Patents

Literature

272 results about "Zero carbon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

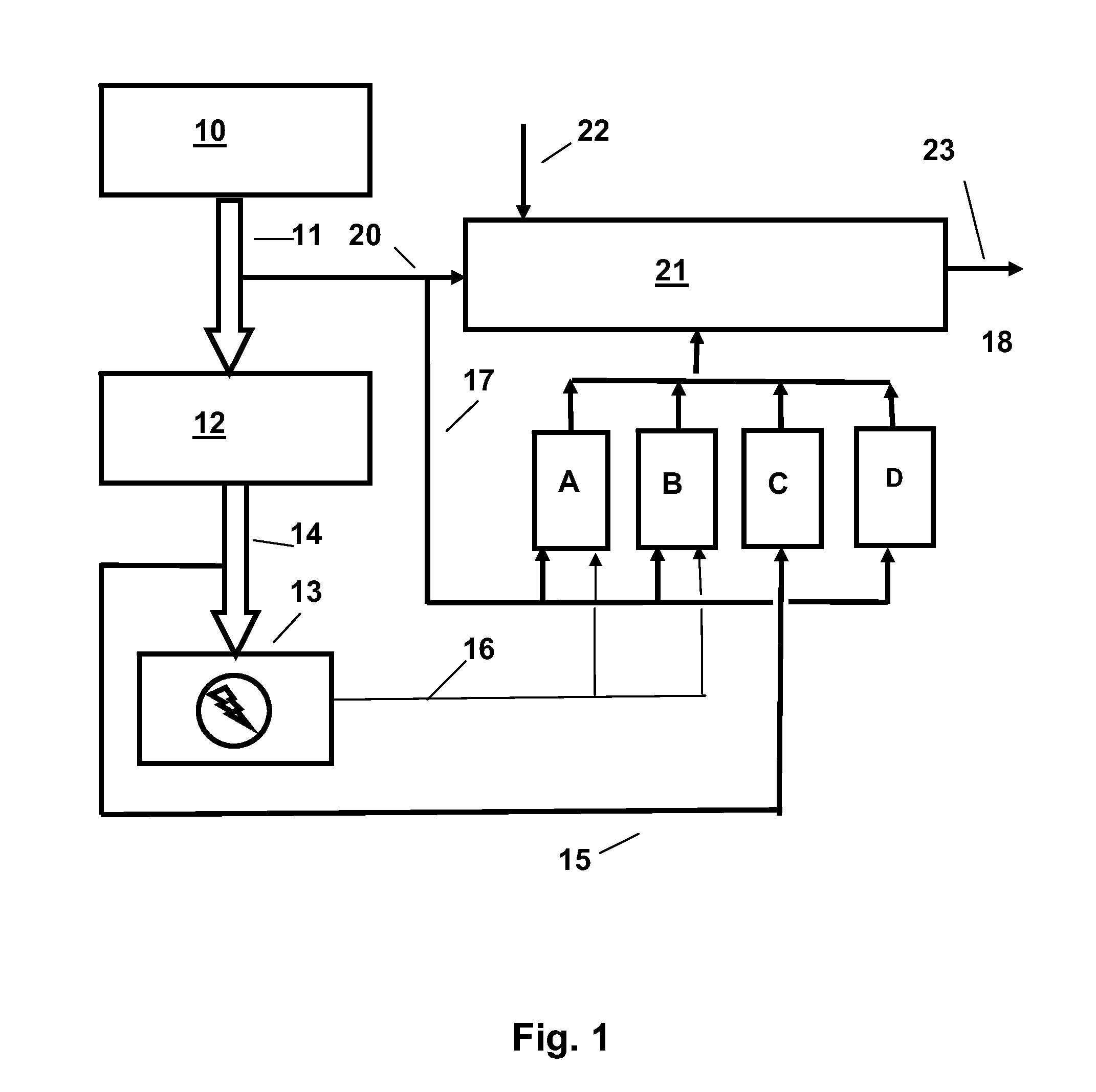

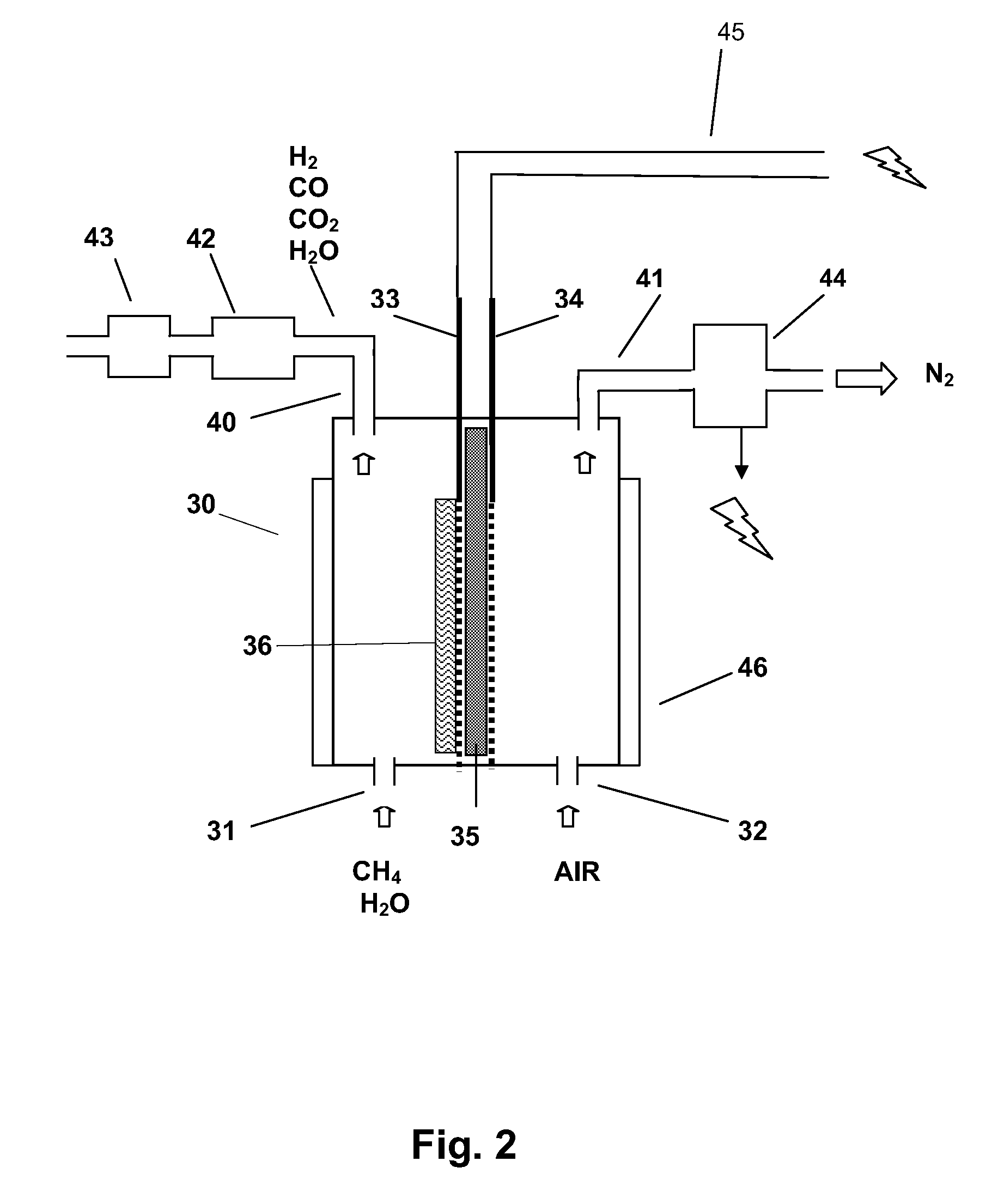

Reduced Carbon Footprint Steam Generation Processes

Processes for the generation of steam are provided for use in an integrated catalytic gasification process for converting carbonaceous materials to combustible gases, such as methane. Generally, the exhaust gas from a steam generating reactor is provided along with steam, a carbonaceous feedstock, and a gasification catalyst, to a catalytic gasifier, wherein under appropriate temperature and pressure conditions, the carbonaceous feedstock is converted into a plurality of product gases, including, but not limited to, methane, carbon monoxide, hydrogen, and carbon dioxide. As substantially all the carbon dioxide produced from the steam generation process and the gasification process are subsequently directed though gas purification and separation processes, substantially all the carbon dioxide may be recovered, yielding a process having a near zero carbon footprint.

Owner:SURE CHAMPION INVESTMENT LTD

All-weather clean energy comprehensive electricity generating and energy saving method and facility manufacturing method thereof

InactiveCN104295448AHigh light transmittanceImprove efficiencyWind motor with solar radiationGeneral water supply conservationNew energyTransmitted power

The invention discloses an all-weather clean energy comprehensive electricity generating and energy saving method and a facility manufacturing method. In ten inventions, having at least one identical or corresponding specific technical characteristic and related to the total inventive concept, of solar gallery buildings, through graphene series facilities under solar gallery buildings, in a land field, a zero-carbon environment-friendly safe type raft-shaped basic-framed-tube-structured huge building group of a universal wind energy tower shape is established and new energy automobiles and trains are manufactured, wherein cheap wind power solids are established, photoelectric benzene expansion optical fibers are manufactured, lightning is utilized firstly for supplying power externally, various spaces are shared through building three-dimensional afforesting, and three-dimensional energy collection is achieved; in a water field, deep water self-floating buildings of a super steel concrete frame-tube structure (preferably, complete steel plates are adopted) are built, the deep water self-floating buildings are connected in series to form a global ocean water and electricity and agriculture and forestry extraction traffic network and a large lake and reservoir water and electricity and agriculture and forestry dredging dam water level traffic network, wherein the deep water automatic floating buildings are free of influences of earthquakes, tsunamis and wars, the Red Cross can rescue people in all-weather conditions; in a space field, multiple receiving and transmitting solar towers are first established on the equator of the earth and the equator of the moon, the receiving and transmitting solar towers are connected in series to operate in a timed mode in the specific direction and transmit power to the whole world through graphene cables which are all packaged with colored insulating films.

Owner:熊凌云 +6

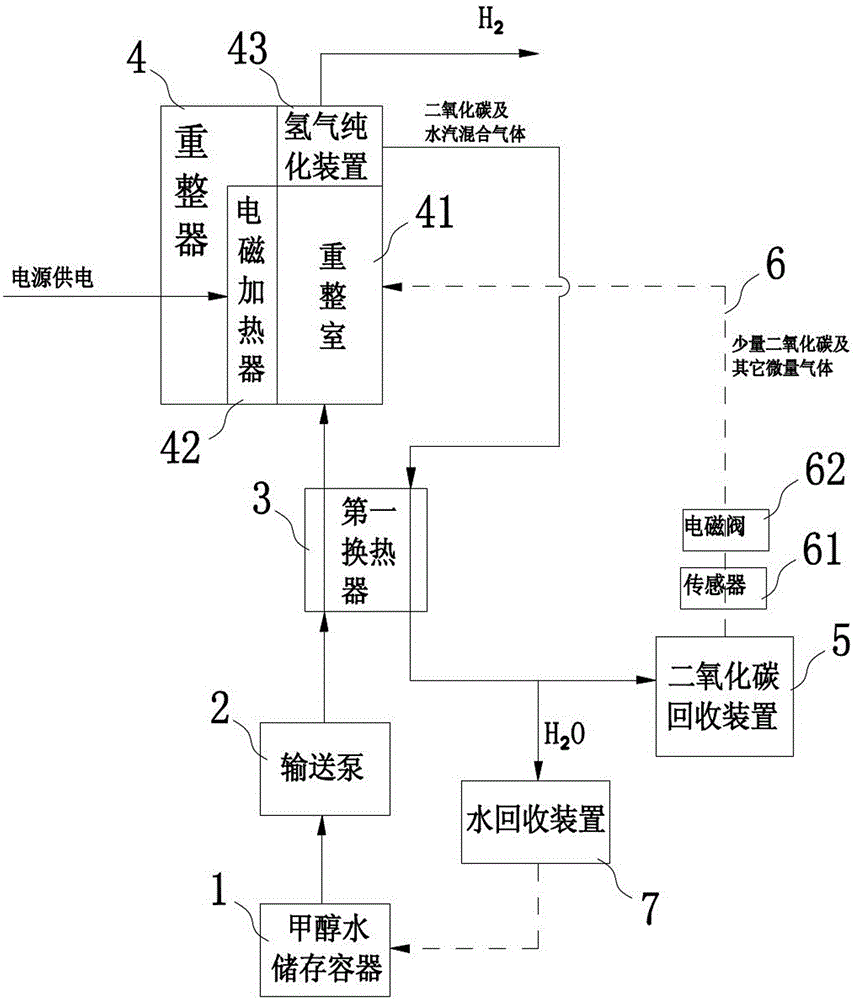

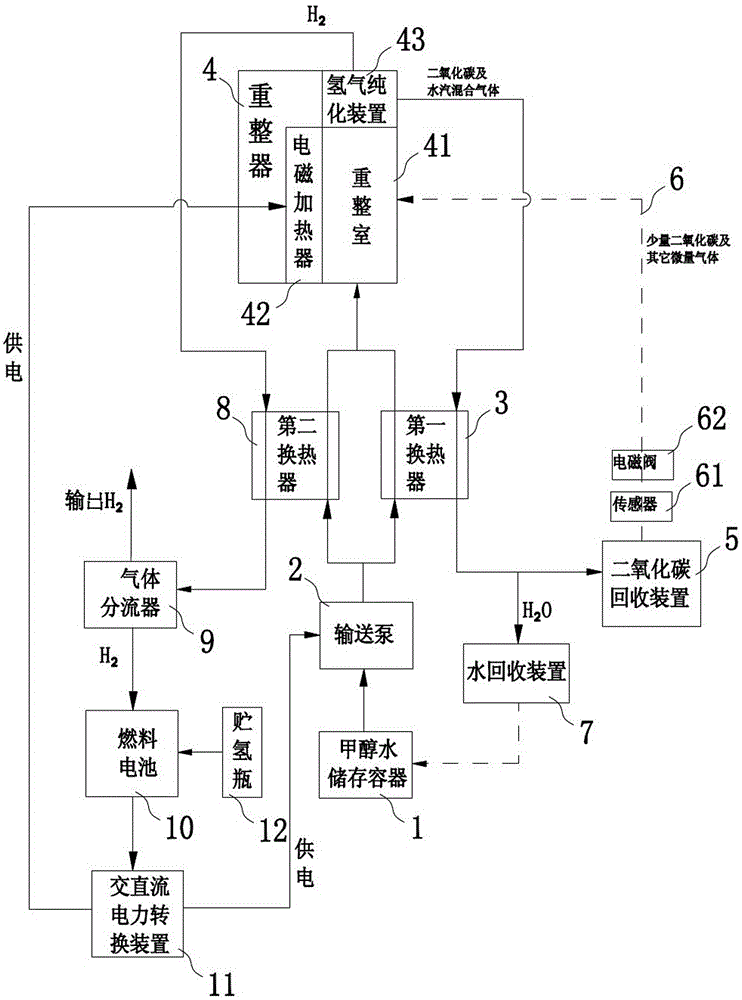

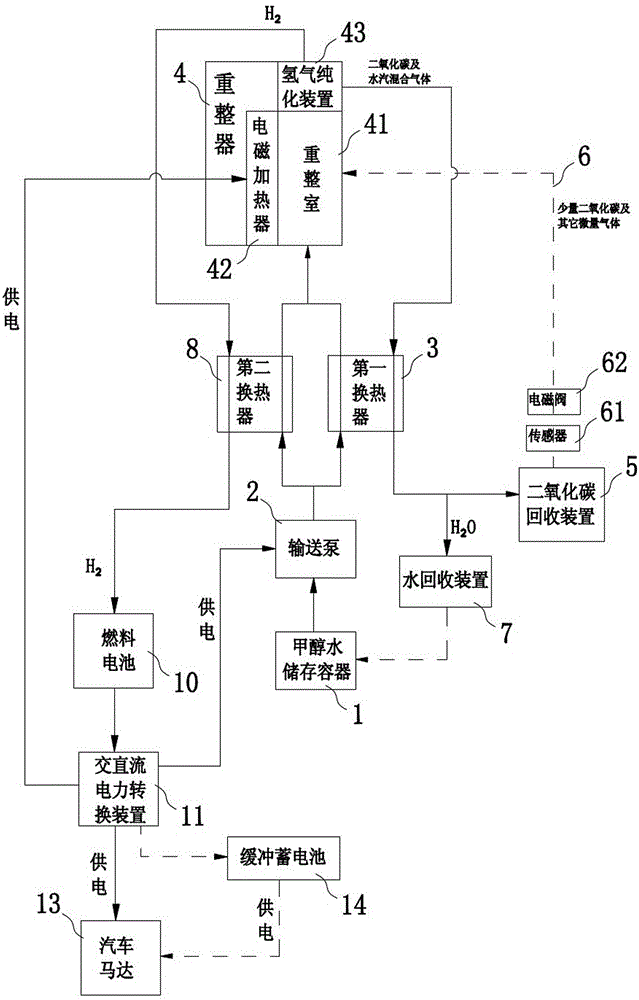

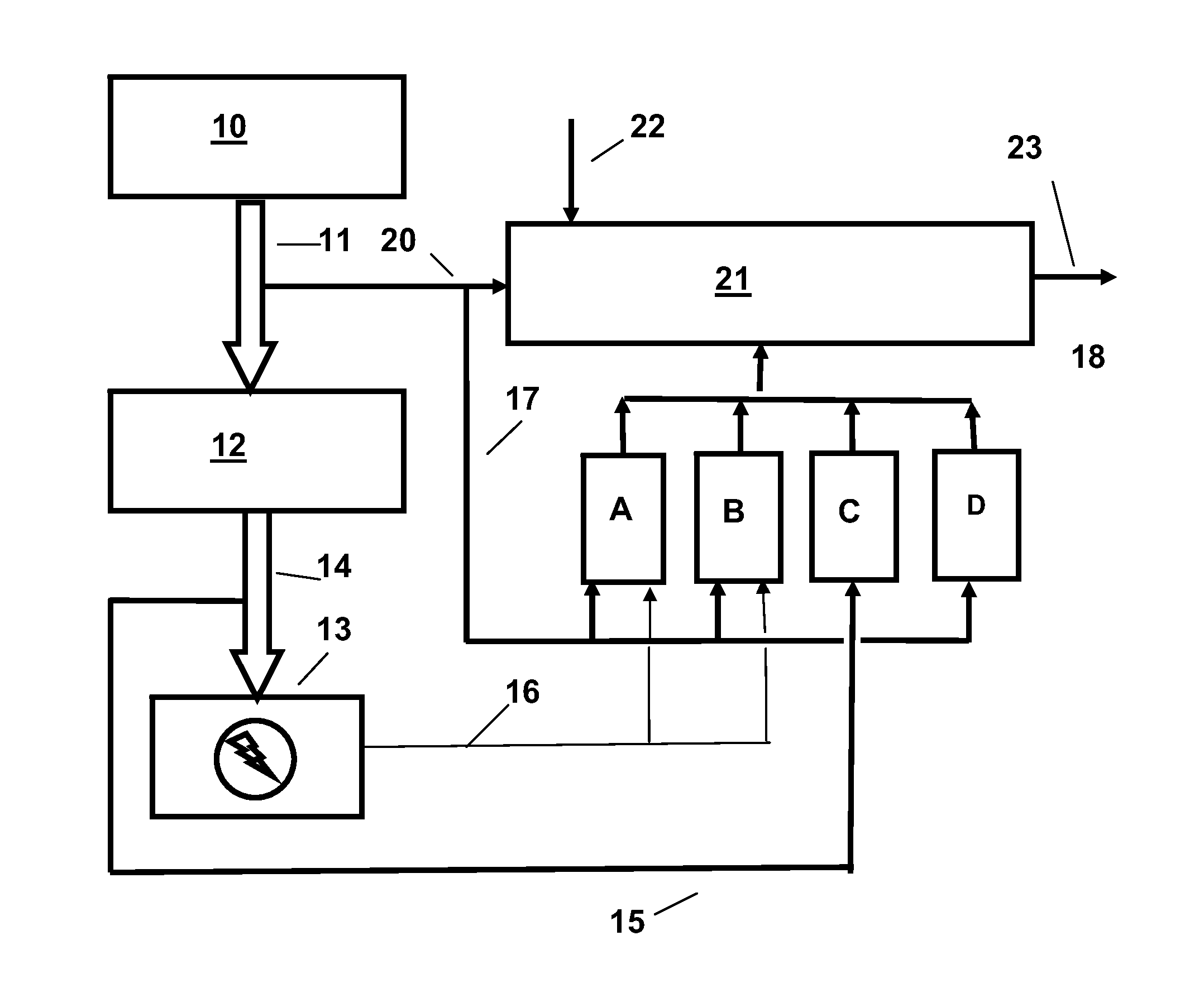

Zero-carbon-emission hydrogen production system by methanol water reforming as well as application and hydrogen production method thereof

The invention discloses a zero-carbon-emission hydrogen production system by methanol water reforming and application and a hydrogen production method thereof. The hydrogen production system comprises a methanol water storage vessel, a delivery pump, a first heat exchanger, a reformer and a carbon dioxide recovery device, wherein the reformer is provided with a reforming chamber, an electromagnetic heater and a hydrogen purification device; the electromagnetic heater provides heat energy for the reforming chamber; the reforming chamber is used for hydrogen production reaction of methanol and water by reforming to obtain carbon dioxide and hydrogen; carbon dioxide and hydrogen are mixed with water vapor to form high-temperature mixed gas, and the high-temperature mixed gas is delivered into the hydrogen purification device; after purification and separation, hydrogen is delivered out, at the same time carbon dioxide and unreacted water vapor mixed gas are also delivered out, and then carbon dioxide and unreacted water vapor mixed gas are delivered into the carbon dioxide recovery device after passing through the first heat exchanger; the carbon dioxide recovery device is a replaceable modular carbon dioxide recovery device and used for recovering carbon dioxide and part of the water vapor. The zero-carbon-emission hydrogen production system provided by the invention can recover carbon dioxide, has no impact on the environment and causes no harm to the hydrogen production system self and is beneficial for popularization and application in the field of new energy resources such as fuel cell cars.

