Patents

Literature

580results about "Extractive distillation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for Preparing Flavorful and Aromatic Compounds

InactiveUS20100037903A1Add flavorIncrease aromaTobacco treatmentSolid sorbent liquid separationMaillard reactionPyrazine

The invention provides a method of preparing a purified, pyrazine-containing aqueous composition by mixing a reducing sugar, a base, and an amino acid in water to produce a mixture; heating the mixture for a time and under conditions conducive to Maillard reactions such that a flavorful and aromatic aqueous solution is formed, the aqueous solution comprising a plurality of pyrazines and a first 4-methylimidazole concentration; distilling the aqueous solution to produce an aqueous distillate comprising a plurality of pyrazines and having a second 4-methylimidazole concentration lower than the first 4-methylimidazole concentration; and collecting the aqueous distillate. The invention also includes flavorful and aromatic aqueous compositions formed by this inventive method, as well as tobacco products (e.g., smokable materials, smoking articles, and smokeless tobacco) incorporating the flavorful and aromatic composition.

Owner:R J REYNOLDS TOBACCO COMPANY

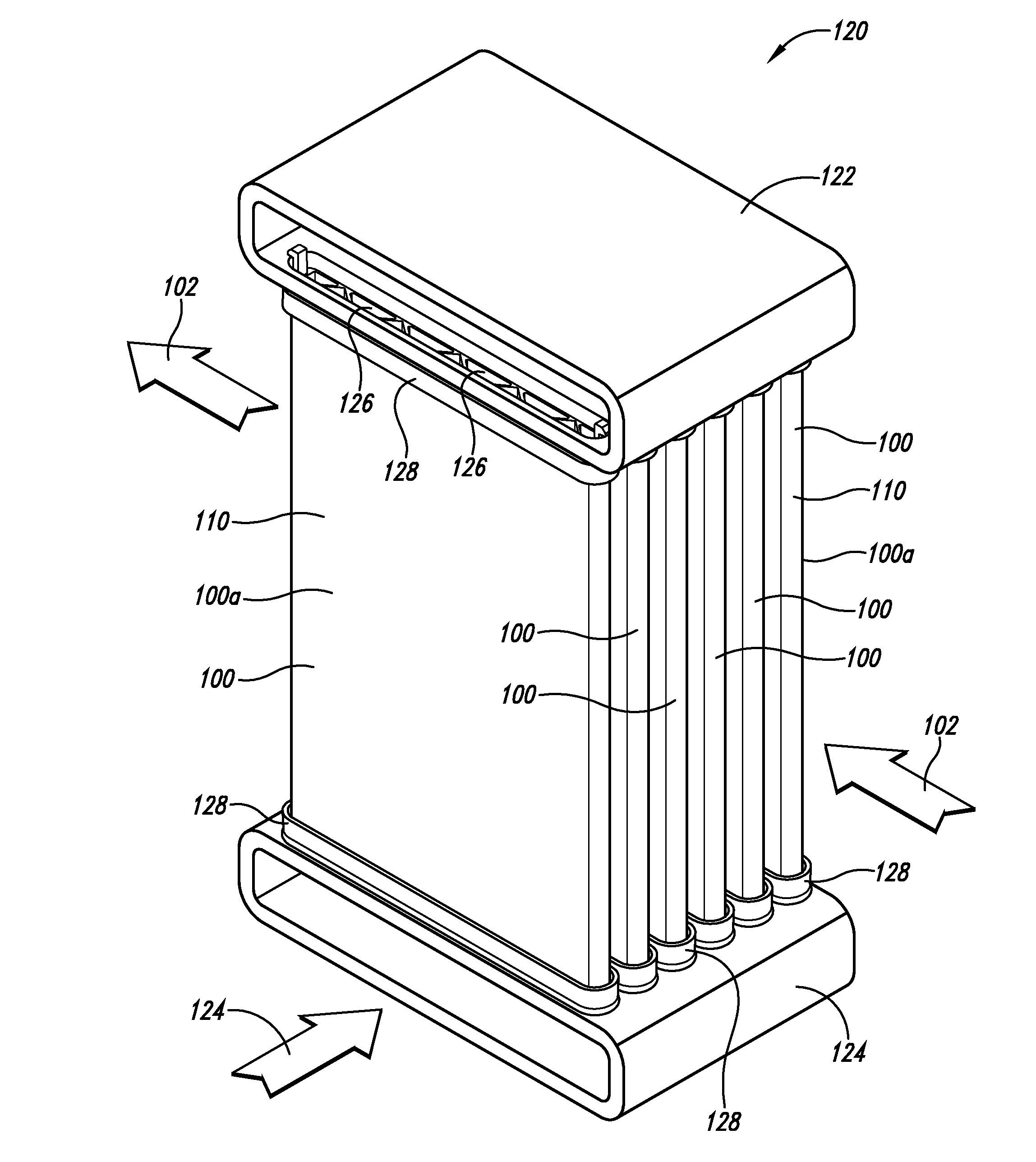

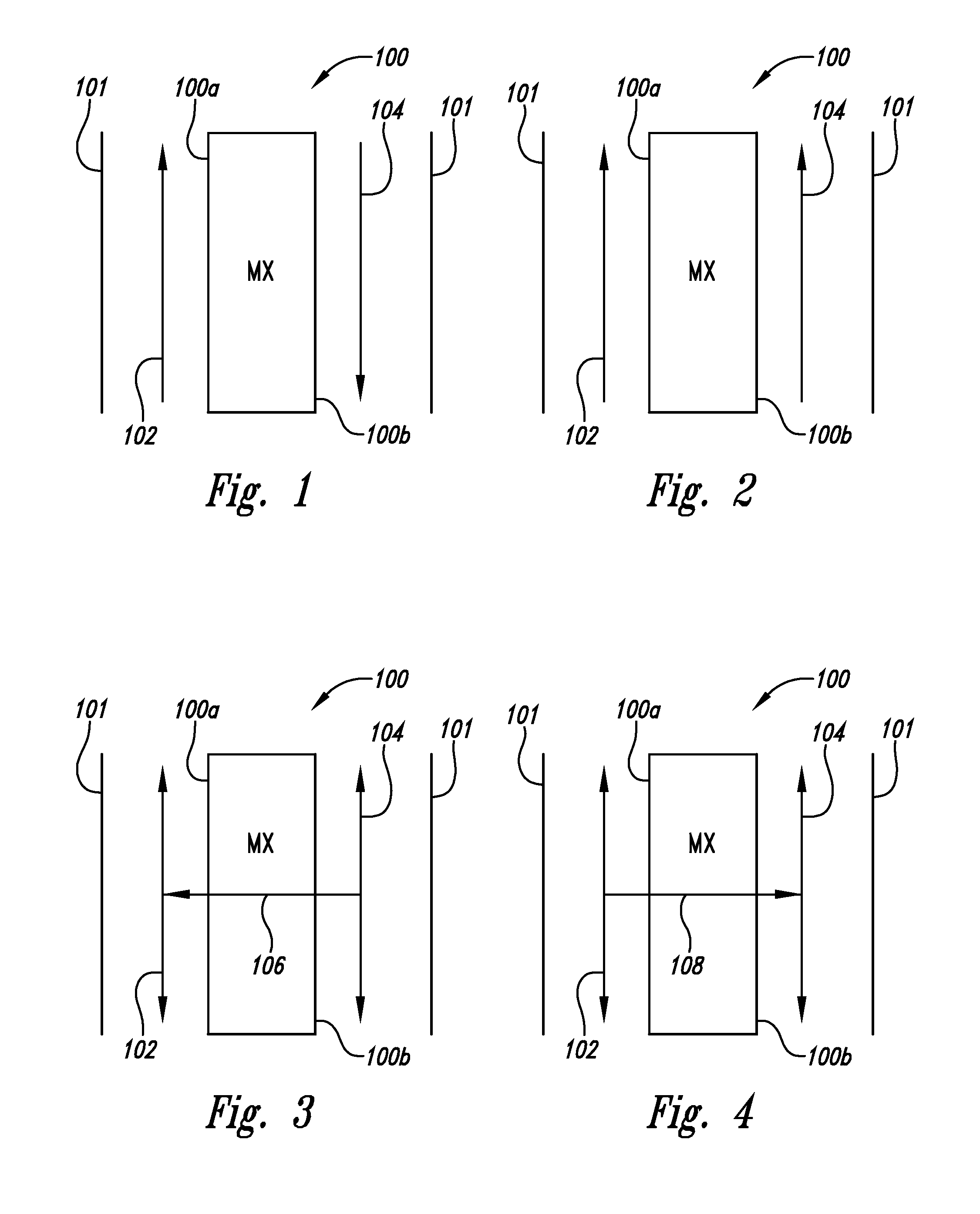

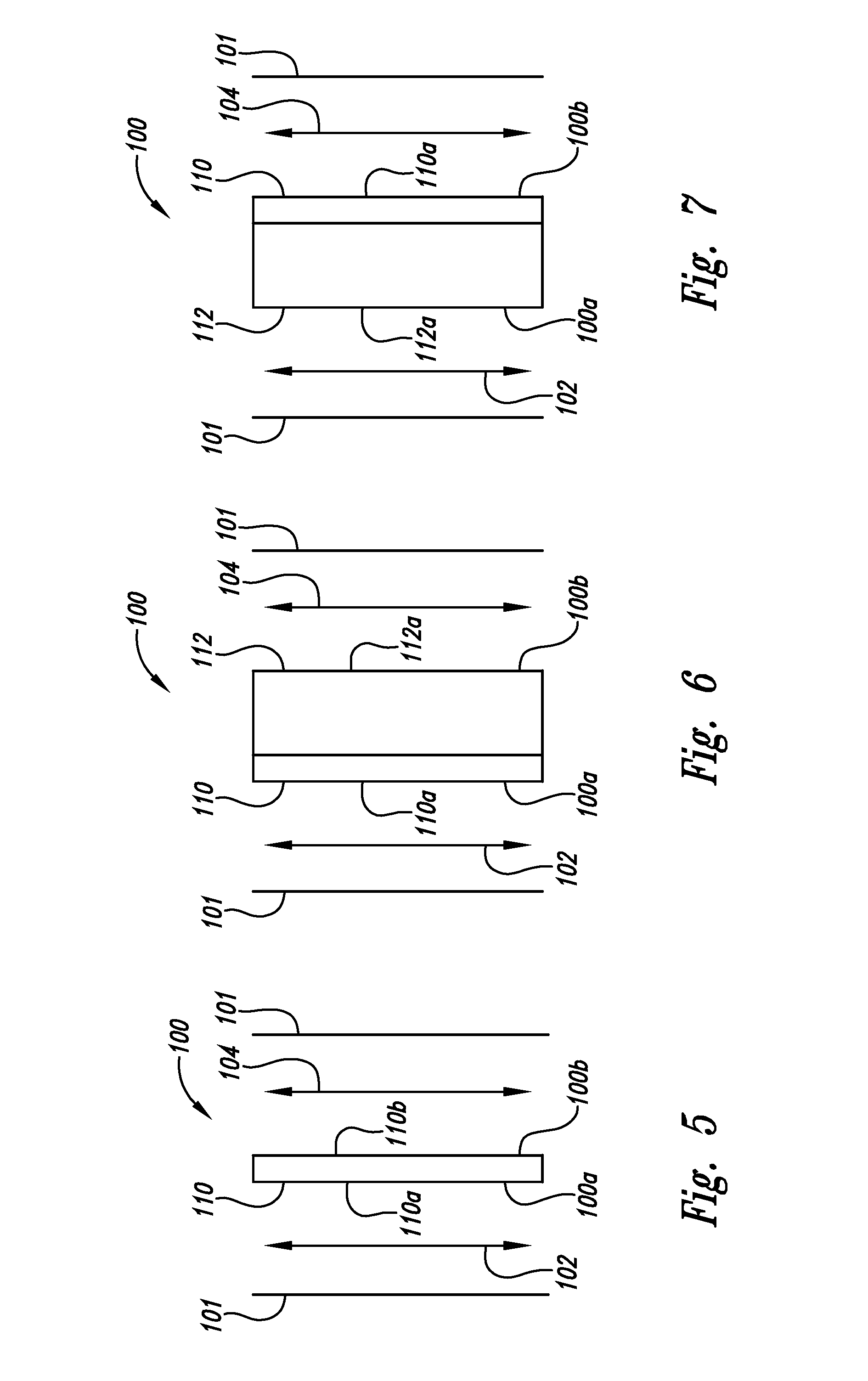

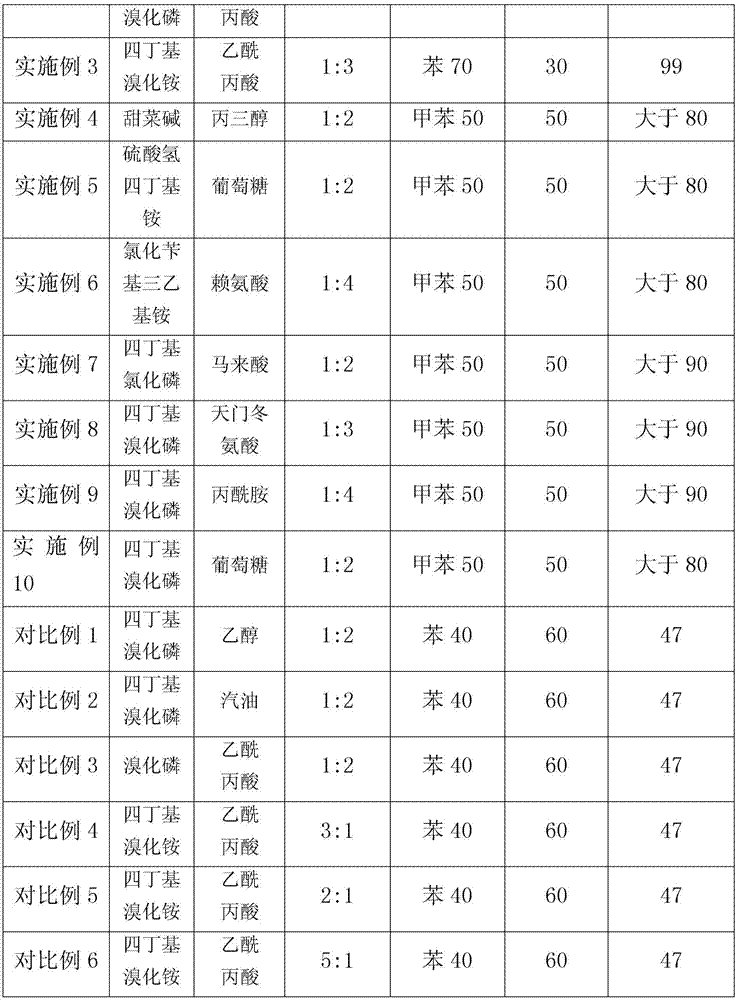

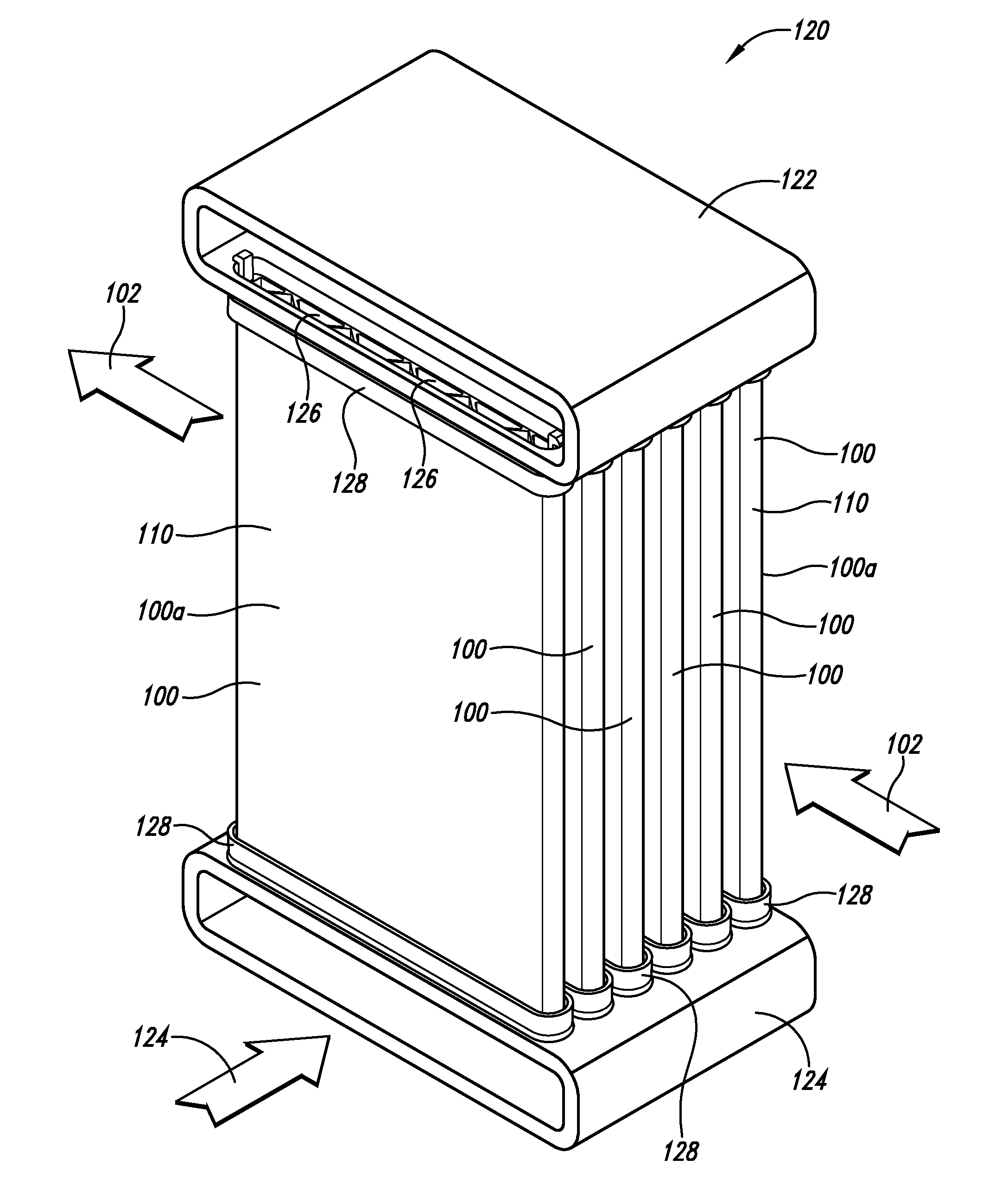

Multi-phase selective mass transfer through a membrane

Disclosed herein are embodiments relating to particular systems comprising a selective transfer membrane that can be utilized in material separation. In certain embodiments, the membrane assembly comprises part of a desalination, distillation, liquid purification, and / or heating and cooling system. Other particular embodiments allow for a high rate of thermal capture by way of the system utilizing a selective transfer membrane. Certain preferred embodiments include a selective transfer membrane comprising an ionomeric polymer that is permeable to high dipole materials.

