Temperature-resistant, salt-resistant and low-tension foam flooding agent and preparation method thereof

A foam flooding, temperature-resistant and salt-resistant technology, applied in chemical instruments and methods, earthwork drilling and production, wellbore/well components, etc., can solve the problems of different structure-activity relationships and mechanisms, lack of foam systems, foam stability and oil-water The problem of difficult interface activity, etc., to achieve the effect of high interface activity, strong interface activity, and excellent foam stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A temperature-resistant salt-resistant low-tension foam oil displacement agent, the composition of raw materials by mass is as follows:

[0032] Coconut oleic acid diethanolamide 42 parts, sulfobetaine 28 parts, water 130 parts. Wherein, coconut oleic acid diethanolamide is prepared by the following method:

[0033] In a 1000L synthetic reaction kettle, add 366 kilograms of coconut oil, add 234 kilograms of diethanolamine while stirring in the above-mentioned synthetic reaction kettle, keep the temperature at 80°C, stir 15g of potassium hydroxide, heat up to 120°C for 5 hours, Get coconut oleic acid diethanolamide.

[0034] In parts by mass, take 42 parts of the above-mentioned coconut oleic acid diethanolamide, add 28 parts of sulfobetaine, add 50 parts of water, stir at 50°C until completely dissolved, then add 80 parts of water, and stir evenly to obtain a low-tension foam The oil displacing agent is labeled LIF-1.

Embodiment 2

[0036] A temperature-resistant salt-resistant low-tension foam oil displacement agent, the composition of raw materials by mass is as follows:

[0037] 49 parts of coconut oleic acid diethanolamide, 21 parts of alkyl alcohol polyoxyethylene ether sulfate, 150 parts of water. Wherein, coconut oleic acid diethanolamide is made according to embodiment 1, and alkyl alcohol polyoxyethylene ether sulfate is the product of Taiyuan Fakai Company, and the model is AE3S.

[0038] In parts by mass, take 49 parts of coconut oleic acid diethanolamide, add 21 parts of alkyl alcohol polyoxyethylene ether sulfate, add 50 parts of water, stir at 50°C until completely dissolved, then add 100 parts of water, stir evenly, That is, the low-tension foam oil displacement agent is obtained, and the label is LIF-2.