Owner:GUANGDONG HYDROGEN ENERGY SCI & TECH

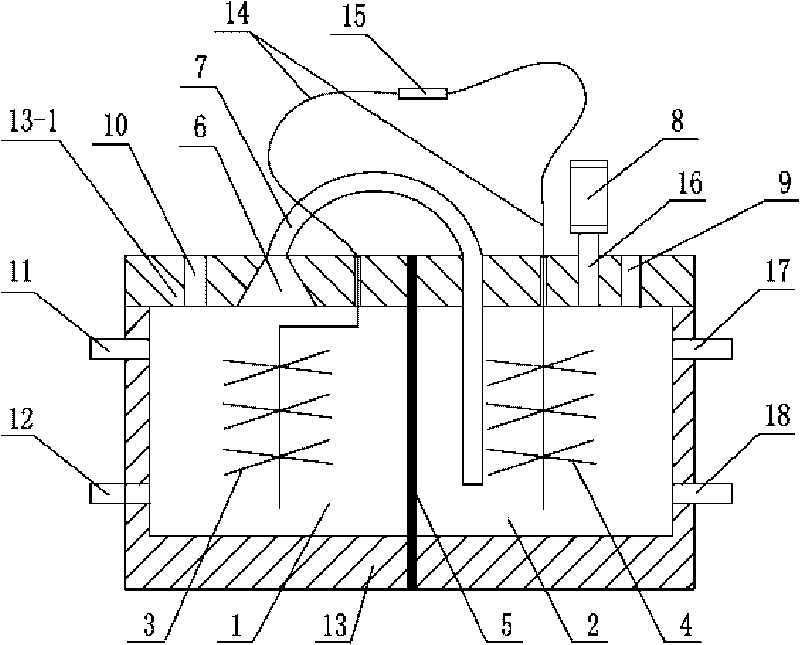

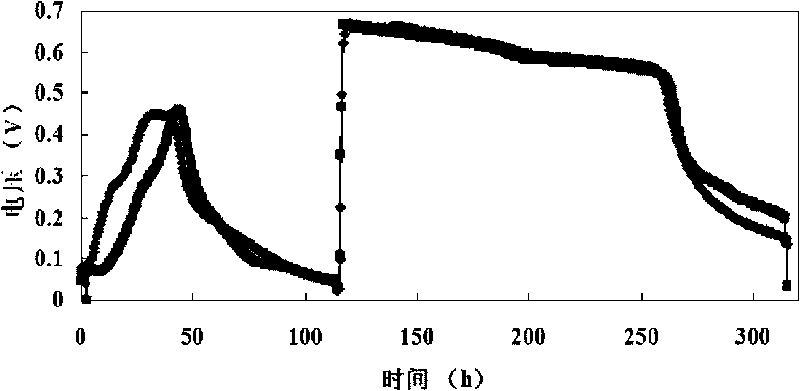

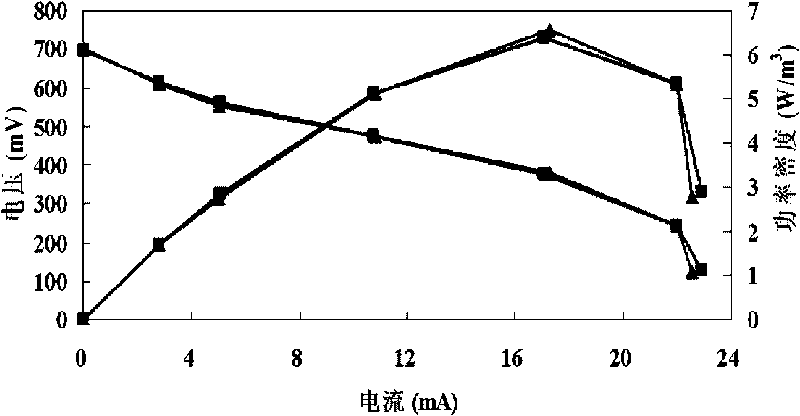

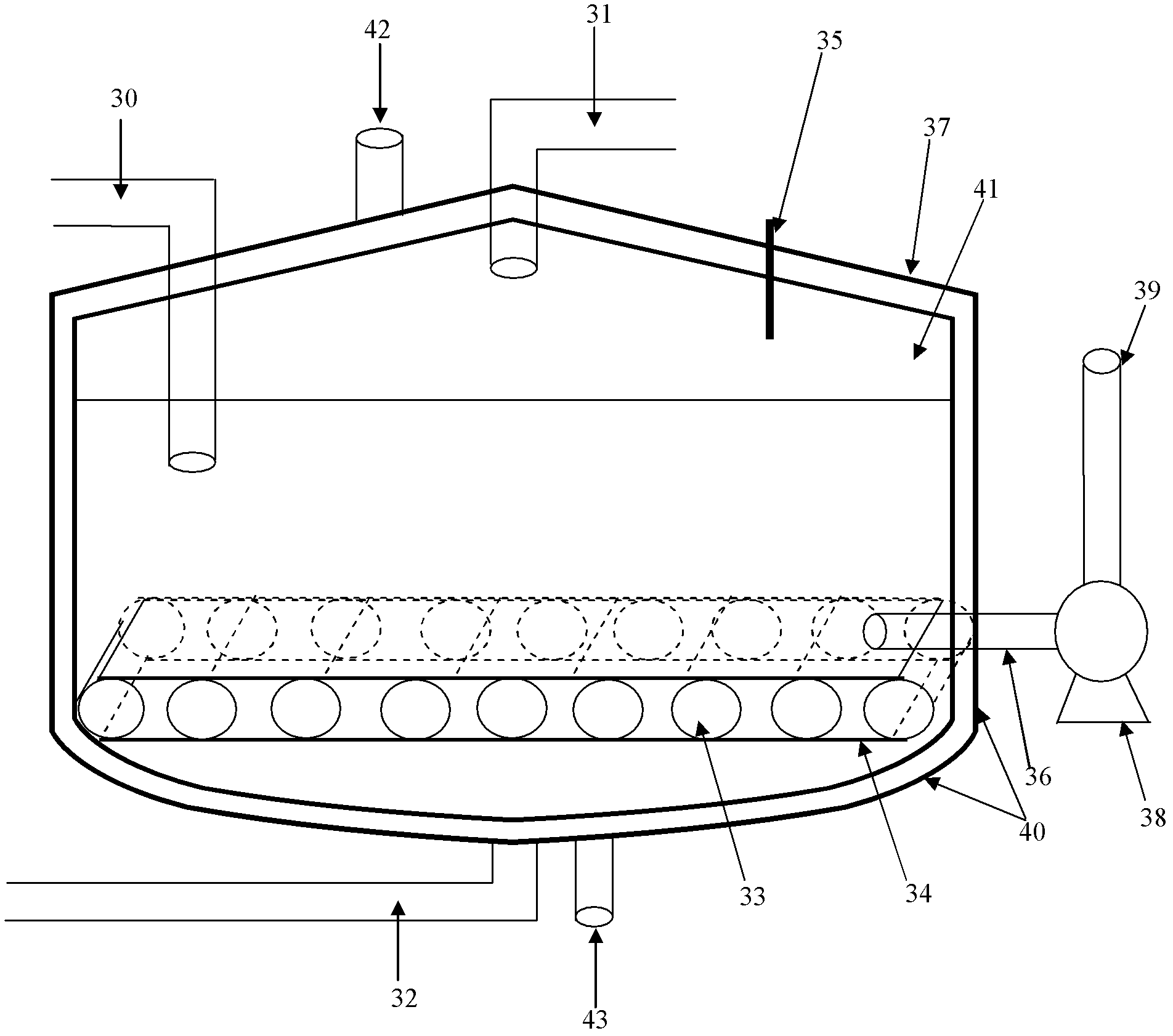

Double-chamber alga microbial fuel cell and method thereof for treating waste water and realizing zero carbon emission

ActiveCN101719555AAchieving zero emissionsAchieving zero carbon emissionsCell electrodesBiochemical fuel cellsPhotosynthesisZero emission

The invention discloses a double-chamber alga microbial fuel cell and a method thereof for treating waste water and realizing zero carbon emission, which relates to a microbial fuel cell and a method for treating waste water. The invention solves the problem that the traditional microbial fuel cell can generate a large amount of CO2 in the process of treating waste water. In the invention, a cation exchange membrane is vertically arranged in a box body of a reactor; an anode chamber and a cathode chamber are formed in the box body of the reactor; an anode is arranged in the anode chamber; a cathode is arranged in the cathode chamber; leads are connected with the anode and the cathode; one end of a gas duct is hermetically connected with a gas collecting chamber, and the other end of the gas duct is arranged at the bottom of the cathode chamber; and a gas collecting device is hermetically installed at a gas outlet. The method comprises the following steps: (1) starting the reactor; and (2) introducing the waste water into the cathode chamber and the anode chamber, catabolizing organic matters by microbes at room temperature, simultaneously obtaining electrical energy, and introducing the CO2 generated in the anode chamber into the cathode chamber to be used by the alga at the cathode for photosynthesis. The invention realizes zero emission of CO2 and simultaneously can recover electrical energy, thereby really changing waste into resources.

