Method for preparing lithium battery current collector by plasma spraying polymer composite positive temperature coefficient (PTC) powder

A plasma and polymer technology, which is applied in the field of plasma spraying polymer composite PTC powder to prepare lithium battery current collectors, can solve the problems of difficult control of processing uniformity and restrictions on the application of PTC materials, and solve the problem of excessive current collectors The rapid temperature rise and chain reaction cause combustion and explosion, improve production efficiency and high-quality product rate, and have the effect of accuracy and convenience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

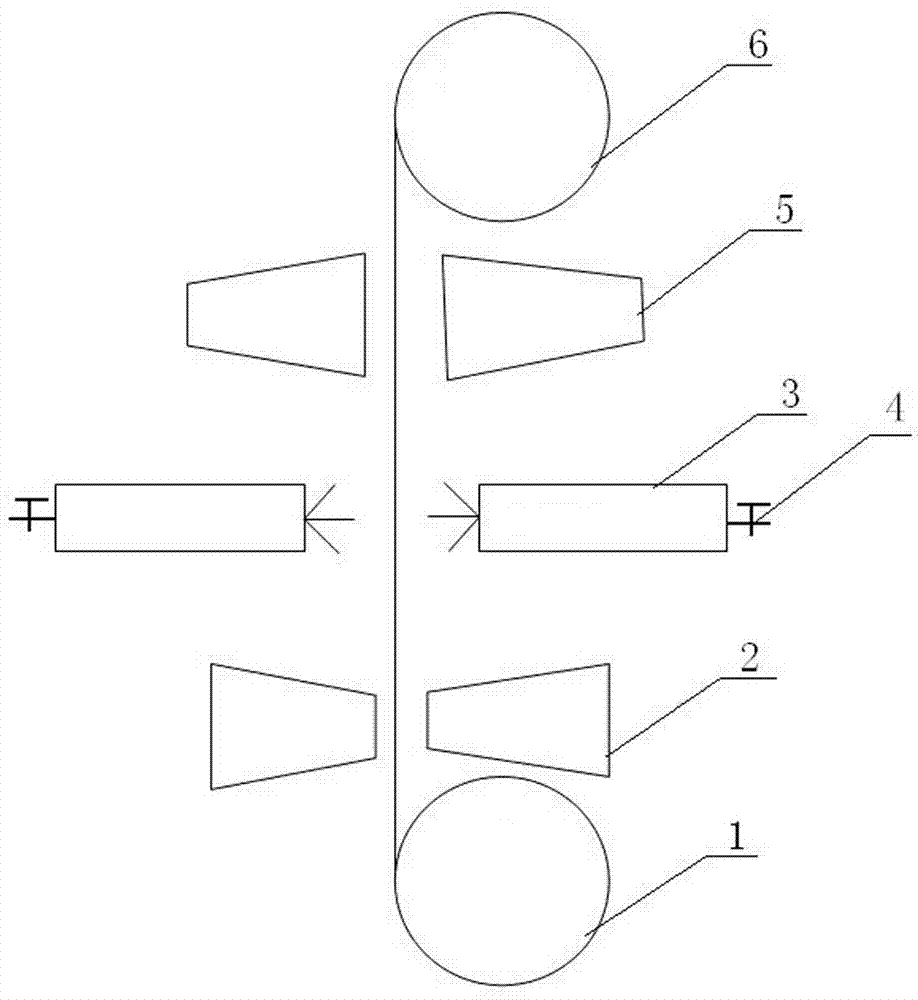

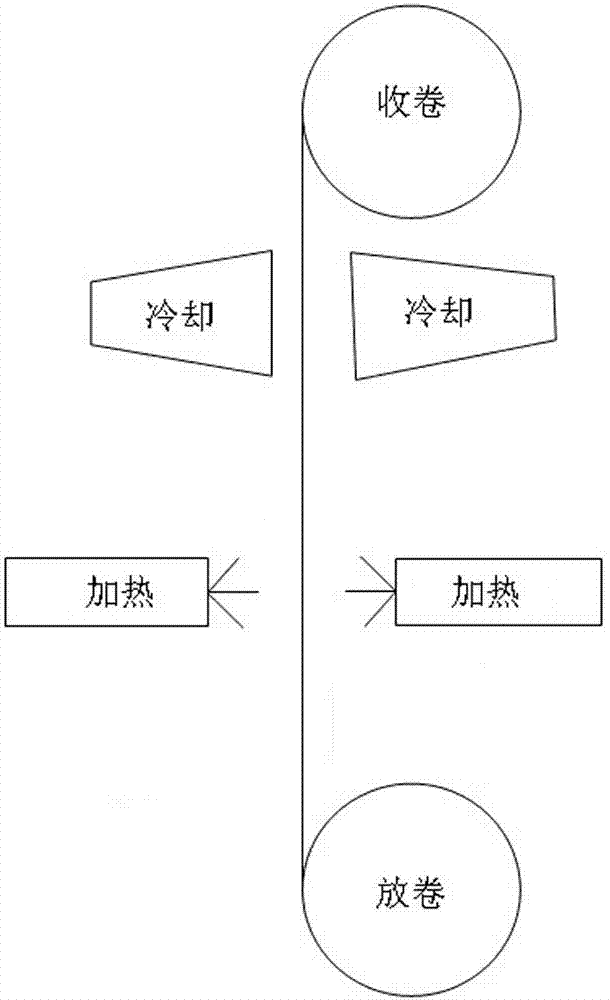

[0024] Such as figure 1 with figure 2 As shown, the method for preparing lithium battery current collectors by plasma spraying polymer composite PTC powder in this example includes the following steps: (1) Take 100 g of polyethylene and 100 g of carbon black, put them into a ball mill under the protection of nitrogen, and mix them by ball milling After 5 hours, the polymer composite PTC powder was prepared; (2) The copper foil with a thickness of 5 μm was released through the unwinding device 1, and the released copper foil was heated to 100 ° C by the heating device 2, and the width was 1.3 meters. On the plasma coating machine 3 with a length of 5 meters, continuously coat 600 meters at a speed of 50 m / min, and control the polymer composite PTC powder coating thickness to 2.5 through the flow control valve 4 provided on the plasma coating machine. μm, cooled and crystallized by the cooling device 5, and then enters the winding device 6 to complete the double-sided plasma s...

Embodiment 2