Embodiment 3

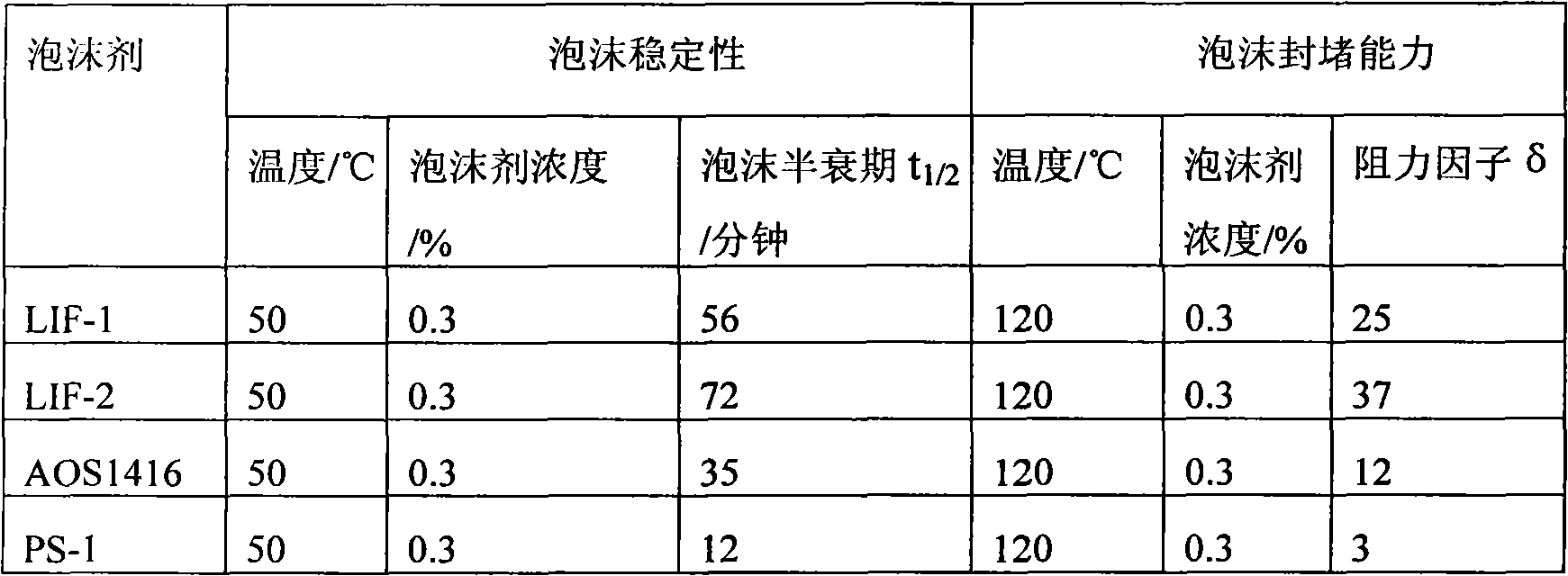

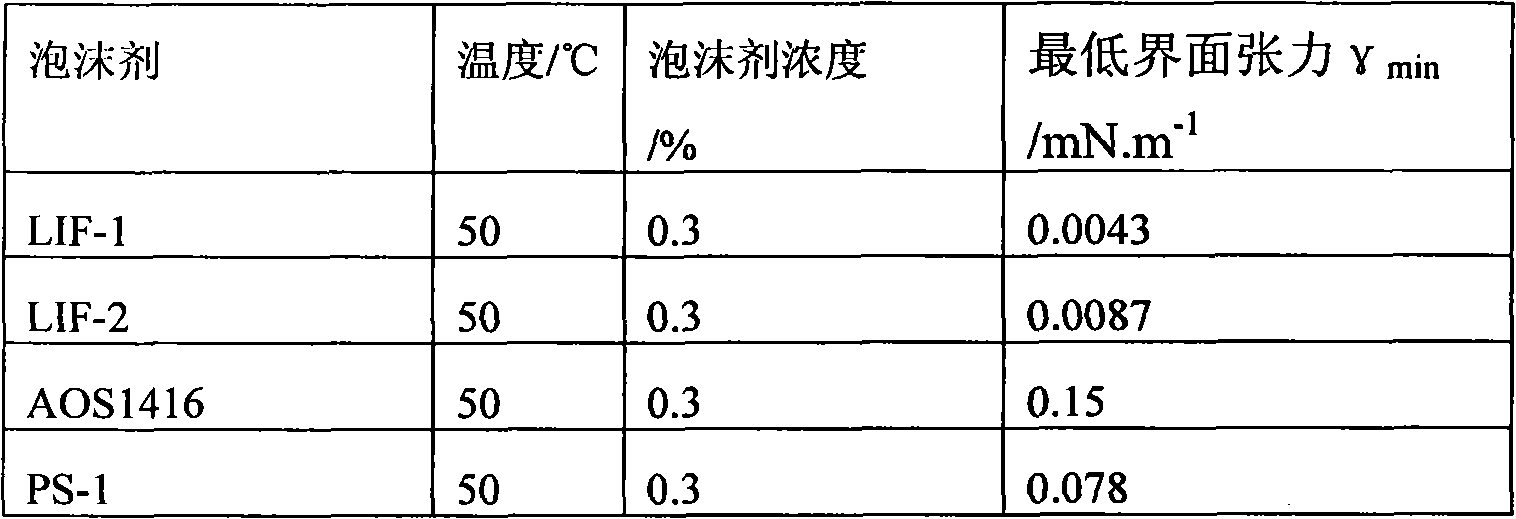

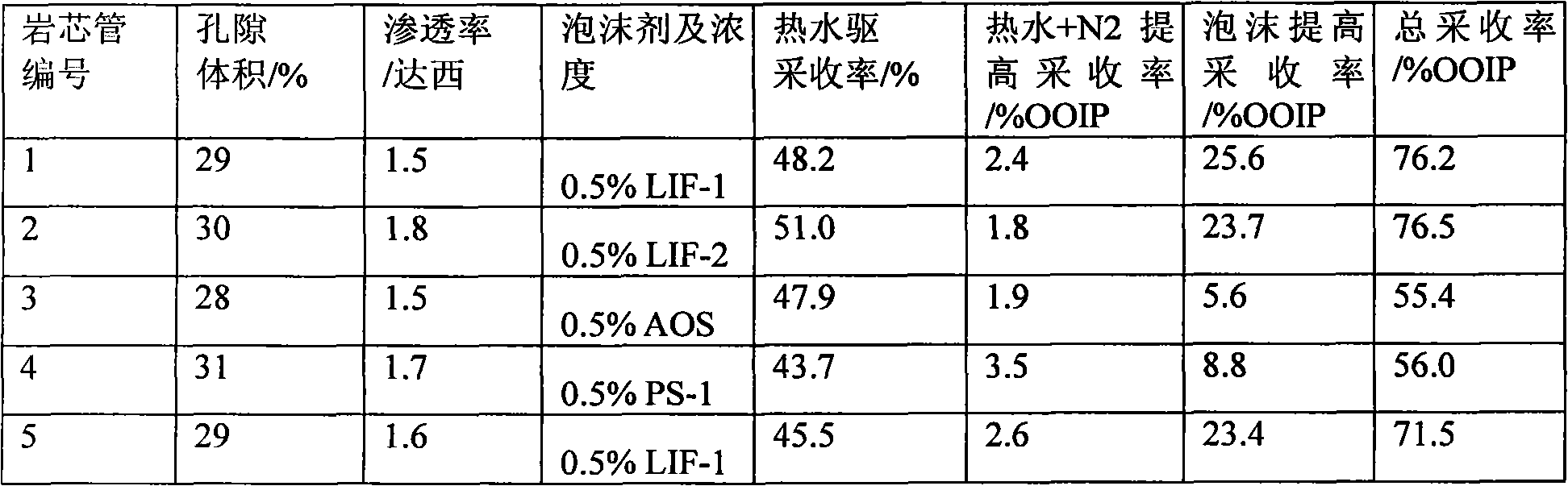

[0039] Example 3: Foam stability and plugging profile control test

[0040] The foam agent is prepared as an aqueous solution with a concentration of 0.3%, and the foam is generated by the air flow method. The temperature of the foam generator is controlled at 50°C. The foam decay curve is obtained by measuring the change of the foam volume with time, and the time when the foam volume decays to half of the initial volume is taken. is the half-life of the foam, marked as t 1 / 2 . Foam stability is directly proportional to half-life.

[0041] Use 80-200 mesh quartz sand to fill a 55cm simulated core tube with a core pore volume of 32% and a permeability of 1.5 Darcy. After being saturated with water, inject aqueous solution and N at speeds of 10ml / min and 160ml / min respectively. 2 , measure the pressure at the inlet and outlet of the core tube, and get the initial pressure difference ΔP 初始 =P 入口 -P 出口 , and then inject 0.3% foaming agent aqueous solution and N at the same ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com