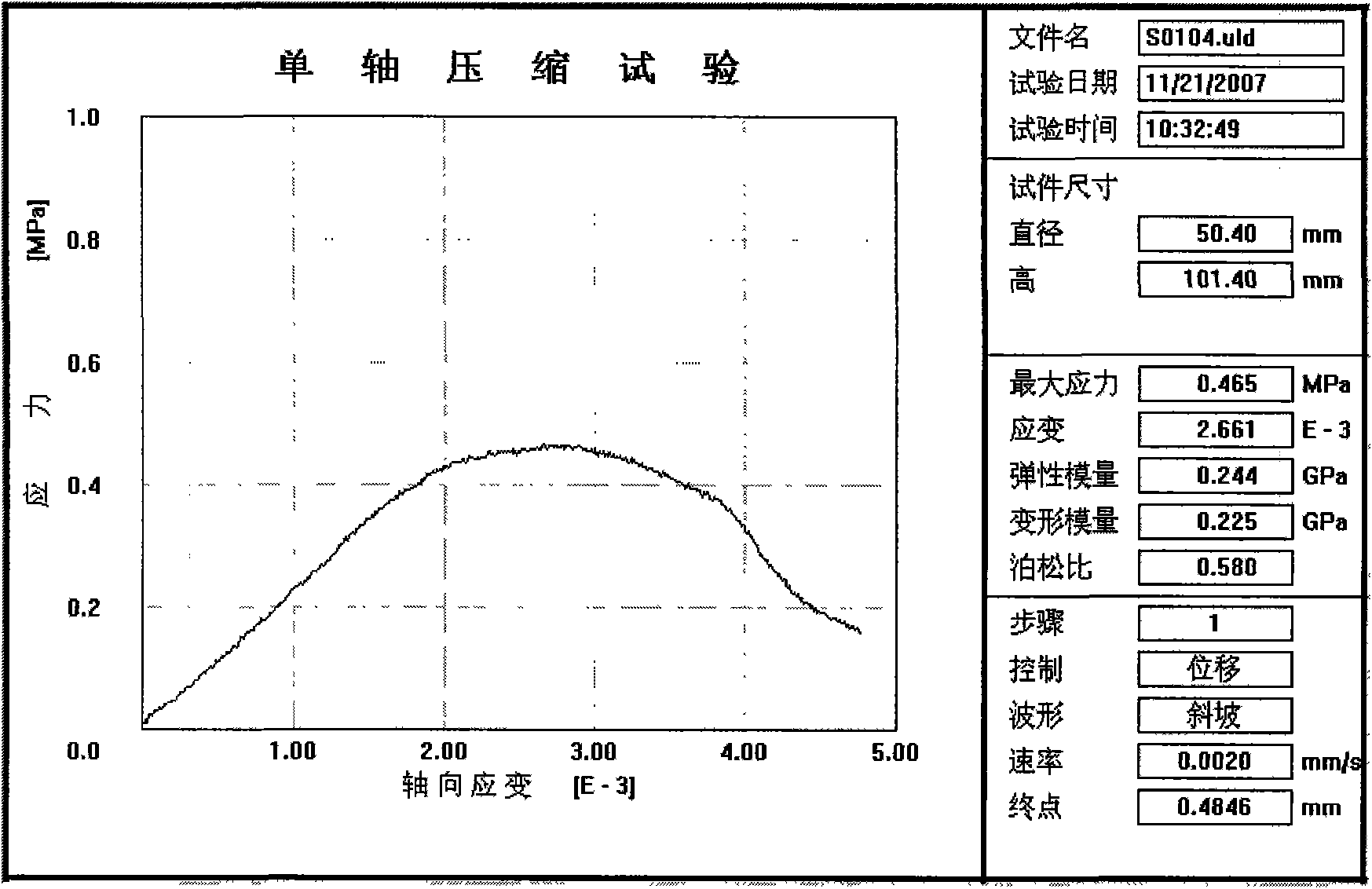

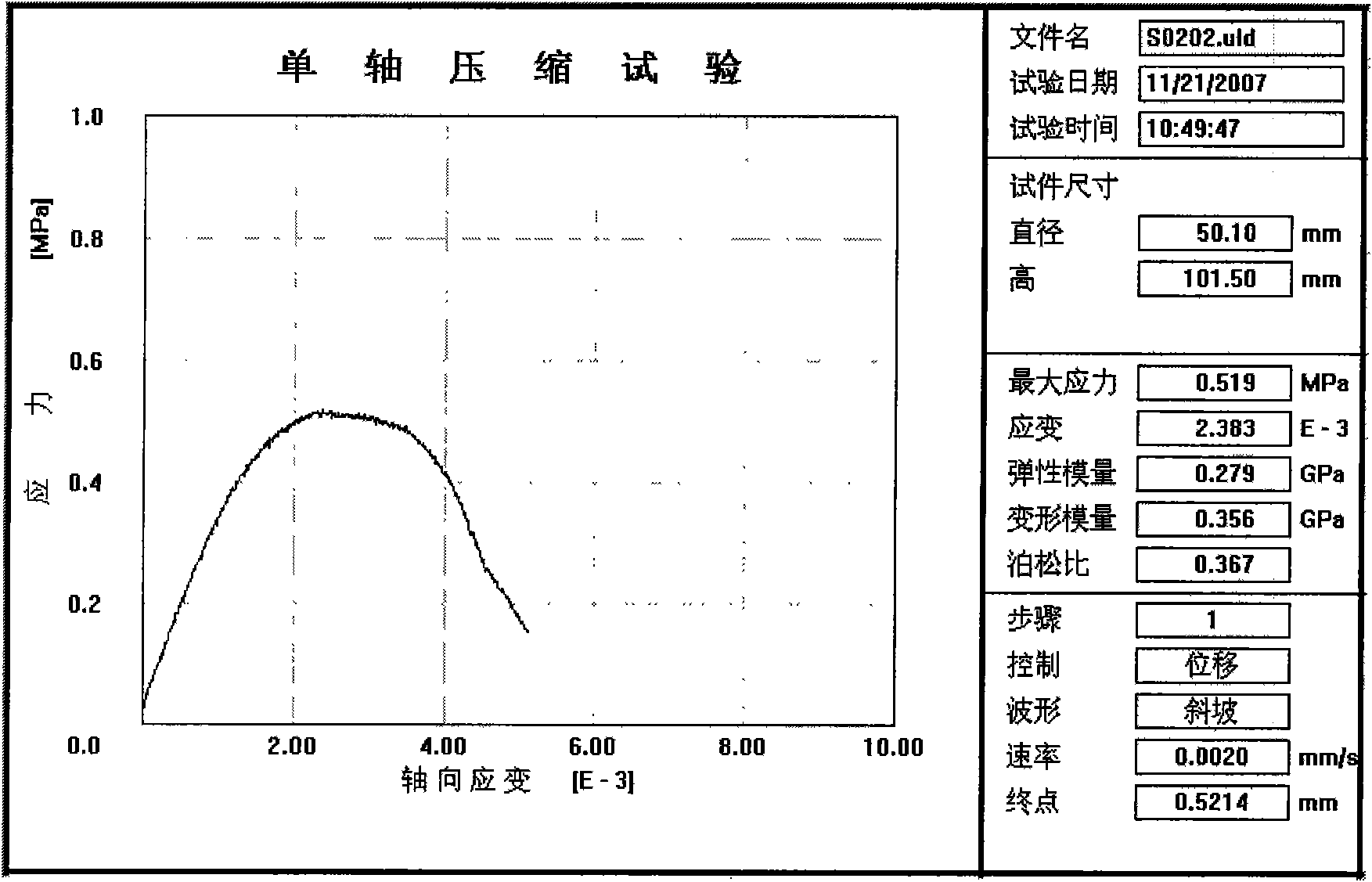

Image

Examples

Embodiment 1

[0064] A kind of soft rock similar material, it is made up of following raw materials in parts by weight:

[0065] Raw material parts by weight

[0066] (1) Filling material 100 parts

[0067] (2) 20 parts of aggregate

[0068] (3) 6.6 parts of cementing material

[0069] (4) 6.6 parts of additives

[0070] (5) Water: 19.4 parts

[0071] Selection of raw materials: The barite powder is selected from the common barite powder produced by Wuhan Zhongyuan Jinbei Industry and Trade Co., Ltd., and its quality indicators are:

[0072] Barium sulfate content: ≥90%

[0073] Fineness: 200 mesh -325 mesh

[0074] Water soluble matter: ≤0.1%

[0075] Clay effect Pa·s: ≤0.125

[0076] The quartz sand is selected from the commercially available 20-mesh white quartz sand produced by Wuhan New Quartz Sand Factory.

[0077] The gypsum is selected from the plaster of paris produced by the Hubei Yingcheng Gypsum Factory on the market, and its quality index is:

[0078] Whiteness: ≥84 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com