Owner:HARBIN INST OF TECH

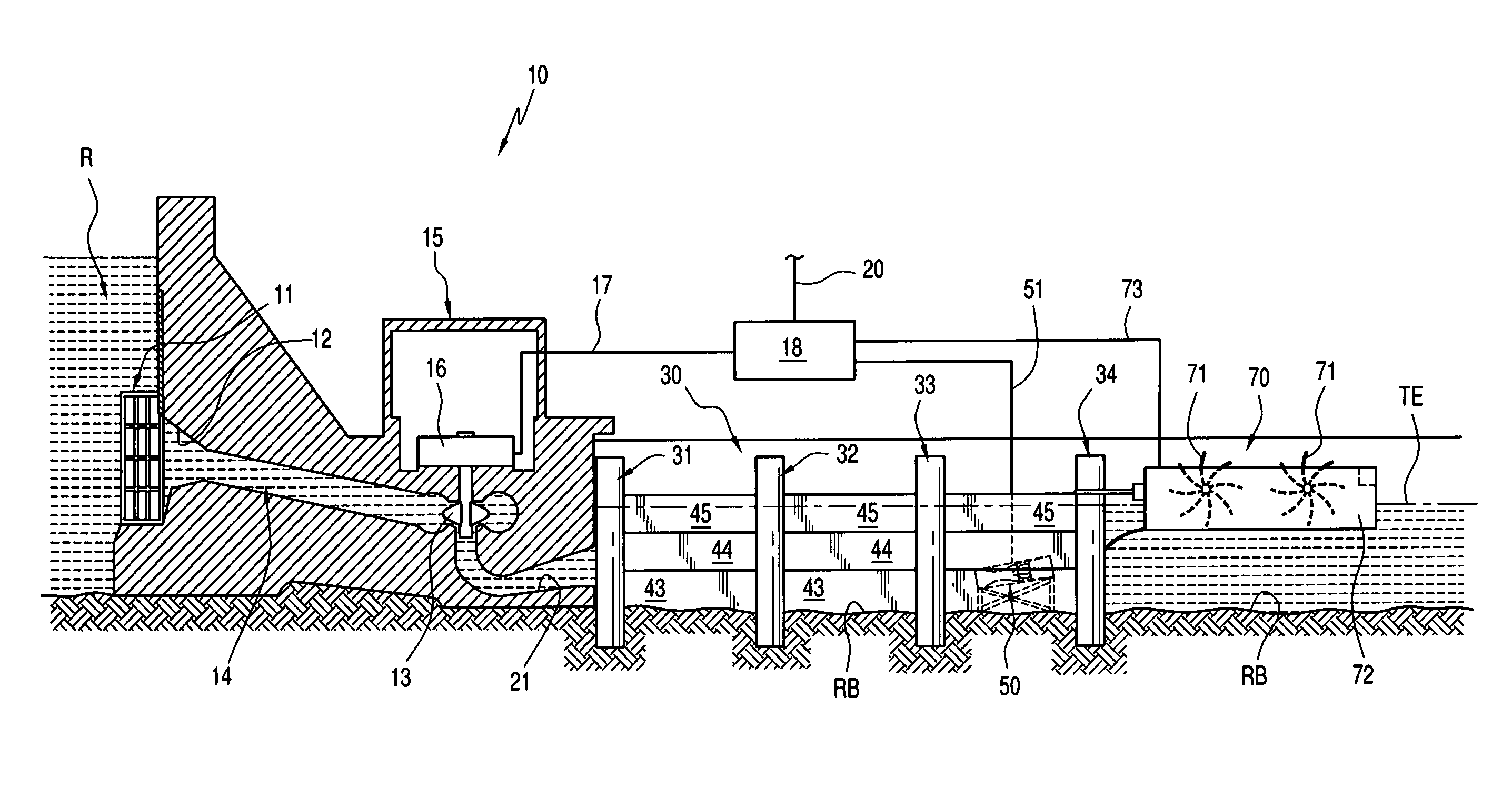

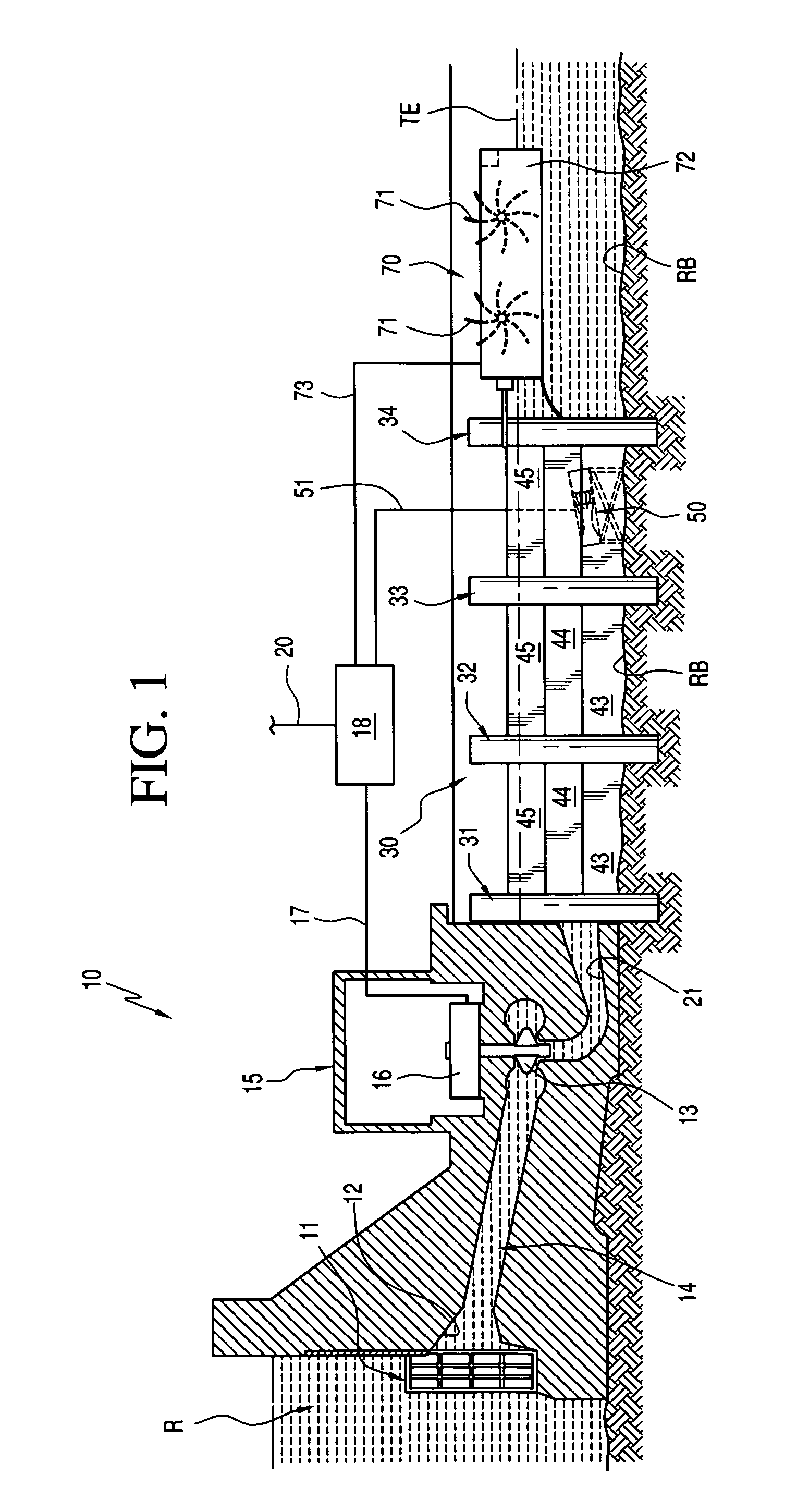

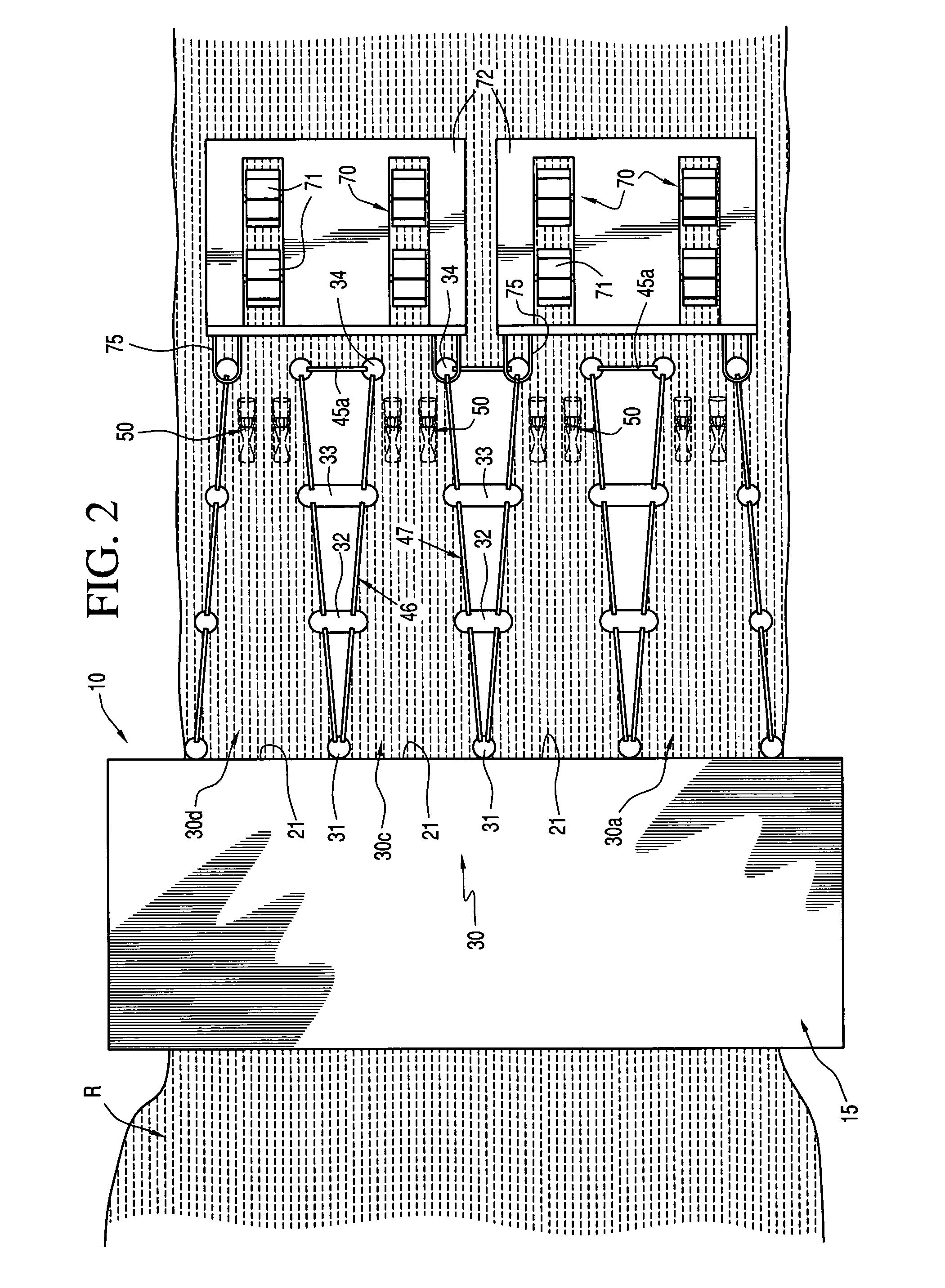

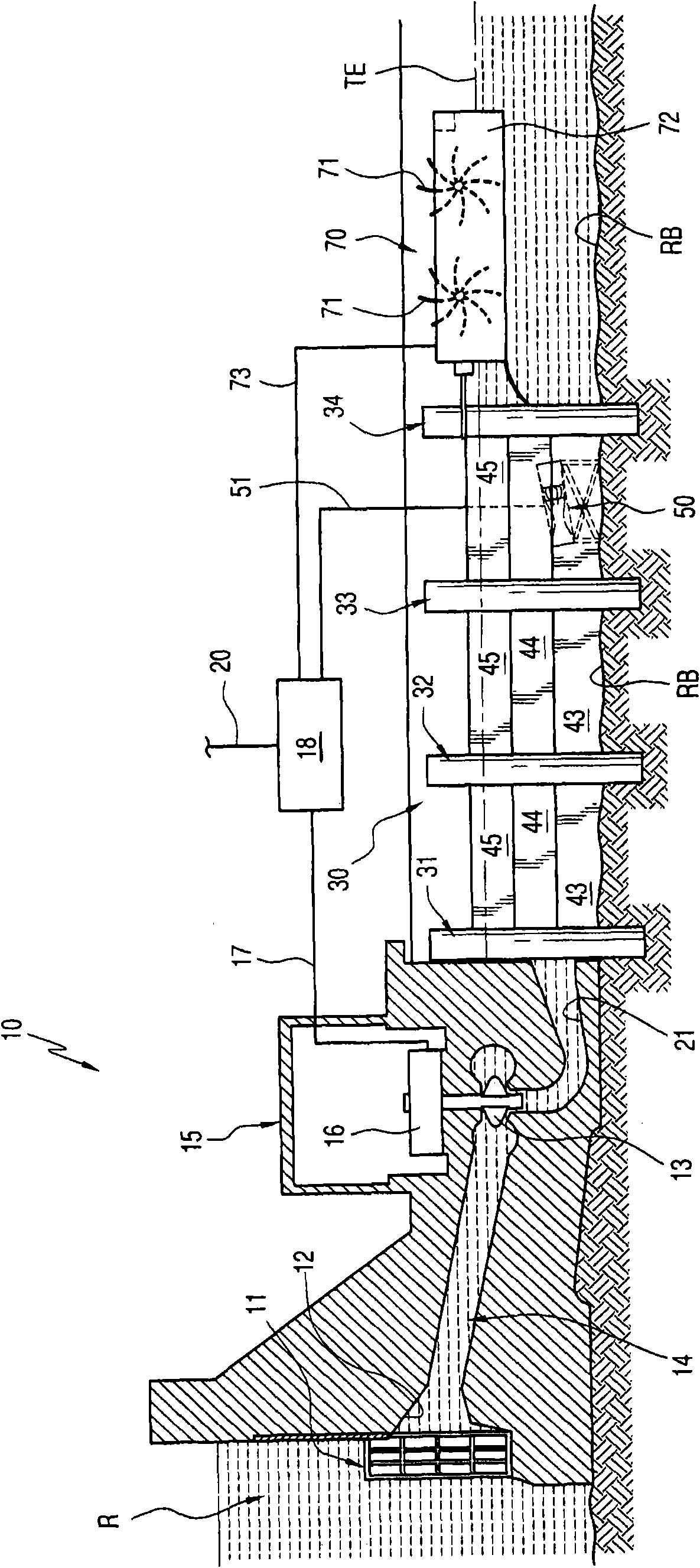

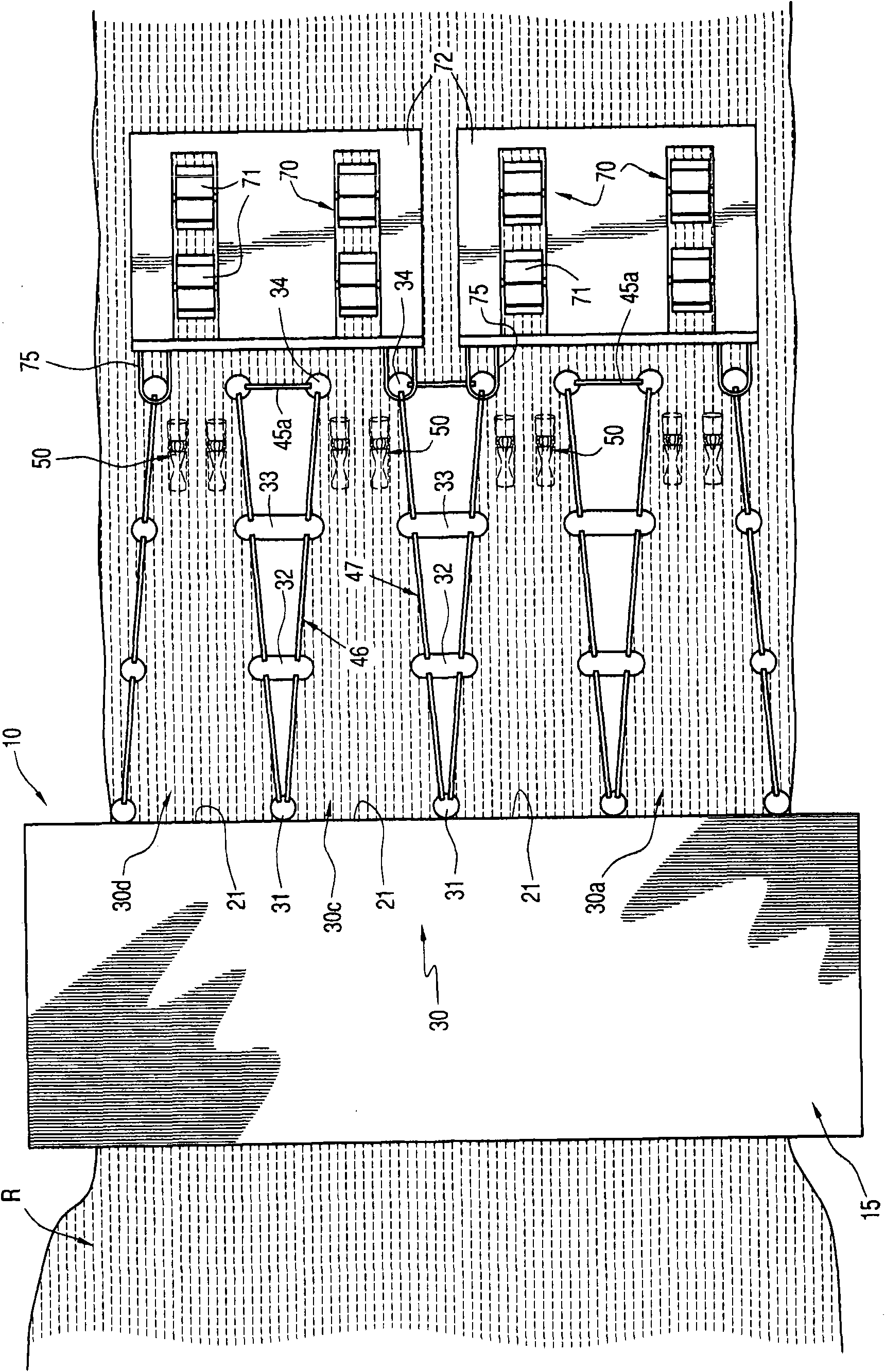

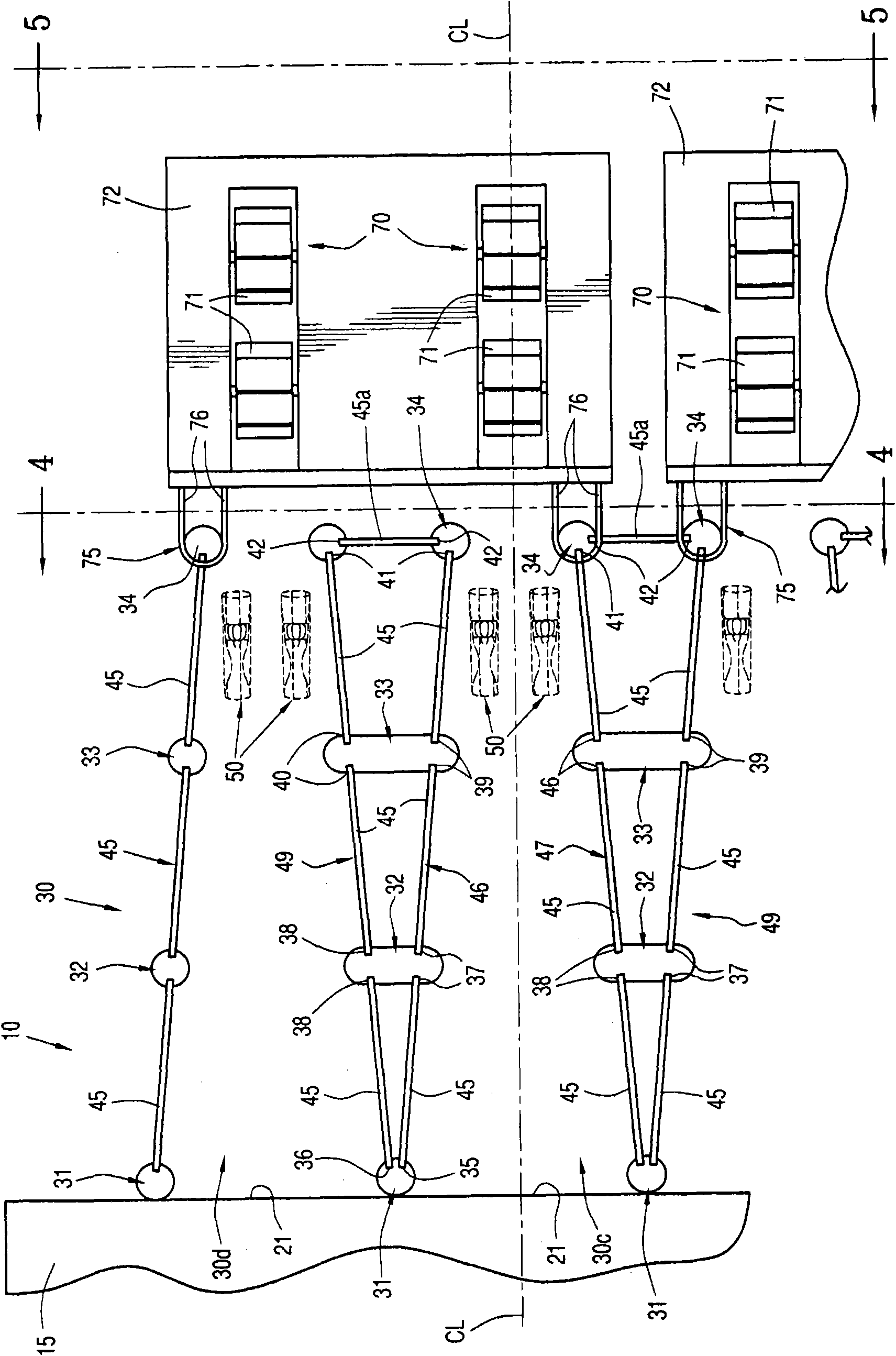

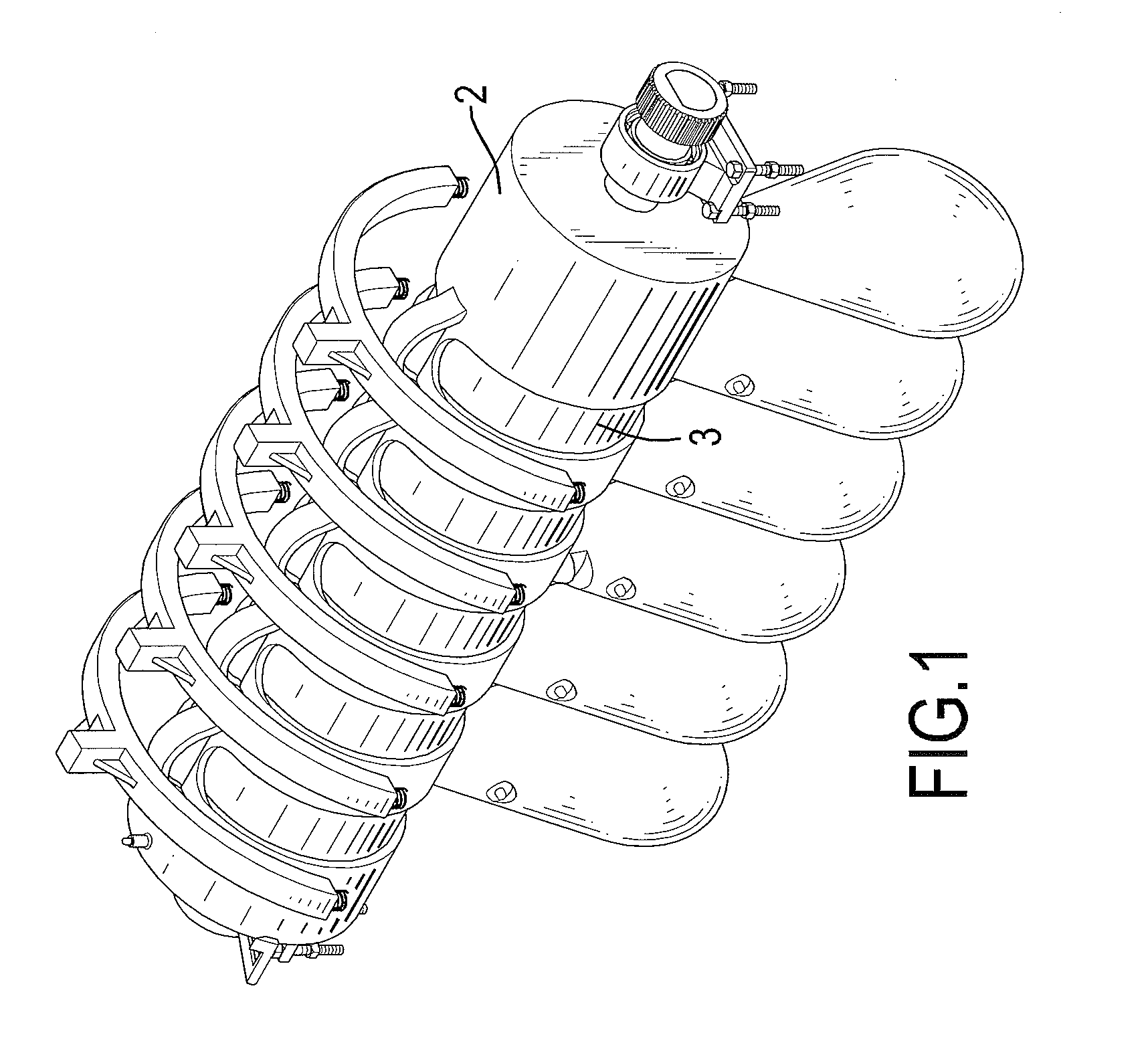

Apparatus for hydroelectric power production expansion

InactiveUS7478974B1Maximize productionLower life cycle costsWater-power plantsReaction enginesEngineeringElectric power

Normally hydroelectric dam powerhouses use river flow once before discharging it as turbulent tailwater, ineffective to spin turbines. The present invention uses tapered channels to confine and constrict turbulent tailwater into laminar flow that drives turbines both submersible and floatable utilizing the same water three times concurrently to generate new electricity. Channels originate adjacent to draft tube outlets, constrict in the downstream direction to create narrow necks where turbine / generators benefit from debris free, increased velocity and laminar flows to generate electricity. Hydroelectricity uses zero fuel, creates zero waste and has zero carbon dioxide emissions. Structures are uncomplicated, construction is within project boundaries minimizing environmental impacts and speeding projects coming online. New facilities are protected by existing dam security. Hydroelectricity replaces less dependable renewable energy systems.

Owner:KELLY WILLIAM LOWELL

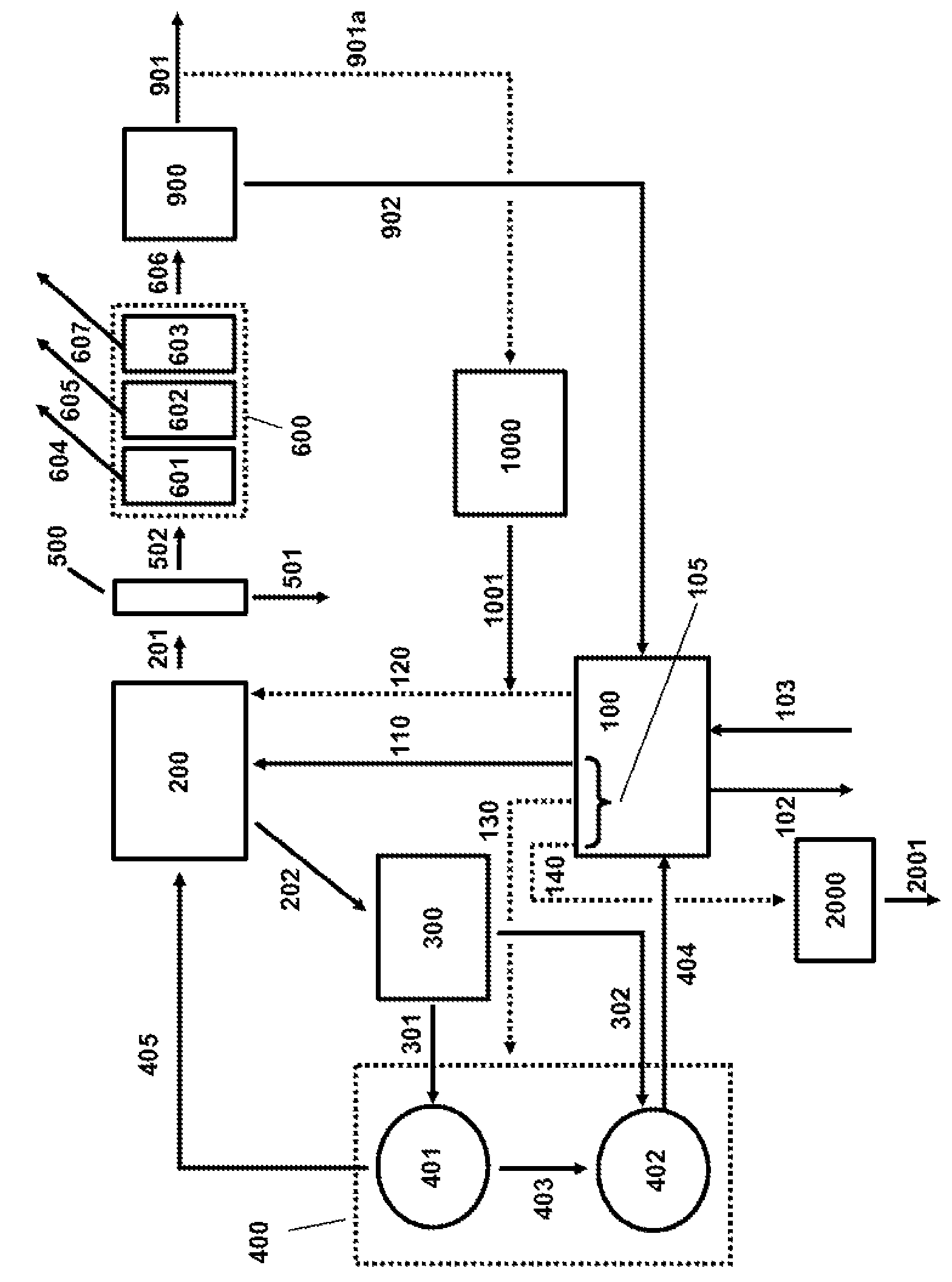

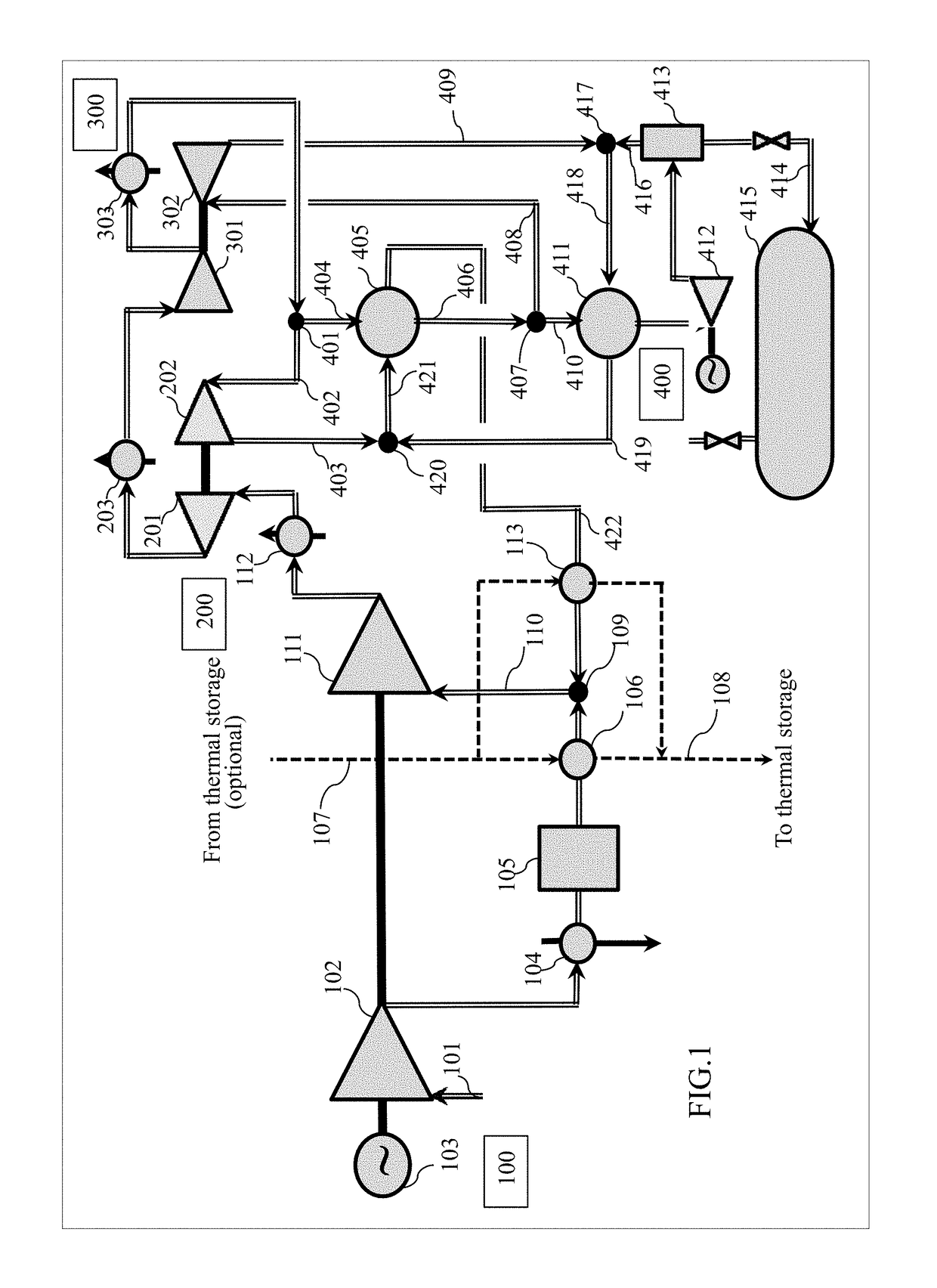

Reduced carbon footprint steam generation processes

Processes for the generation of steam are provided for use in an integrated catalytic gasification process for converting carbonaceous materials to combustible gases, such as methane. Generally, the exhaust gas from a steam generating reactor is provided along with steam, a carbonaceous feedstock, and a gasification catalyst, to a catalytic gasifier, wherein under appropriate temperature and pressure conditions, the carbonaceous feedstock is converted into a plurality of product gases, including, but not limited to, methane, carbon monoxide, hydrogen, and carbon dioxide. As substantially all the carbon dioxide produced from the steam generation process and the gasification process are subsequently directed though gas purification and separation processes, substantially all the carbon dioxide may be recovered, yielding a process having a near zero carbon footprint.

