Patents

Literature

74results about How to "Recycling is possible" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

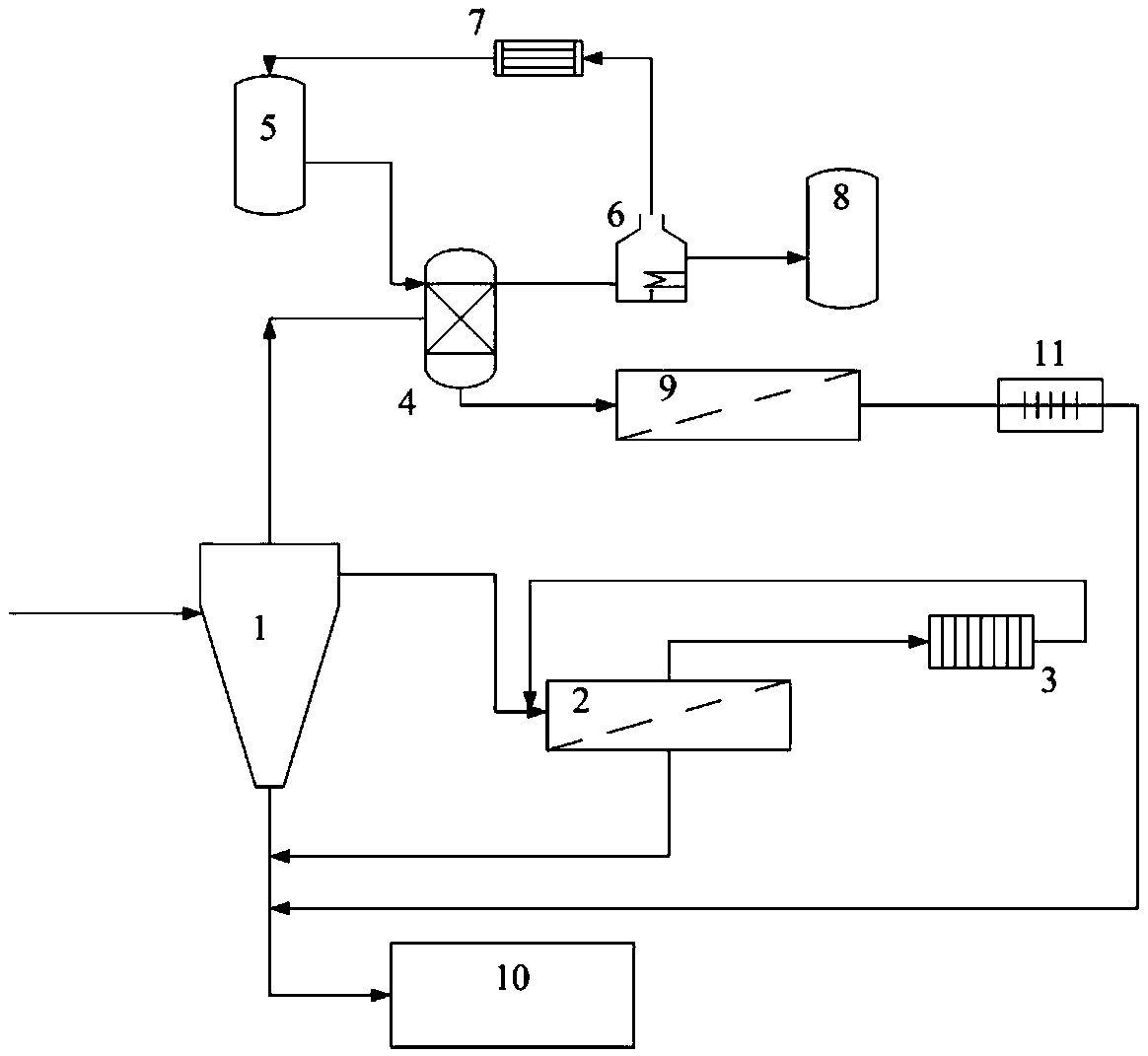

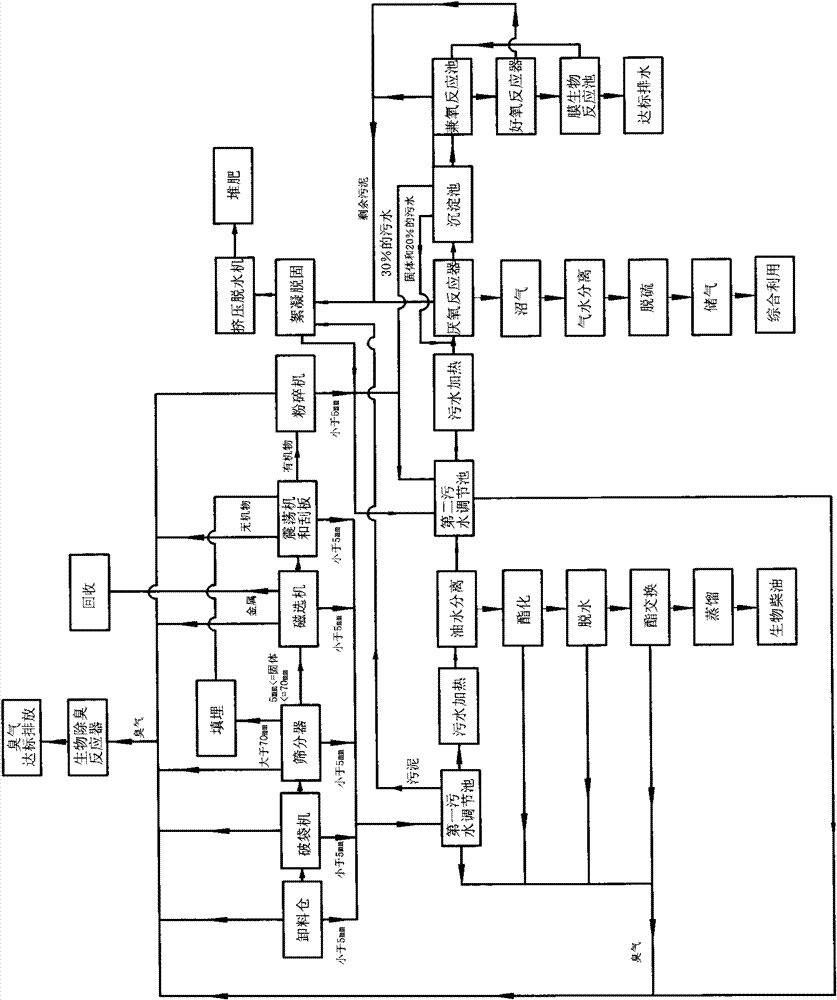

Centralized kitchen waste treatment method

ActiveCN101837366ARealize harmless treatmentRecycling is possibleFatty oils/acids recovery from wasteBio-organic fraction processingResource utilizationOil water

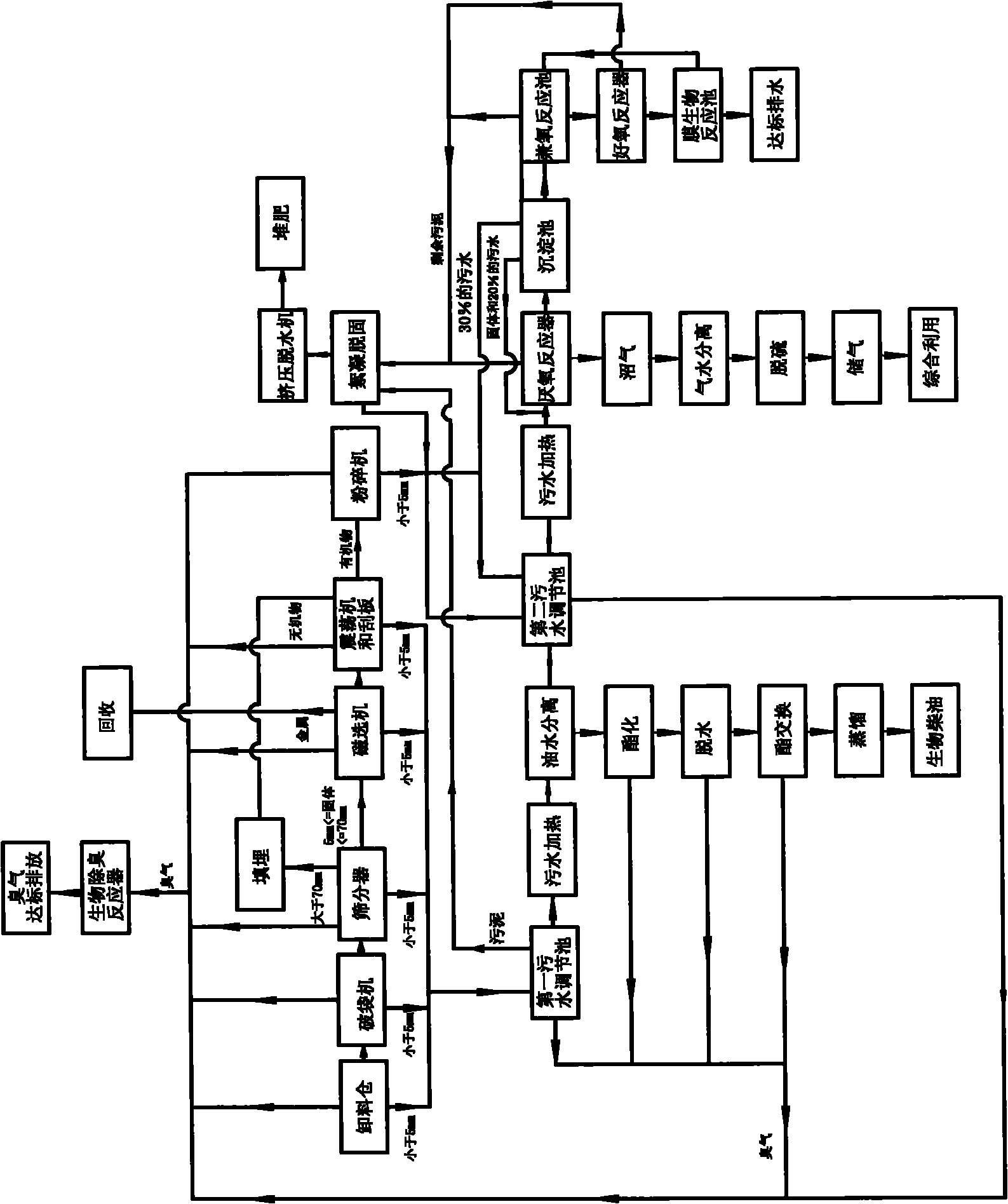

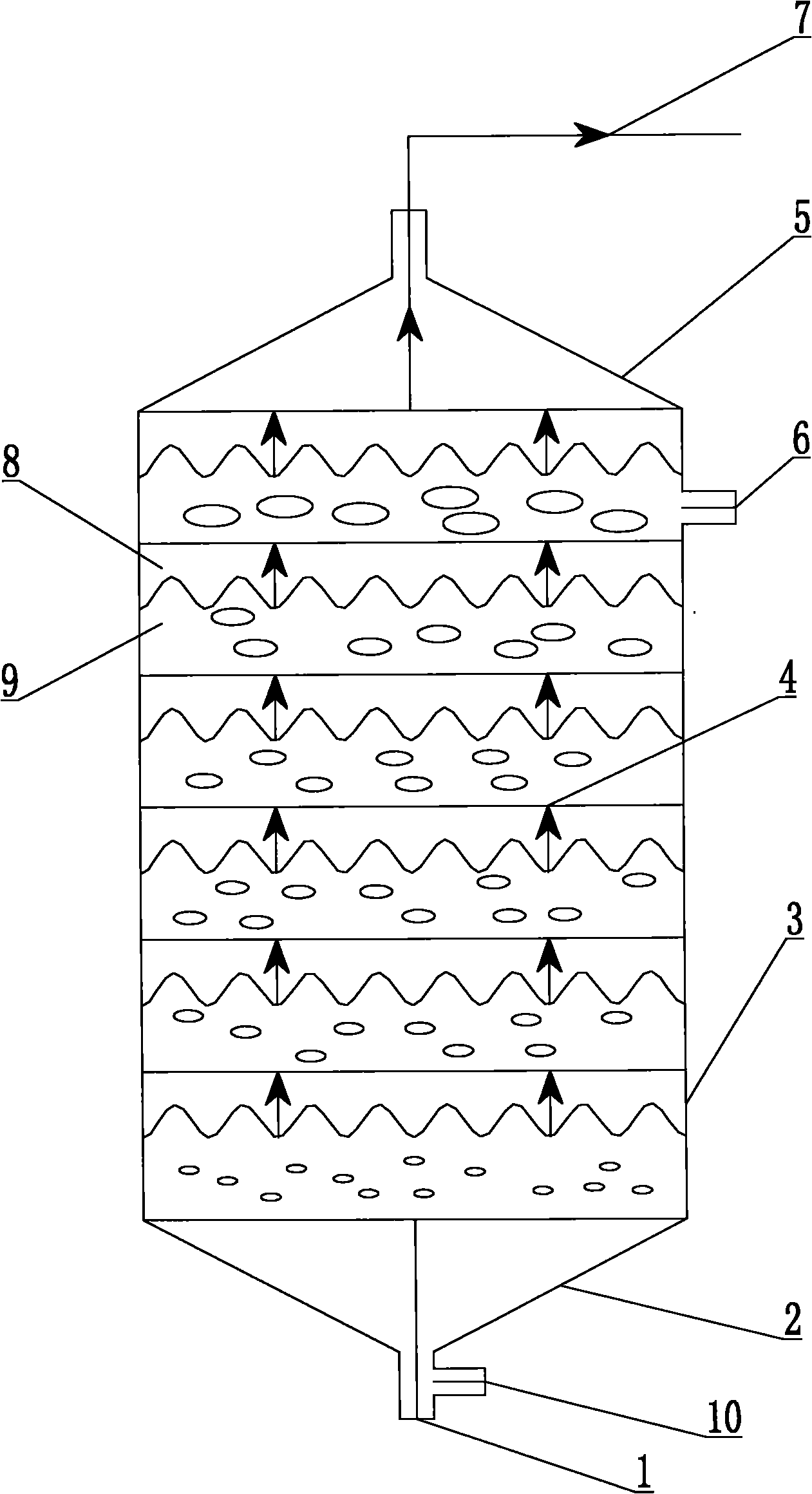

The invention relates to a centralized kitchen waste treatment method which comprises the following steps of: (A) sorting kitchen waste; (B) separating oil from water; (C) treating oil; (D) treating sewage; and (E) treating odor. Compared with a traditional kitchen waste burying method, by using the centralized kitchen waste treatment method, a great amount of soil is saved and an available methane resource is generated, kitchen waste reaches 100 percent of harmlessness, more than 95 percent of resource utilization and more than 95 percent of quantitative reduction, and the harmless treatmentof waste and the recycle of resources are truly realized.

Owner:北京昊业怡生科技有限公司

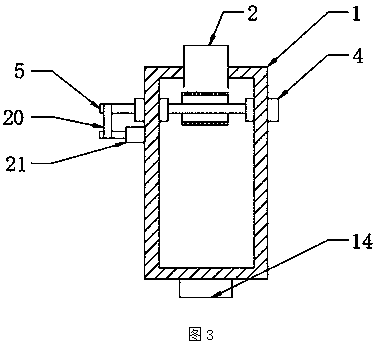

Garbage disposal machine

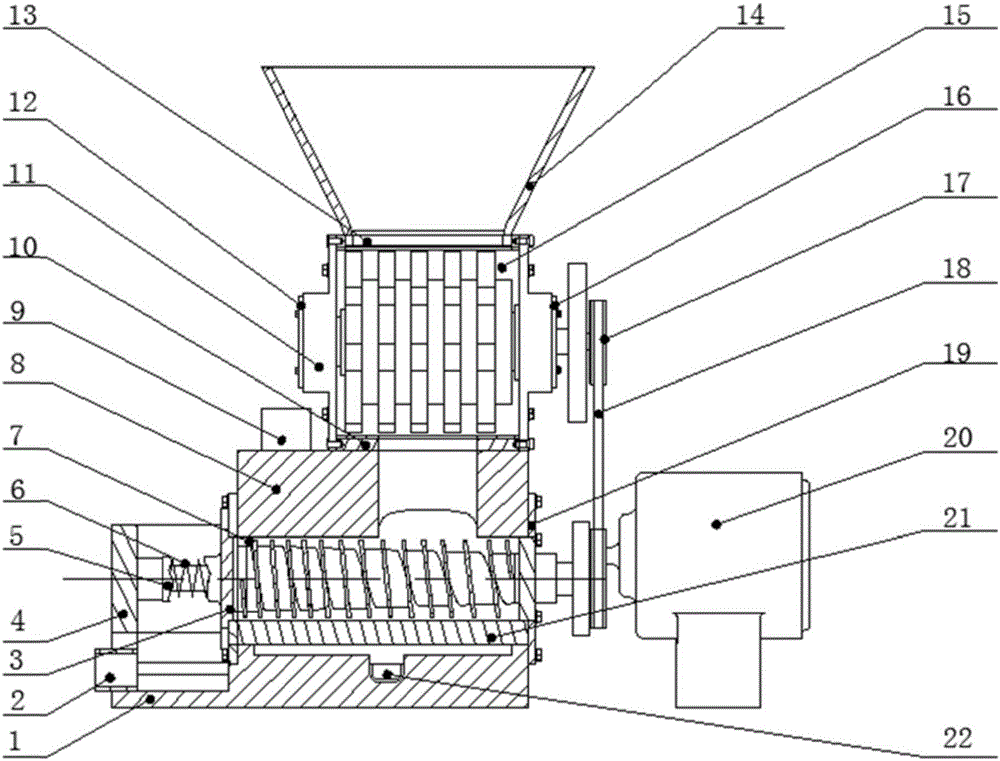

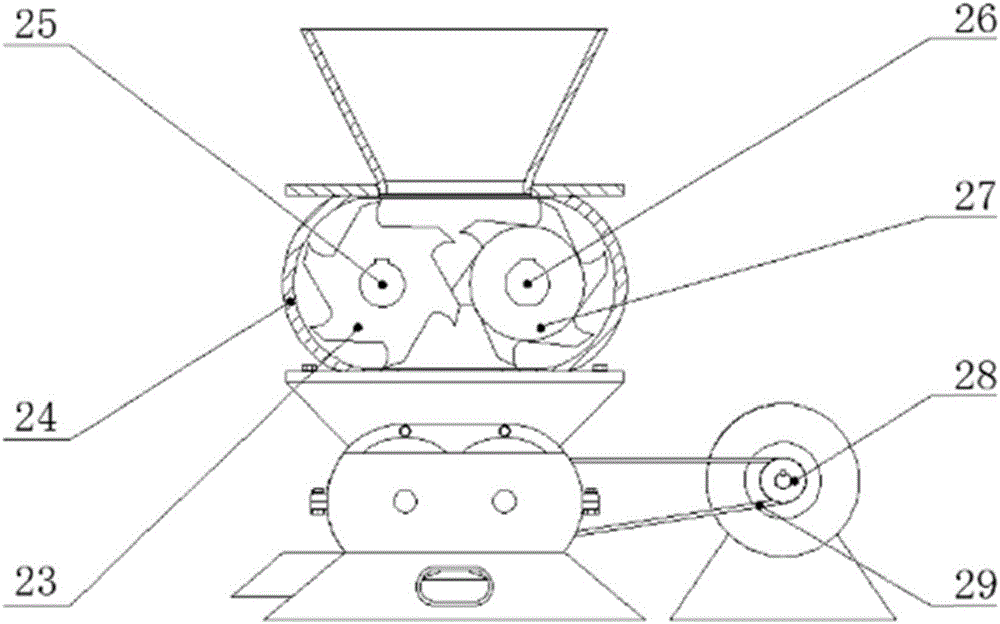

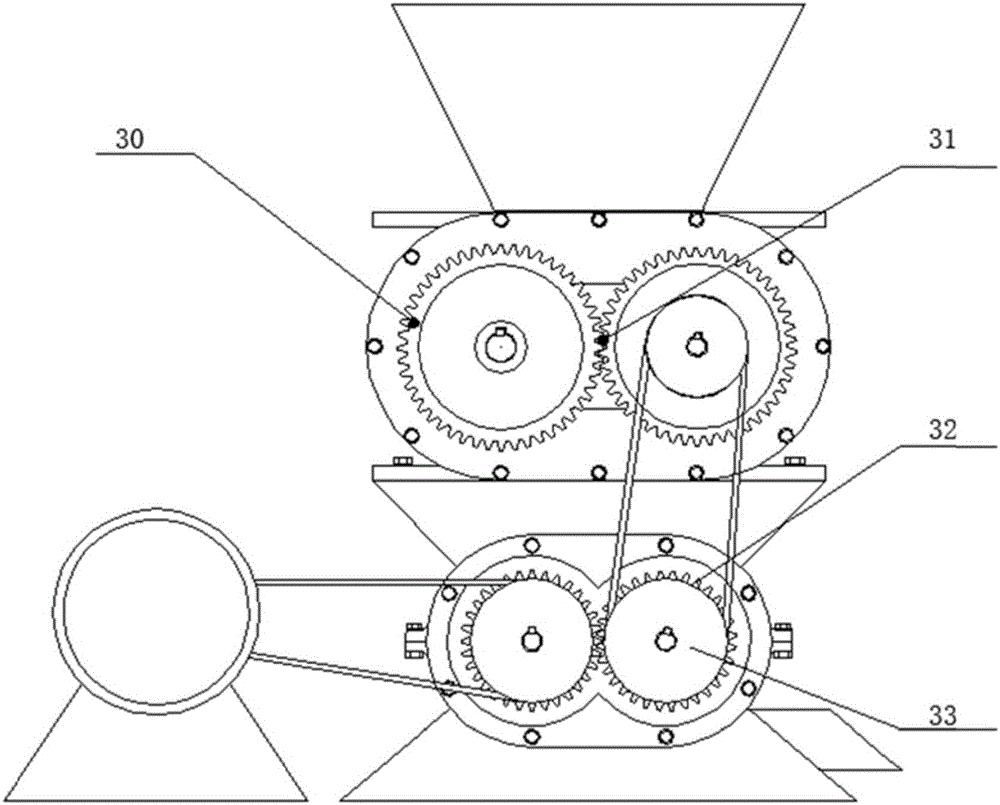

InactiveCN106000576AReasonable space layoutSimple designGrain treatmentsPressesAutomatic controlMotor drive

The invention discloses a garbage processing machine, which comprises a machine base, an extrusion mechanism, a crushing mechanism, a control unit, and a transmission mechanism; the upper end of the crushing mechanism is connected with a material inlet, and the crushing mechanism is used for crushing the garbage materials introduced from the material inlet processing; the extrusion mechanism and the crushing mechanism each include a box body, the extrusion box body is connected with the crushing box body, and the two boxes are fixed, and the extrusion mechanism is used to squeeze and dehydrate the crushed garbage materials; one end of the extrusion mechanism is The discharge port is equipped with a spring platen mechanism for controlling the extrusion discharge speed; the transmission mechanism includes a motor, a pulley and a transmission gear, and the motor operates through a pulley variable speed transmission and a gear meshing transmission drive device; the control The unit is used to realize automatic control of the working state of the garbage disposal device. The device solves the problem of secondary pollution to the environment caused by inefficient and improper garbage disposal, and relieves the pressure on the disposal of kitchen garbage in daily life.

