Patents

Literature

94results about How to "Solve combustion problems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

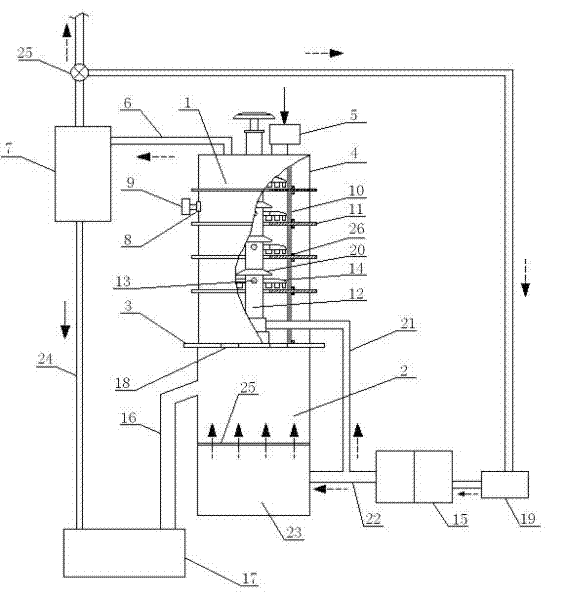

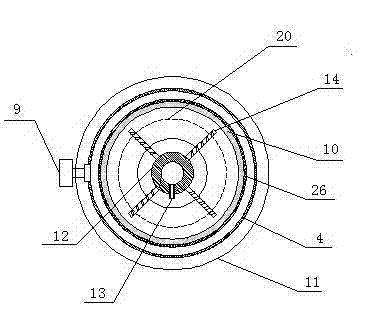

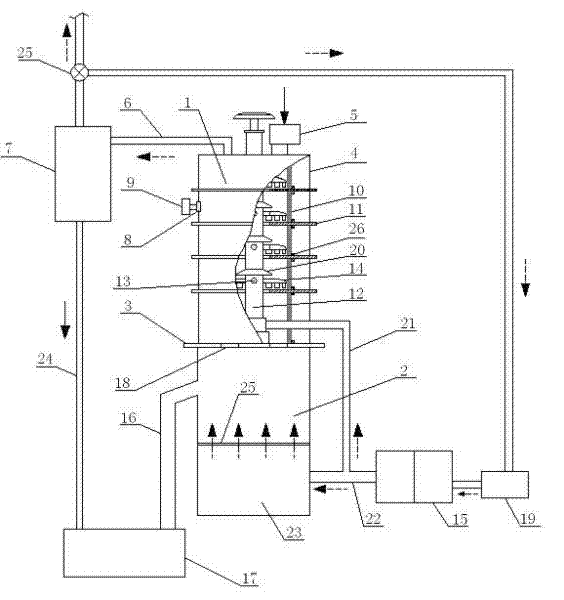

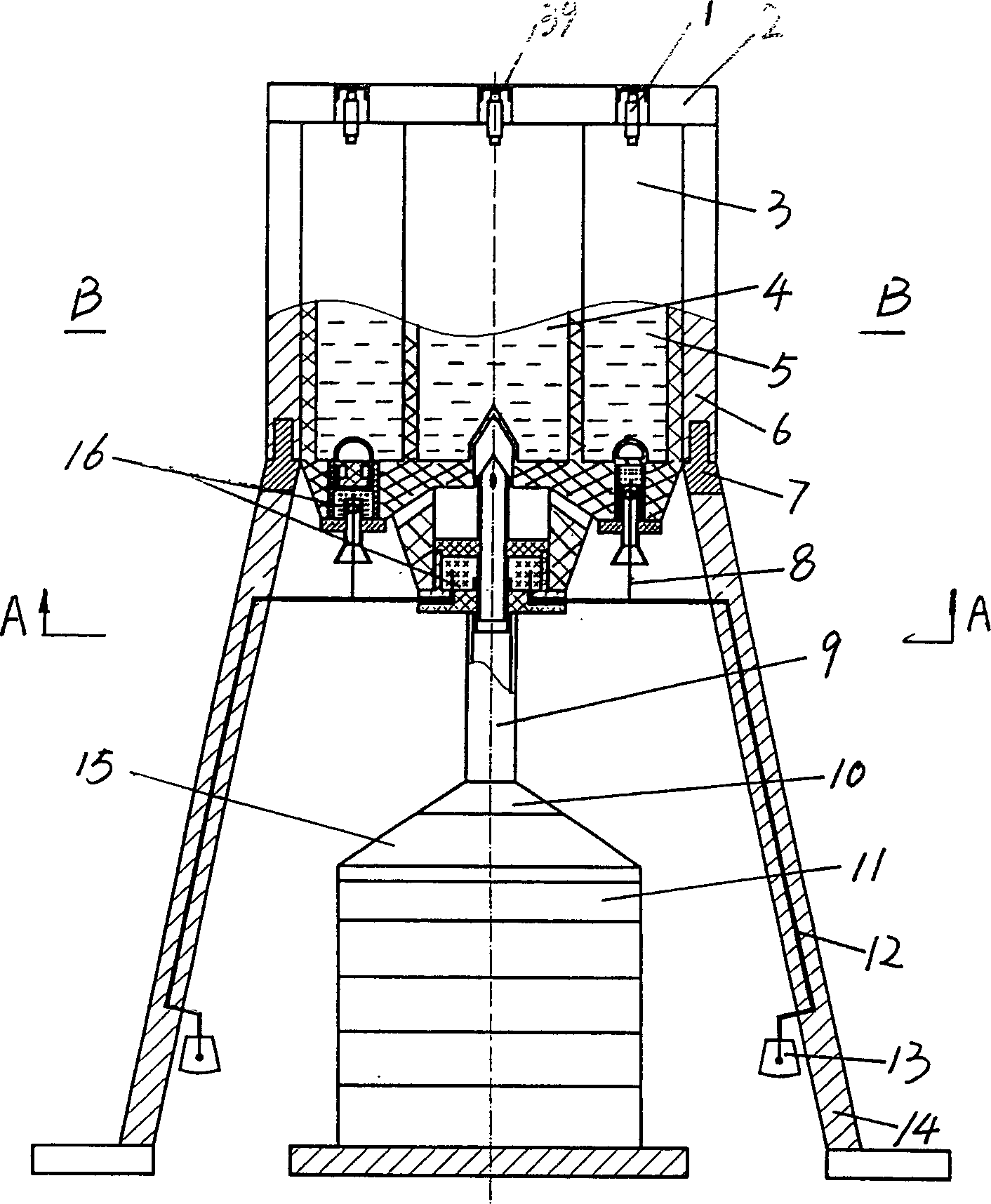

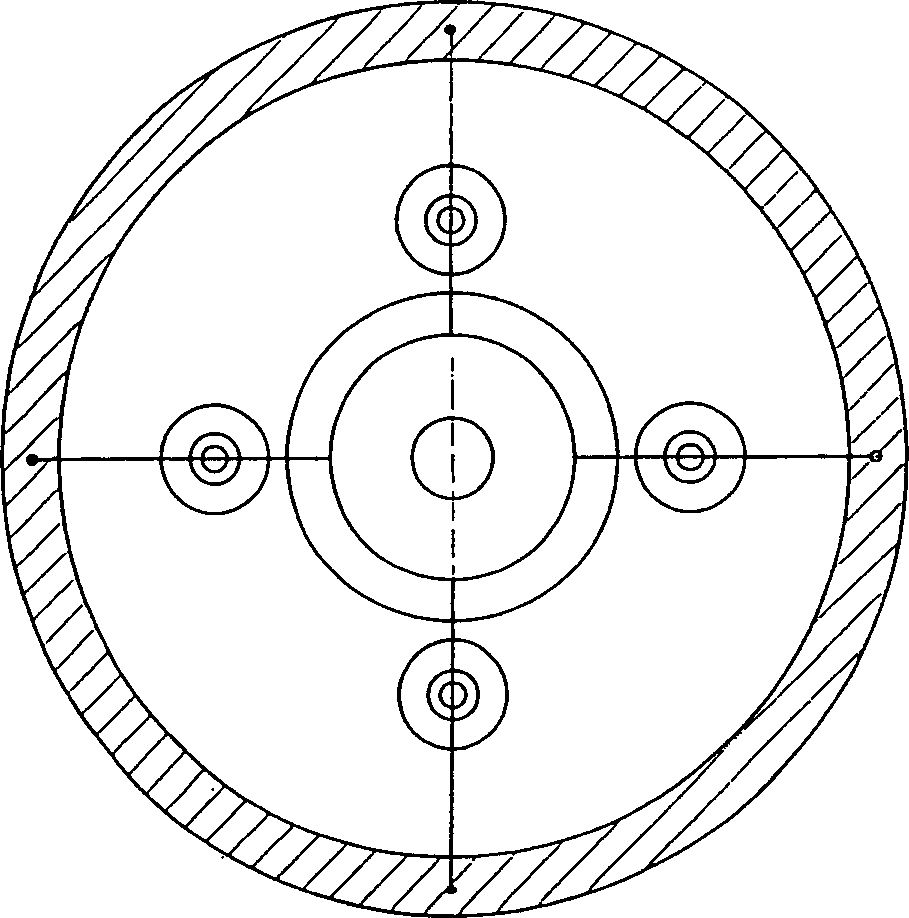

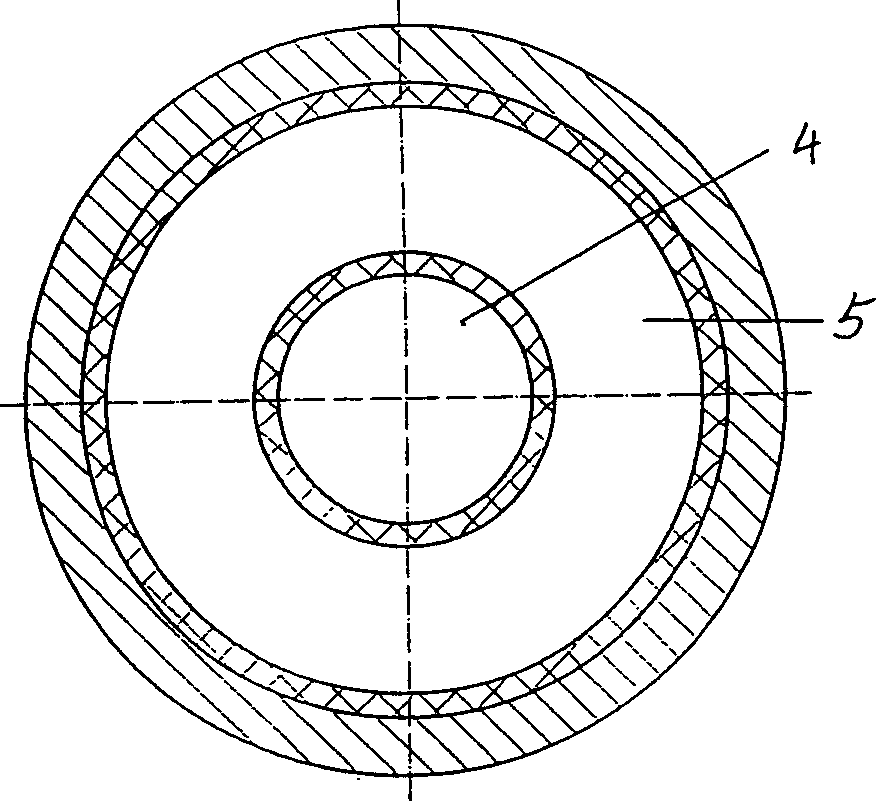

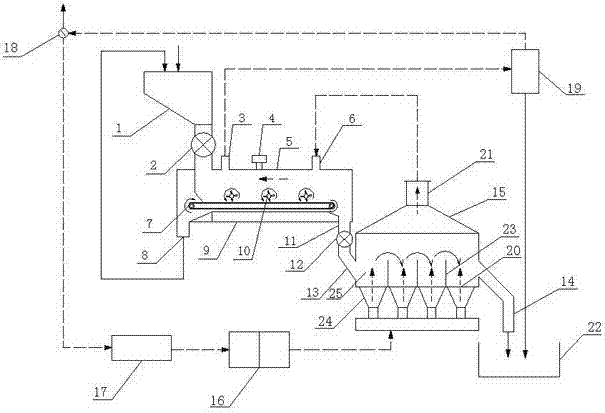

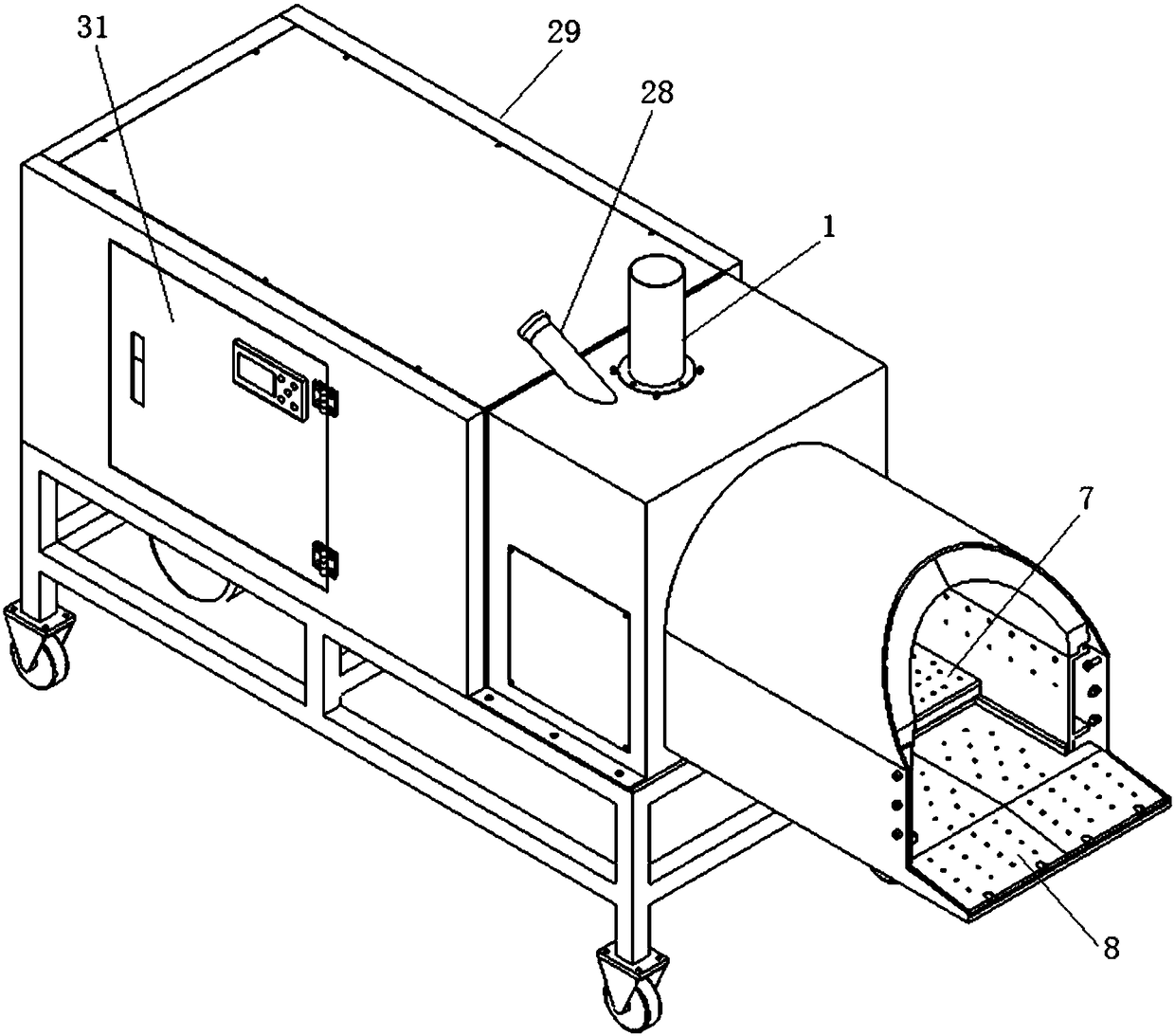

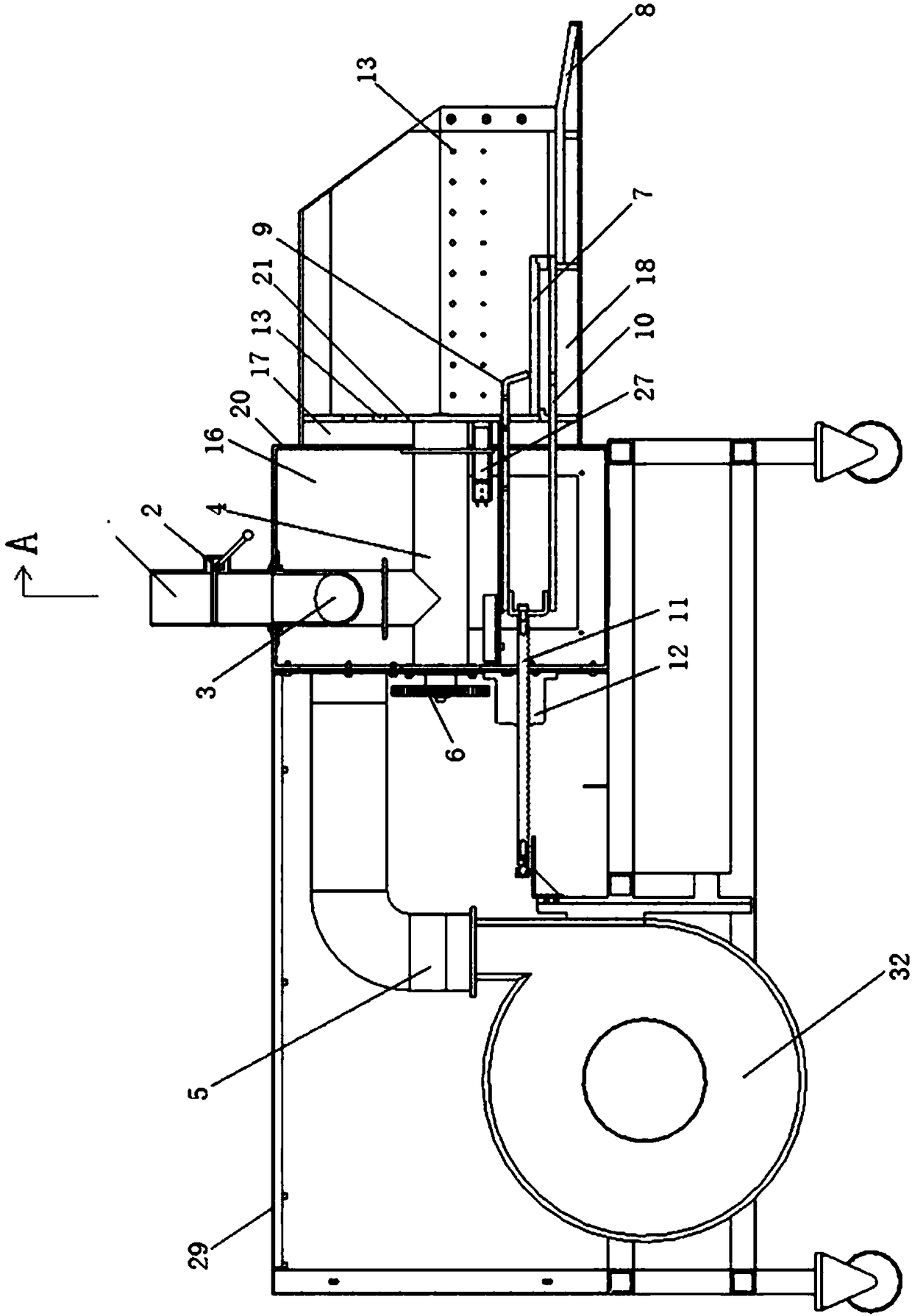

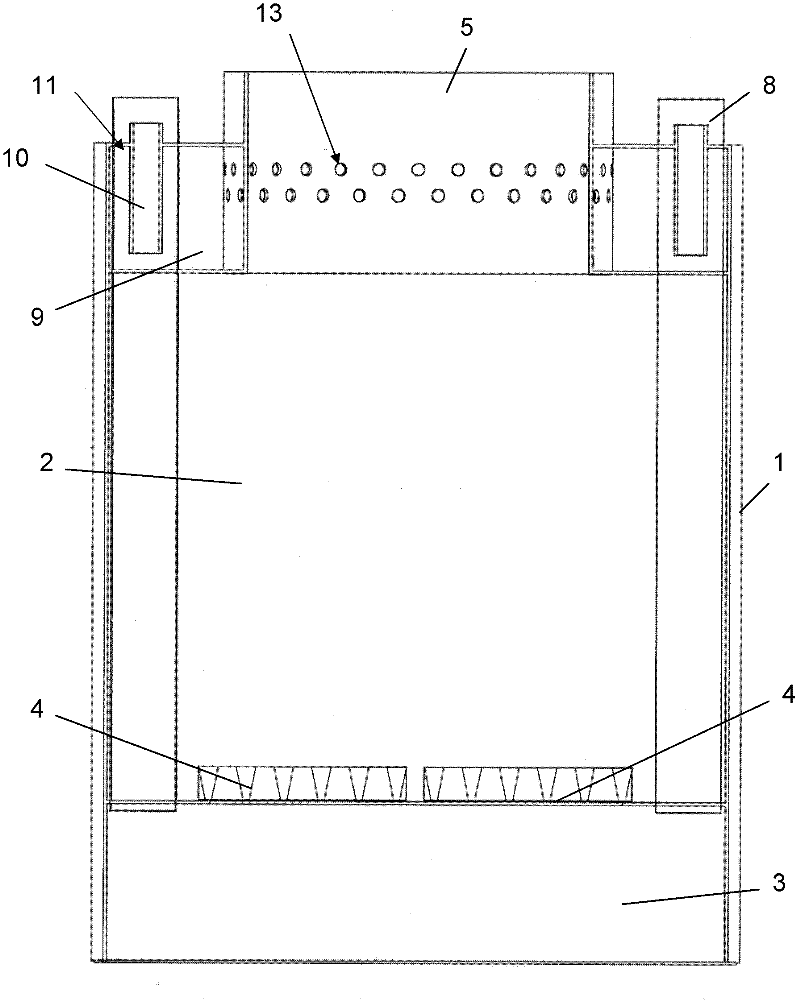

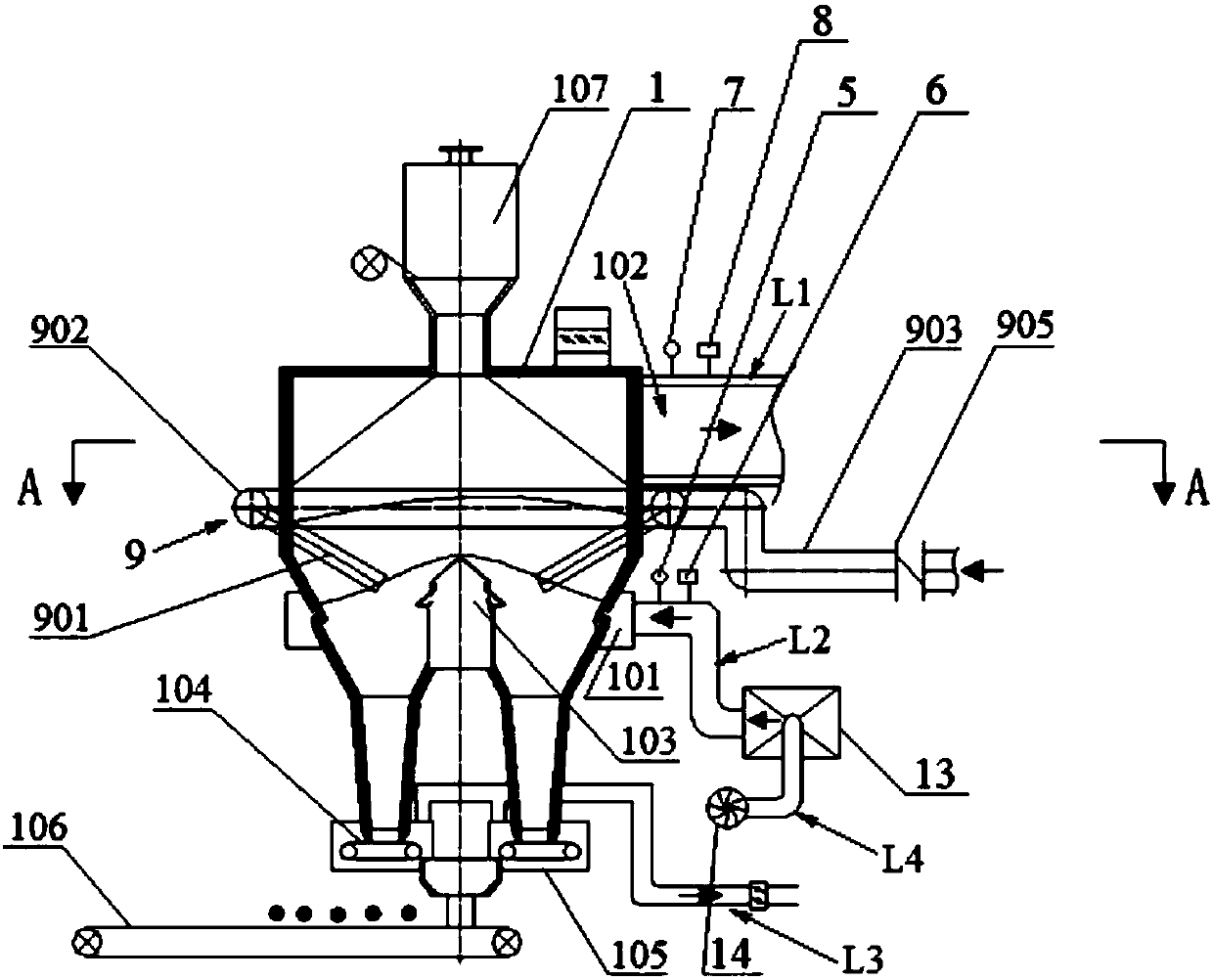

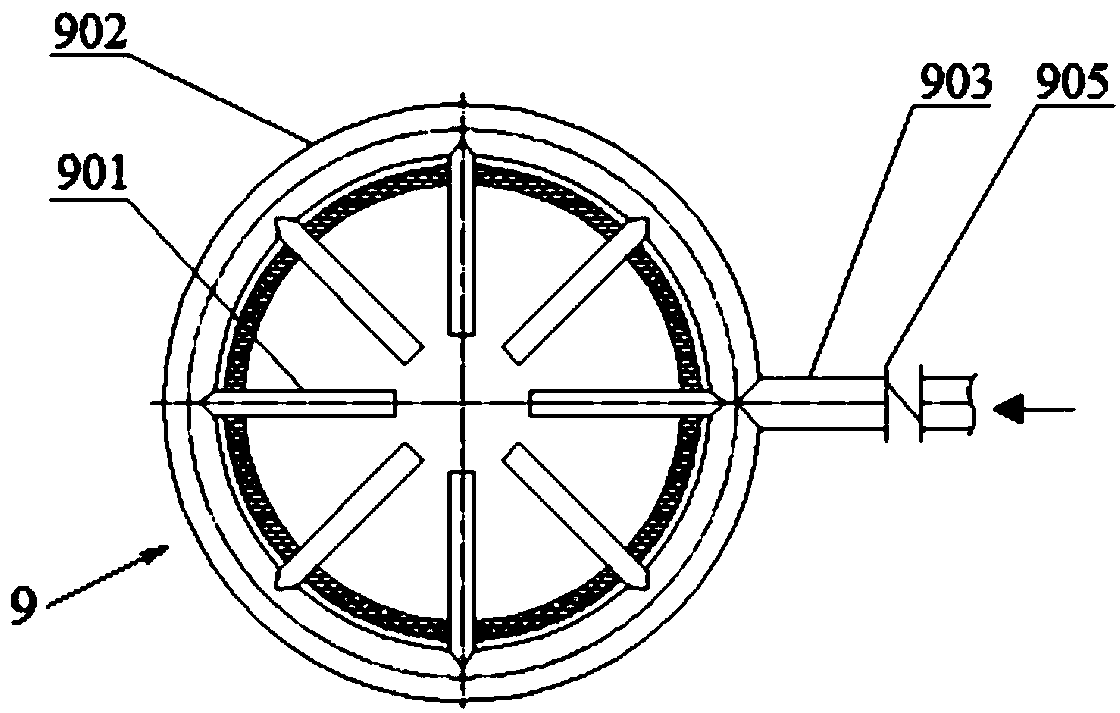

A device for microwave fluidized drying lignite

InactiveCN102261822ALow drying temperatureImprove energy utilizationDrying solid materials with heatHearth type furnacesEngineeringMicrowave

