Oil-gas separation device for air compressor

A technology for air compressors and separation devices, which is applied to the components of pumping devices for elastic fluids, mechanical equipment, machines/engines, etc., and can solve problems such as explosions, combustion of oil-gas separation devices, and blockage of oil-gas separation cores. Avoid collecting effects with too low strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

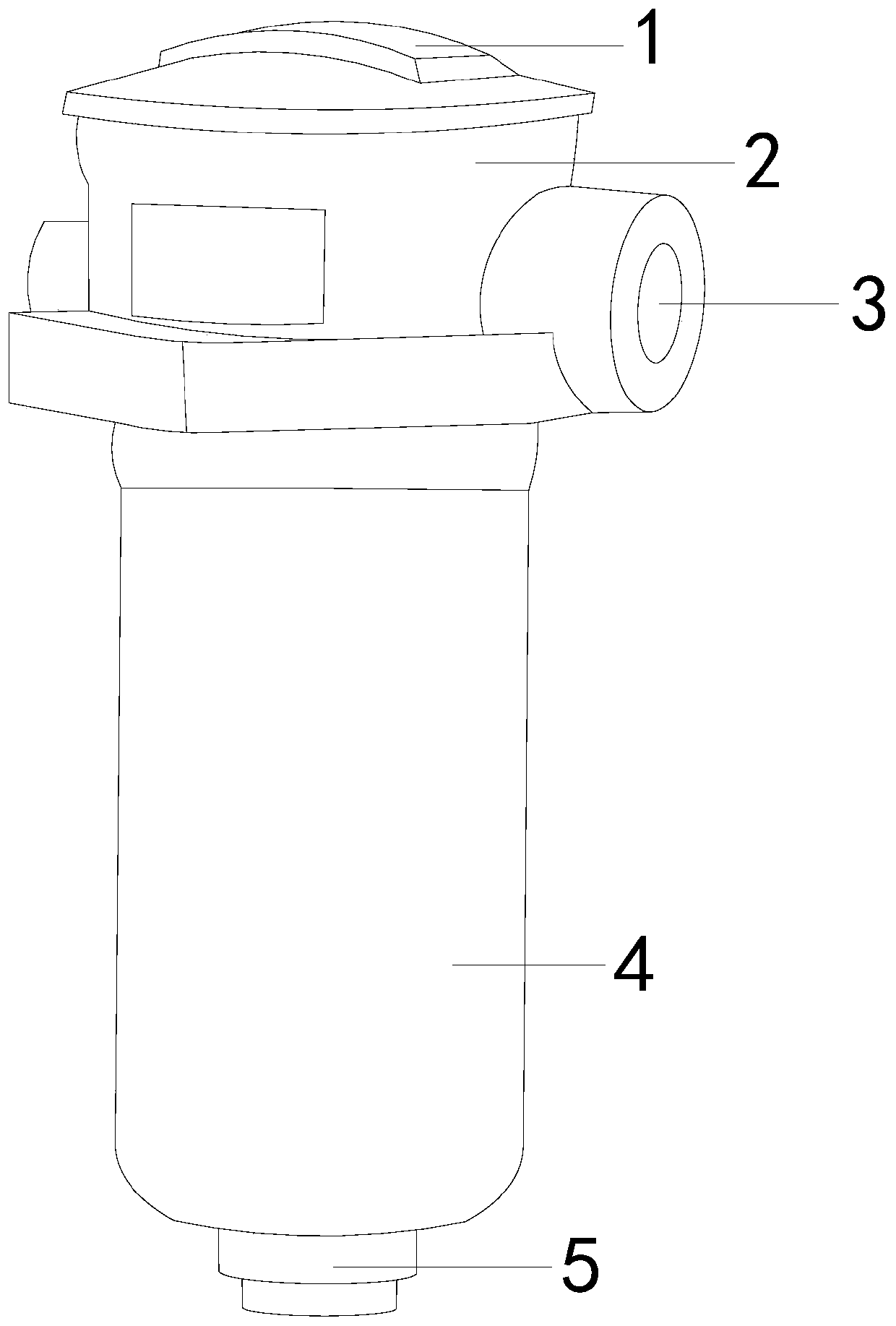

[0020] see figure 1 , the present invention provides an oil-gas separation device for an air compressor, the structure of which includes: a pressure control valve 1, an oil controller 2, a mist collecting mechanism 3, a device housing 4, and an oil return pipe 5. The pressure control valve 1 is connected to The oil controller 2, the oil controller 2 is connected with the mist collecting mechanism 3, the outer layer of the mist collecting mechanism 3 is sleeved with the device casing 4, and the bottom of the device casing 4 is connected to the oil return pipe 5, when the device starts to separate the oil and gas, the collecting The mist mechanism 3 is running to capture and collect the oil mist in the compressor. The pressure control valve 1 and the oil controller 2 are in the monitoring state at any time, and the mist collection mechanism 3 is continuously monitored to avoid overloading of the oil index of the device and over stressed.