Owner:范志杰

Pollution-free recycling method for photovoltaic module

InactiveCN108262332ASolve pollutionAvoid pollutionWaste processingGlass recyclingRecovery methodEngineering

The invention discloses a pollution-free recycling method for a photovoltaic module. The method comprises disassembling an aluminum frame, separating a back plate from a component, separating a battery sheet layer, carrying out high-temperature calcination treatment, and treating the back plate. The back plate treatment process comprises crushing the back plate through a crusher so that the average size of the crushed back plate is controlled within 10mm, adding 0.1-15% of an acid absorbent, 0.1-20% of inorganic powder, 0.1-25% of a compatilizer and 0.1-5% of an anti-aging aid into the crushedback plate, carrying out uniform mixing at a high speed, putting the mixture into a casting extruder and carrying out extrusion casting at 250-320 DEG C to obtain sheets with the sizes of 150 to 800micrometers.

Owner:ZHONGTIAN PHOTOVOLTAIC MATERIALS

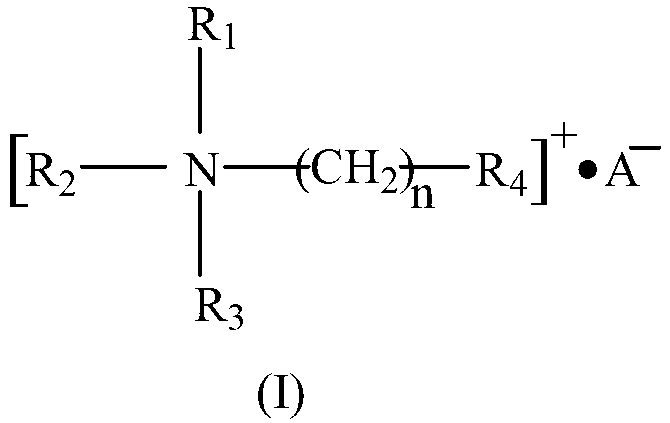

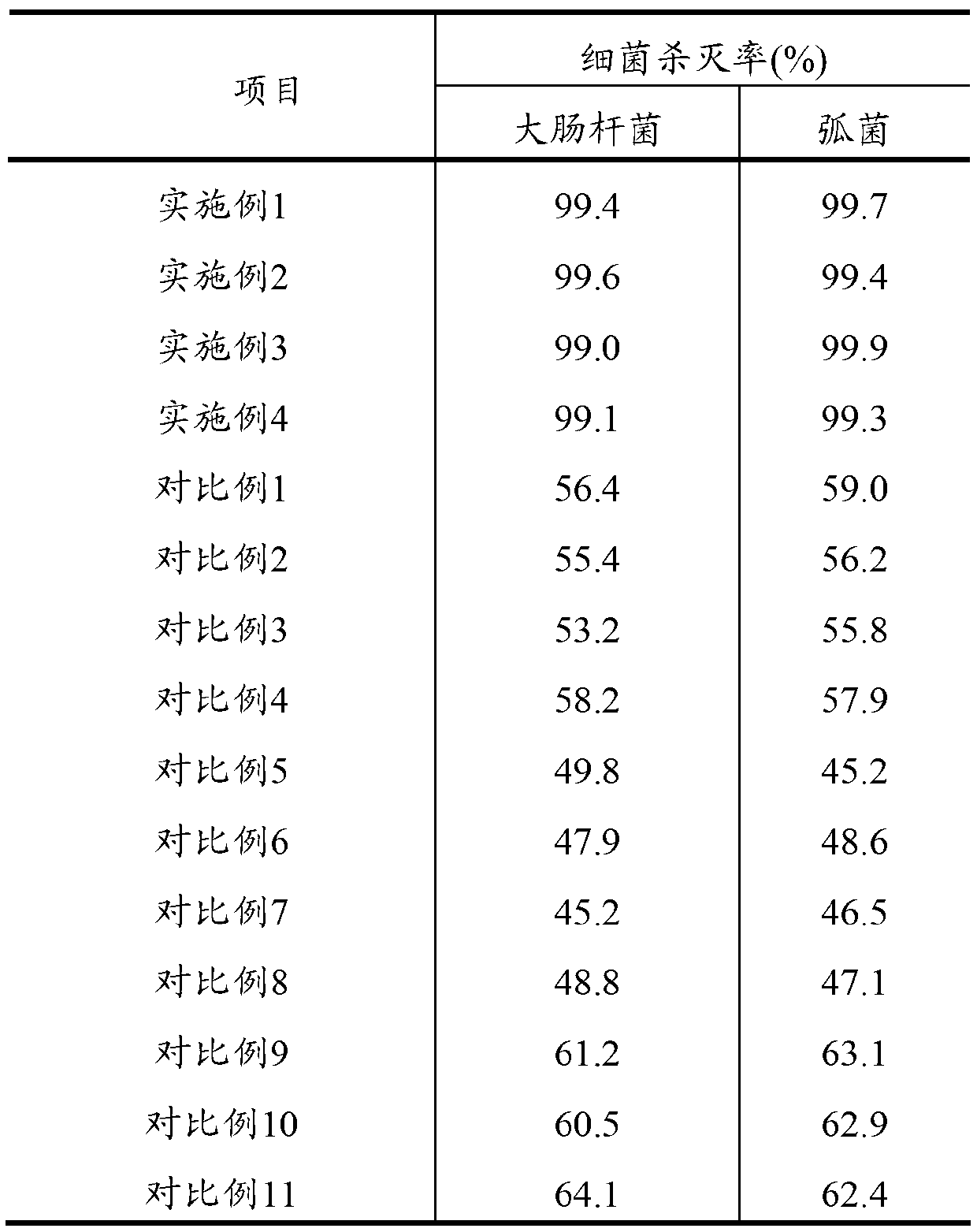

Ballast water bactericide and preparation method thereof

InactiveCN103125484AGood synergyImprove the bactericidal effectBiocideDisinfectantsCompound aTherapeutic effect

The invention discloses a ballast water bactericide and a preparation method thereof. The preparation method uses a natural biological material, namely a shell, as a main raw material, forms an active material for a shell framework through pretreatment and modification of an activating agent, and prepares the bactericide by compounding a positive ion surfactant. The bactericide not only can be used for removing possible external plankton in ballast water, but also has stronger killing effect on various pathogenic bacteria in the ballast water through the synergistic effect of the micro-porous adsorption function of the shell material and the sterilization function of the positive ion surfactant, so that the killing rate can be more than 99%. The ballast water bactericide provided by the invention is applicable to the microbiological treatment of the ballast water of a tanker and other ships, and has obvious sterilization treatment effect and very good application prospect.

Owner:ZHEJIANG OCEAN UNIV

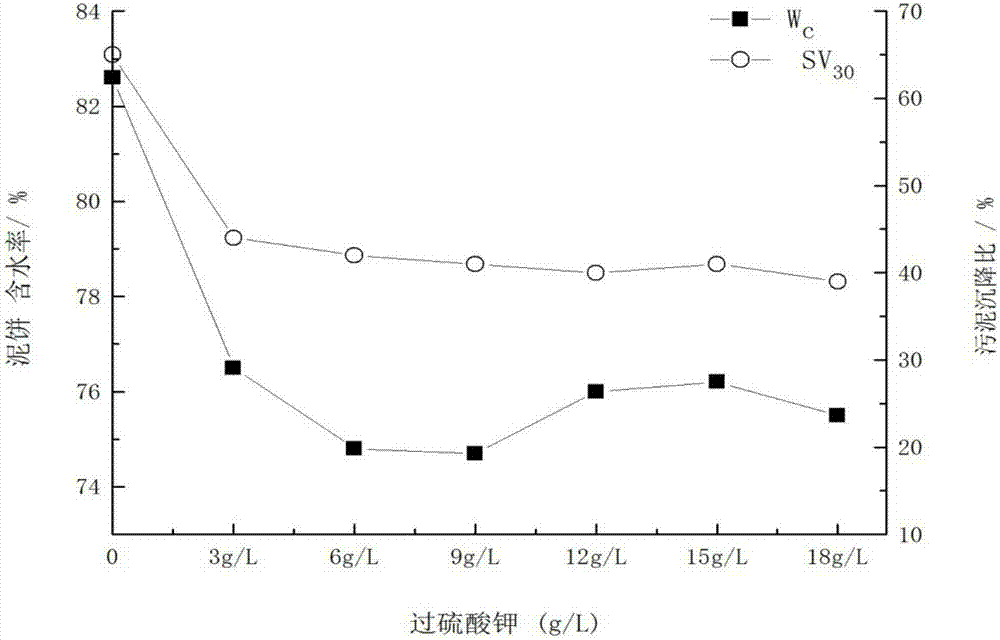

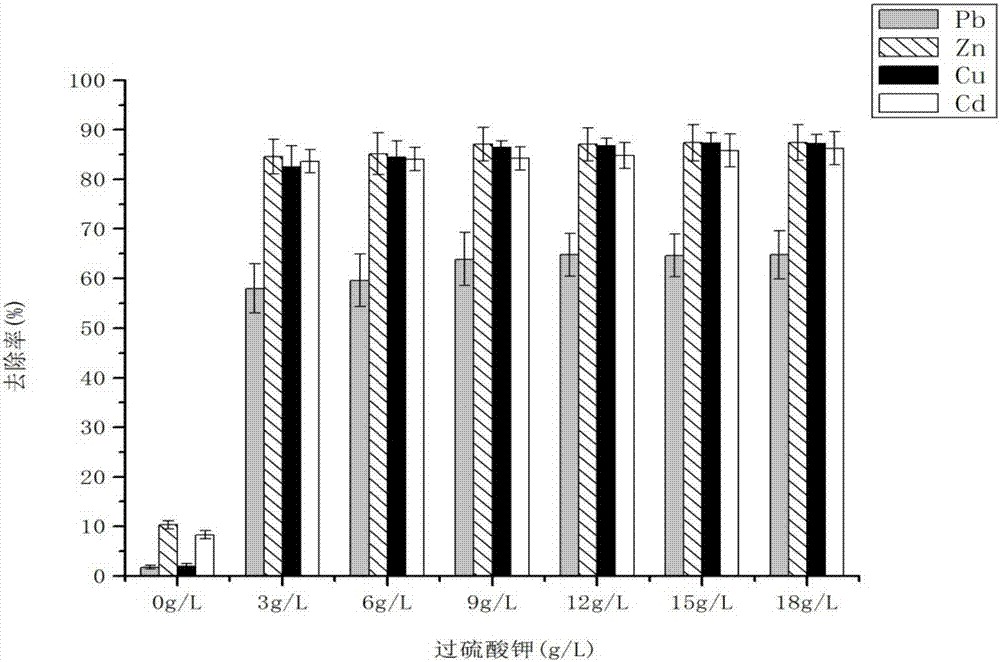

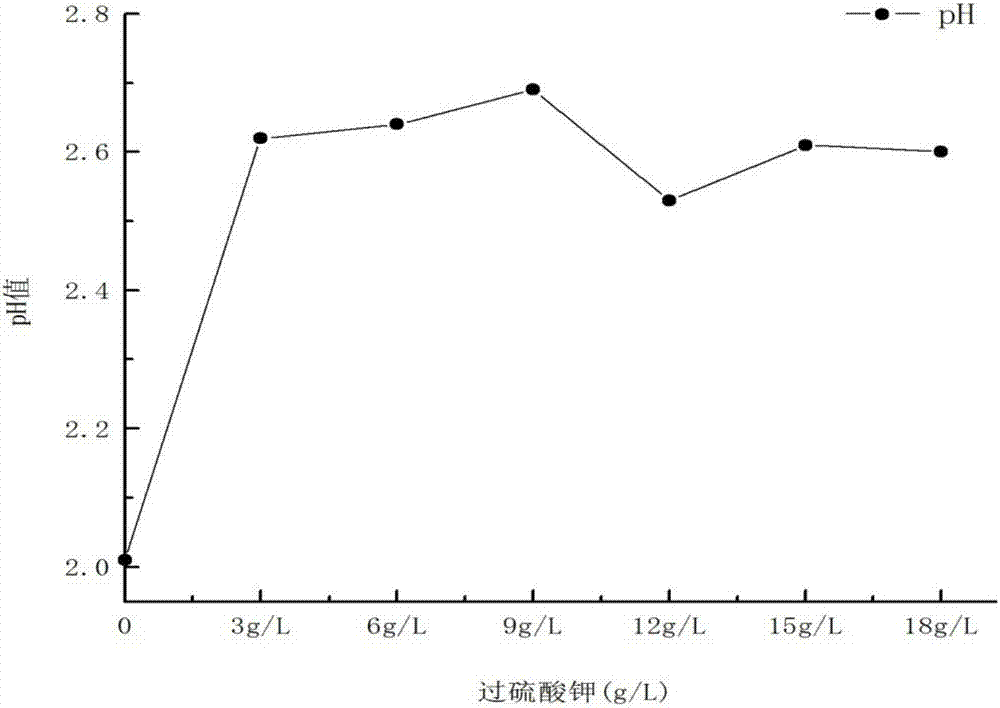

Sludge treatment method

InactiveCN107188384AImprove dehydration effectWith reduction processingSludge treatment by oxidationSpecific water treatment objectivesPersulfateMedicine

The invention discloses a sludge treatment method. The sludge treatment method comprises the following step: carrying out oxidization treatment on sludge under an acidic condition by adopting persulfate, so as to finish the treatment of the sludge. By adopting the treatment method disclosed by the invention, the sludge is treated under the acidic condition by adopting the persulfate, so that the dehydration performance of the sludge can be improved, and the content of heavy metal in the sludge can also be reduced; the sludge treatment method has the advantages of simple and convenient process, convenient operation, little required equipment, low operation cost, convenience for large-scale industrial production and the like; reducing, stabilized, harmless and subsequent resourceful utilization of the sludge is realized, and the sludge treatment method has a very good application prospect.

Owner:HUNAN AGRICULTURAL UNIV

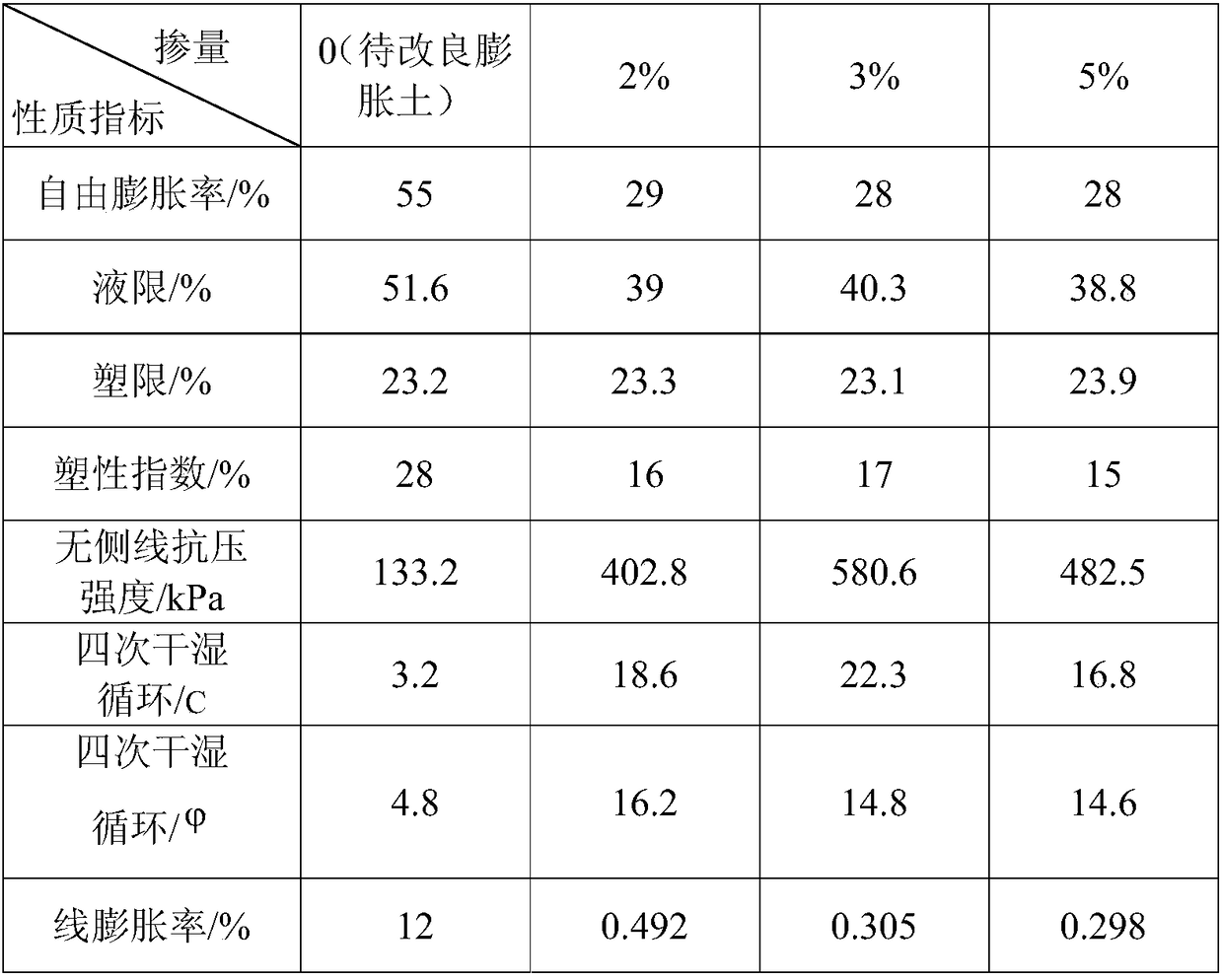

Method for improving properties of expansive soil by utilizing silica fume

InactiveCN108385662AEmission reductionSmall expansion and contractionSoil preservationSilica fumeGreenhouse gas

The invention discloses a method for improving properties of expansive soil by utilizing silica fume. The method realizes resource utilization of the silica fume by utilizing the silica fume to improve the expansive soil; the silica fume can be used for replacing or partially replacing the use of traditional expansive soil modifying agents such as lime and cement, so emission of greenhouse gases in cement and lime production processes is reduced, and the method satisfies the concept of sustainable development. The method disclosed by the invention gives an optimal mass mixing ratio of the silica fume as the expansive soil modifying agent; after the expansive soil is processed by using the silica fume of which the mixing amount is 3%, the swell-shrink characteristic of the expansive soil isobviously reduced, the improved expansive soil can maintain relatively good water stability in drying and watering circulation process and is free of surface peeling; and the improved expansive soilmeets the requirements of engineering fillers.