Owner:SURE CHAMPION INVESTMENT LTD

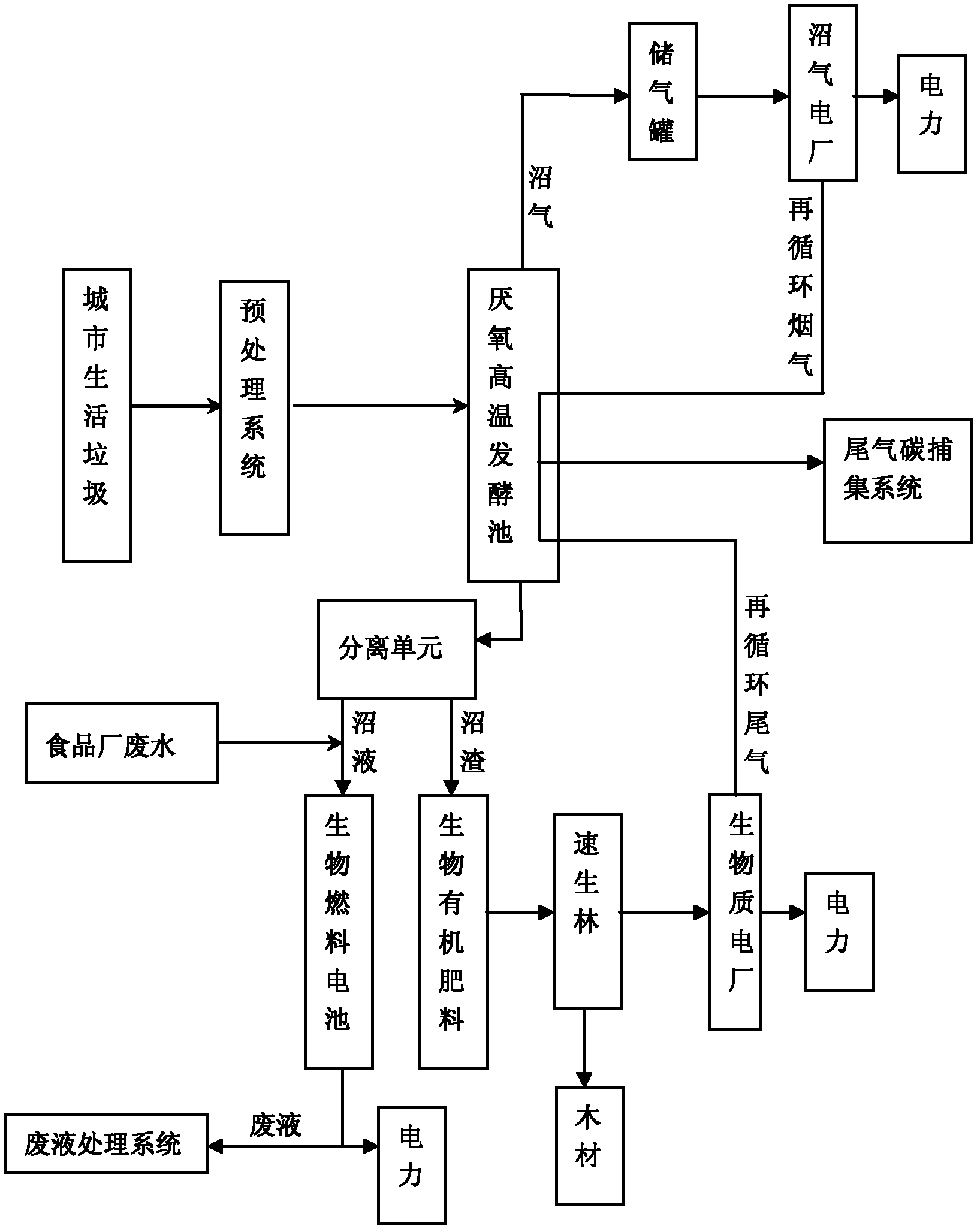

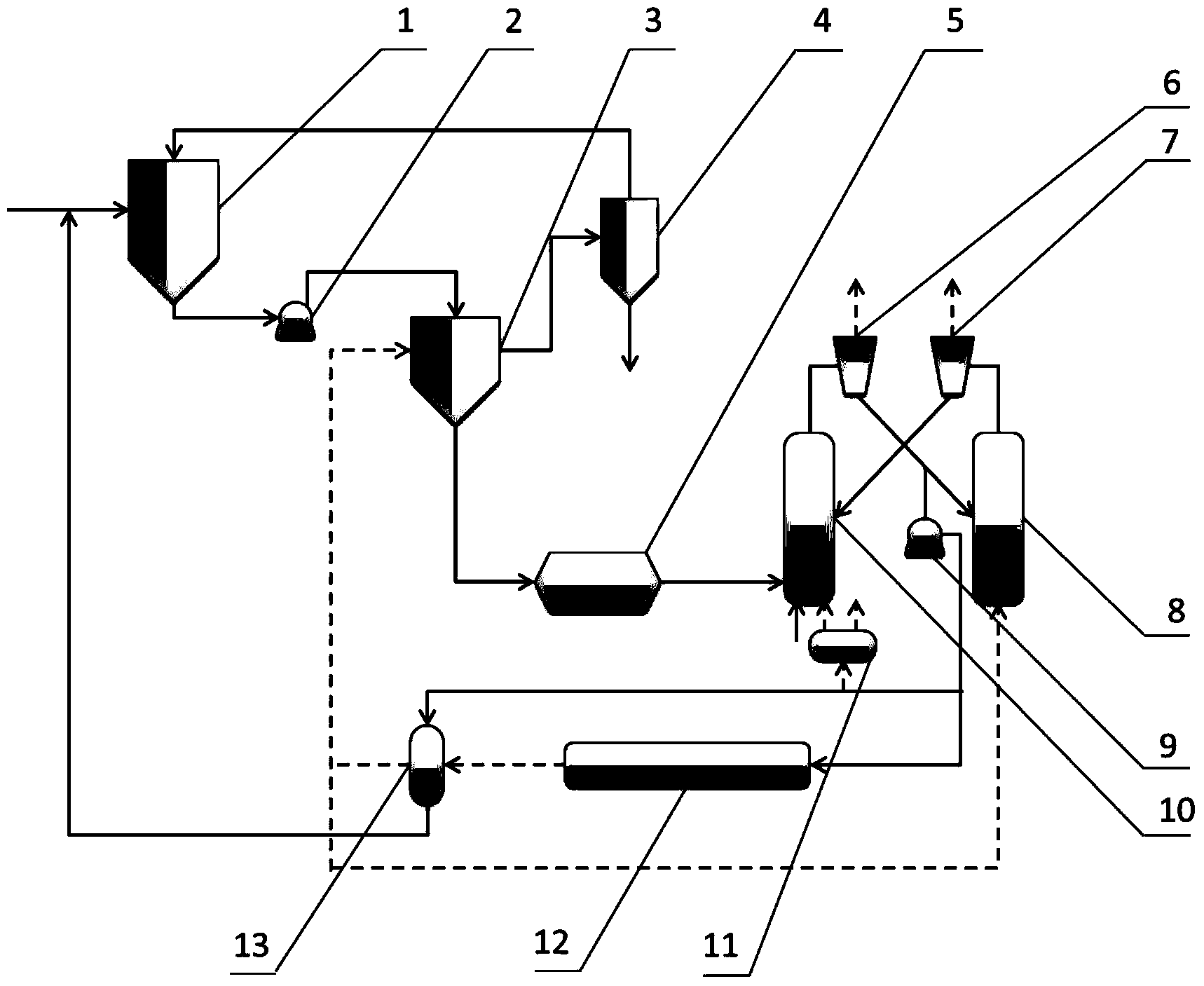

Household solid garbage recycling and renewable biological carbon circulating technology

ActiveCN102500604ARemarkable effectSignificant innovationWaste processingSolid waste disposalBiogas productionSlurry

The invention discloses household solid garbage recycling and renewable biological carbon circulating technology, which solves the problem that biogas generated from household garbage is difficult to ferment at places with low temperature, and realizes an integral circulating zero-carbon emission system and a large-size renewable biological carbon circulating system simultaneously. The technical scheme includes that pretreated household garbage is fed into a large-size biogas digester to ferment, biogas is supplied for oxygen-enriched combustion of a gas turbine gas to generate power, biogas slurry is used as a biofuel cell substrate and is cleaned and used for power generation, and biogas residue is used as biological organic fertilizer and used for growth of fast-growing trees for biomass fuel power plants. Flue gas generated in combustion in the power plants circulates to guarantee fermenting temperature of the biogas digester so as to realize biogas production stably and efficiently. Pure oxygen and recycled tail gas are used as combustion supporting gas of the power plants, and accordingly combustion efficiency can be improved while cost for treatment of tail gas is reduced. CO2 in the flue gas is captured according to the carbon capture technology, and accordingly the zero-carbon emission system is realized. In addition, the renewable biological carbon cycling system is realized by means of biological treatment to biogas slurry and biogas residue.

Owner:UNIV OF SCI & TECH LIAONING

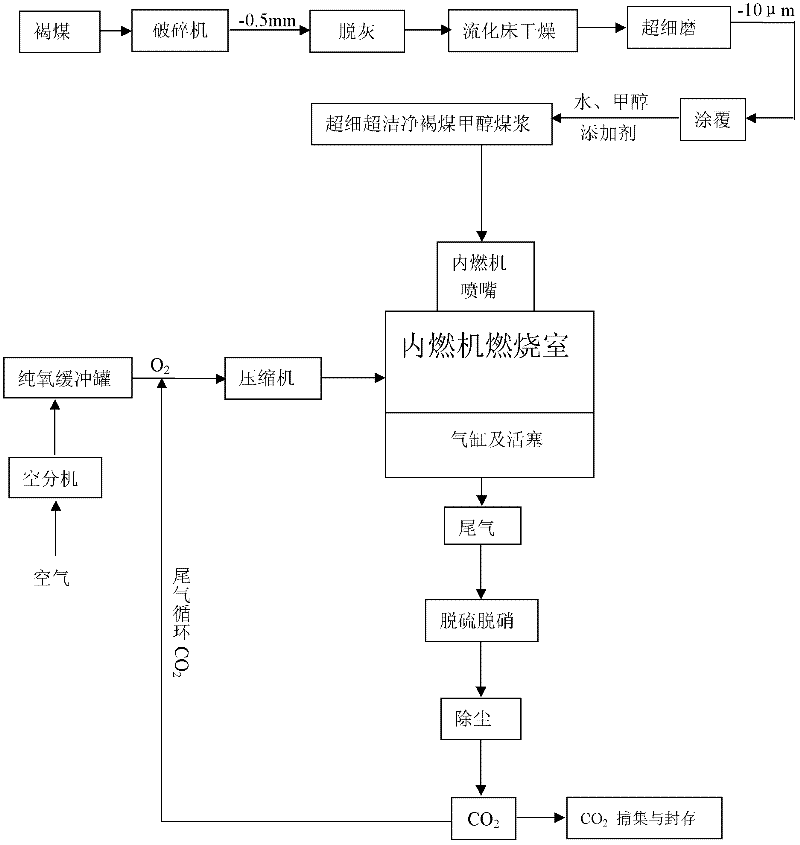

Oxygen-enriched combustion method of lignite methyl alcohol coal slurry fuel material in compression-type internal combustion engine

InactiveCN102434343AObvious beneficial effectImprove pressure and wear resistanceInternal combustion piston enginesNon-fuel substance addition to fuelHigh concentrationExternal combustion engine

The invention discloses an oxygen-enriched combustion method of a lignite methyl alcohol coal slurry fuel material in a compression-type internal combustion engine. The problem of difficulty in ignition of the traditional water coal slurry in the internal combustion engine is solved by utilizing the methyl alcohol coal slurry and oxygen-enriched combustion technology; and zero carbon emission of the whole system is realized through collecting CO2 generated by tail gas, and the pollution to environment is eliminated. The method provided by the invention adopts the following technical scheme which comprises the following steps of: taking ultra-fine ultra-clean ignite methyl alcohol coal slurry as a fuel material; taking pure oxygen and CO2 mixed gas with high concentration in recycled tail gas as a combustion-supporting gas; and carrying out enriched-oxygen combustion in the compression-type internal combustion engine, and generating a driving force by the compression-type internal combustion engine. Combustion is carried out by adopting pure oxygen and the recycled CO2 in the tail gas of the internal combustion engine as the combustion-supporting gas, the formation of NOX in the tail gas is reduced effectively, the concentration of CO2 in the tail gas is improved, the tail gas treatment expense is reduced, and the treated tail gas is easy to compress and store. The combustion method is suitable for a distribution-type power generation system and a large ship motive power system.

Owner:UNIV OF SCI & TECH LIAONING

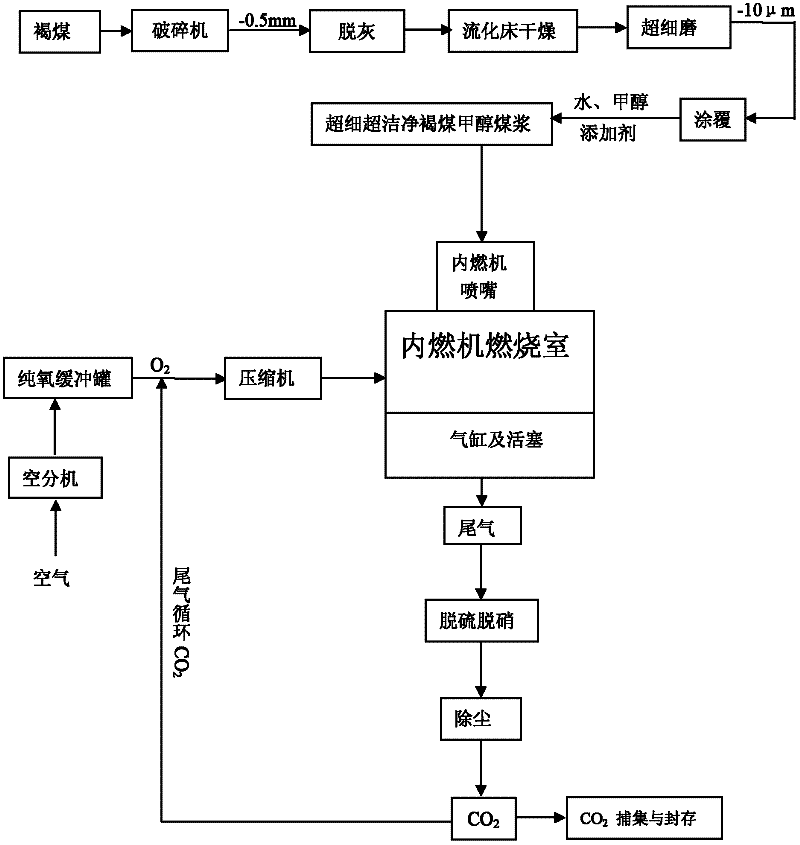

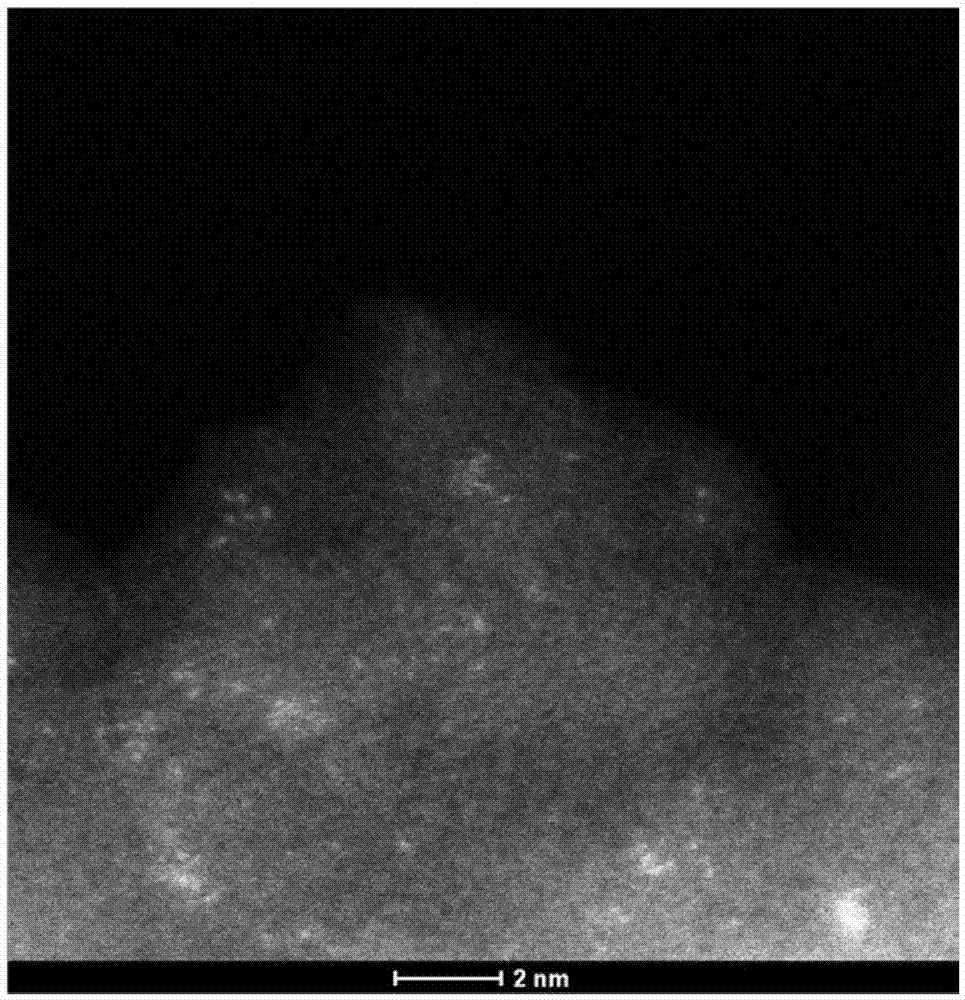

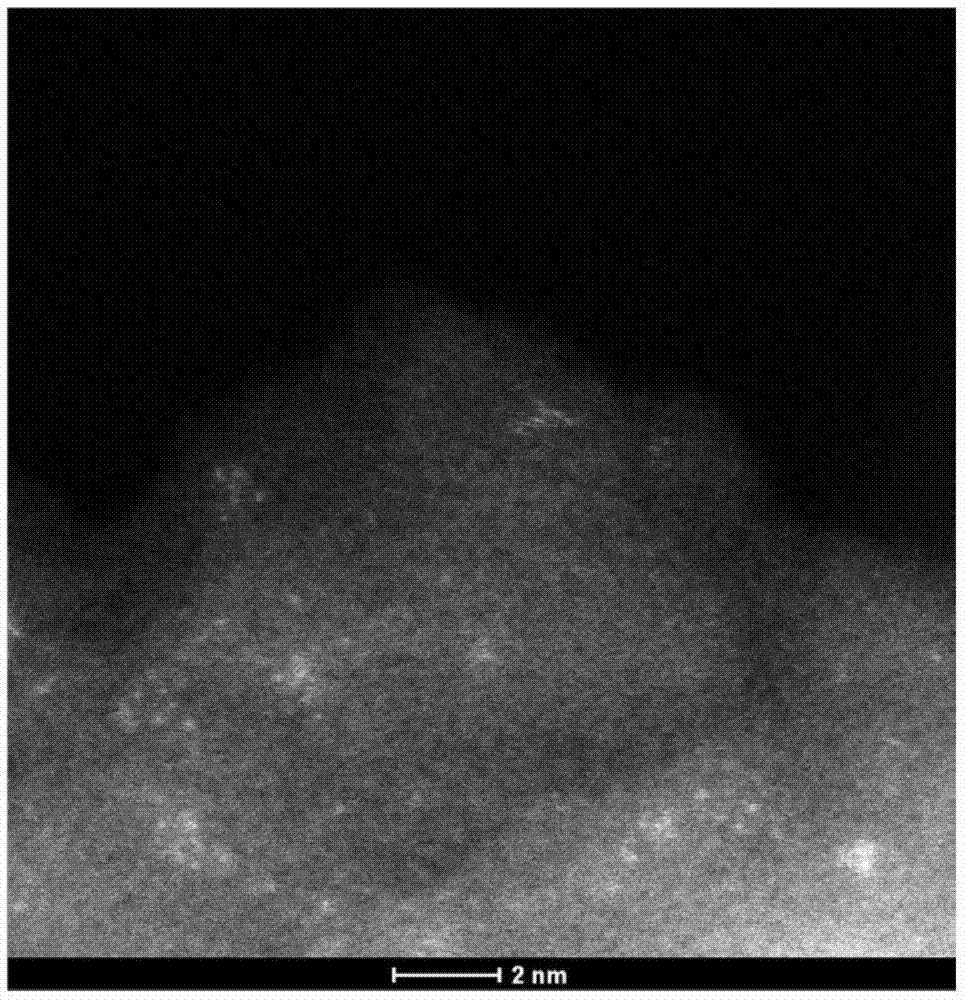

Preparation method for catalyst prepared from Si-based material having undergone lattice doping by metallic element, and method for oxygen-free preparation of ethylene from methane

ActiveCN106914243AHigh selectivitySolution to short lifeCatalystsHydrocarbon preparation catalystsFixed bedReaction temperature

The invention relates to a preparation method for a catalyst prepared from a Si-based material having undergone lattice doping by a metallic element, and a method for oxygen-free preparation of ethylene from methane. The methods realize zero carbon formation of methane and high-selectivity synthesis of ethylene. According to the invention, in a fixed-bed reaction mode, reaction temperature is 750 to 1100 DEG C and reaction pressure is 0.1 to 0.3 Mpa; the mass space velocity of raw reaction gas is 1000 to 30000 ml / g / h; the conversion rate of methane is 10 to 60%; the selectivity of olefins is 60 to 95%; the selectivity of propylene and butylene is 5 to 25%; the selectivity of aromatic hydrocarbons is 0 to 25%; and zero carbon formation is formed. The methods provided by the invention has the characteristics of long service life (greater than 500 h) of the catalyst, good redox performance and hydro-thermal stability at a high temperature (less than 1400 DEG C) of the catalyst, high product selectivity, zero carbon formation, easy separation of products, good process repeatability, safe and reliable operation, etc., and have good industrial application prospects.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