Owner:TANGREDI PATRICIA

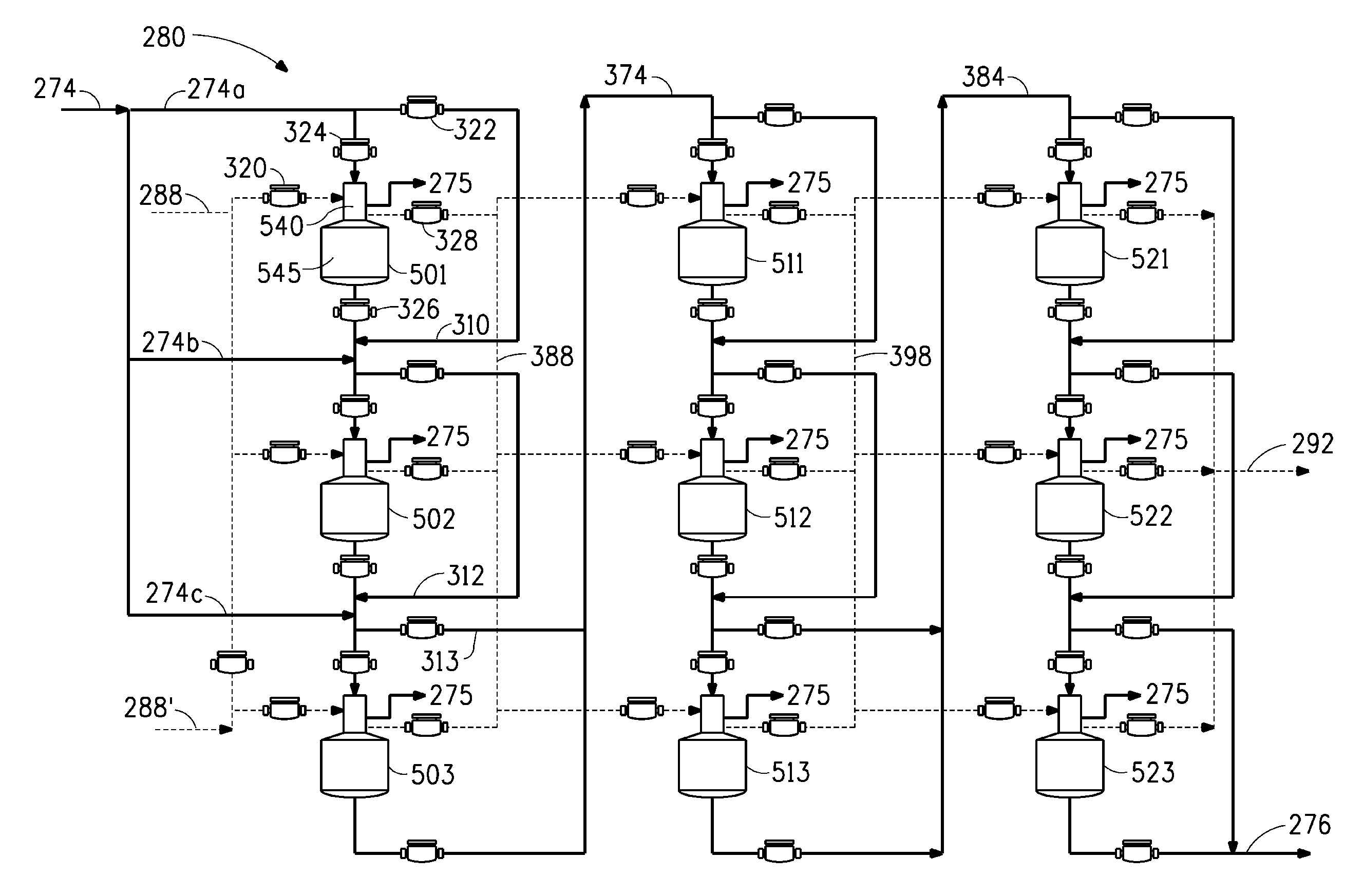

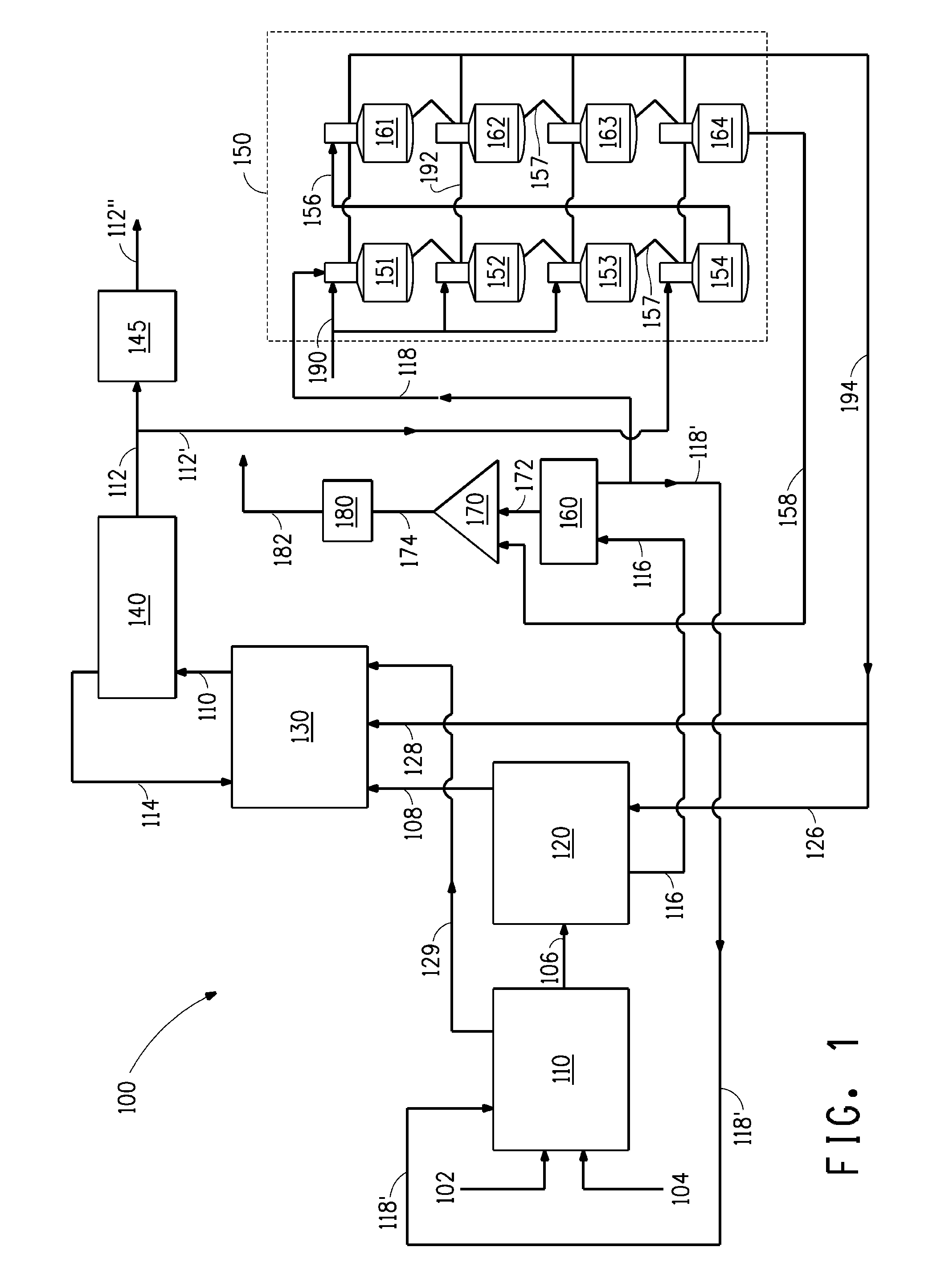

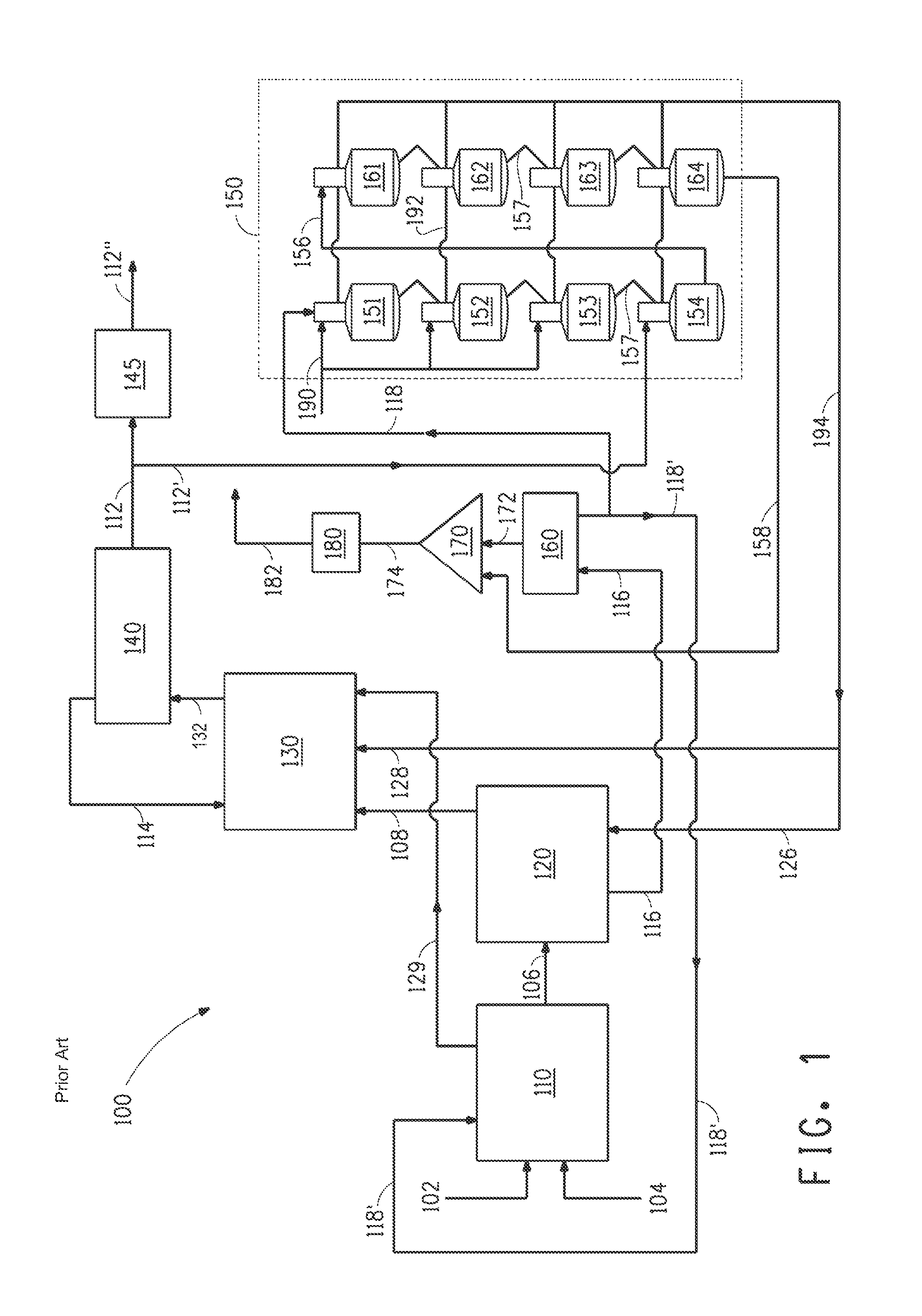

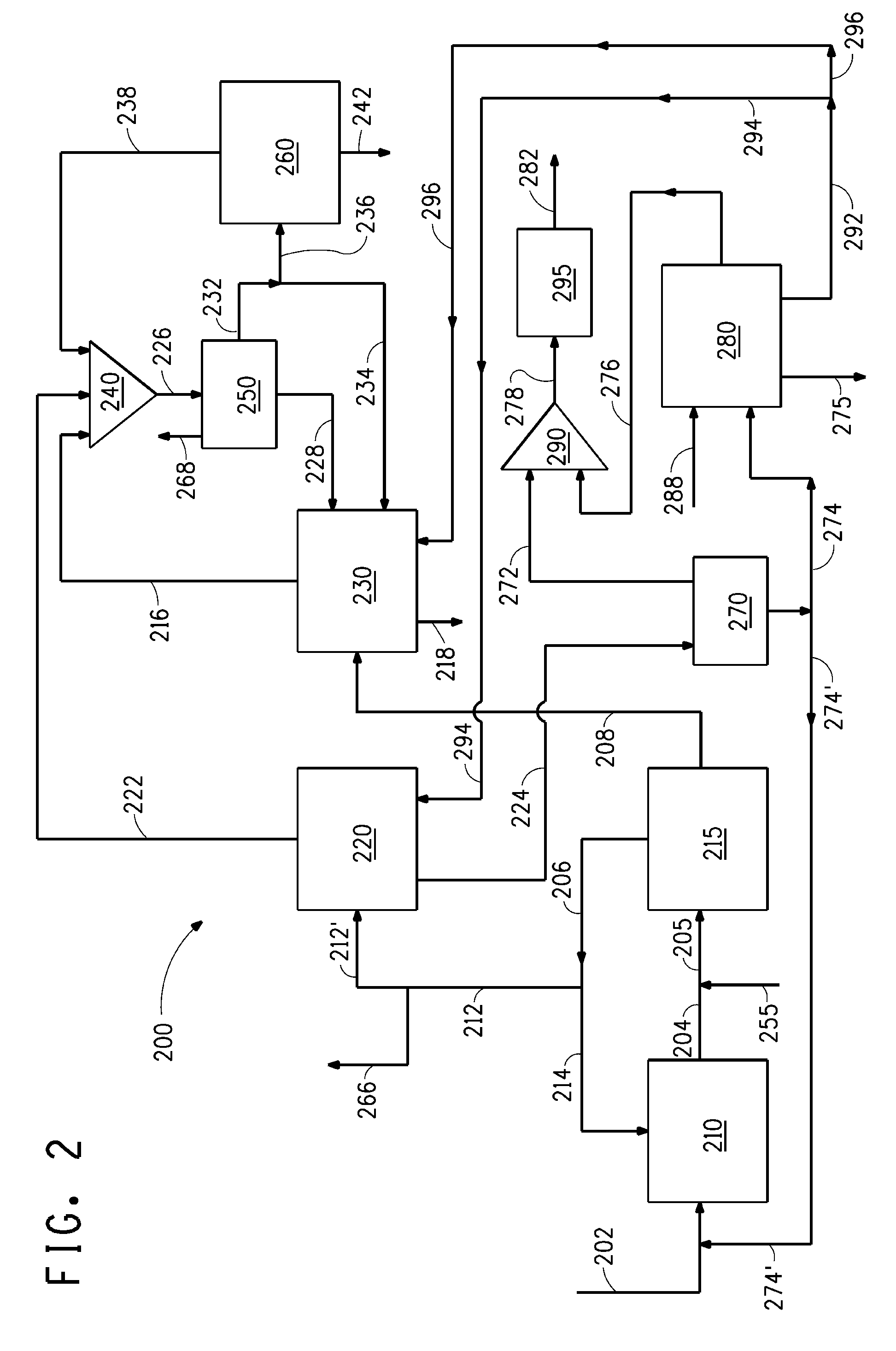

Systems and methods for alcohol recovery and concentration of stillage by-products

ActiveUS20110315541A1Efficient use ofHydrocarbon purification/separationHydroxy compound preparationAlcoholDistillation

Systems and methods for separating an alcohol, and in particular butanol, from a fermented feed and concentrating thin stillage into syrup includes operation of one or more alcohol recovery distillation columns using the heat supplied by steam generated from concentration of the thin stillage in a multi-train, multi-effect evaporation system.

Owner:GEVO INC

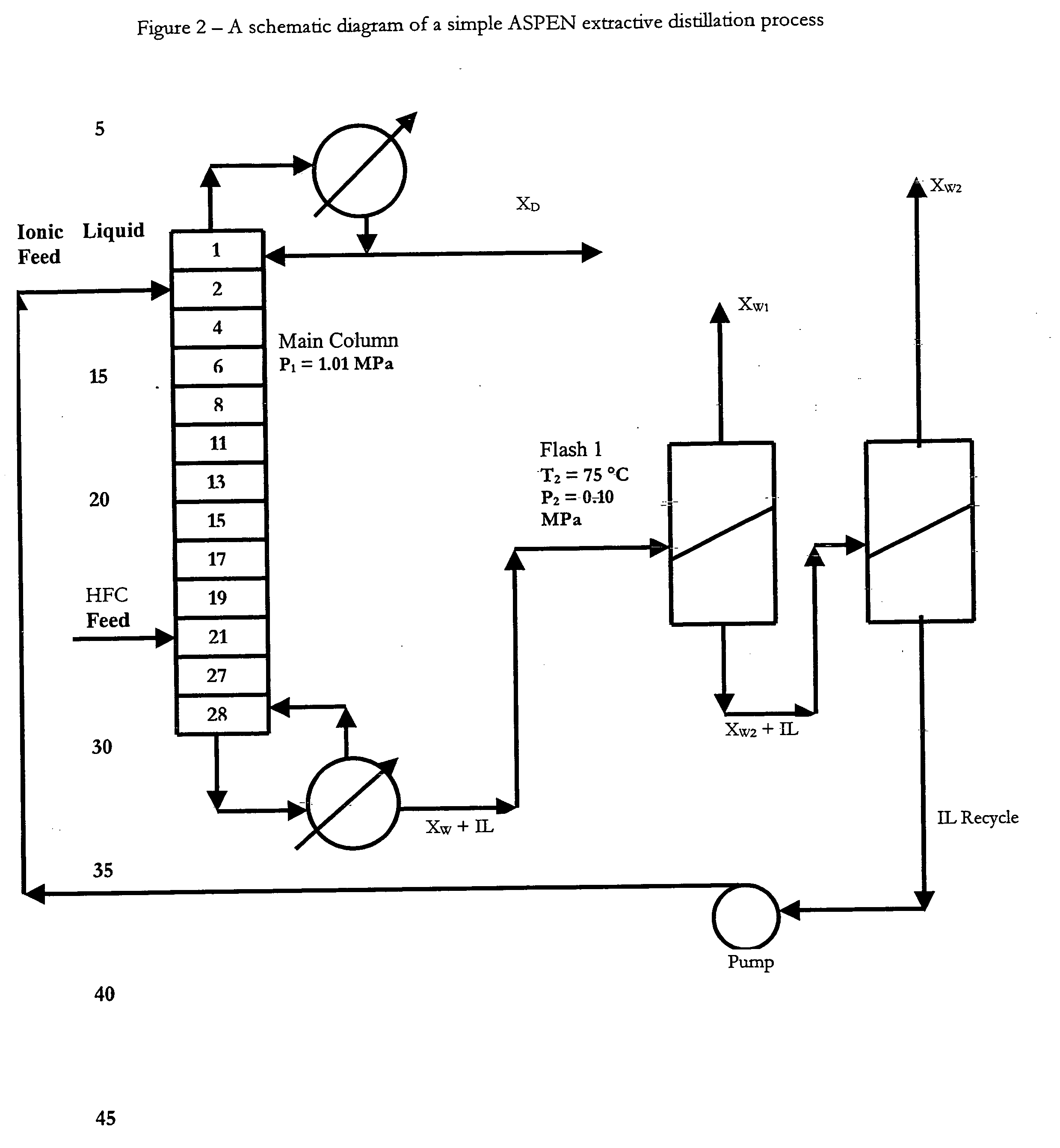

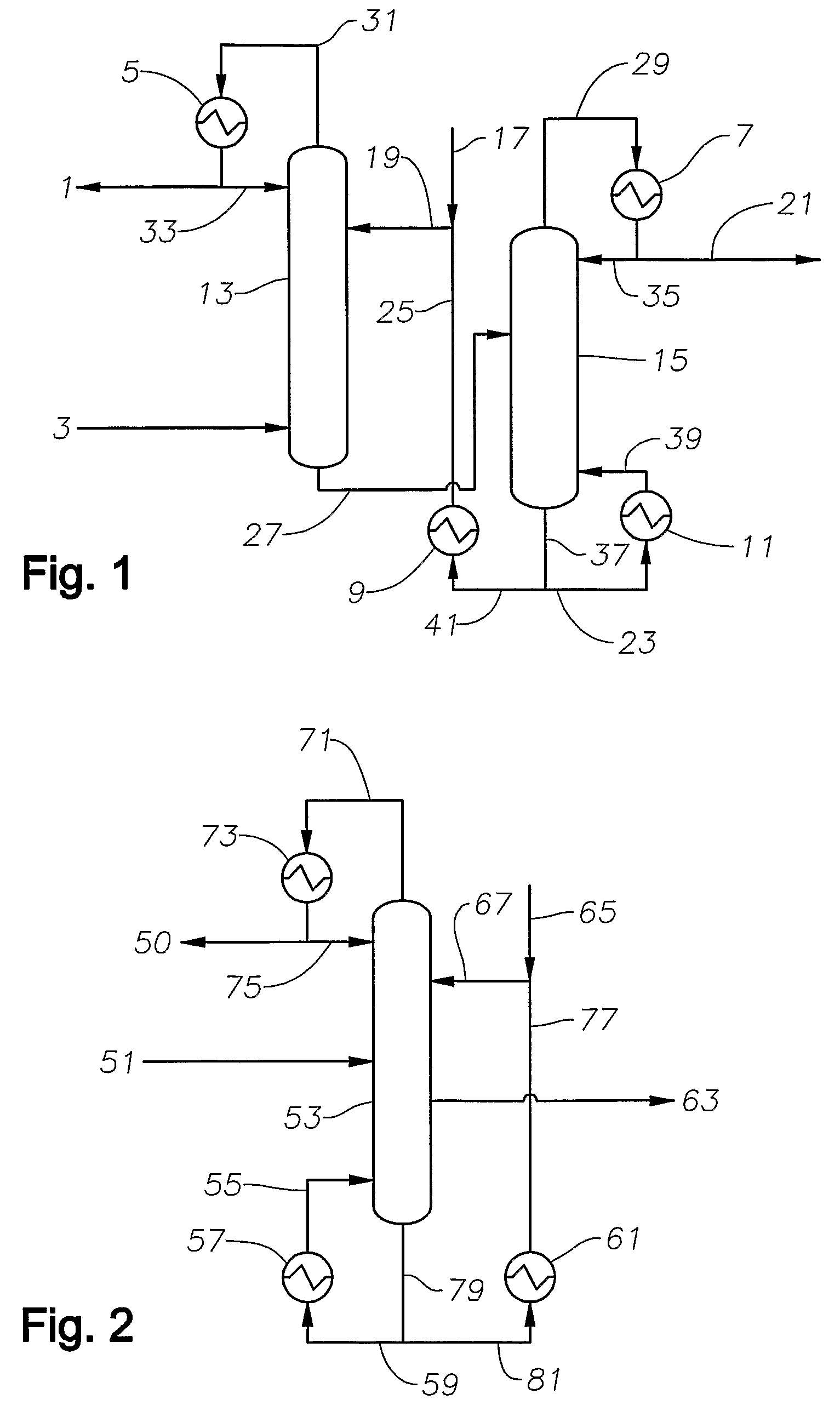

Utilizing ionic liquids for hydrofluorocarbon separation

InactiveUS20070131535A1Organic compounds purification/separation/stabilisationGroup 5/15 element organic compoundsPhysical chemistryOrganic chemistry

The present invention relates to a process for separating close-boiling and azeotropic components of mixtures, wherein said mixtures comprise at least one hydrofluorocarbon compound, using at least one ionic liquid.

Owner:THE CHEMOURS CO FC LLC

Propylene oxide purification

A mixture of propylene oxide and methanol is separated by liquid / liquid extraction using water and a hydrocarbon such as n-octane as extractive solvents.

