Process method for recycling rubber by utilizing light energy

A technology for recycling rubber and process methods, which is applied in the field of rubber recycling using light energy, which can solve the problems of complex formula, unfavorable energy saving and environmental protection, and long time, and achieve the effects of simple process flow, reduced labor expenditure, and high safety index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The preparation of embodiment 1 rubber powder

[0028] At normal temperature, the waste tire film is cut and rolled by mechanical shear force and finally pulverized into powder. The rubber powder of the present invention is prepared through the following steps:

[0029] (1) Use a rubber breaker to break the waste tire film into small pieces about 5 cm square.

[0030] (2) Use a coarse crusher to break small pieces of 5 cm square into coarse rubber particles with a particle size of 2 cm. Finally, use a magnetic separator to separate impurities such as steel wires in these coarse rubber particles, and use a wind separator to remove those useless fibers.

[0031] (3) Send the above-mentioned coarse rubber particles from which steel wires and fibers have been filtered out into a rubber fine crusher, and further grind, screen and separate to obtain 50-60 mesh rubber powder.

Embodiment 2

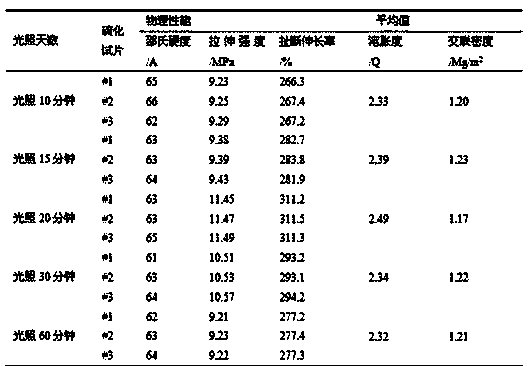

[0033] Stir and mix 100 parts of rubber powder and 15 parts of nano-zinc oxide with a high-speed plasticizing reaction unit. First, adjust the speed of the reaction unit to 1000 rpm. No need for heating process), stop stirring, put the material into the cooling mixer, the speed is 35 rpm, and the temperature is about 30°C for discharging. Put the stirred material into the mixer, and irradiate the material with ultraviolet light for different durations. The ultraviolet lamp used is a 3KW high-pressure mercury lamp, and the ultraviolet wavelength is 365nm.

[0034] Adjust the roller distance of the open mill to the minimum, put in the rubber powder, and after about 7-8 minutes of rolling, the rubber powder is no longer loose and forms a thin sheet, then, increase the roller distance of the open mill, and put the pressed Thin slices are put in, and thick slices are formed after pressing 10 times to obtain reclaimed rubber.

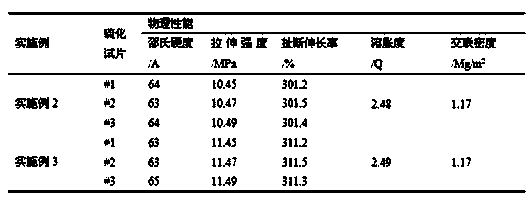

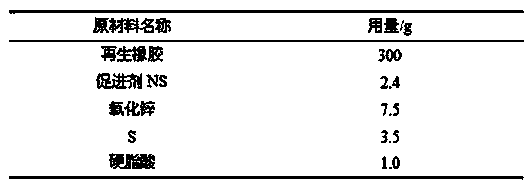

[0035] In order to test the physical properties of th...

Embodiment 3

[0042] Use a high-speed plasticizing reaction unit to mix 100 parts of rubber powder and 15 parts of nano-zinc oxide evenly. First, adjust the speed of the reaction unit to 1000 rpm. No heating process), stop stirring, put the material into the cooling unit, the speed is 35 rpm, and the temperature is about 30°C for discharging. Put the stirred material into the mixer, and irradiate the material with ultraviolet light for different durations. The ultraviolet lamp used is a 3KW high-pressure mercury lamp, and the ultraviolet wavelength is 365nm.

[0043] Adjust the rotation speed of the main engine of the twin-screw extruder to 220 rpm, and the feed rotation speed to 15 rpm. There are 7 heating and cooling zones in the twin-screw extruder, and the temperatures are 55°C—68°C—76 ℃—75°C—78°C—75°C—41°C, the temperature in each area is not higher than 100°C, and the normal temperature and pressure production state is realized.

[0044] After the rubber powder came out of the twin-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com