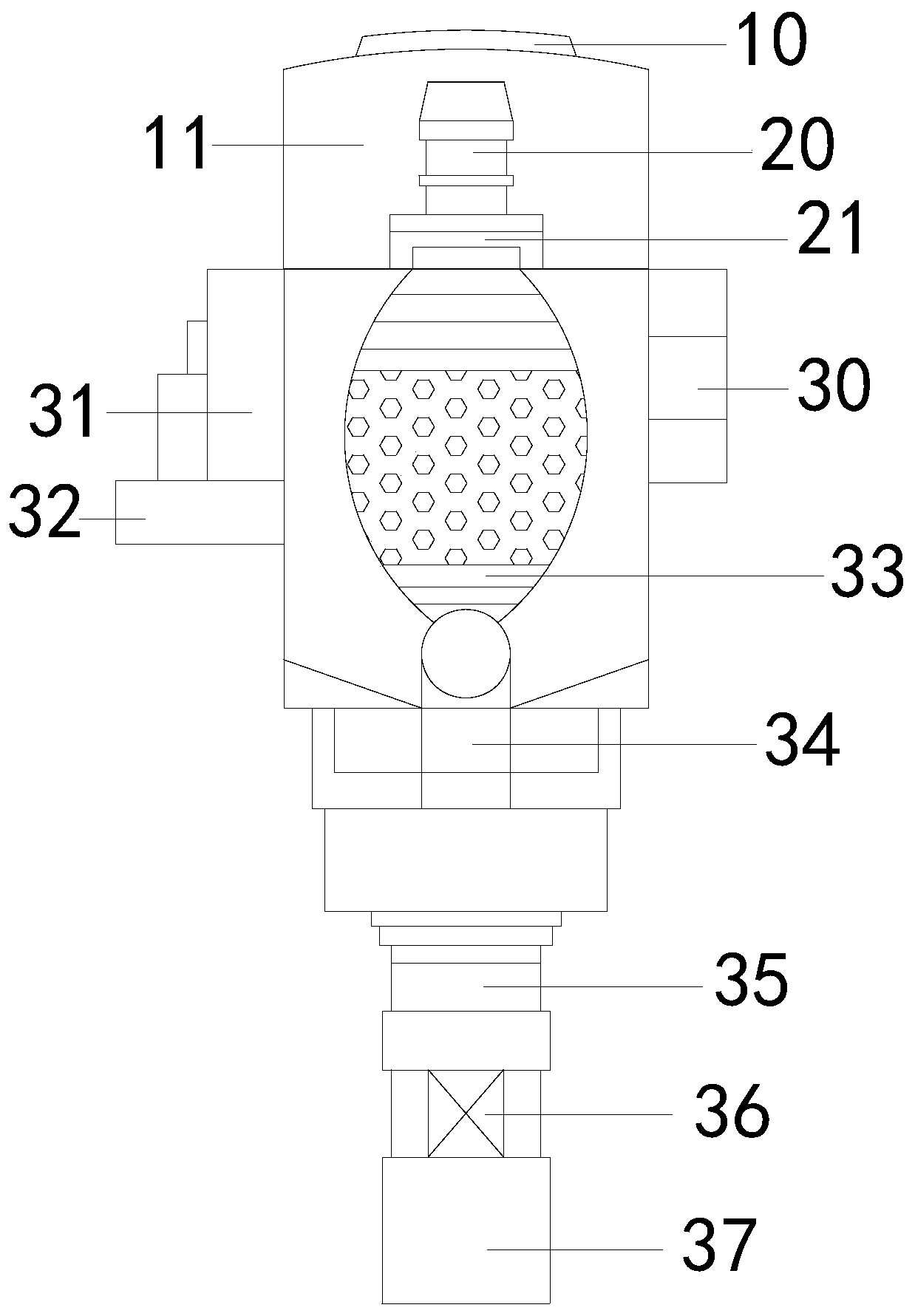

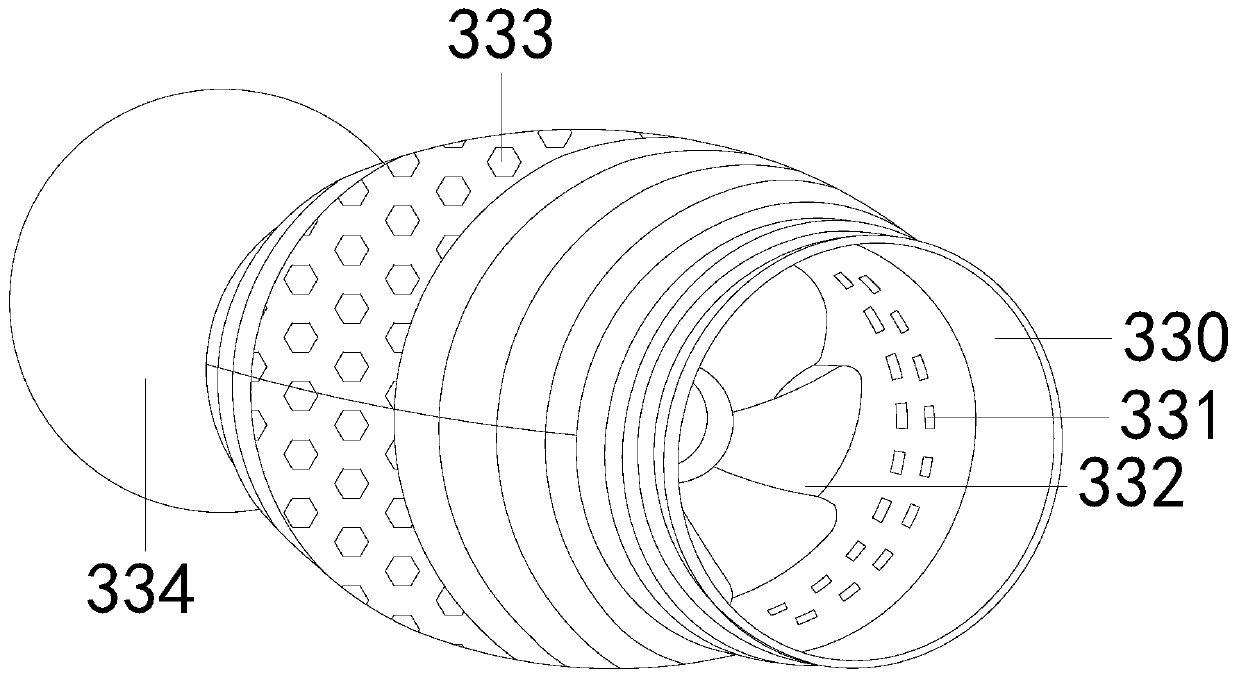

[0021] see figure 2 , Figure 5 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com