Owner:LYONDELL CHEM TECH LP

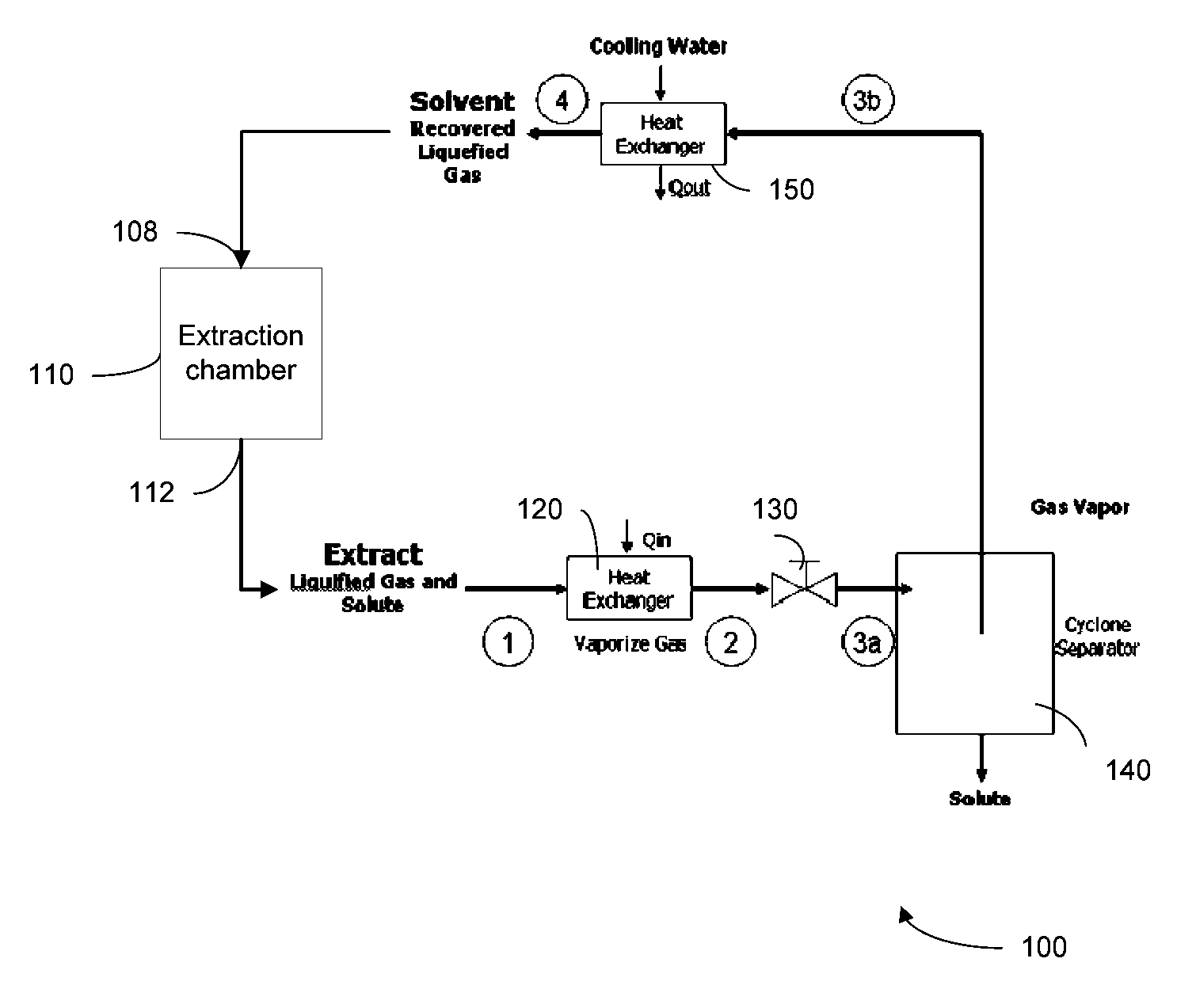

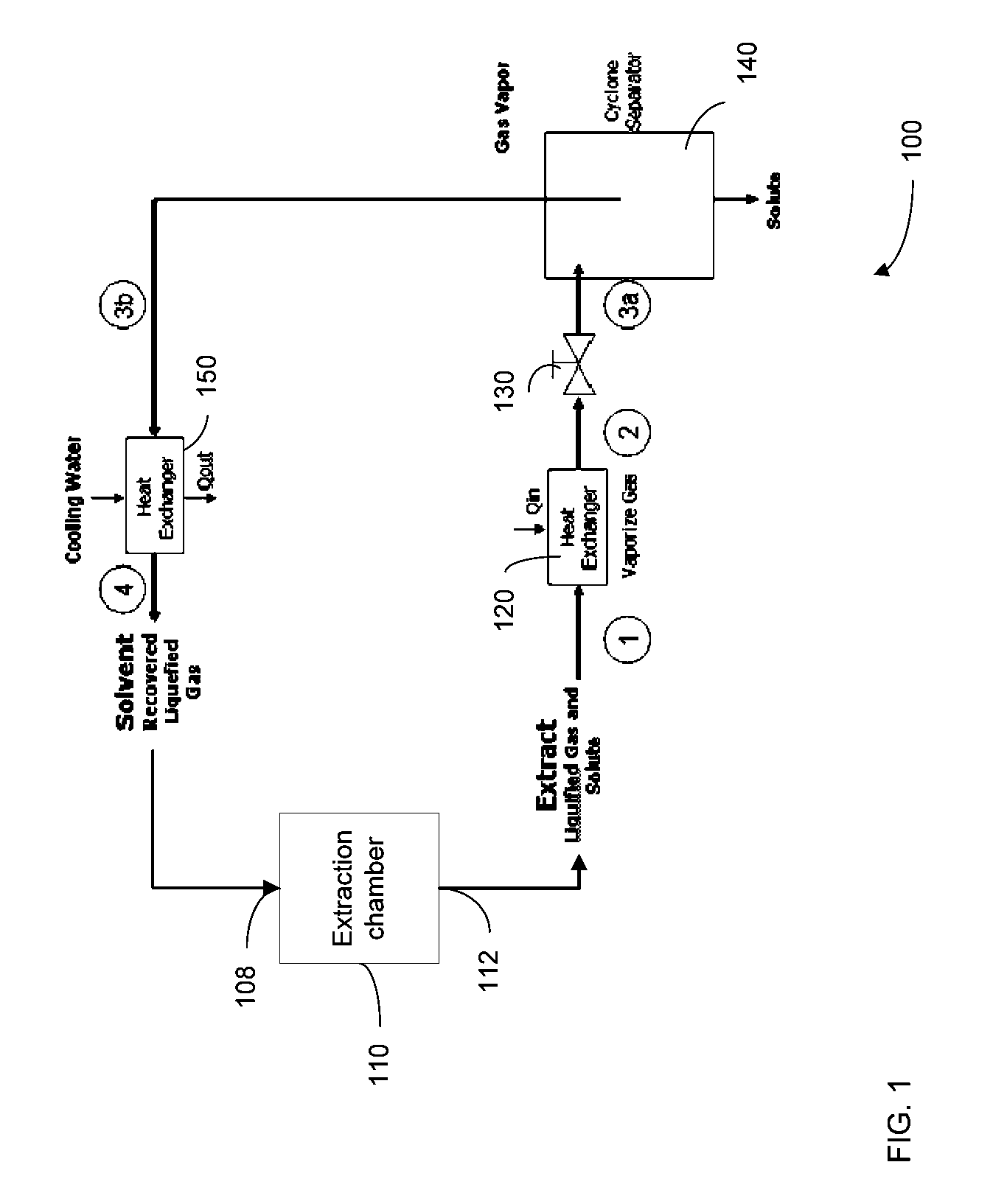

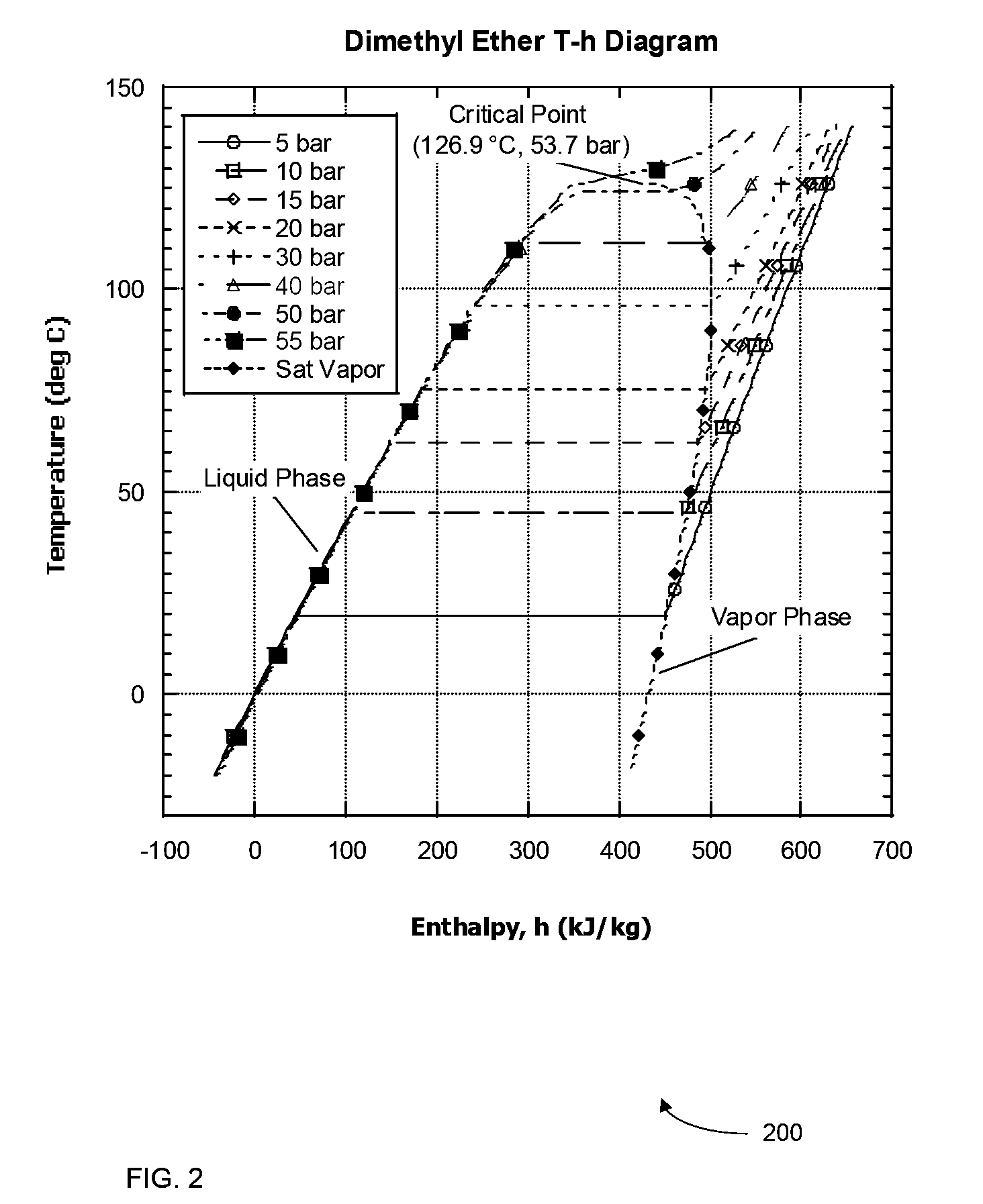

Solvent extraction and recovery

ActiveUS20090166175A1Improve solubilityReduce the amount requiredLiquid degasificationHeat recovery systemsSolubilityProduct gas

Systems and methods for improving dense gas solvent extraction of a solute and recovery of the solvent are provided. A pressure of the solvent / solute mixture obtained from an extraction chamber is increased, e.g. with a pump, thereby providing the mixture above saturation conditions. The increased pressure provides greater solubility of the solute and less solvent being vaporized in a heat exchanger. A buildup of solute in the system is reduced, thus improving system longevity. Also, process conditions of the separation process are isolated from those of the extraction process. Accordingly, the process conditions for the separating process are maintained while the process conditions of the extraction chamber vary with ambient temperature, thus saving cost and energy. This isolation also provides an ability to use, in the gas recovery cycle, a heat pump that can be used for many applications and environmental conditions while still using a conventional refrigerant.

Owner:YOURST MATT T +3

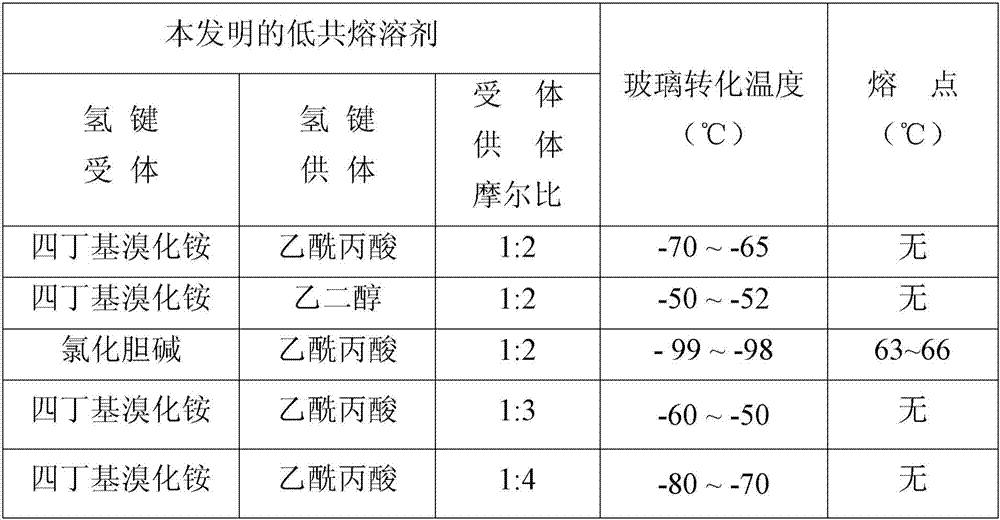

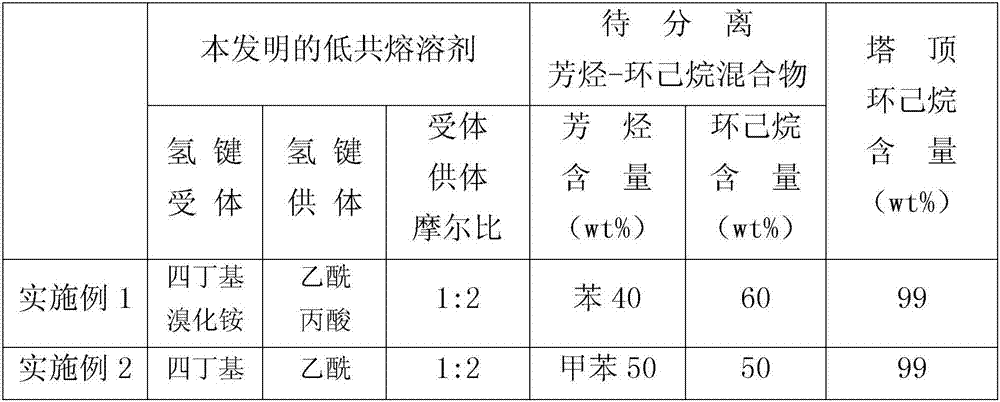

Low eutectic solvent for aromatic hydrocarbon separation and application thereof to extractive distillation

ActiveCN107311833AOvercome dosageOvercoming a large amountDistillation purification/separationExtractive distillationExtractive distillationReactive distillation

The invention discloses a low eutectic solvent for aromatic hydrocarbon separation. The low eutectic solvent is obtained by mixing hydrogen bond receptors and hydrogen bond donors according to a certain ratio (the molar ratio of 1: 1 to 1:10), and stirring till being in a uniform transparent state at 70-100 DEG C. The low eutectic solvent is low in toxicity, environment-friendly and high in efficiency, and can be applied to the process of separating aromatic hydrocarbons from non-aromatic hydrocarbons in coal tar and petroleum oil.

Owner:烟台中科恩吉科创新产业园管理有限公司

Multi-phase selective mass transfer through a membrane

Disclosed herein are embodiments relating to particular systems comprising a selective transfer membrane that can be utilized in material separation. In certain embodiments, the membrane assembly comprises part of a desalination, distillation, liquid purification, and / or heating and cooling system. Other particular embodiments allow for a high rate of thermal capture by way of the system utilizing a selective transfer membrane. Certain preferred embodiments include a selective transfer membrane comprising an ionomeric polymer that is permeable to high dipole materials.

Owner:TANGREDI PATRICIA

Process for Recovering Halogen Promoters and Removing Permanganate Reducing Compounds

ActiveUS20120090981A1Solvent extractionCarboxylic preparation from carbon monoxide reactionAcetic acidHalogen

This invention relates to processes for producing acetic acid and, in particular, to improved processes for recovering C2+ alkyl halides and removing permanganate reducing compounds formed during the carbonylation of methanol in the presence of a Group VIII metal carbonylation catalyst to produce acetic acid.

