Zero-carbon-emission hydrogen production system by methanol water reforming as well as application and hydrogen production method thereof

A technology for reforming hydrogen production and methanol water, applied in chemical instruments and methods, hydrogen, fuel cells, etc., can solve problems such as unfavorable promotion and application of fuel cell vehicles, affecting the operation of hydrogen production system equipment, and threatening human survival, etc. The effect of maintenance and replacement cost, no maintenance, and extensive application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

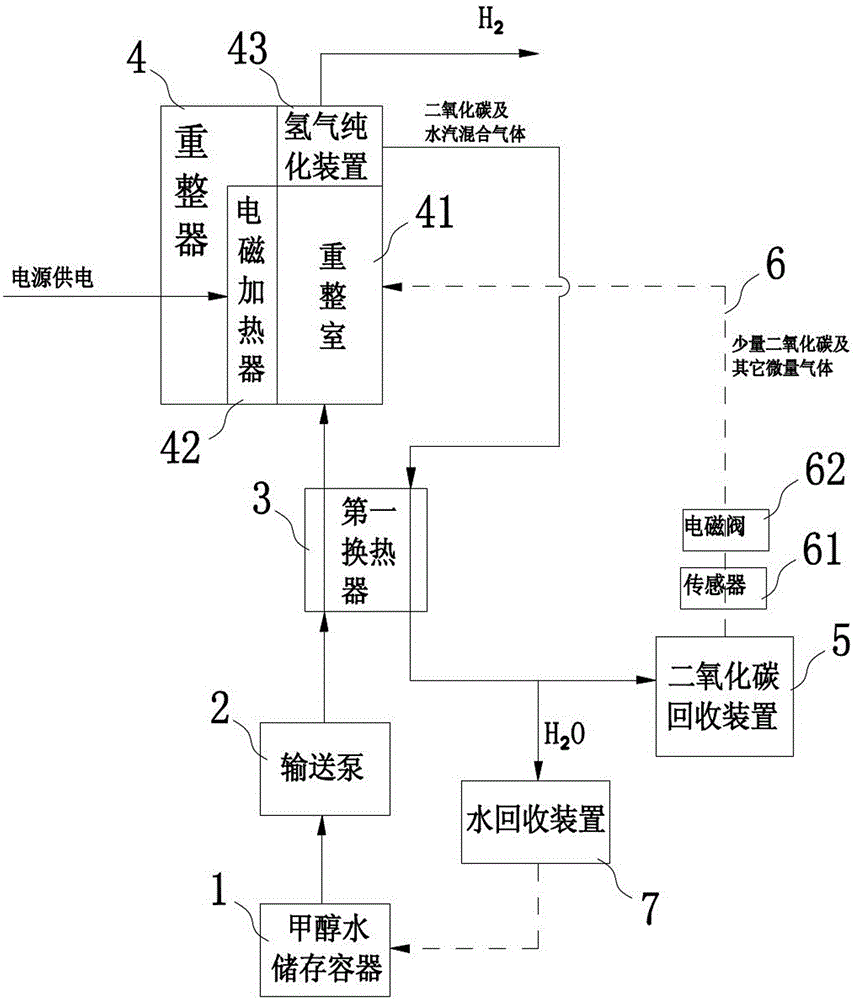

[0046] Such as figure 1 As described above, a methanol-water reforming hydrogen production system with zero carbon emissions includes a methanol-water storage container 1, a delivery pump 2, a first heat exchanger 3, a reformer 4, and a carbon dioxide recovery device 5, wherein:

[0047] Methanol-water storage container 1, which stores liquid methanol and water;

[0048] Delivery pump 2, used to deliver the methanol and water in the methanol-water storage container 1 to the reforming chamber 41 of the reformer 4;

[0049] The first heat exchanger 3 is installed on the delivery pipeline between the delivery pump 2 and the reformer 4, and the low-temperature methanol and water are mixed with the high-temperature carbon dioxide and water vapor output by the reformer 4 in the first heat exchanger 3 The gas performs heat exchange, the temperature of methanol and water increases, and the temperature of carbon dioxide and water vapor mixture decreases;

[0050] The reformer 4 is pr...