Owner:HOHAI UNIV

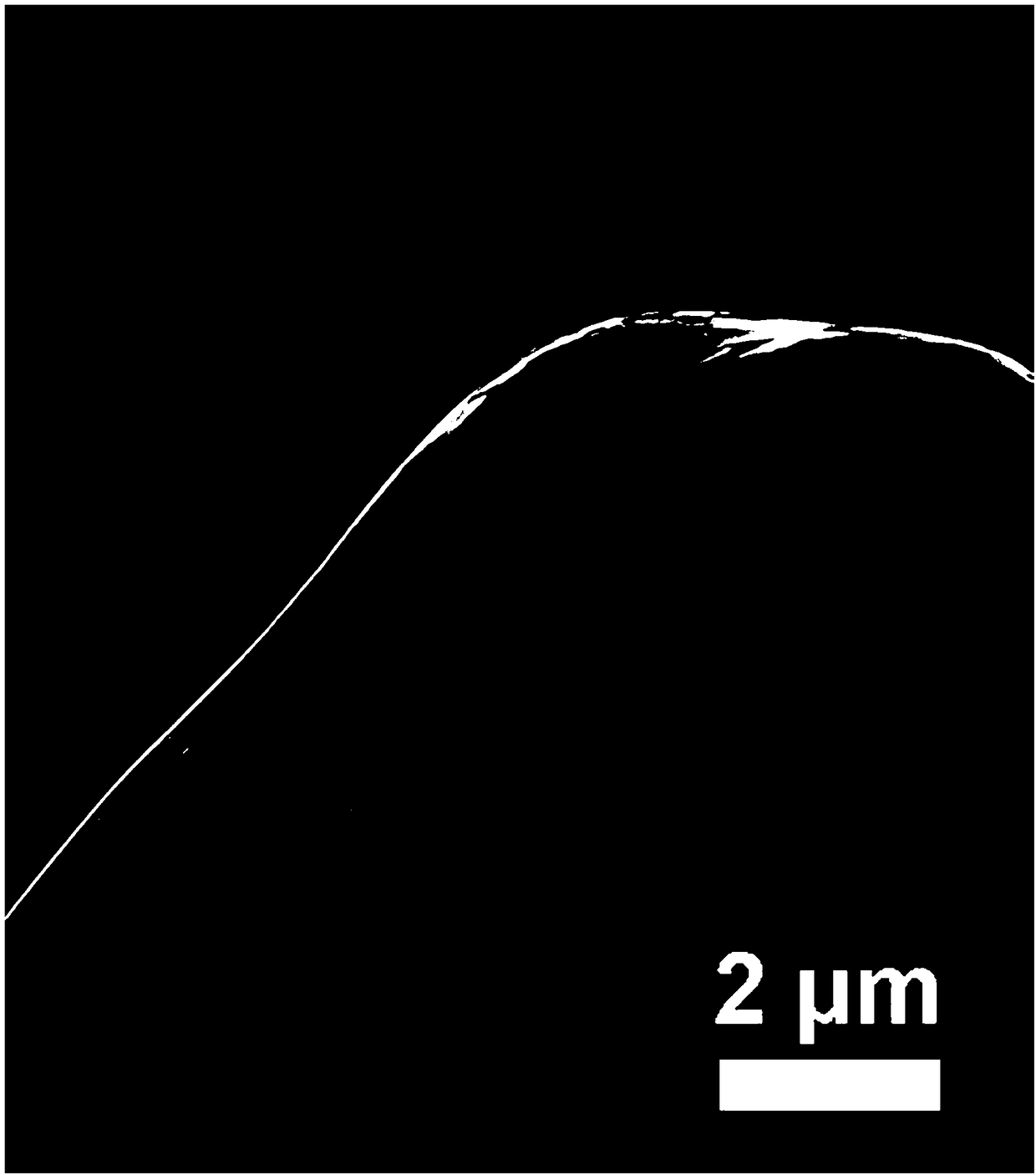

Preparation method for super-wetting foam titanium for oil water separation

InactiveCN108179454AHigh mechanical strengthHigh liquid penetration rateFatty/oily/floating substances removal devicesSurface reaction electrolytic coatingElectrochemical anodizationOil water emulsion

The invention relates to the field of porous foam titanium materials for oil water separation, in particular to a preparation method for super-wetting (super-hydrophilic and super-hydrophobic) foam titanium applicable to oil water separation. The problems that oil-water emulsion (oil-in-water emulsion and water-in-oil emulsion) separation porous materials are low in mechanism strength, liquid permeation rate and separation efficiency, poor in repeatability and the like at the present stage are solved. Commercial foam titanium is used as a raw material, an electrochemical anodizing method is adopted for preparing the super-wetting foam titanium material, and the advantages of high mechanism strength, liquid permeation rate and separation efficiency, good repeatability, low cost and the likeare achieved. The preparation method has the advantages that operation is easy to conduct and feasible, the product cost is low, industrialization production is easy to achieve, and the preparation method is environmentally friendly and can be widely applied to the fields of oil water separation and the like.

Owner:CHONGQING UNIV +2

Zero-emission treatment process of cutting liquid wastewater

ActiveCN109534581ARecycling is possibleReduce formationWater/sewage treatment by centrifugal separationWater treatment parameter controlWastewaterCeramic membrane

The invention relates to a zero-emission treatment process of cutting liquid wastewater and belongs to the technical field of water treatment. According to the zero-emission treatment process, metal components and cutting liquid of the cutting liquid wastewater can be recycled, forming of an organic-inorganic composite pollution layer on the surface of a ceramic membrane is reduced advantageously,and the membrane flux is increased advantageously.

Owner:大连博斯特科技有限公司

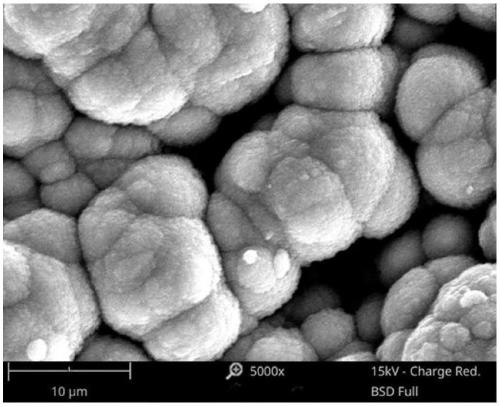

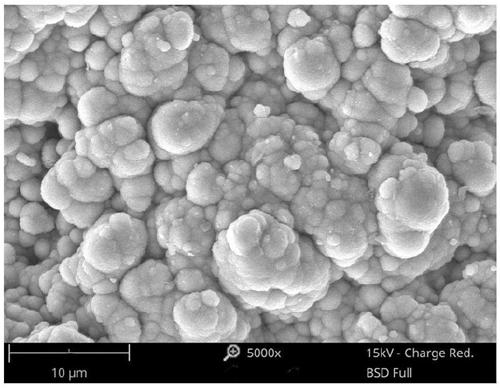

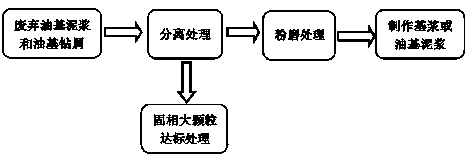

Processing technology of waste oil-based mud and oil-based drilling cuttings

InactiveCN104389557ARecycling is possibleReduce the proportionBorehole/well accessoriesSocial benefitsEconomic benefits

The invention relates to a processing technology of waste oil-based mud and oil-based drilling cuttings, in particular to a technology for manufacturing base mud and oil-based mud through the waste oil-based mud and the oil-based drilling cuttings. The technology comprises the steps of 1, collecting the waste oil-based mud and the oil-based drilling cuttings, 2, utilizing equipment for carrying out separation processing on solid phases of the waste oil-based mud and solid phases of the oil-based drilling cuttings, 3, carrying out grinding processing on the waste oil-based mud and the oil-based drilling cuttings after large-particle sold phases are removed, 4, manufacturing the ground waste oil-based mud and the ground oil-based drilling cuttings into the base mud and the oil-based mud, and 5, carrying out up-to-standard release processing on the large-particle sold phases obtained after separation. According to the technology, reclamation and innocent processing can be carried out on the waste oil-based mud and the oil-based drilling cuttings, and the solid phases in the original waste mud and the oil-based drilling cuttings are ground and then are manufactured into the base mud and the oil-based mud, and then are recycled. Secondary pollution hardly exists, and equipment investment and operation cost are low. The technology has the obvious environment benefits, social benefits and economic benefits.

Owner:SOUTHWEST PETROLEUM UNIV

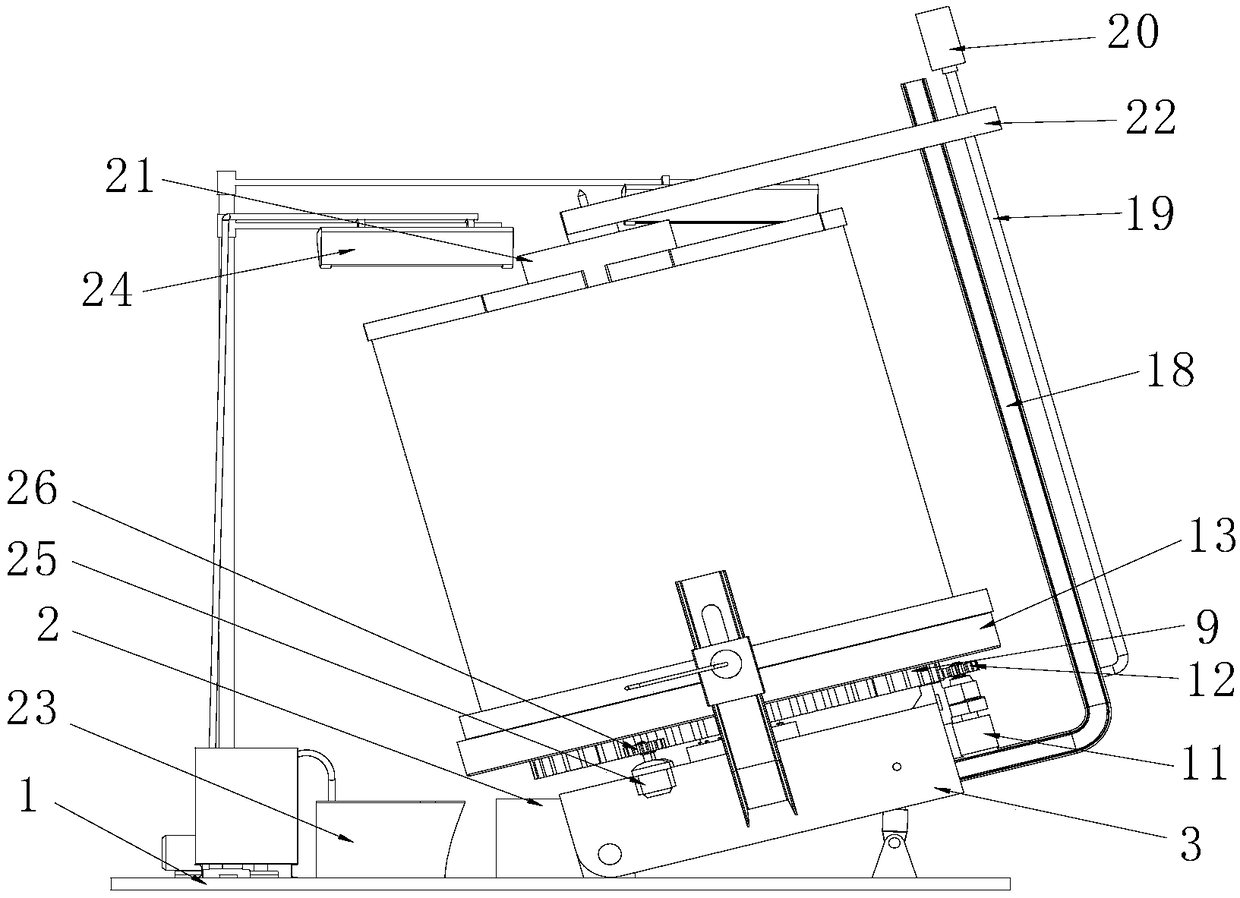

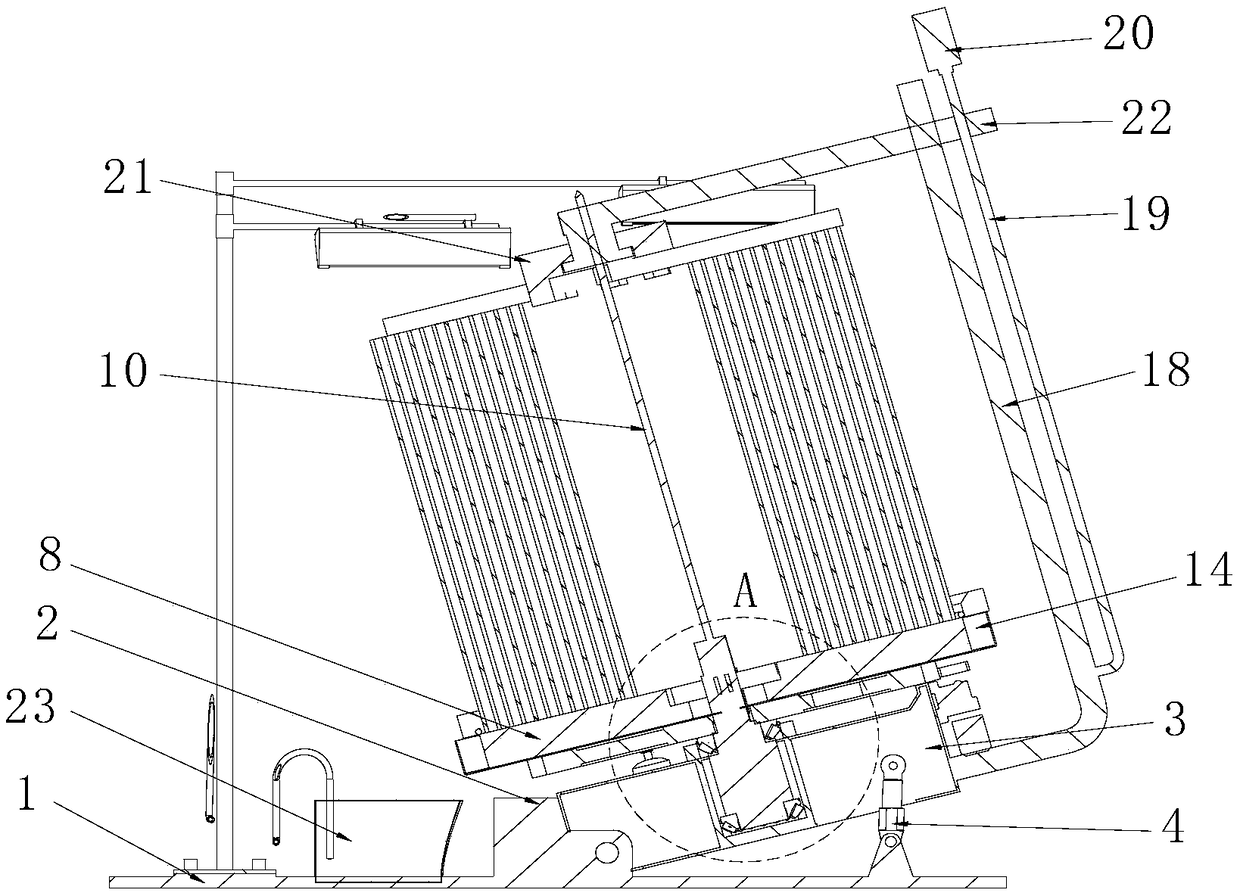

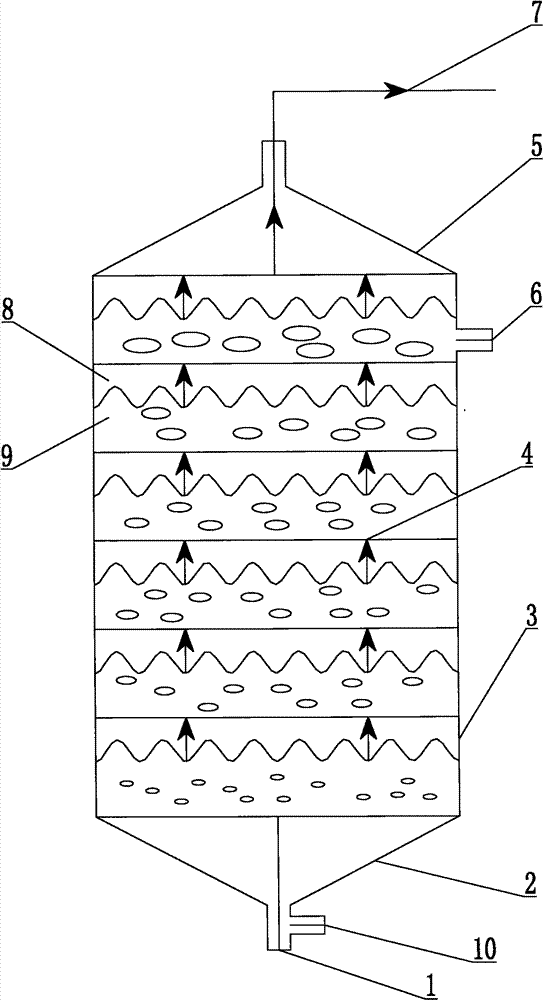

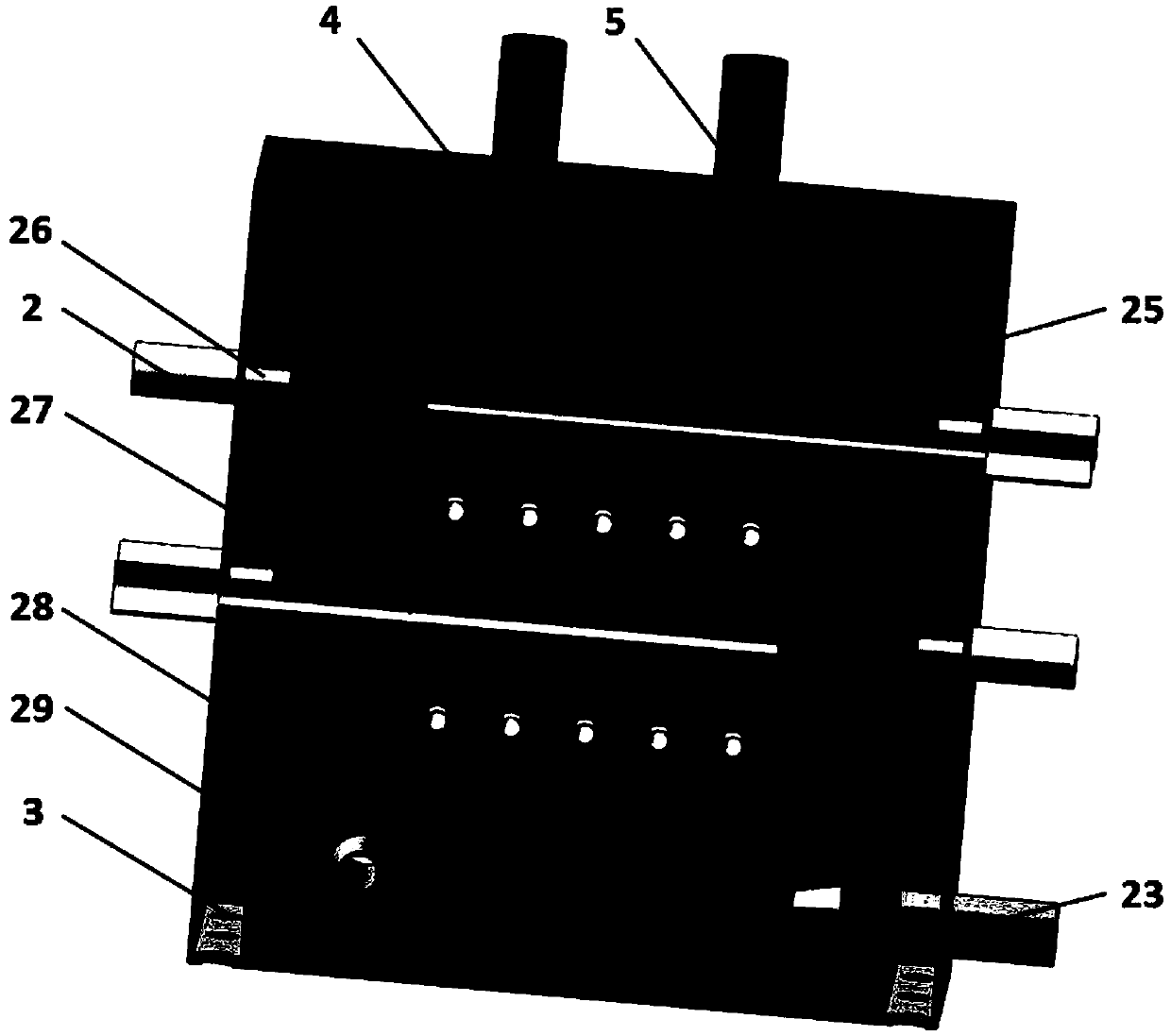

Spraying device for surface treatment of air reactor

PendingCN108787224AAchieve rotary sprayingRecycling is possibleLiquid spraying apparatusSurface finishingEngineering

The invention discloses a spraying device for surface treatment of an air reactor. The spraying device comprises a clamping assembly and a spraying assembly. The clamping assembly comprises a supporting base. A power assembly capable of driving the supporting base to turn towards the spraying assembly is connected to the supporting base. A vertical bearing column is arranged in the supporting base. A plurality of load bearing blocks used for bearing radial and axial loads are arranged on the bearing column. One end of the bearing column stretches out of the supporting base and is connected with a rotary disc capable of rotating relative to the supporting base. Lower clamps used for clamping workpieces are arranged on the periphery of the rotary disc. Upper clamps matched with the lower clamps are connected to the supporting base and are located above the rotary disc. The spraying assembly comprises a paint storage device and a plurality of nozzles located above the rotary disc. The paint storage device communicates with the nozzles. The spraying device has the advantages that rotary surface spraying of an inclinable hollow air reactor can be achieved, paint can be recycled, and thespraying effect is good.