Owner:CELANESE INT CORP

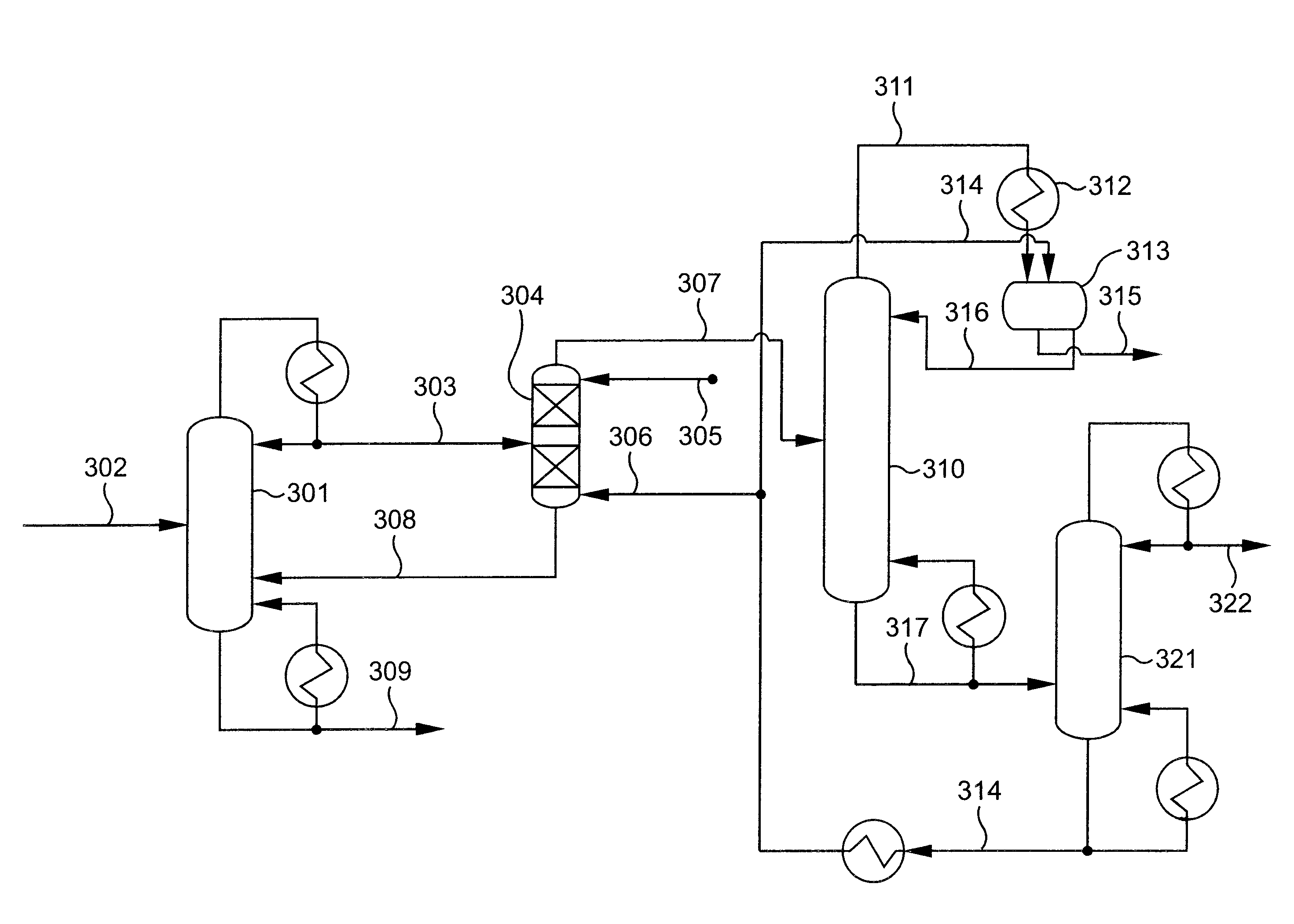

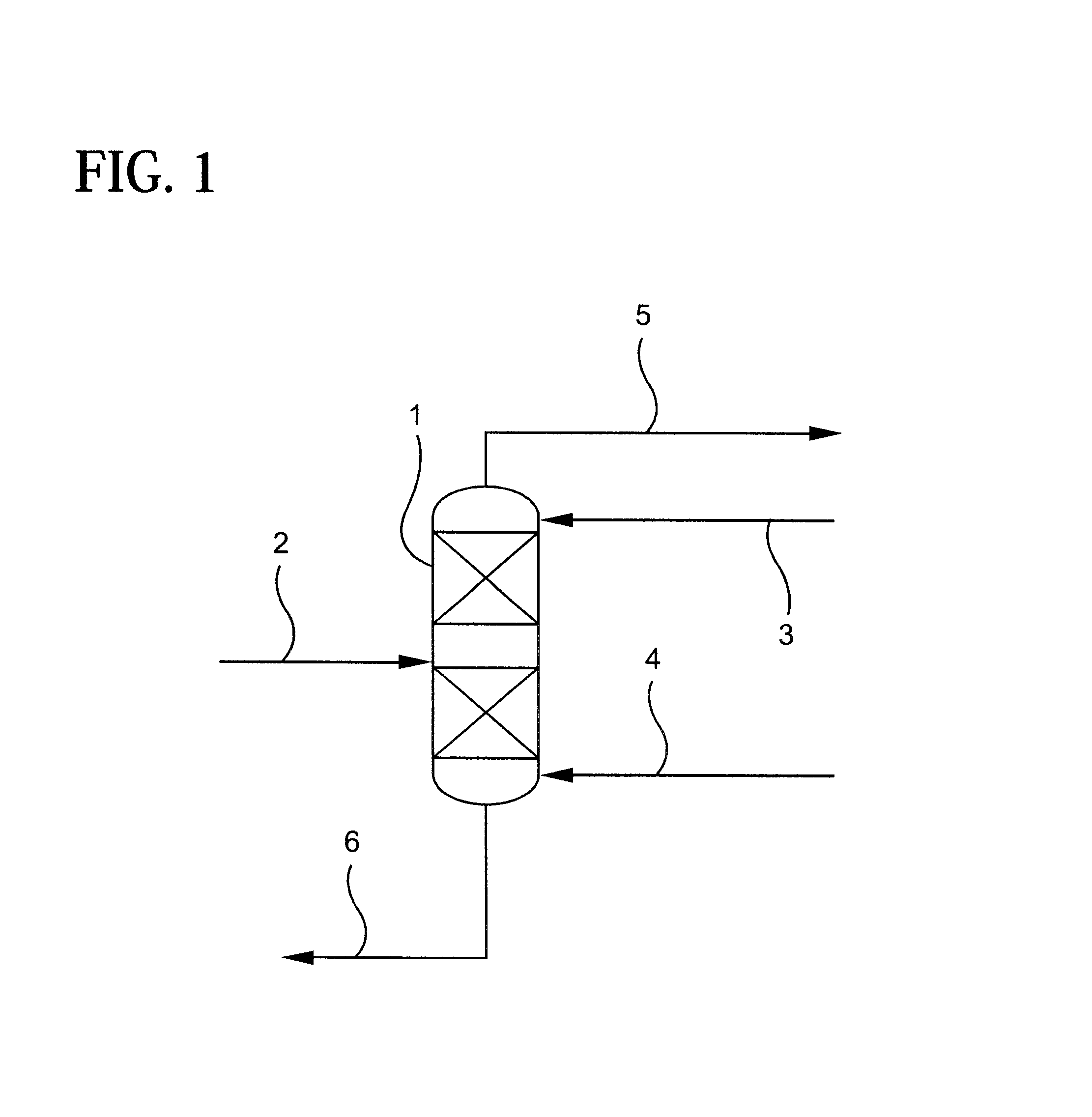

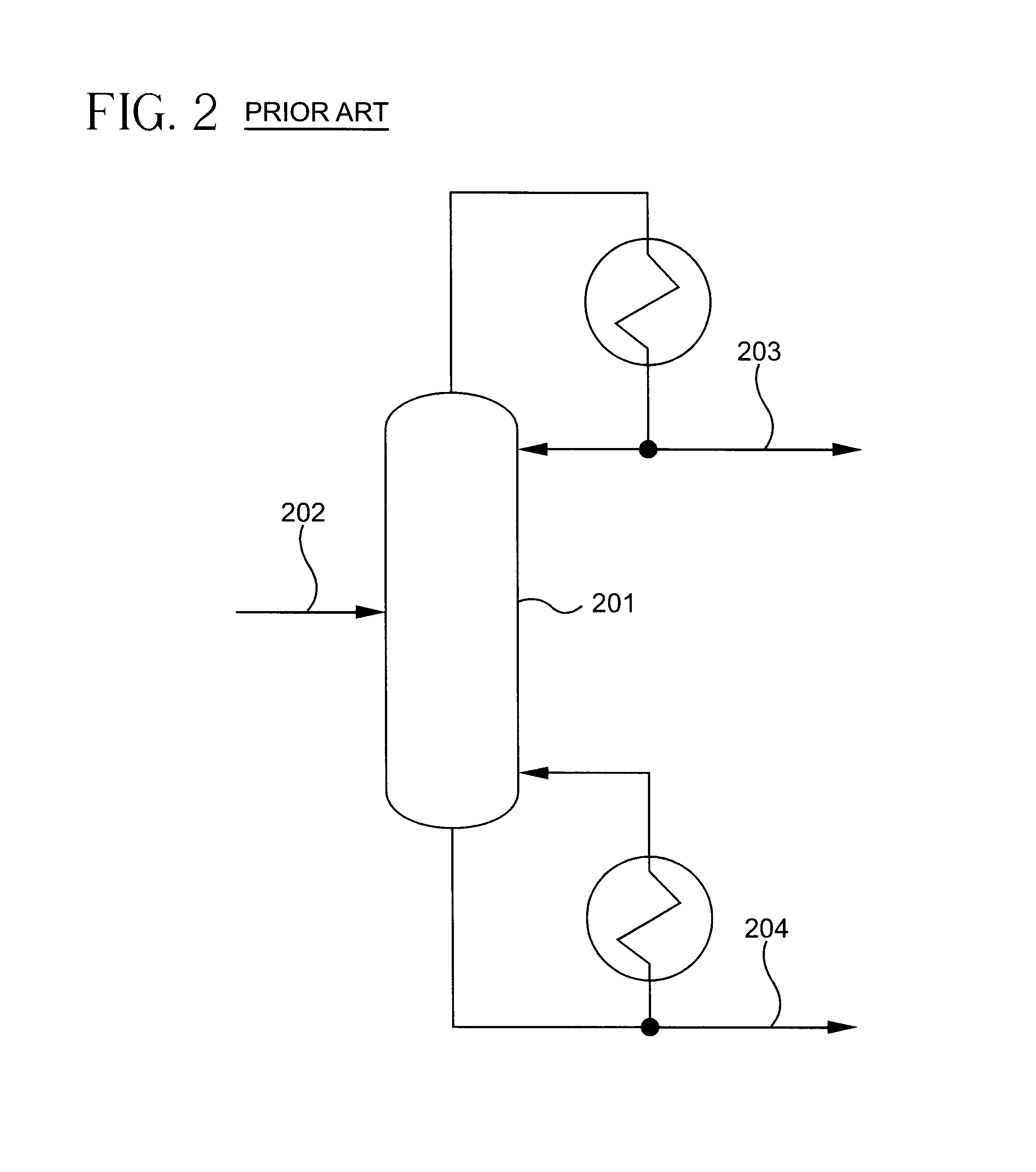

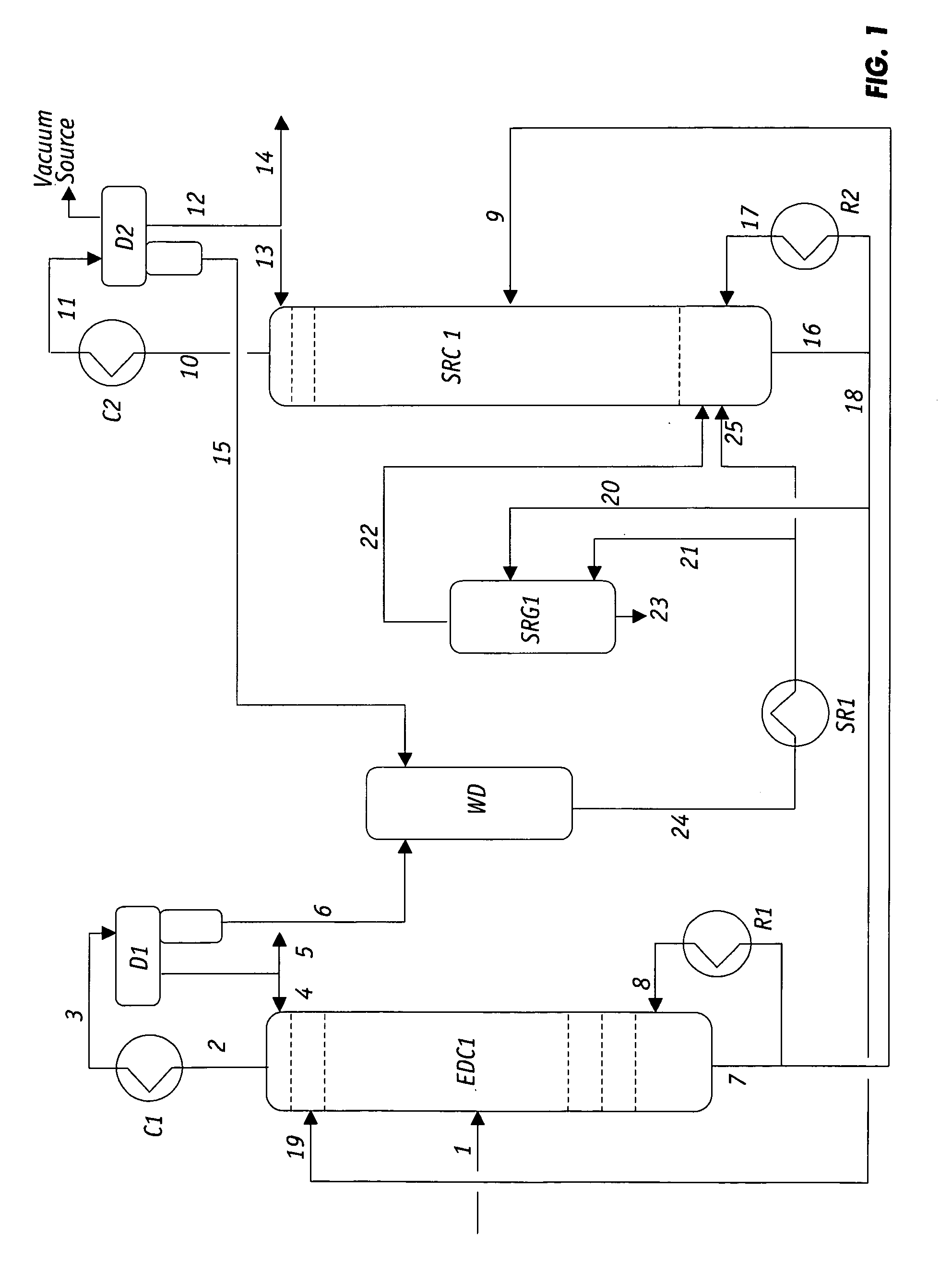

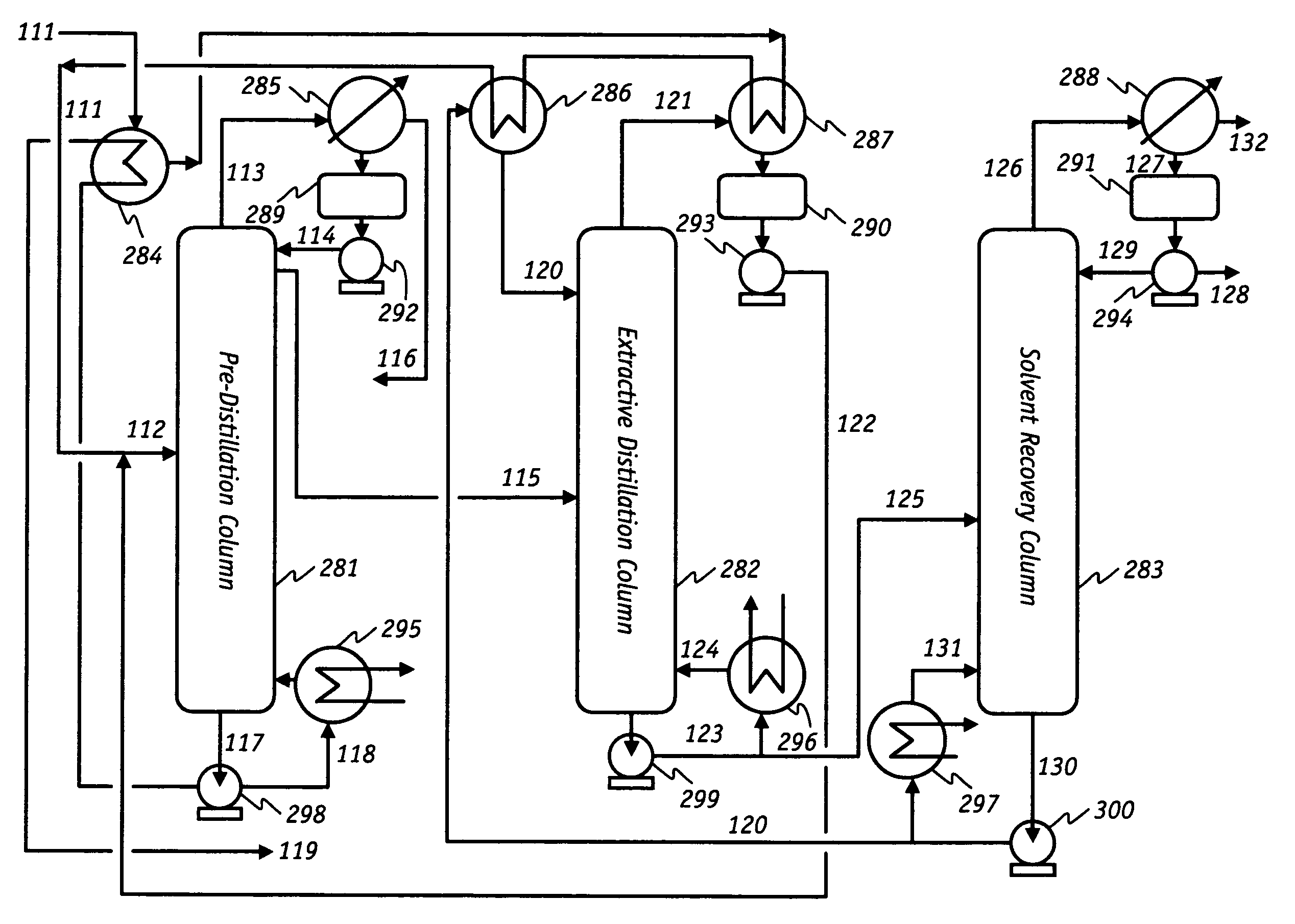

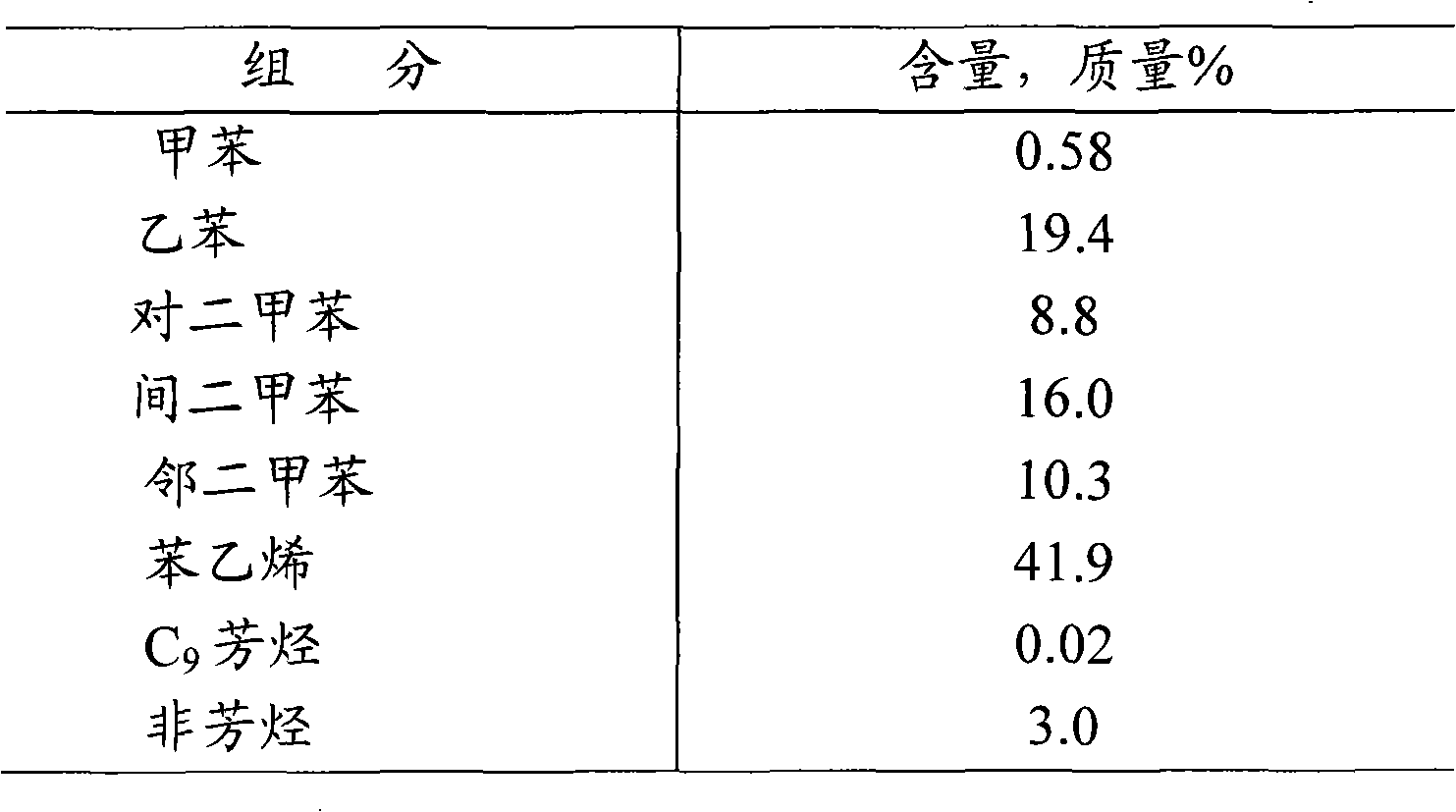

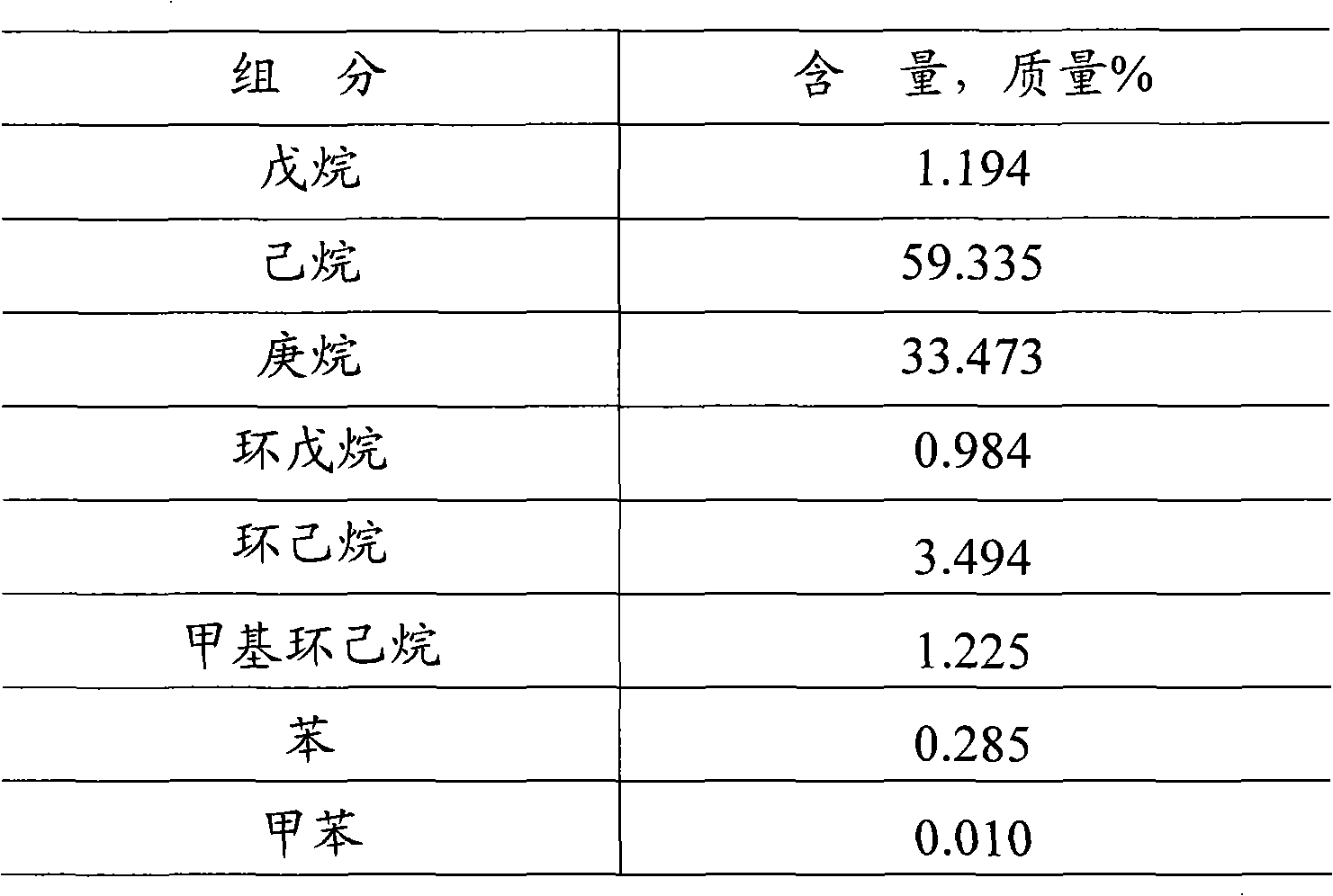

Extractive distillation process for recovering aromatics from petroleum streams

InactiveUS7666299B2Treatment with plural serial cracking stages onlyHydrocarbon oils refiningAlkaneExtractive distillation

A process for recovering polar hydrocarbons from non-polar hydrocarbons, such as aromatics from non-aromatics, naphthenes from paraffins and isoparaffins, or olefins from paraffins and isoparaffins, in feed mixtures containing at least a measurable amount of heavier hydrocarbons. This improved extractive distillation (ED) process recovers aromatic hydrocarbons including benzene, toluene, and xylenes from the C6-C8 petroleum streams containing a measurable amount of C9+ hydrocarbons. The ED process also recovers benzene and toluene from the C6-C7 petroleum streams containing a measurable amount of C8+ hydrocarbons. The ED solvent utilized to recover and purify the aromatic hydrocarbons from the petroleum stream with a heavier than intended feedstock of hydrocarbons is also regenerated and recovered.

Owner:AMT INT INC +1

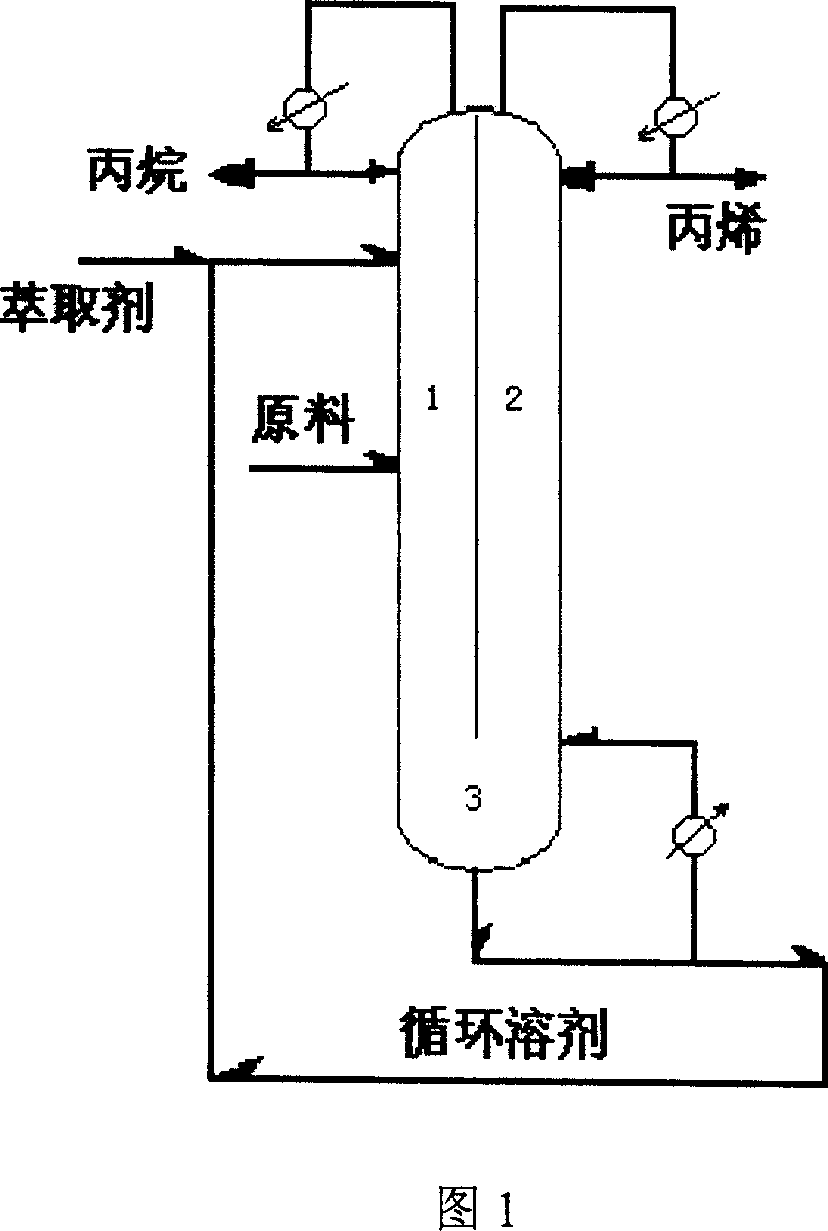

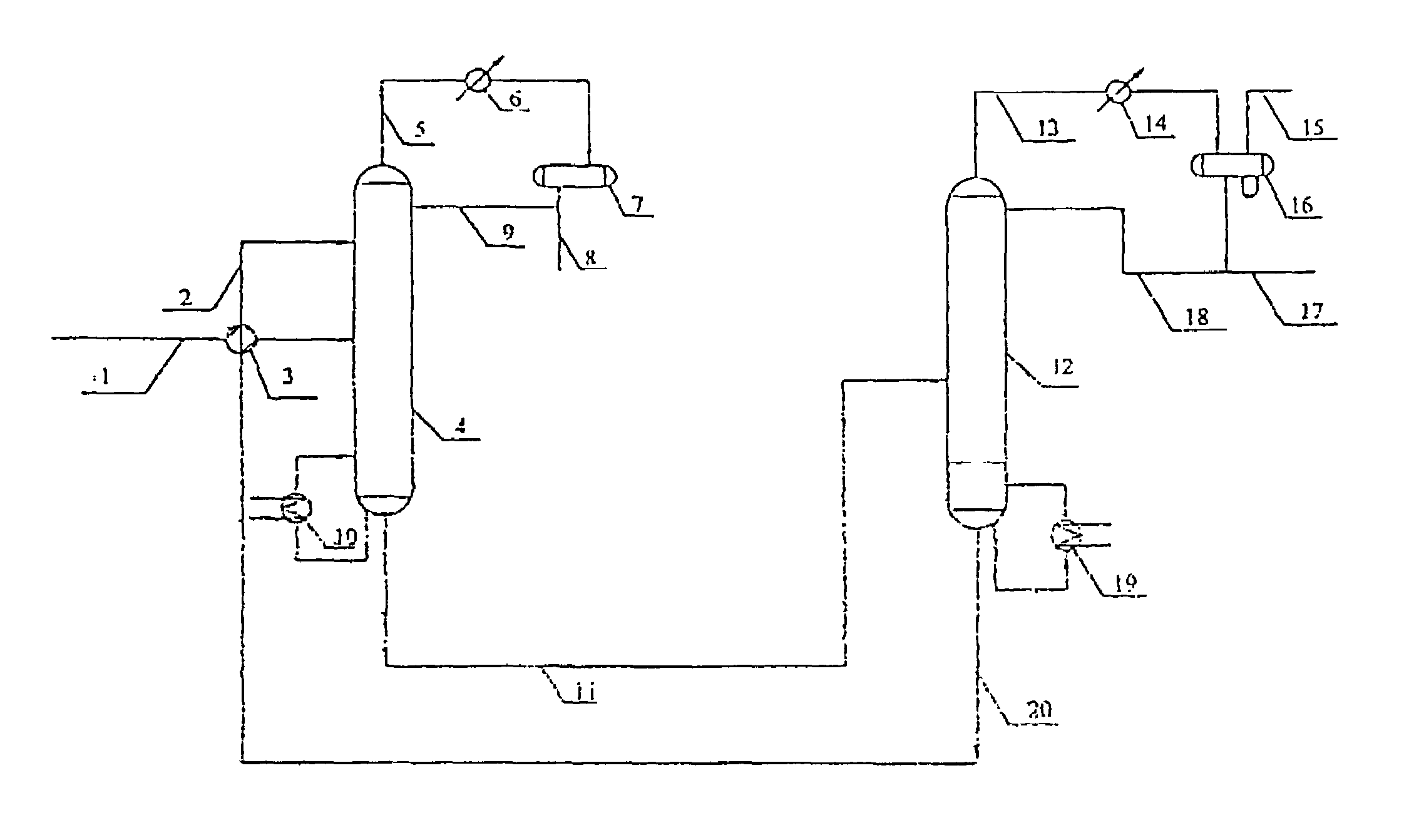

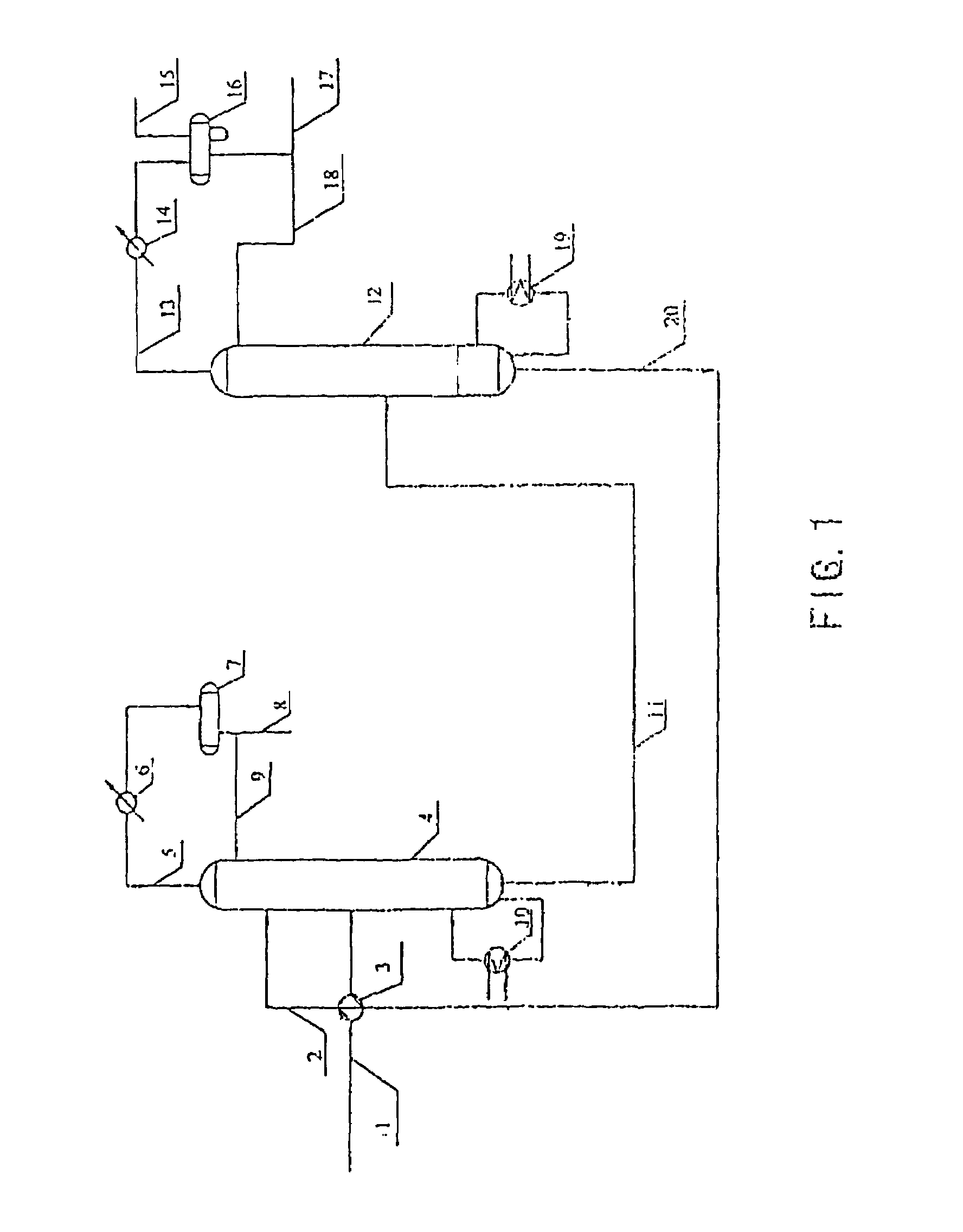

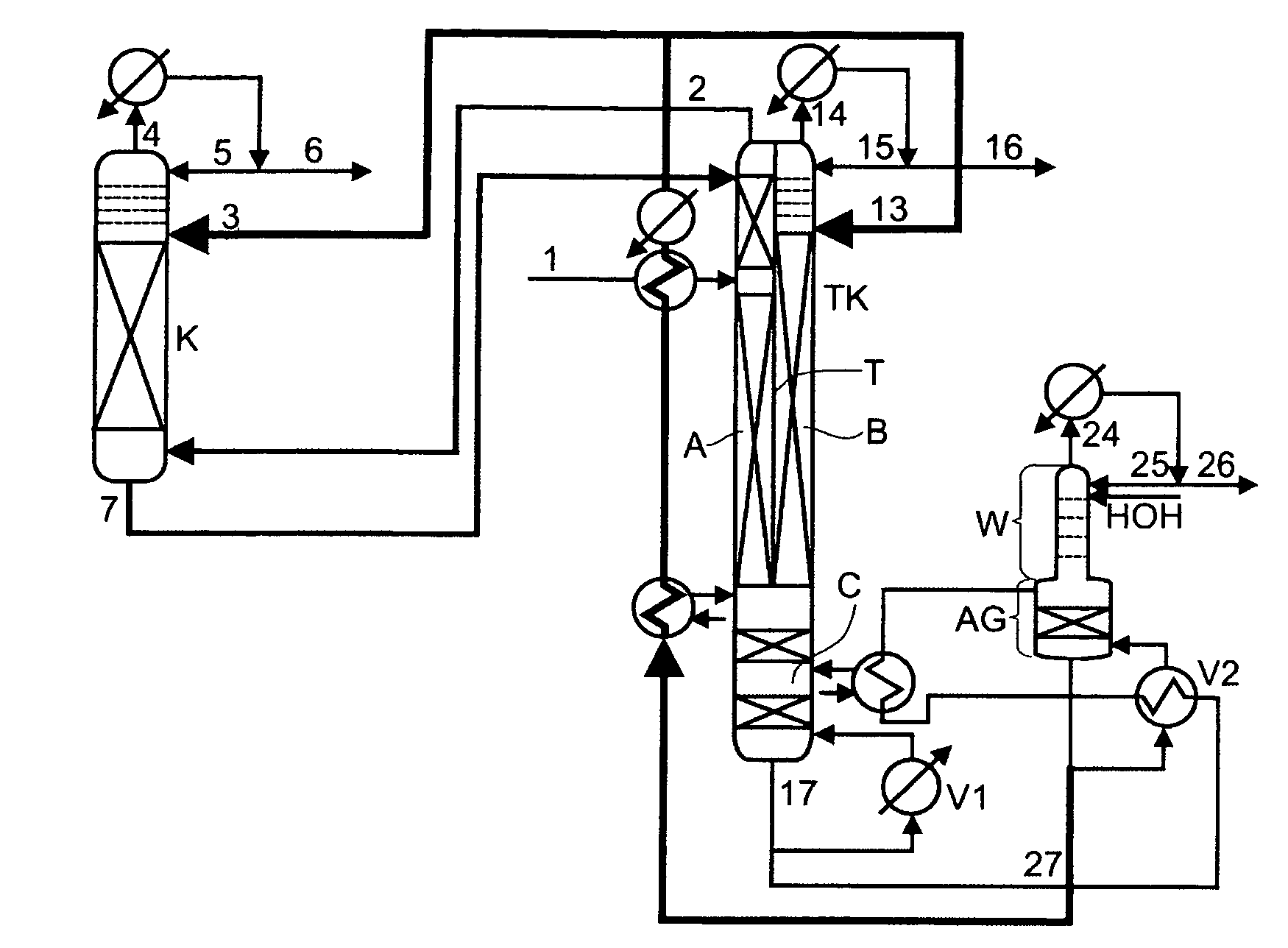

Method and apparatus for extracting, rectifying and separating propane and propylene by separated wall tower

InactiveCN101028987AHigh yieldReduce heat loadDistillation purification/separationExtractive distillationDesorptionAcetonitrile

An apparatus for separating propane from propene by extracting-rectifying in a divided wall column (DWC) in which the water contained acetonitrile is used as the extractant is disclosed. Said DWC has a vertical bulkhead to divide it into three regions: the region A for extracting rectifying of propene and propane, the region B for separating propane from propene, and the region C as common desorption region. Its separation method is also disclosed.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for separating methyl acetate-methanol mixture by ionic liquid intermittent extractive rectification

InactiveCN102180791AIncrease relative volatilityNo pollution in the processOrganic compound preparationCarboxylic acid esters preparationMethyl acetateMass content

The invention discloses a method for separating a methyl acetate-methanol mixture by ionic liquid intermittent extractive rectification, which is realized in a way that: a rectifier of an extractive rectification tower is adopted, an ionic liquid 1-ethyl-3-methyl imidazolyl acetate is used as an extractant, and the operation is carried out intermittently, so the top of the extractive rectification tower sequentially produces a methyl acetate product of which the mass content is up to 98-99.9%, a methyl acetate-methanol transitional fraction and methanol of which the mass content is 97-99%; and finally, the extractant of which the mass percent is 99% is left in the heating kettle. The invention has the following advantages: the extractant is adopted to enhance the relative volatility of the methyl acetate-methanol system, the purity of the separated methyl acetate product is high, and the ionic liquid used as the extractant is easy to recover and does not pollute the environment; and only one single tower needs to be operated, so that operation is flexible and the equipment investment is low.

