Device for detecting metal body of underground gas storage well

A detection device and technology for gas storage wells, which are applied in the field of fatigue crack detection and corrosion, can solve the problems of metal wellbore corrosion and fatigue crack detection, and achieve high reliability and strong field adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

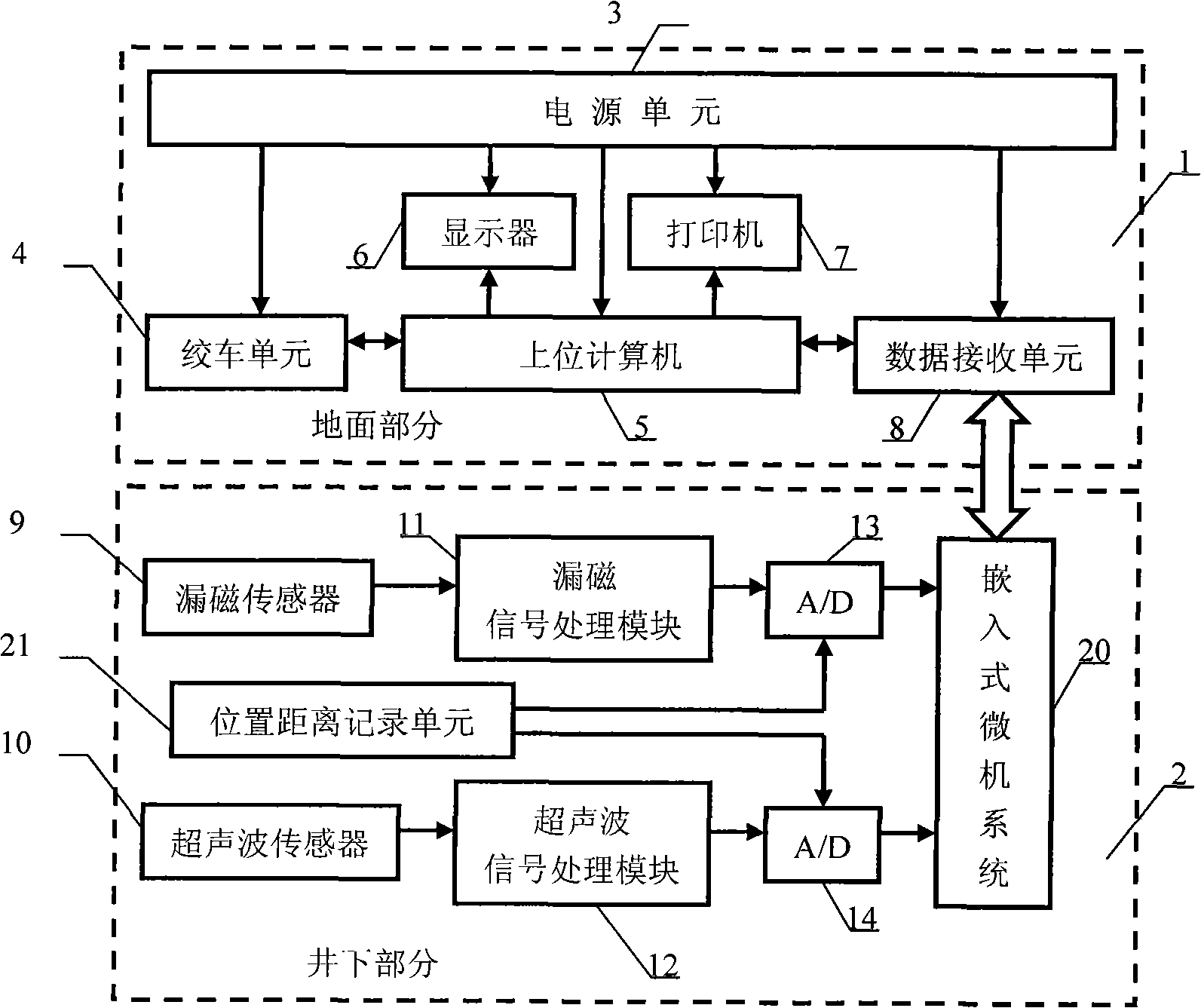

[0011] Such as figure 1 As shown, the present invention includes a ground processing part 1 and a downhole detection part 2, and the connection of power supply and signal is realized through an armored cable between the two. Wherein the downhole detection part 2 includes a magnetic flux leakage sensor 9, a magnetic flux leakage signal processing module 11, a first A / D conversion unit 13, an ultrasonic sensor 10, an ultrasonic signal processing module 12, a second A / D conversion unit 14, and an embedded microcomputer system 20 and a position distance recording unit 21. The ground processing part 1 includes a data receiving unit 8 , a winch unit 4 , a host computer 5 , a display 6 , a printer 7 and a power supply unit 3 .

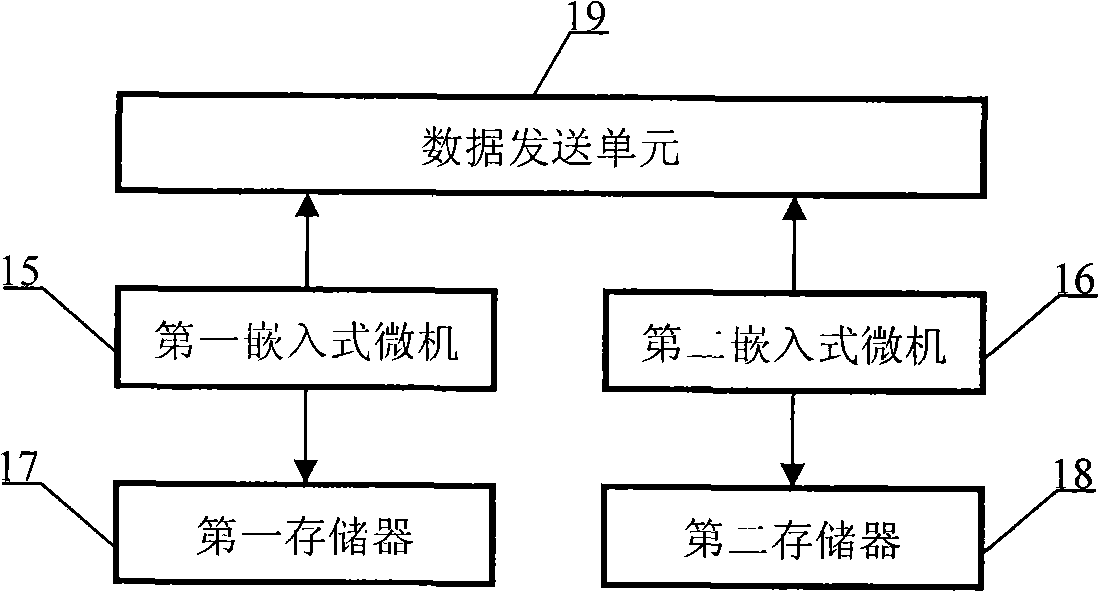

[0012] Such as figure 2 As shown, the embedded microcomputer system 20 includes first and second embedded microcomputers 15 and 16 for data collection and analysis and a data sending unit 19 connected to the first and second embedded microcomputers 15 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com