Owner:FOSHAN CHUANGSEN ELECTROMECHANICAL CO LTD

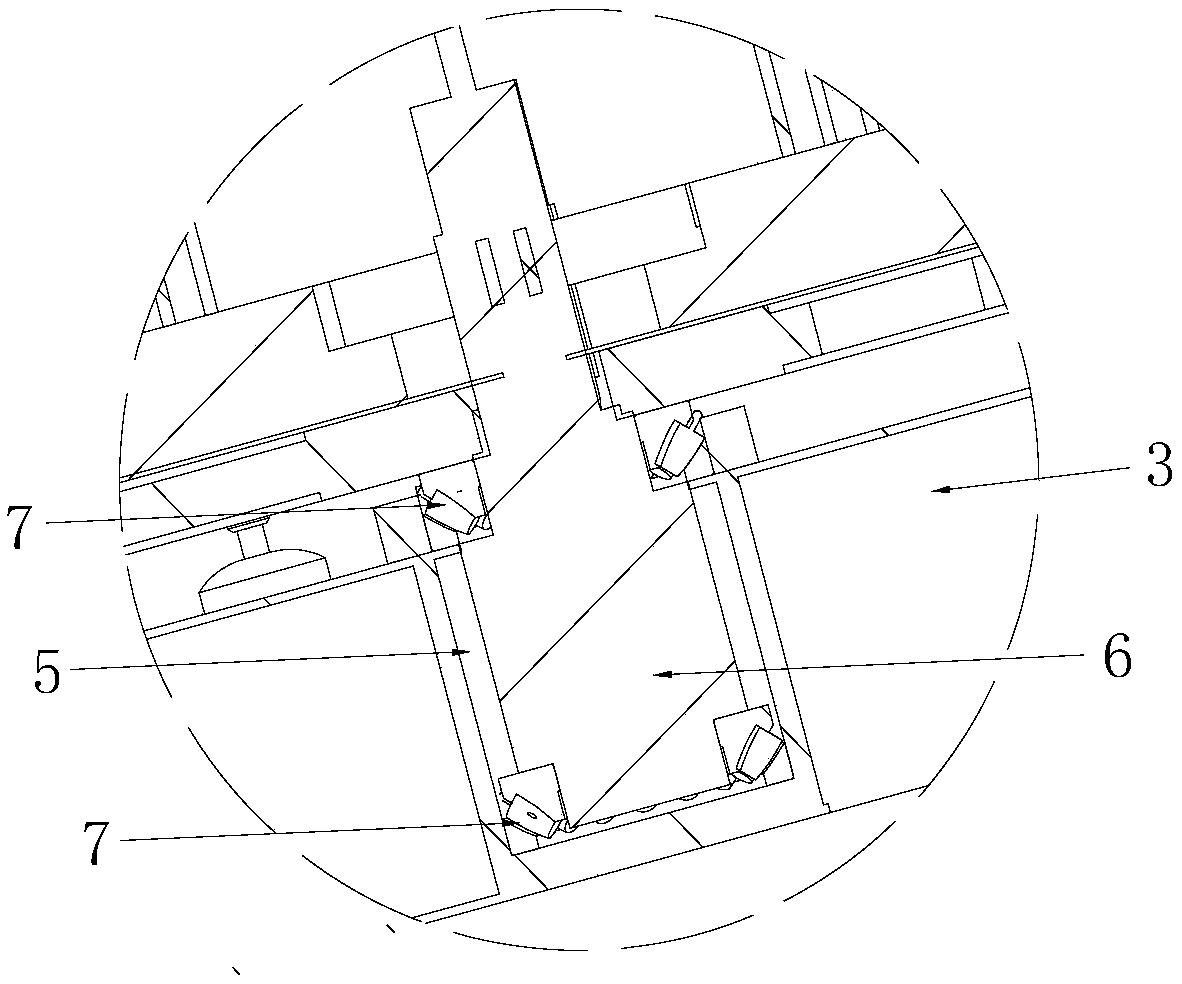

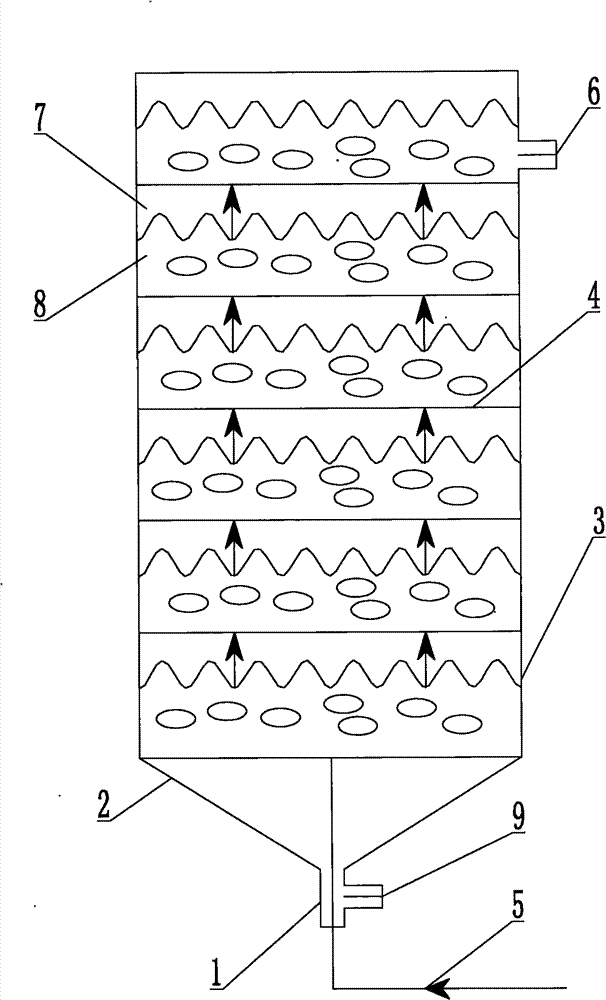

Drying, dehydrating and dehumidifying device

InactiveCN104019644ARecycling is possibleReduce environmental pollutionDrying gas arrangementsDrying machines with local agitationMoistureWaste heat

The invention discloses a drying, dehydrating and dehumidifying device, and relates to a device for conducting drying, dehydrating and dehumidifying with waste heat. The drying, dehydrating and dehumidifying device is composed of an air inlet pipe, an air adjusting valve, a dehydrating and dehumidifying pipe and a box body, the dehydrating and dehumidifying pipe is connected with the air inlet pipe through the air adjusting valve, the other end of the dehydrating and dehumidifying pipe is provided with a blind plate, holes are evenly formed in the surface of the dehydrating and dehumidifying pipe, a feeding opening is formed in the top of the box body, a discharging hopper is arranged at the bottom of the box body, a discharging opening is formed in the tail end of the discharging hopper, and a discharging device is arranged at the discharging opening. By means of the drying, dehydrating and dehumidifying device, the waste heat discharged by an enterprise is sufficiently used, redundant energy power is not required to be increased, the waste heat is used for drying and dehydrating materials with moisture, energy recycle is achieved, and environmental pollution is further reduced.

Owner:刘可心

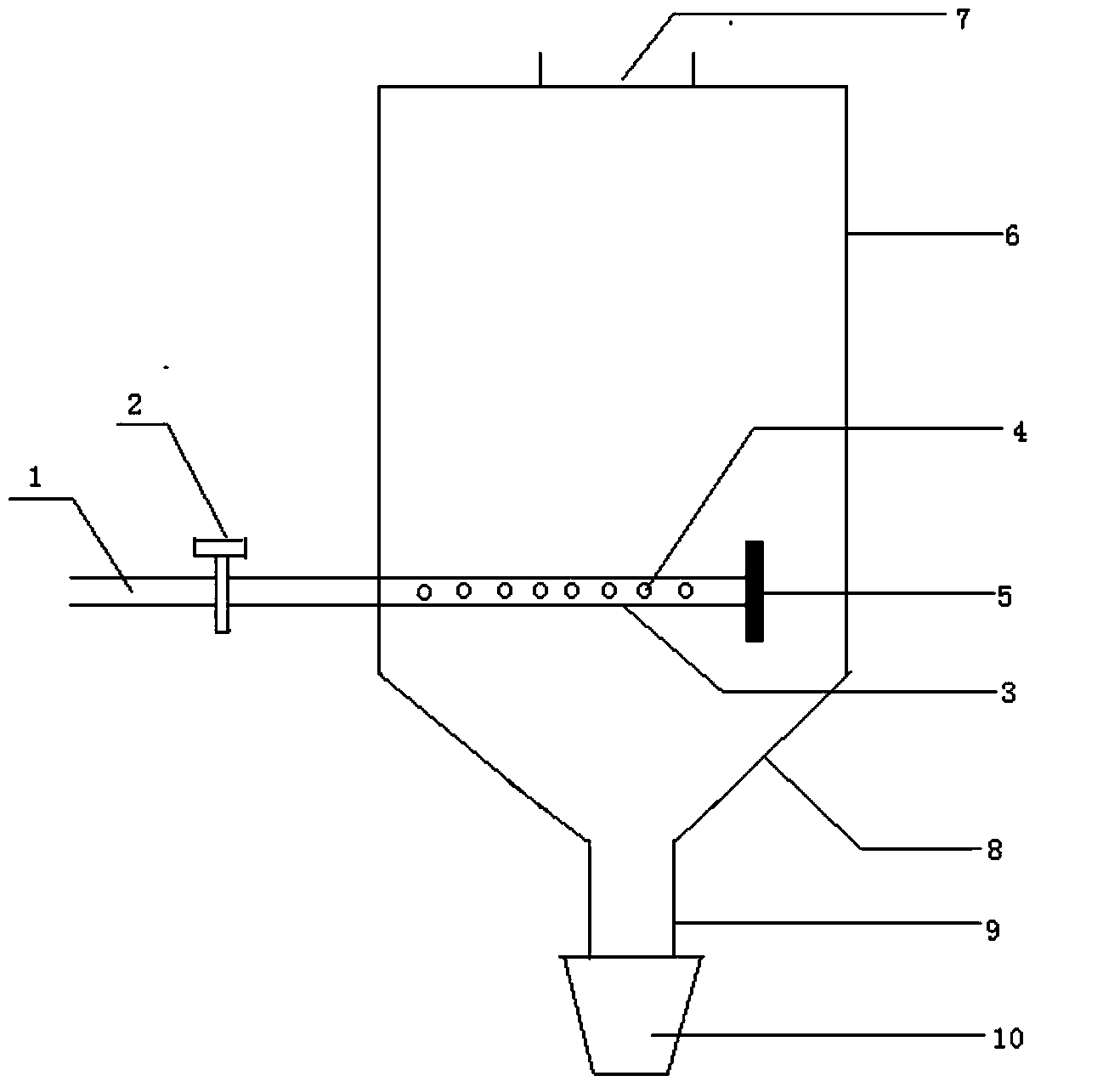

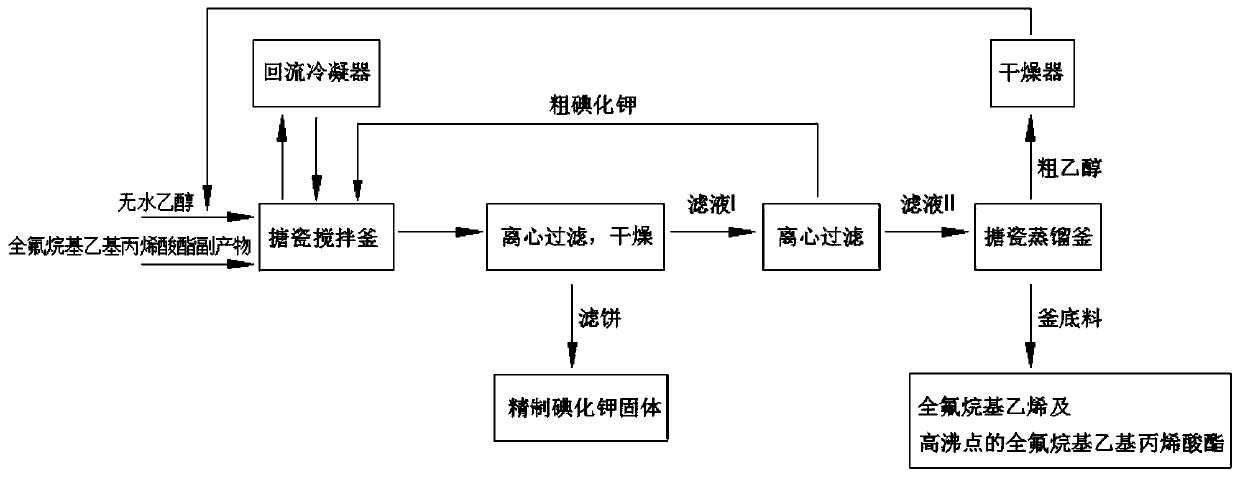

Method for purifying potassium iodide from perfluoroalkylethyl acrylate byproduct

ActiveCN110002470AEasy to operateRecycling is possibleOrganic compound preparationCarboxylic acid esters preparationPotassium iodineChemistry

The invention discloses a method for purifying potassium iodide from a perfluoroalkylethyl acrylate byproduct. The method comprises the following steps: washing, centrifugal filtration, and drying forobtaining the finished refined potassium iodide solid. The method for purifying potassium iodide has the advantages of simplicity in process operation, realization of the purity of the purified potassium iodide of 99%, no generation of three wastes in the whole process, safety ensuring and low energy consumption.

Owner:SICHUAN XIAIFU TECH

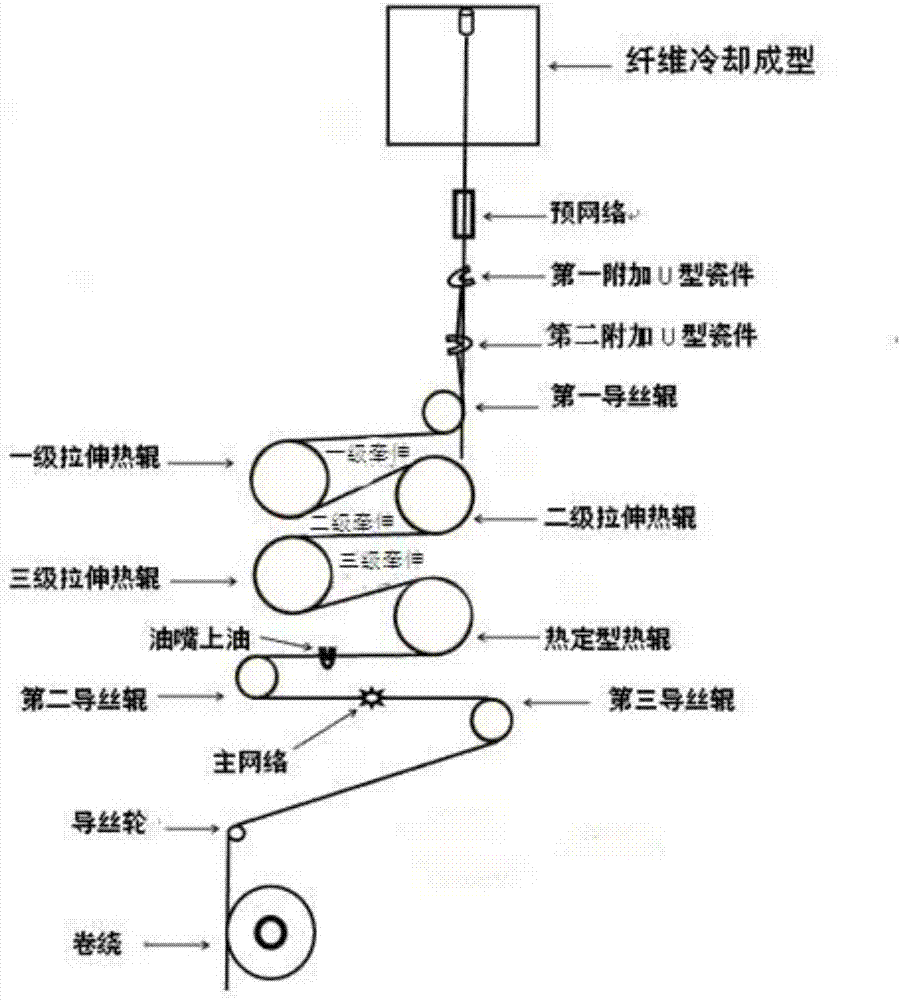

Production process of polyester FDY multi-roll oil-free full-draft fibers

InactiveCN107034533AAvoid slipping and shakingGuaranteed spinnabilityArtificial thread manufacturing machinesFilament manufacturePolyesterDistributor

The invention discloses a production process of polyester FDY multi-roll oil-free full-draft fibers. The production process includes the following steps that polymerization is conducted in a final polymerization autoclave, raw materials are then processed by means of a melt conveying pump, a melt distributor and a melt booster pump in sequence, the obtained melt is conveyed and then processed by means of a melt cooler, a static mixer, a melt distribution valve and a spinning box in sequence, then the melt is extruded in a metering pump and processed by means of a spinning assembly, fiber cooling and molding is conducted, then semi-finished fibers are processed by means of a U-shaped ceramic piece, a secondary network, a spinning channel, a first additional U-shaped ceramic piece1, a second U-shaped ceramic piece 2, a first silk guide roller, a first-level hot pulling roller, a second-level hot pulling roller, a third-level hot pulling roller and a heat-setting hot roller in sequence, a lubricating nipple is used for oiling, and the obtained fibers are processed by means of a second silk guide roller, a primary network, a third silk guide roller and a guide wheel and subjected to coiling, doffing, quality testing and packaging. According to the production process of the polyester FDY multi-roll oil-free full-draft fibers, the product quality is improved, the running environment of equipment and the working environment of workers in a FDY production place are optimized, yarn path operation is simplified, and energy conservation and high efficiency are achieved.

Owner:TONGKUN GRP ZHEJIANG HENGTONG CHEM FIBER

Injection molding device for plastic barrel production

InactiveCN110900960ARecycling is possibleSolve the problem that plastic recyclables cannot be directly usedPlastic recyclingProcess engineeringInjection molding machine

The invention relates to the injection molding device technology field and discloses an injection molding device for plastic barrel production. The injection molding device for plastic barrel production comprises a crushing box. A top end of the crushing box is connected with a bottom end of a feeding port, a front surface and a back surface of the crushing box penetrate through a rotating shaft,the rotating shaft is movably connected with the crushing box, two shaft sleeves are arranged at a joint of the rotating shaft and the crushing box, and the two shaft sleeves are fixedly connected with the front surface and the back surface of the crushing box. By using the injection molding device for plastic barrel production, through combination of a fixed roller, the shaft sleeve and a first belt, waste plastic bottles can be thoroughly decomposed, decomposed waste plastics are fed into a melting box by arranging a connecting pipe, the decomposed waste plastics can be heated to a molten state by arranging a heating machine and a melting bottle, recycling of waste plastic products is achieved, and a problem that plastic recycled products cannot be directly used by a traditional injection molding machine is solved.

Owner:倪程凯

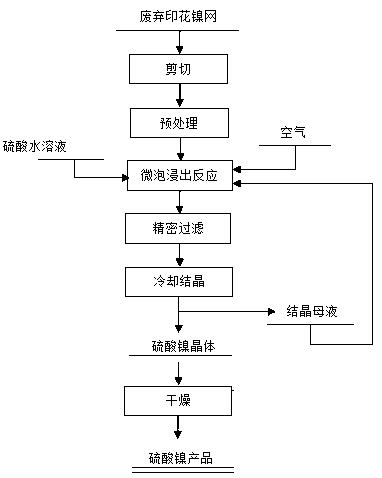

Recycling and treatment method for waste printing nickel screen

The invention discloses a recycling and treatment method for a waste printing nickel screen. The recycling and treatment method comprises the following steps: shearing the waste printing nickel screeninto fragments; after immersing the fragments in an acidic solution, taking out the fragments and putting the fragments into a micro-bubble nickel dissolving kettle containing an inorganic acid watersolution; stirring and introducing air or oxygen into the micro-bubble nickel dissolving kettle; emulsifying separated liquid through a circulating pump, a liquid-gas spraying pump and a baffling plate in sequence, and returning emulsified liquid back into the micro-bubble nickel dissolving kettle to form the circulation of the solution in the micro-bubble nickel dissolving kettle; carrying out micro-bubble leaching reaction; and after reaction is finished, carrying out filtering, pre-cooling, freezing and crystallization, solid-liquid separation and drying in sequence to obtain a nickel saltproduct. According to the recycling and treatment method, the separation of a nickel screen and a surface thin film of the waste printing nickel screen is realized through a micro-bubble nickel dissolving technology; meanwhile, high-quality nickel is recycled; in a whole system, waste residues, wastewater, waste gas and the like are not generated; and the metal recycling rate is high, the treatment cost is low and the environment-friendly meaning is obvious.

Owner:浙江科菲科技股份有限公司

Method for producing machine-made charcoal from rubber timber waste

The invention discloses a method for producing machine--made charcoal from rubber timber waste. The rubber timber waste is prepared into wood shavings and saw dust through a conventional method, the wood shavings and the saw dust are dried until the water content is 6-8%, carbon powder, the wood shavings and the saw dust are mixed and pressed in a hot mode to prepare bars, bar carbon is placed into a seal kiln, heated at the temperature of 950 DEG C-980 DEG C and kept at the temperature for 3 days to be carbonized, heating is stopped, and the bar carbon is naturally carbonized for 3-4 days in the seal kiln, so that carbon stress of the bar carbon is uniform; the bar carbon is moved from the seal kiln to the outside to be aired for 5-6 days, and temperature and humidity can be balanced with the outside to obtain the machine--made charcoal. The machine-made charcoal is high in packing degree, large in density and high in heat quantity, the density can reach 1.1-1.2 g / cm<3>, the content of fixed carbon is larger than 80%, the combustion value is larger than 7500 kcal, the combustion time is longer than 4 h, the ash content is smaller than 4%, and the water content is smaller than 6%.