Owner:TIANJIN UNIV

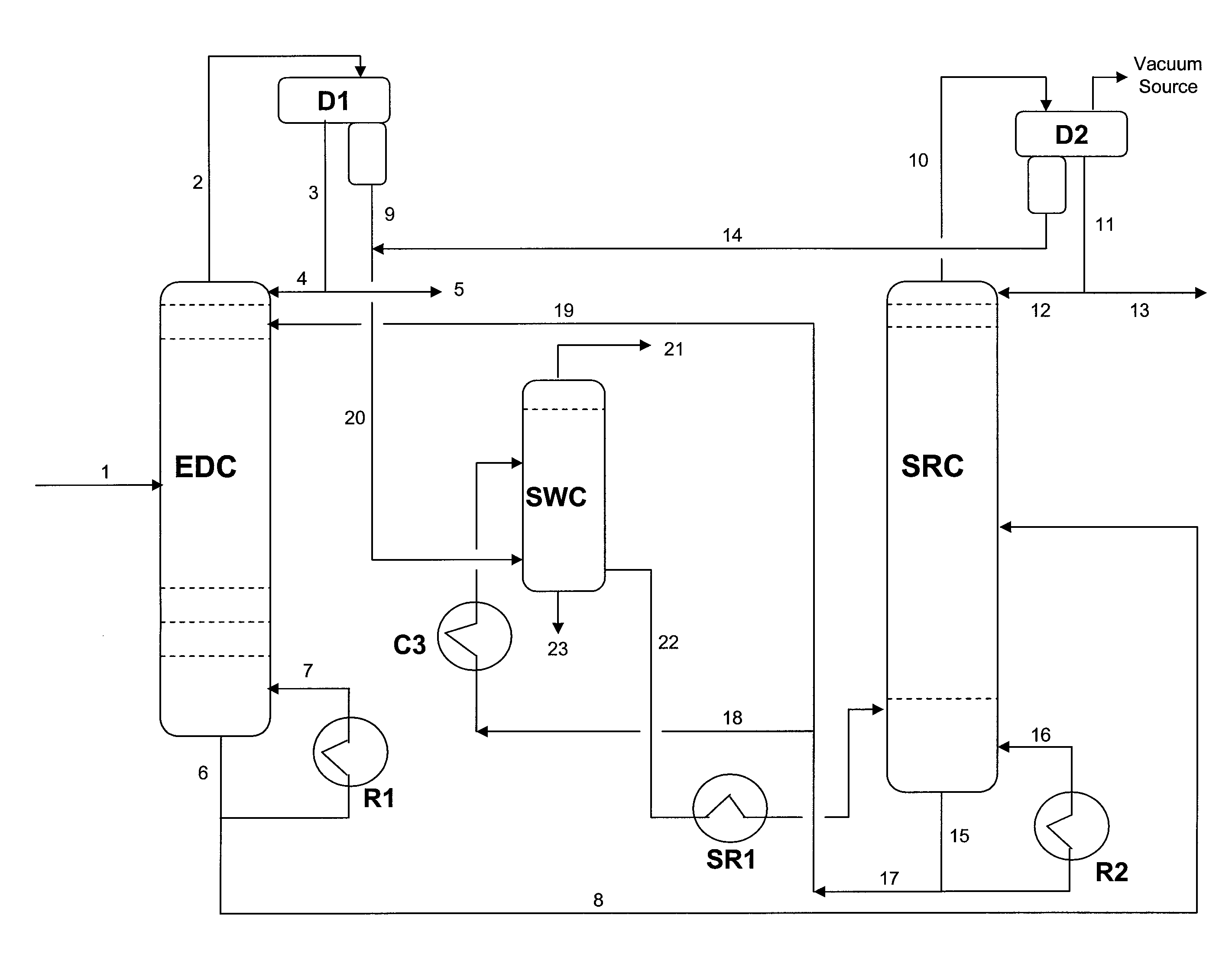

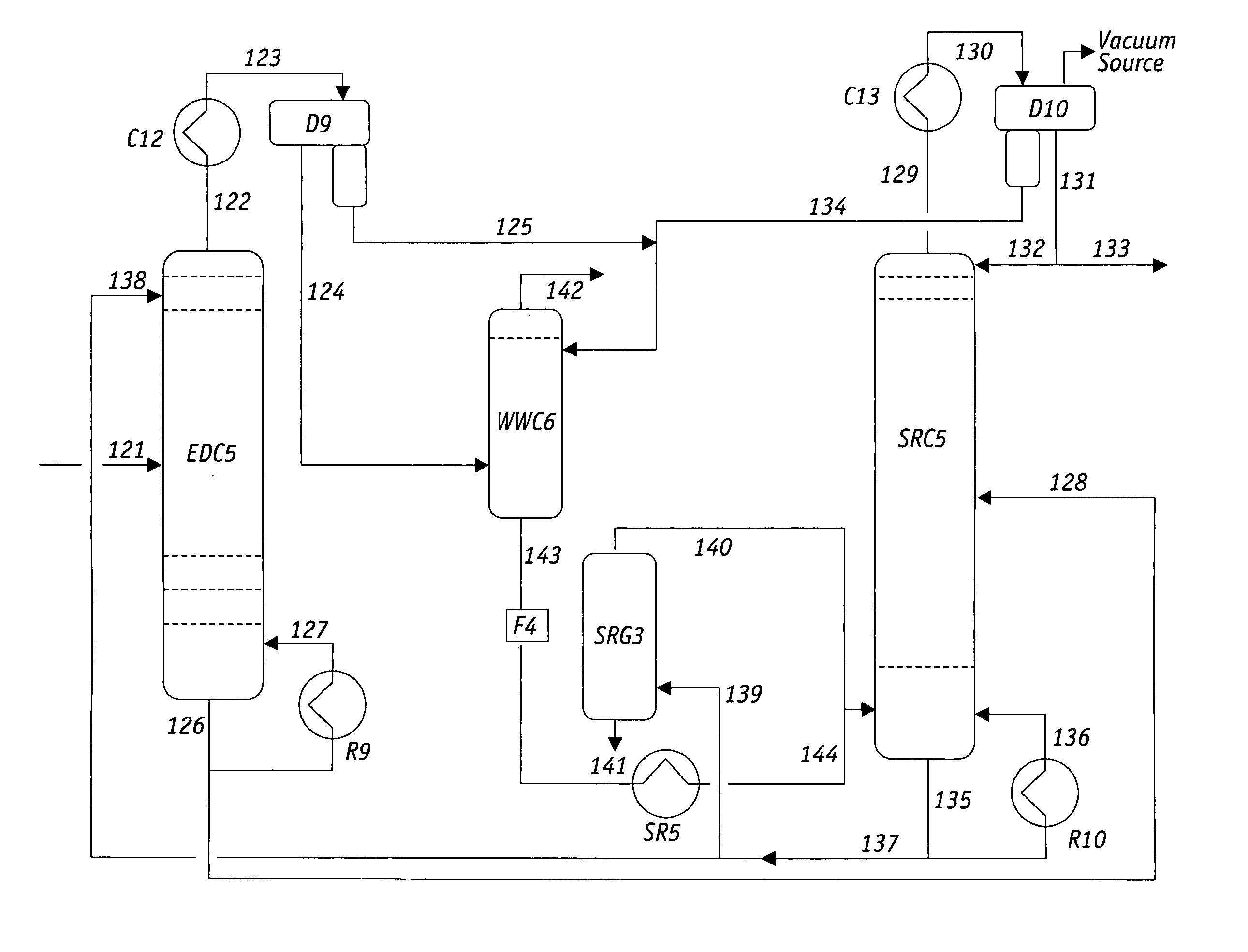

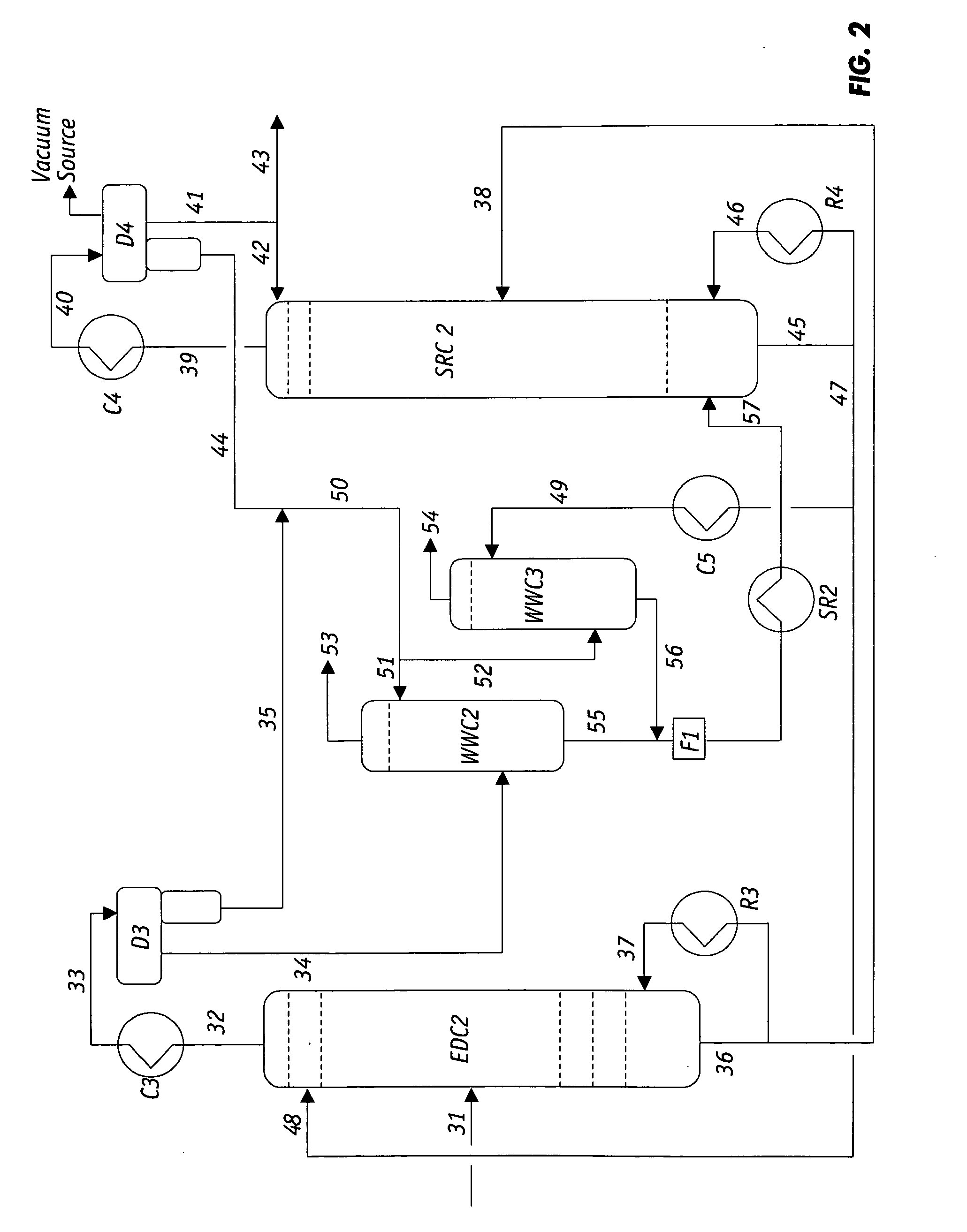

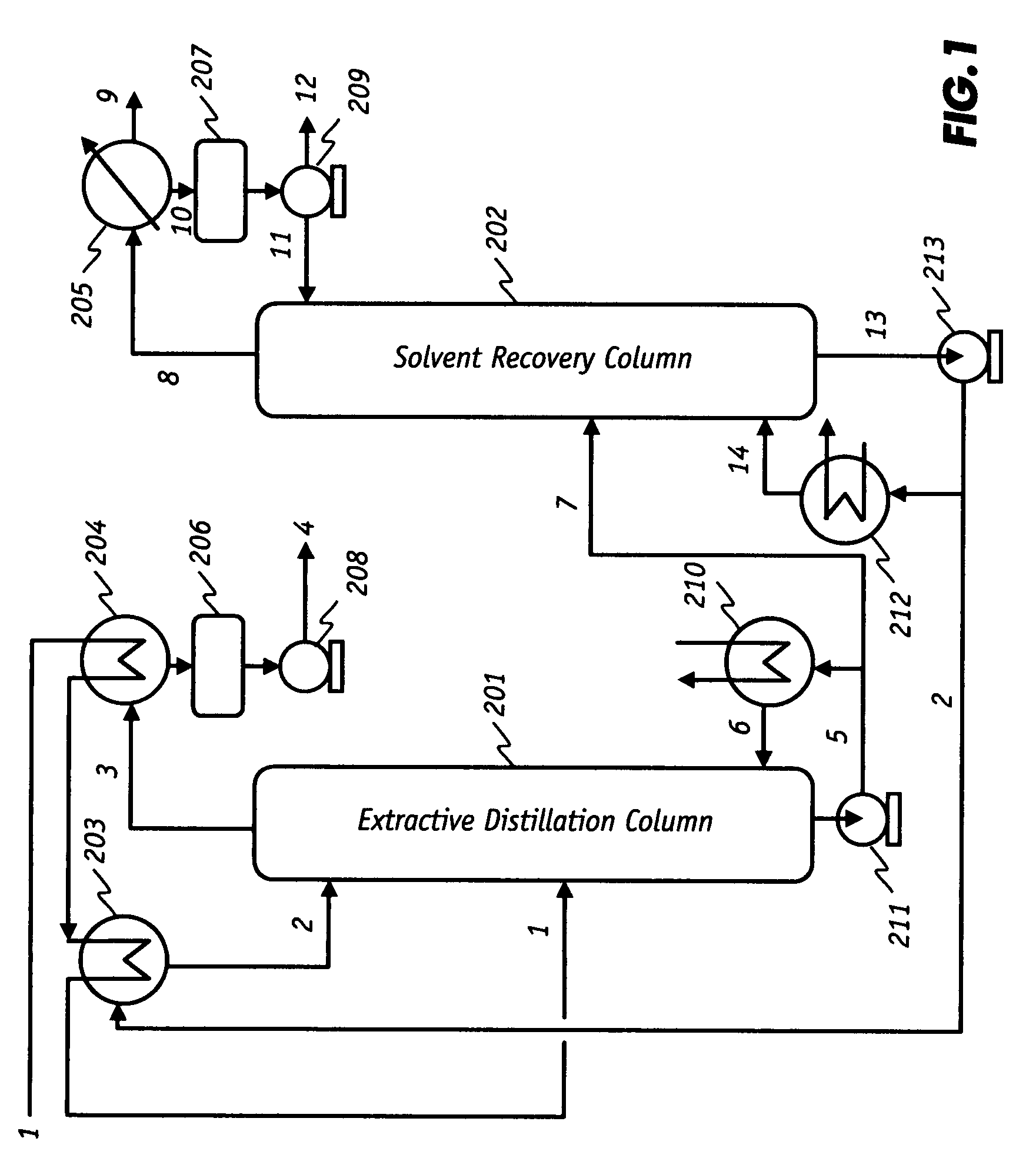

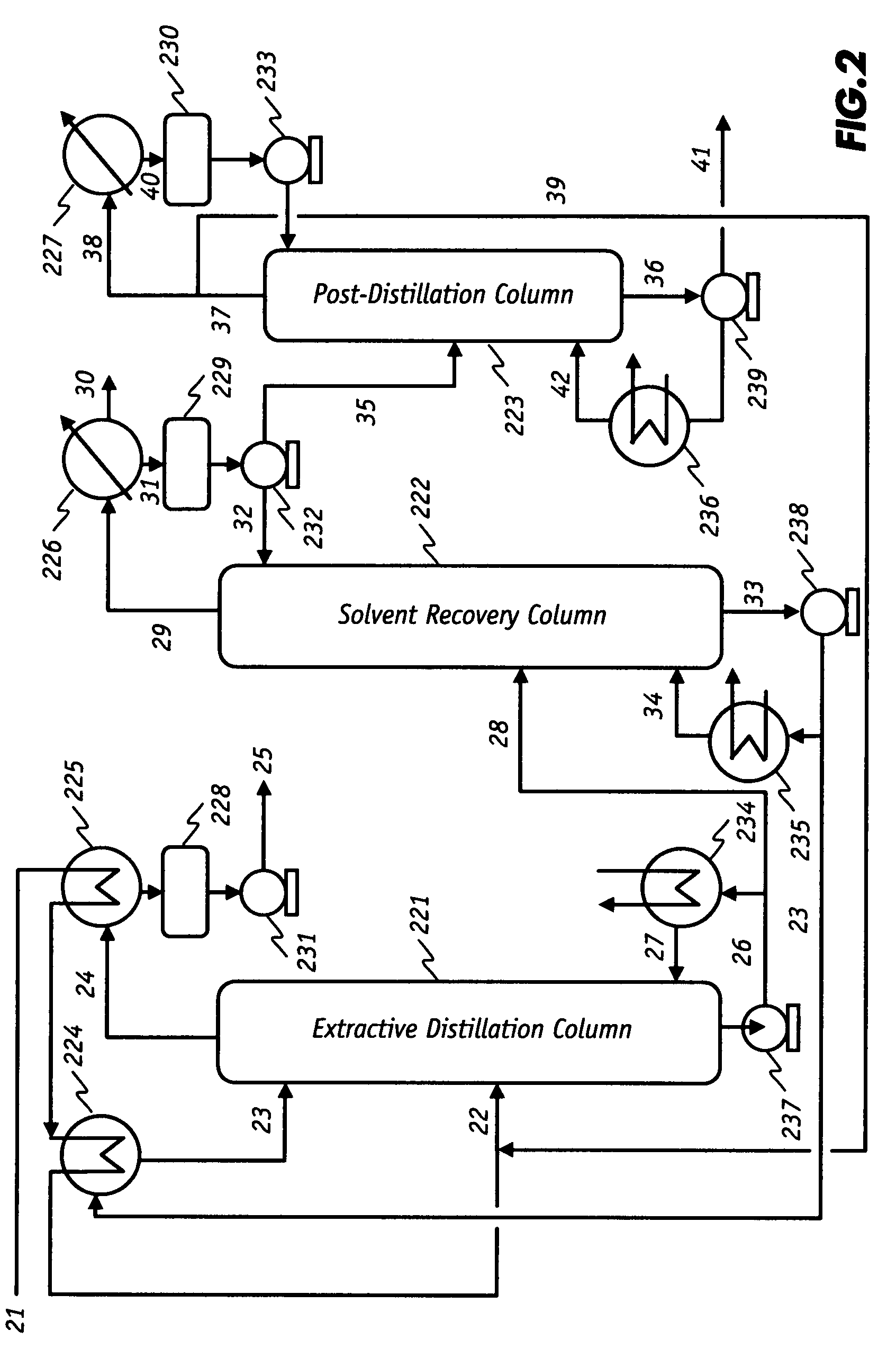

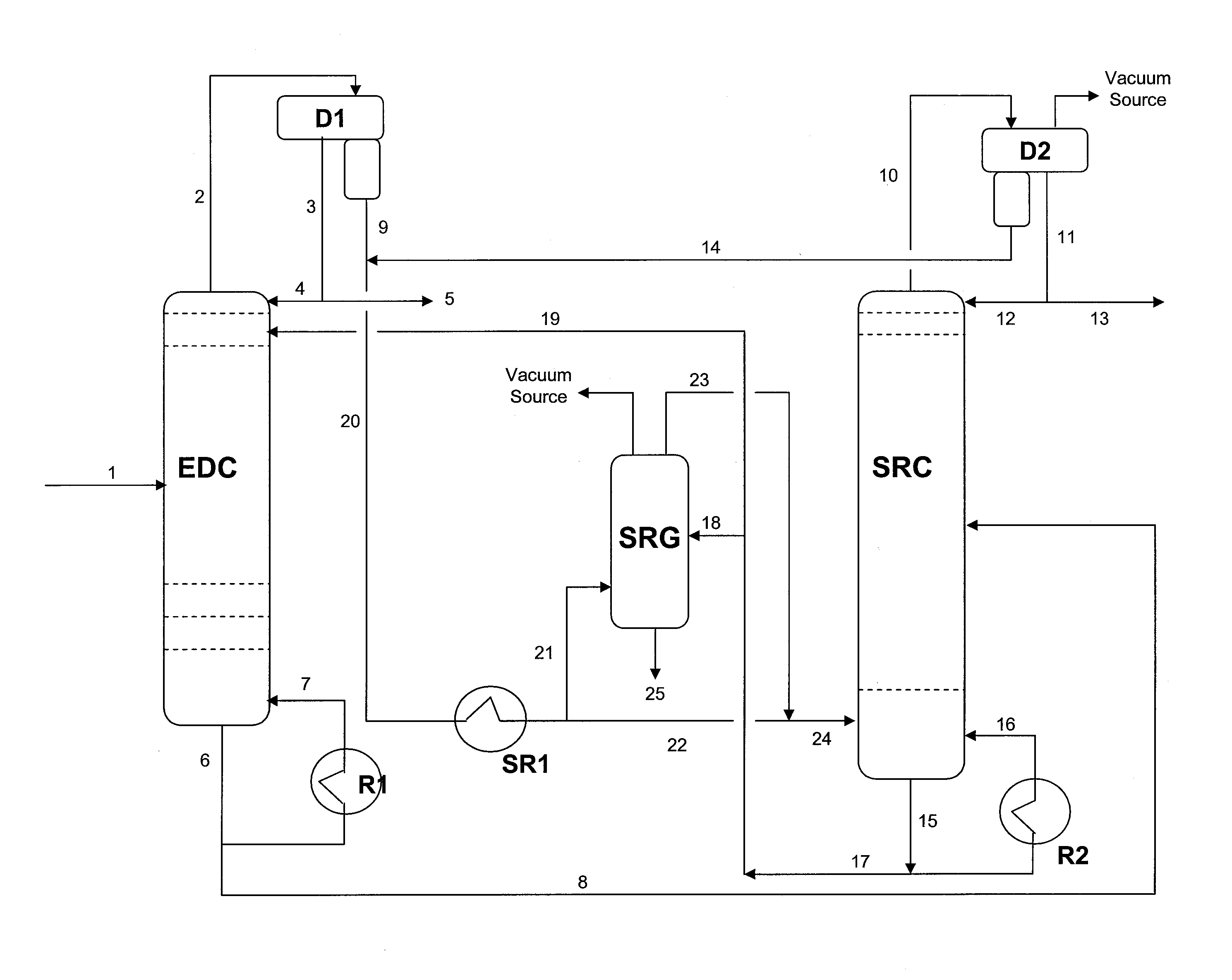

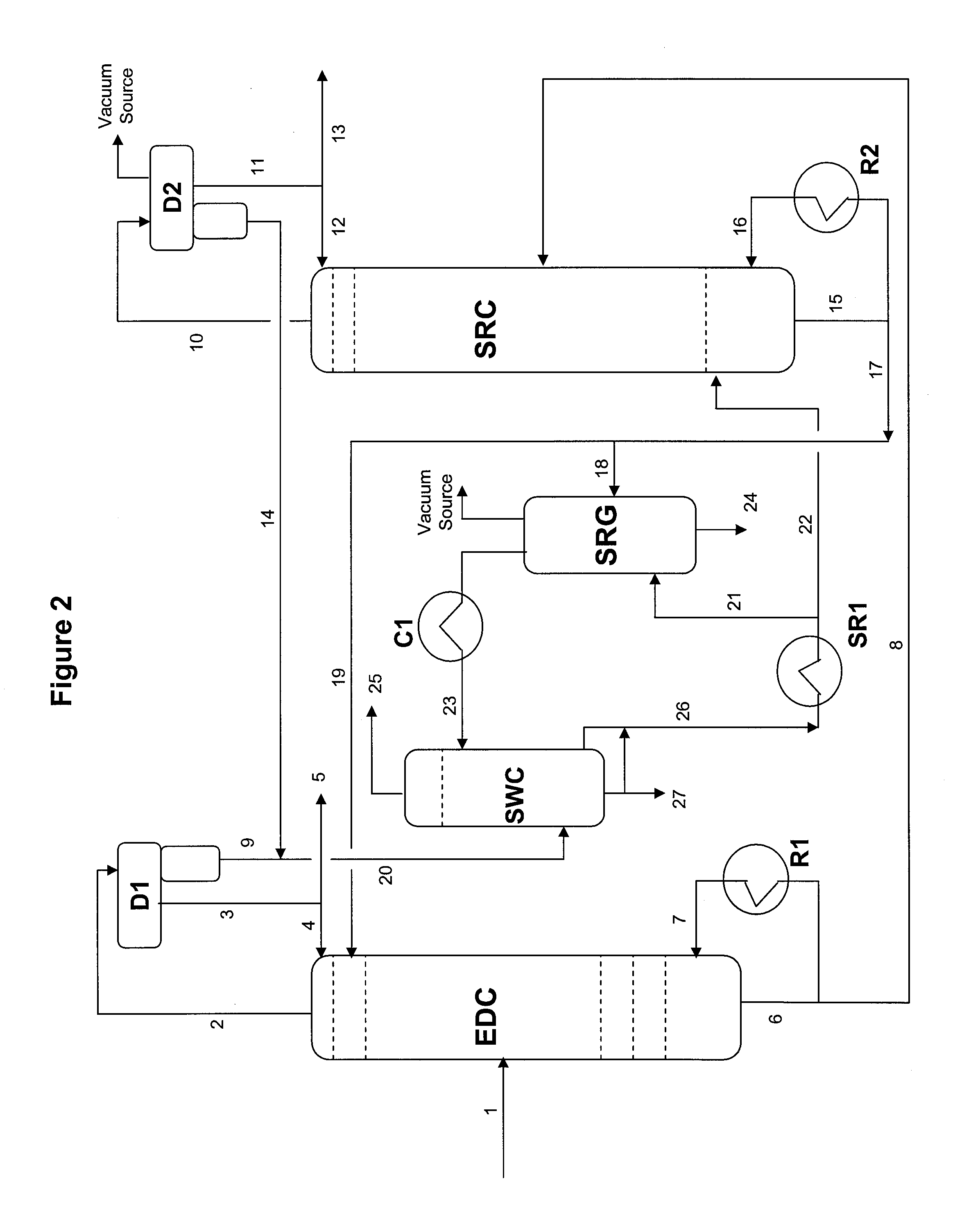

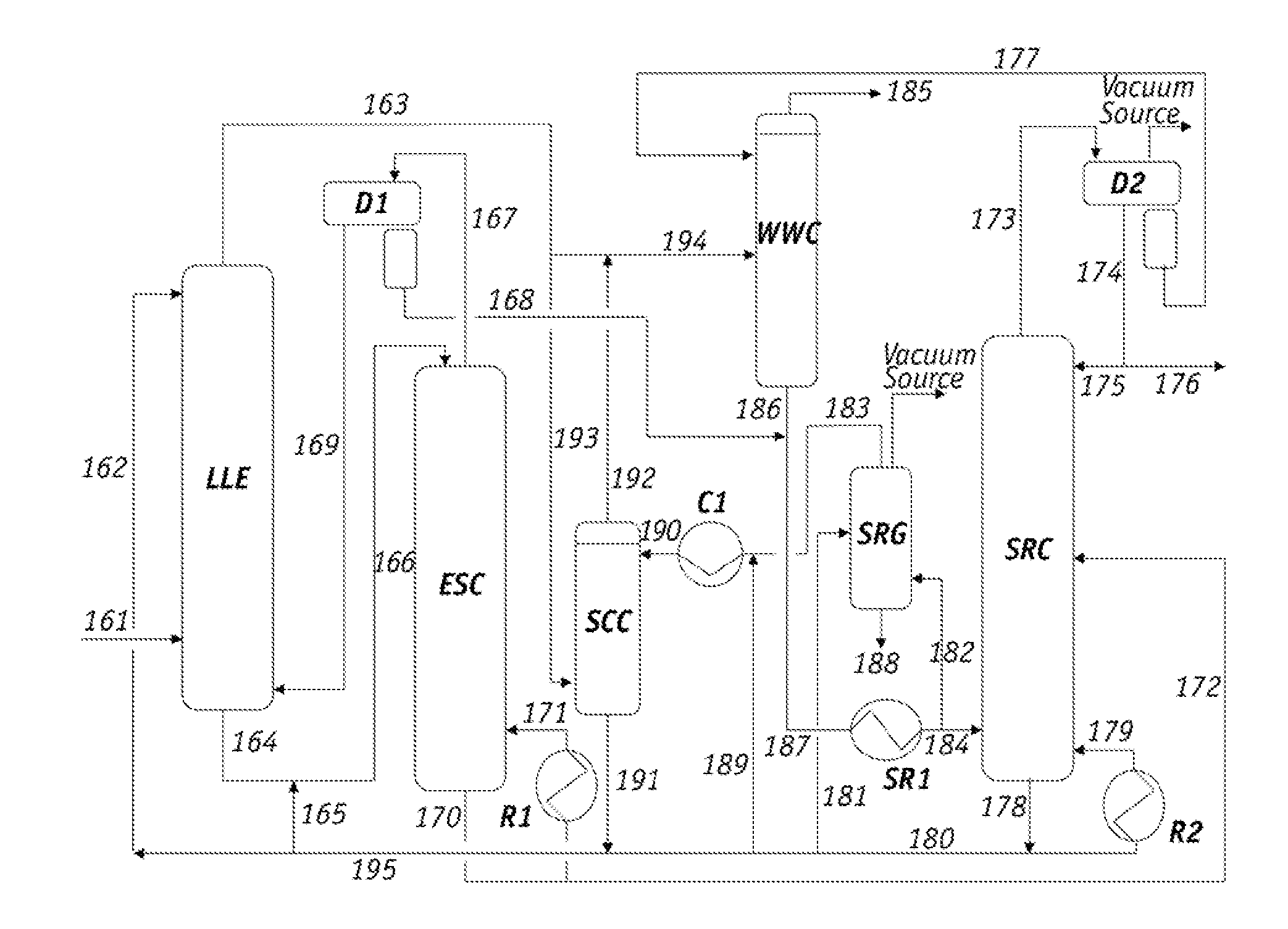

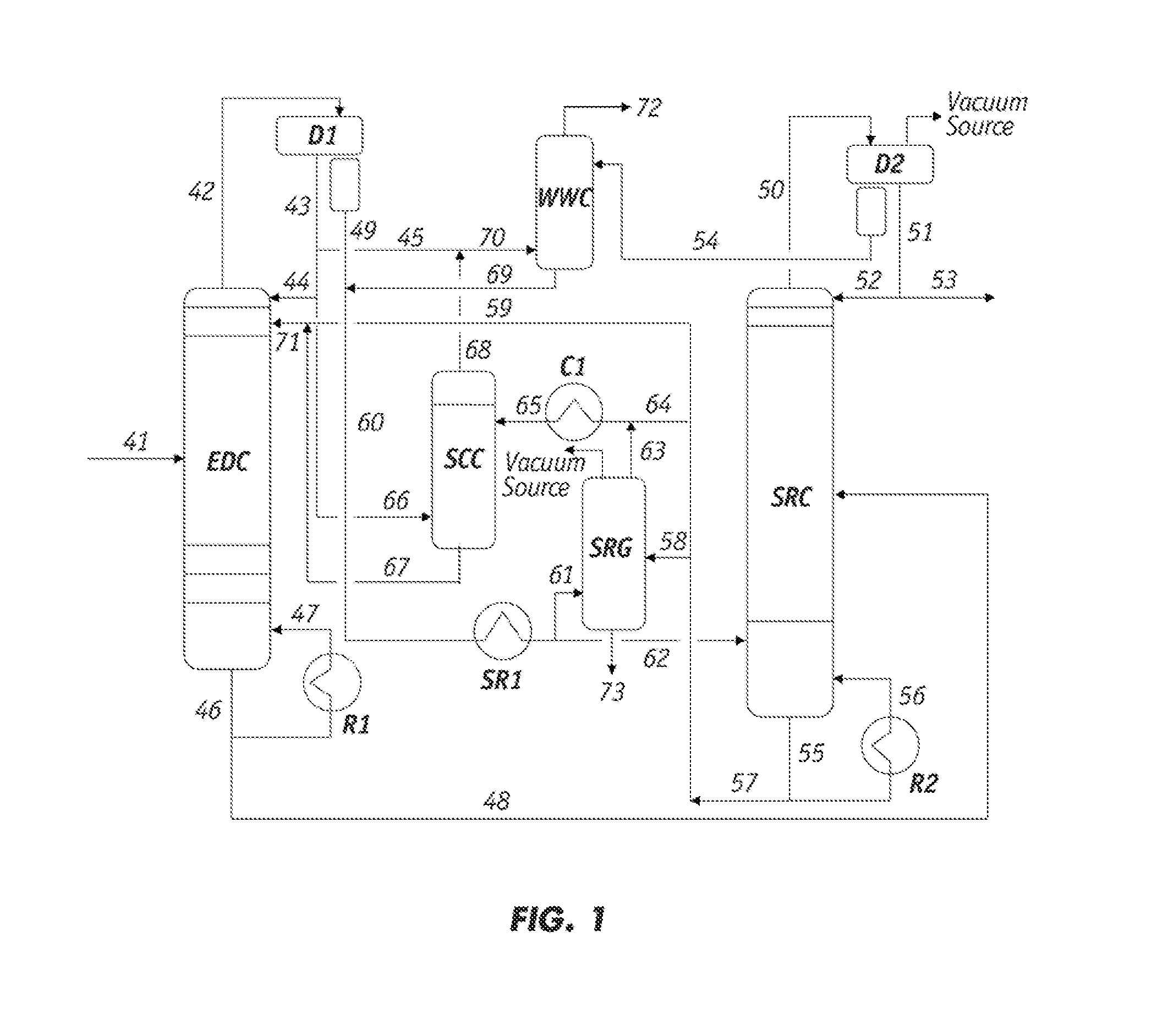

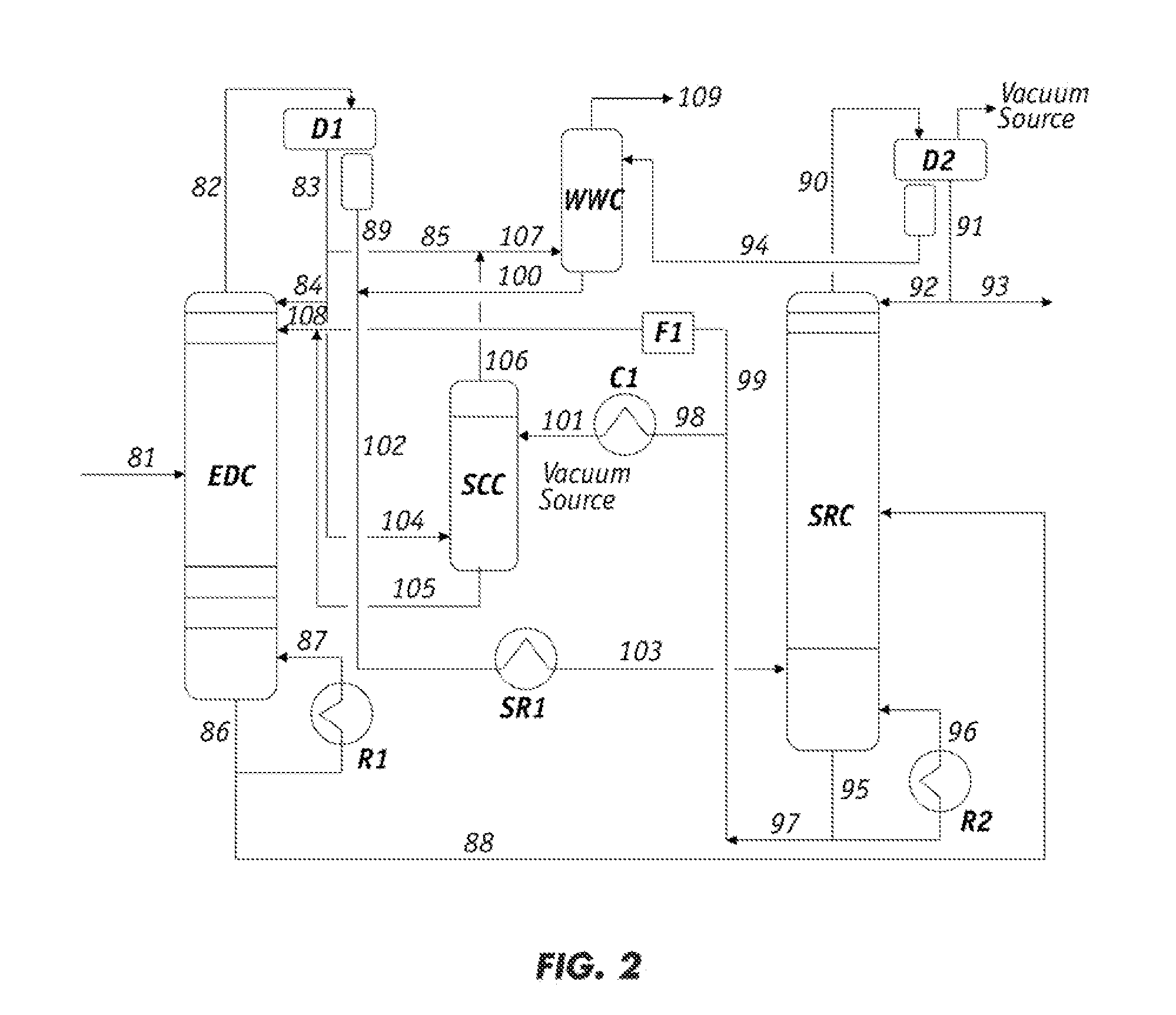

Extractive distillation processes using water-soluble extractive solvents

ActiveUS20090105514A1Reduce steam consumptionGood solvent resistanceHydrocarbon purification/separationHydrocarbonsExtractive distillationWater soluble

Extractive distillation processes whereby water-soluble extractive distillation (ED) solvents are regenerated and recovered employ improved operations of the extractive distillation column (EDC) so that polar hydrocarbons are recovered and purified from mixtures containing polar and less polar hydrocarbons and measurable amounts of hydrocarbons that are heavier than intended feedstock and / or polymers that are generated in the ED process. The improved process can effectively remove and recover the heavy hydrocarbons and / or remove polymer contaminants from the solvent in a closed solvent circulating loop through mild operating conditions with no additional process energy being expended. With the improved process, the overhead reflux of the EDC may be eliminated to further reduce energy consumption and to enhance the loading and performance within the upper portion of the EDC, especially when two liquid phases exists therein.

Owner:CPC CORPORATION +1

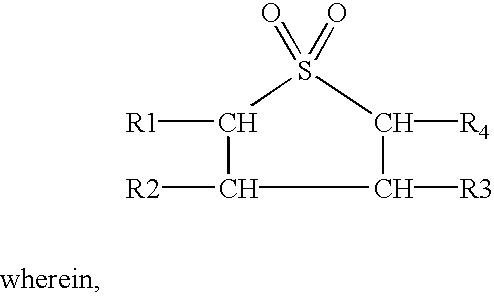

Process for separating aromatics by extractive distillation and a composite solvent used therein

InactiveUS7078580B2Improve solubilityWide boiling rangeDistillation purification/separationHydrocarbonsSulfolaneAlkalinity

This application relates to a composite solvent for separating aromatics by extractive distillation, comprising a main solvent, a solutizer and a modifier. Said solutizer is selected from any one or mixtures of any two of C8–C11 aromatics having different number of carbon atoms, the content of which is 3–39 wt %, and the number of carbon atoms of the lowest aromatic in the