The invention discloses a device for drying lignite by microwave fluidization. The device comprises a microwave heating chamber and a fluidized bed, wherein the fluidized bed is arranged at the bottom of the microwave heating chamber and communicated with the microwave heating chamber; the microwave heating chamber comprises a metal furnace shell capable of shielding microwaves, a material inlet and a smoke gas exhaust port are arranged at the top of the furnace shell, at least one microwave generation device is arranged on the side surface of the furnace shell, a cylindrical ceramic furnace tube through which microwaves can penetrate is further arranged in the furnace shell, a plurality of layers of annular metal baffle plates are arranged along the inner wall of the ceramic furnace tubefrom top to bottom, a rotating shaft is arranged at the center of the ceramic furnace tube, a plurality of rake-shaped structural members which correspond to the metal baffle plates respectively are fixedly arranged on the rotating shaft along the axial direction, and a tapered material guide disc is fixedly arranged on each rake-shaped structural member; and the fluidized bed is in vertical structure, an air chamber of the fluidized bed is connected with a hot air furnace through a first hot air inlet pipe and an overflow pipe connected with a finished product warehouse is arranged at the upper part of the fluidized bed. By adopting the device, the large-scale, fast, low-energy-consumption and deep-drying production of the lignite can be realized.

Owner:KEDA INDUSTRIAL GROUP CO LTD

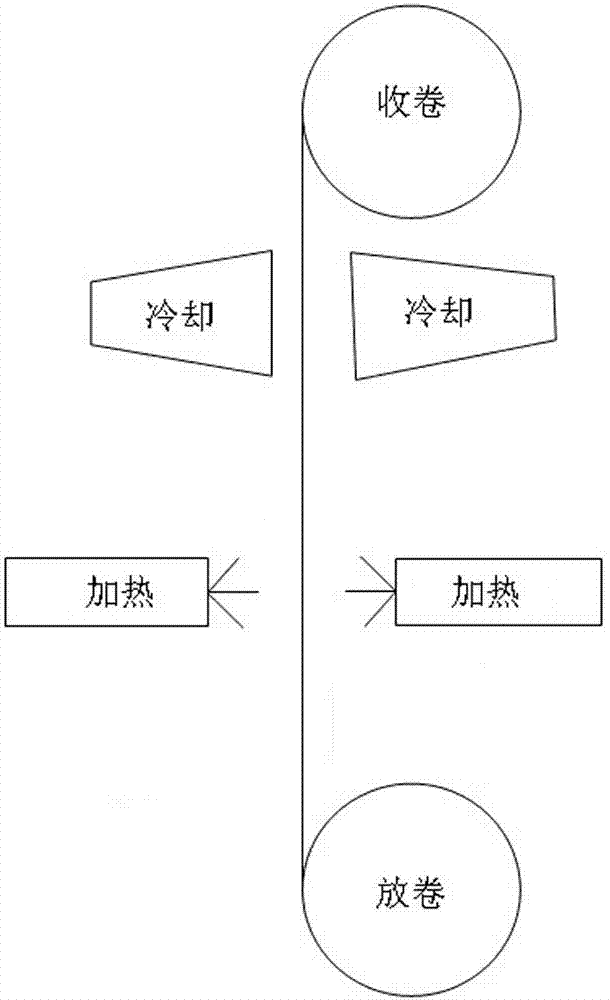

Method for preparing lithium battery current collector by plasma spraying polymer composite positive temperature coefficient (PTC) powder

InactiveCN103794801AHigh quality and reliabilityFast thermal responseElectrode carriers/collectorsManufacture by sprayingState of artReaction speed

The invention discloses a method for preparing a lithium battery current collector by plasma spraying polymer composite PTC powder. The method comprises the steps of (1) preparing the polymer composite PTC powder; (2) heating the lithium battery current collector up to 100-300 DEG C by a heating device, and coating the lithium battery current collector with the polymer composite PTC powder obtained in the step (1) through a plasma spraying device to form a polymer composite PTC powder coating on the lithium battery current collector; (3) baking the lithium battery current collector coated with the polymer composite PTC powder coated in the step (2), and carrying out a recrystallization technology to obtain the lithium battery current collector provided with the polymer composite PTC powder coating. Compared with the prior art, the method has the advantages that the processing process is simple and convenient, the production efficiency is improved, the yield is increased, the product thickness consistency is high, the product quality reliability is high, the thermosensitive reaction speed is high, and capacity adjustment is accurate and convenient.

Owner:ZHONGYUAN ENGINEERING COLLEGE

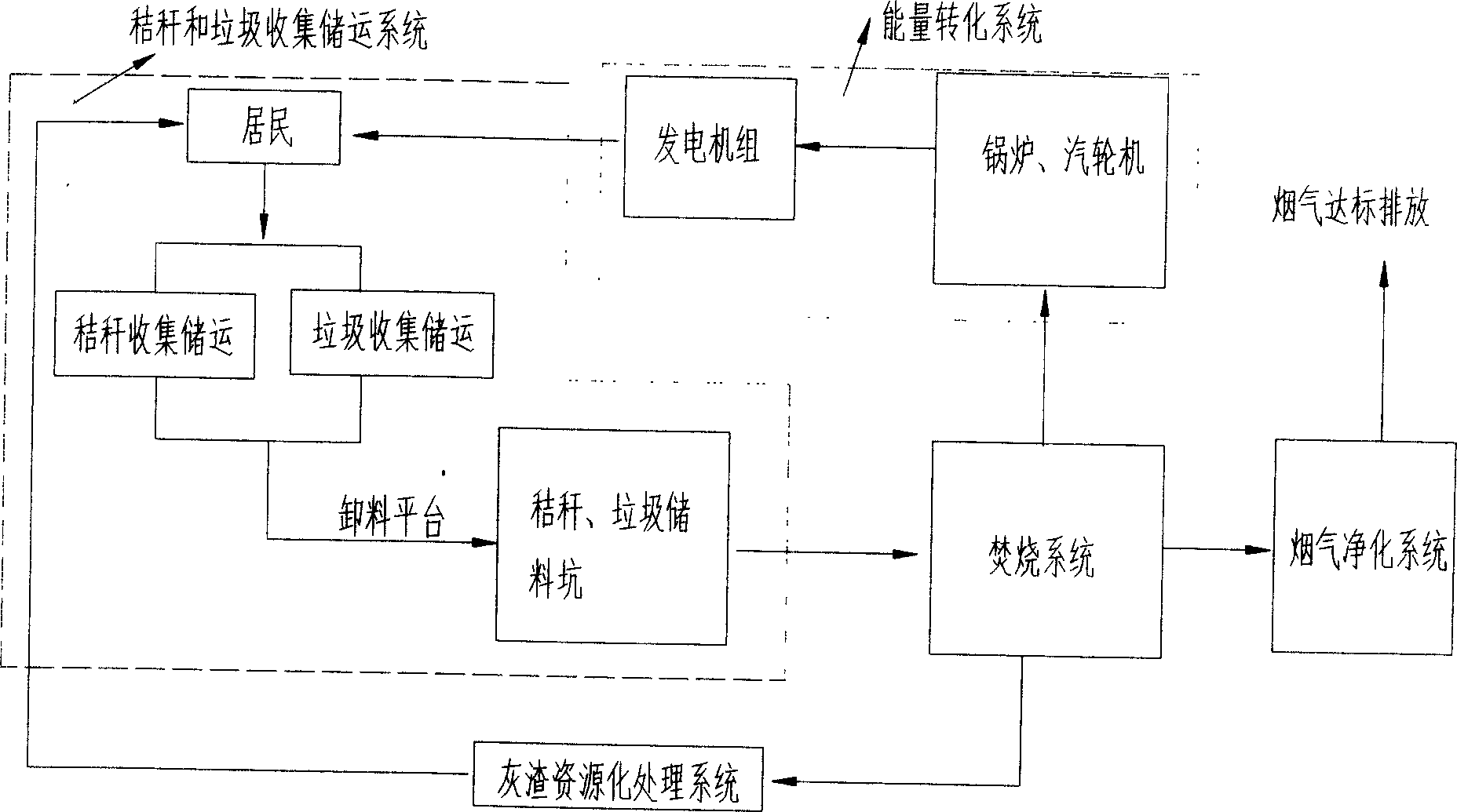

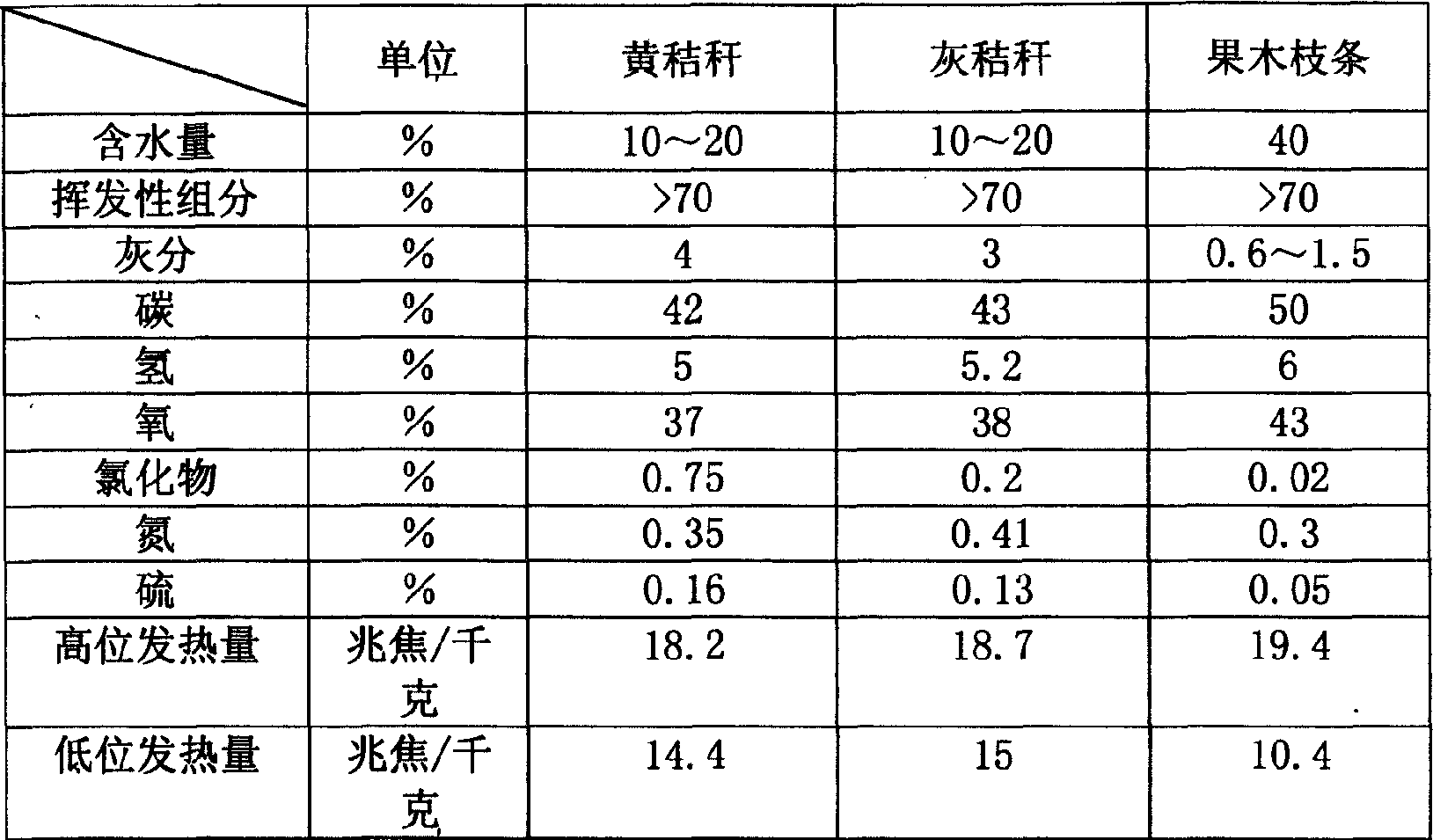

Method for electric generating utilizing stalks mixed burned with city life refuses

The invention relates a method of generating by using mixed combustion of stalks and municipal house refuse. The heat energy produced by the mixed combustion of the stalks and the municipal house refuse in the refuse burner is coverted into the generating energy by a boiler, a turbine and a generator, so as to supply the power for cities. The proportion of the stalks and the house refuse in their mixed combustion must be adjusted continually according to the differences of refuse water ratio and dust composition. When the combustion temperature in the burner is in the range of 870-1200 deg. C, the combustion can be fully burned and the combustion product can be discharged up to the standard.

Owner:TIANJIN TEDA ENVIRONMENTAL PROTECTION

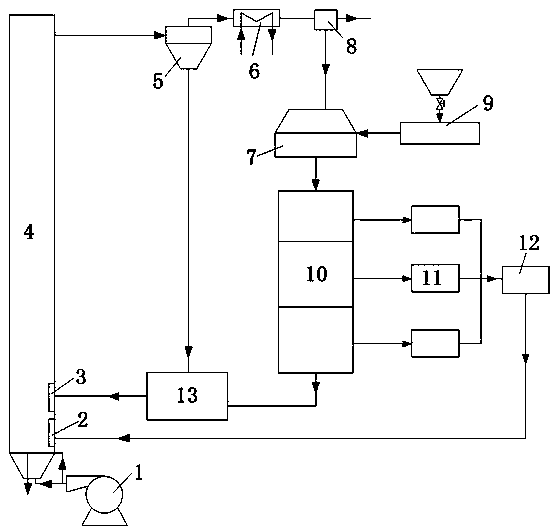

Combustion method and device for preventing combustion coking and contamination of high-sodium coal

InactiveCN104061570AEfficient and clean utilizationLow costFluidized bed combustionApparatus for fluidised bed combustionHigh sodiumCombustion

The invention relates to a combustion method and device for preventing combustion coking and contamination of high-sodium coal. An outlet of a fluidized bed is connected with an inlet of a cyclone separator, one outlet of the cyclone separator is connected with one inlet of a coal mill through a heat exchanger and a dust remover, the other outlet of the cyclone separator is connected with one inlet of a coke preprocessing device, an outlet of the coal mill is connected with the other inlet of the coke preprocessing device through a three-grade pyrolysis bed, an outlet of the coke preprocessing device is connected with an inlet of a turbulent burner on the fluidized bed, and a forced draught fan is respectively connected with a primary air inlet in the bottom of the fluidized bed and a secondary air inlet in the middle of the fluidized bed. According to the combustion method and device, a common pyrolysis device is replaced by the three-stage fluidized bed, pyrolysis gas sodium-removal purification devices are connected behind the three stages of the three-grade pyrolysis bed respectively, the problem that alkali metal sodium elements are transformed between forms in the pyrolysis process and can not be effectively removed can be effectively solved, the problem that coke can not be easily and effectively combusted in a common pulverized coal furnace can be well solved, and energy can be effectively used.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