Owner:景洪市新源木业加工有限公司

Centralized kitchen waste treatment method

ActiveCN101837366BRealize harmless treatmentRecycling is possibleFatty oils/acids recovery from wasteBio-organic fraction processingResource utilizationSewage

The invention relates to a centralized kitchen waste treatment method which comprises the following steps of: (A) sorting kitchen waste; (B) separating oil from water; (C) treating oil; (D) treating sewage; and (E) treating odor. Compared with a traditional kitchen waste burying method, by using the centralized kitchen waste treatment method, a great amount of soil is saved and an available methane resource is generated, kitchen waste reaches 100 percent of harmlessness, more than 95 percent of resource utilization and more than 95 percent of quantitative reduction, and the harmless treatmentof waste and the recycle of resources are truly realized.

Owner:北京昊业怡生科技有限公司

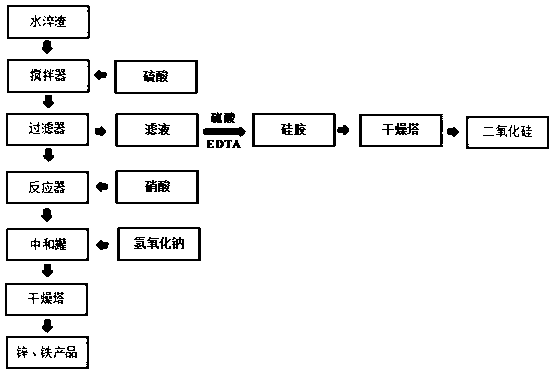

Method for separating components such as iron, zinc and silicon dioxide from lead and zinc smelting water quenching slag

InactiveCN110422851ARecycling is possibleGood economic valueSilicaZinc oxides/hydroxidesZinc hydroxideFerric hydroxide

The invention discloses a method for separating components such as iron, zinc and silicon dioxide from lead and zinc smelting water quenching slag. The method comprises the steps that the water quenching slag and sulfuric acid are simultaneously delivered to a stirrer through a tool; after even mixing is conducted, the acidity is measured, after the expected acidity is reached, mixed liquor is conveyed to a filter, and filtrate and filter residue are separated; the filtrate is delivered into a liquid accumulator, after natural gelling is achieved, acid pickling, EDTA and water washing are sequentially conducted, then silica gel is delivered to a drying tower, and silicon dioxide is obtained; and the filter residue and nitric acid are delivered to a reactor, after full reaction is conducted, sodium hydroxide is added, a mixed solution is delivered into a neutralization tank, the pH value is adjusted to be about 3.2 and 10, then ferric hydroxide slurry and zinc hydroxide slurry are sequentially obtained, the ferric hydroxide slurry and the zinc hydroxide slurry are respectively delivered to the drying tower through a delivery pump, and thus iron trioxide and zinc oxide are obtained.According to the method, the water quenching slag resources are effectively recovered, comprehensive utilization of water quenching slag recovery enterprises is achieved, and the problem that water quenching slag is difficult to treat in the industry is solved.

Owner:XIANGTAN UNIV

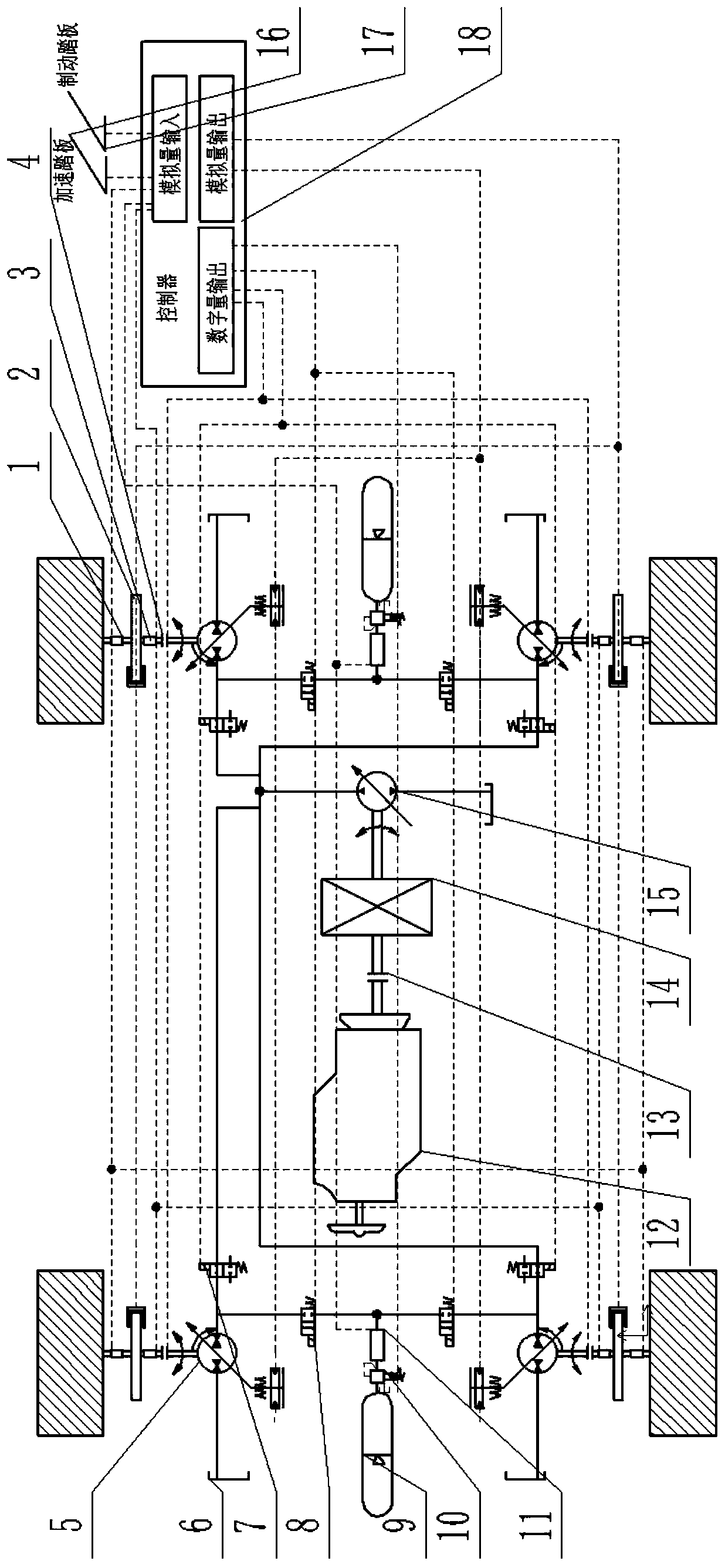

Regenerative braking energy recovery system of hydraulically-driven automobile

PendingCN110979002AReduce complex transmission structureImprove passabilityBraking element arrangementsBraking action transmissionRegenerative brakeElectromagnetic clutch

A regenerative braking energy recovery system of a hydraulically-driven automobile is characterized in that each wheel half axle of the automobile is provided with a secondary element pump / motor, andthe wheel half axles are connected with the secondary element pumps / motors through electromagnetic clutches; a torque sensor and a rotating speed sensor are installed on each wheel half axle; each secondary element pump / motor is connected with a hydraulic oil cylinder; each secondary element pump / motor is connected with a high-pressure energy accumulator through a second two-position two-way electromagnetic reversing valve; a pilot pressure control valve and a pressure sensor are connected with the oil outlet of each high-pressure energy accumulator, and each high-pressure energy accumulator is controlled to be connected and disconnected through the pilot pressure control valve; the secondary element pump / motor is connected with a hydraulic master pump through a first two-position two-wayelectromagnetic reversing valve; the hydraulic master pump is connected with the hydraulic oil cylinders through hydraulic pipelines; and the hydraulic master cylinder is sequentially connected with areduction gearbox, a clutch and an engine. All components are connected with a controller. The hydraulic regenerative braking recovery system is applied to an internal combustion engine passenger vehicle, so the complexity of the transmission structure of a traditional internal combustion locomotive is reduced.

Owner:ZHEJIANG UNIV OF TECH

A kind of porous biological ceramsite prepared from waste incineration fly ash and biomass pyrolysis gasification residue and preparation method thereof

InactiveCN105712733BHarmlessRealize resource processingCeramicwareProcess engineeringEnvironmental engineering

The invention discloses a method used for producing porous biological ceramsite by taking waste incineration fly ash and biomass pyrolysis-gasification residue as raw materials. The method comprises following steps: household garbage incineration fly ash is subjected to high temperature treatment in the presence of a gasification agent so as to obtain residual ash; biomass is subjected to low temperature pyrolysis-high temperature steam gasification so as to obtain a pyrolytic residue; the residual ash, the pyrolytic residue, flyash, clay, and a pore-forming agent are subjected to mixing, pelleting, drying, and high temperature roasting so as to obtain the porous biological ceramsite product. Technology of the method is simple; operation is convenient; harmlessness treatment of fly ash and biomass pyrolysis gasification residue can be realized; the porous biological ceramsite product is prepared from waste incineration fly ash and biomass pyrolysis residue; quantity demand of ceramsite industrial on natural raw materials is reduced; and environment-protection value and economic value are both high.

Owner:PEKING UNIV SHENZHEN GRADUATE SCHOOL

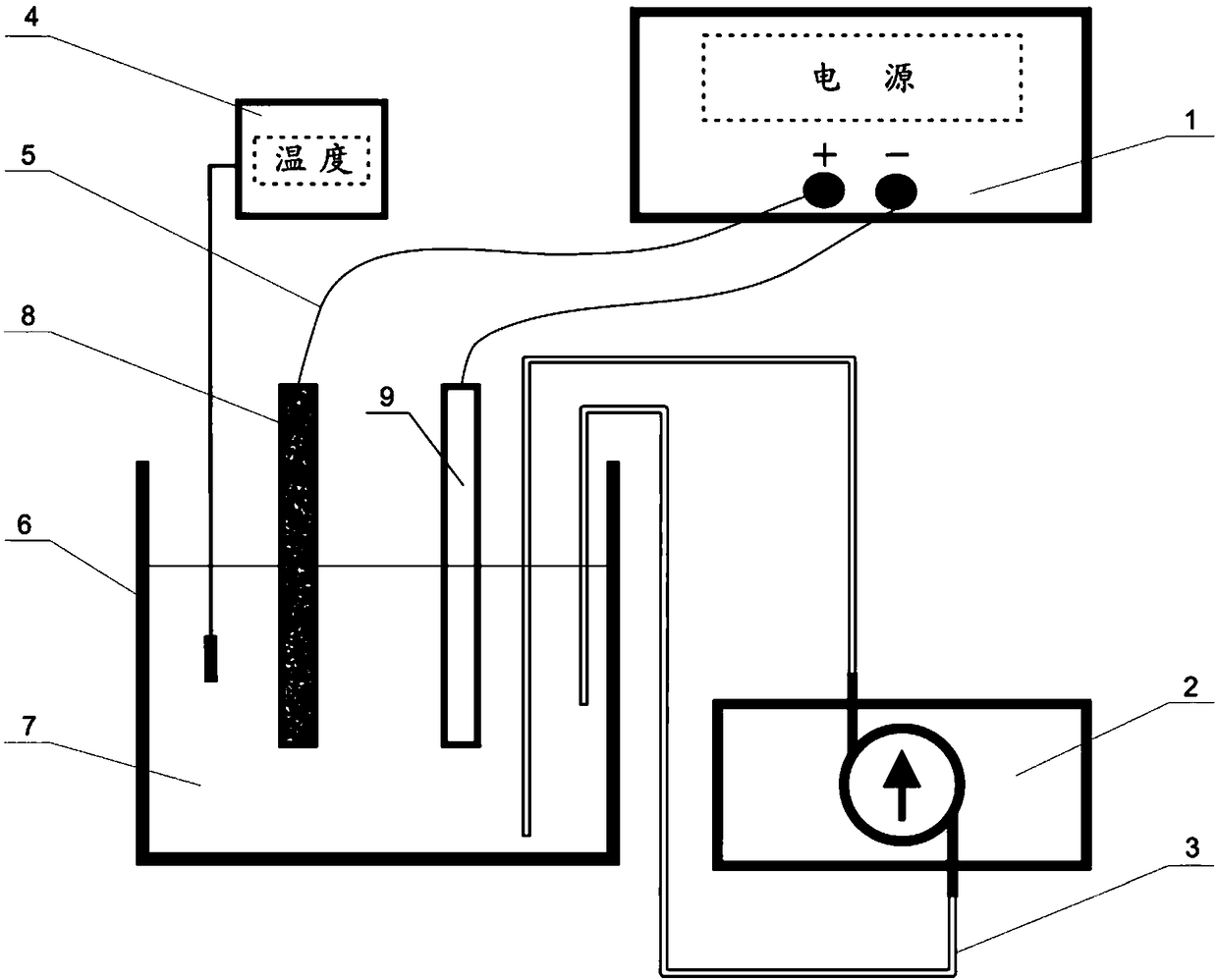

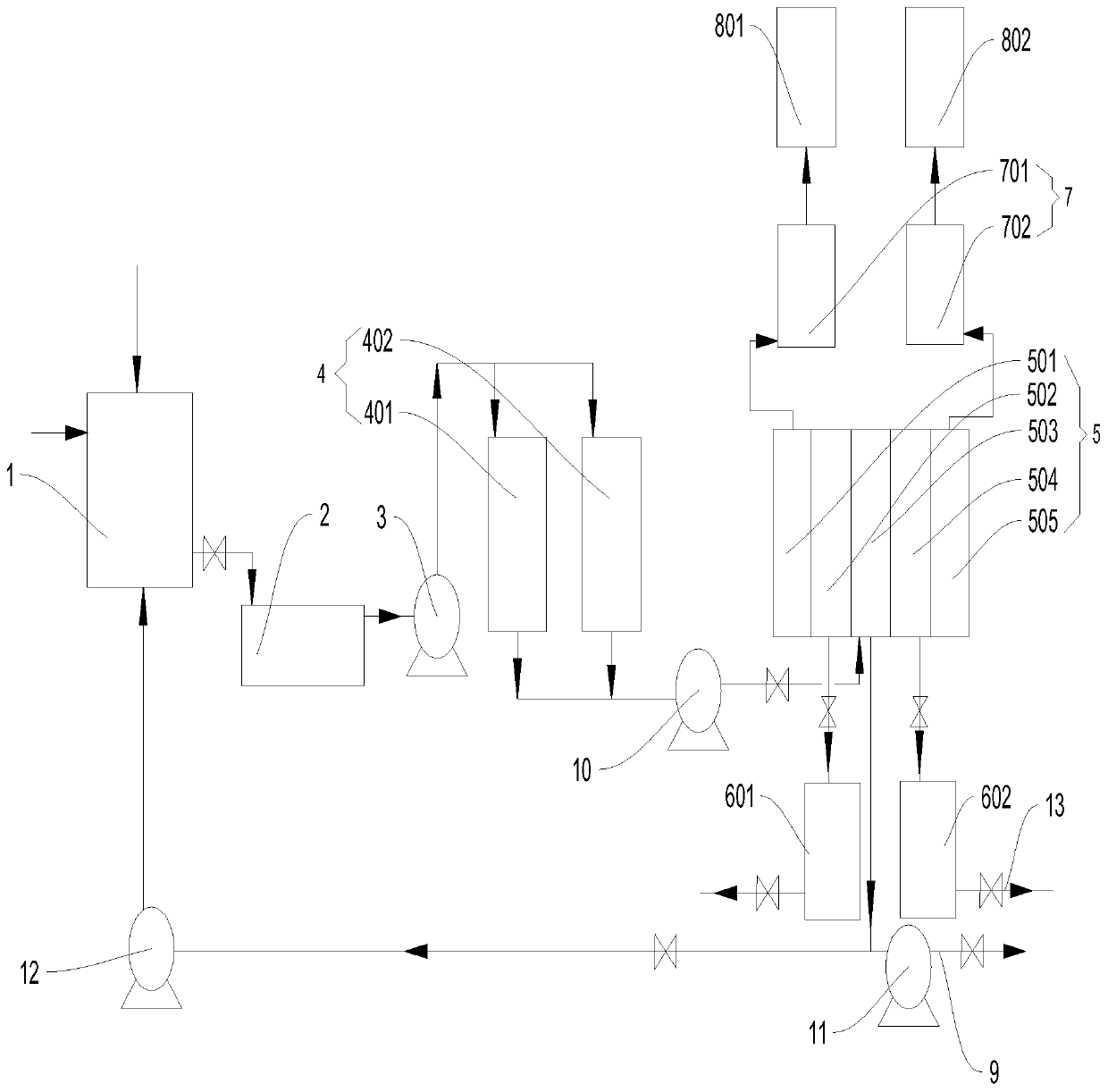

Device and method for electrolytically treating mirabilite by utilizing bipolar membrane electrodialysis equipment

PendingCN111003854AReduce manufacturing costReduce sales pressureCellsWater contaminantsElectrolysisPhysical chemistry

The invention belongs to the technical field of solid waste treatment processes, and particularly relates to a device and a method for electrolytically treating mirabilite by utilizing bipolar membrane electrodialysis equipment. The device comprises a dissolving tank, a settling tank, a first delivery pump, a second delivery pump, a third delivery pump, an ion exchange resin device and bipolar membrane electrodialysis equipment. The method for treating mirabilite comprises the following steps: mixing mirabilite and soft water in a dissolving tank, and standing in a settling tank to settle impurities such as silt and the like in the mirabilite solution; feeding into an ion exchange resin device, and intercepting calcium, magnesium, zinc and other ions in the solution; feeding the filtrate into a salt chamber in bipolar membrane electrodialysis equipment, respectively adding water with the same volume as the filtrate into the acid chamber and the alkali chamber of the bipolar membrane electrodialysis equipment, and starting the electrolyzing of the bipolar membrane electrodialysis equipment; and when the electric conductivity of the filtrate in the salt chamber of the bipolar membrane electrodialysis equipment is less than or equal to 20 mS / cm, completing the sodium sulfate treatment of the filtrate in the salt chamber to achieve the emission standard.