solutizer should be greater than that of the highest aromatic in the aromatics to be separated. When the solutizer is selected from any one of C8–C11 aromatics, the composite solvent contains 0.01–10.0 wt % of the modifier; when the solutizer is selected from mixtures of any two of C8–C11 aromatics having different number of carbon atoms, the composite solvent contains 0–10.0 wt % of the modifier. Said main solvent and modifier are independently selected from sulfolane derivatives, N-formyl morpholine, and N-methyl pyrrolidone, provided that the acidity and basicity of the modifier are opposite to those of the main solvent. When the composite solvent is used to recover aromatics by extractive distillation, it is possible to moderate the operation conditions of solvent recovery, increase the yield of aromatics, and make the separated aromatics to be neutral.

Owner:CHINA PETROCHEMICAL CORP +1

Low-energy extractive distillation process for dehydration of aqueous ethanol

ActiveUS8002953B2Energy efficiencyReduce energy inputFermented solutions distillation/rectificationOrganic compound preparationGas phaseExtractive distillation

Owner:AMT INT INC +1

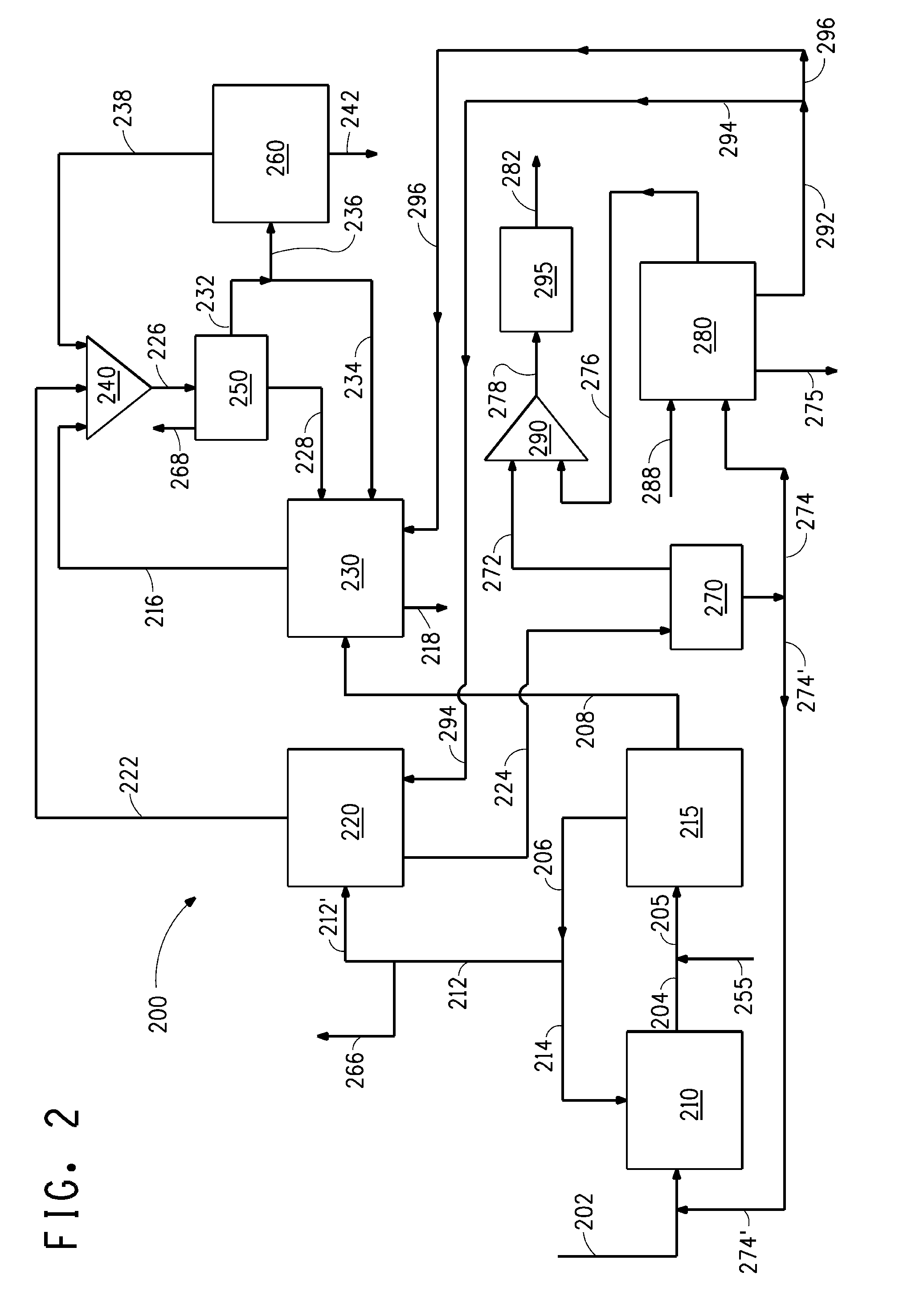

Process and Apparatus for para-Xylene Production Using Multiple Adsorptive Separation Units and a Split Fractionating Column

ActiveUS20130158330A1Distillation purification/separationMultistage water/sewage treatmentFractionating columnRaffinate

A process for separating para-xylene from a plurality of xylene isomers, wherein the process introduces at a first feed point a first mixed xylene stream comprising a plurality of xylene isomers into a first adsorptive separation unit to produce a first para-xylene enriched stream and a first raffinate stream, and introduces a second mixed xylene stream comprising a plurality of xylene isomers into a second adsorptive separation unit to produce a second raffinate stream. The process feeds both the first raffinate stream and the second raffinate stream into a raffinate column. The process further introduces an extract stream from the second adsorptive separation unit into a first input of a split extract column comprising an internal partition defining a first distillation zone and a second distillation zone.

