Waste incineration boiler

A technology of waste incineration and boiler, which is applied in the field of waste recycling, can solve the problems of difficult burning of waste, poor combustion condition of waste, difficulty in fermentation of waste, etc., and achieves a wide range of adaptable calorific value, low heat reduction rate and high degree of automation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is specifically described below by the embodiment, only for further illustrating the present invention, can not be interpreted as the limitation of protection scope of the present invention, the technical engineer of this field can make some non-essential improvements and improvements to the present invention according to the content of the above-mentioned invention Adjustment.

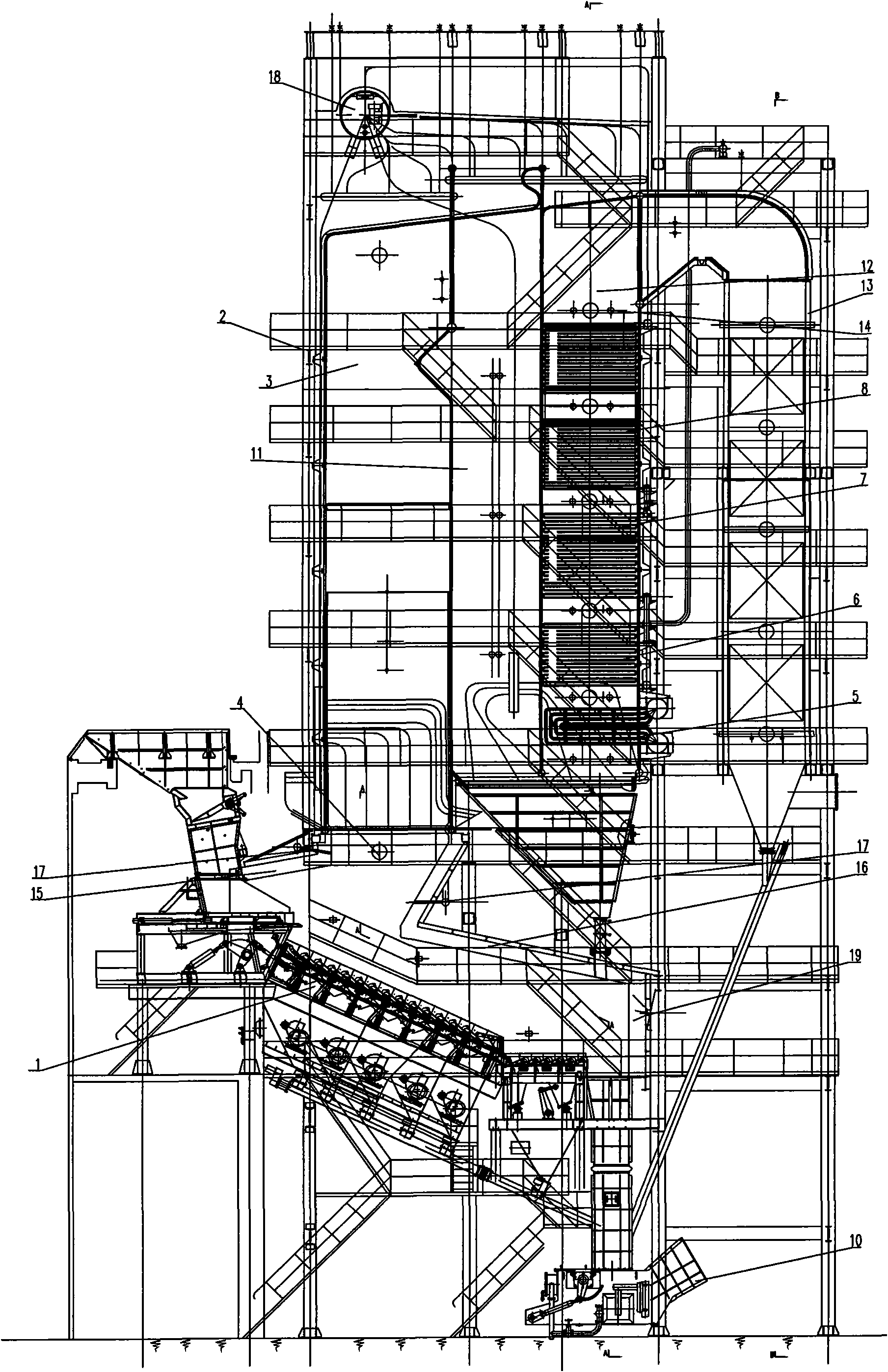

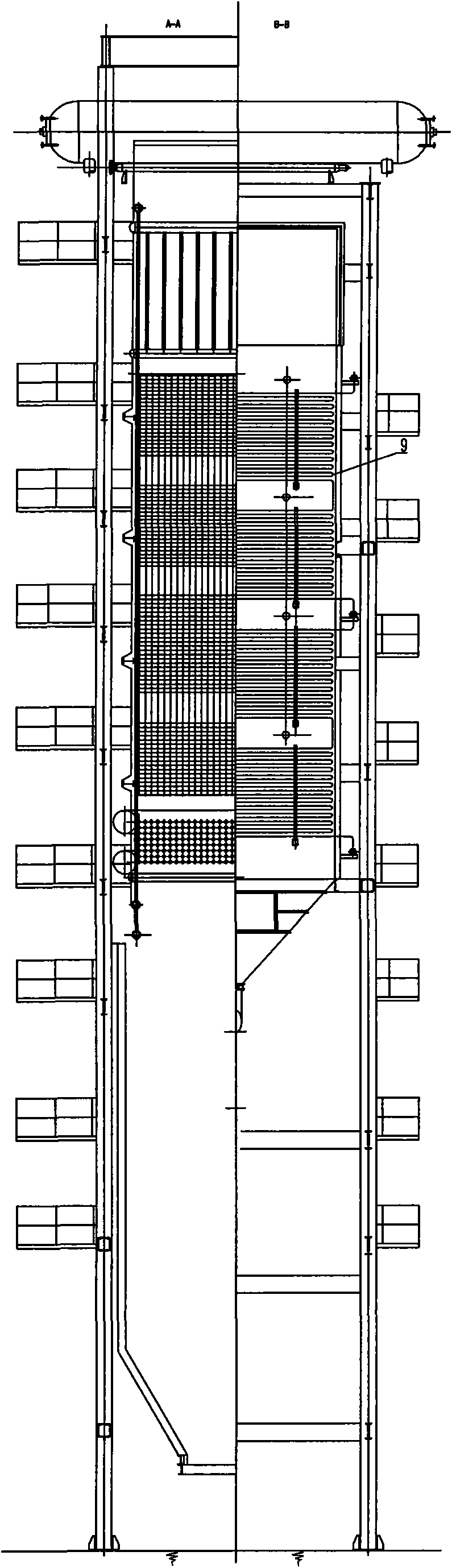

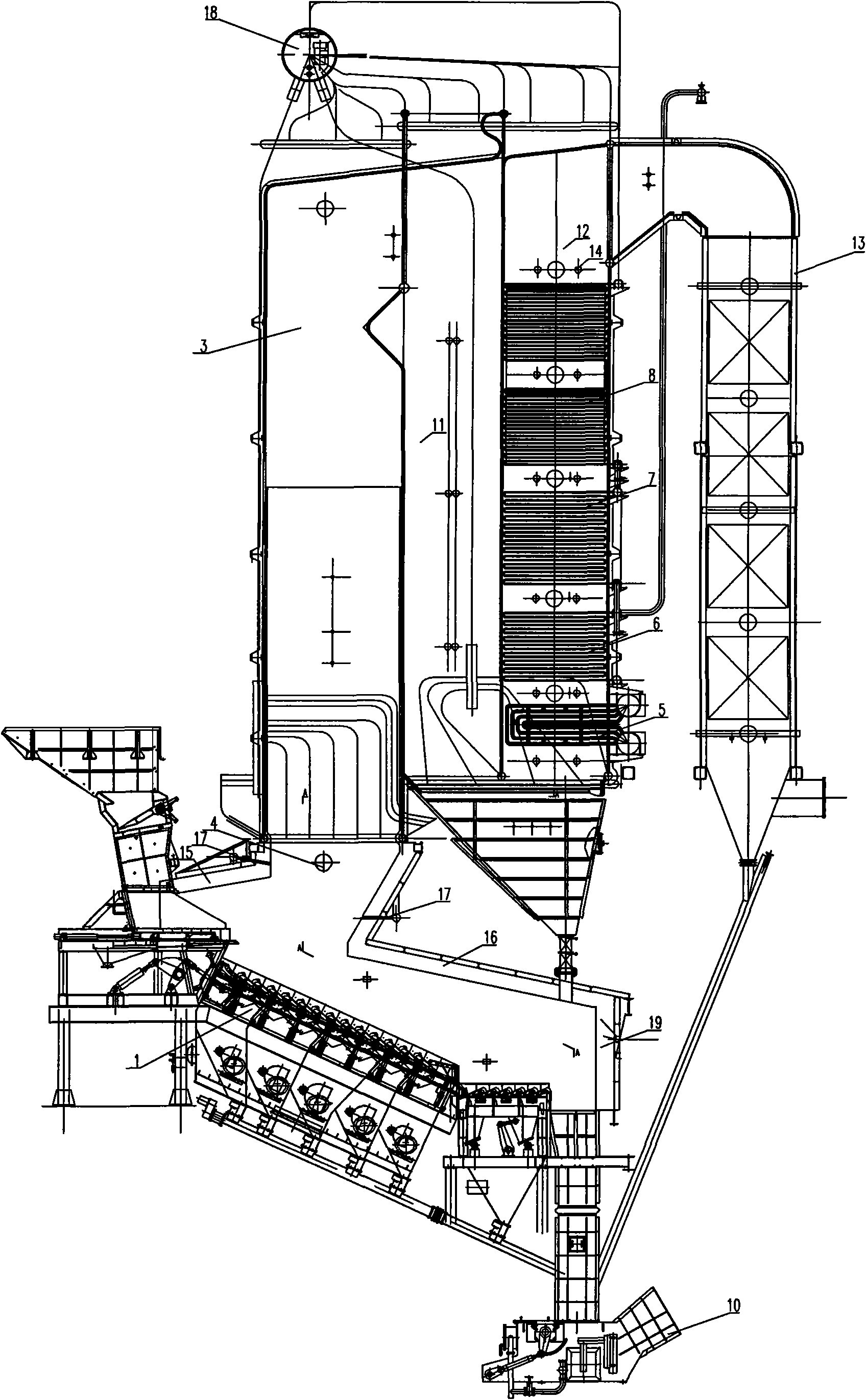

[0025] The furnace 3 is installed on the steel frame, and the drum 18 is installed above the furnace 3, and the reciprocating multi-row fire grate 1 is arranged at the lower part of the furnace 3, and the auxiliary burner 4 is installed on the side wall at the lower part of the furnace 3, and at the lower part of the furnace 3 Ignition burner 19 is installed on the rear wall of the furnace, and after the furnace 3, an ember chamber 11, three flues 12 and tail flue 13 are arranged successively, and slag and ash removal equipment 10 are installed below the reciprocating multi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com