Method and system for collectively removing NOx and mercury (Hg) in coal-fired flue gas by utilizing secondary combustion of biomass charcoal

A biomass charcoal and combined removal technology, applied in the field of combustion, can solve the problems of high fineness requirements of coal powder, high natural gas prices, limited reserves, etc., to improve flue gas denitration and mercury removal efficiency, calorific value and energy. The effect of high density, easy transportation and storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

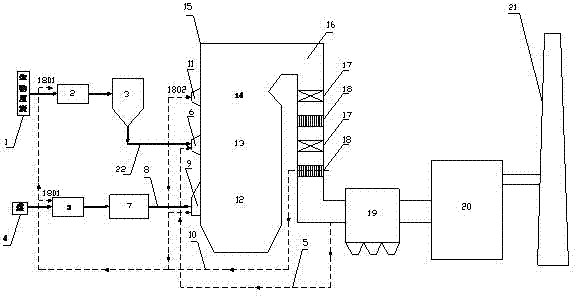

[0021] The present invention will be further described in conjunction with the accompanying drawings.

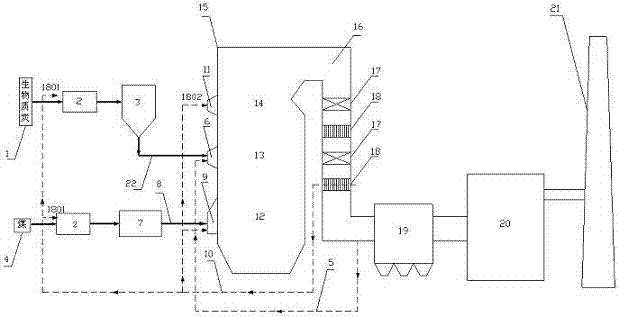

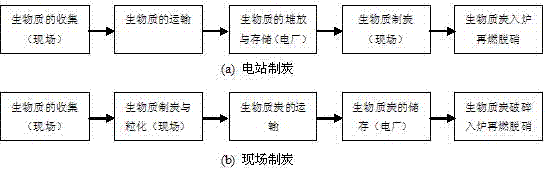

[0022] The preparation of biochar can adopt two processes of power station carbon production and on-site carbon production. figure 1 As shown, charcoal production in power stations refers to carbonization after transporting biomass fuel to the power station, while on-site charcoal production refers to carbonizing biomass on site before transporting it to the power station. The main difference between the two processes lies in the location of biomass carbonization. In comparison, the on-site carbonization process can not only increase the calorific value and energy density of biomass, but also is suitable for storage and long-distance transportation. This embodiment uses on-site charcoal production, which is more economical for biomass fuels that are transported over a long distance.

[0023] The coal 4 of the power plant boiler pulverizing system is pretreated by the mill 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com