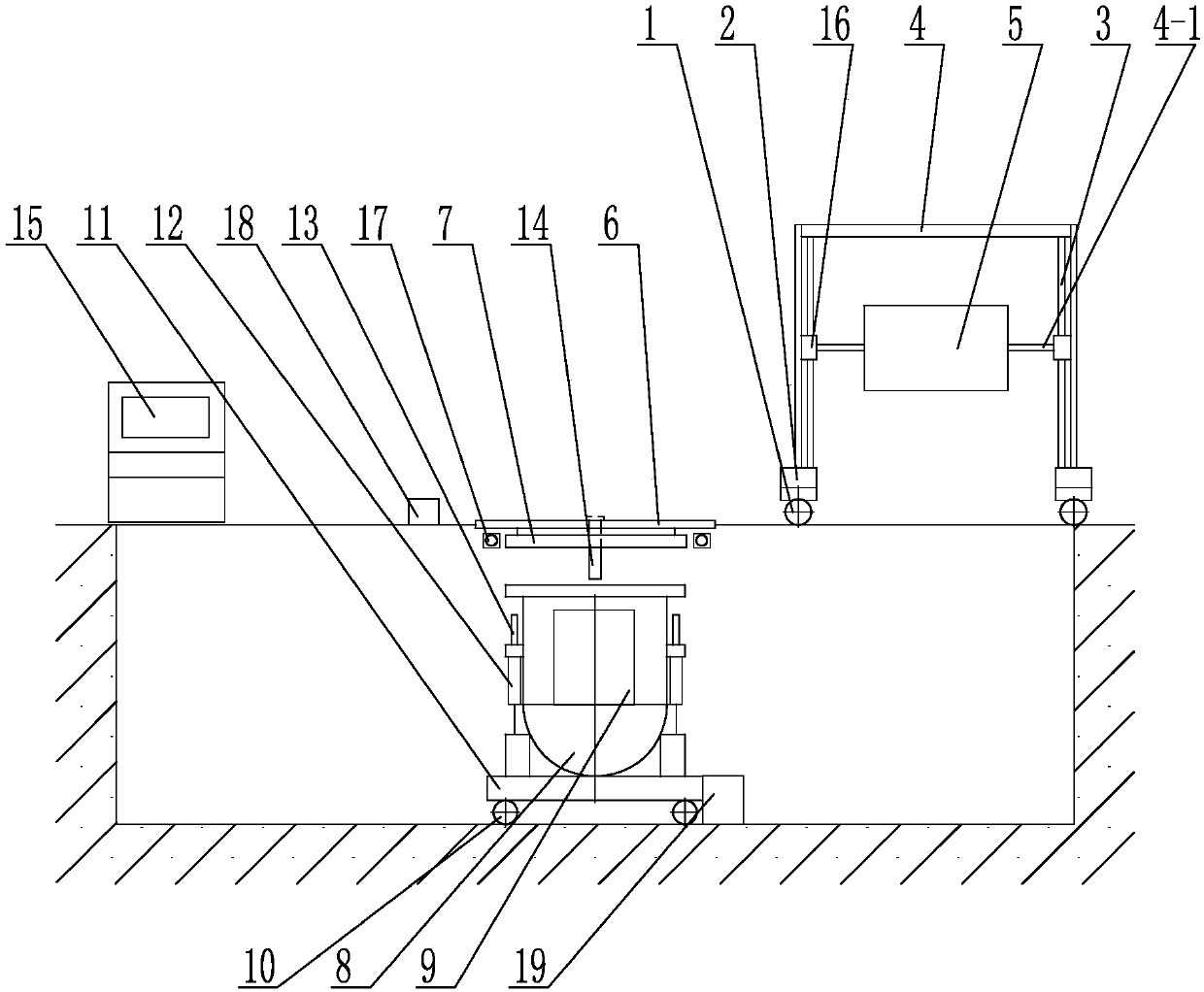

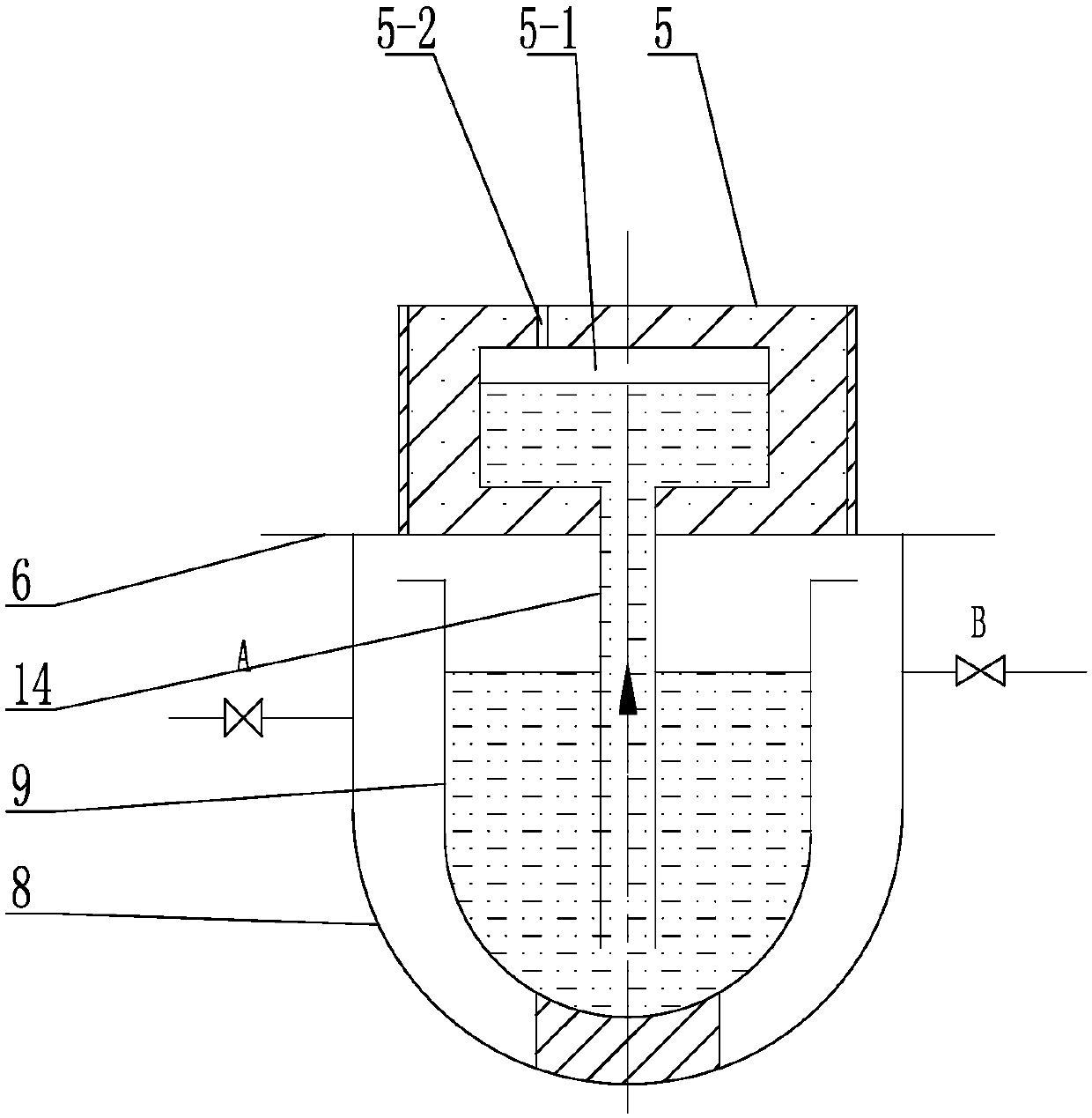

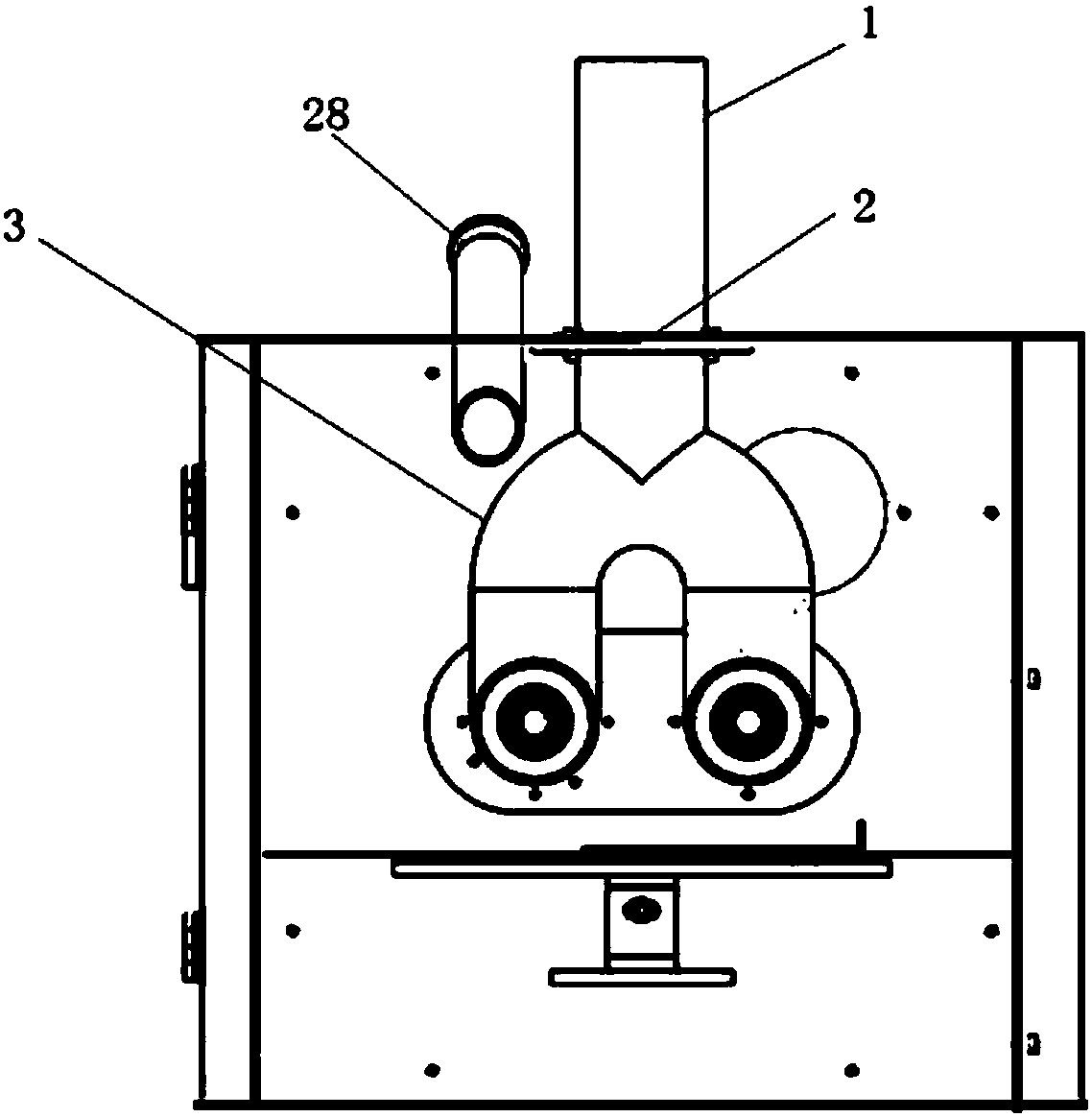

Automatic magnesium alloy low-pressure casting machine

The invention discloses an automatic magnesium alloy low-pressure casting machine, and relates to the technical field of casting. The automatic magnesium alloy low-pressure casting machine solves theproblems that burning accidents are extremely prone to occurrence in the existing magnesium casting process, castings are prone to forming shrinkage porosity, and oxidation slag inclusion exists. Theautomatic magnesium alloy low-pressure casting machine comprises a casting mould running mechanism, a pouring platform, a working tank, a working tank motion trolley, a liquid rising pipe and a controller; the casting mould running mechanism moves at the upper end of the pouring platform in the horizontal direction, a casting mould is borne on the casting mould running mechanism, the working tankmotion trolley moves at the lower end of the pouring platform in the horizontal direction, the working tank is arranged on the working tank motion trolley, the two sides of the working tank are each provided with a working tank lifting mechanism, the working tank is lifted on the working tank motion trolley through the working tank lifting mechanisms, the liquid rising pipe is inserted into the pouring platform, an air inlet pipe and an air exhaust pipe are connected to the working tank, and the casting mould running mechanism, the working tank motion trolley and the working tank lifting mechanisms are connected with the controller. The automatic magnesium alloy low-pressure casting machine is used for magnesium alloy casting.

Owner:哈尔滨卡斯鼎智能装备科技有限公司

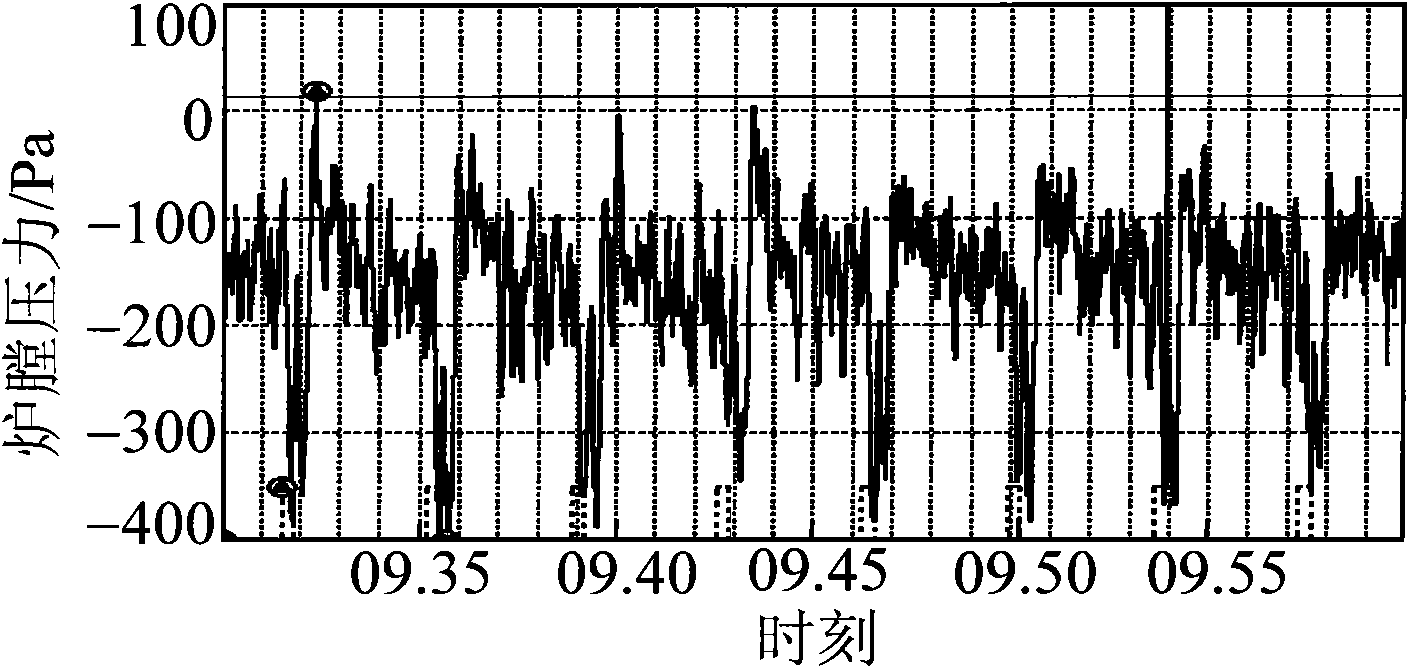

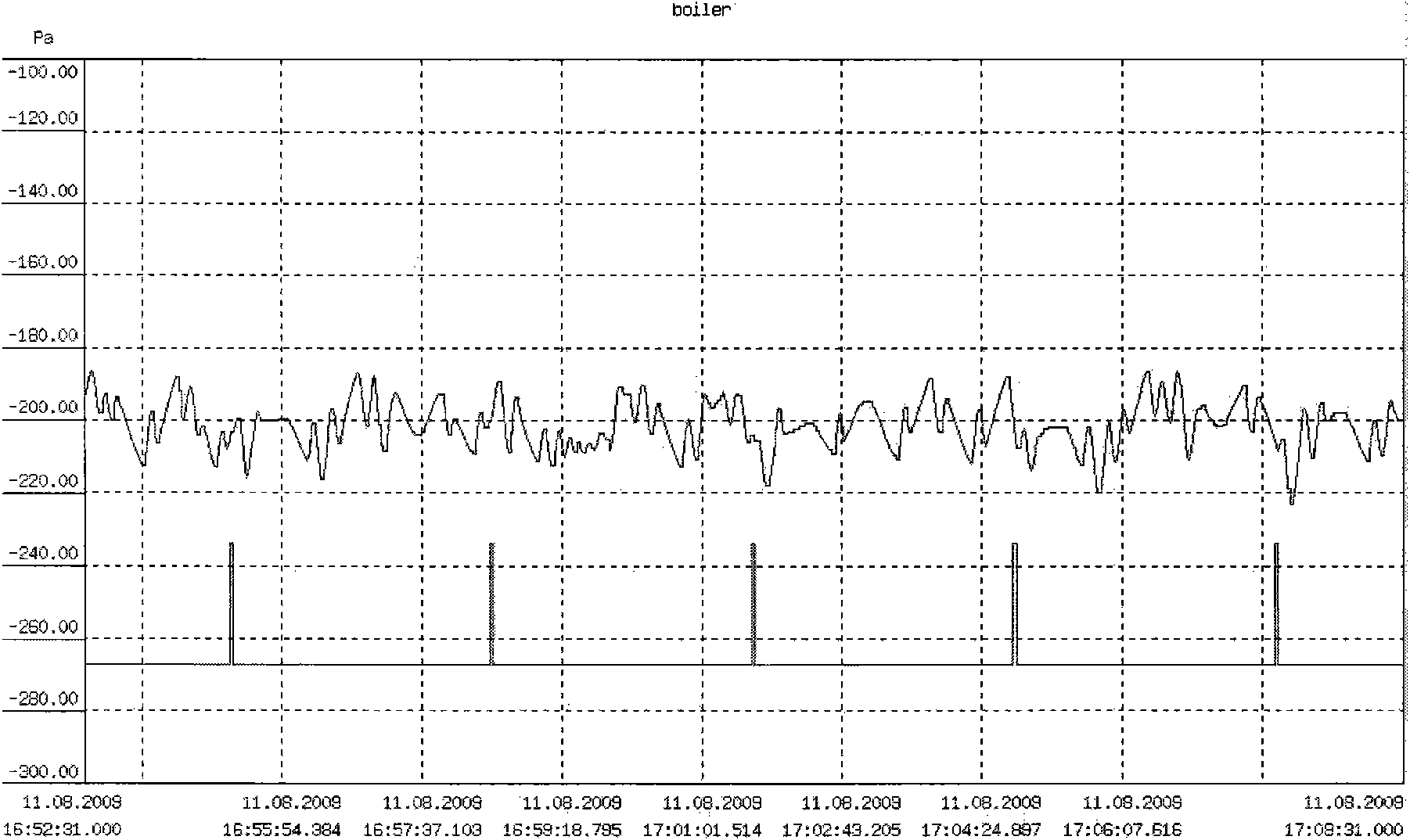

Hearth pressure control method of vibrating grate boiler

InactiveCN101660766AImprove efficiencyCombustion state is stableCombustion regulationCombustionAir volume

The invention relates to a hearth pressure control method of a vibrating grate boiler, which is an assistant adjusting method aiming at grate vibrating on the basis of an original hearth pressure control system, and can judge the hearth pressure change according to the influence of the grate vibrating on the flow of all the parts of an air and flue system, reduce grate air flow in due time and increase secondary air flow through advanced adjustment of all the executing mechanisms of the air and flue system, and provide guarantee for the safe combustion of the fuel while realizing the stable control of the hearth pressure. The method well solves the problems of raising, oscillating and the like of the hearth pressure along with the grate vibrating, improves the efficiency of the control system, improves the control effect, and is beneficial to the stabilization of the boiler burning state, and the improvement of the economical and safe operation level of the boiler.

Owner:CHINA ELECTRIC POWER RES INST +1

Efficient bio-organic fertilizer

InactiveCN105084987AIncrease organic matterImprove water and fertilizer retention performanceFertilizer mixturesAdditive ingredientBacterial strain

The invention discloses efficient bio-organic fertilizer which comprises straw, livestock excrement, leftovers, winery sewage, lees, bagasse, discarded traditional Chinese medicine, mildewed grain, magnesium nitrate, egg shells, waste paper, wheat bran, rape seed cake, bean pulp and strains. The efficient bio-organic fertilizer is free from toxicity, harmless, environmentally friendly and antibacterial, prevents diseases, and can improve and repair soil, increase organic matter of soil, improve the water and fertilizer preserving ability of the soil, increase the yield, prevent water from being polluted and protect environment; waste is used as a raw material, the problem of environmental pollution caused by industry, agriculture and life garbage is reduced, the waste is turned into wealth, nutritional ingredients of the organic fertilizer can be increased, crops grow well, and the yield and the nutritional ingredients of the crops are increased; multiple compound bacteria are fermented to form the fertilizer, the content of effective living bacteria is high, fermentation time is shortened obviously, working efficiency is improved, the multiple bacterial strains grow coordinately, and the shelf life can be prolonged to be 5 years.

Owner:JIESHOU ZHENHAI AGRI DEV CO LTD

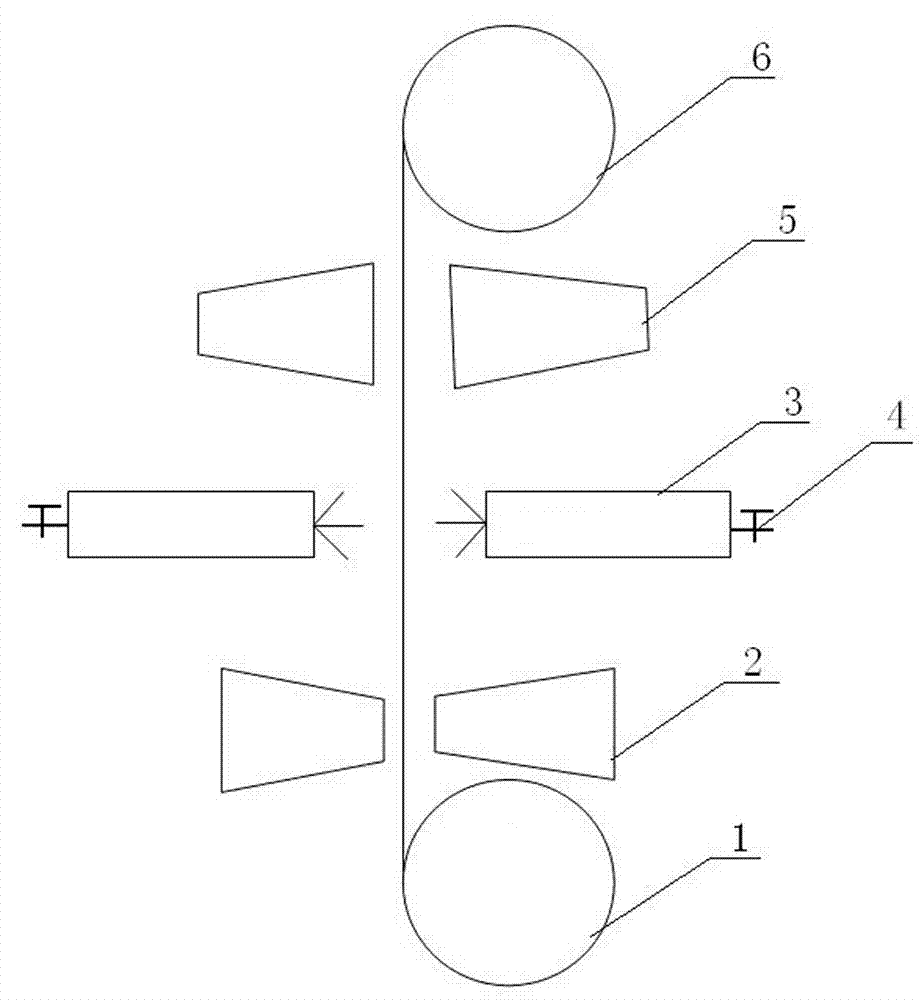

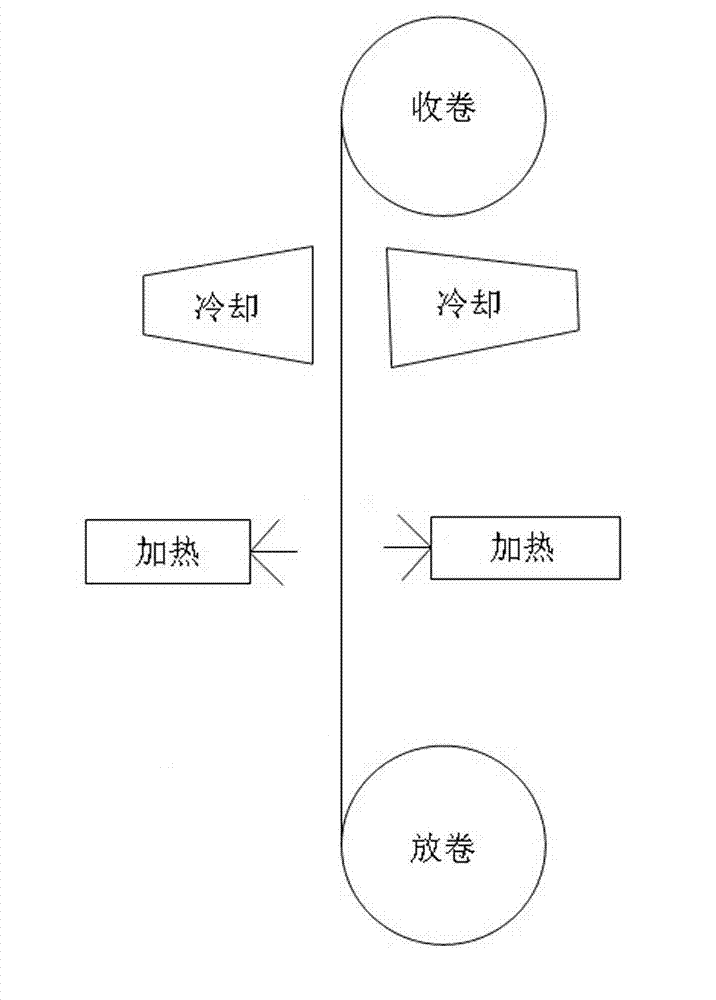

Method for preparing lithium battery current collector by electrostatic coating polymer composite PTC powder

InactiveCN103794802AHigh quality and reliabilityFast thermal responseElectrode carriers/collectorsSecondary cellsCombustionElectrostatic coating

The invention discloses a method for preparing lithium battery current collector by electrostatic coating polymer composite PTC powder. The method comprises the steps of (1) preparing the polymer composite PTC powder; (2) heating the lithium battery current collector up to 100-300 DEG C by a heating device, and coating the lithium battery current collector with the polymer composite PTC powder obtained in the step (1) through an electrostatic coating device to form a polymer composite PTC powder coating on the lithium battery current collector; (3) baking the lithium battery current collector coated with the polymer composite PTC powder coating in the step (2), and carrying out a recrystallization technology to obtain the lithium battery current collector provided with the polymer composite PTC powder coating. After the method is adopted, the problems of damage and explosion caused by heating of a lithium battery can be solved, so that the problems of combustion and explosion caused by rapid heating and chain reaction since the current of the current collector is overhigh due to overheating of the interior of the lithium battery can be further solved.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Storage device with self-destroying and fire self-extinguishing device for semi-finished product of firework and firecracker

InactiveCN1800770ASolve the explosionSolve combustion problemsPackagingFireworksFirecrackerWork in process

The invention relates to a firecracker semi-finished product storage device with safe self-destruction and automatic fire extinction device, which can solve the problems of present semi-finished safe self-destruction device which can not extinct around fire. It comprises a bracket, a cage storage box, and a safe self-destruction device. Wherein, the safe self-destruction device comprises a top cover, a high-pressure water chamber case and a safe self-destruction element. The safe self-destruction element comprises a fodder chamber, a quick-fire wire leaded from the fodder and the fire-proof sheath, and a water conductor; the high-pressure water chamber case is a dual-chamber structure which comprises a central chamber whose bottom has a self-destruction element and an annular chamber. The invention has significant fire-extinction self-destruction effect, while the self-destruction device has been tested for thousands times in 13 years and the self-destruction fire extinction effect can reach 100%.

Owner:赵子刚 +1

Method for carrying out fluidized drying on lignite by microwaves

InactiveCN102207350BCan not solve the depthReduce consumptionDrying solid materials with heatHearth type furnacesMicrowaveFluidized bed

The invention discloses a method for carrying out fluidized drying on lignite by microwaves. The method comprises the steps of: pre-drying crude lignite by a microwave device with hot air, and then carrying out fluidized drying on the lignite by a fluidizing bed with hot air so that the free water content in the crude lignite is lower than 1 percent. By utilizing the method disclosed by the invention, large-scale, rapid, low-energy-consumption and deep drying production of lignite can be realized.

Owner:KEDA INDUSTRIAL GROUP CO LTD

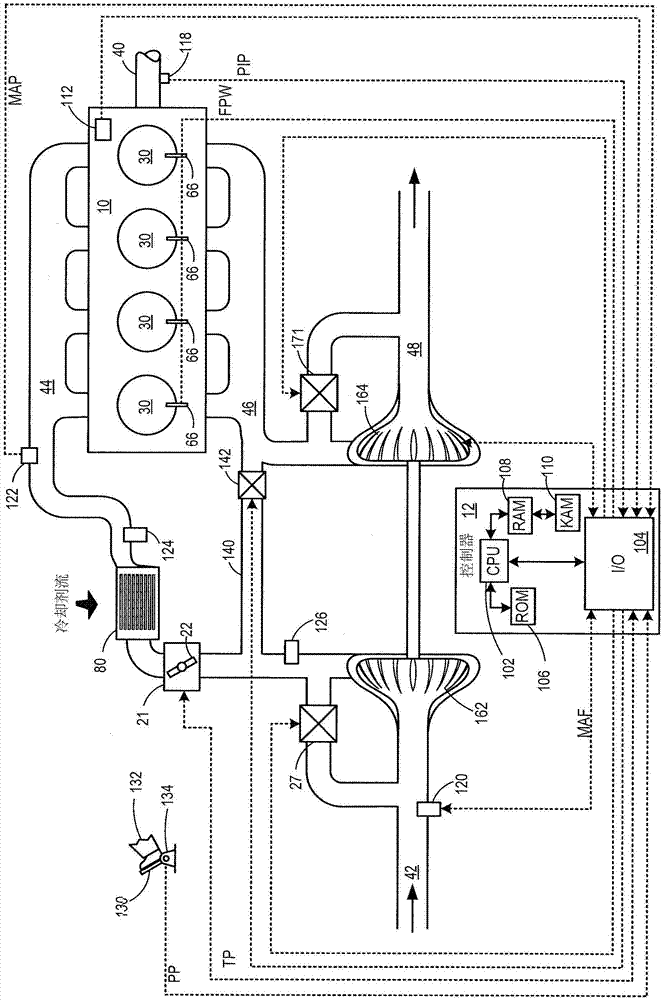

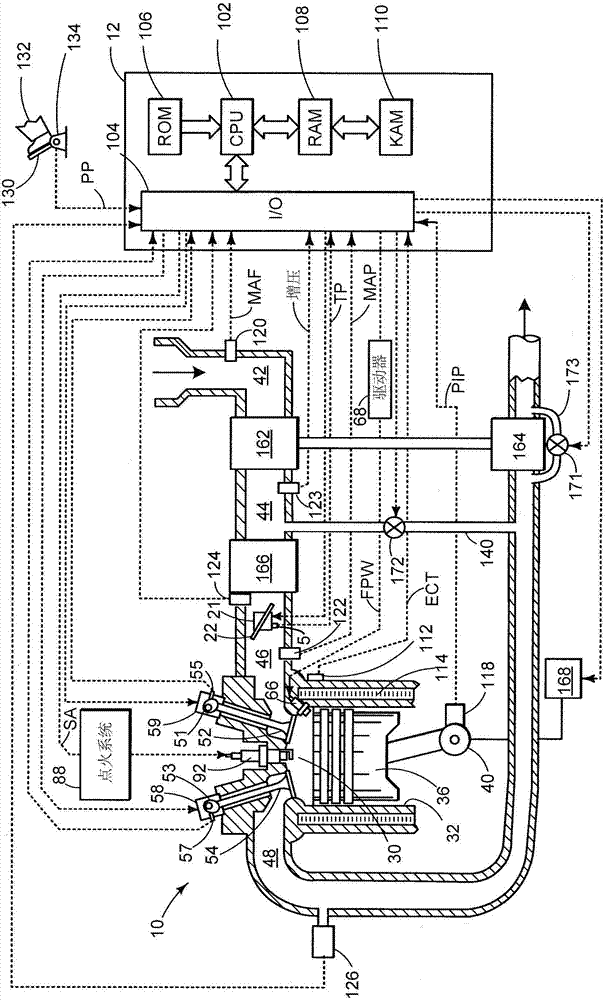

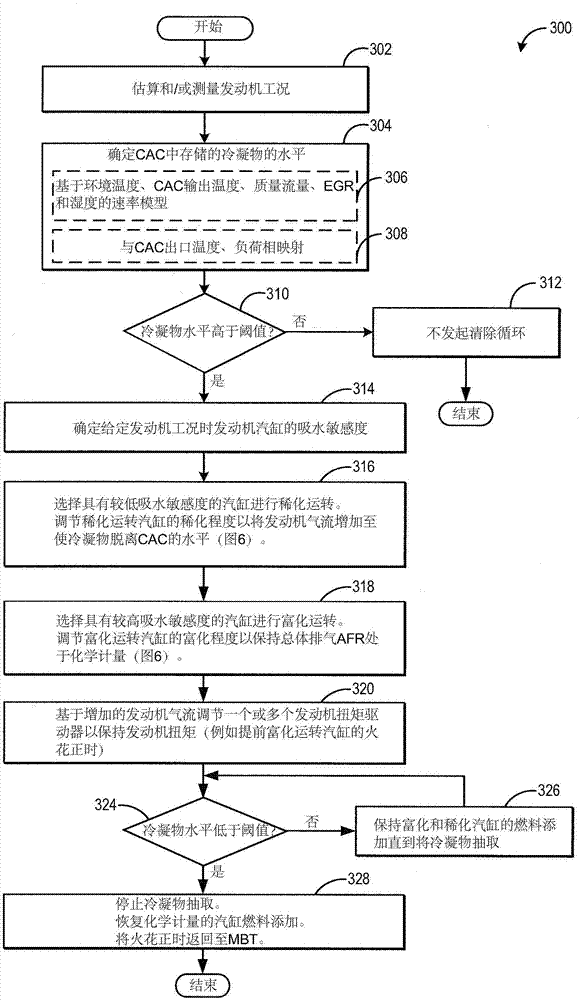

Method for purging condensate from a charge air cooler

InactiveCN104213972AImprove exhaust emissionsIncrease airflow levelsElectrical controlInternal combustion piston enginesThermodynamicsEngineering

Methods and systems are provided for cleaning out condensate stored at a charge air cooler. In response to increased condensate accumulation at a charge air cooler, airflow through the engine is increased to purge the condensate while an engine actuator is adjusted to maintain engine torque. Combustion stability issues of engine cylinders are addressed by adjusting fueling of each cylinder individually during condensate ingestion.