Owner:UOP LLC

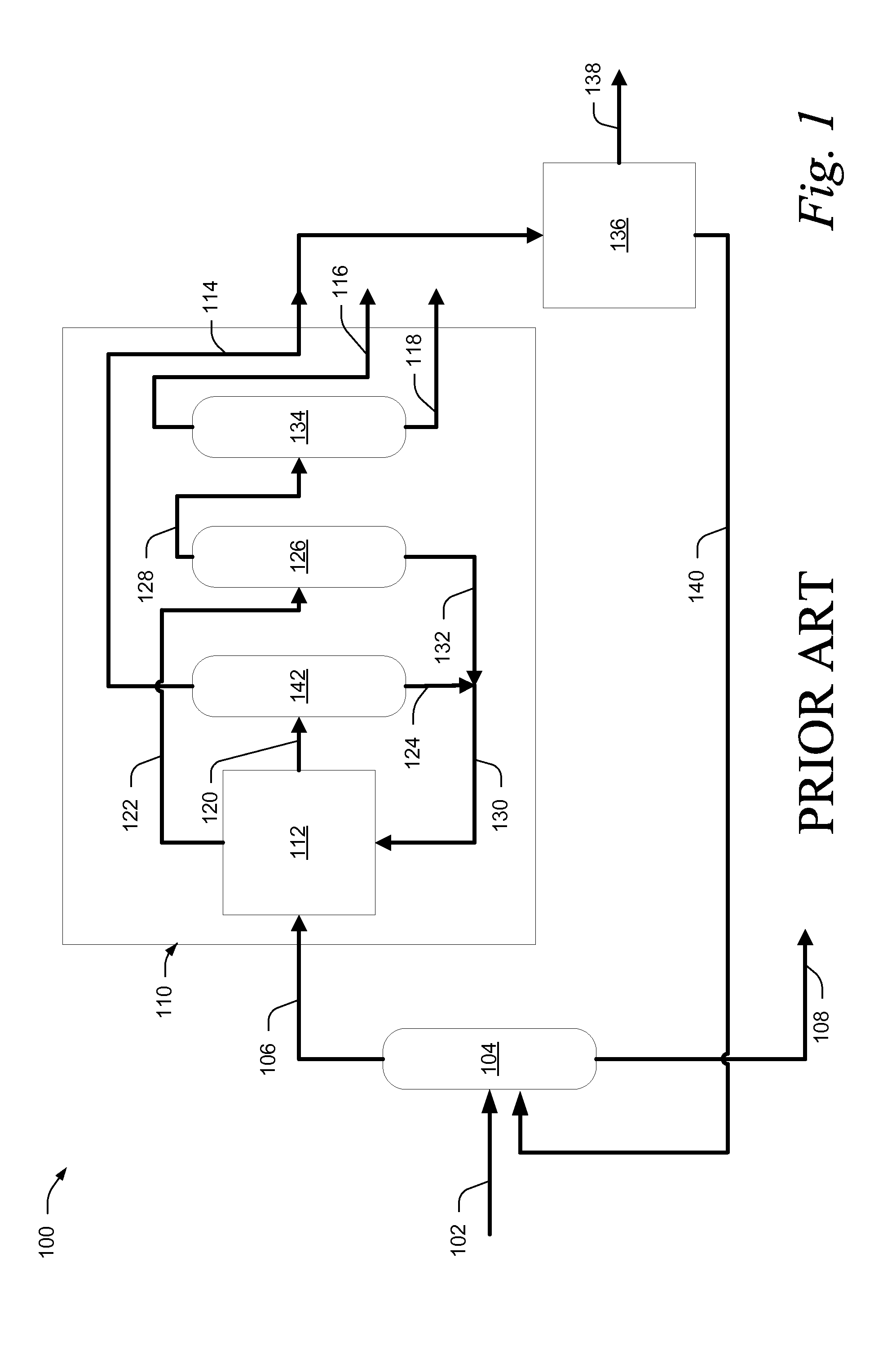

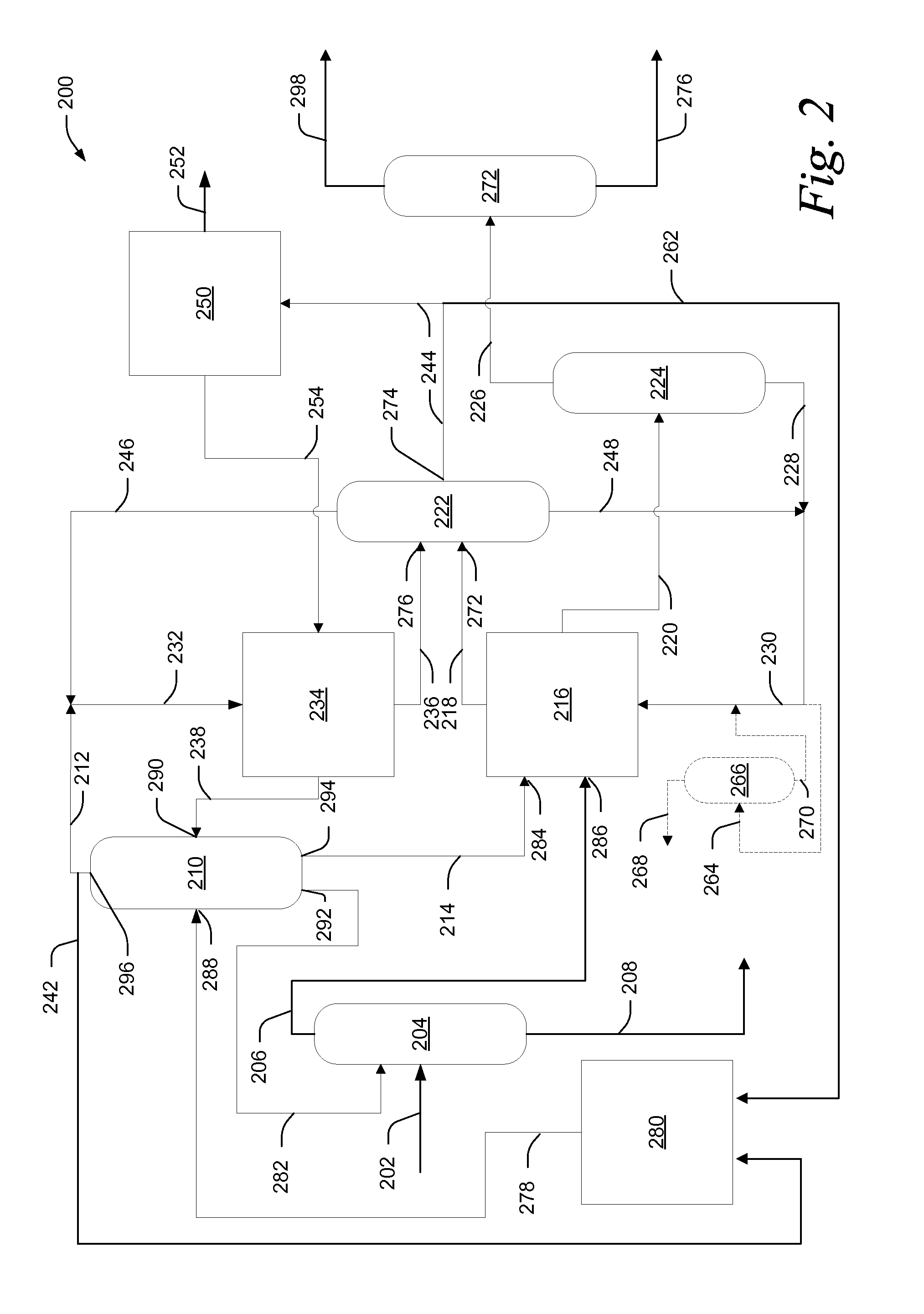

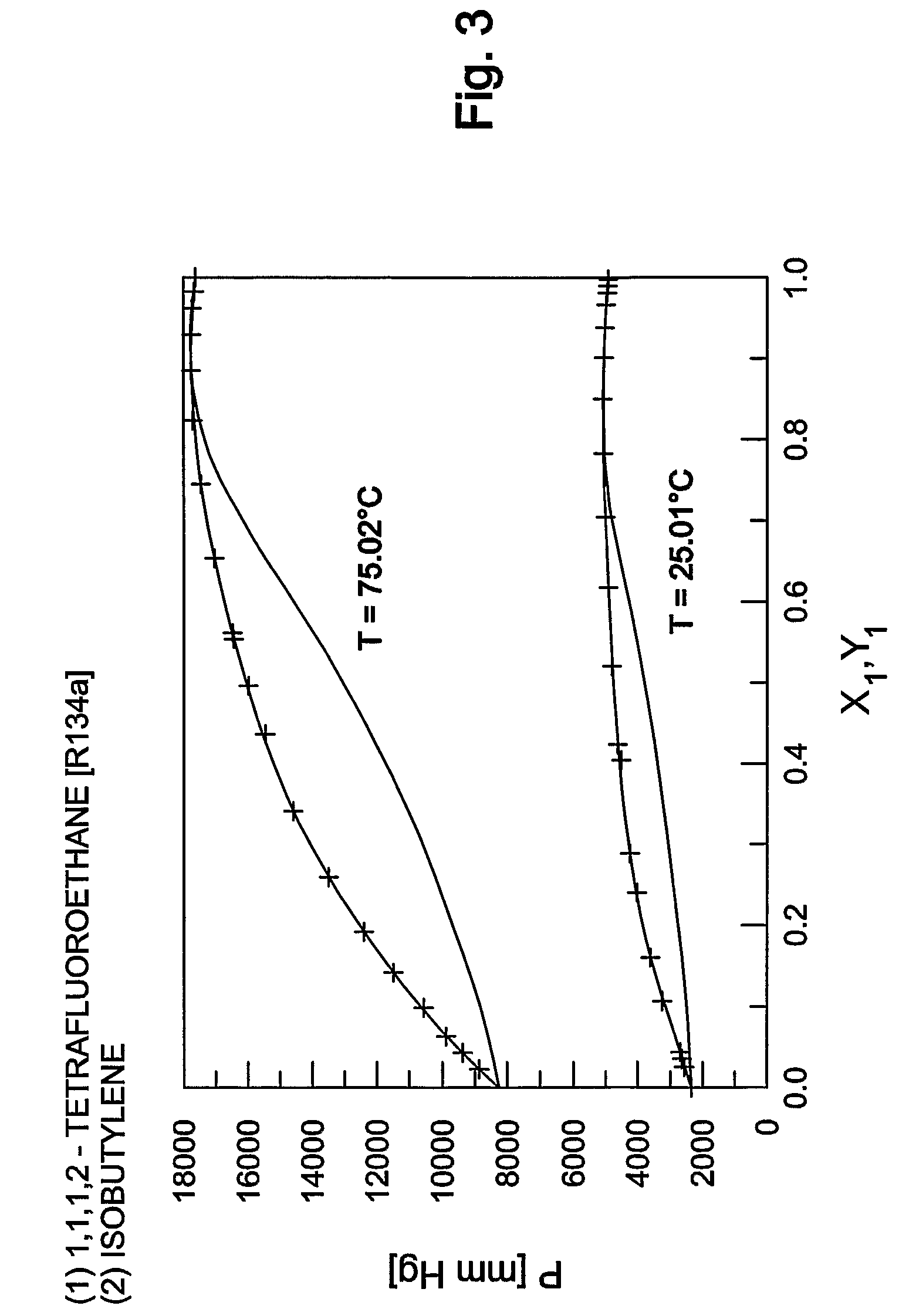

Processes utilizing extractive distillation

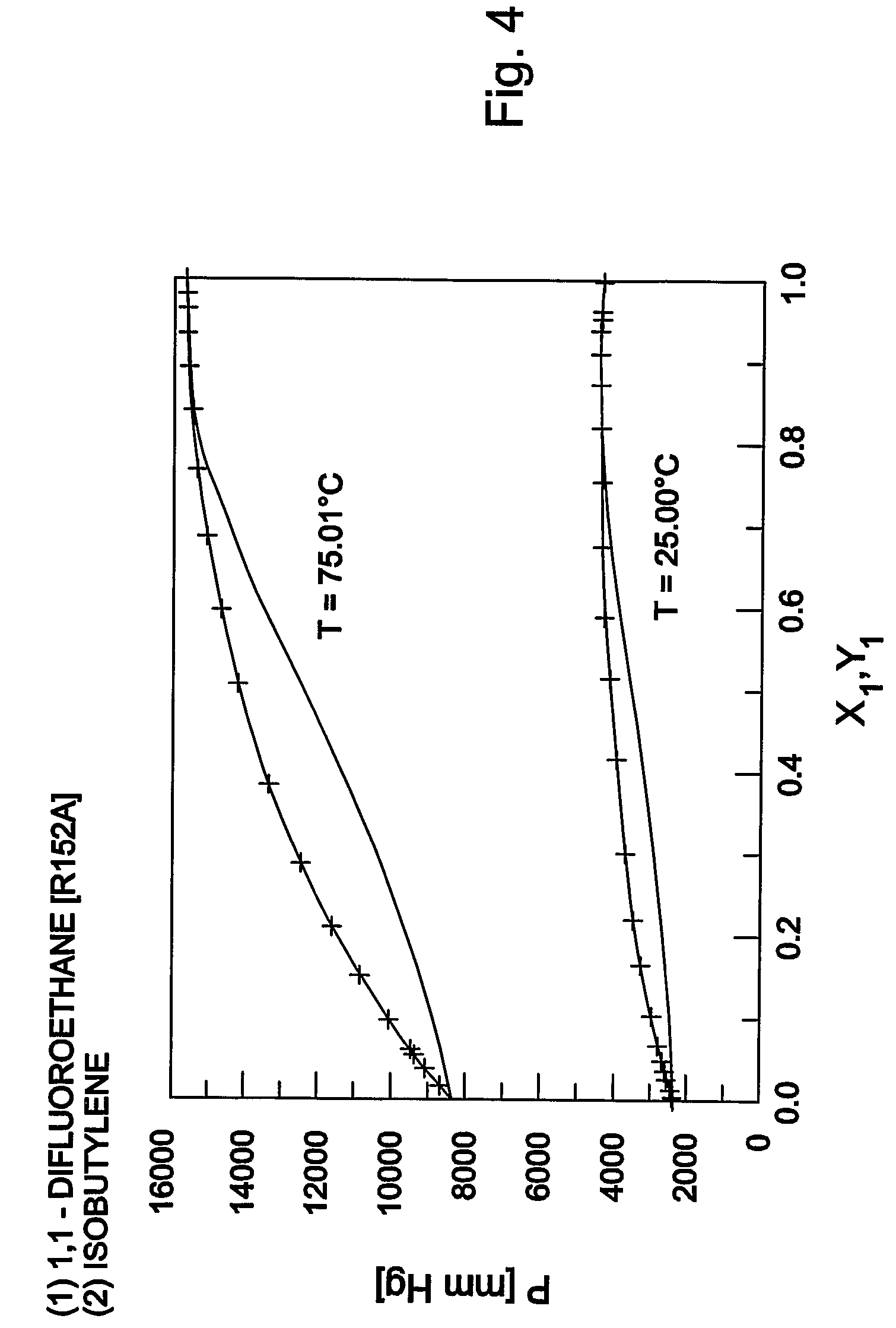

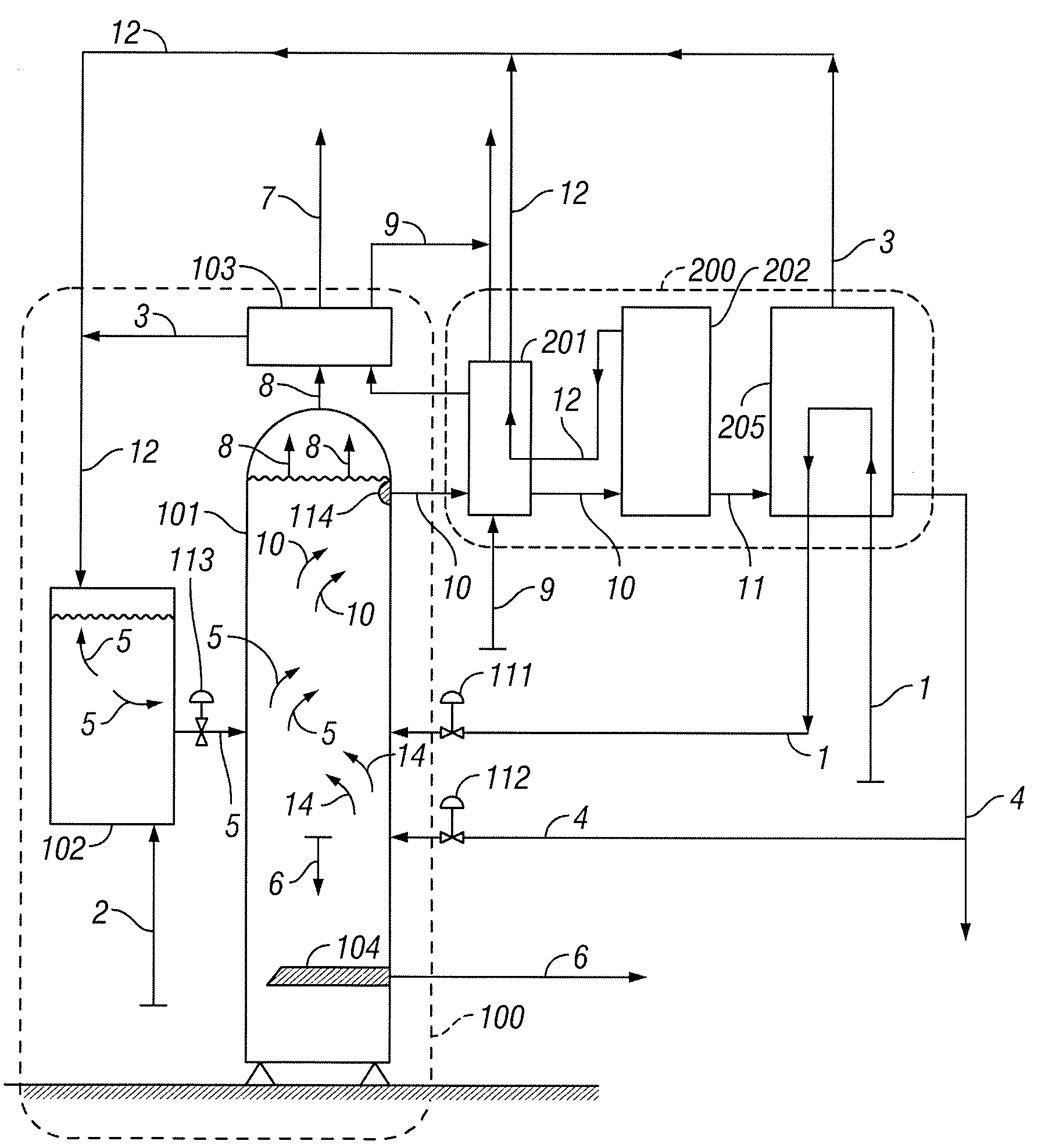

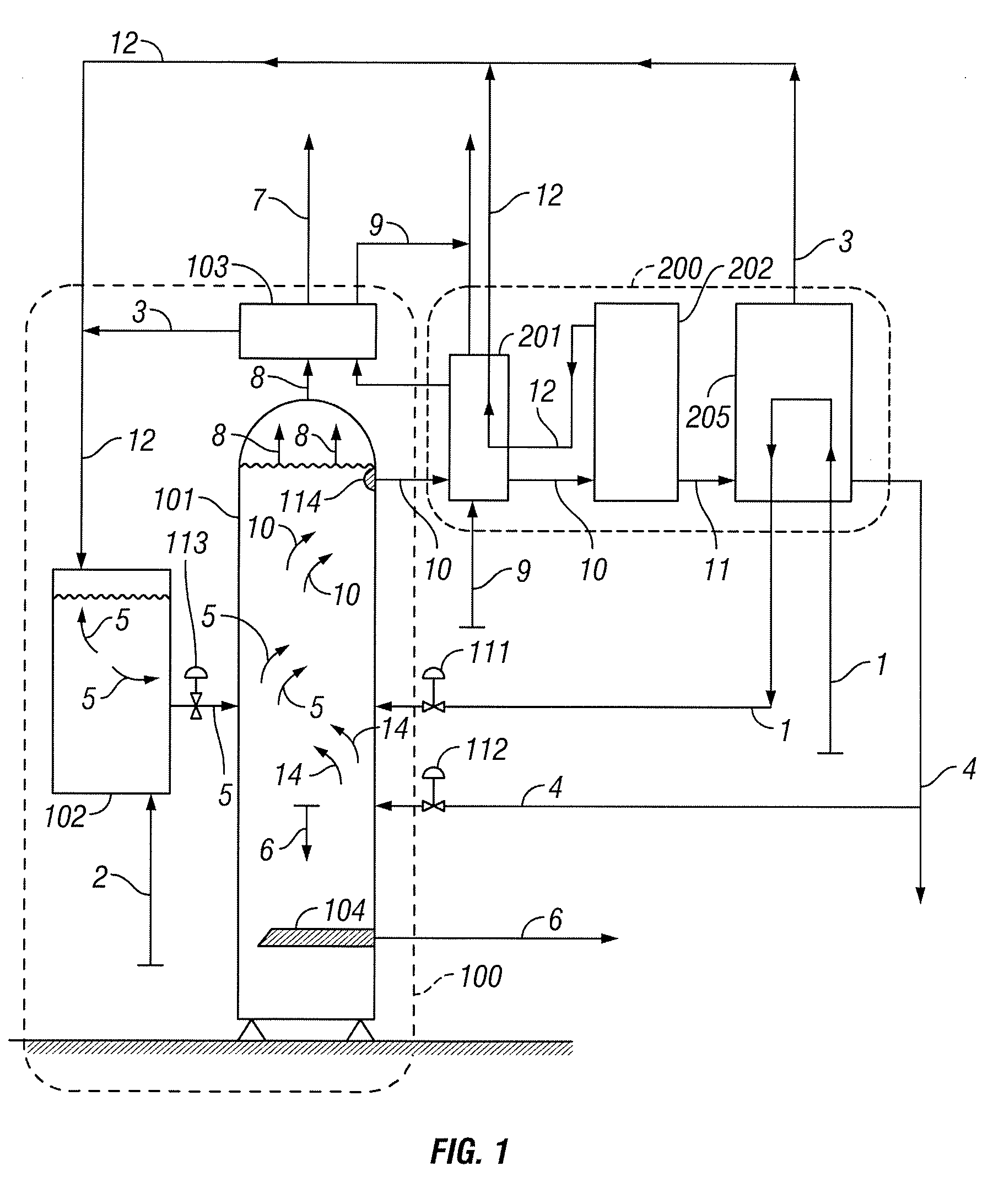

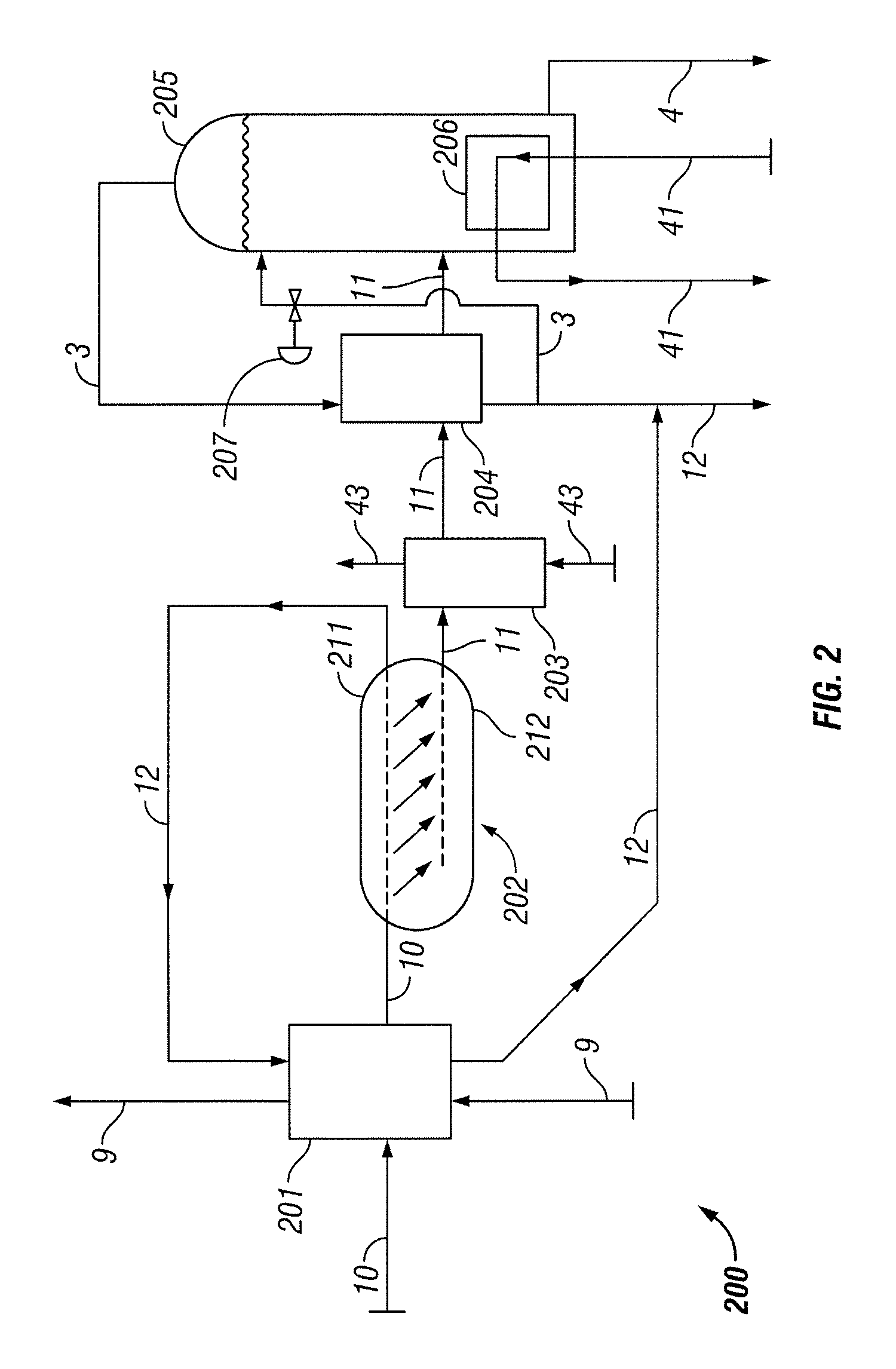

InactiveUS7699962B2Distillation purification/separationHalogenated hydrocarbon separation/purificationExtractive distillationMIXTURE COMPONENT

The invention relates to methods for separating mixture components such as reactor effluent components. In particular, the invention relates to the use of an extractive agent such as a hydrocarbon in an extractive distillation process to separate monomers such as a C4-C7 isoolefins such as isobutylene from mixtures such as reactor effluents including one or more hydrofluorocarbon(s) (HFC).

Owner:EXXONMOBIL CHEM PAT INC

System and method of carbon capture and sequestration

Systems and methods of capturing and sequestering carbon dioxide, comprising mixing a substantially non-aqueous solvent and an alkali such that the solvent and alkali form a solvent suspension, mixing water and a flue gas containing carbon dioxide with the solvent suspension such that a reaction occurs, the reaction resulting in the formation of a carbonate, water and heat.

