Coal-fired power generating system and method with carbon capture device

A power generation system and coal-burning technology, applied in pump devices, steam engine devices, machines/engines, etc., to reduce net energy consumption, improve economy, and improve power generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Below in conjunction with specific embodiment, further illustrate the present invention.

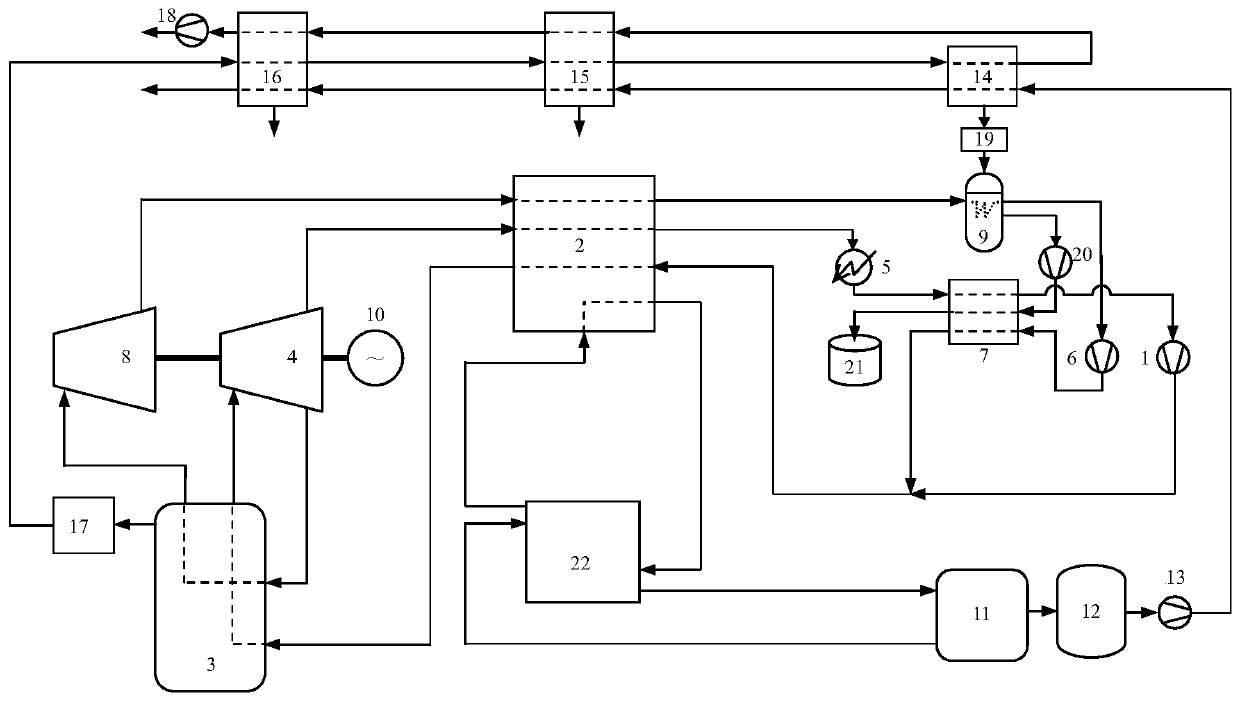

[0040] figure 1 It is a schematic diagram of a coal-fired power generation system with a carbon capture device provided in this embodiment. The coal-fired power generation system with a carbon capture device includes a supercritical carbon dioxide circulation subsystem and a carbon capture subsystem.

[0041] The supercritical carbon dioxide circulation subsystem includes a carbon dioxide compressor 1, a carbon dioxide regenerator 2, a coal-fired boiler 3, a high-pressure turbine 4, a precooler 5, a high-pressure carbon dioxide pump 6, a cooler 7, a low-pressure turbine 8, a condensing Device 9, generator 10.

[0042] The carbon dioxide compressor 1 outlet is connected to the carbon dioxide regenerator 2 high-pressure carbon dioxide inlet, the carbon dioxide regenerator 2 high-pressure carbon dioxide outlet is connected to the coal-fired boiler 3 high-pressure carbon dioxide inle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com