Owner:FORD GLOBAL TECH LLC

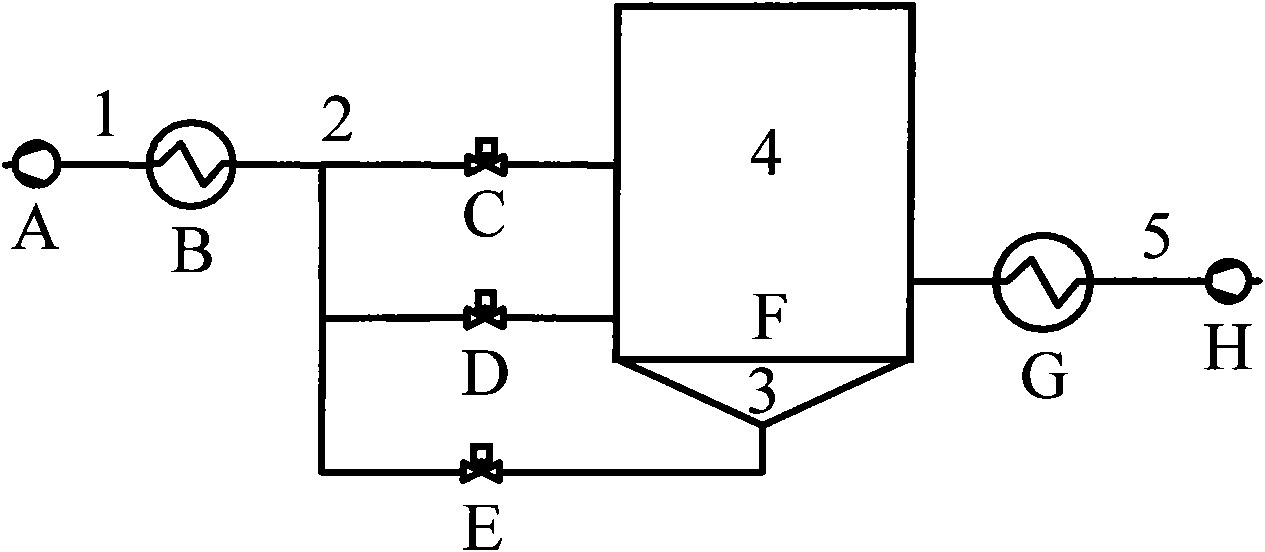

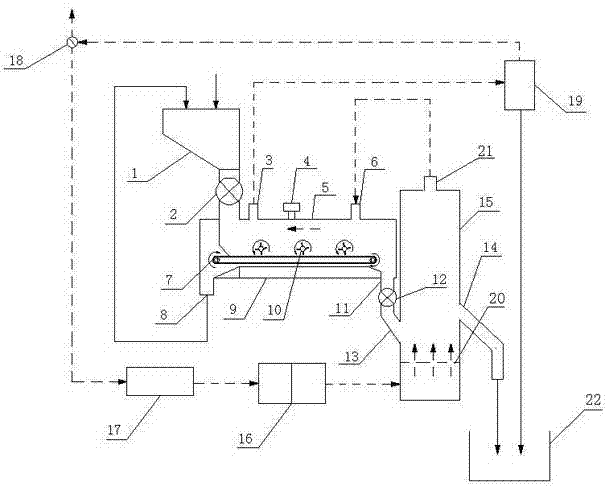

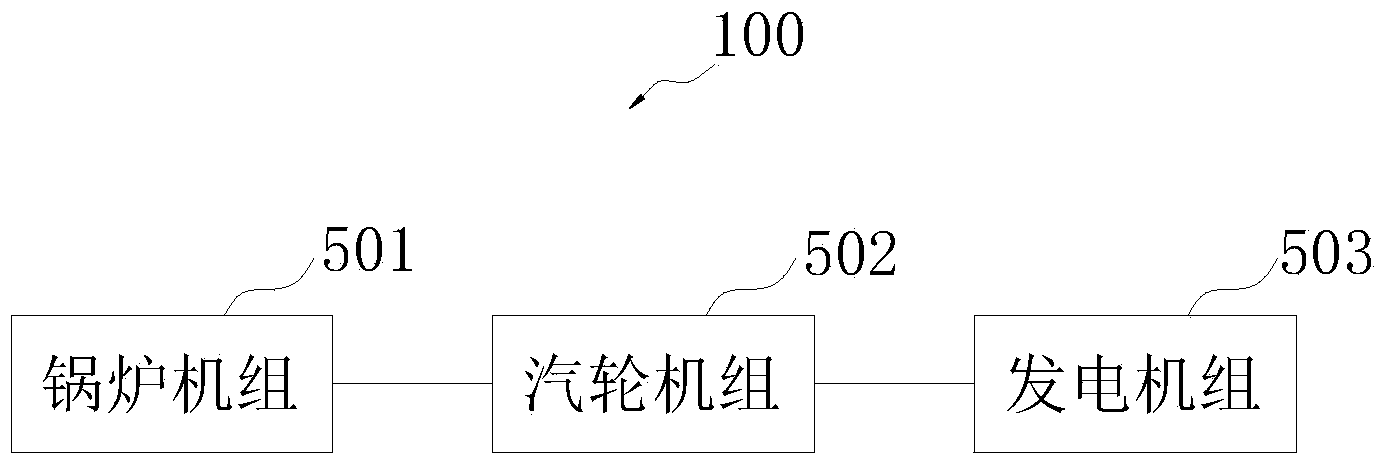

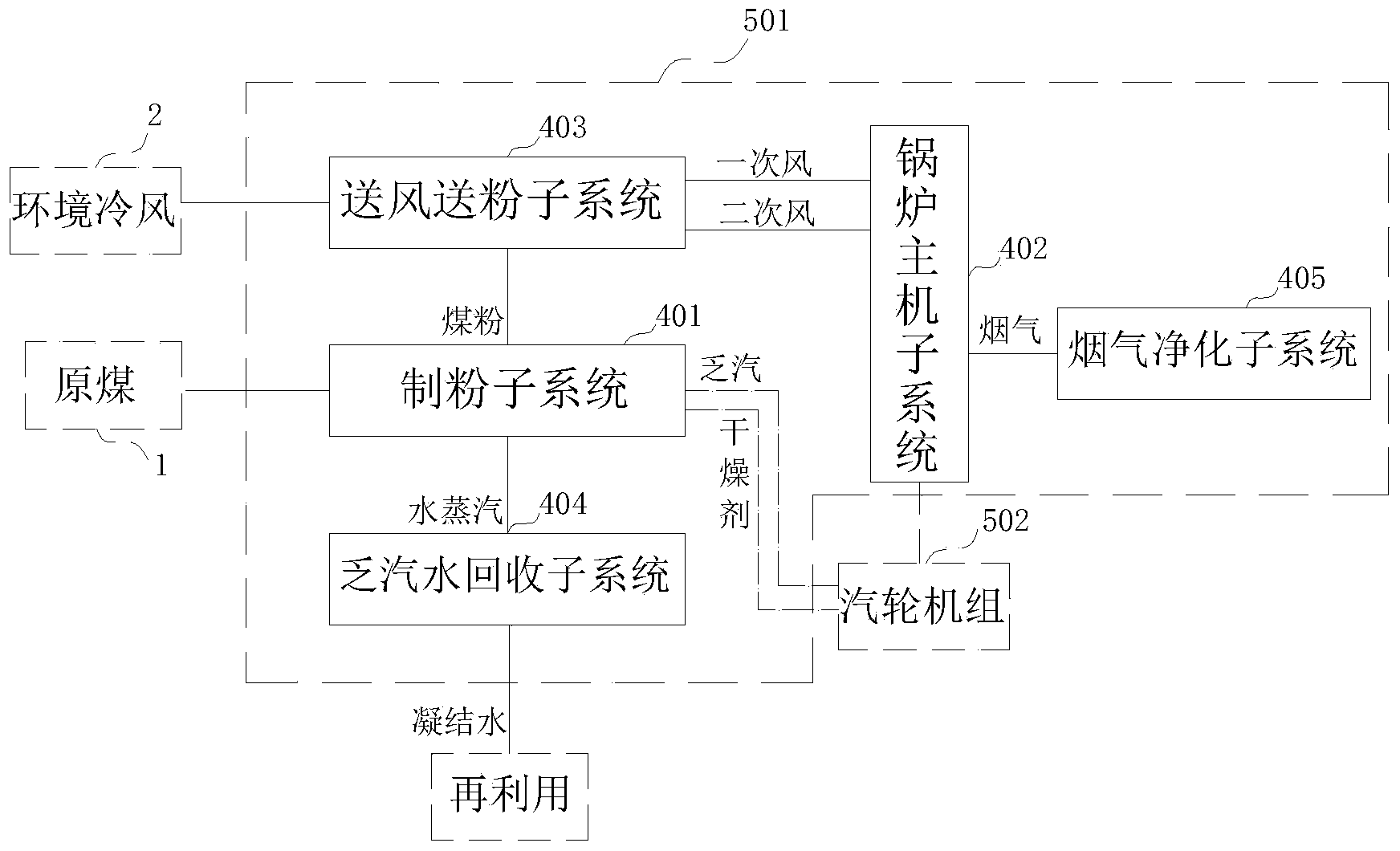

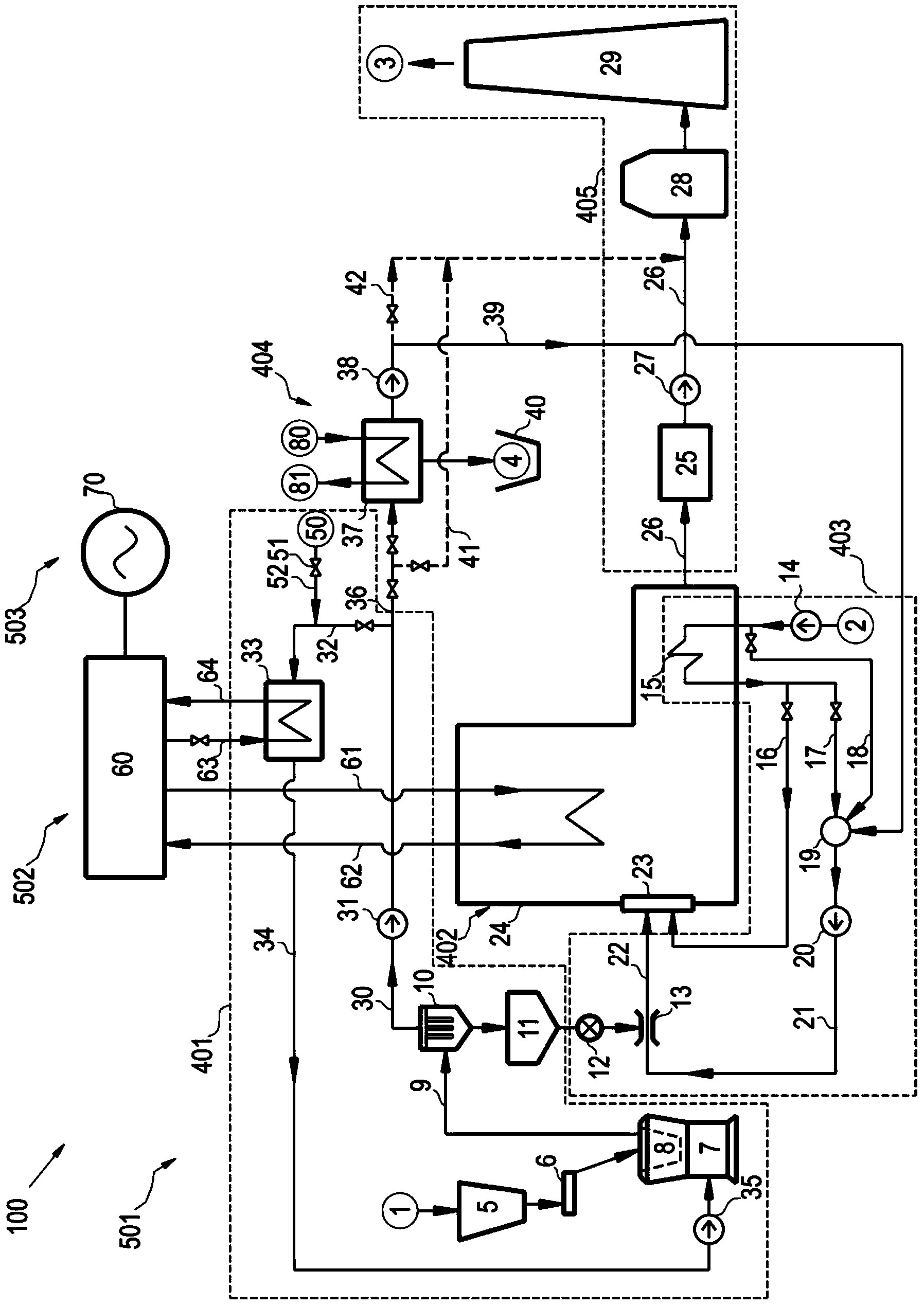

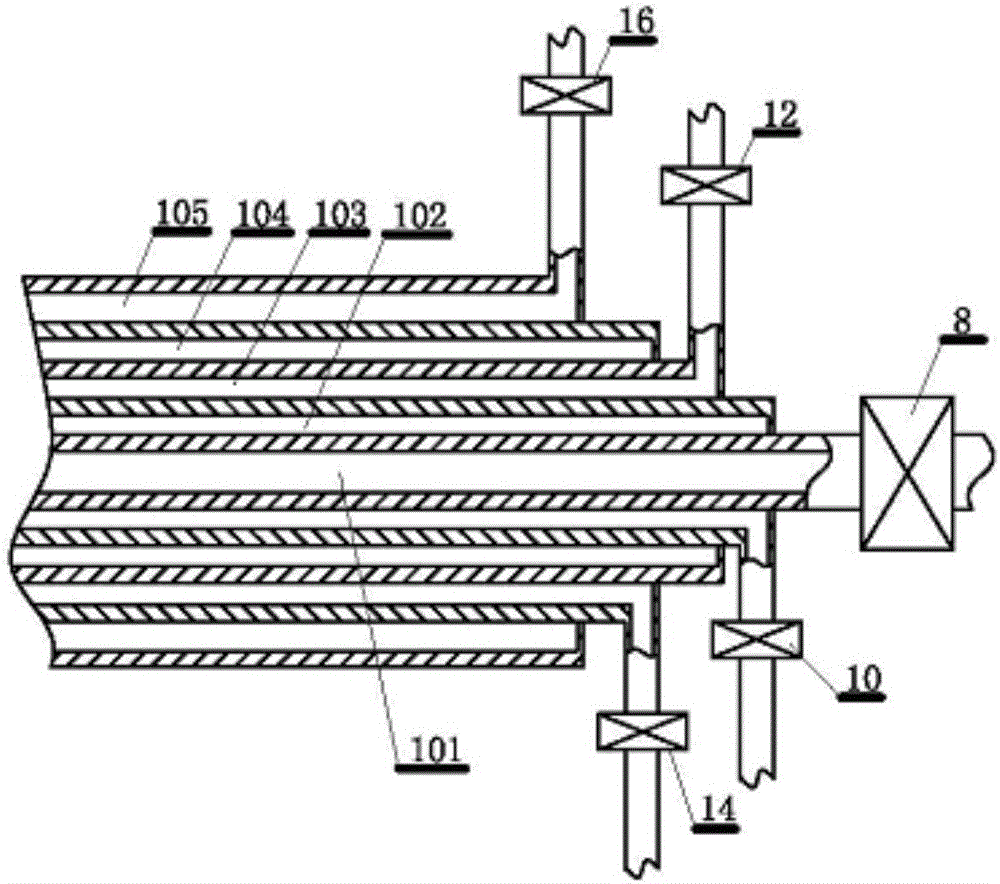

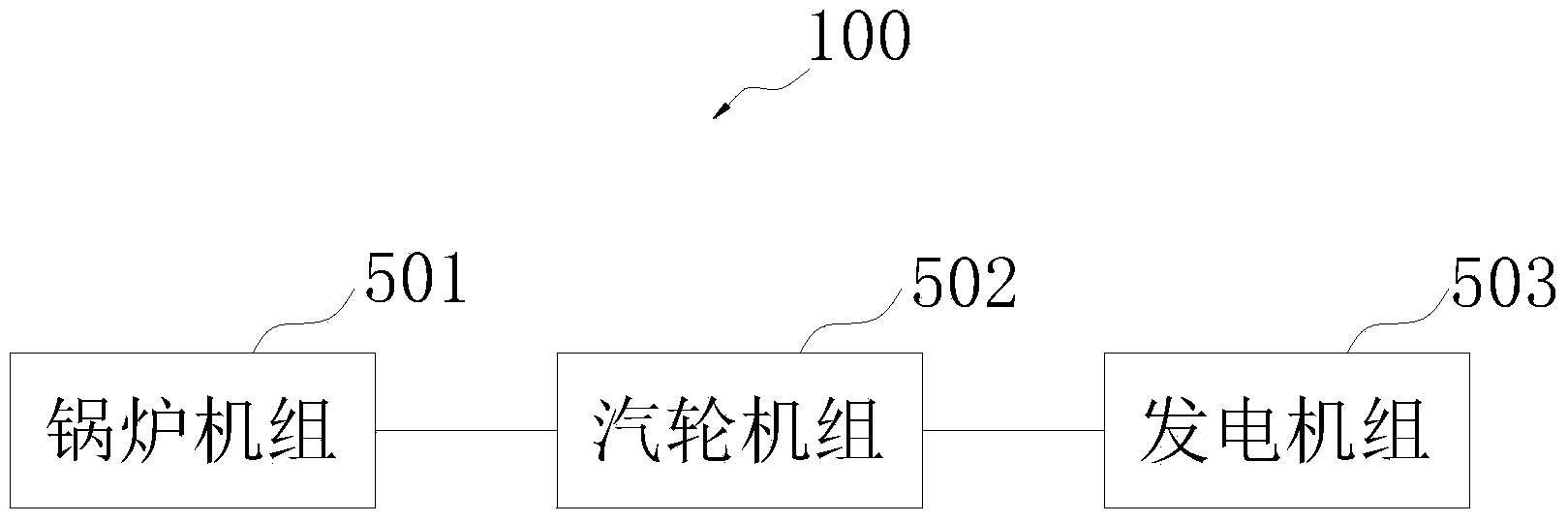

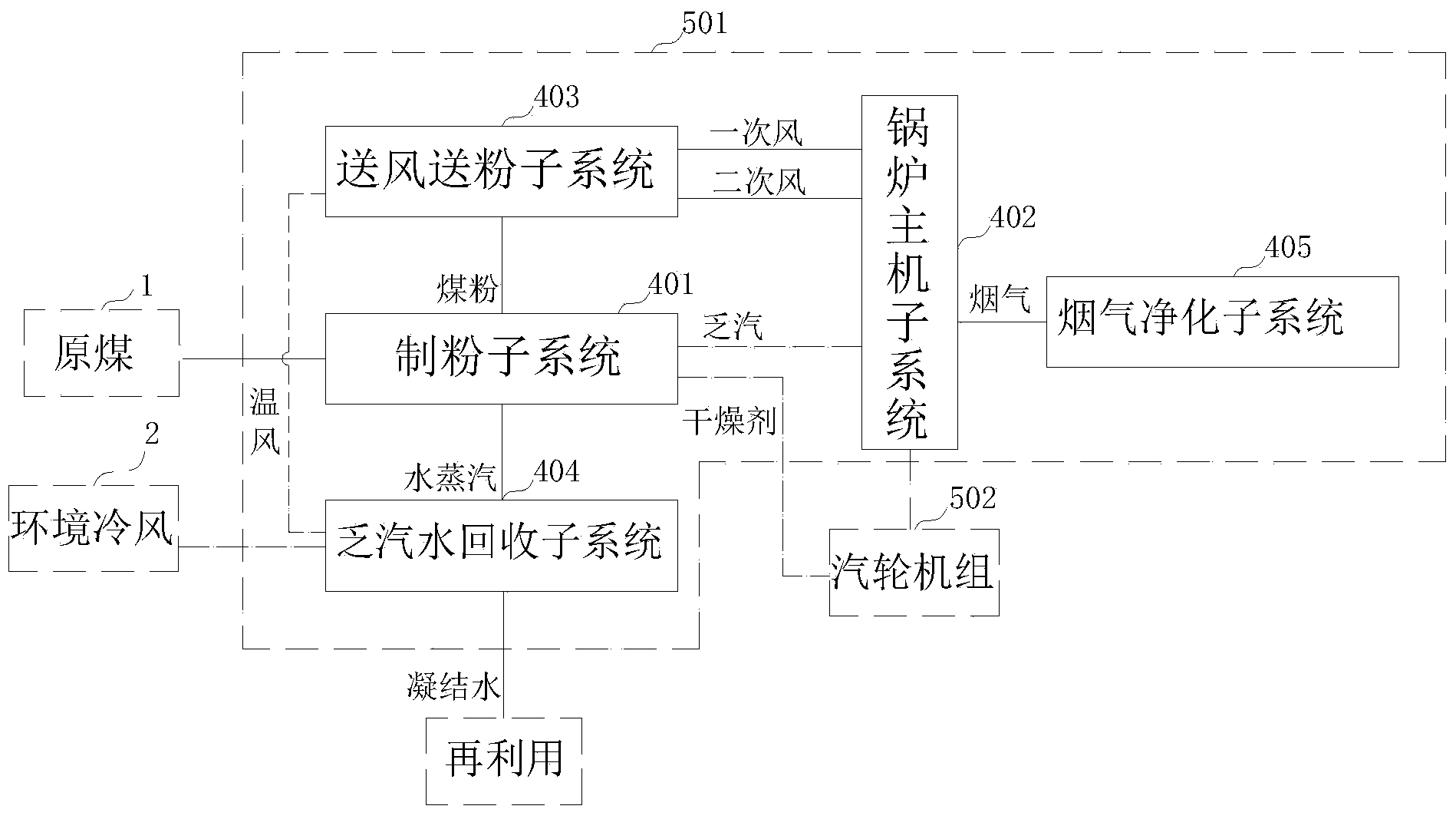

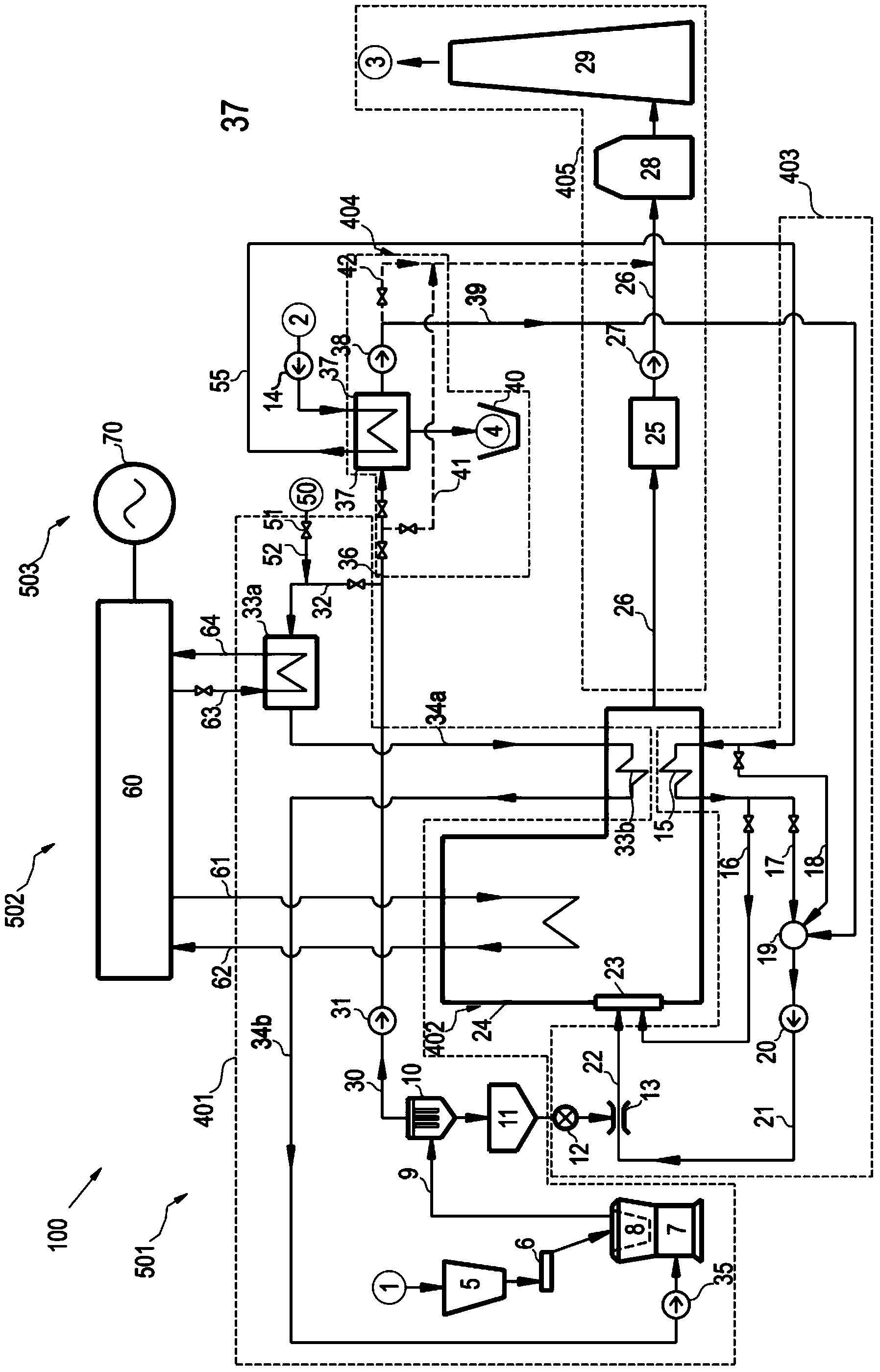

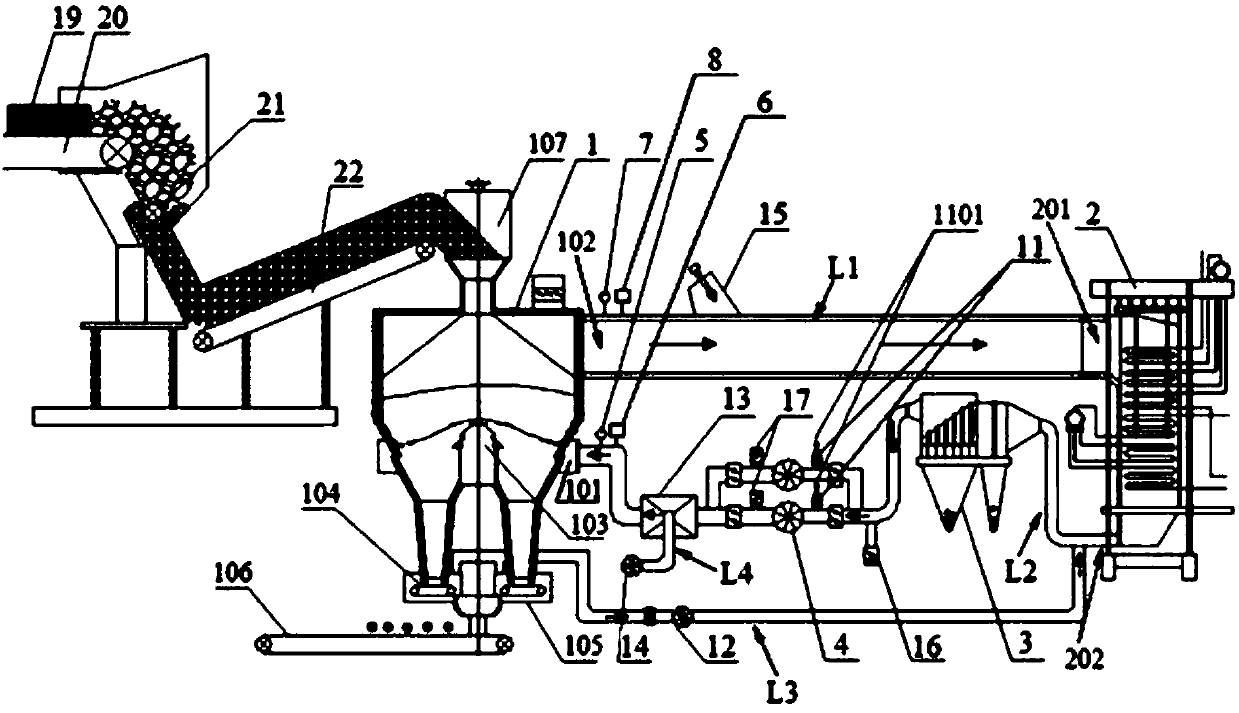

Superheated steam drying power-making coal-fired power generation system

ActiveCN104329667AGuaranteed uptimeAchieve recyclingSteam useDrying gas arrangementsAir preheaterPowder mixture

The invention provides a superheated steam drying powder-making coal-fired power generation system, which is used for driving a generator to generate power after burning of raw coal. The superheated steam drying power-making coal-fired power generation system comprises a boiler unit and a turboset, wherein the boiler unit comprises a powder-making subsystem, a boiler host machine subsystem, an air supply and powder supply subsystem and a dead steam water recovery subsystem; the powder-making subsystem comprises a steam and powder generating and drying device, a steam and powder separating device and a drying agent generating device; a dead steam heater of the drying agent generating device is used for heating dead steam in the dead steam heater by using steam extracted from a steam turbine to form superheated steam; an air preheater is used for heating a portion of environmental cold air to obtain hot air; a portion of the hot air is mixed together with the other portion of the environmental cold air in a primary air mixing chamber, and the mixed air enters an air and powder mixer as primary air; the other portion of the hot air is directly supplied to a pulverized coal burner as secondary air; the pulverized coal burner is used for burning pulverized coal in an air-powder mixture; the pulverized coal burns in a hearth together with the primary air and the secondary air to generate flue gas.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

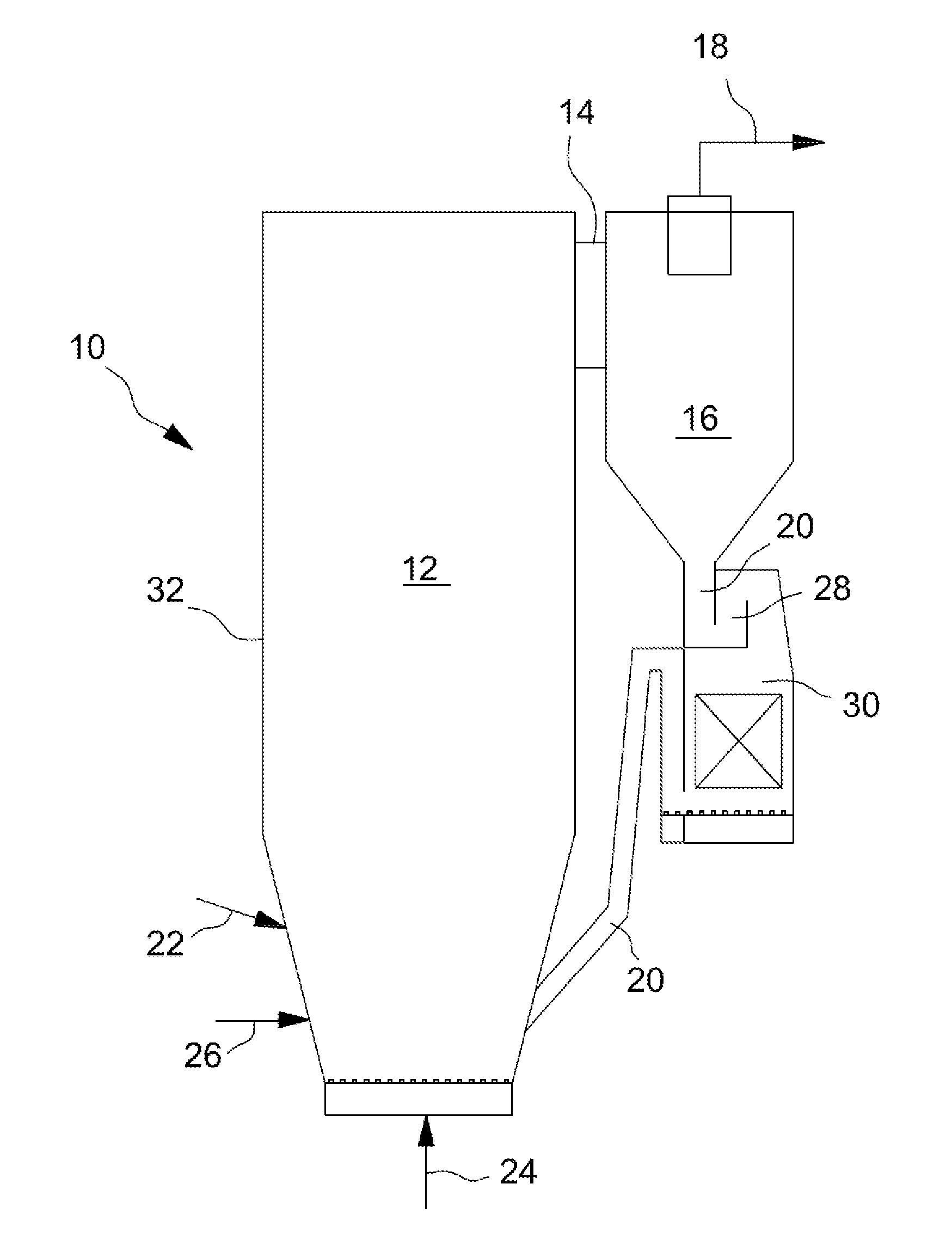

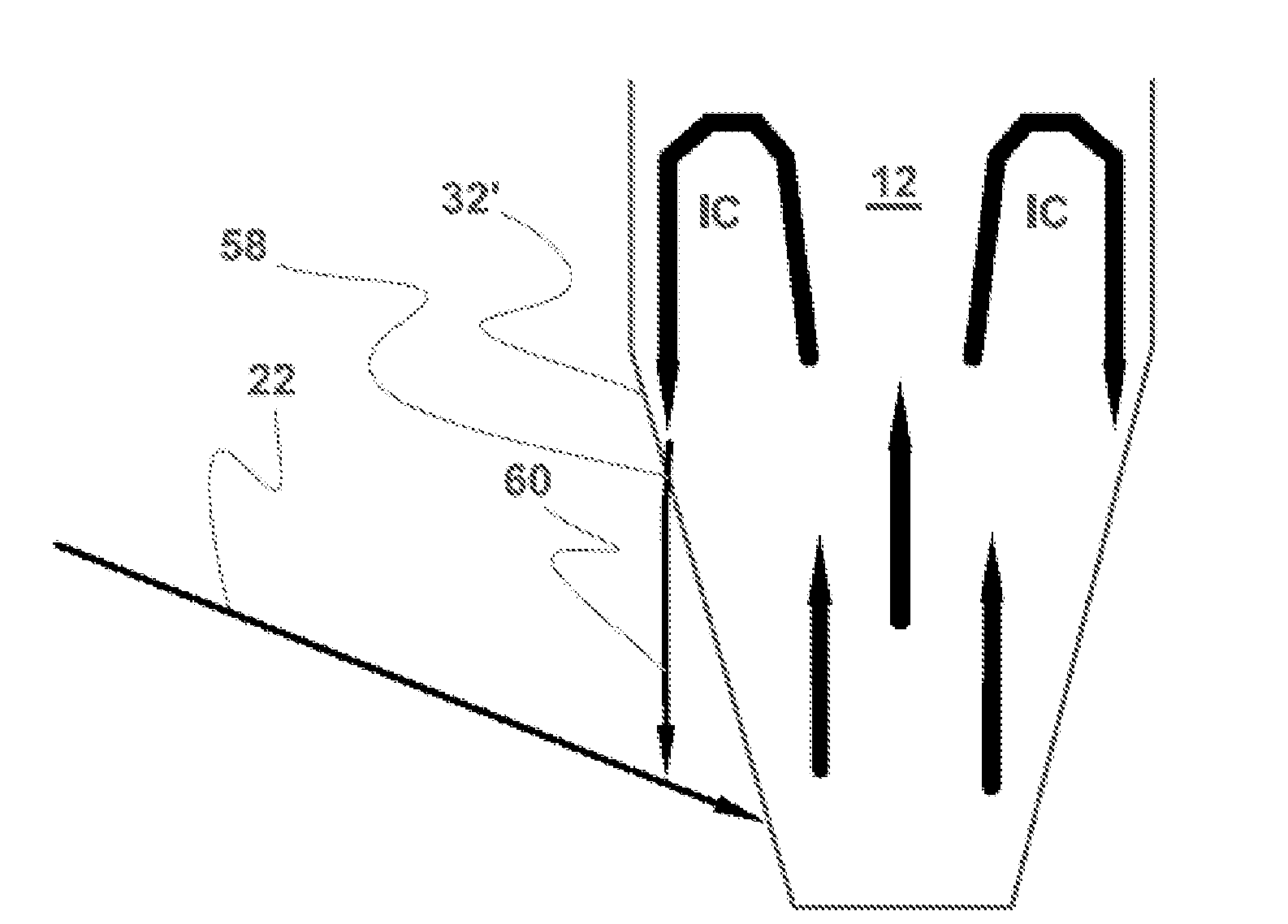

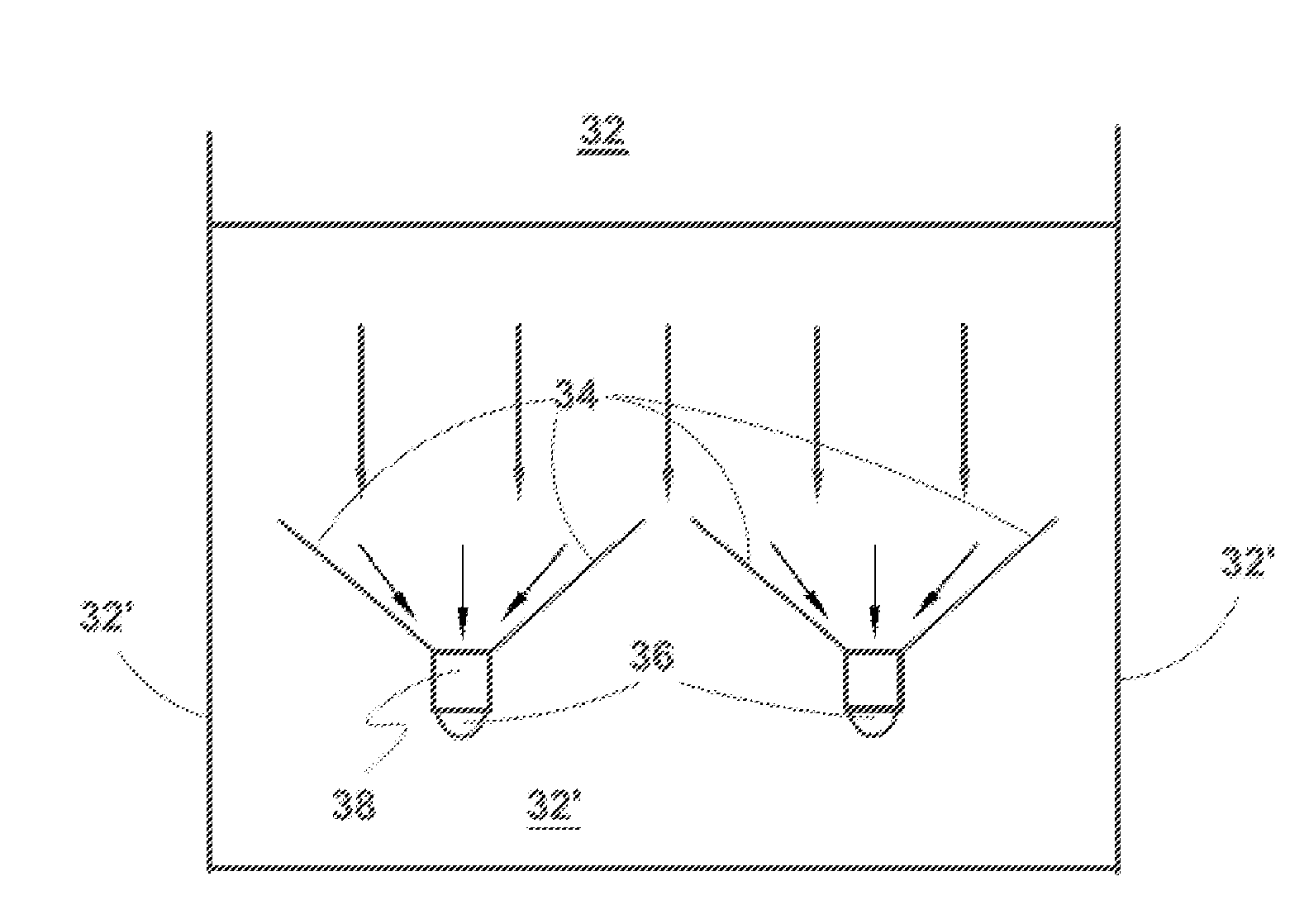

Method and arrangement for feeding fuel into a circulating fluidized bed boiler

InactiveCN102725588AEliminates the need for mixingSolve supply problemsFluidized bed combustionSteam boilersCombustion chamberFluidized bed

The present invention relates to a method and an apparatus for feeding fuel into a circulating fluidized bed boiler. The invention is specifically concerned on feeding fine, light and / or moist fuel into the boiler. The method and apparatus for feeding light, fine, volatile and / or moist fuel into a circulating fluidized bed boiler is based on collecting circulating bed material to a return flow and introducing the return flow into communication with the fuel being introduced in the furnace (12) so that the bed material return flow and the fuel are mixed together and flow downwards in the furnace (12) for increasing the residence time of the fuel in the furnace (12).