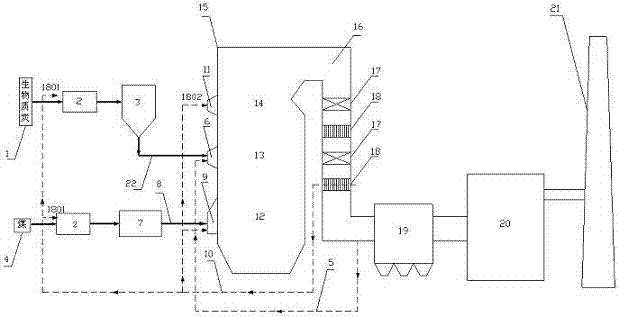

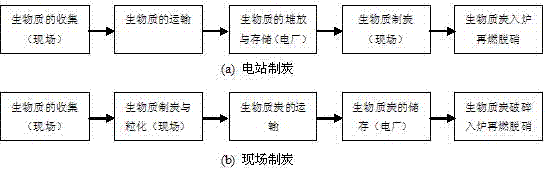

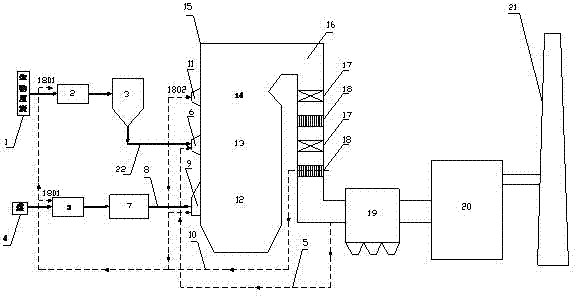

Method and system for collectively removing NOx and mercury (Hg) in coal-fired flue gas by utilizing secondary combustion of biomass charcoal

InactiveCN102364246AHigh calorific valueIncrease energy densityDispersed particle separationSolid fuel combustionLow nitrogenHigh energy

The invention discloses a method for collectively removing NOx and mercury (Hg) in coal-fired flue gas by utilizing the secondary combustion of biomass charcoal, which is characterized in that: on the basis of the secondary combustion denitrification and the recycling of flue gas, the biomass charcoal is used as secondary-combustion fuel, the characteristics of the biomass charcoal such as low sulfur, low nitrogen, chloride containing, high ash-coke activity, high energy density, zero carbon dioxide (CO2) net emission and the like are utilized, and the biomass charcoal is sent into a secondary-combustion area of a hearth, the combined removal of multiple pollutants such as NOx, Hg and the like in the coal-fired flue gas can be realized through the catalyst reduction effect of anoxic combustion and biomass charcoal as well as the catalyst oxidation effect of chloride contained flue gas and high-activity ash and coke. The invention also discloses a system for realizing the method, which comprises a biomass charcoal preparing system, a coal pulverizing system, a hearth, a combustion system of the hearth, a flue gas recycling system and a boiler tail-gas processing system. The biomass charcoal is used as the secondary-combustion fuel, so the technical advantages of the secondary combustion of the fuel and the recycling of the flue gas can be integrated, and the method and the system have the advantages that: the investment cost and the running cost are low, the denitrification efficiency and the mercury removal efficiency are high, the CO2 net emission can be reduced, and the like.

Owner:NANJING NORMAL UNIVERSITY

Method for herbaceous plants to cope with global climate change

InactiveCN108370881AHigh energy storageReduce the greenhouse effectAgriculture gas emission reductionPlant cultivationCoastal erosionSoil horizon

The invention provides a method for herbaceous plants to cope with global climate change. The method comprises the steps of 1, with herbaceous plants being the main body, managing stony desertification and desertification, controlling coastal erosion and water and soil loss and preventing an earth ecological system from collapsing and breaking down; 2, planting the herbaceous plants in regions with the stony desertification, the desertification, the coastal erosion and the water and soil loss, fixing the surface soil layer, recovering or rebuilding vegetation and controlling emission of carbonin lithosphere to atmosphere and hydrosphere; 3, utilizing the characteristics that the fast-growing herbaceous plants are fast in growth and development, high in carbon capturing efficiency and hugein biomass, convert movable carbon in the atmosphere into fixed carbon, develop new climate economy, further promote the increase of the amount of the fixed carbon in the industries of agriculture, forestry, animal husbandry, side-line production and fishery and achieving a world zero carbon development mode. Ecological development is the best carbon emission reduction mode, and carbon dioxide isprecious wealth of the human. Respecting the nature, conforming to the nature, protecting the nature and guiding the nature solve the problem of ecology, environment, resources, economy and global climate warming.

Owner:雷学军

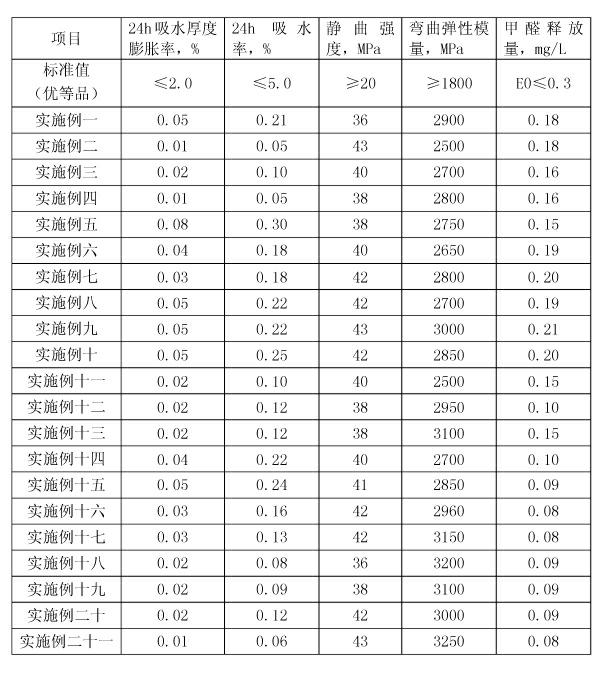

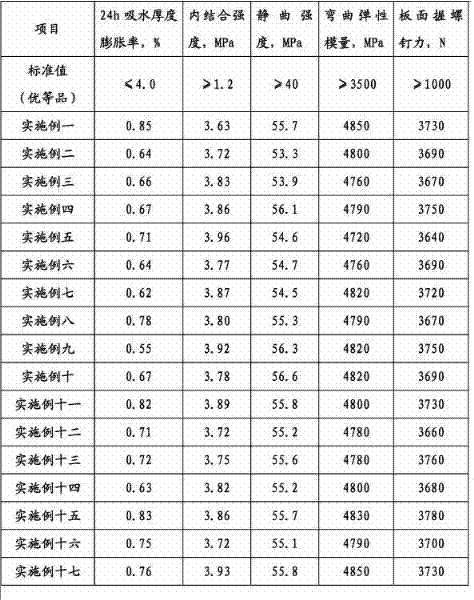

Zero-carbon high-fiber environment-friendly sheet synthesized by waste circuit board powder and production process thereof

The invention discloses a zero-carbon high-fiber environment-friendly sheet synthesized by waste circuit board powder and a preparation process thereof. The pressing raw materials of the environment-friendly sheet comprise: circuit board recycled powder, wood fiber powder, a cross-linking agent, a waterproofing agent, and carbon filament fiber; the production process of the sheet comprises the following steps of: drying the circuit board recycled powder at a constant temperature; converting high fiber auxiliary materials into wood fiber powder above 80 meshes, drying, and then stirring under 180 DEG C to form carbon fiber powder; adding a processing assistant and blending uniformly again; and feeding materials, paving pressing plates, pressurizing, standing, complementing pressure, and gently decompressing to produce the sheet. The pressure during the production process is controlled so that the sheet is stable in quality and high in intensity; the sheet synthesized by wood fiber powder obtained by recycling crop straw, bamboo and wood saw powder and the like with the waster circuit board powder can be sawn, drilled, processed, and shaped easily; furthermore, the sheet is excellent in waterproof and fireproof performances, and high in static bending strength; and the utilization of waste materials reaches the purposes of environmental protection and low carbon.

Owner:清远炬众节能环保科技有限公司

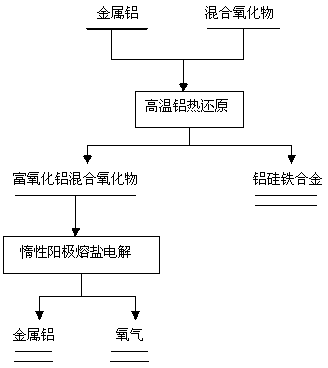

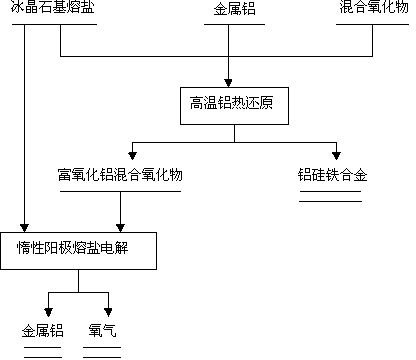

Method for extracting metal and preparing oxygen from lunar soil/lunar rock mixed oxides

ActiveCN103643259AWill not restore precipitationEasy to separateElectrolysis componentsMetallic aluminumSlag

The invention belongs to the field of metallurgy, and particularly relates to a method for extracting metal and preparing oxygen from lunar soil / lunar rock mixed oxides. The method comprises the following steps: carrying out aluminothermic reduction on lunar soil / lunar rock mixed oxides at 940-2200 DEG C for 2-6 hours by using metal aluminum as a reducer, carrying out slag-metal separation to obtain an Al-Si-Fe alloy and Al2O3-rich mixed oxides, dissolving the Al2O3-rich mixed oxides in a cryolite-base fused salt electrolyte Na3AlF6-AlF3, and carrying out electrolysis at 930-985 DEG C by using a Fe-Ni alloy and a Fe-Ni-Al2O3 metal-base composite material as an anode while controlling the current density in the electrolysis process at 0.4-1.2A / cm<2>, thereby bubbling oxygen at the anode and obtaining metal aluminum at the cathode. According to the method, the mixed oxides containing SiO2, Al2O3, Fe2O3, MgO, CaO and Na2O are subjected to aluminothermic reduction at high temperature, and the electrolysis is performed by using the inert anode to prepare the metal aluminum and oxygen; and thus, the method can be used in industrial practice to implement green metallurgy and clean production with zero carbon consumption and zero greenhouse gas emission, and has important meanings for establishing lunar bases and front base stations in future.

Owner:NORTHEASTERN UNIV LIAONING

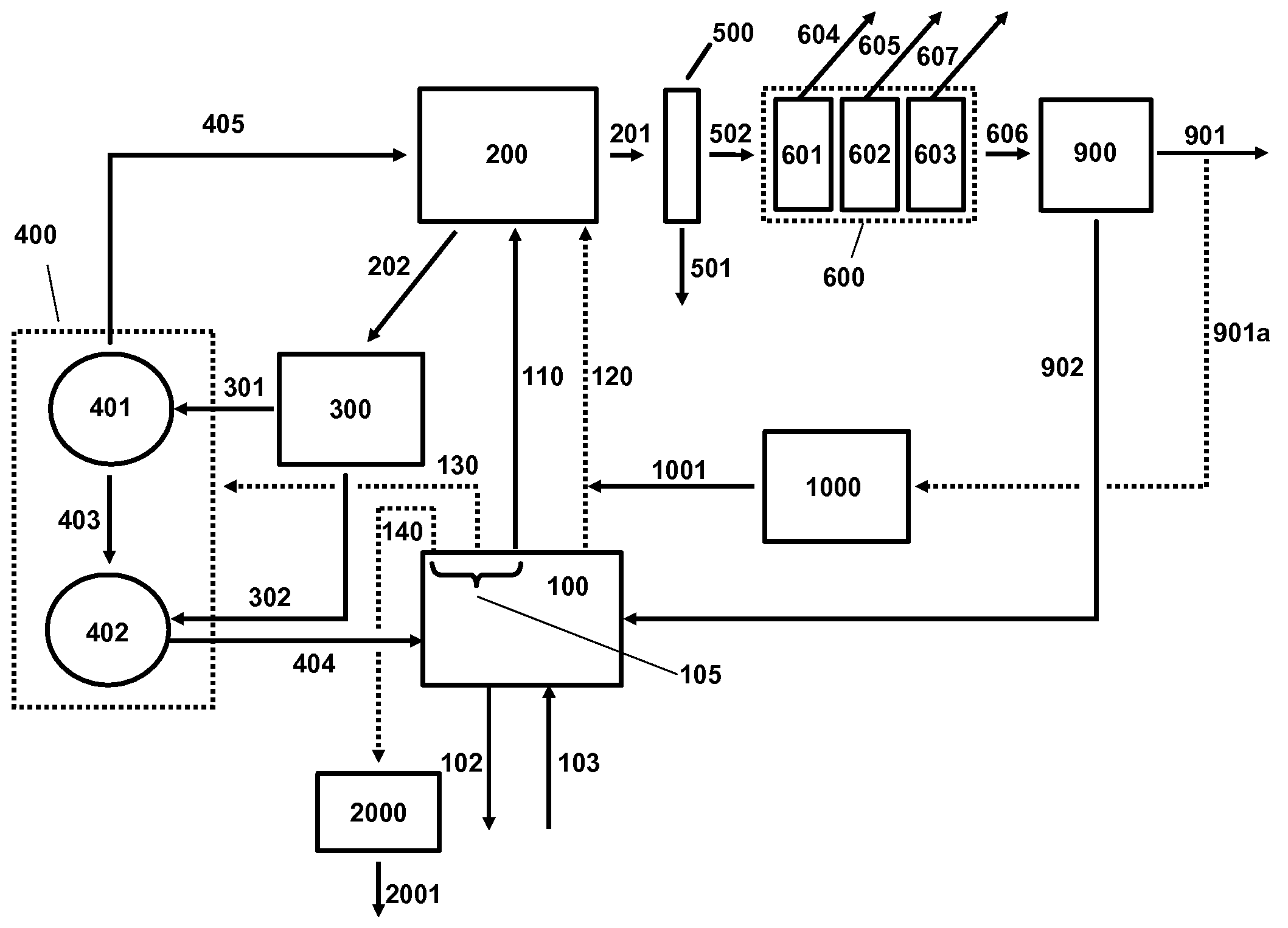

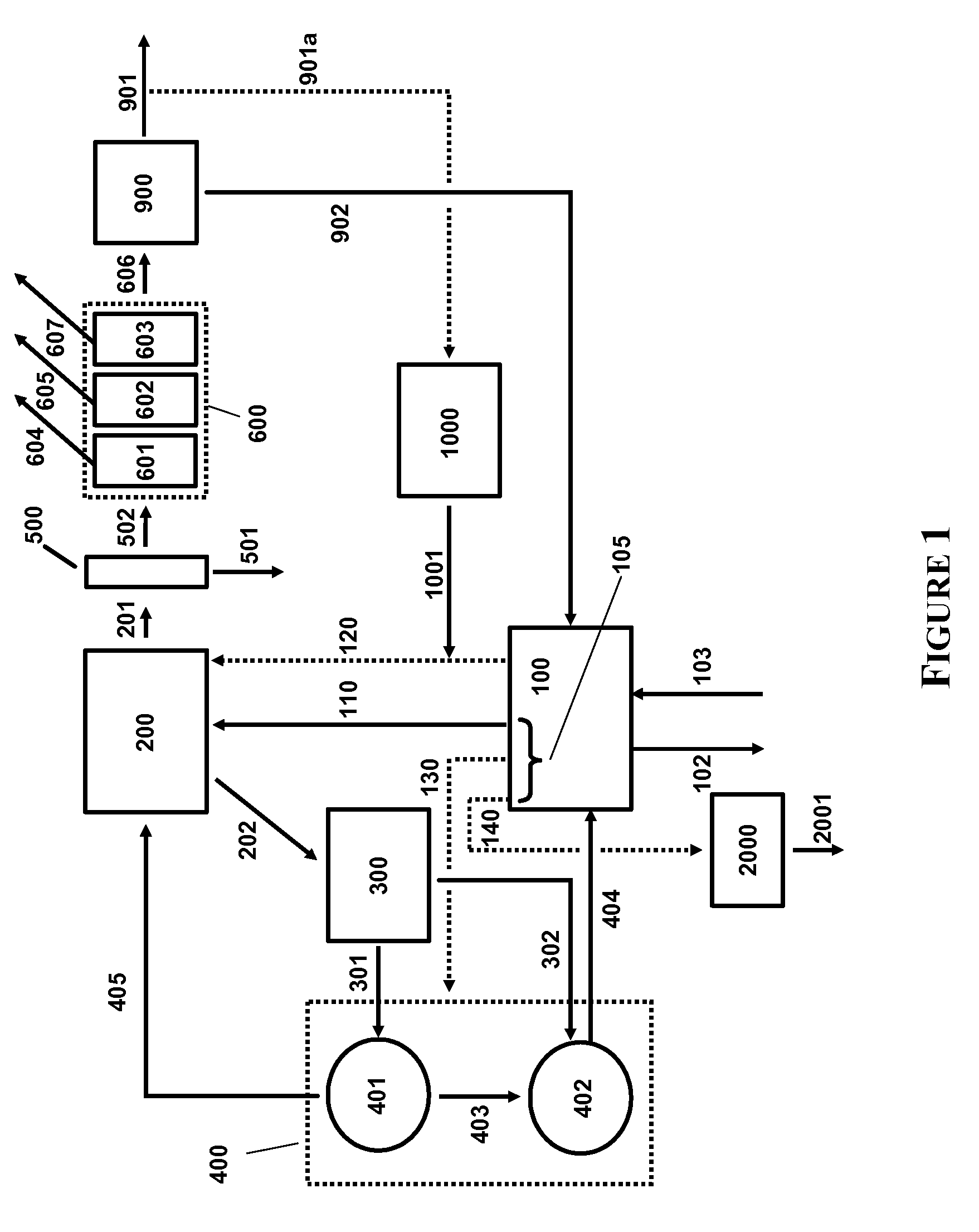

High temperature hydropyrolysis of carbonaceous materials

InactiveUS20100314235A1Efficient supplyMinimizes problemCombustible gas coke oven heatingFuel cell heat exchangeSulphur iodideResource utilization

Heat from a concentrated solar power source is applied to the conversion of carbonaceous materials such as heavy petroleum crude oils, coals and biomass to liquid hydrocarbons. The solar heat is applied to provide at least a portion of the process heat used in the high temperature, short contact time hydropyrolysis of the carbonaceous material which is supplied with hydrogen generated by a high temperature process such as high temperature steam electrolysis, the sulfur-iodine cycle, the hybrid sulfur cycle, the zinc-zinc oxide cycle or by methane steam cracking. The heat from the solar source may be used to generate electricity to operate high temperature steam electrolysis used in generation of the hydrogen. By the use of solar thermal energy sources, hydrocarbon resource utilization for process heat is eliminated along with carbon dioxide evolution associated with burning of the hydrocarbon resource to generate process heat. The substitution of zero carbon emission sources therefore offers the potential for significant carbon emission reductions in refinery operations where external process heat can be applied and effectively utilized.

Owner:EXXON RES & ENG CO

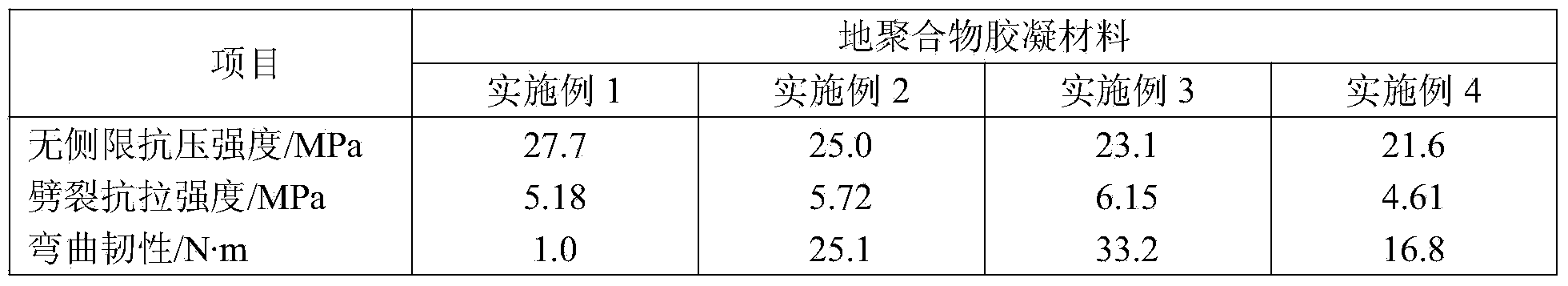

Corn straw fiber enhanced fly ash polymer gel material and preparation method thereof

The invention discloses a corn straw fiber enhanced fly ash polymer gel material and a preparation method thereof. In the preparation method, the corn straws are mixed into an alkali-excited fly ash polymer gel material, and then the mixture is subjected to certain maintenance conditions so as to enable the material system to have good properties. The corn straw, namely a waste which has not been effectively utilized, is used to enhance a poly gel material prepared from an industrial waste fly ash. A novel way is provided for waste utilization, the environment burden is relieved, the energy consumption is reduced, and the material performances are strengthened. The corn straw fiber enhanced fly ash polymer gel material is an unfired and clinker-free material, is a zero-carbon-emission environment-friendly engineering material, is according with the social development trend, and has a good social benefit and economic benefit.