Owner:阿拉尔市中泰纺织科技有限公司 +1

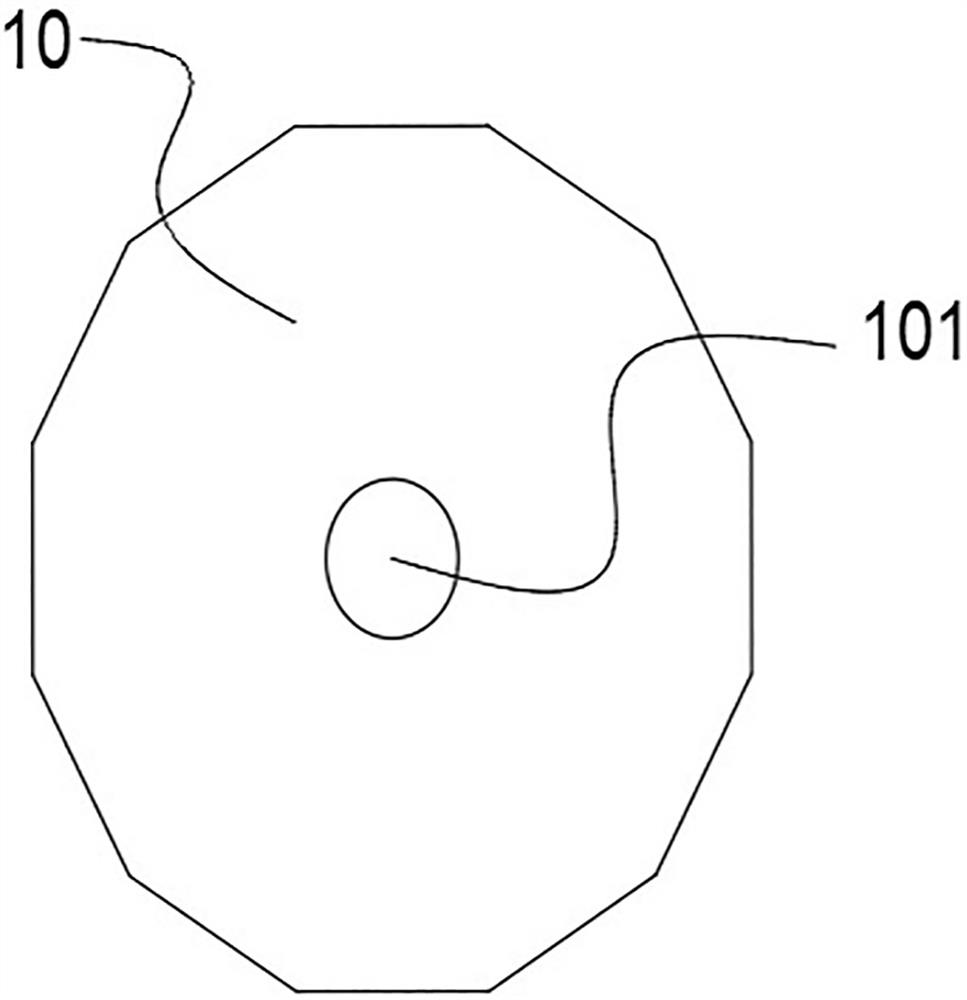

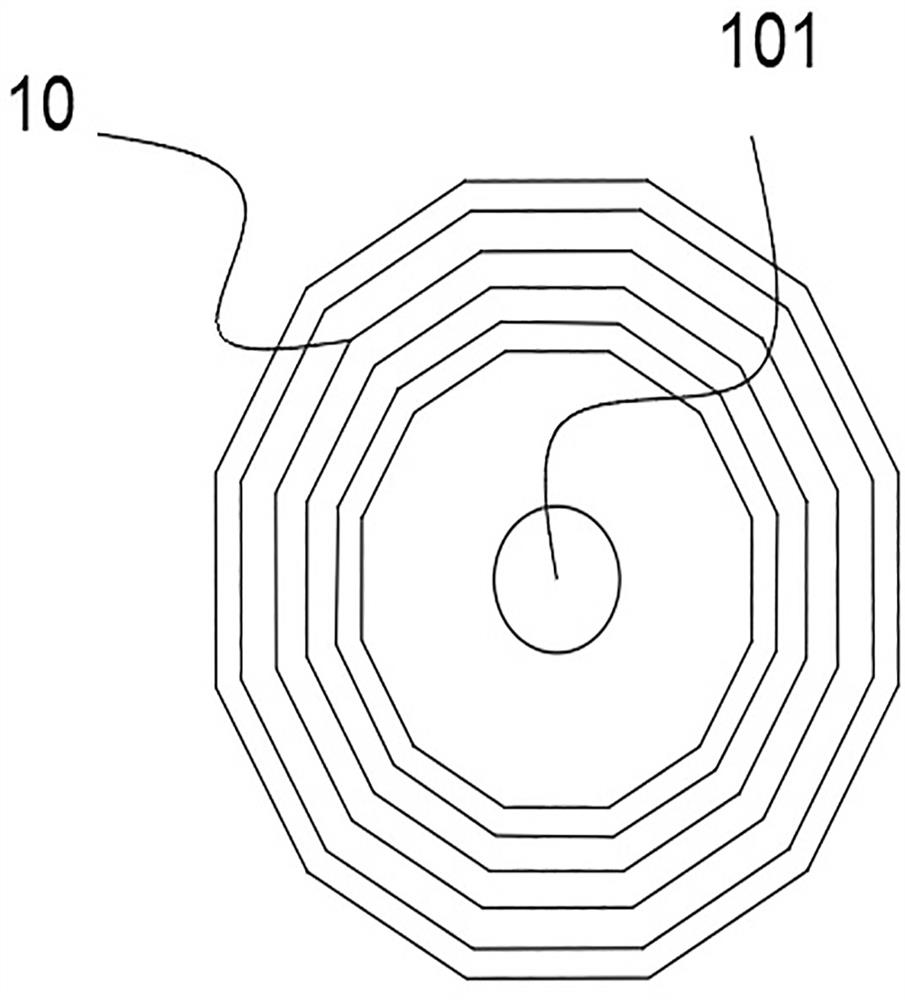

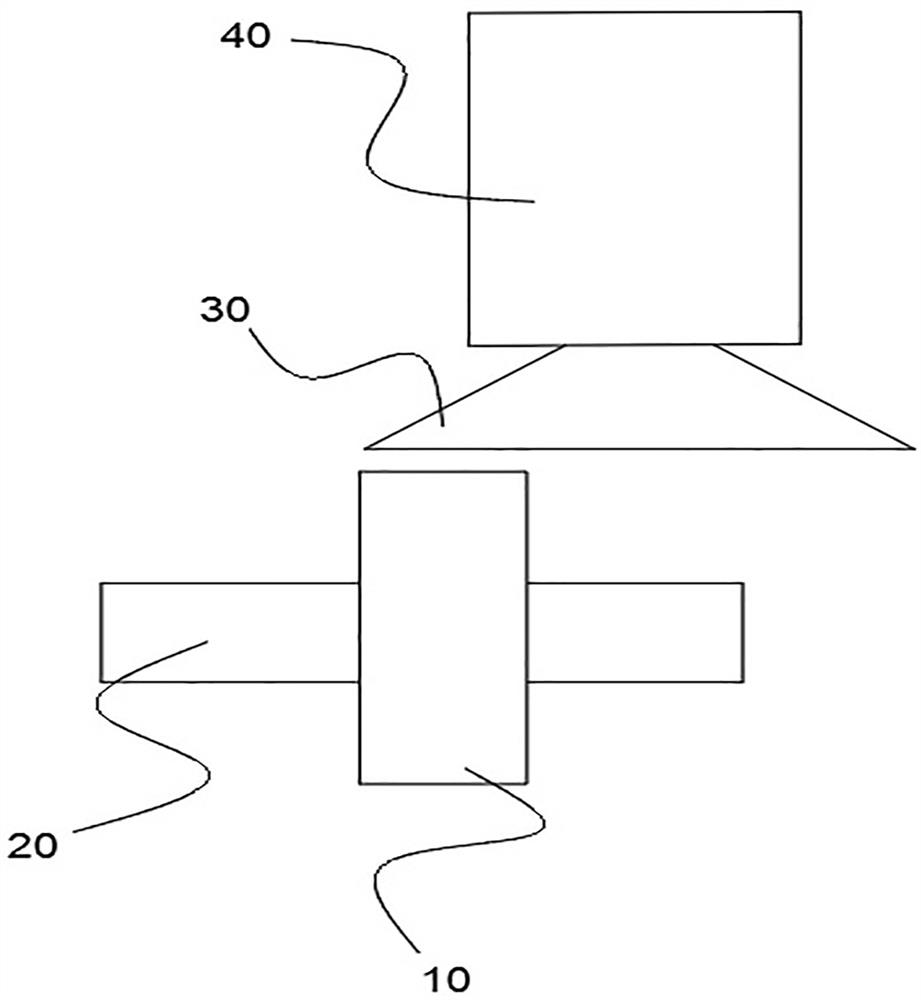

Workpiece for thermal error detection, detection method and processing method

ActiveCN113500459AEasy to makeMeet the measurementMeasurement/indication equipmentsPrismMachine tool

The invention discloses a workpiece for thermal error detection, a detection method and a processing method. The workpiece comprises a workpiece body, wherein the workpiece body comprises a prism, the axis of the prism is provided with a central through hole for a clamp to clamp, the side surface of the prism is provided with a color coating; according to the detection method, thermal error data can be obtained by judging the surface abrasion condition of the workpiece body, and detection of the thermal error data of the machine tool under the actual working condition under the condition that cuttings and cutting fluid exist is achieved; and according to the processing method, recycling of the workpiece after error detection is achieved, social resources are saved, and operation and execution are easy.

Owner:SICHUAN UNIV

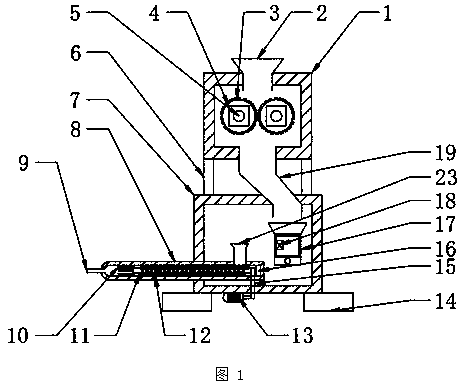

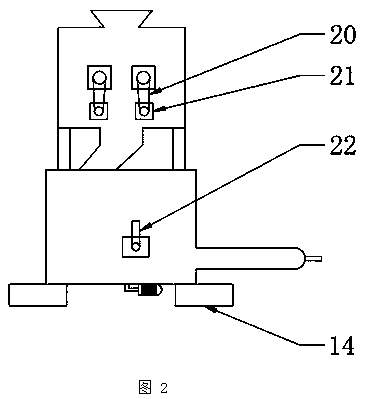

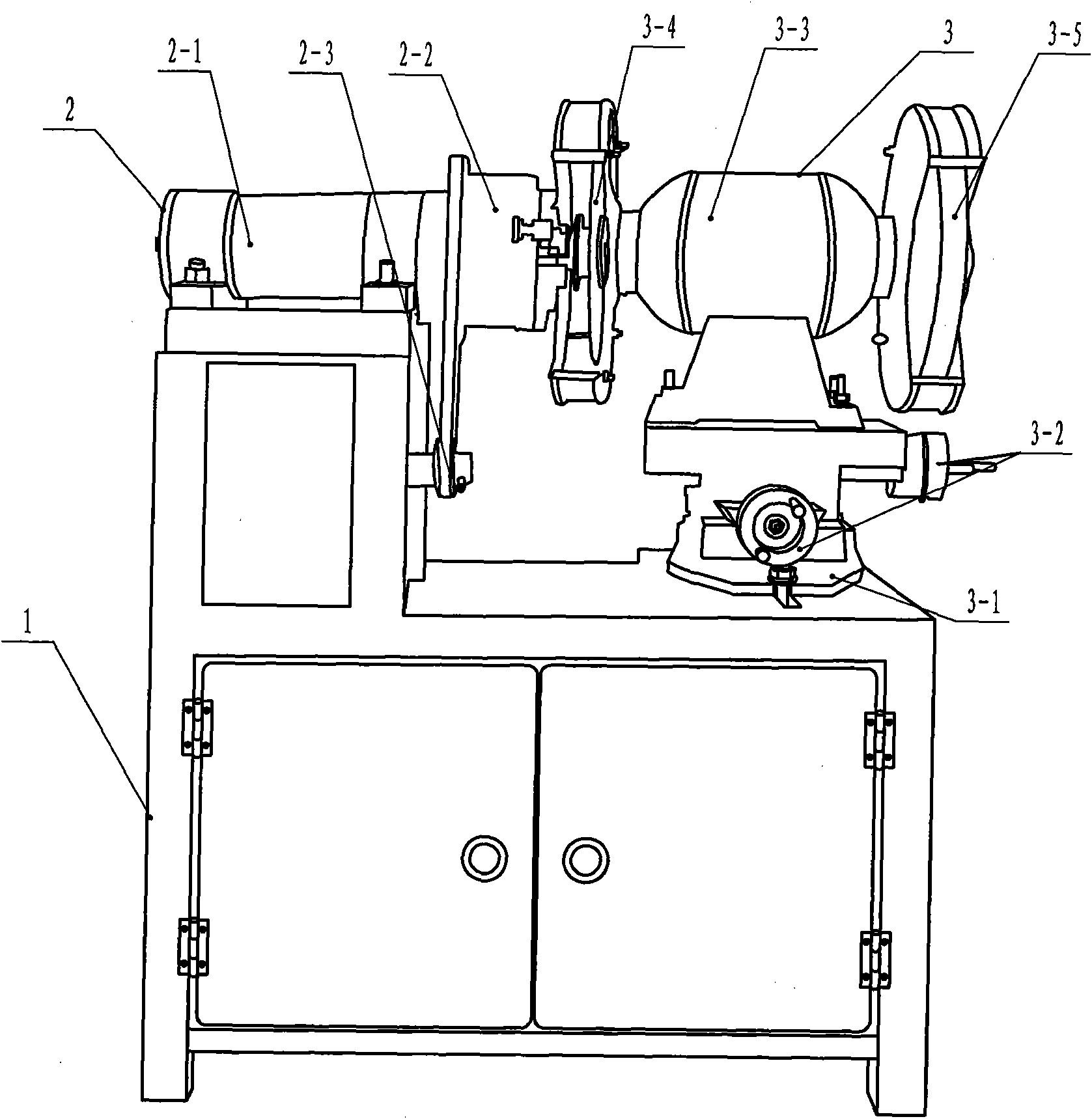

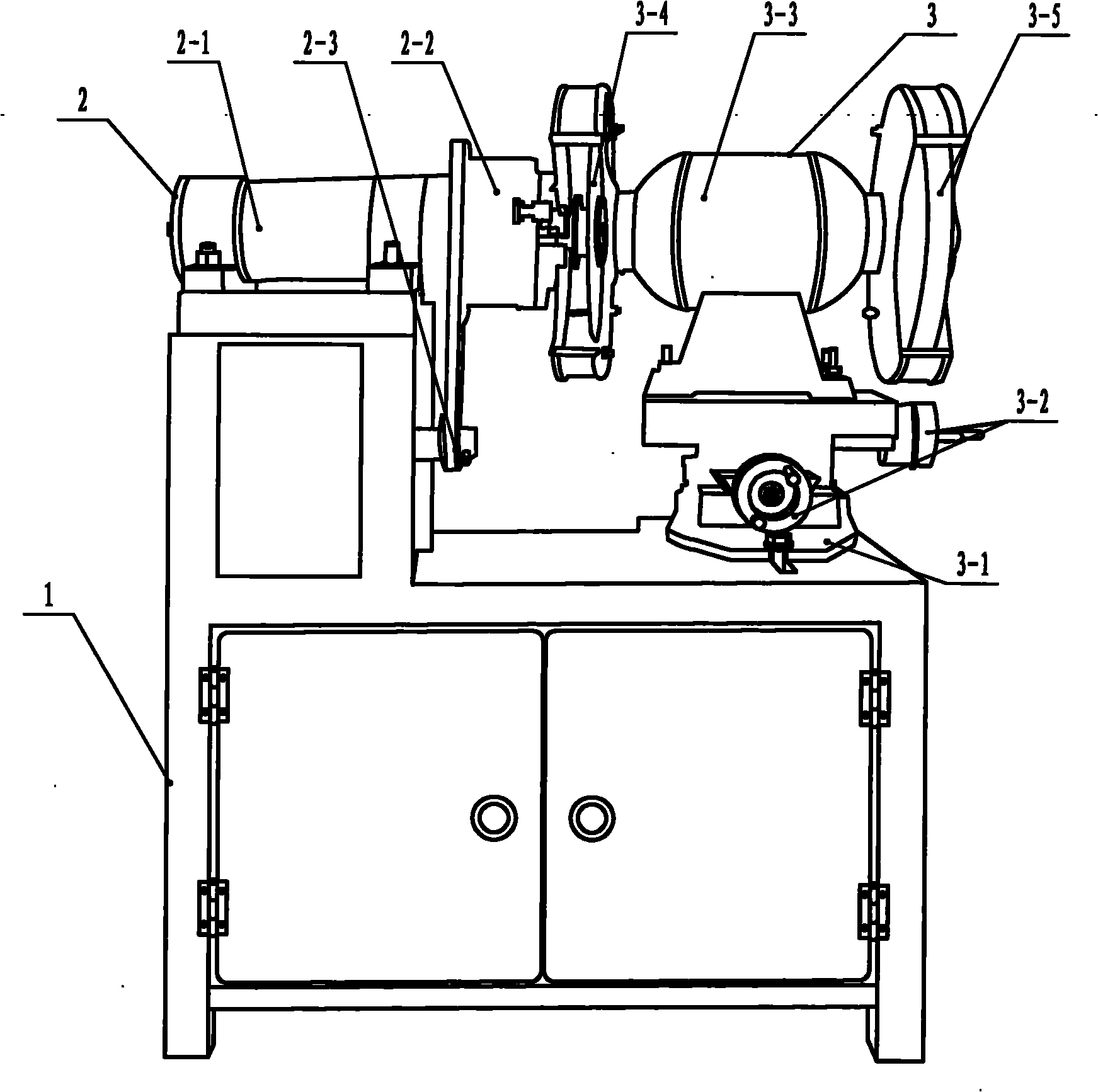

Drill grinder

The invention discloses a drill grinder, which is characterized by consisting of a counter, a chuck mechanism fixedly connected to the counter and a rotary cross workbench which is arranged on the counter and opposite to the chuck mechanism. The drill grinder has the advantages of low cost, simple structure, compaction, light weight, simple operation, low power consumption, high working efficiency, suitability for grinding on a construction site, three functions of cutting, grinding a conical surface and grinding an alloy drill bit, great reduction in steel consumption and capital due to repair and reuse of waste drill bars, and stable size and angle, and high product quality because of using a grinding wheel for grinding the conical surface..

Owner:潘双津 +1

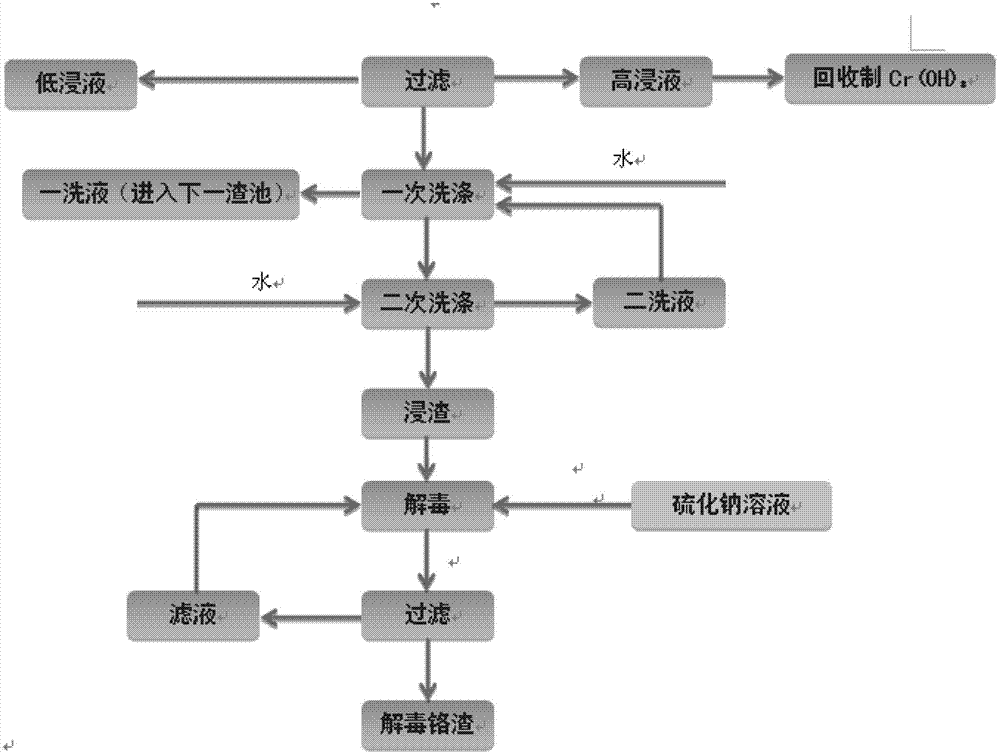

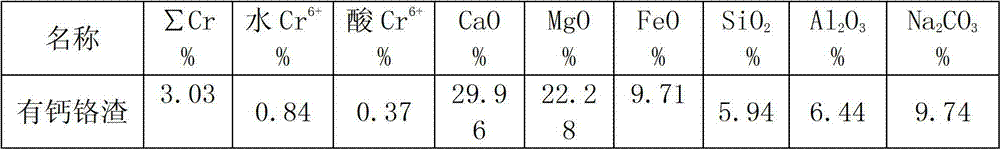

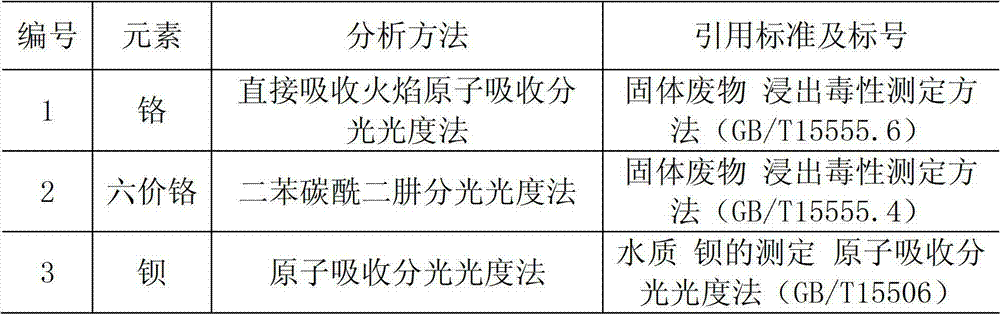

Integral leaching detoxication and landfill treatment method of chromium slag

InactiveCN102755985ARecycling is possibleRemove the risk of pollutionSolid waste disposalPregnant leach solutionSlag

The invention discloses an integral leaching detoxication and landfill treatment method of chromium slag. The method comprises the steps of: 1) creating a detoxication pool on the ground: arranging an impermeable layer on the wall surface of a landfill pool, and arranging a flow guide system for guiding the flow outwards in the detoxication pool; 2) conveying the chromium slag to be treated in the detoxication pool, adding water in the detoxication pool, enabling the chromium slag to leach out hexavalent chromium and / or compound hexavalent chromium in the water, and the added water becomes lixivium; 3) recycling the lixivium through the flow guide system, adding water in the detoxication pool to perform circular percolation until the chromium slag is soaked for 5 months, adding alkali sulfide in the detoxication pool to reduce the hexavalent chromium if the content of the hexavalent chromium in the lixivium is not larger than 0.5-1g / L, and executing the detoxication reaction; and 4) burying and closing the detoxication pool after the detoxication treatment. The method disclosed by the invention treats the chromium slag through the integral leaching detoxication and landfill treatment technology, so that the method is an efficient chromium slag treatment having no secondary pollution and capable of really recycling the chromium resource.