Owner:A AHLSTROM CORP

Multi-air-chamber stratified biomass particle burner and burning method

InactiveCN108317505AScientific and reasonable designImprove combustion efficiencySolid fuel combustionCombustion apparatusSlagBurning out

The invention discloses a multi-air-chamber stratified biomass particle burner and burning method. According to the burner, an upper burning plate and a lower burning plate are arranged in a burning chamber and are each provided with a slag pushing plate, the two slag pushing plates can make reciprocating motion, the upper slag pushing plate is used for pushing fuel burning on the upper burning plate to the lower burning plate, and the lower slag pushing plate is used for pushing ash generated after the fuel is burnt out on the lower burning plate towards an ash outlet. By adoption of a stratified burning mode and through burning with a multi-air-chamber structure, pyrolysis and gasification burning and charring burning are completed, the problems that accumulated burning is prone to slagging and is insufficient are solved, and meanwhile problems about burning of biomass particle fuel of various types and various ash contents are solved. The multi-air-chamber stratified biomass particle burner and burning method is scientific and reasonable in design, high in burning efficiency and low in operation cost and have extremely high economical value and social value.

Owner:XIAN SENWAS AGRI SCI & TECH

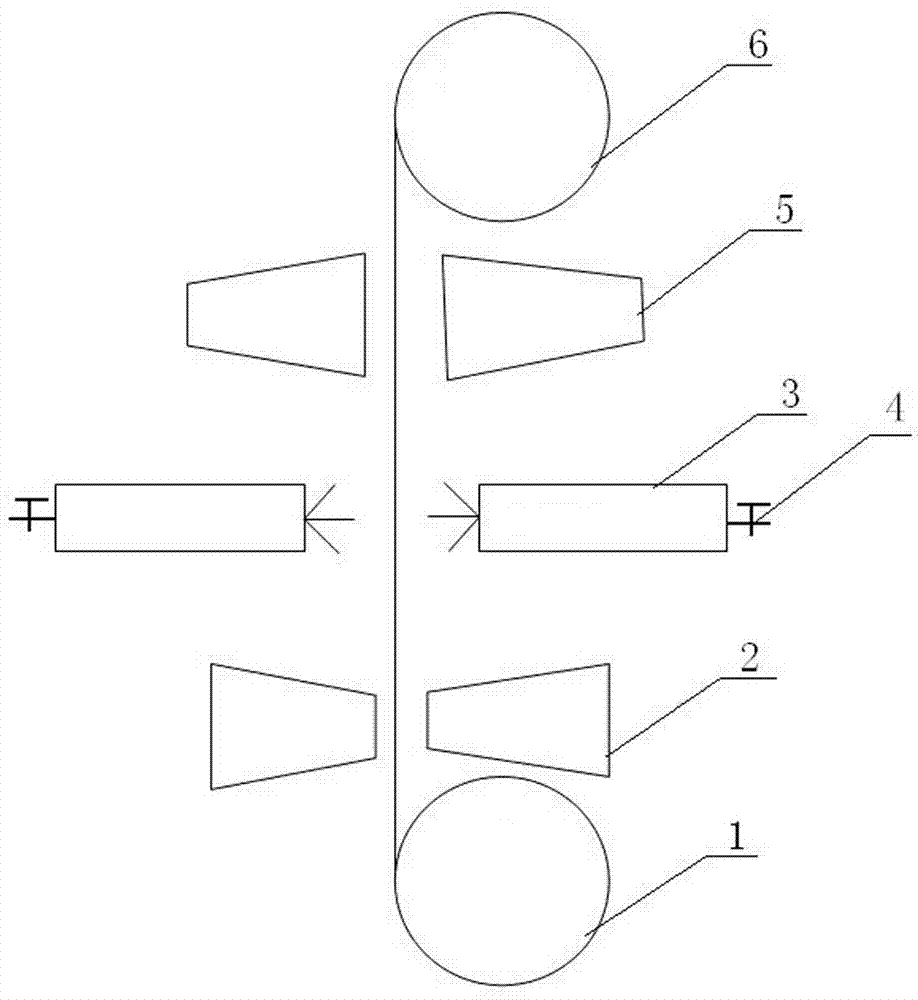

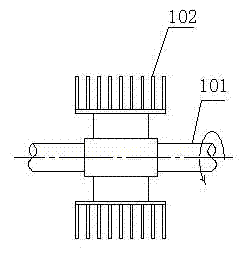

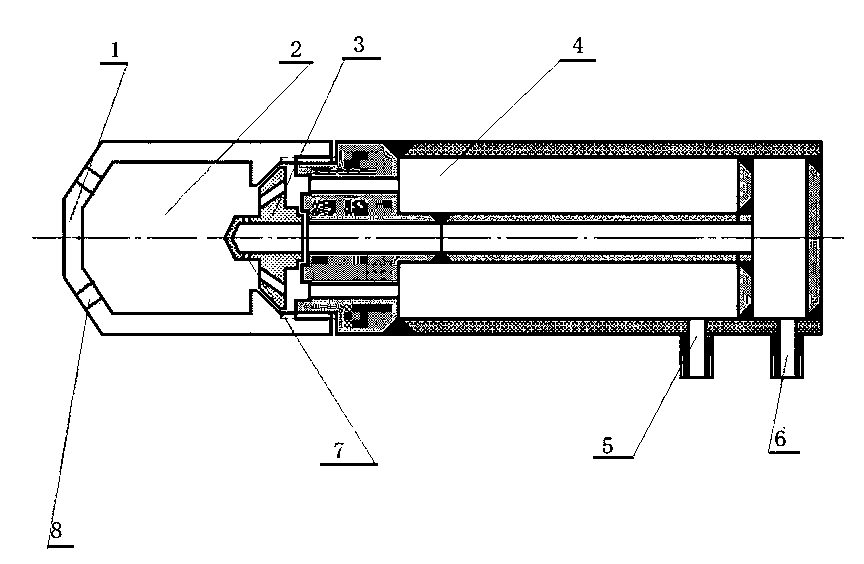

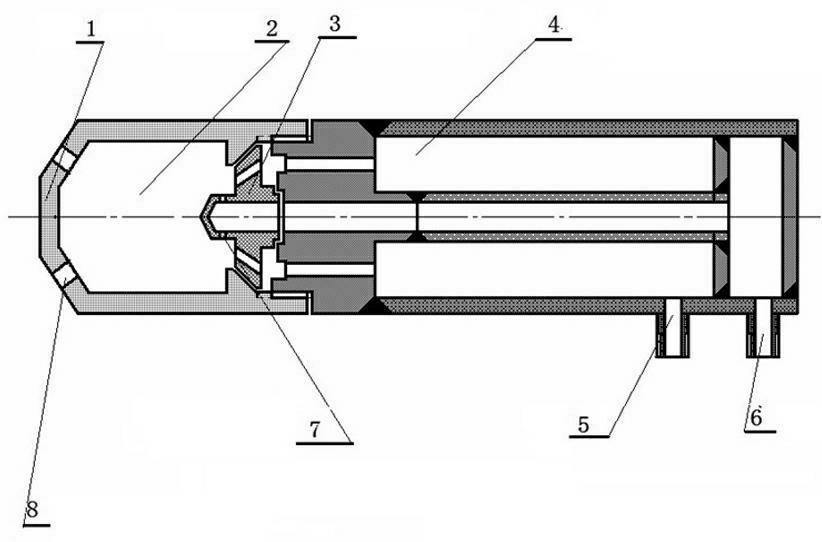

Oil gun capable of combusting various fuel oil

InactiveCN102705826AAchieve full coverageSolve the problem of deficiencies in combustionBurnersSpray nozzleFuel oil

The invention relates to a fuel oil preparation technology, and particularly relates to a gas explosion atomizing oil gun capable of combusting various fuel oil simultaneously. The oil gun comprises a spray head 3 and a gun barrel 4, wherein an oil gas distributor 3 is arranged between the spray head 1 and the gun barrel 4 and is provided with a first-stage rotational flow atomizing slice 7, the spray head 1 is provided with a second-stage gas explosion atomizing spray nozzle 8, the spray head 1 and the oil gas distributor 3 form an air bubble generating chamber, and the gun barrel 4 is provided with an air inlet 5 and an oil inlet 6. The oil gun capable of combusting the various fuel oil has the beneficial effect of eliminating the limitation that after being molded, the existing oil gun can only combust one designed fuel oil. The oil gun disclosed by the invention is capable of combusting the various fuel oil, thereby bringing great convenience to fuel oil units and simultaneously improving the combustion efficiency.