[0026] In this example, the method of plasma spraying polymer composite PTC powder to prepare a lithium battery current collector includes the following steps: (1) Take 10 g of polypropylene and 100 g of barium titanate micropowder, and put them into a three-screw blending reactor under nitrogen protection (2) Unwind the aluminum foil with a thickness of 3 μm through the unwinding device, and heat the released aluminum foil to 150°C through the heating device. On a 5-meter plasma coating machine, continuously coat 600 meters at a speed of 50 m / min. The coating thickness of the polymer composite PTC powder is controlled by the flow control valve on the plasma coating machine to be 1 μm. Cool and crystallize, and then enter the winding device to complete the electrostatic spraying of the polymer composite PTC powder on the aluminum foil; (3) Take out the aluminum foil roll in the winding device and install it in a 10-meter-long dragon kiln, and then experience 80 ° C, Heating at...

Embodiment 3

[0028]In this embodiment, the method for preparing a lithium battery current collector by plasma spraying polymer composite PTC powder includes the following steps: (1) Take 50 g of polyimide and 100 g of barium titanate micropowder with a lead content of 0.3% by mass, Put it into a three-screw blending reactor under protection, and mix for 5 hours to obtain a polymer composite PTC powder; (2) Release the copper foil with a thickness of 15 μm through the unwinding device, and heat the discharged copper foil through the heating device To 180°C, on a plasma coating machine with a width of 1.3 meters and a length of 5 meters, continuously coat 600 meters at a speed of 50 meters per minute, and control polymer compounding through the flow control valve on the plasma coating machine The PTC powder is coated with a thickness of 2.5 μm, cooled and crystallized by the cooling device, and then enters the winding device to complete the double-sided plasma spraying of the polymer composit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com