Owner:LIAONING SING HORN GROUP CO LTD

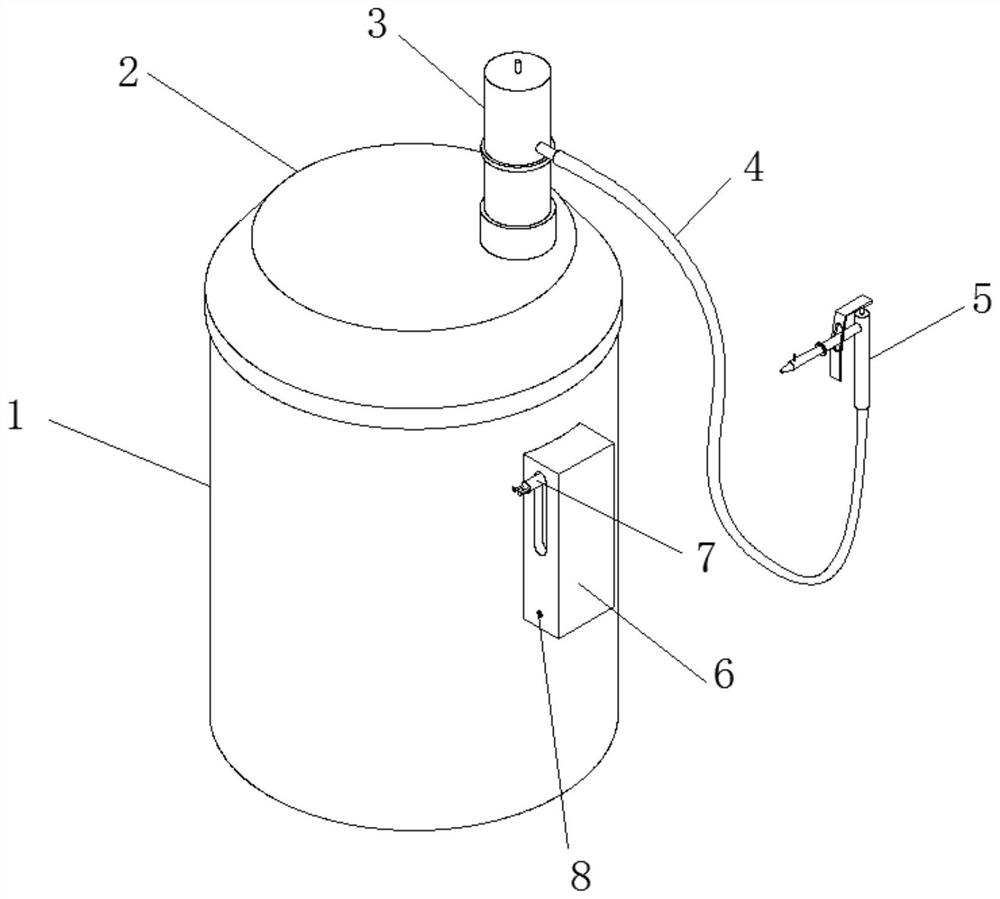

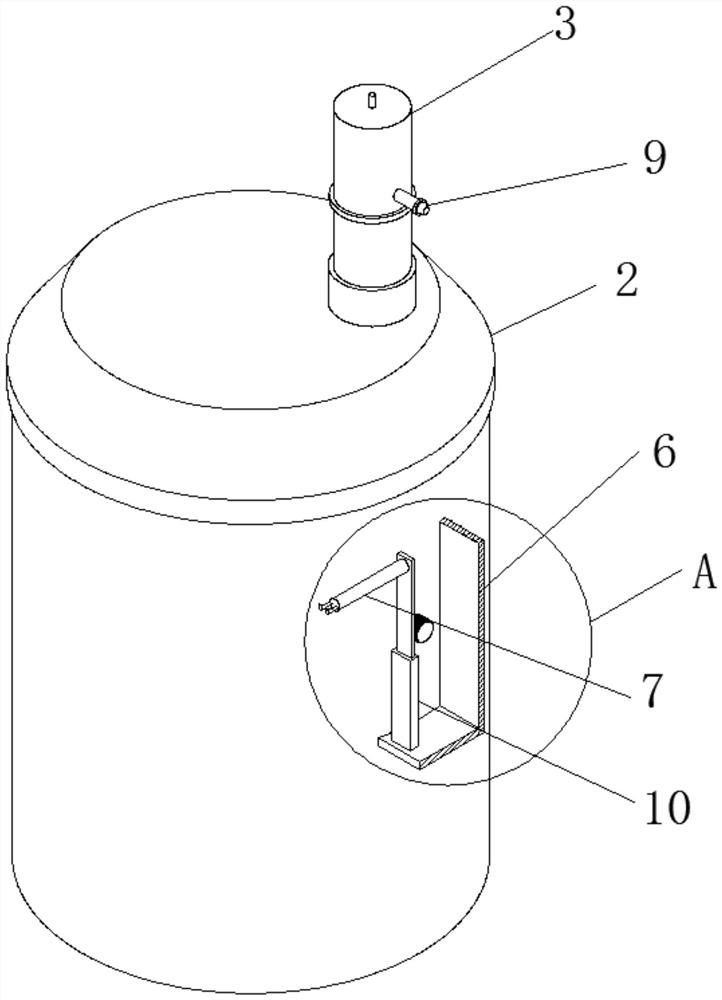

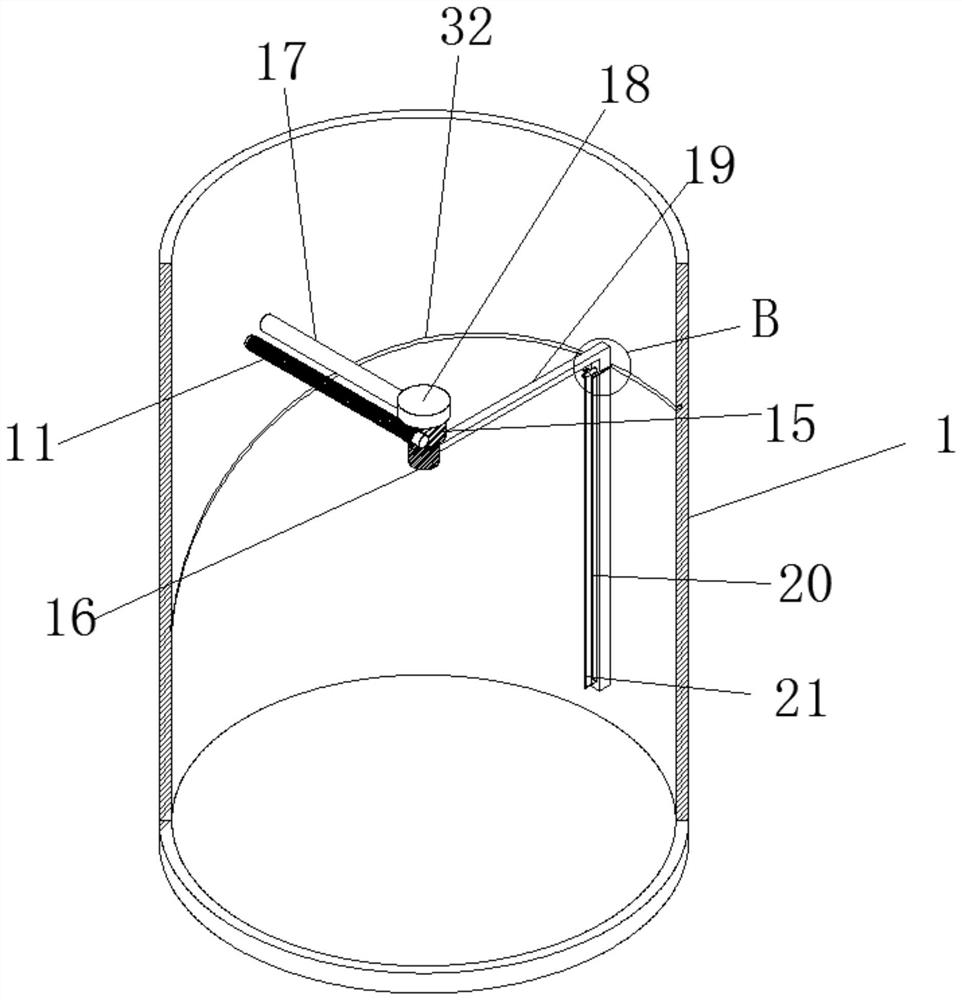

Lubricating and oiling equipment for mechanical equipment parts

PendingCN114646011AEffective scraping and reusePrevent spoilageHollow article cleaningCleaning using toolsOil and greaseGear wheel

The invention provides lubricating and oiling equipment for mechanical equipment parts. The lubricating and oiling equipment is novel in structural design. Comprising a barrel body, a barrel cover covers the upper end of the barrel body, a pump head is vertically fixed to one side of the upper portion of the barrel cover through bolts, an oil gun is inserted into the end, away from the pump head, of a high-pressure oil pipe, an L-shaped scraper is horizontally welded to the lower portion of one side of a tooth column, and a strip-shaped through groove is vertically formed in the side, away from a gear, of the L-shaped scraper in the length direction of the L-shaped scraper. By means of the oil gun containing frame, attached grease can be effectively scraped and reused, the phenomenon that the grease is attached to the barrel wall for a long time and goes bad and expires is avoided, the oil gun containing frame is used for containing the oil gun, the oil gun containing frame is used for containing the oil gun, and the oil gun containing frame is convenient to use. The operation habit of people is met, the scraper is separated from the surface of the L-shaped scraper when ascending, and the situation that grease is scraped back to the upper end of the L-shaped scraper when the scraper moves upwards is avoided.

Owner:安徽耀达电机股份有限公司

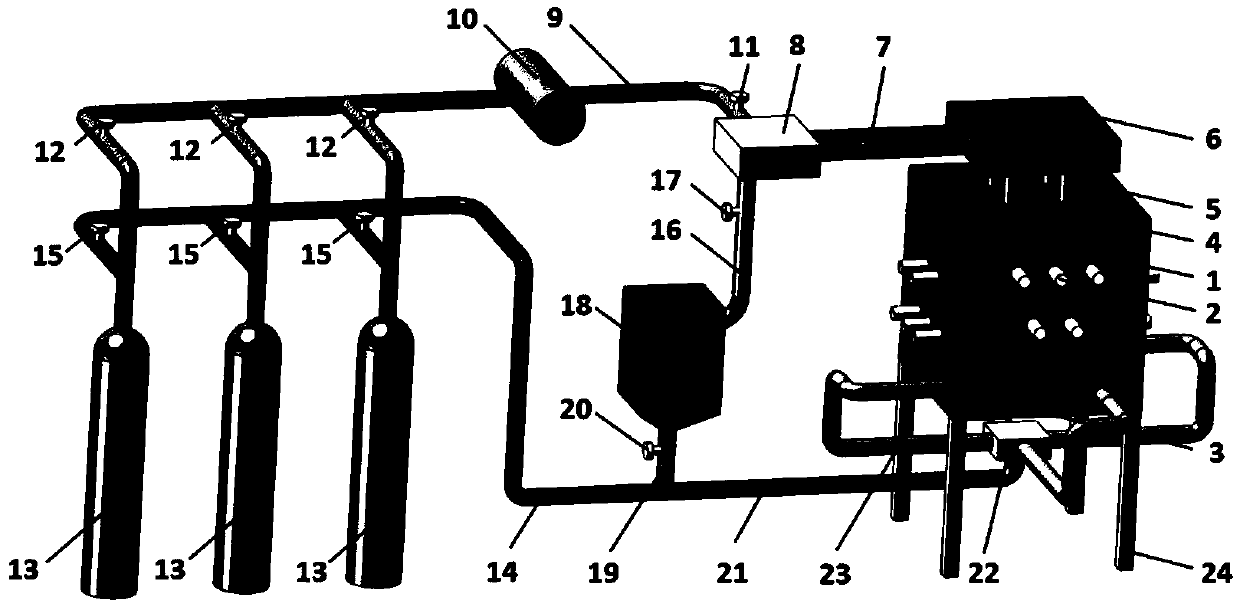

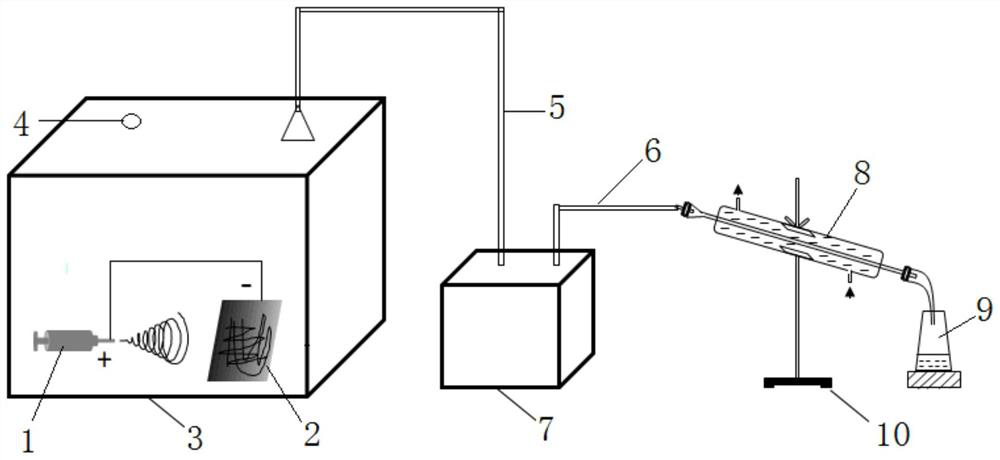

Direct carbon solid oxide fuel cell stack and power generating apparatus thereof

ActiveCN109599582AIncrease disturbanceIncrease contact areaReactant parameters controlFuel cellsElectrical battery

The present invention discloses a direct carbon solid oxide fuel cell stack and a power generating apparatus thereof. The CO2 gas cylinder provides high pressure CO2 to be mixed with carbon powder supplied to a carbon machine. Then a mixture of CO2 and the carbon power enters the stack by using a mixed inlet pipe to make the mixture of CO2 and the carbon powder spirally flow inside the stack. In addition, adjacent upper and lower SOFC cells in the stack are staggered by 90 degrees, the adjacent cells are reversely arranged, and the spirally flowing carbon fuel is disturbed, so that the carbonfuel is uniformly distributed on a surface of an anode of the cell. After reaction, tail gas is filtered and separated, and then is recycled and reused by using a CO2 recycling pipeline and a carbon recycling pipeline to improve efficiency. After air enters a stack reaction, the air is discharged through an air outlet hole at the bottom of an air chamber, and the fuel is reheated by using a heat preservation effect of an air layer and high temperature residual heat of the discharged air, and heat compensation is provided for a Boudouard reaction, to ensure that the Boudouard reaction is quickly and steadily performed.

Owner:创电(上海)新能源科技有限公司

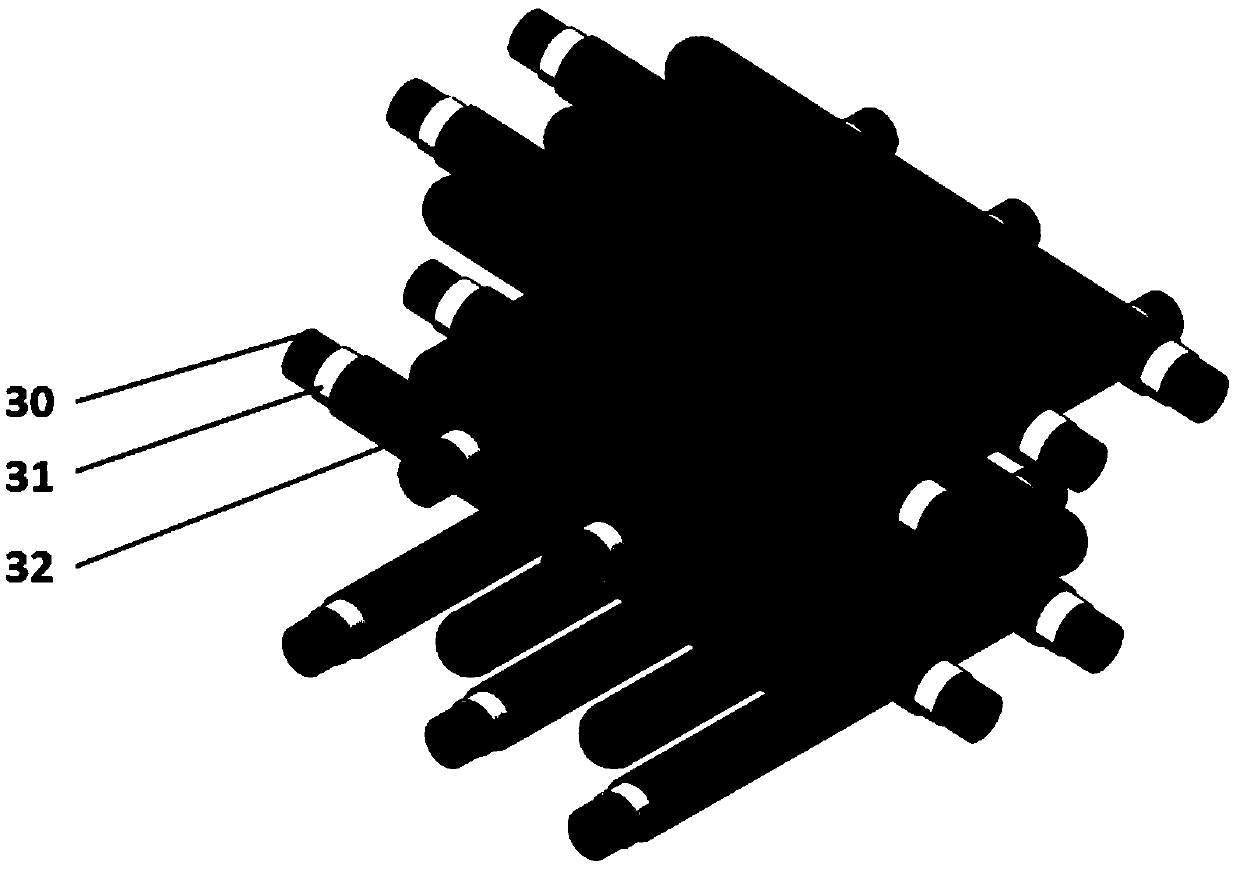

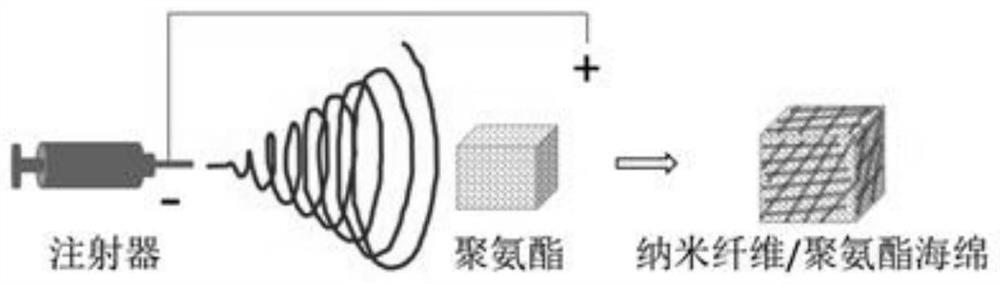

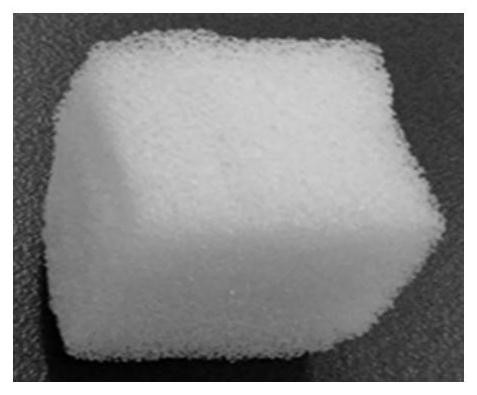

A kind of preparation method and application of nanofiber/polyurethane hydrophobic sponge

ActiveCN110746639BSimple preparation processImprove production efficiencyOther chemical processesElectro-spinningPolymer scienceHigh humidity

The invention discloses a preparation method and application of a nanofiber / polyurethane hydrophobic sponge. The preparation method includes the following steps: step 1, dissolving polyvinylidene fluoride-hexafluoropropylene (PVDF-HFP) in a solvent to form electrospinning liquid, the mass fraction of polyvinylidene fluoride-hexafluoropropylene in the electrospinning solution is 10-25%; step 2, the polyvinylidene fluoride-hexafluoropropylene nanofiber Covering the polyurethane sponge to form a hydrophobic composite sponge; step 3, drying the hydrophobic composite sponge to obtain a polyvinylidene fluoride-hexafluoropropylene nanofiber / polyurethane hydrophobic sponge. The invention has the characteristics of simple preparation process, high efficiency, avoiding the use of strong poisonous and harmful reagents, and realizing the recycling and utilization of oil substances.

Owner:ANHUI POLYTECHNIC UNIV

Pretreatment process and device for industrial continuous waste tire cracking production

PendingCN108085045AWarm up evenlyGuaranteed sealing performanceProductsReagentsProcess engineeringTemperature difference

The invention belongs to the technical field of waste cracking, and particularly relates to a pretreatment process and device for industrial continuous waste tire cracking production. The process canrealize the whole tire automatic feeding of waste tires; during the feeding, the whole tire cleaning, preheating and drying can be realized; the device consists of an impurity removal device, a cleaning device, a water sealing feeding device, a drying device and the like; impurities can be prevented from entering the subsequent cracking process along with the whole tire; meanwhile, the sealing ofthe feeding device is realized; the better connection with the cracking device can be realized; the weight of the sealing structure is reduced; meanwhile, the preheated whole tire enters the crackingprocess, so that the temperature difference can be reduced; the cracking efficiency is improved.