Owner:深圳中兴新源环保股份有限公司

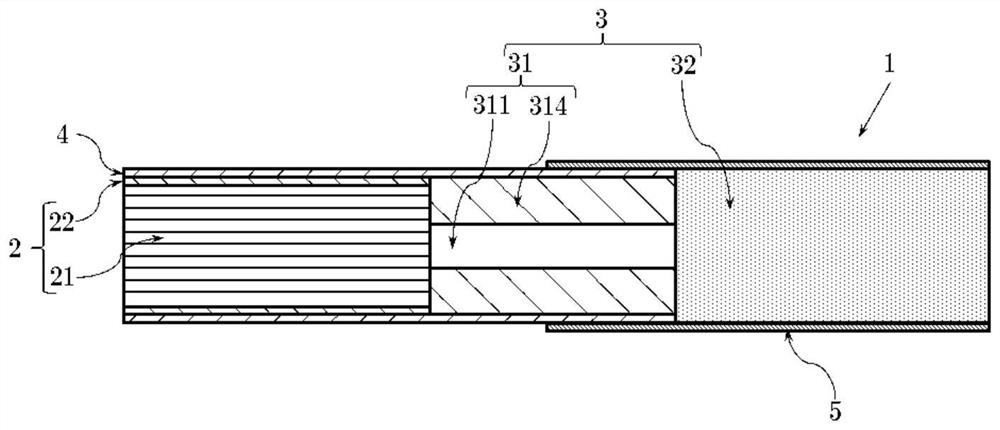

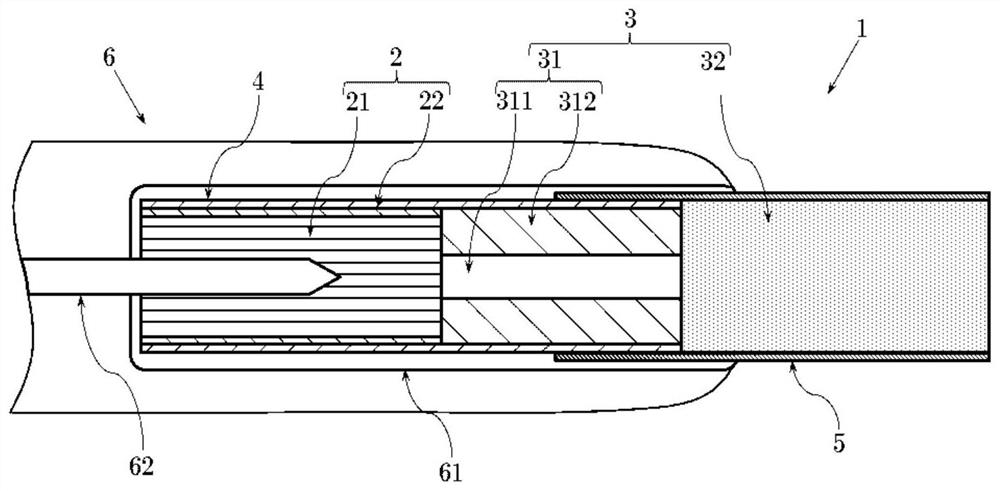

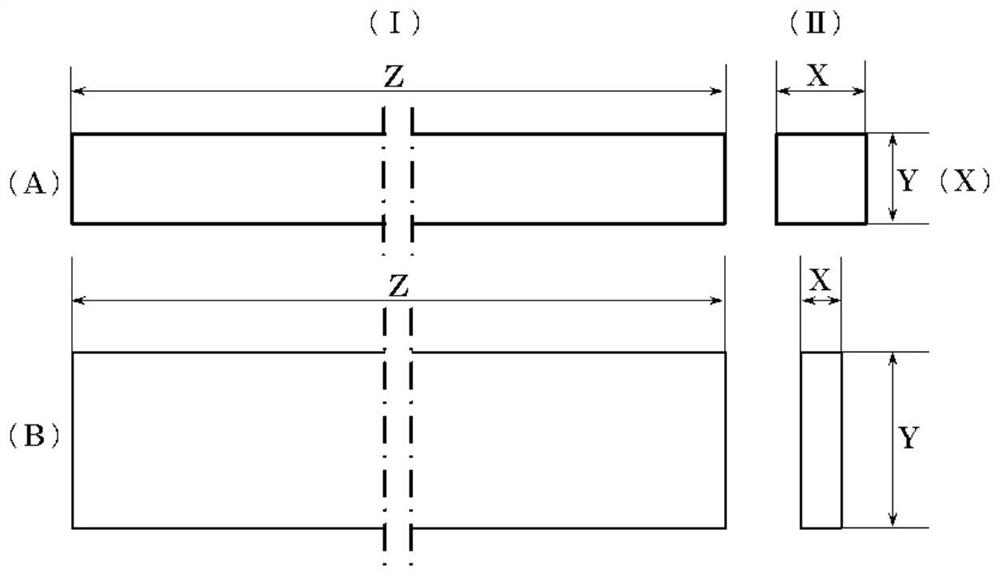

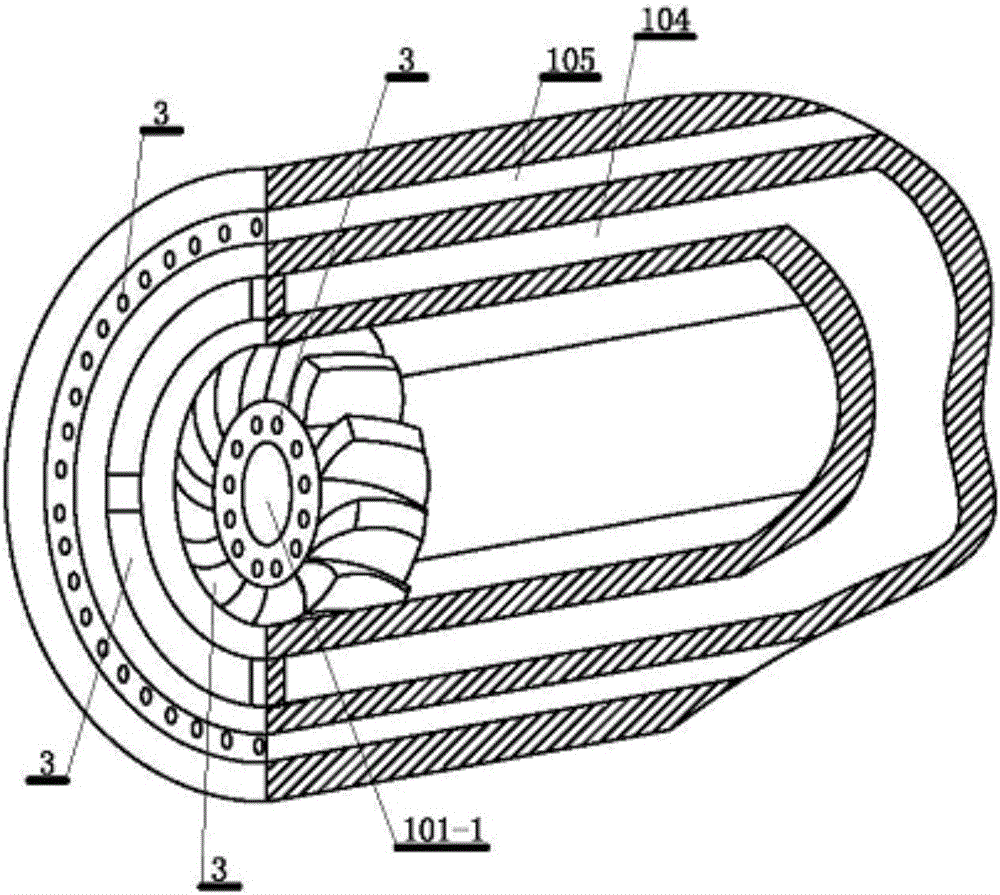

Heated aroma-producing body, aroma cartridge, and manufacturing method and manufacturing device for heated aroma-producing body

PendingCN112384088AEasy to insertImprove fill rateTobacco preparationTobacco treatmentAromaEngineering

Provided are a heated aroma-producing body and an aroma cartridge that is provided therewith, as well as a manufacturing method and a manufacturing device for the heated aroma-producing body, which can solve the problems of a heated aroma-producing substrate burning during a draw and the heated aroma-producing substrate falling during installation / removal of an aroma cartridge, in addition to increasing the filling rate of the heated aroma-producing substrate and ensuring a suitable number of instances of smoking, while also forming a vapor flow path that allows pleasant smoking of an aroma cartridge that is provided with a heated aroma-producing body in which a heated aroma-producing substrate including an aerosol former is rolled up in a packaging material. Provided are a heated aroma-producing body and an aroma cartridge that is provided therewith, as well as a manufacturing method and manufacturing device for this heated aroma-producing body, said heated aroma-producing body beingcharacterized by comprising: a vapor flow path of gaps that are formed by noodle-shaped heated aroma-producing substrates being gathered into a primary aggregate; a vapor flow path of gaps that are formed by noodle-shaped heated aroma-producing substrates and this primary aggregate being gathered into a secondary aggregate; and a vapor flow path of gaps that are formed by contact of a heated aroma-producing body packaging material and heated aroma-producing substrates, wherein these vapor flow paths penetrate in the lengthwise direction of the heated aroma-producing body.

Owner:MIRE TECH CO LTD

Honeycomb briquette capable of igni ting by paper

The invention discloses a honeycomb paper ignitable. With weeds, crop straw carbide, organic binder and adequate water mixed together, and repressed into coal by uniform system, it can be used after nature or artificial drying. The honeycomb has the following advantages: 1 paper ignitable and easy to use; 2 The raw materials were non-chemical oxidants, cost-low, safety and environmental protection; 3 Solved the burning issues of weeds and crops straw, and provides a new way for the comprehensive utilization of agricultural and forestry waste . The invention has certain social benefits and promotional value.

Owner:毛光辉

Method for rapidly recycling condensates in electron beam cooling bed furnace smelting chamber

The invention discloses a method for rapidly recycling condensates in an electron beam cooling bed furnace. The method comprises the following steps: after completion of cast ingot smelting in the furnace, decreasing the final cast ingot to the station of an ingot puller of the electron beam cooling bed furnace, turning off the isolating valve of a smelting chamber and an ingot pulling chamber, the isolating valve of a vibrating feeding hole and the smelting chamber, the lift valve of a diffusion pump unit, a booster pump and a holding pump bypass-valve to enable the entire smelting chamber to be in the isolated seal state; then, filling argon in the smelting chamber until the air pressure in the smelting chamber to be consistent with the barometric pressure; connecting a refrigerating machine with the smelting chamber, starting the refrigerating machine to cool the indoor temperature, after cooling, turning off the refrigerating machine and the valve of the refrigerating machine and the smelting chamber; finally, loosening the furnace door bolt of the smelting chamber, opening the furnace lid of the smelting chamber, and starting an axial draught fan to blow argon in the smelting chamber out so as to recycle the condensates. With adoption of the method, temperature in the furnace hearth can be rapidly decreased to the required temperature, and the condensates in the furnace can be rapidly recycled without affecting the production cycle.

Owner:YUNNAN TITANIUM IND

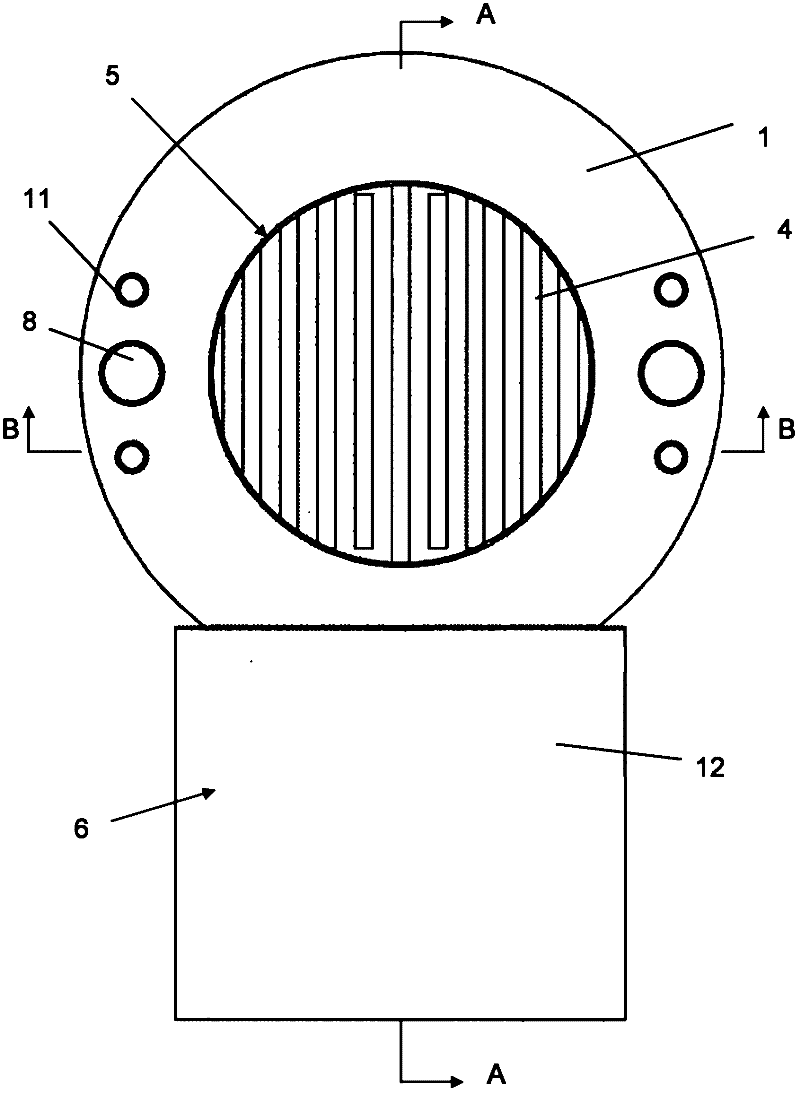

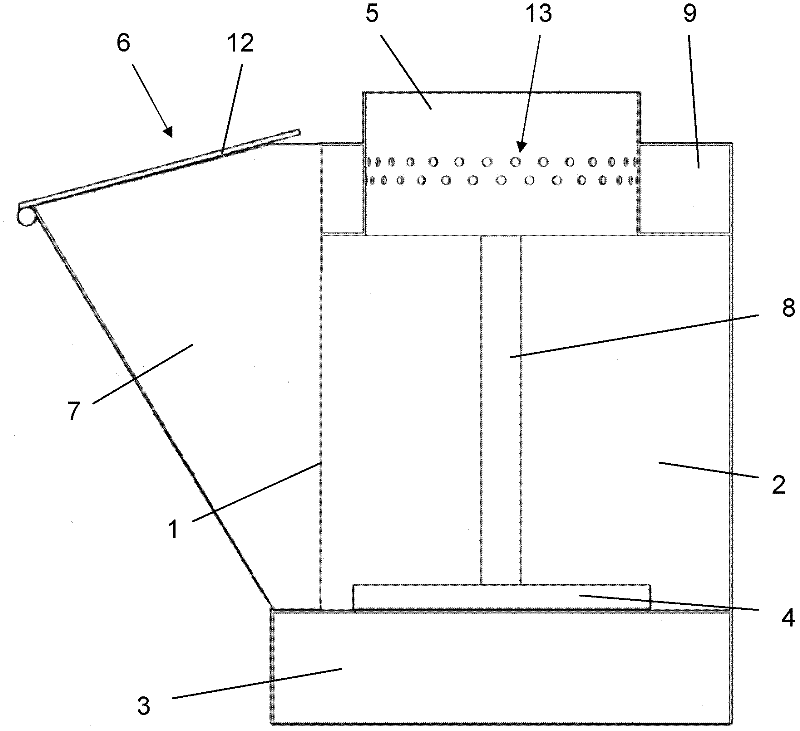

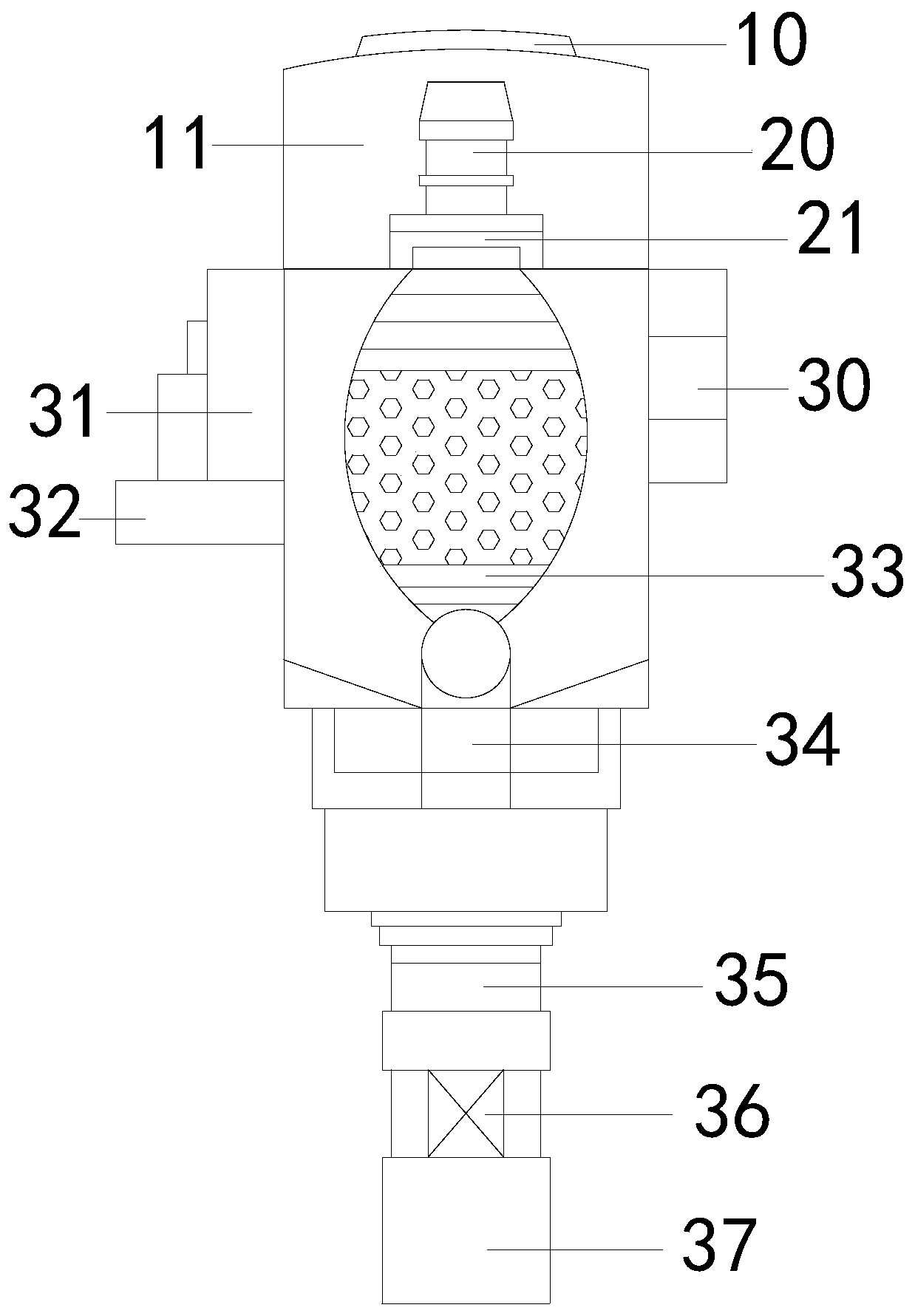

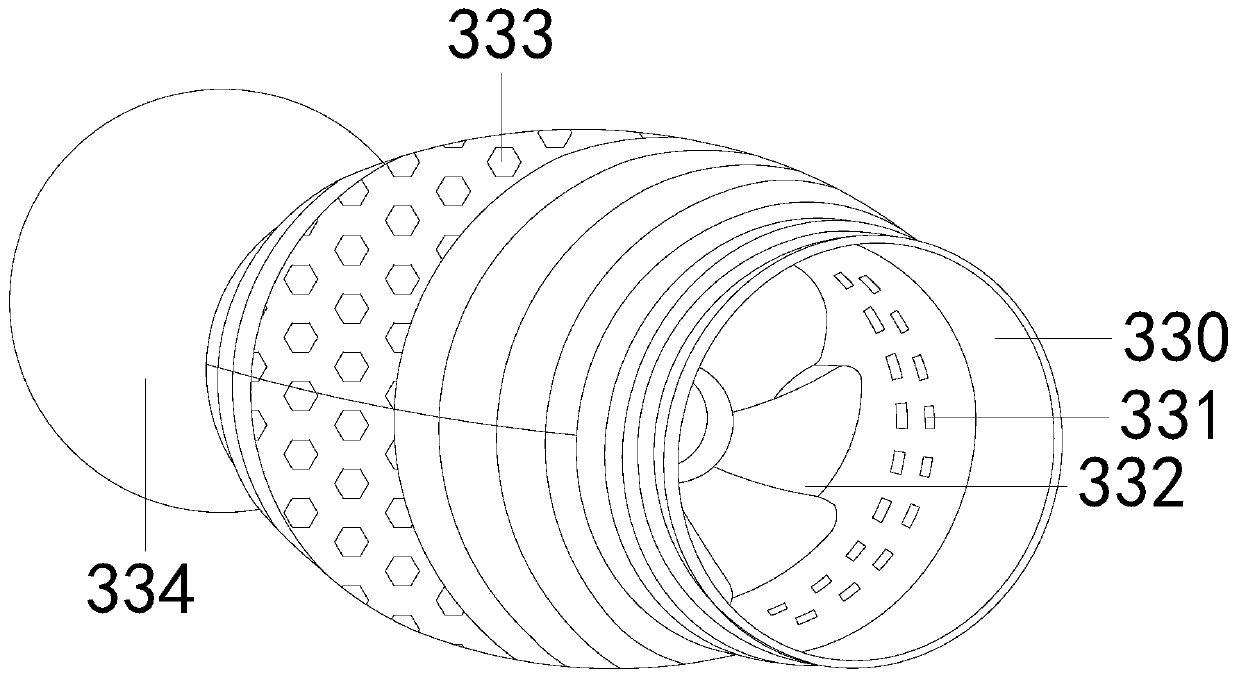

Combustible solid waste utilization composite burner in cement production

InactiveCN105782968ASolve combustion problemsSolve the problem of low scale that cannot be scaledPulverulent fuel combustion burnersIncinerator apparatusCycloneCombustor

The invention discloses a combustible solid waste utilization composite burner in cement production. The composite burner comprises a variety of fuel nozzles and a fuel conveying pipeline connected with the fuel nozzles, wherein the pipeline is connected with a variable frequency fan, the pipeline is a multi-layer surrounding structure, the center layer is a combustible solid waste particle conveying pipeline, an oxygen conveying pipeline surrounds the combustible solid waste particle conveying pipeline, a cyclone conveying pipeline surrounds the oxygen conveying pipeline, a coal powder conveying pipeline surrounds the cyclone conveying pipeline, and a whirlwind conveying pipeline surrounds the coal powder conveying pipeline; combustible solid waste particle spray ports are arranged in the center of the front end surface of the burner, and a plurality of oxygen nozzles are uniformly distributed around the combustible solid waste particle spray ports.