Owner:SOUTHEAST UNIV

Hydrogen and ammonia fueled internal combustion engine

ActiveUS8025033B2Non-fuel substance addition to fuelInternal combustion piston enginesHydrogenExternal combustion engine

Owner:STRATEGIC DESIGN FEDERATION W LLC

Combined production device of hydrocarbon production through methanol dehydration and hydrogen and carbon dioxide production through methanol reforming

InactiveCN101712883ALow calorific valueHigh calorific valueHydrogenCarbon compoundsGeneration processCarbon dioxide production

The invention relates to a combined production device of hydrocarbon production through methanol dehydration and hydrogen and carbon dioxide production through methanol reforming, which is characterized in that methanol is utilized as raw materials to co-produce petroleum, liquefying gas, hydrogen and carbon dioxide; heat generated during hydrocarbon production through methanol dehydration is used for a methanol reforming process; water generated during the hydrocarbon production through the methanol dehydration is used for the methanol reforming process; hydrogen generated by reforming can be used for a thermoelectric device and the like, and generated carbon dioxide is recovered and can be used for producing products such as food grade carbon dioxide and the like. The raw material methanol has rich sources. Petroleum and liquefying gas products satisfy the standards of clean fuel and has large product market demands. The hydrogen generated by a methanol reforming device is used as fuel and can realize near zero carbon dioxide emission in a thermoelectricity generation process.

Owner:国科瑞德(北京)能源科技发展有限公司

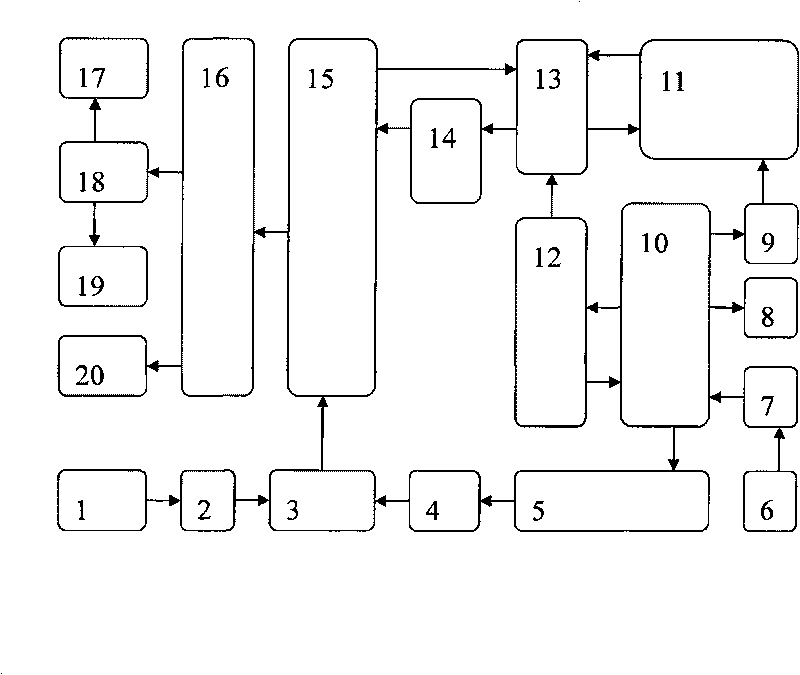

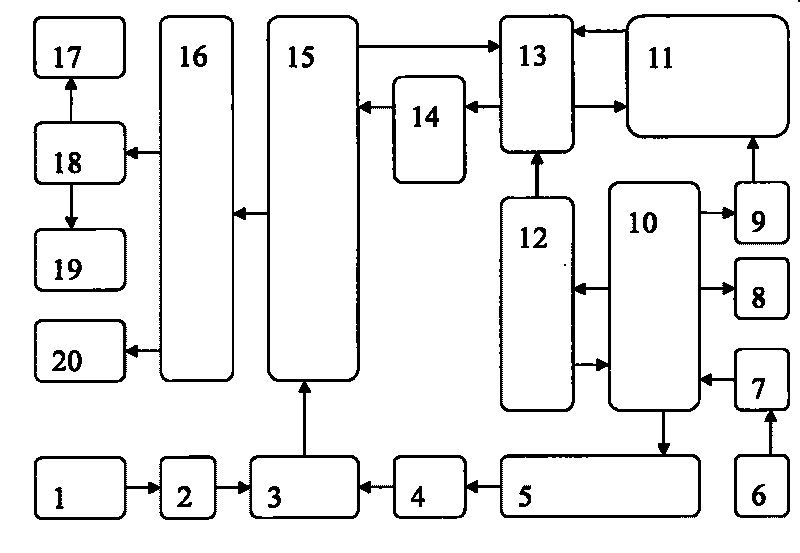

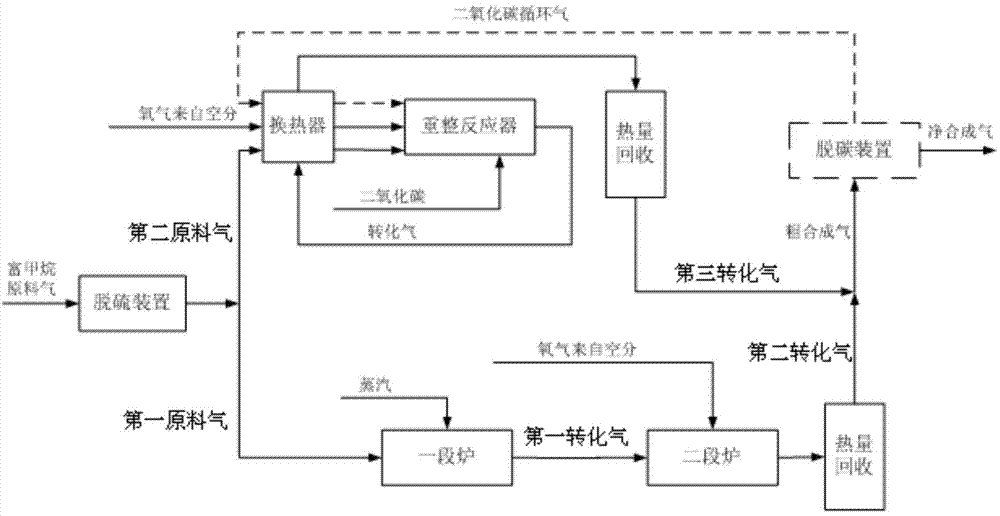

Process method for preparing synthesis gas by using zero carbon or negative carbon emission system

ActiveCN104709876AEmission reductionAchieve recyclingHydrogenChemical industrySyngasNegative carbon dioxide emission

The present invention discloses a process method for preparing synthesis gas by using a zero carbon or negative carbon emission system. The process method comprises that: 1) first raw material gas is subjected to desulfurization, steam is matched, pressurization and heating are performed, a reaction is performed to obtain first conversion gas, the first conversion gas is output, the output first conversion gas and pure oxygen are mixed and then enter a two-stage furnace to react so as to obtain second conversion gas, and the second conversion gas is output from the two-stage furnace; 2) second raw material gas is subjected to desulfurization, pressurization and heating and then is mixed with pure oxygen and carbon dioxide, then a reforming reaction is performed to obtain third conversion gas, and the third conversion gas is output from the reforming reactor; and 3) the second conversion gas is subjected to heat recovery and then is mixed with the third conversion gas to form crude synthesis gas, wherein the crude synthesis gas is adopted as the subsequent synthesis gas with or without a decarbonization device. According to the present invention, the greenhouse gas emission is reduced, the carbon efficiency is improved, the recycling of the carbon resources of the energy source chemicals is achieved, the hydrogen-carbon ratio of the synthesis gas achieves the ideal ratio of the downstream process requirement, and the zero carbon or negative carbon emission of the whole system is achieved.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI +1

Carbon Sequestration in Municipal Solid Waste to Energy Plants

InactiveUS20130019785A1Limited applicationReduce carbon emissionsDirect carbon-dioxide mitigationHydrogen/synthetic gas productionRefuse-derived fuelExhaust fumes

This invention describes a process for a complete sequestration of carbon (CO2) from Municipal Solid Waste (MSW) to energy plants which produce Refuse Derived Fuel and the associated exhaust gases. The described process results in production of energy from the waste and disposal of the MSW with zero carbon emission.

Owner:SAXENA SURENDRA

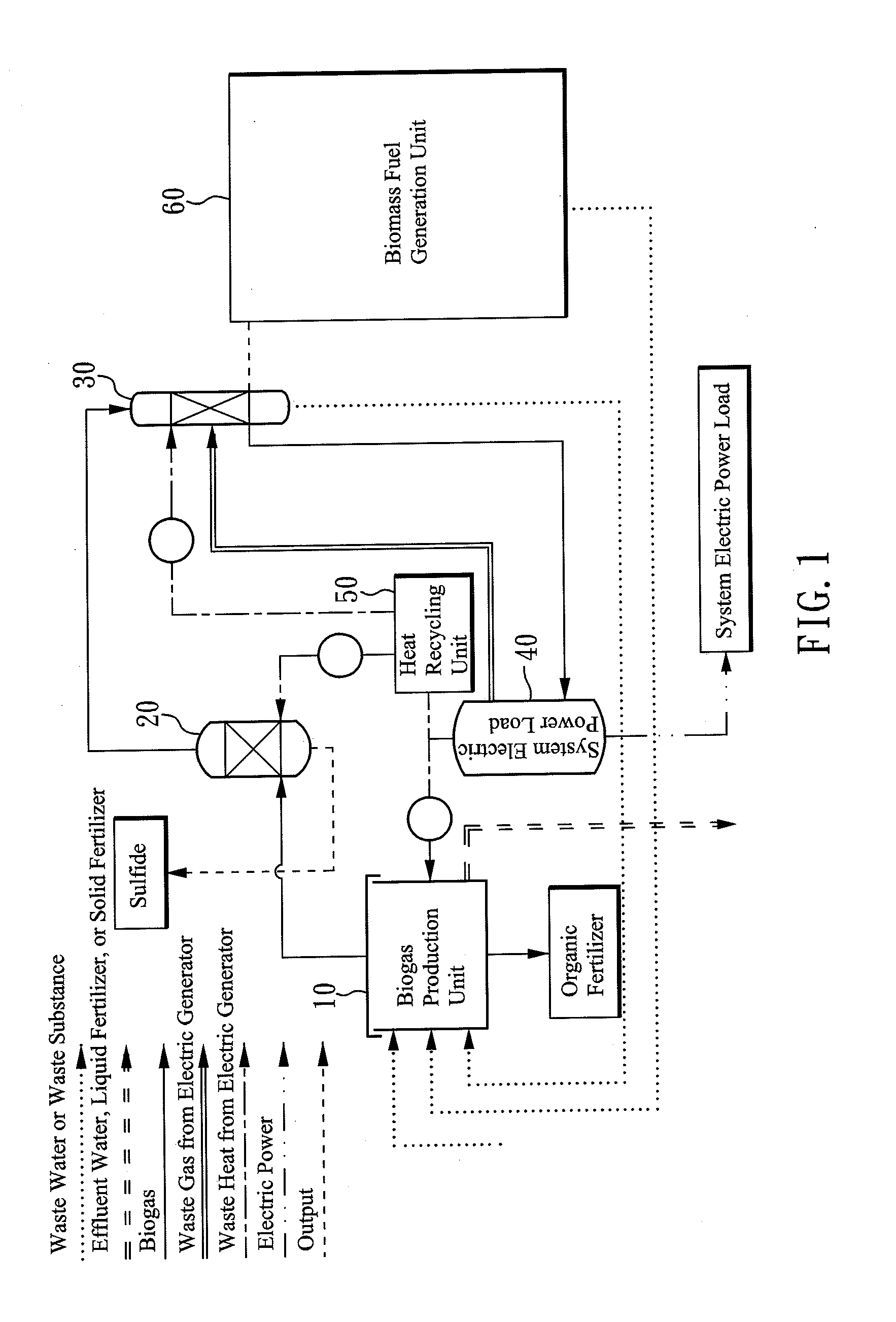

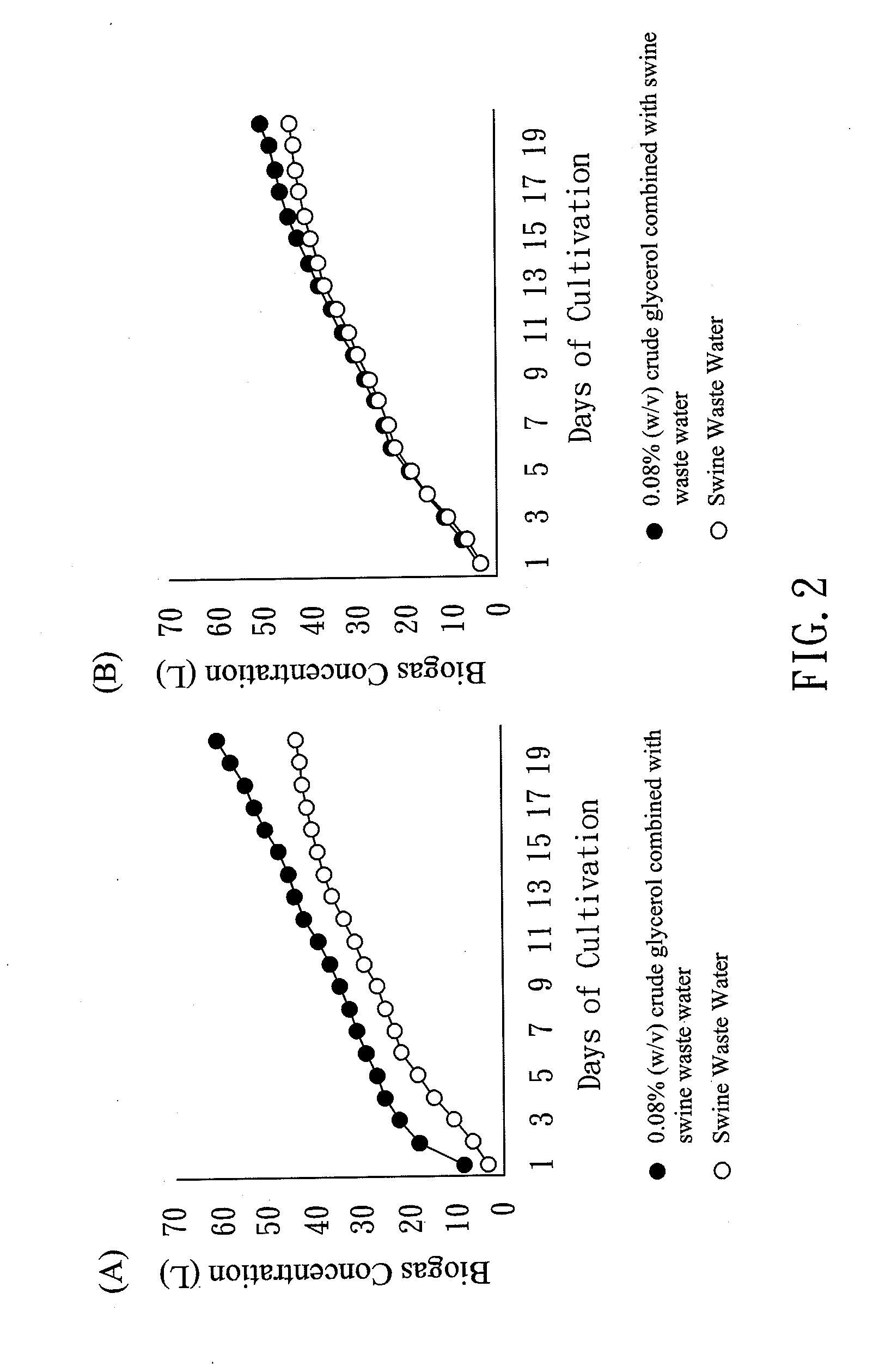

Microalgae for Removal of Carbon Dioxide Generated from Biogas and Biogas Electric Generator

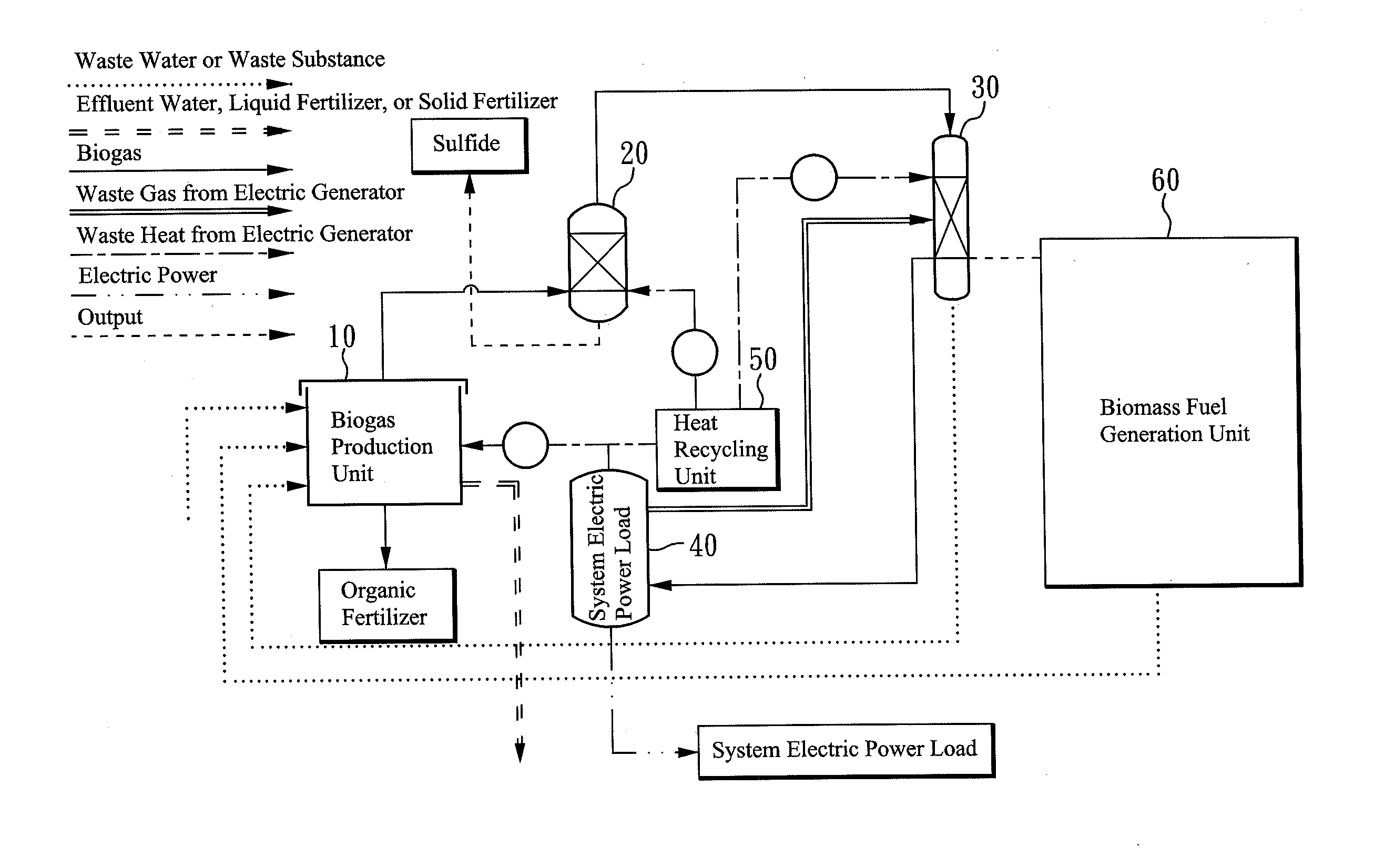

InactiveUS20130236951A1Easy to disassembleAvoid damageBioreactor/fermenter combinationsBiological substance pretreatmentsEnvironmental engineeringBiogas production

The present invention relates to biogas and biogas electric generator and a biogas electricity generation method by use microalgae for removal of carbon dioxide generated from biogas and biogas electric generator. The electric generator integrates biogas production and purification, microalga culture, electricity generation, heat recycling and others into a unit volume, and, during microalgae culturing, uses carbon dioxide contained in biogas and that produced from electricity generation as a carbon source for photosynthesis to reduce the carbon dioxide contained in the biogas and the electricity generation exhaust gas, thereby attaining the goal of zero carbon emission.