Owner:NIUTECH ENVIRONMENT TECHNOLOGY CORPORATION

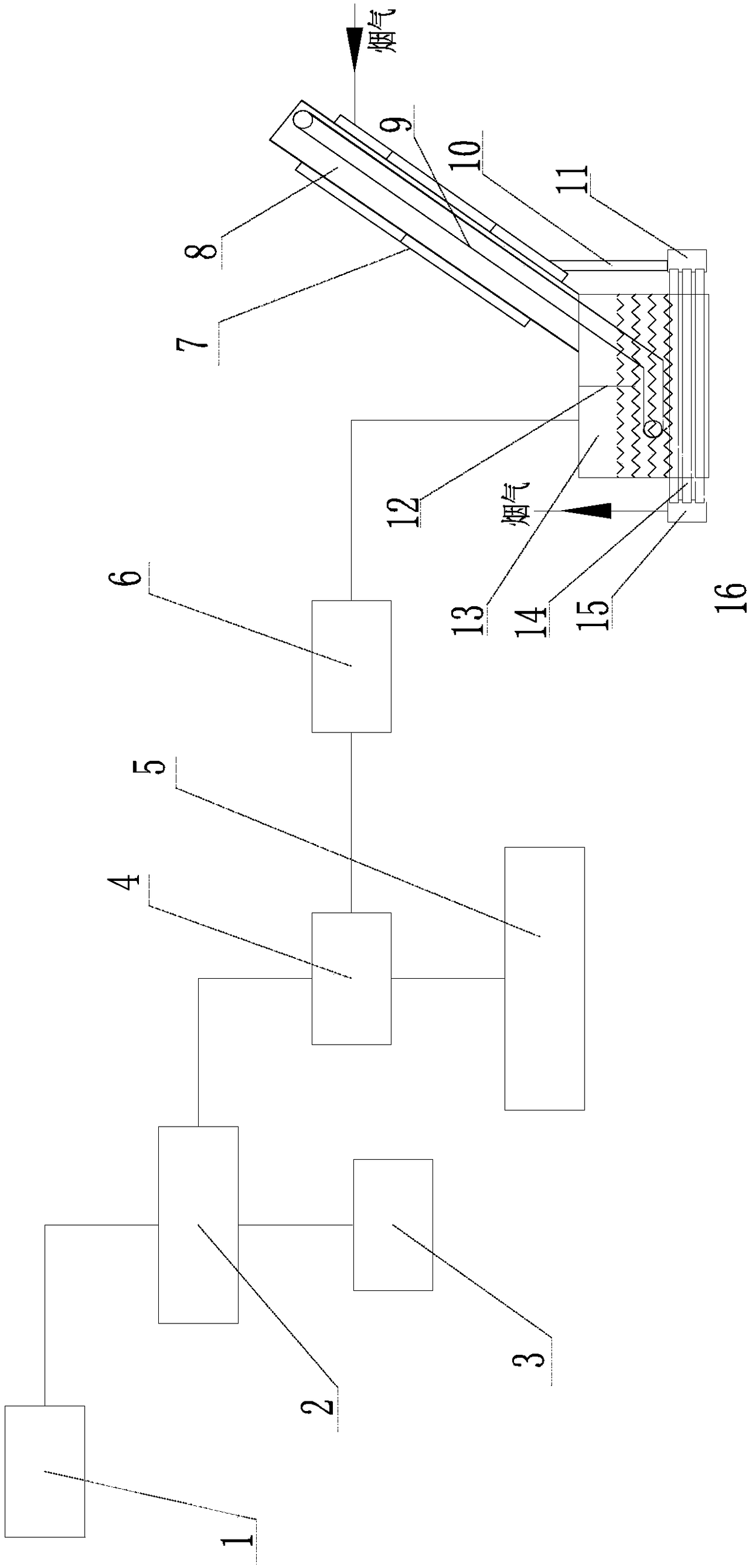

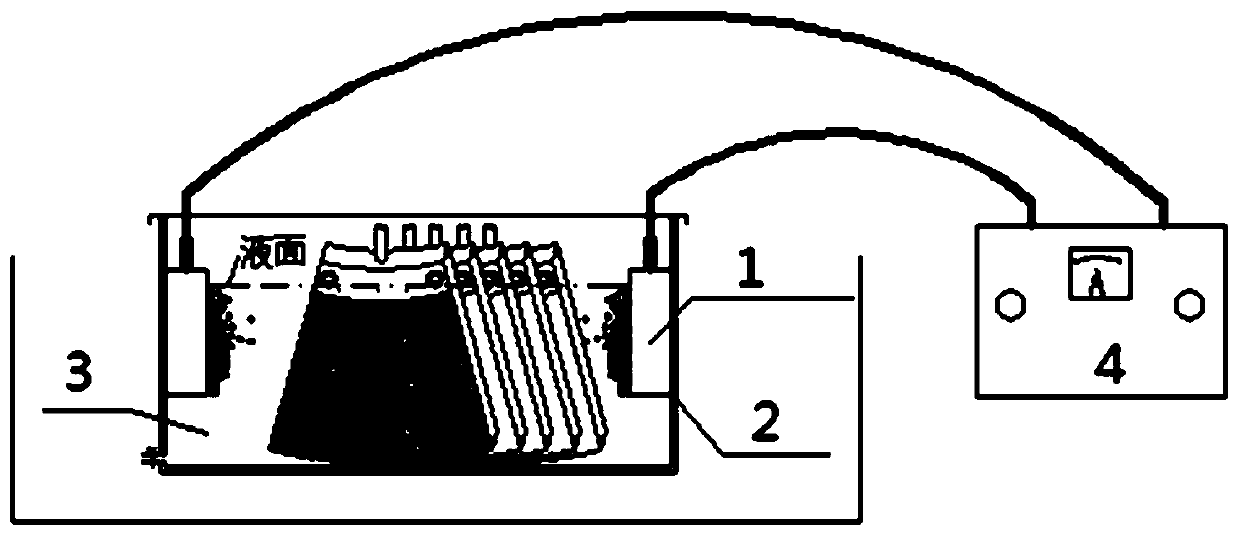

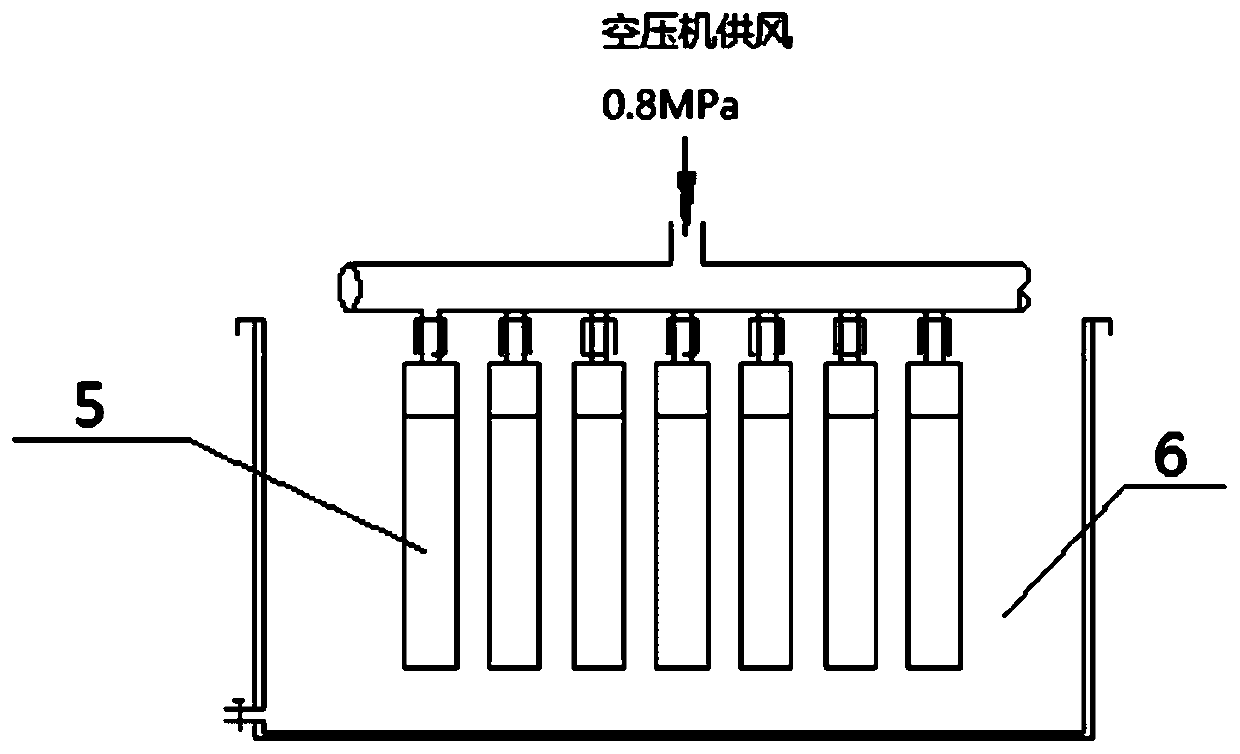

Mining ceramic filter plate cleaning device and using method thereof

InactiveCN110947244ARecycling is possibleMeet the requirements of industrial useCleaning using gasesCleaning using liquidsTransducerProcess engineering

The invention discloses a mining ceramic filter plate cleaning device and a using method thereof. The mining ceramic filter plate cleaning device comprises an ultrasonic oscillation device, a soakingdevice and a back flushing device, wherein the ultrasonic oscillation device comprises an ultrasonic transducer (1) and an ultrasonic signal generator (4); the soaking device comprises a cleaning tank(2), and the cleaning tank (2) contains concentrated hydrochloric acid with the mass fraction of 36%; and the back flushing device comprises a back flushing device tank body, and a pressure tank, anair compressor and a connecting hose which are connected in sequence. By utilizing the mining ceramic filter plate cleaning device, the surfaces and capillary micropores of blocked waste ceramic filter plates can be cleaned up, the industrial use requirement is met, the waste ceramic filter plates are recycled, and the production cost is saved.

Owner:中矿金业股份有限公司

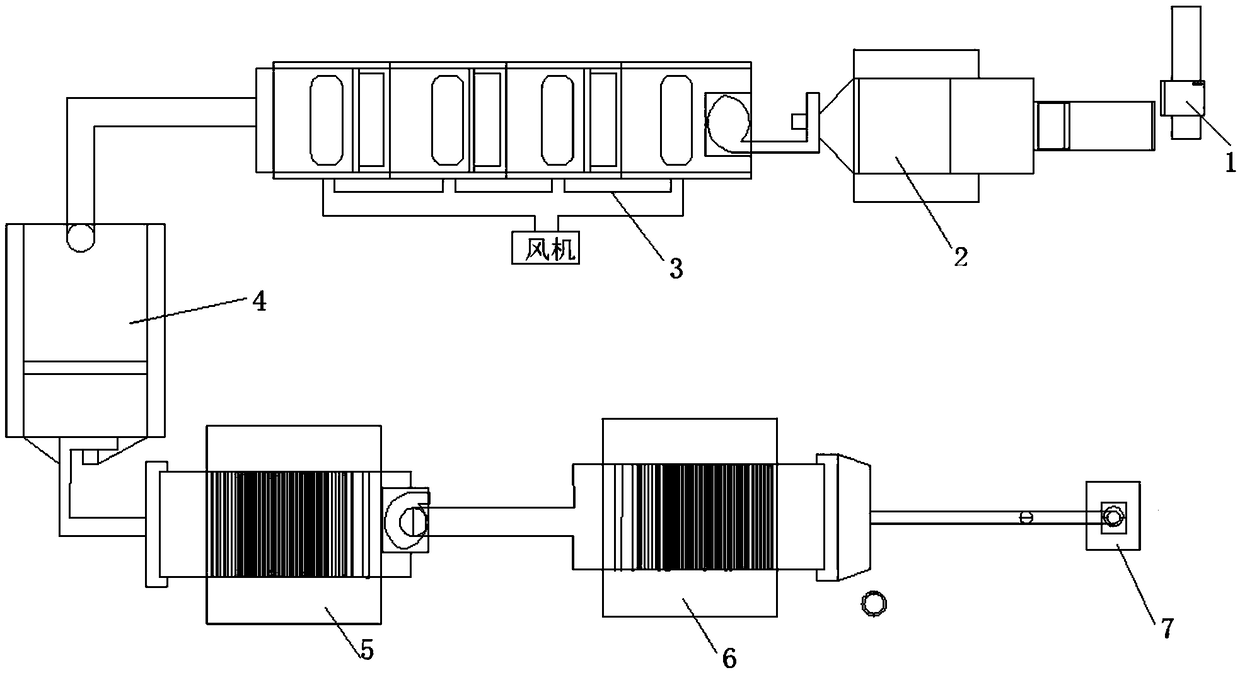

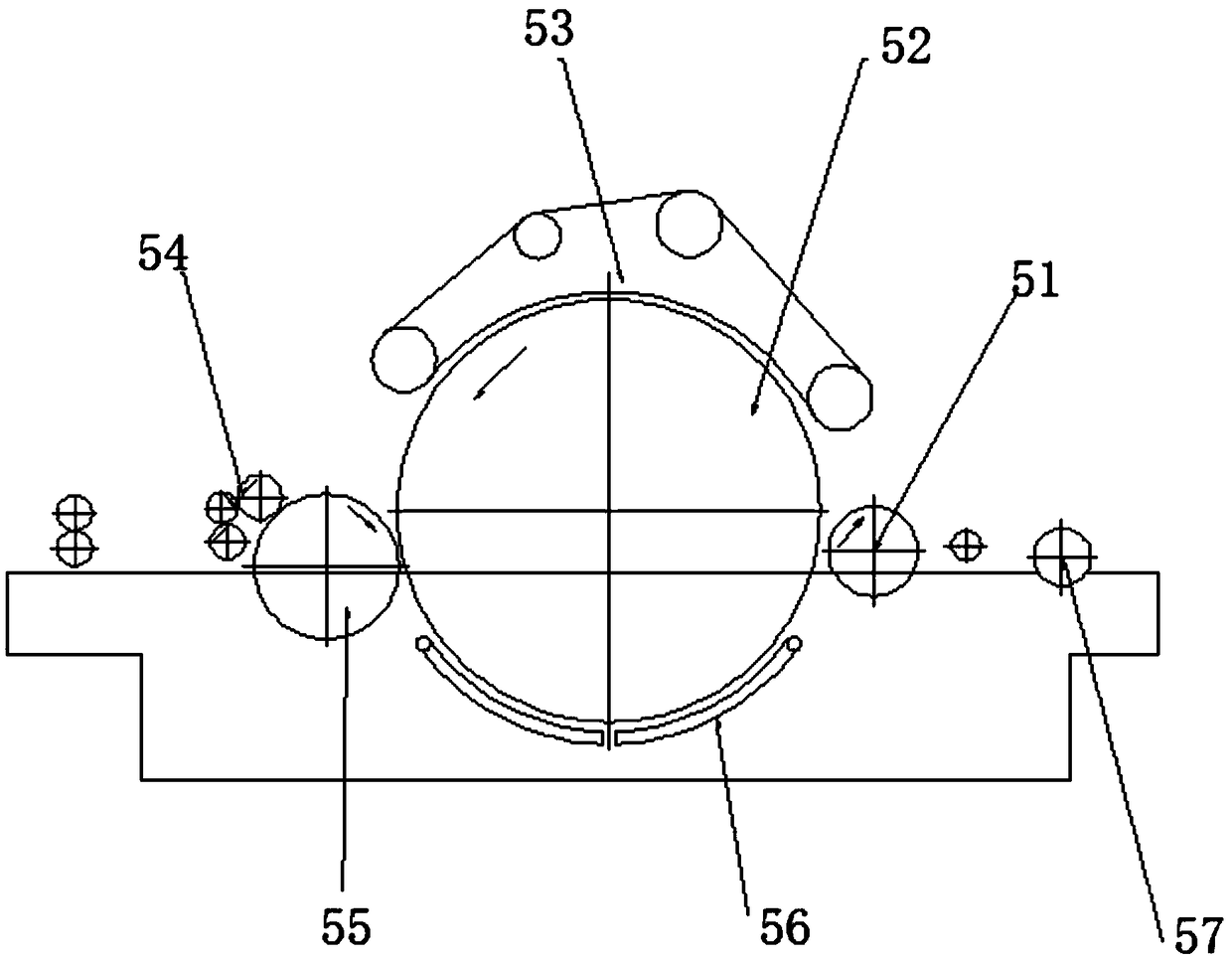

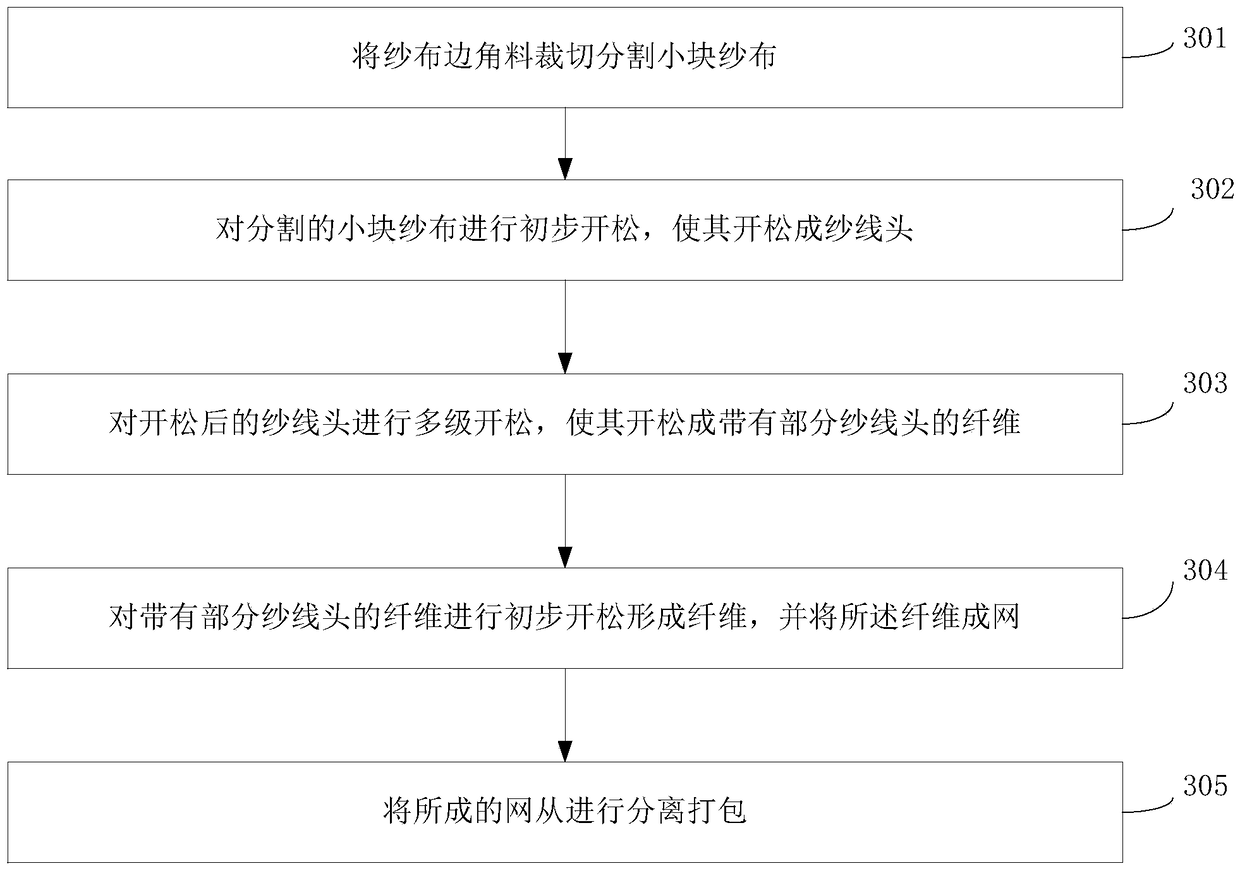

Medical gauze waste recycling equipment and method

PendingCN109371510ARecycling is possibleOvercoming the problem of yarn endsTextile disintegration and recoveryFibre disintegrationYarnFiber

The invention relates to the technical field of waste recycling, in particular to medical gauze waste recycling equipment and method. The equipment comprises a cutting machine, a feeding machine, an opener, a first carding machine and an air-fiber separator. The cutting machine is used for cutting and segmenting input gauze waste to form small gauze pieces; the feeding machine is used for conducting primary opening on the small gauze pieces cut by the cutting machine to obtain yarn ends; the opener is used for conducting multi-stage opening on the yarn ends subjected to opening by the feedingmachine to form fibers with partial yarn ends; the first carding machine is used for conducting opening on the fibers with the partial yarn ends which are subjected to opening by the opener to form fibers, and the fibers are made into a net; the air-fiber separator is used for separating the formed fiber net from the air and packaging the fiber net into a bag. Through the equipment and the method,the medical gauze waste is converted into the medical fiber net without using and adding any chemical materials, and recycling is achieved; meanwhile, the problem that yarn ends are generated in an existing medical gauze waste recycling technology is solved.

Owner:AOMEI MEDICAL SUPPLIES CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com