Owner:徐光武

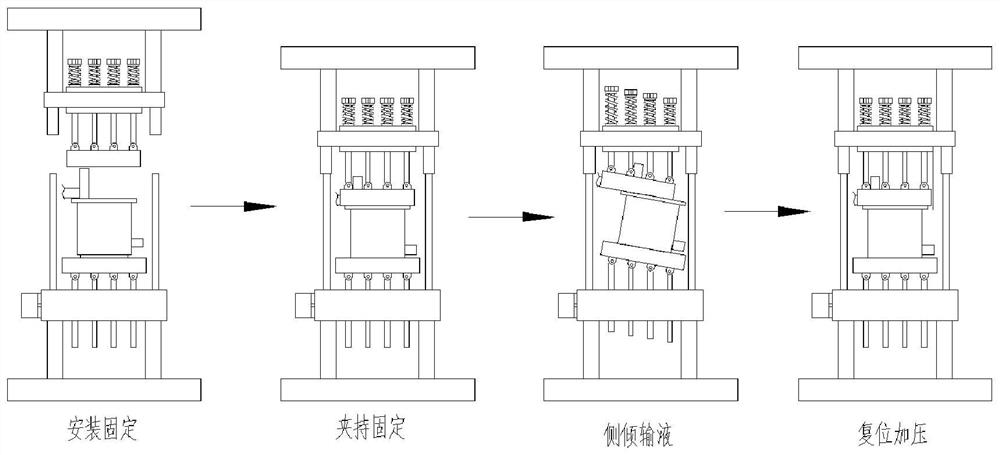

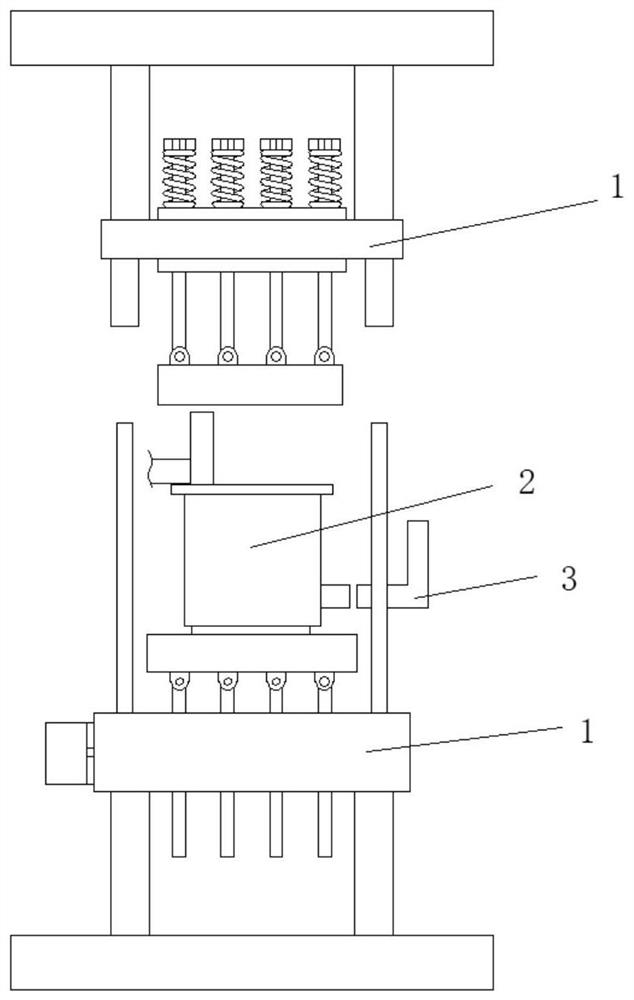

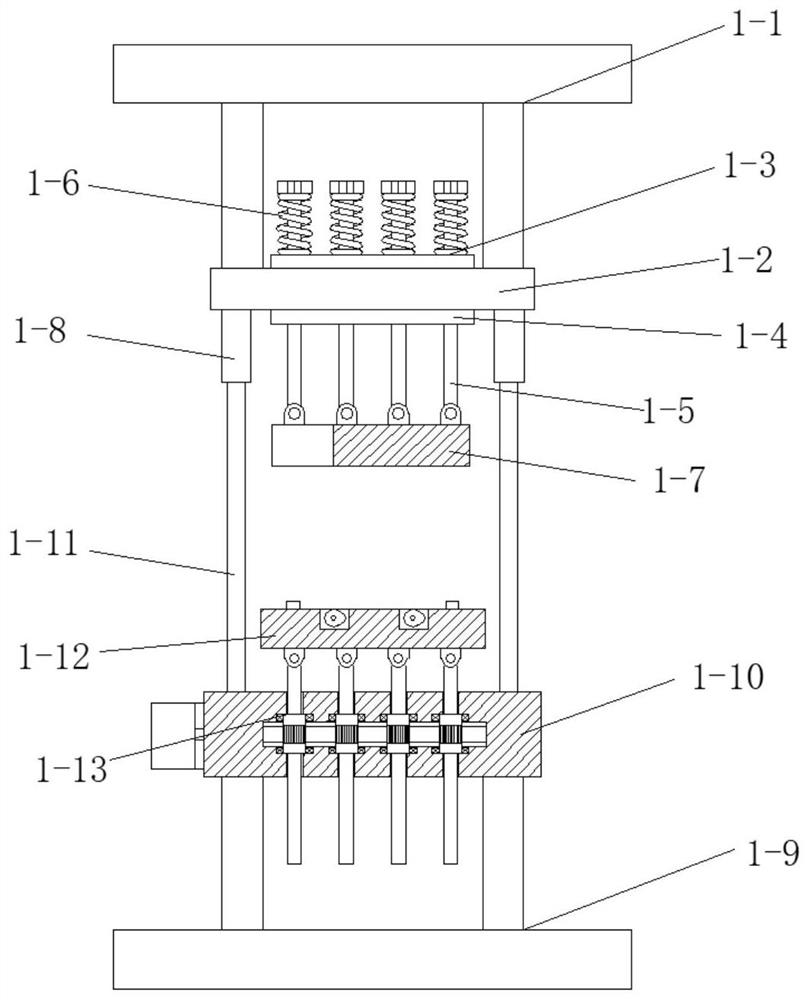

Magnesium-aluminum alloy casting method and magnesium-aluminum alloy casting position adjusting method

The invention discloses a magnesium-aluminum alloy casting method and a magnesium-aluminum alloy casting position adjusting method, and relates to the technical field of alloy processing. The method aims at solving the problems of how to ensure that liquid magnesium-aluminum alloy burns in the die-casting process of a magnesium-aluminum alloy casting, harm exists when a covering agent is used forretarding flame, and the magnesium-aluminum alloy is misrun and contains bubbles in the prior art. A magnesium-aluminum alloy die-casting device comprises a clamping component and a die-casting die; the clamping component comprises an upper supporting frame, a supporting table, an upper beating plate, an upper die plate, an upper connecting rod, a reset spring, an upper clamping plate, a guide sleeve, a lower supporting frame, a supporting table, a guide rod, a lower clamping plate and a deflection component; and an upper supporting table is arranged at the lower end of the upper supporting frame, and the upper beating plate and the upper die plate are sequentially arranged on the upper end face and the lower end face of the upper supporting table. According to the method, the problems ofharm caused by combustion of liquid magnesium-aluminum alloy and flame retardance by using a covering agent and misrun and air bubble content of the magnesium-aluminum alloy are solved, so that the environmental safety of production is ensured, and the produced magnesium-aluminum alloy can meet the requirement of reaching the standard.

Owner:HEILONGJIANG UNIV OF TECH

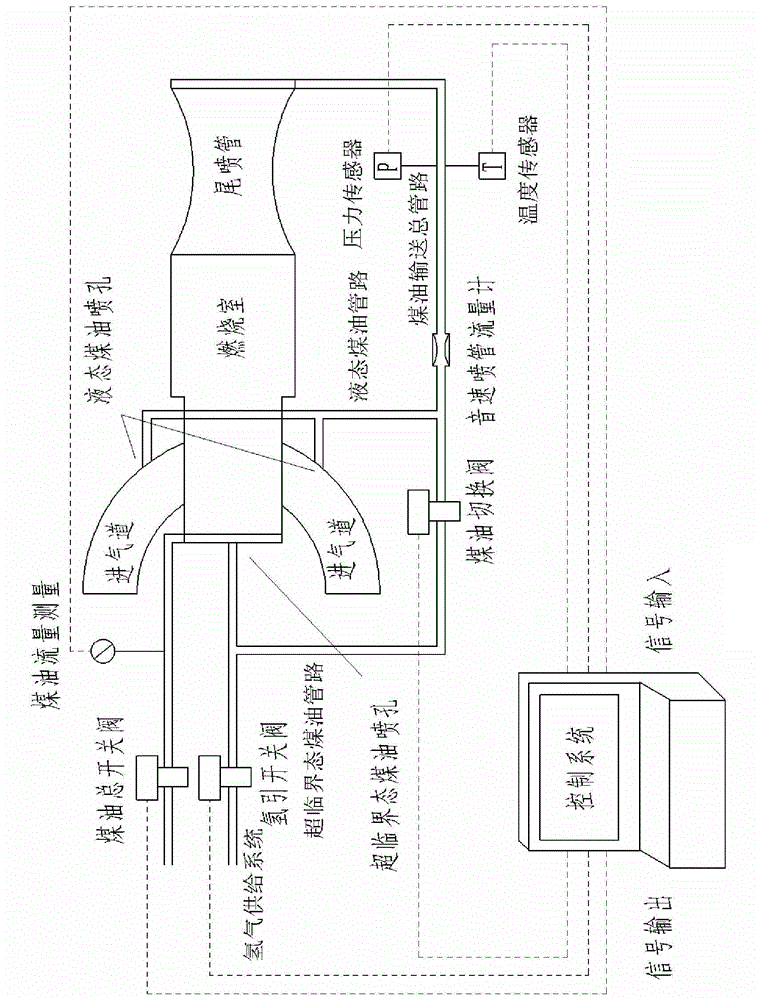

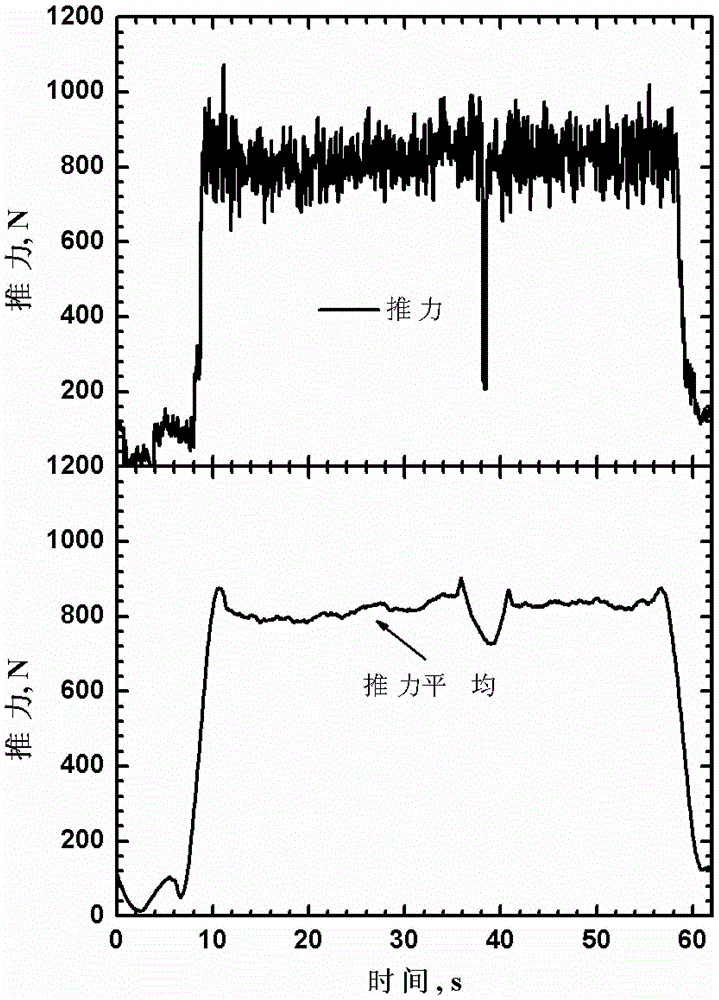

System and method of kerosene switching of active cooling subsonic combustion ramjet engine

ActiveCN103557091ASolve the problem of spraying into the combustion chamber for combustionSolve combustion problemsRam jet enginesKeroseneRamjet

The invention discloses a system and a method of kerosene switching of an active cooling subsonic combustion ramjet engine. The system comprises a main kerosene transport pipe, a supercritical kerosene pipe, a liquid kerosene pipe, a control system, a kerosene switching valve, a temperature sensor and a sonic nozzle flow meter. The sonic nozzle flow meter is arranged on the main kerosene transport pipe and an outlet of the sonic nozzle flow meter is connected with the supercritical kerosene pipe and the liquid kerosene pipe. The control system is connected with the temperature sensor and the kerosene switching valve. The kerosene switching valve is opened for enabling the supercritical kerosene pipe and the liquid kerosene pipe to be in the connected state when the control system detects that the kerosene temperature is in the supercritical state through the temperature sensor. According to the system and the method of the kerosene switching of the active cooling subsonic combustion ramjet engine, the subsonic combustion ramjet engine can be smoothly changed from the operating state of a liquid kerosene combustion state to a supercritical kerosene combustion state, so that the prior condition that the subsonic combustion ramjet engine can only use liquid kerosene combustion can be changed.

Owner:合肥中科重明科技有限公司

Stove

InactiveCN102313300ASolve combustion problemsEasy to useDomestic stoves or rangesLighting and heating apparatusCombustionEngineering

The invention discloses a stove, which comprises a hearth, wherein the hearth is arranged underground; a heat outlet of the hearth is located above the ground; a feeding port of the hearth is close to the ground; the lower part of the hearth is communicated with an ash chamber through a grate; and an air duct which is communicated above the ground is arranged in the ash chamber. The stove has the beneficial effect that compared with the prior art, the hearth of the stove is arranged underground and the feeding port is close to the ground so that when being added, fuel does not have to be lifted, is pushed into the feeding port and can enter the hearth directly merely through gravity; and moreover the air duct which is communicated above the ground is arranged in the ash chamber so that the normal combustion problem of the fuel of the underground hearth is solved and the normal use of the underground hearth is ensured. In such a way, crop straws and other low density combustibles can be conveniently used as the fuel in the stove and consequently the utilization ratio of the stove is greatly improved, the use of coal is reduced, environment is protected better, energy is saved, and the cost of processing the straws is reduced.

Owner:BORTALA MONGOLIA AUTONOMOUS PREFECTURE WANLIYUAN SCI & TECH DEV

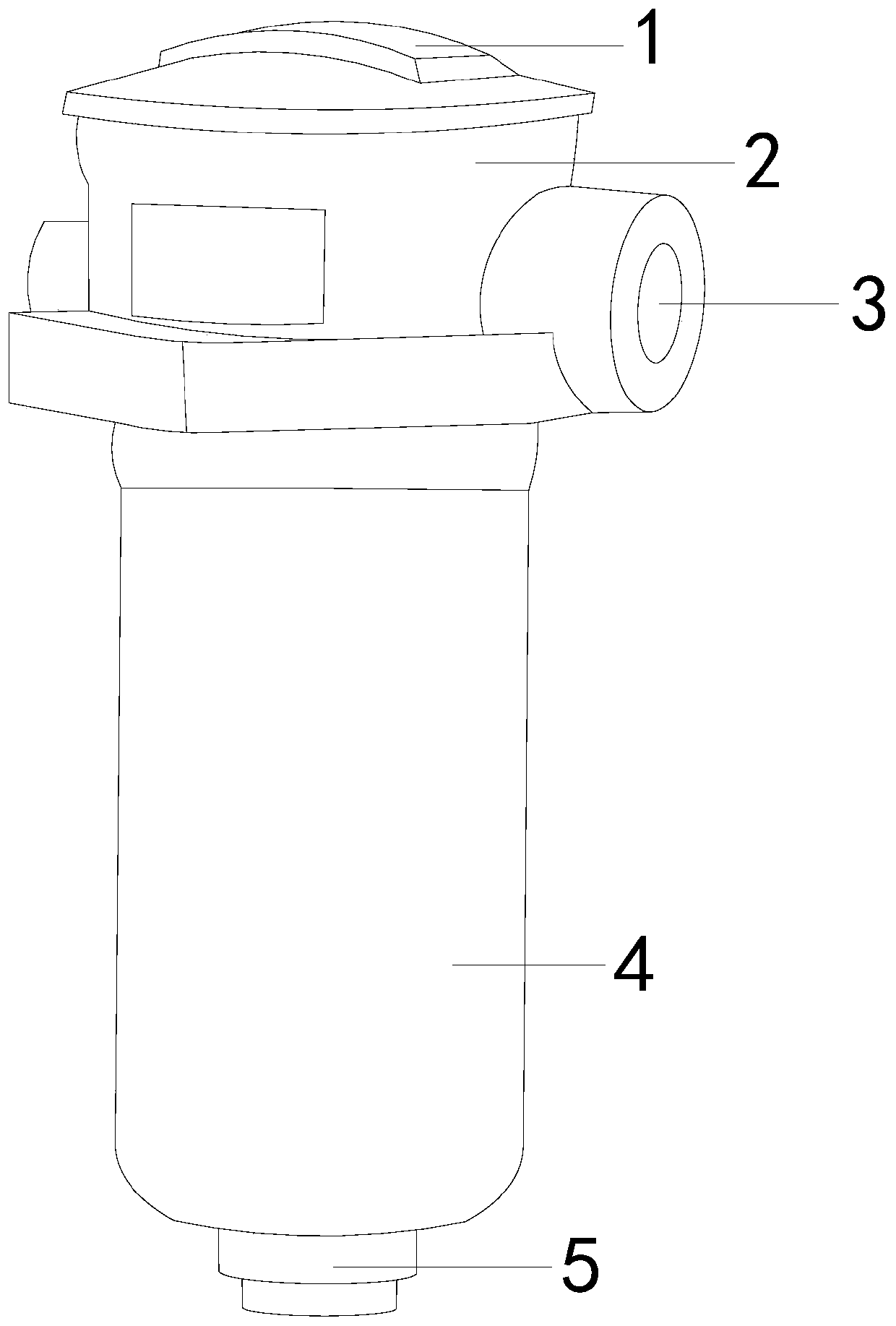

Oil-gas separation device for air compressor

ActiveCN110017280AExhaust oil content index is lowAvoid the problem of clogging leading to serious accidentsRotary/oscillating piston pump componentsLiquid fuel engine componentsSafety indexSuction force

The invention discloses an oil-gas separation device for an air compressor. The structure of the oil-gas separation device comprises a pressure control valve, an oil controller, a mist collecting mechanism, a device housing and an oil return pipe. The oil-gas separation device has the following beneficial effects: by developing the mist collecting mechanism, an oil guide device in the mist collecting mechanism is used for achieving four mechanisms, i.e. capturing, collecting, filtering and precipitating of oil; the unique blade structures of eagle's beak-shaped blades in the oil guide device can not only generate a strong suction force to suck oil mist diffused in the compressor to the surfaces of the eagle's beak-shaped blades, but also guide collected oil to drip downwards smoothly; mostoil mist is collected through the oil guide device, and subjected to two times of filtration through a precipitator and three times of absorption through a filter cartridge, so that the oil content index of exhaust in the compressor can be ensured to be reduced to a minimum and thus to reach a safety index; and therefore, the problems that when the compressor uses the filter cartridge only, the capacity of collecting oil mist is too low and that because the filter cartridge is not replaced timely after being used for a long time, blockage is caused to lead to a serious accident are avoided.

Owner:艾珍机械设备制造(上海)有限公司

Super lubricant of nano grade iron powder

The invention relates to a method for producing ultra-lubricant nanometer iron powder, wherein it comprises under -10 to -20Deg. C, high-speed cutting the iron powder, while the cutting times is 5700-5900n / min, to product nanometer iron powder, then high-frequency grinding the iron particles at 4500-5500n / min, selecting the iron power in ball shape and 35nm-60nm size, furnishing the surface. The inventive iron powder has high mechanical strength and stable suspension property, etc.

Owner:王惠民

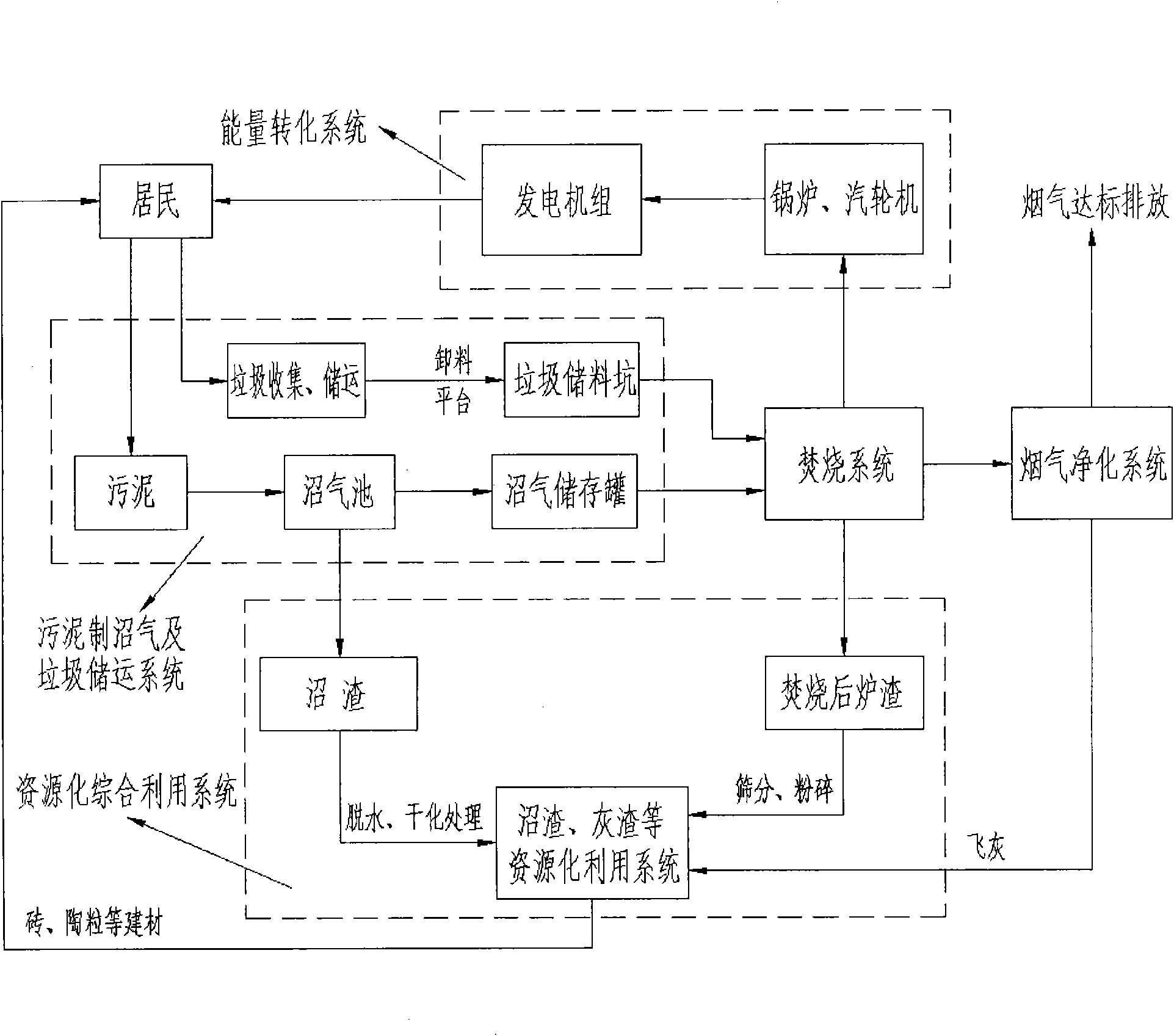

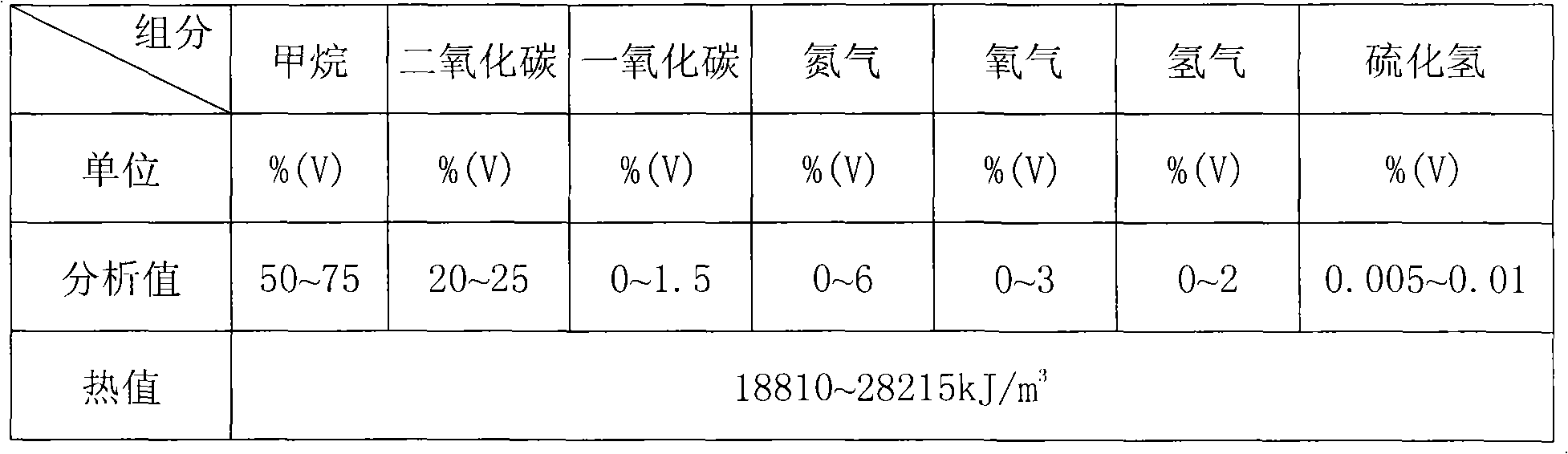

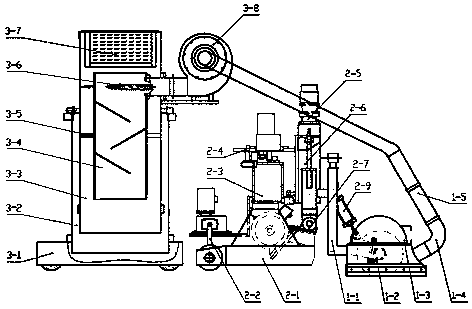

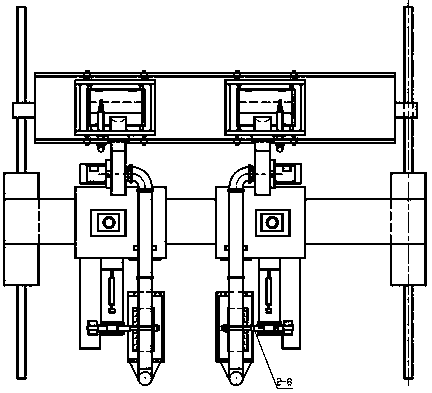

Electricity generated by mixing and burning garbage and methane prepared by using mud and comprehensive utilization method thereof

InactiveCN101575163ANo secondary pollutionImprove burnout rateSolid waste disposalWaste based fuelElectricityResource utilization

The invention discloses electricity generated by mixing and burning garbage and methane prepared by mud and a comprehensive utilization method thereof. In the invention, mud is mixed and assimilated to generate methane in a methane tank, and the methane is transferred to a burning furnace to be burnt together with garbage to generate heat energy which is converted into electric energy through a boiler, a steam turbine and a generator. The burning mixture ratio of transferred methane and household garbage is adjusted continuously according to different garbage characters. 50-500m of the methane is mixed with one ton of the garbage and sufficiently burnt with the same at 850-1300 DEG C in the burning furnace, the discharge of burning product reaches the standard, and biogas residues, clinker, and the like are comprehensively utilized. The invention also realizes the resource utilization and the complementary advantages of two wastes.