Owner:NAT CHIAO TUNG UNIV

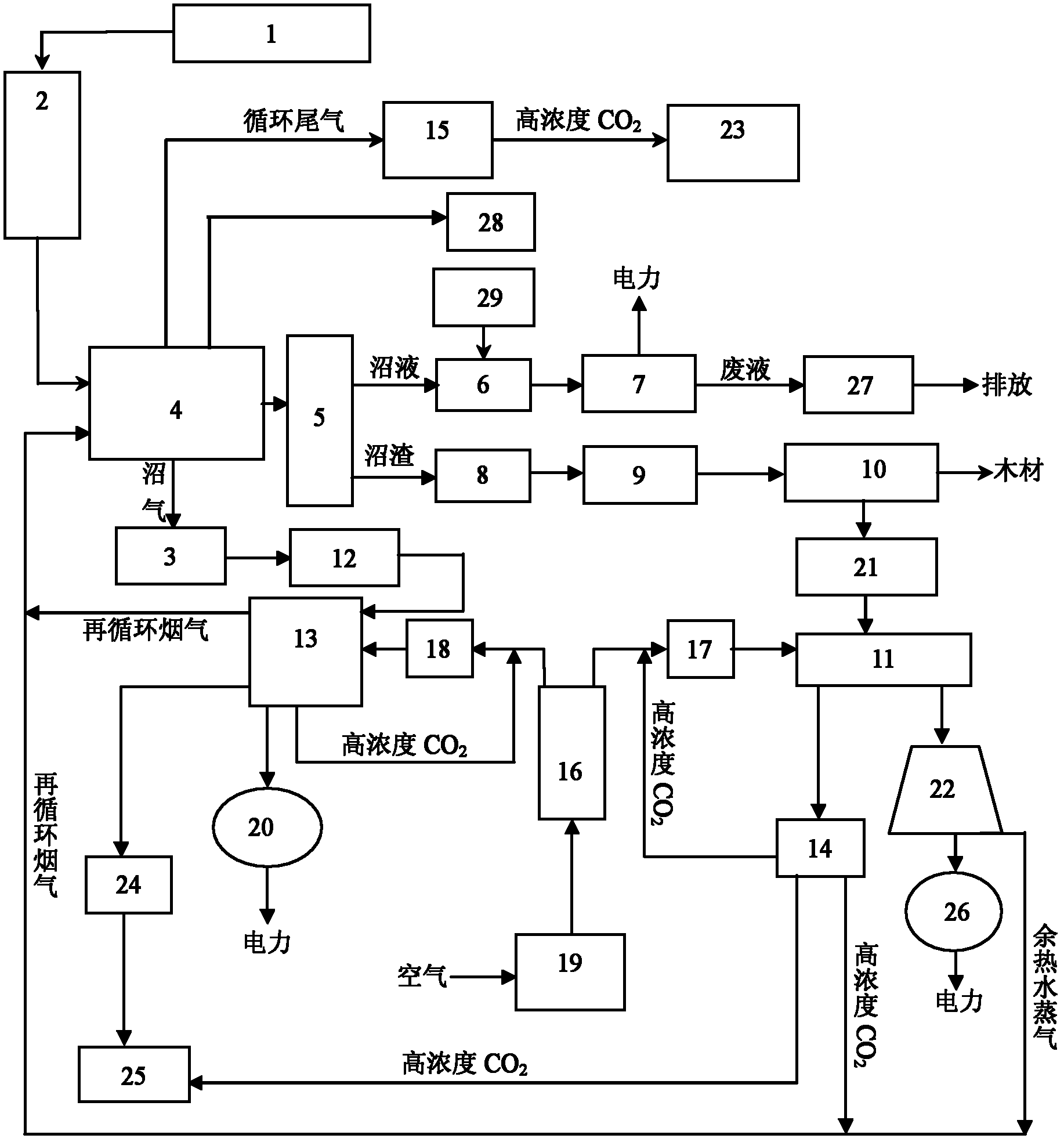

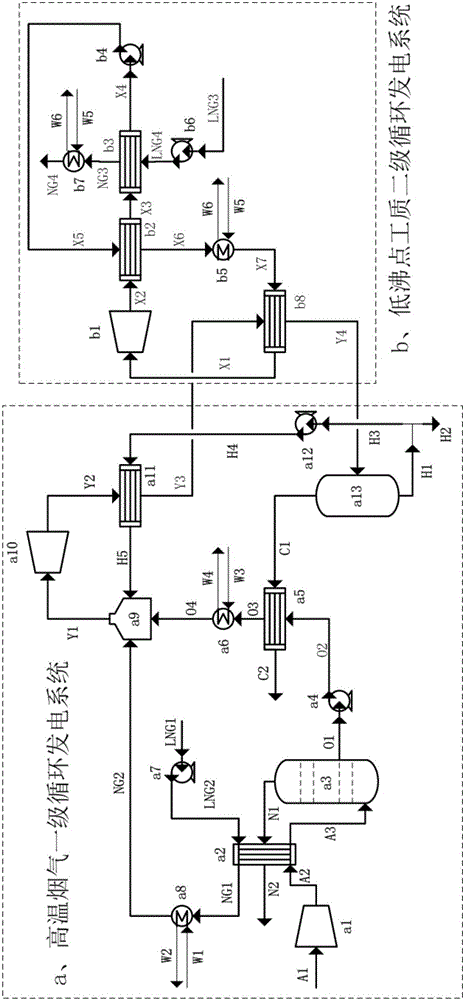

Zero-carbon-emission multistage circulating power generation integrated system

InactiveCN106224024AReduce compressed air pressureReduce energy consumption for air separation and oxygen productionSolidificationLiquefactionHigh pressureIntegrated systems

The invention discloses a zero-carbon-emission multistage circulating power generation integrated system which comprises a high-temperature flue gas first-stage circulating power generation system and a low-boiling-point working medium second-stage circulating power generation system. In the high-temperature flue gas first-grade circulating power generation system, LNG cold energy and liquid nitrogen cold energy are applied to the precooling process of the compressed air, and therefore air separation oxygen production power consumption is reduced. The liquid oxygen cold energy is applied to condensation recovery of CO2 in combustion flue gas, and the approximate zero power consumption process of carbon capture is achieved. In the low-boiling-point working medium second-stage circulating power generation system, LNG is adopted as a cold source, environment and combustion flue gas waste heat is adopted as a heat source, the Rankine cycle power generation process of a low-boiling-point working medium is completed, and the output electrical efficiency of the low-boiling-point working medium second-stage circulating power generation system is improved. The zero-carbon-emission multistage circulating power generation integrated system depends on an O2 / H2O high-pressure combustion system of LNG, the low-boiling-point working medium second-stage circulating power generation system is additionally arranged, gradient utilization of energy is achieved, the output electrical efficiency of the integrated system is improved, and meanwhile zero carbon emission of the system is achieved.

Owner:HUAZHONG UNIV OF SCI & TECH

Method for developing new-climate economy and realizing global net zero carbon emission

ActiveCN107251724ADevelop carbon circular economyIncrease carbon sinkAgriculture gas emission reductionCultivating equipmentsCarbon storageClean energy

A method for developing new-climate economy and realizing global net zero carbon emission comprises steps of selecting excellent and high-yield biological kinds and repeatedly harvesting in unit time to increase biological carbon catching amount, planting trees, irrigating and planting weeds to form a multi-coverage composite ecological system to expand plant carbon storage amount, improving a ploughing way, utilizing biological fertilizers and improving soil carbon storage amount, producing carbon products and biological products in a bio-manufacturing way and expanding biological carbon sealing amount, breeding high-yield aquatic organisms to increase hydrosphere carbon conversion amount, developing animal husbandry to expand animal carbon transmission amount, collecting organisms to fill and bury to limit atmosphere total carbon amount, replacing fossil fuel by clean energy to control atmosphere carbon increase amount, conserving energy and reducing consumption and reducing man-made carbon emission, comprehensively developing and utilizing atmosphere carbon resource, building a manual carbon stock to create atmosphere carbon dividing amount. Through ways of carbon capture, storage, sealing, conversion, transmission, limit, control, decrease and utilization, global net zero carbon emission can be realized; and ecological, environmental, resource-related, economic and climatic problems can be solved.

Owner:雷学军 +1

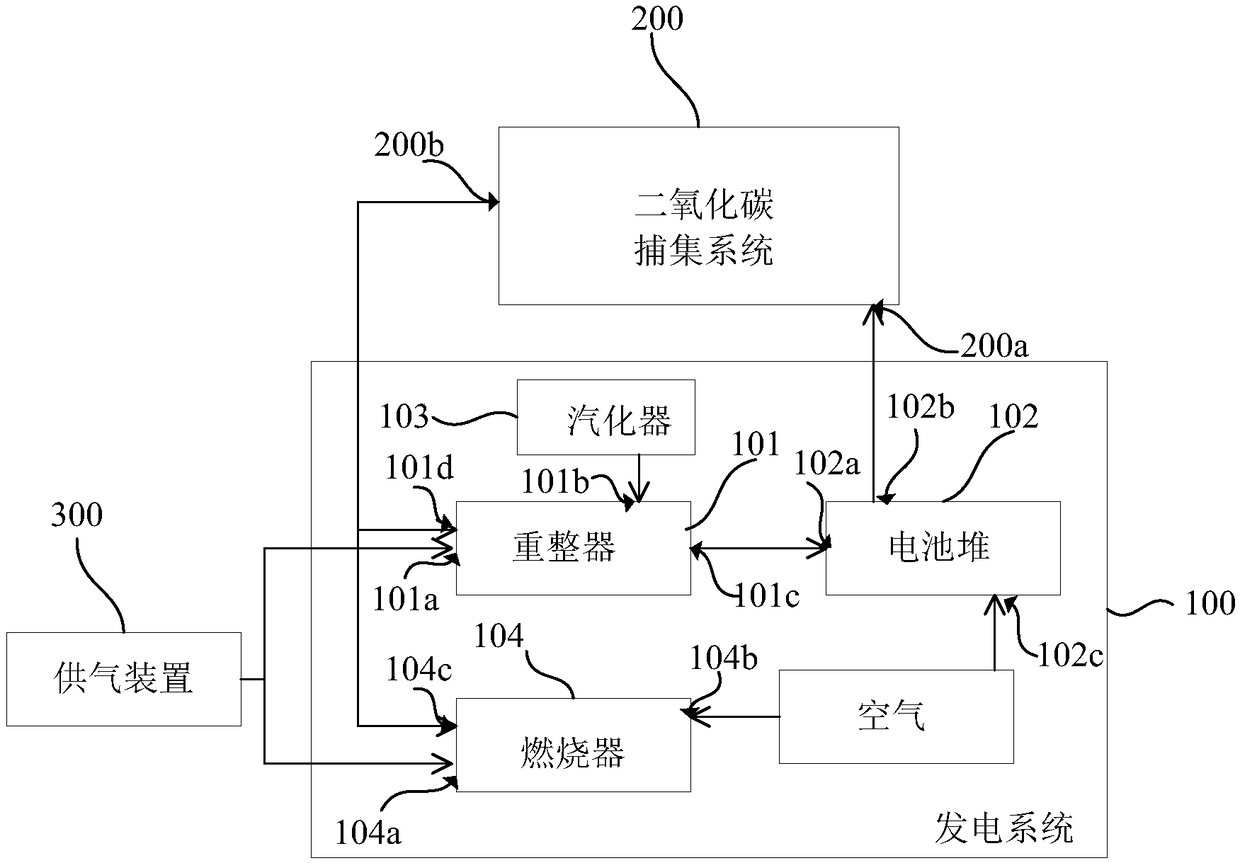

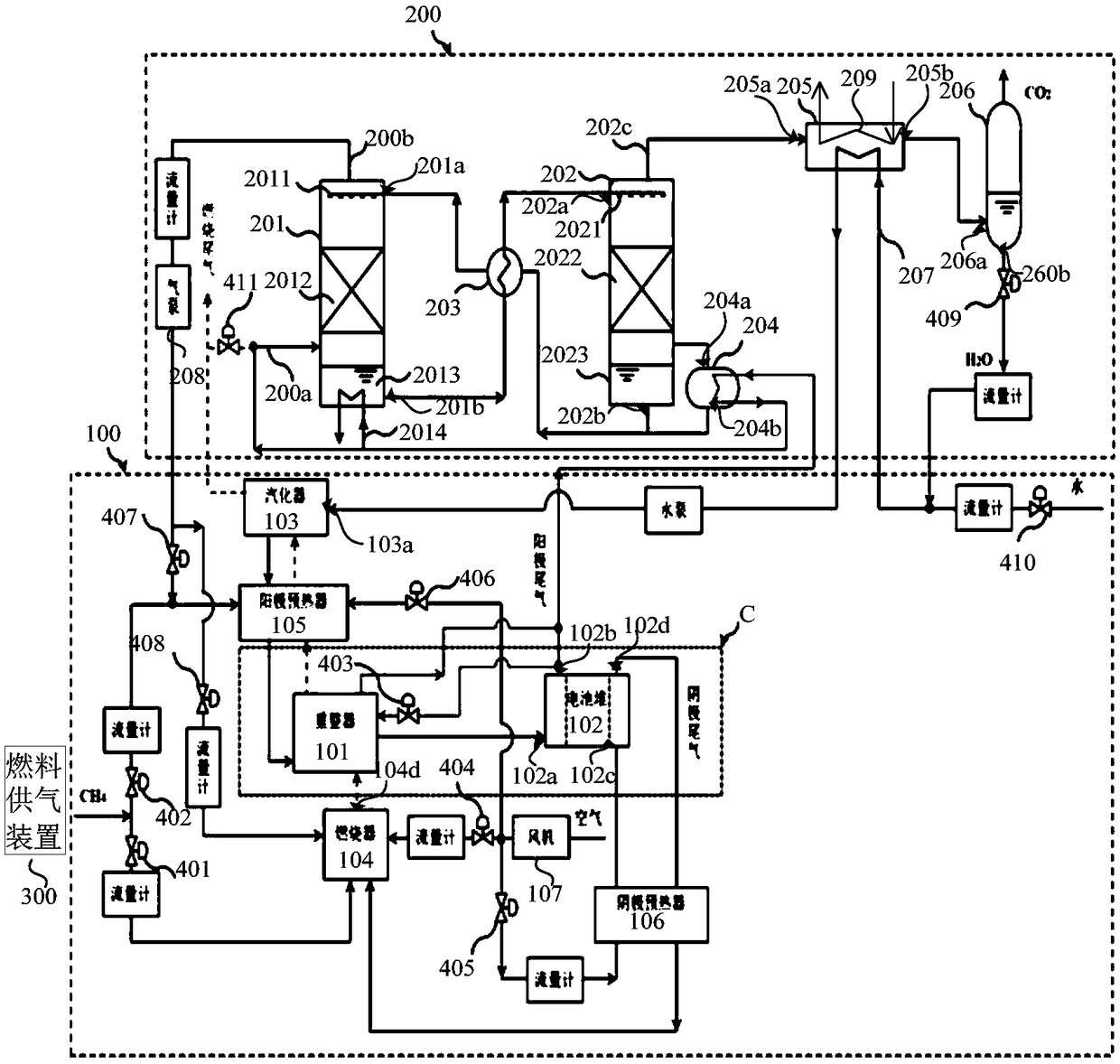

Solid oxide fuel cell composite system and method of use

A solid oxide fuel cell composite system and method of use are provided, including a reformer, a battery stack, a carburetor and a combustor. The first input end of the reformer is communicated with afuel gas supply device, the second input end of the reformer is communicated with the carburetor, and the first output end of the reformer is communicated with the battery stack. A first input end ofthe burner is in communication with the fuel air supply device, and a second input end of the burner is in communication with air; a trap system inlet communicates with an anode outlet of the stack,and the trap system outlet is selected from at least one of communication with the burner, communication with the reformer, and direct discharge into the air. The invention separates the combustible components from the generated water in the anode tail gas of the battery stack, and realizes the recovery and utilization of the combustible components; Making full use of the high-grade thermal energyof fuel gas to drive the carbon dioxide capture system, the carbon dioxide recovery can be realized on the basis of low energy consumption or zero energy consumption, so that the system can generateelectricity efficiently while achieving near-zero carbon dioxide emissions.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

Production technology of 'zero-carbon emission' cement combined with industrial gypsum waste treatment

InactiveCN103641344ASolve stacking pollutionReduce processing costsClinker productionCarbon captureSorbentWaste treatment

The invention relates to a production technology of 'zero-carbon emission' cement combined with industrial gypsum waste treatment, and mainly comprises the following steps: carbonizing industrial waste gypsum; moulding and processing the obtained calcium carbonate, and the moulded calcium carbonate particles can be used as adsorbent for capturing CO2 in the cement kiln tail gas in circulation; the inactivated calcium adsorbent can sinter cement clinker. The invention not only can solve the treatment problem of industrial gypsum waste for changing waste into valuable and reasonably using resource; but also can substantially reduce CO2 discharged in the cement production process, thereby according with national low carbon policy.

Owner:HUAZHONG UNIV OF SCI & TECH

Formaldehyde-free zero-carbon environmentally-friendly board synthetized by circuit board and manufacture technology thereof

ActiveCN102304280AImprove waterproof performanceImprove utilization efficiencyFiberManufacturing technology

The invention discloses a formaldehyde-free zero-carbon environmentally-friendly board synthetized by circuit board and a manufacture technology thereof. The compaction raw material of the environmentally-friendly board comprises circuit board powder, isocyanate, release agent and water, and wood fiber powder and carbon filament fiber also can be added. The manufacture technology of the board comprises the following steps of: evenly stirring isocyanate and release agent; adding water to stir; drying the circuit board powder at constant temperature; adding processing accessory ingredient to beevenly mixed; feeding, paving a platen; smoothly releasing pressure to obtain the board after pressurizing; and standing and supplementing pressure. The board manufactured by the manufacture technology by the above raw material ingredients is the formaldehyde-free environmentally-friendly board which is completely free from formaldehyde, and the use amount of recovery powder of the circuit board can be above 95%, therefore improving waste use ratio. In the board manufacture process, the isocyanate and water can react to absorb water, so that the material moisture rate is lowered, no bubbles are formed, and the problem of exploring boards can be solved. The board manufactured by taking the circuit board recovery powder as the main raw material has good water-proof performance.

Owner:广州世环板材有限公司

Processes for preparing and using high-energy biomass and biological carbon

InactiveCN101824349ASolve the bottleneck of power generationReasonable useAgriculture tools and machinesBiofuelsHigh carbonHigh energy

The invention discloses processes for preparing and using a high-energy biomass and biological carbon. The high-energy biomass comprises one type of but is not limited to high-energy biomass plant of C4 plants such as Chinese silvergrass plants, Switchgrass and the like, and the high-energy biomass plant is cultured until maturation, then is harvested and dried, and is processed by the following steps of: firstly, using high-carbon hydrate parts of the high-energy biomass plant to produce an ethanol or butanol bio-fuel by using a microbial fermentation process; secondly, drying and extruding high-fuel-value parts of the high-energy biomass plant to produce biological fuel blocks; and finally, crushing and drying other parts of the high-energy biomass plant to produce the biological carbon. The processes not only can solve the bottleneck of the conventional biomass power generation, but also can reasonably use power generation raw materials, reduce the cost and optimize the reasonable circulation of energy and carbon to achieve zero carbon emission power generation in the real sense.

Owner:HANGZHOU XINWEI LOW CARBON TECH R&D

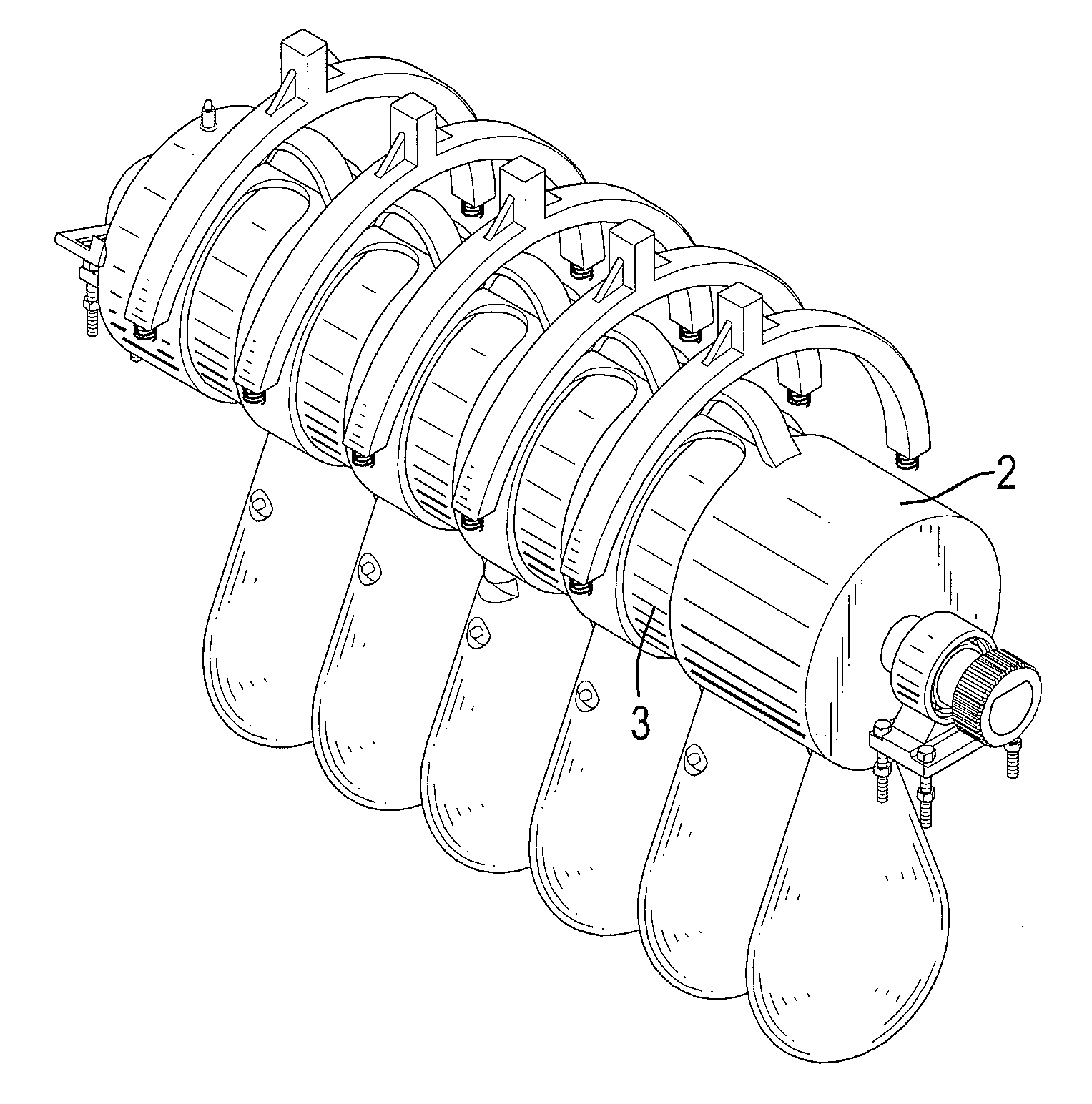

Apparatus for hydroelectric power production expansion

InactiveCN101560941AOptimum hydraulic surface flow conditionsWill not emitWater-power plantsReaction enginesEngineeringElectric generator

Normally hydroelectric dam powerhouses use river flow once before discharging it as turbulent tailwater, ineffective to spin turbines. The present invention uses tapered channels to confine and constrict turbulent tailwater into laminar flow that drives turbines both submersible and floatable utilizing the same water three times concurrently to generate new electricity. Channels originate adjacent to draft tube outlets, constrict in the downstream direction to create narrow necks where turbine / generators benefit from debris free, increased velocity and laminar flows to generate electricity. Hydroelectricity uses zero fuel, creates zero waste and has zero carbon dioxide emissions. Structures are uncomplicated, construction is within project boundaries minimizing environmental impacts and speeding projects coming online. New facilities are protected by existing dam security. Hydroelectricity replaces less dependable renewable energy systems.