Embodiment 2

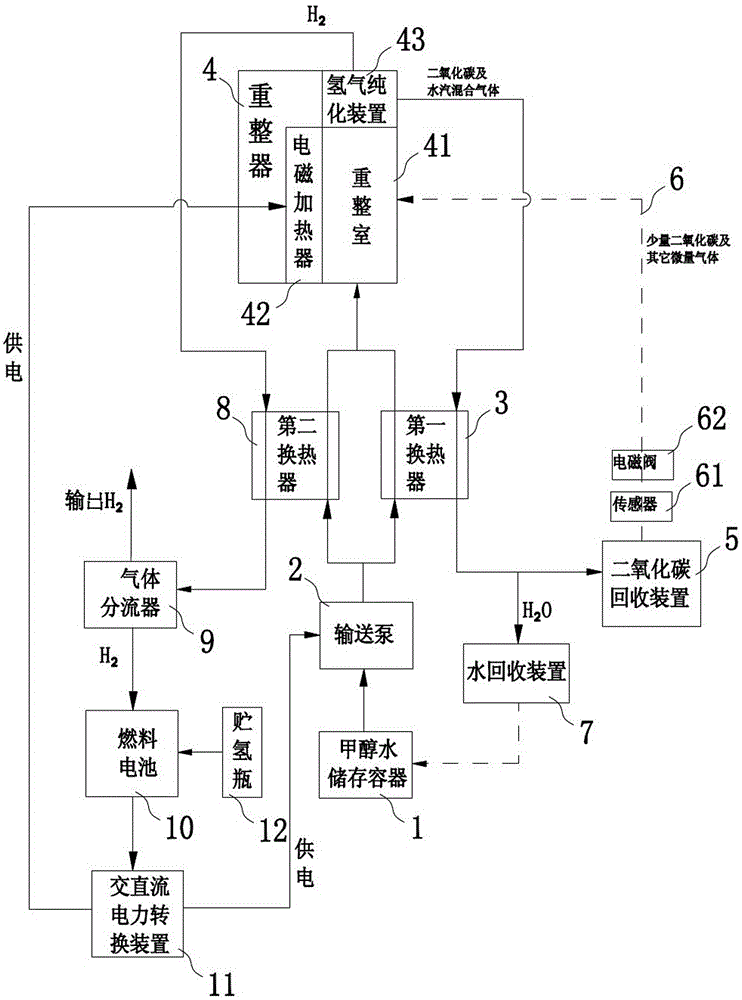

[0057] Embodiment 2 is to add a fuel cell power generation device on the basis of Embodiment 1, so that the methanol water reforming hydrogen production system can maintain operation through its own fuel cell power generation, such as maintaining the operation of electrical control devices, transfer pumps and electromagnetic heaters . Such as figure 2As shown, the methanol water reforming hydrogen production system with zero carbon emissions also includes a second heat exchanger 8, a gas splitter 9, a fuel cell 10 and an AC / DC power conversion device 11, and the second heat exchanger 8 is installed On the delivery pipeline between the delivery pump 2 and the reformer 4, and the second heat exchanger 8 is set in parallel with the first heat exchanger 3, the low-temperature methanol and water are in the second heat exchanger 8, and the reformer The high-temperature hydrogen output by the device 4 performs heat exchange, the temperature of methanol and water increases, and the ...

Embodiment 3

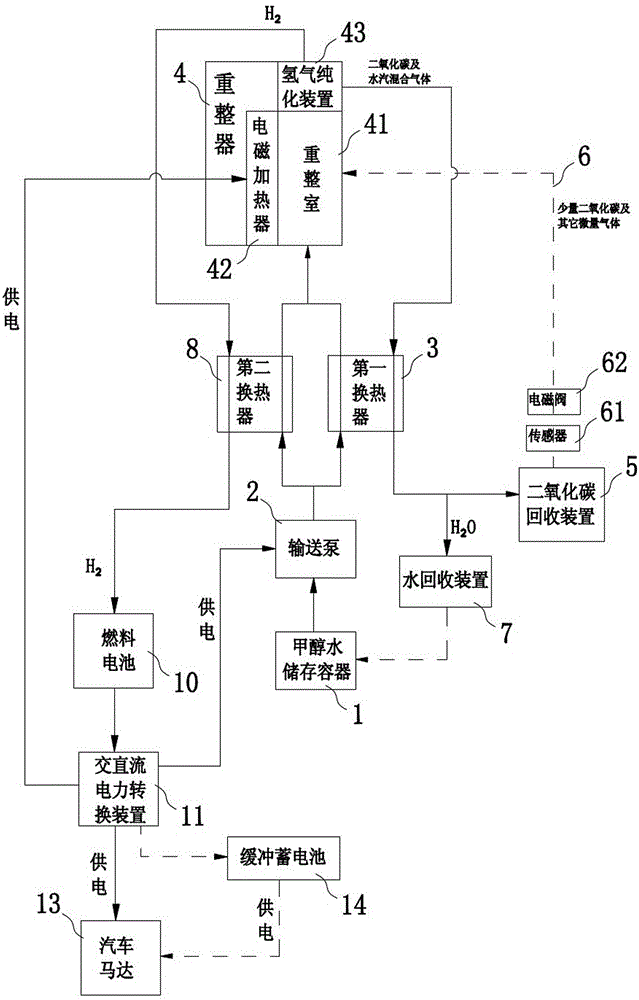

[0059] Such as image 3 As shown, the fuel cell vehicle using the methanol water reforming hydrogen production system with zero carbon emissions includes a methanol water storage container 1, a delivery pump 2, a first heat exchanger 3, a reformer 4, a carbon dioxide recovery device 5, The second heat exchanger 8, the fuel cell 10, the AC / DC power conversion device 11 and the automobile motor 13, wherein:

[0060] Methanol-water storage container 1, which stores liquid methanol and water;

[0061] Delivery pump 2, used to deliver the methanol and water in the methanol-water storage container 1 to the reforming chamber 41 of the reformer 4;

[0062] The first heat exchanger 3 is installed on the delivery pipeline between the delivery pump 2 and the reformer 4, and the low-temperature methanol and water are mixed with the high-temperature carbon dioxide and water vapor output by the reformer 4 in the first heat exchanger 3 The gas performs heat exchange, the temperature of met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com