Owner:北京博朗环境工程技术股份有限公司

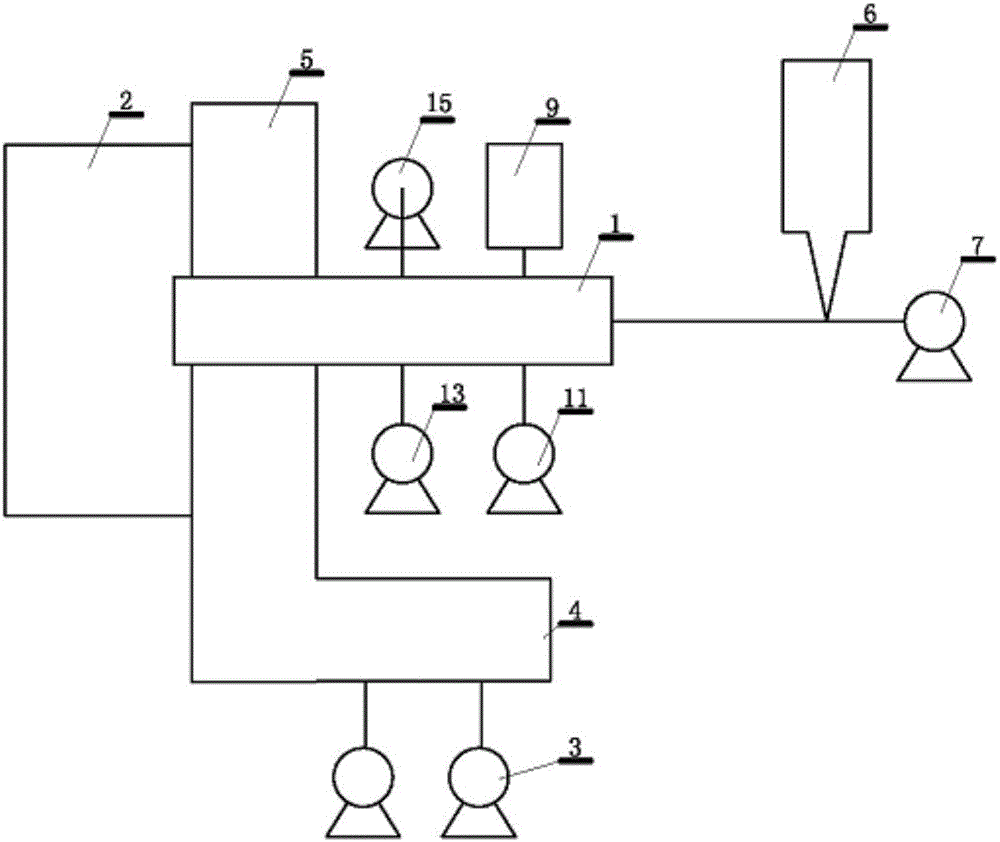

Polishing grinding water bath dedusting system

PendingCN108356681AEasy to collectEasy to captureGrinding carriagesPolishing machinesWater bathsCombustion

The invention discloses a polishing grinding water bath dedusting system. The polishing grinding water bath dedusting system comprises a polishing grinding device, a dust collection device and a waterbath dedusting device, wherein a lot of dust and sparks generated by a grinding head during the grinding processing process of an automatic grinding device are completely sealed through a drainage tube and the water bath dedusting device; a fireproof, high temperature-resistant and abrasion-resistant conveying device is designed to convey dust into an inner fire extinguishing cabinet through a centrifugal fan in the motion direction of dust and sparks; most high-temperature combustion flue gas and dust are mixed with water through a spiral anti-blocking high-pressure water injection device and a drainage technology, and a mixture is drained into a water bath dedusting tank; secondary filtration is utilized at the interior and the top of the water bath dedusting tank, and escaped flue gasis prevented from entering the periphery of equipment; and combustible dust and mixtures generated during the processing process are collected in a water bath absorption tank, and are automatically discharged regularly.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Superheated steam drying powder making type coal-fired power generation system

InactiveCN104373949AGuaranteed uptimeAchieve internal generationMachines/enginesIndirect carbon-dioxide mitigationCold airPulp and paper industry

The invention provides a superheated steam drying powder making type coal-fired power generation system which is used for driving a power generator to generate power after raw coal is burned. The coal-fired power generation system comprises a boiler unit and a turbine unit, wherein the boiler unit comprises a powder making sub system, a boiler main machine sub system, a wind and powder feeding sub system and a waste steam and water recycling sub system; the turbine unit comprises a water feeding pipe, a steam conveying pipe and a steam turbine. The powder making sub system comprises a steam powder generating and drying device, a steam powder separating device and a drying agent generating device. The drying agent generating device comprises a waste steam pumped steam heater and a waste steam smoke heater, wherein the waste steam pumped steam heater is used for preheating the waste steam through the condensation released heat generated by the steam pumped from the steam turbine to form the hot waste steam, and the waste steam smoke heater is used for further heating the hot waste steam through the smoke from a hearth to form the superheated steam serving as the drying agent. The waste steam and water recycling sub system comprises a waste steam and water recycling device for conducting condensation recycling on one part of the waste steam through the environmental cold air.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Device and method for monitoring and controlling residual carbon combustion during hot sintering mineral cooling process

ActiveCN109654892ASolve the problem that the combustion state cannot be judgedIntelligent elimination of secondary combustionCharge treatment typeIncreasing energy efficiencyCombustionResidual carbon

The invention relates to a device for monitoring and controlling residual carbon combustion during a hot sintering mineral cooling process. The device for monitoring and controlling residual carbon combustion during the hot sintering mineral cooling process comprises a vertical cooler, a waste heat boiler, a dust collector and a circulating fan. According to an exhaust gas flowing direction, a high-temperature gas outlet located in the upper part of a tower wall of the vertical cooler is connected to an air inlet of the waste heat boiler through a first pipeline; a second pipeline drawn from an air outlet of the waste heat boiler is connected to a low-temperature gas inlet located in the lower part of the tower wall of the vertical cooler through the dust collector and the circulating fan;and the low-temperature gas inlet communicates with an air supply device on the bottom part of a tower body of the vertical cooler. The device for monitoring and controlling residual carbon combustion during the hot sintering mineral cooling process is characterized in that a first temperature measurement device and a first flow detection device are arranged on the low-temperature gas inlet of the vertical cooler, and a second temperature measurement device and a second flow detection device are arranged on the high-temperature gas inlet of the vertical cooler. According to the device for monitoring and controlling residual carbon combustion during the hot sintering mineral cooling process provided by the invention, whether secondary combustion occurs on residual carbon during the hot sintering mineral cooling process or not can be accurately judged, and meanwhile, secondary combustion on the residual carbon is effectively controlled through a nitrogen spraying device.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

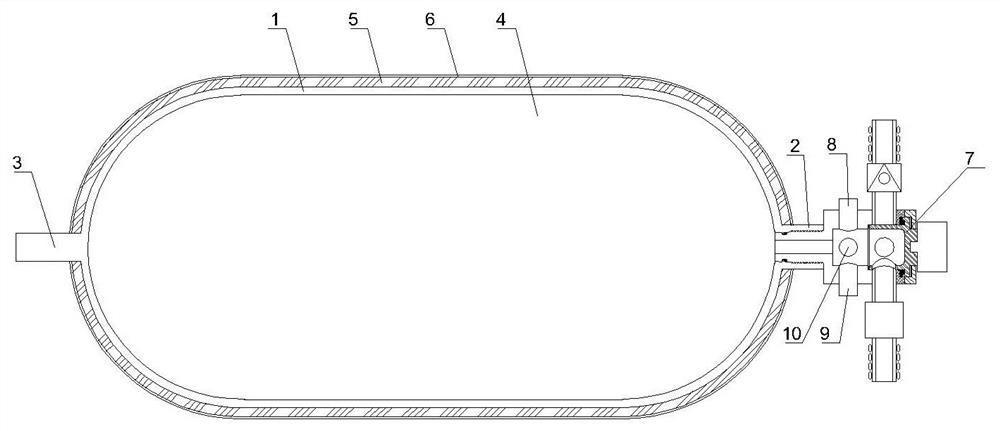

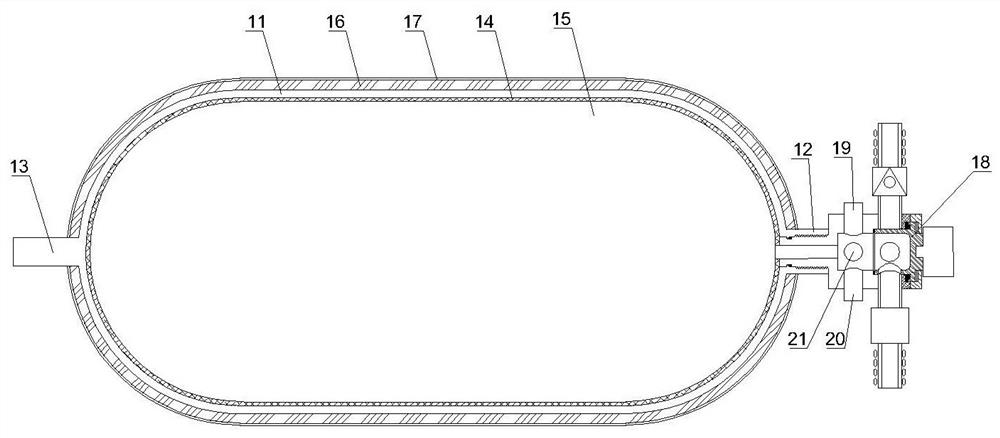

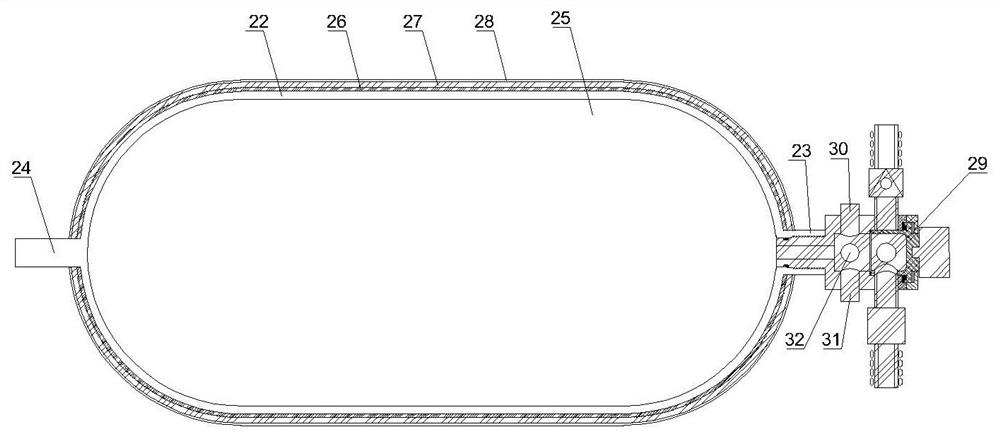

Hydrogen storage cylinder externally wrapped with fireproof vibration-damping thermal insulation material

PendingCN113124307AImprove securityWith heat preservation functionVessel manufacturingVessel geometry/arrangement/sizeThermal insulationProtection layer

The invention discloses a hydrogen storage cylinder externally wrapped with a fireproof vibration-damping thermal insulation material. The hydrogen storage cylinder is externally wrapped with the fireproof vibration-damping heat-insulating material, and the fireproof vibration-damping heat-insulating material is externally wrapped with the protective layer.

Owner:王广武

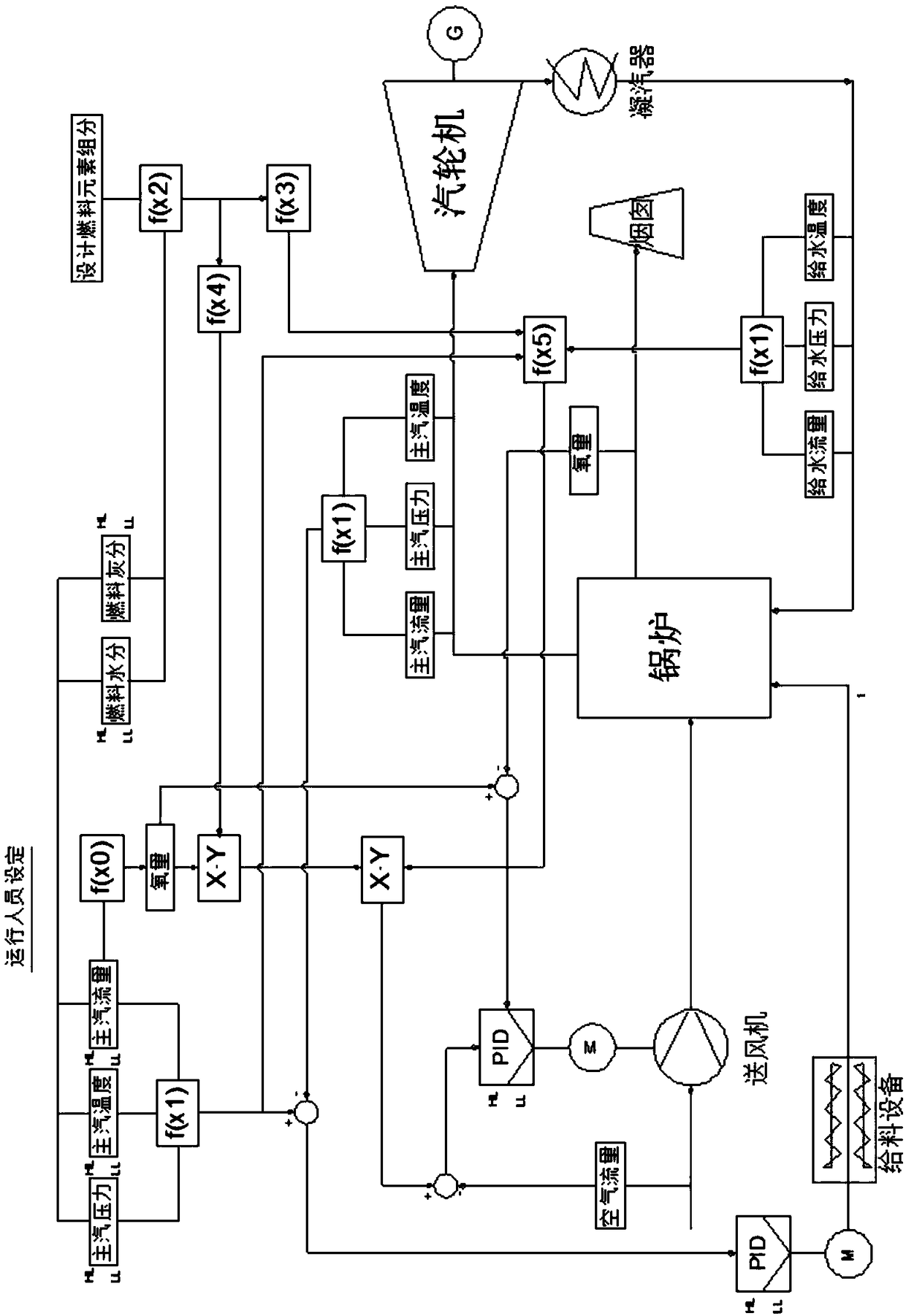

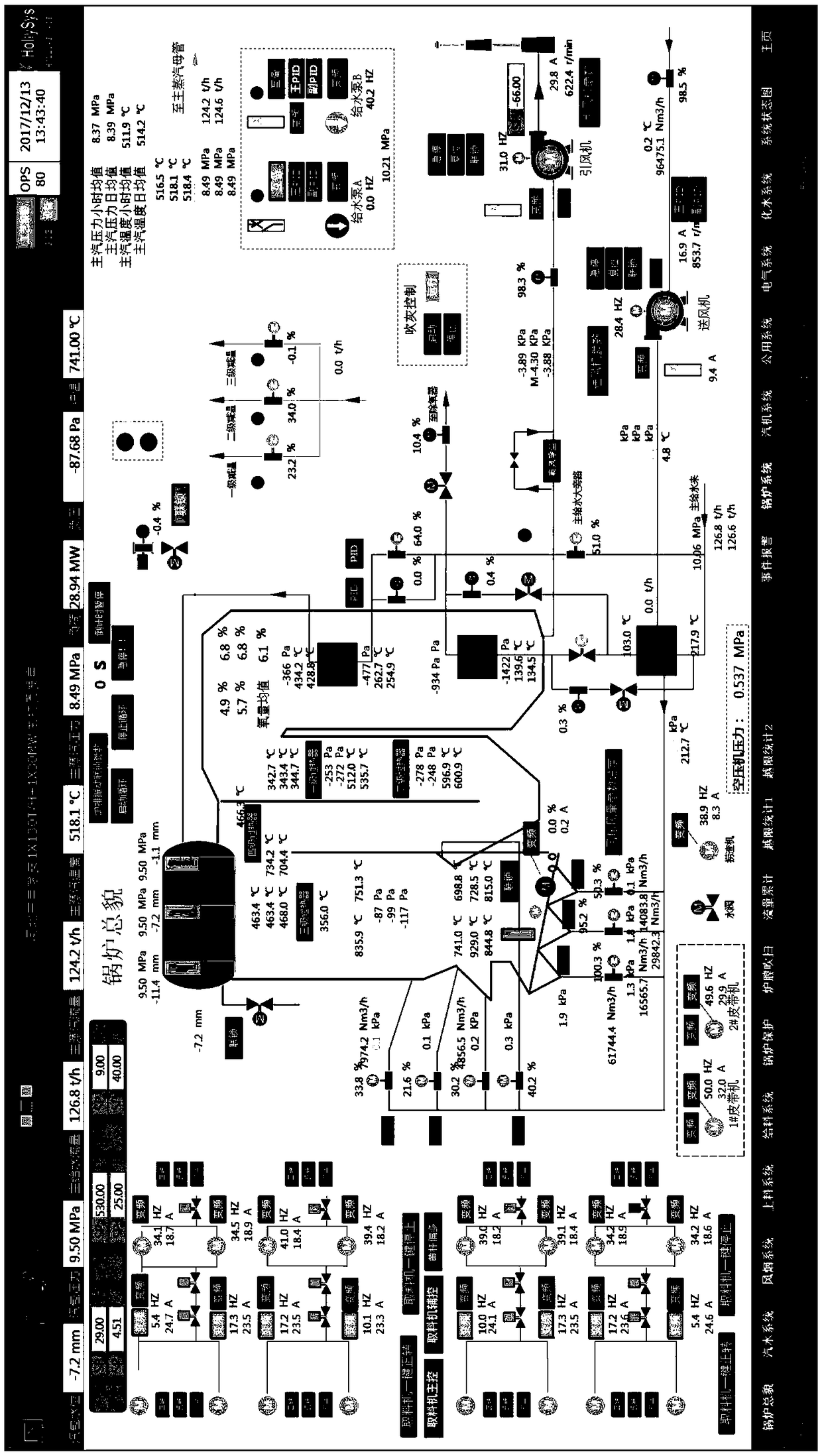

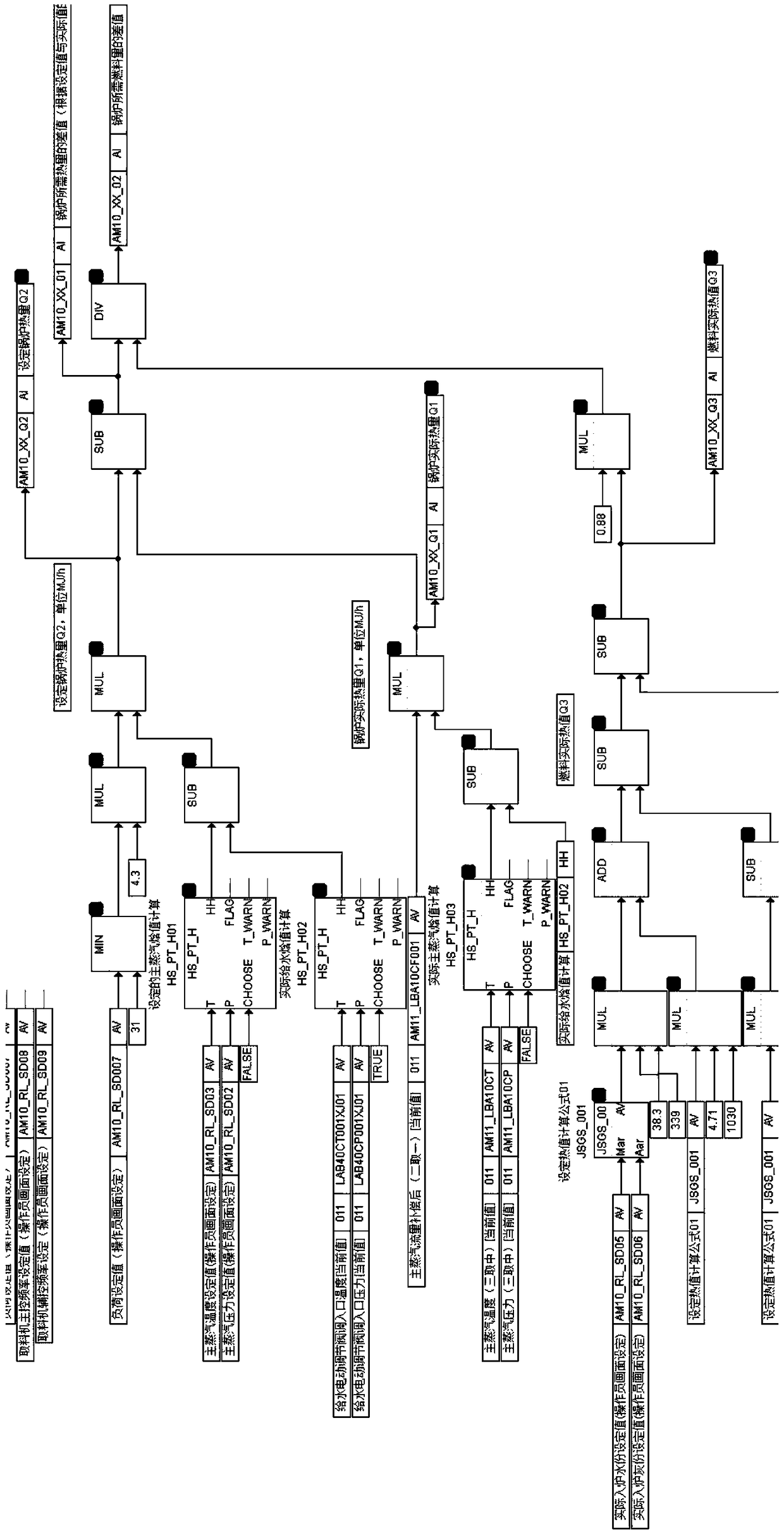

Automatic control strategy and method for load of biomass water-cooled vibrating grate boiler

ActiveCN108954285ASolve combustion problemsSolve the problem that there is a certain hysteresis in feedingFuel supply regulationBoiler controlHysteresisAir volume

The invention relates to an automatic control strategy and method for the load of a biomass water-cooled vibrating grate boiler. The difference between the set value and actual value of a main steam enthalpy value is used as a load instruction signal of a feeding controller to adjust and control the rotation speed of a variable-frequency feeding device; according to the moisture numerical value and the ash content numerical value of fed fuel, on the basis of designed fuel elementary compositions, the actual elementary compositions of the actually fed fuel meeting demands is obtained through fitting, the difference between the air supply volume of a set load and the air supply volume of the actual load is worked out and used as the main instruction signal for adjusting the rotation speed ofa variable-frequency air feeder. By the adoption of the automatic control strategy and method for the load of the biomass water-cooled vibrating grate boiler, the features of biomass fuel and a water-cooled vibrating grate boiler device are taken into full consideration, the main steam enthalpy value is used as a load instruction signal to achieve accurate and timely adjustment, the fuel diversity problem is solved through the fitting algorithm of the biomass fuel composition elements, the problem that certain hysteresis exists between burning and feeding in the water-cooled vibrating grate boiler is solved through 'interval air-material ratio', and the automatic control strategy and method are the scientific and effective control strategy and method.

Owner:中电行唐生物质能热电有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com