Owner:威廉・洛厄尔・凯利

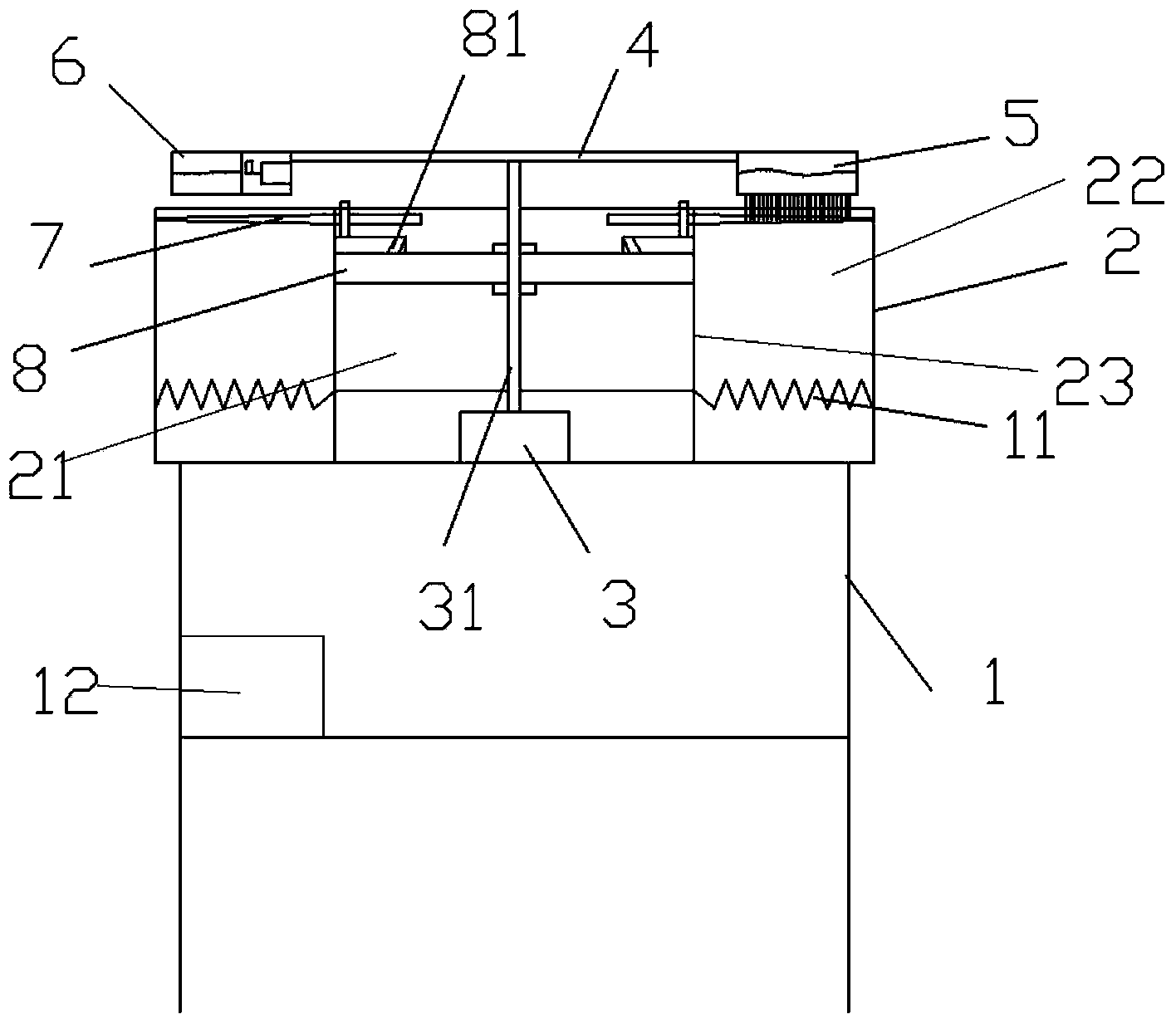

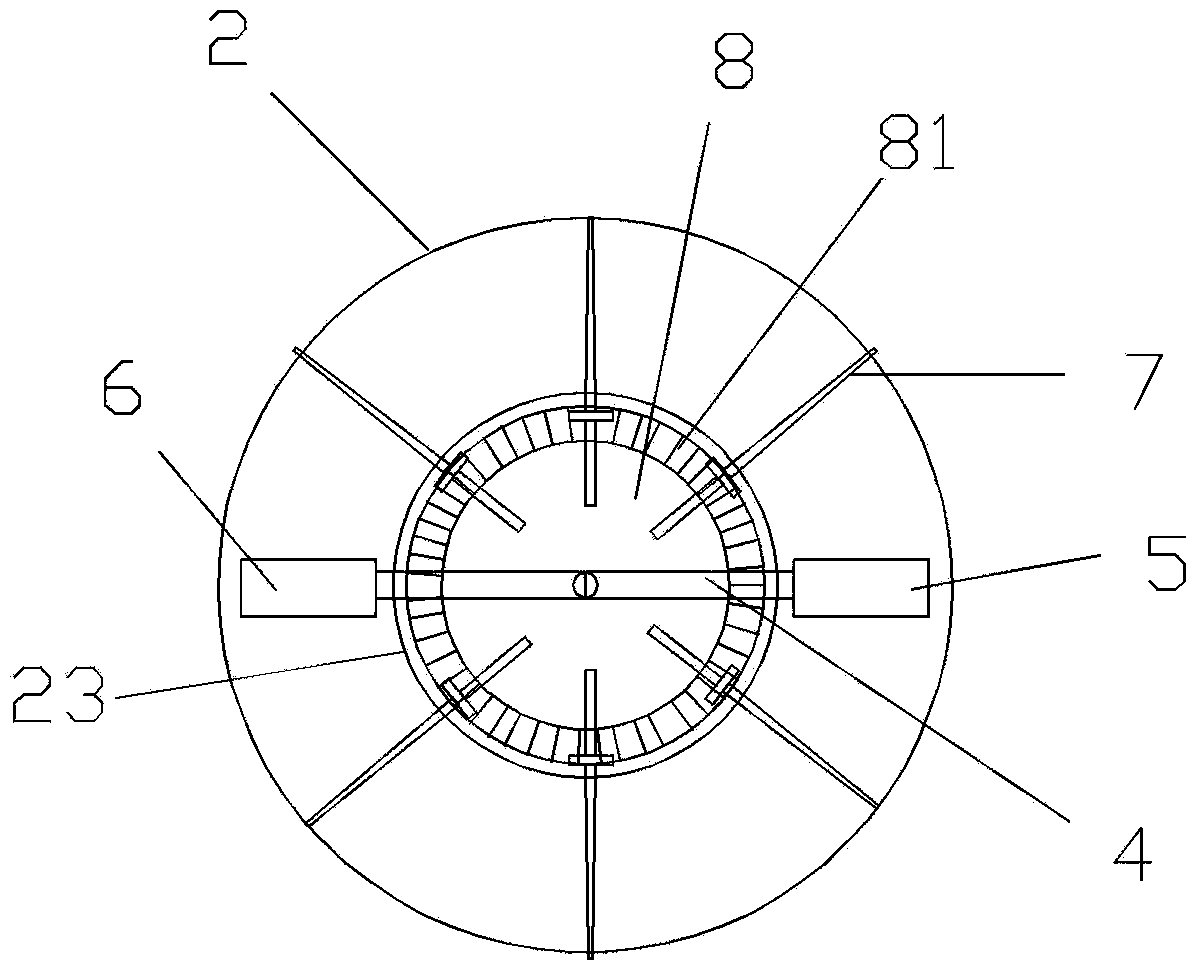

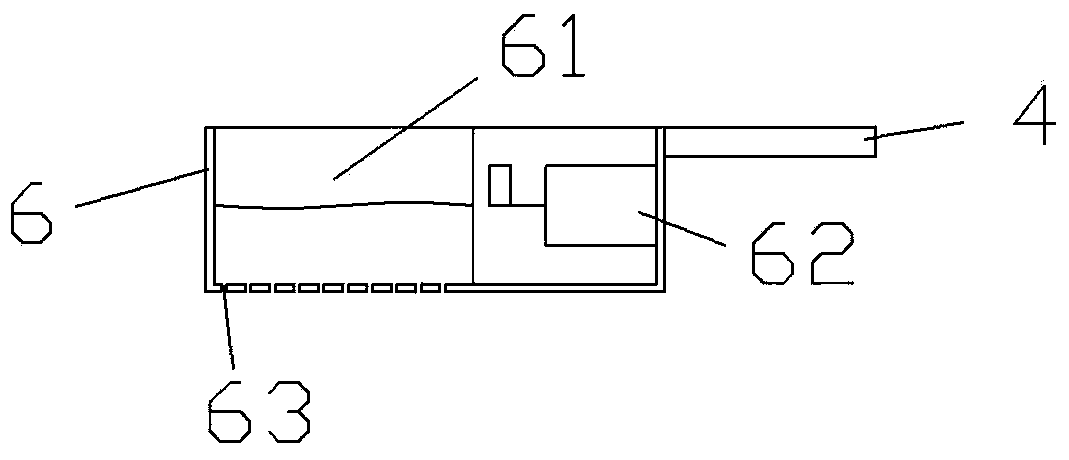

Automatic barbecue machine

The invention discloses an automatic barbecue machine which comprises a barbecue box, a motor control box and the like. Automatic grilling, material sprinkling and oil brushing are achieved through a specially-designed rotating disc and specially-designed grilling needles. Compared with the prior art, the automatic barbecue machine has the advantages that the breakthrough of zero carbon grilled cancerogen is achieved, health and environmental friendliness are achieved, and heating is fast; a disc-shaped stirring tooth automatic overturn mechanism is adopted, the grilling needles are arranged in the circumferential direction so that food can be evenly heated, and the grilling quantity is large; an automatic oil brushing and material sprinkling mechanism is adopted, the automatic level of the product is further improved, and manpower and time cost are saved; the automatic barbecue machine is high automatic level, simple in operation, low in cost, sanitary, healthy, safe, reliable, high in grilling quality, convenient to place and carry and the like, people can feel the charm of science while enjoying the foot, and the automatic barbecue machine is quite suitable for living at home and field and beach barbecue.

Owner:ANHUI POPULAR SCI PROD ENG RES CENT

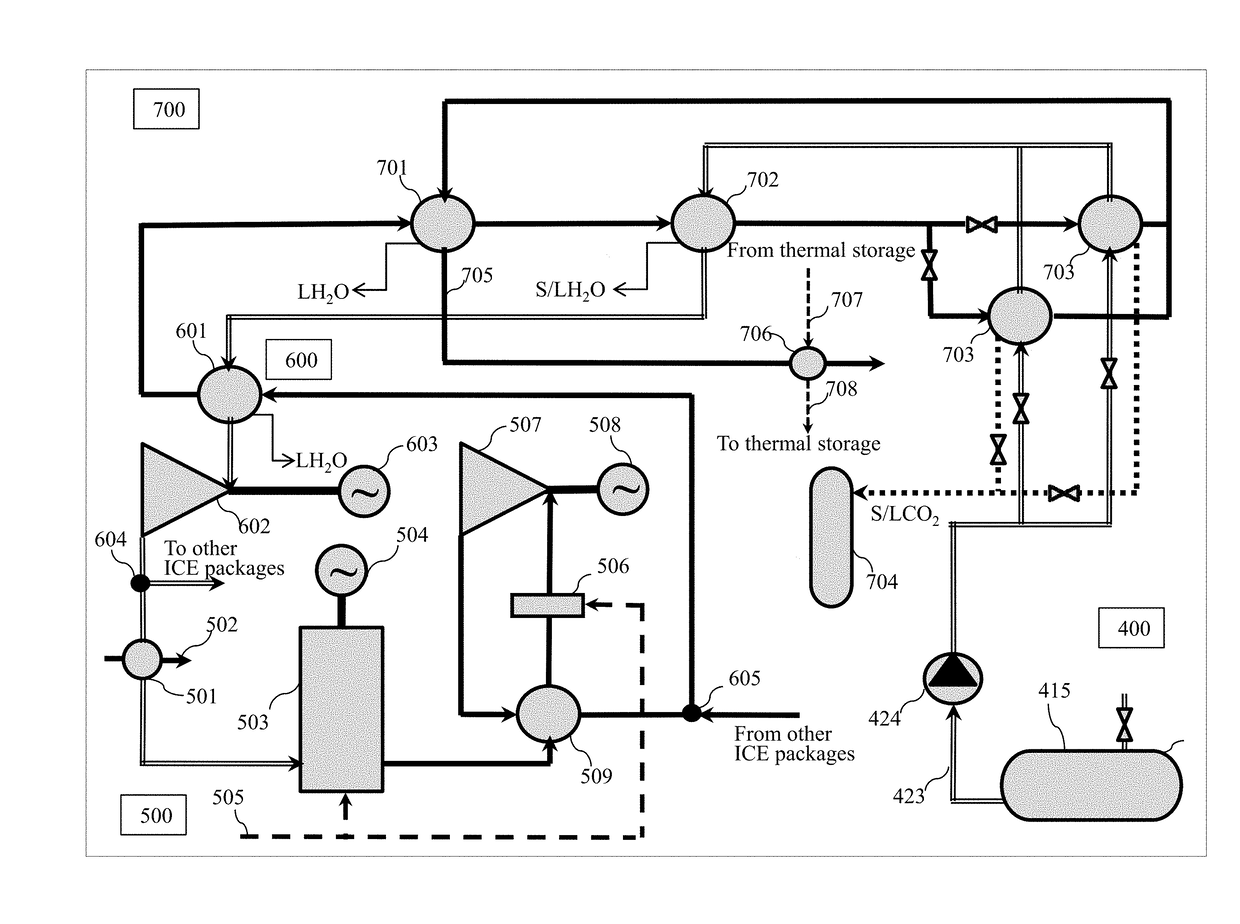

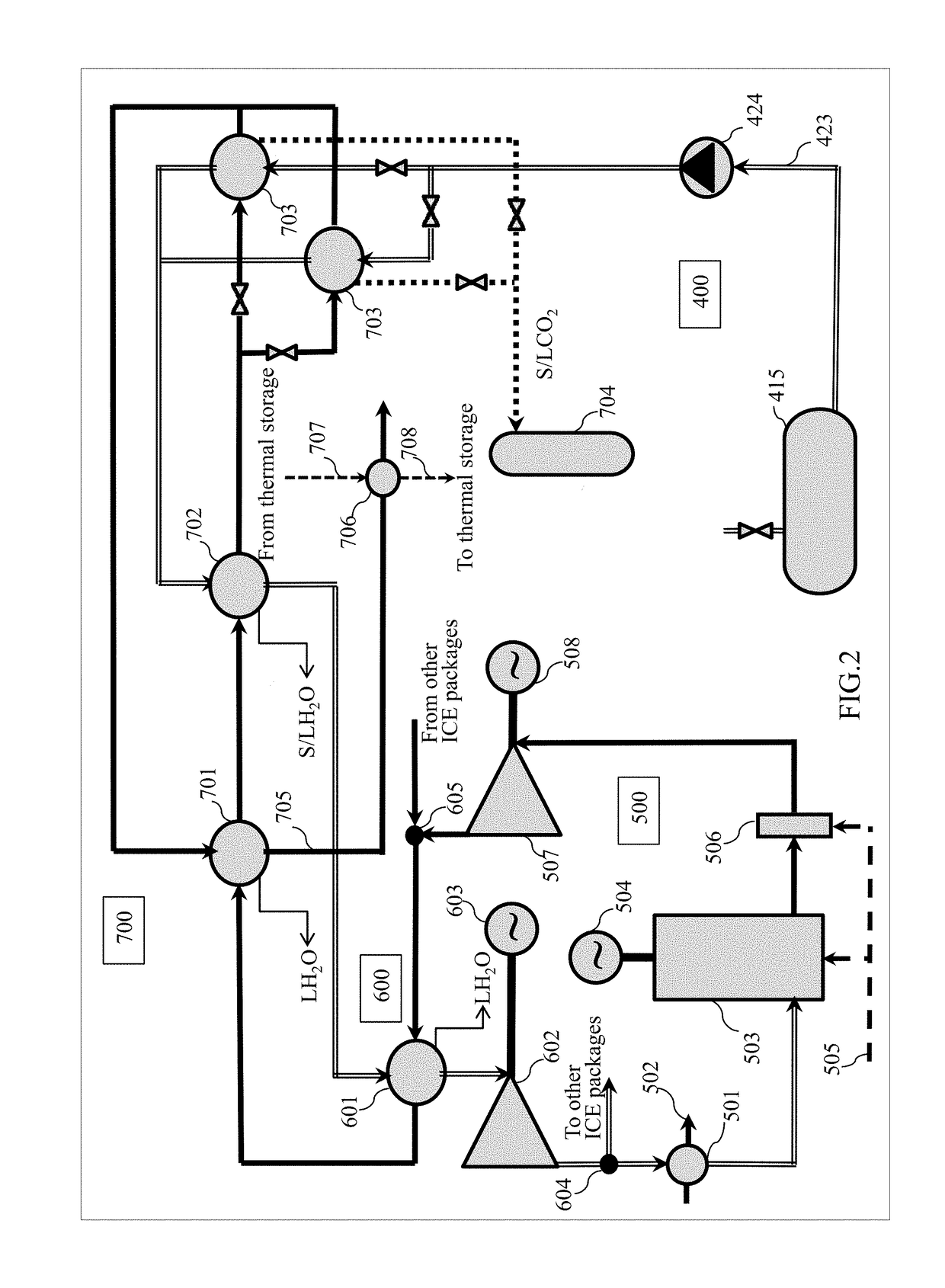

Method for Liquid Air Energy Storage with Fueled and Zero Carbon Emitting Power Output Augmentation

ActiveUS20180221807A1High power outputIncrease temperatureSolidificationLiquefactionThermal energyEngineering

A proposed method provides a highly efficient fueled power output augmentation of the liquid air energy storage (LAES) with zero carbon emissions of its exhaust. It combines the production of liquid air using excessive power from the renewable or / and conventional energy sources and an effective recovery of stored air for production of on-demand power in the fueled supercharged reciprocating internal combustion engine (ICE) and associated expanders. A mutually beneficial integration between the LAES and ICE makes possible to recover the ICE exhaust energy for increase in power produced by the LAES expanders and to use a cold thermal energy of air re-gasified at the LAES facility for cryogenic capture of CO2 emissions from the ICE exhaust.

Owner:SINATOV STANISLAV

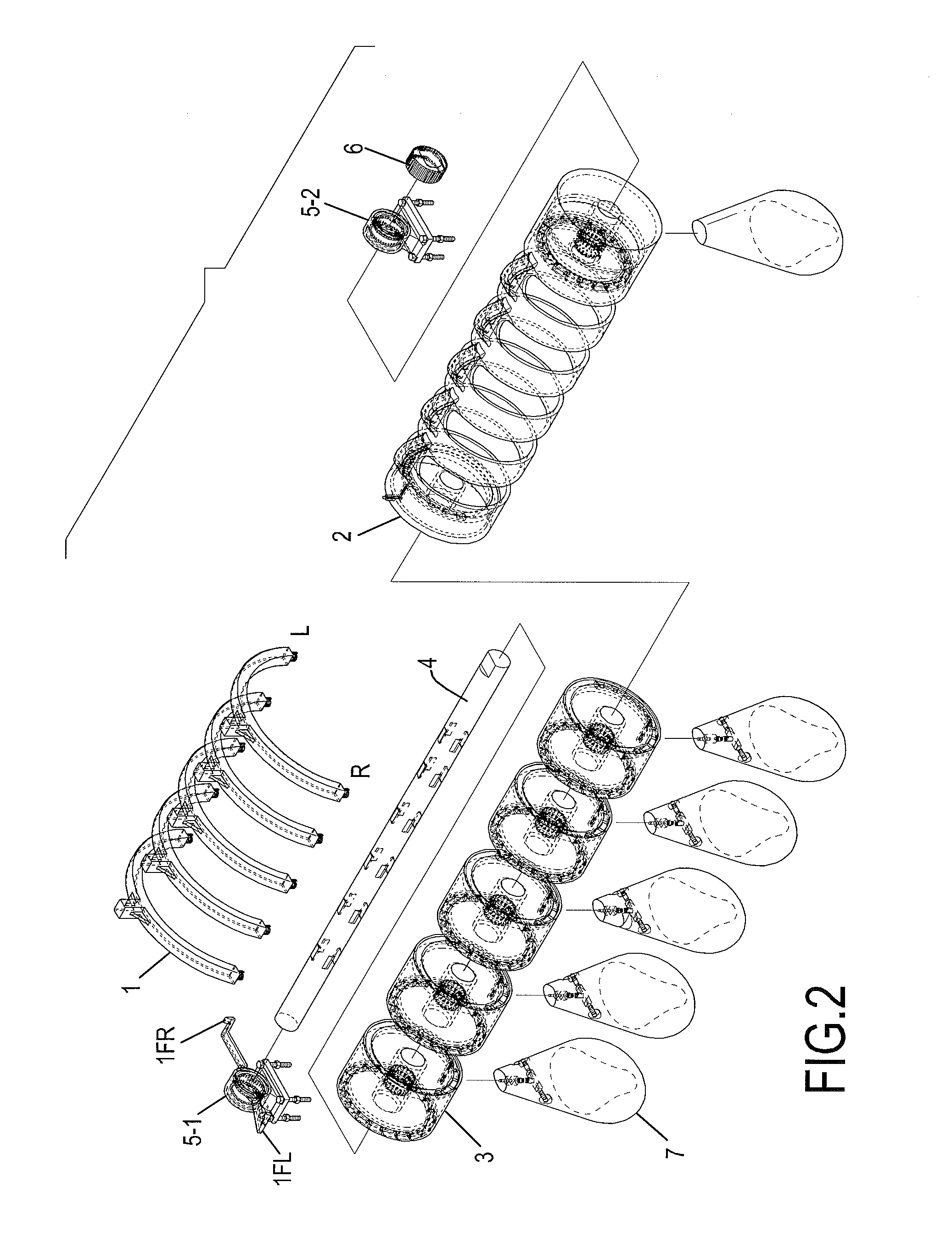

Zero-Carbon Clean Energy Generator and Operating Method Thereof

A zero-carbon clean generator has a rotating rod, multiple swings, a sleeve and multiple pendulums. The rotating rod acts as a spindle pole and a fulcrum. The swings are mounted around the rotating rod and each swing has a structure of two flywheels to rotate clockwise and counter-clockwise. The sleeve is connected with the rotating rod. The pendulums respectively are connected with the swings and the sleeve. Each pendulum has an inner space filled with fluid. Accordingly, the pendulums are swung back and forth reciprocatingly, make the rotating rod rotate continuously in a fixed direction and eternally generate power.

Owner:HU HUANG HSING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com