Direct carbon solid oxide fuel cell stack and power generating apparatus thereof

A technology of fuel cell stacks and solid oxides, applied in fuel cells, fuel cell additives, electrochemical generators, etc., can solve the problems of slow Boudouard reaction, increase the reaction rate, increase the contact area, and avoid a large amount of stacked effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the purpose, technical solution and advantages of the present invention clearer, the direct carbon solid oxide fuel cell stack and its power generation device of the present invention will be further described in detail below in conjunction with the accompanying drawings.

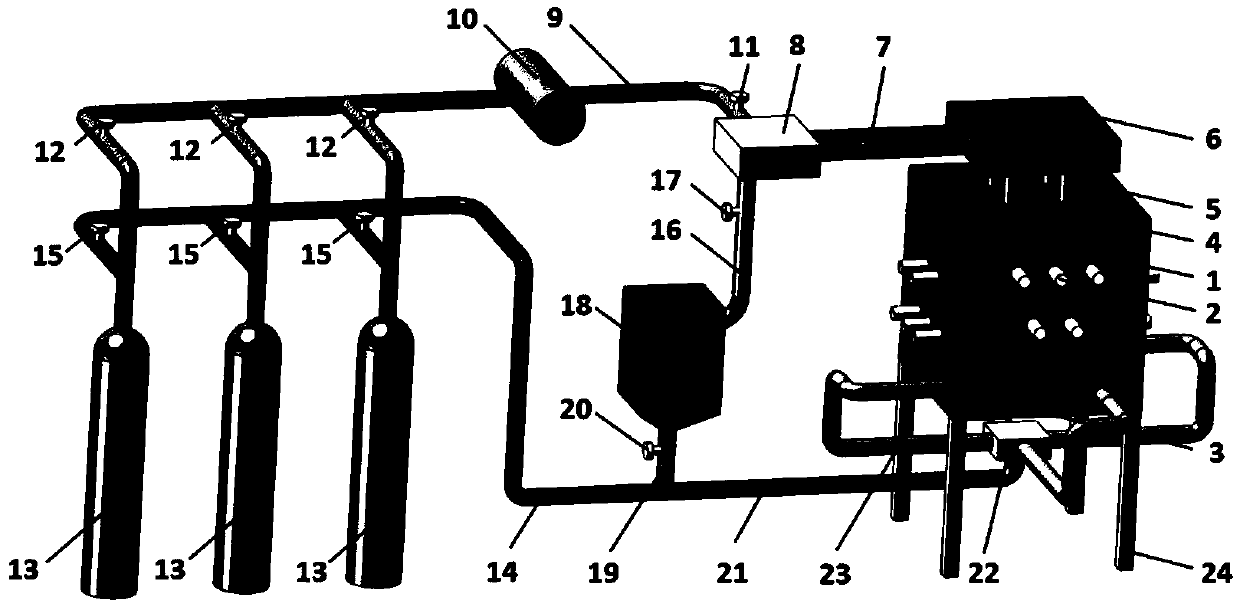

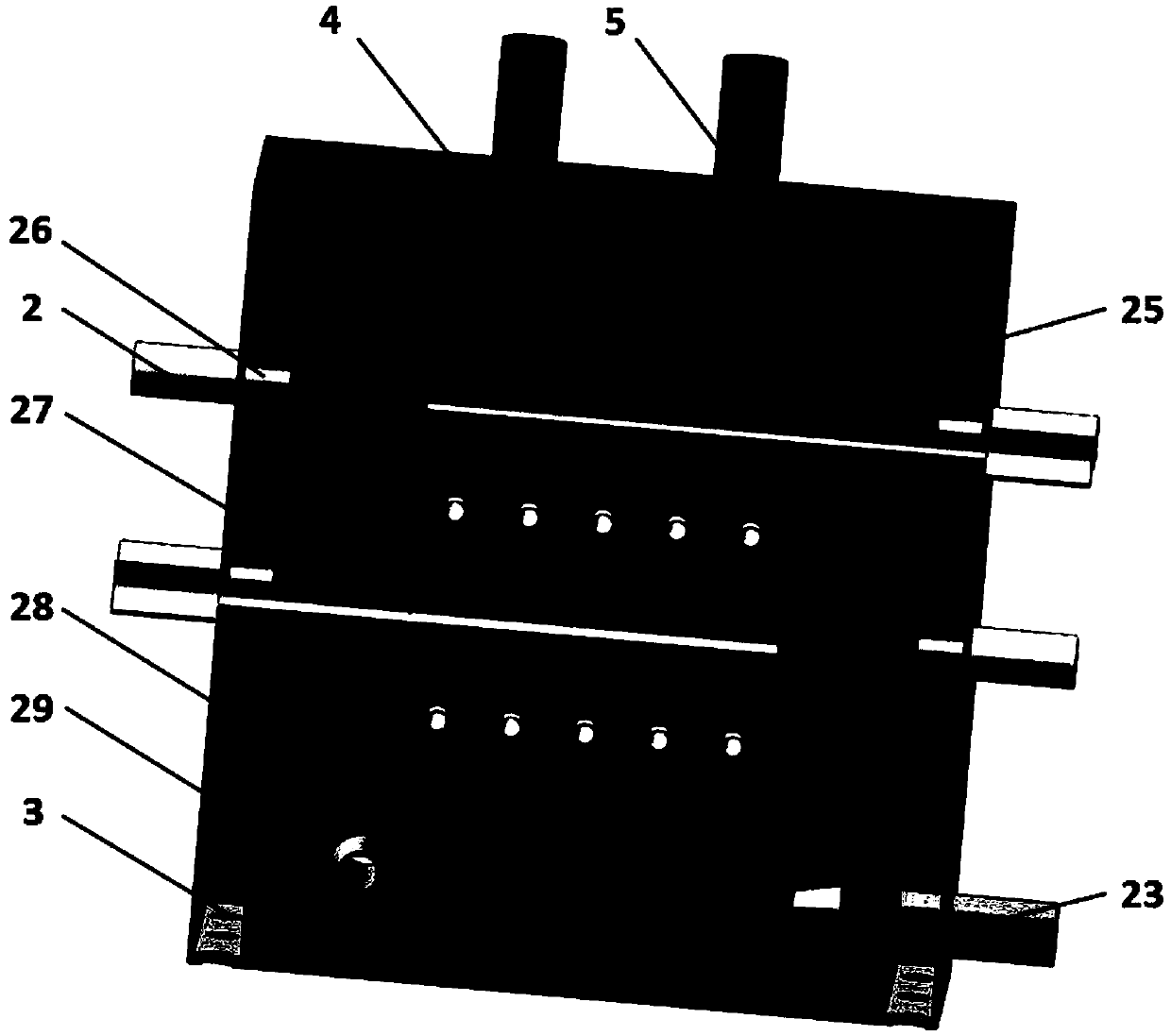

[0028] Such as figure 1 As shown, the direct carbon solid oxide fuel cell stack power generation device in this embodiment includes a SOFC stack 1, an air inlet pipe 2, an air outlet hole 3, a fixed end cover 4, and a CO 2 Outlet pipe 5, CO 2 Combiner box 6, transportation pipeline 7, filter 8, CO 2 Recovery pipeline 9, compressor 10, first control valve 11, intake valve 12, CO 2 Gas cylinder 13, CO 2 Gas outlet pipeline 14, gas outlet valve 15, carbon recovery pipeline 16, second control valve 17, carbon feeder 18, carbon delivery pipe 19, third control valve 20, gas-carbon mixing pipe 21, combiner box 22, mixing inlet pipe 23 and Stack support 24. A number of air inlet pipes 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com