Construction method for rock salt cavity gas storage house

A construction method and technology of salt rock karst cave, which is applied in the field of rapid dissolution construction and gas storage operation of underground storage in salt rock deposits, can solve the problems of prolonging the cavity building period, high oil-water interface detection cost, and affecting the quality of brine, so as to achieve saving cost, the effect of saving the cost of brine purification treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 2

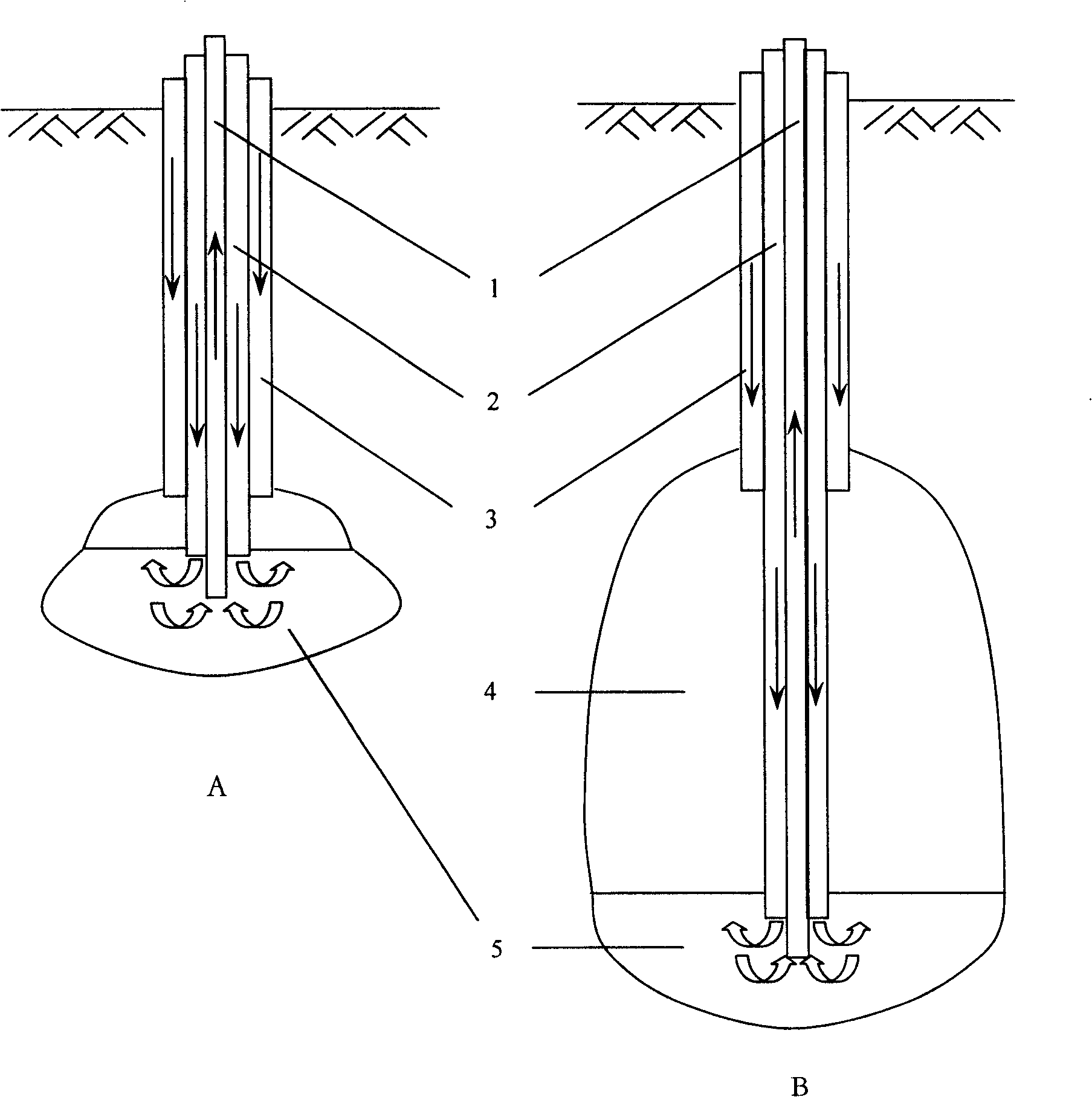

[0035] III. After well cementing, run the water injection pipe 2 and the brine collection pipe 1 into the surface casing 3, the water injection pipe 2 and the brine collection pipe 1 are concentric pipe strings, wherein the outer pipe is the water injection pipe, and the inner pipe is the brine collection pipe;

[0036] VII. When the difference between the thickness of the salt layer and the height of the solution cavity reaches 45m, the injection of fresh water and brine extraction will be stopped, and the downward construction of the gas storage will be completed by gas injection and extraction of brine.

Embodiment approach 3

[0038] VII. When the difference between the thickness of the salt layer and the height of the solution cavity reaches 55m, stop the fresh water injection and brine extraction, and complete the construction of the gas storage by gas injection and extraction of brine, and the rest are the same as in Embodiment 1.

Embodiment approach 4

[0040] VI. When the radial dimension of the dissolution cavity at the level of the lower part of the natural gas 4 reaches 50 meters, lower the water injection pipe 2 and the brine extraction pipe 1, continue to inject the natural gas 4 to the level of the lower port of the water injection pipe 2, repeat steps IV to VI, and the rest are the same Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com