Owner:EXPANSION ENERGY

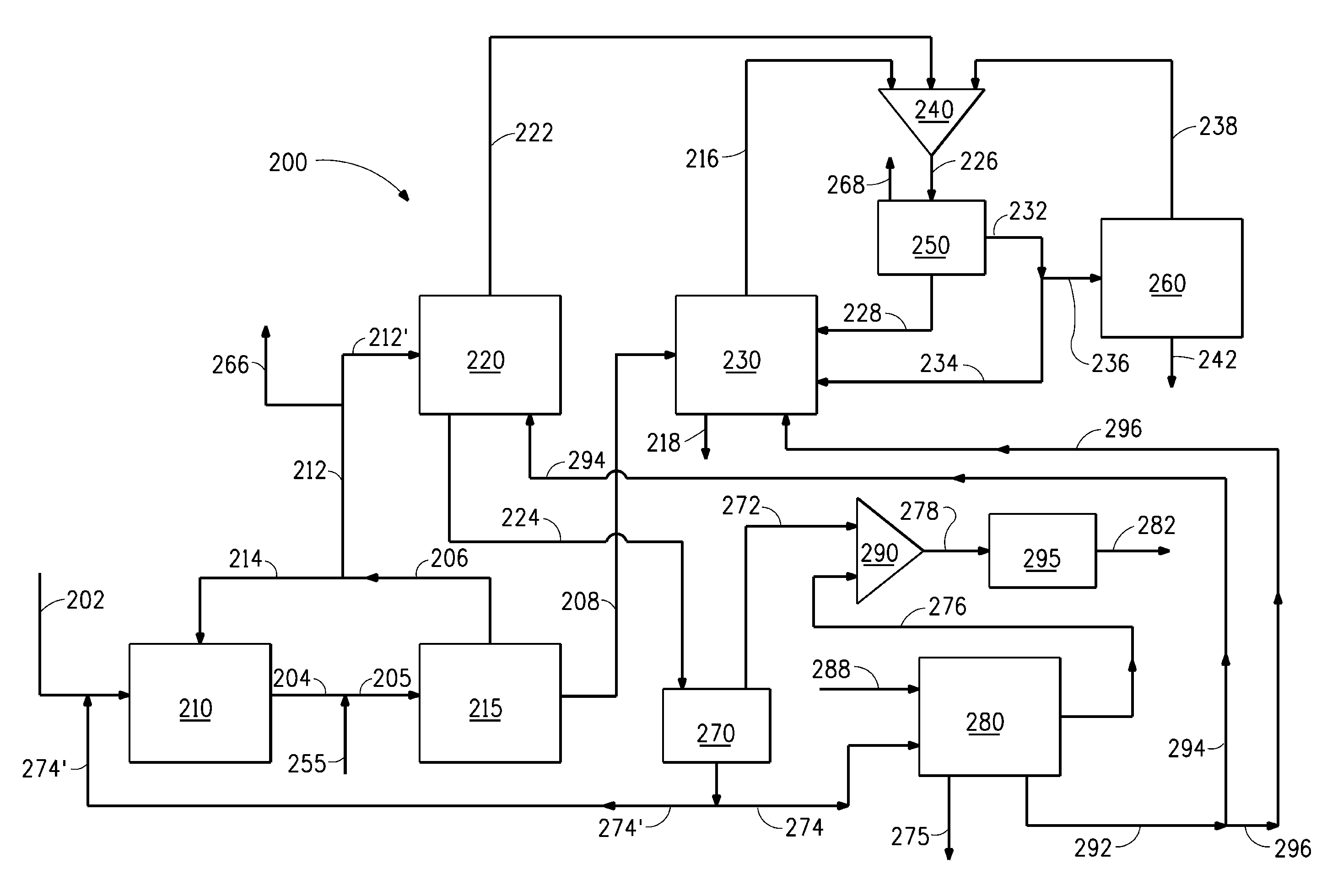

Methods for alcohol recovery and concentration of stillage by-products

ActiveUS8906204B2Efficient use ofHydrocarbon purification/separationAlcoholic beverage preparationAqueous alcoholDistillation

Systems and methods for separating an alcohol, and in particular butanol, from a fermented feed and concentrating thin stillage into syrup includes operation of one or more alcohol recovery distillation columns using the heat supplied by steam generated from concentration of the thin stillage in a multi-train, multi-effect evaporation system.

Owner:GEVO INC

Process for obtaining crude 1,3-butadiene from a C4 cut

ActiveUS7692053B2Distillation regulation/controlDistillation purification/separationSecondary componentExtractive distillation

1,3-butadiene is obtained by extractive distillation with a selective solvent from a C4 cut comprising C4 acetylenes as secondary components in a dividing wall column having a bottom evaporator, in which a dividing wall is disposed in the longitudinal direction of the column to form a first subregion, a second subregion and a lower combined column region. The column is disposed upstream of an extractive wash column. The energy input into the dividing wall column via the bottom evaporator is controlled in such a way that a bottom stream containing solvent, C4 acetylenes and 1,3-butadiene restricted such that the loss of 1,3-butadiene is economically acceptable, is drawn off and fed to an acetylenes outgasser where the C4 acetylenes are stripped out overhead and purified solvent is obtained as the bottom stream.

Owner:BASF AG

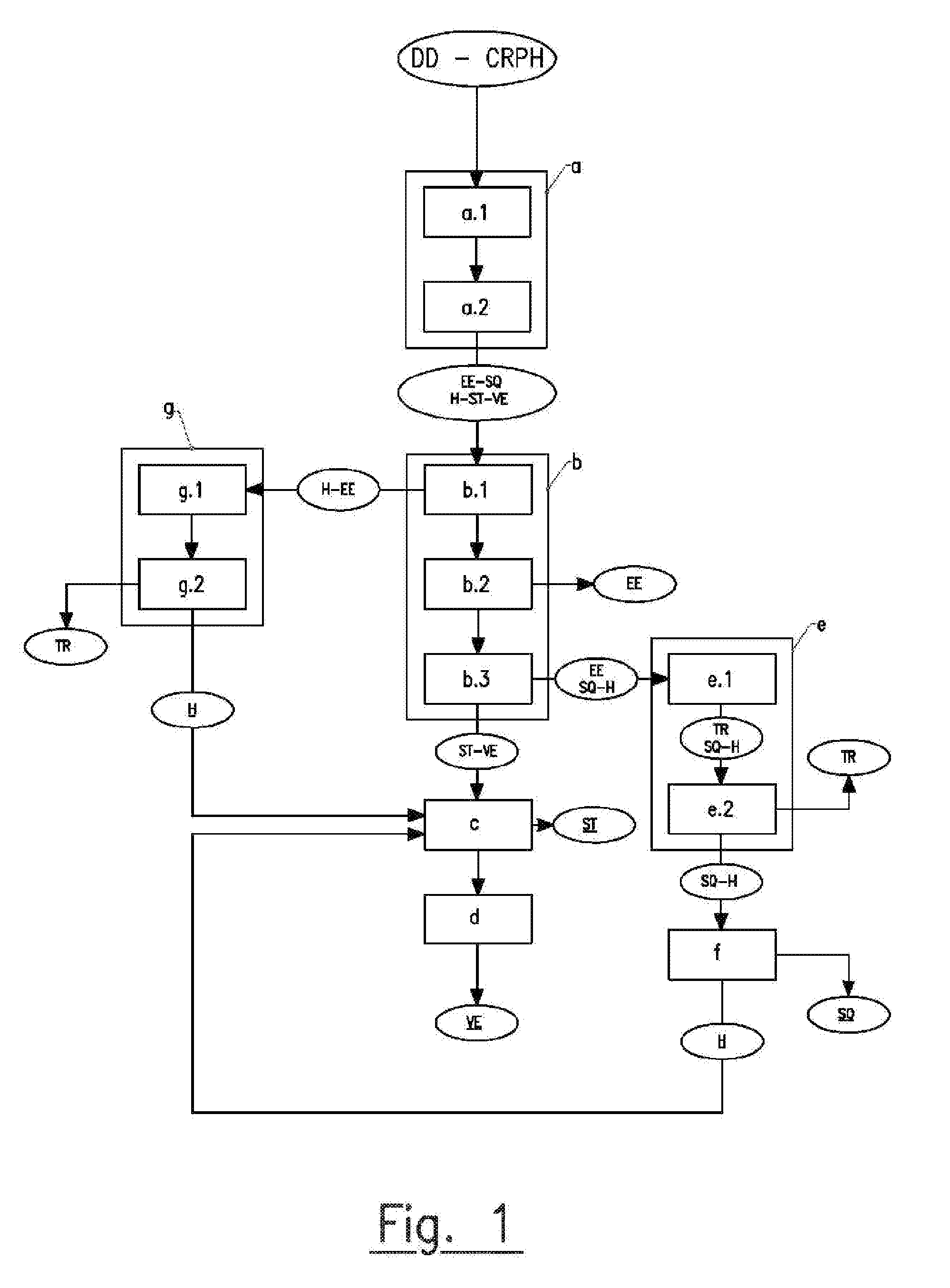

Process for the extraction of squalene, sterols and vitamin e contained in condensates of physical refining and/or in distillates of deodorization of plant oils

InactiveUS20110220483A1High priceEasy to useFatty acid esterificationMetabolism disorderSterolVegetable oil

The invention describes a global method for extracting sterols, vitamin E, squalene and other vegetable hydrocarbons from deodorization distillates of vegetable oils. After esterification of the free fatty acids, followed by trans-esterification of the combined fatty acids (glycerides and sterides) with the same short alcohol, three successive distillations allow successive recovery of a first fraction of the hydrocarbons, the main fraction of alkyl esters, and then the heaviest alkyl esters with squalene. The third distillate will be used for producing squalene and a second fraction of hydrocarbons. The residue of the third distillation will be used for producing sterols and vitamin E. By using bio-ethanol, vegetable glycerol and the vegetable hydrocarbons of the method, with the method it is possible to extract each of the four unsaponifiables without any solvent of petroleum origin and claim the labels of products obtained by natural physical and chemical methods.

Owner:SOPHIM

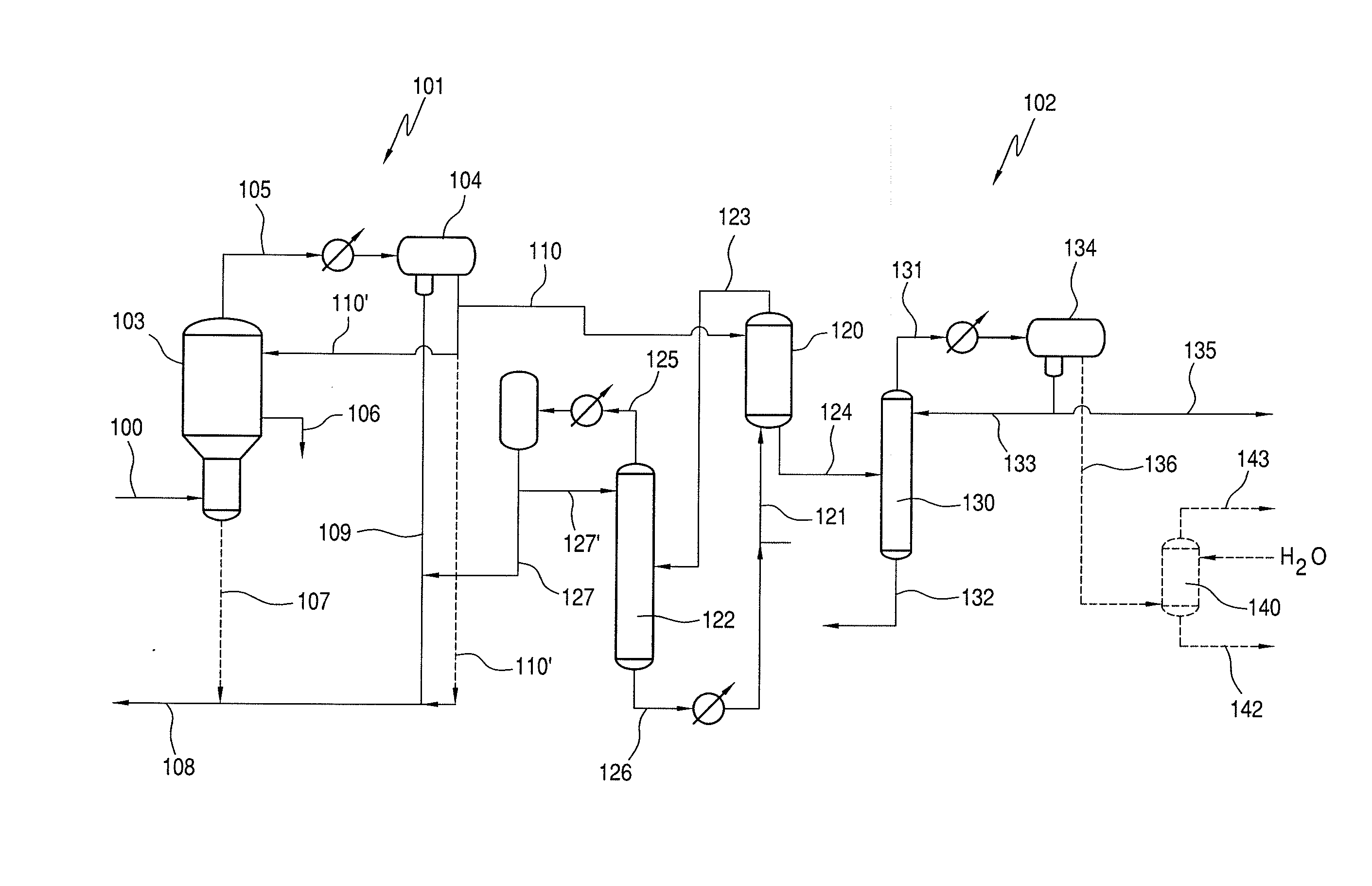

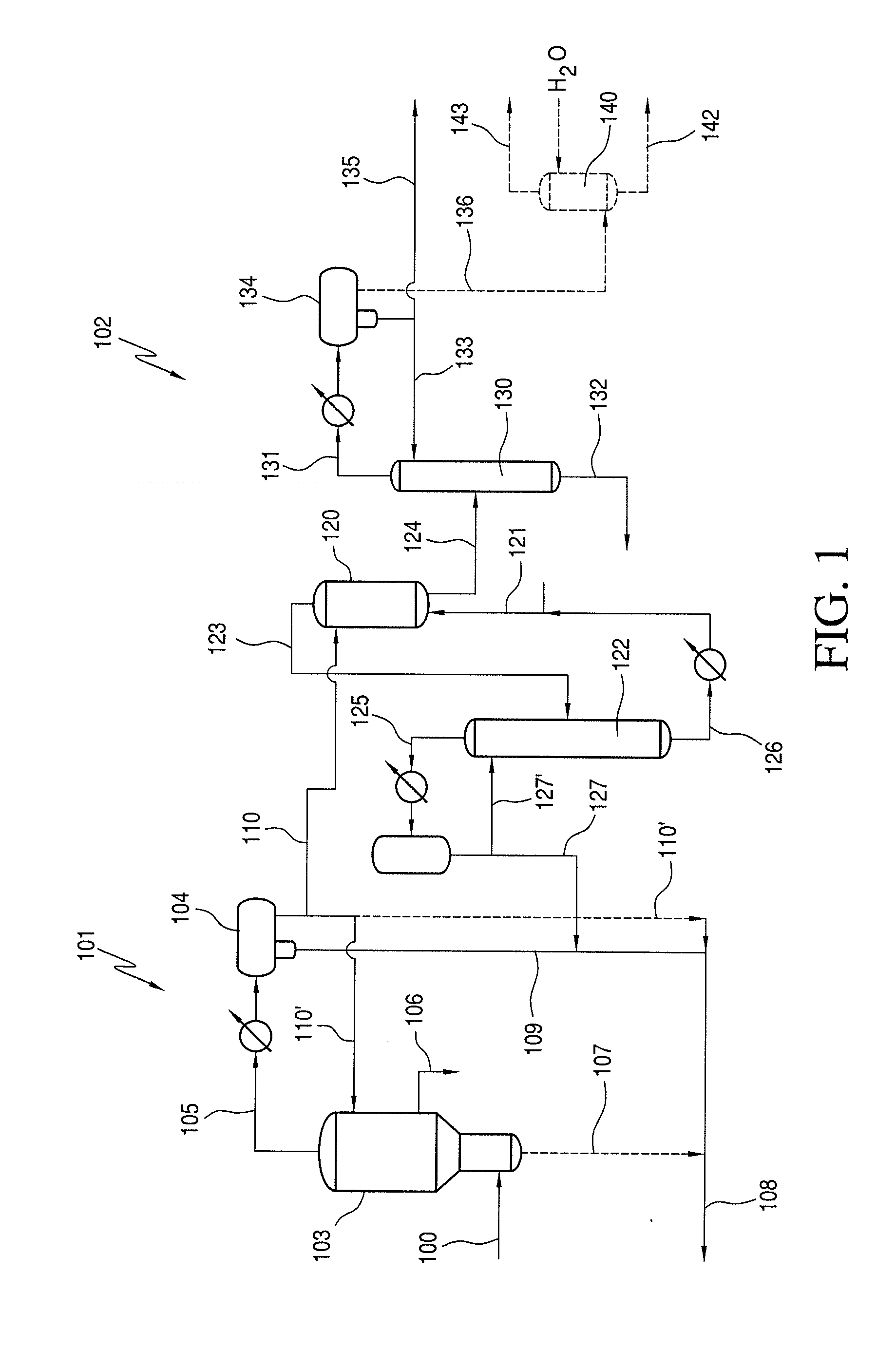

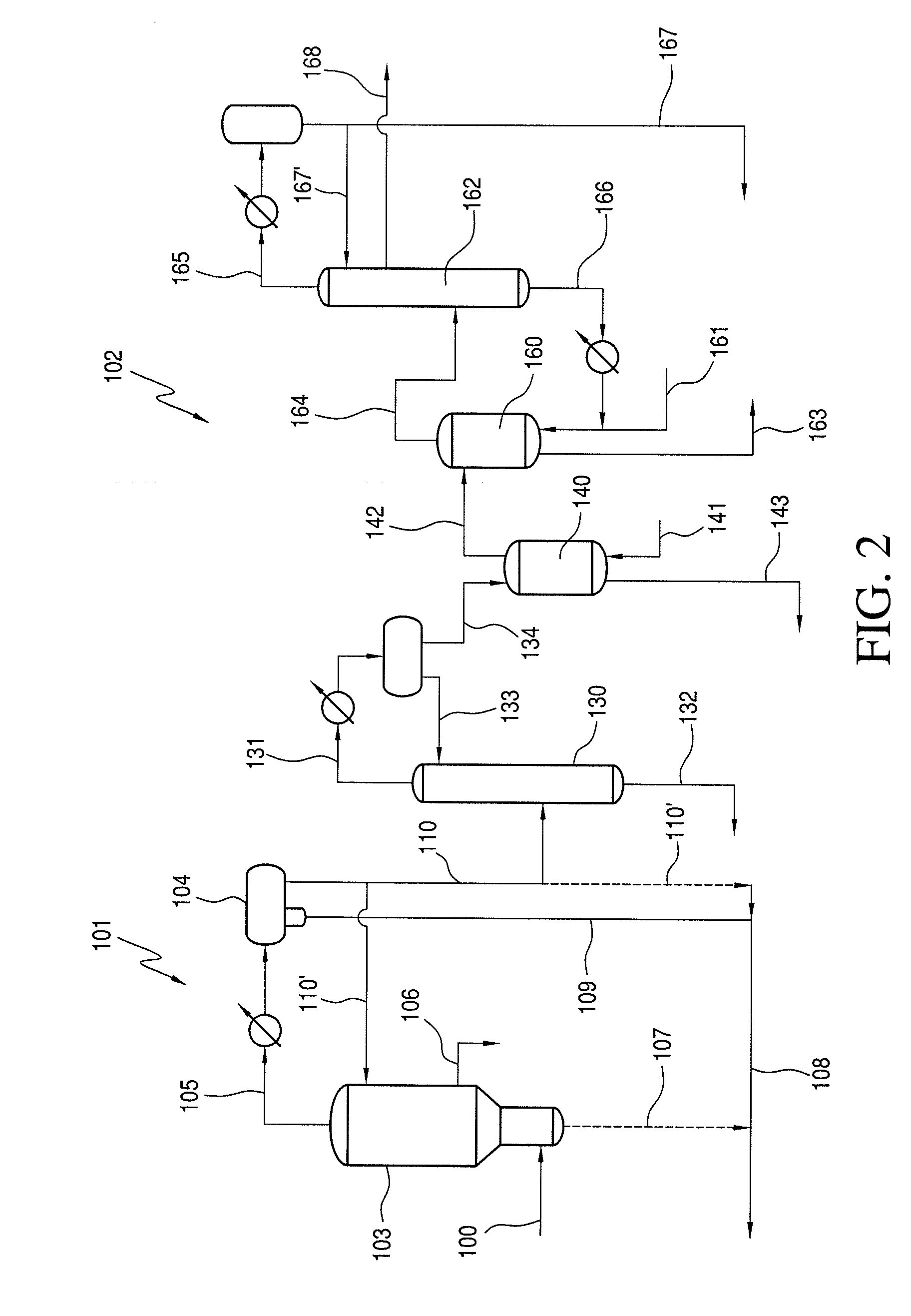

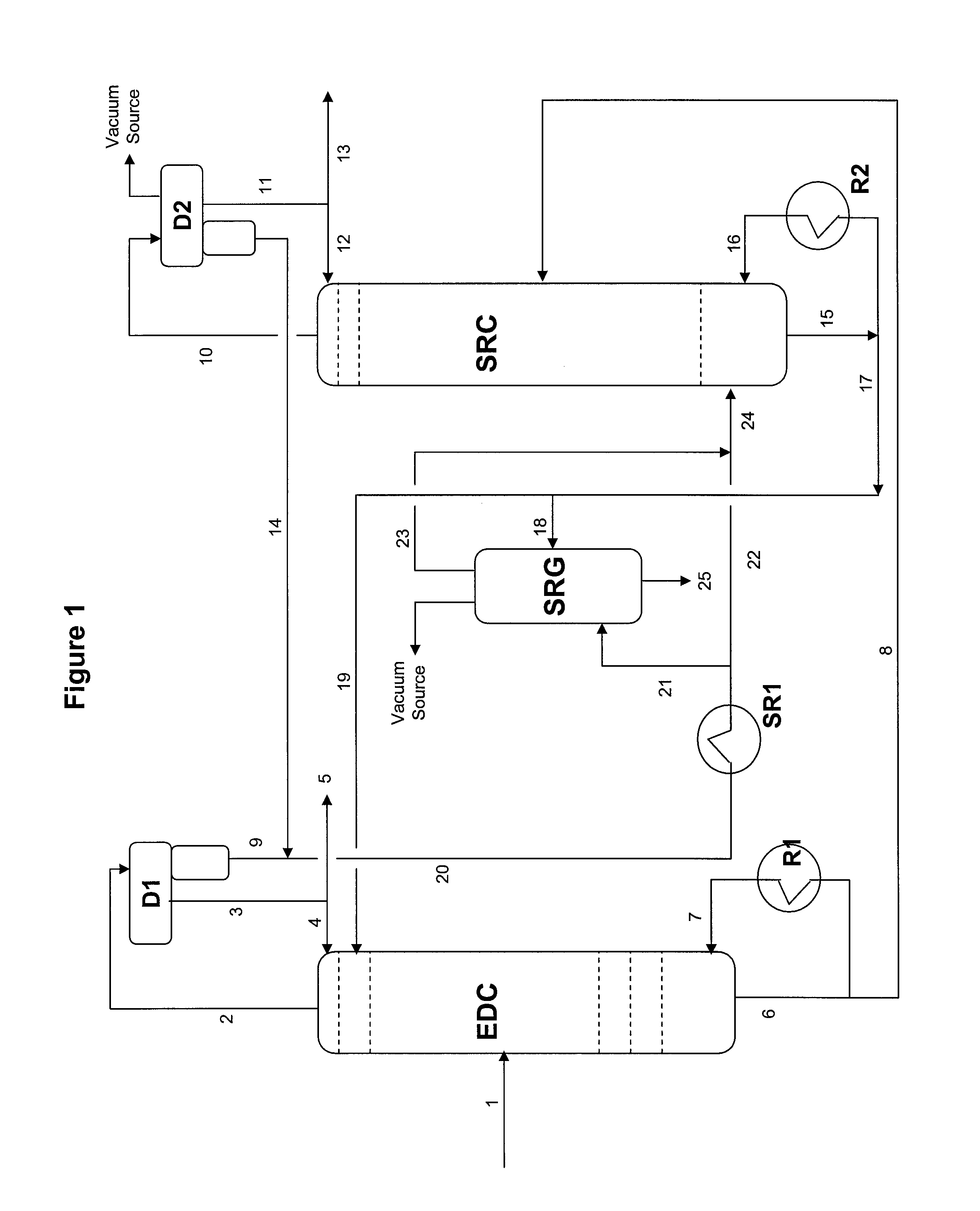

Extractive distillation process for recovering aromatics from petroleum streams

The present invention relates to a process for recovering polar hydrocarbons from non-polar hydrocarbons, such as aromatics from non-aromatics, naphthenes from paraffins and isoparaffins, or olefins from paraffins and isoparaffins, in feed mixtures containing at least a measurable amount of heavier hydrocarbons. According to the invention, an improved extractive distillation (ED) process is disclosed for recovering aromatic hydrocarbons including benzene, toluene, and xylenes (BTX aromatics) from the C6-C8 petroleum streams containing at least a measurable amount of C9+ hydrocarbons.The invention also relates to an improved ED process for recovering mainly benzene and toluene from the C6-C7 petroleum streams containing at least a measurable amount of C8+ hydrocarbons. This invention is further directed toward the regeneration and recovery of the ED solvent utilized to recover and purify the aromatic hydrocarbons from the petroleum stream containing at least a measurable amount of hydrocarbons heavier than intend feedstock.

Owner:AMT INT INC +1

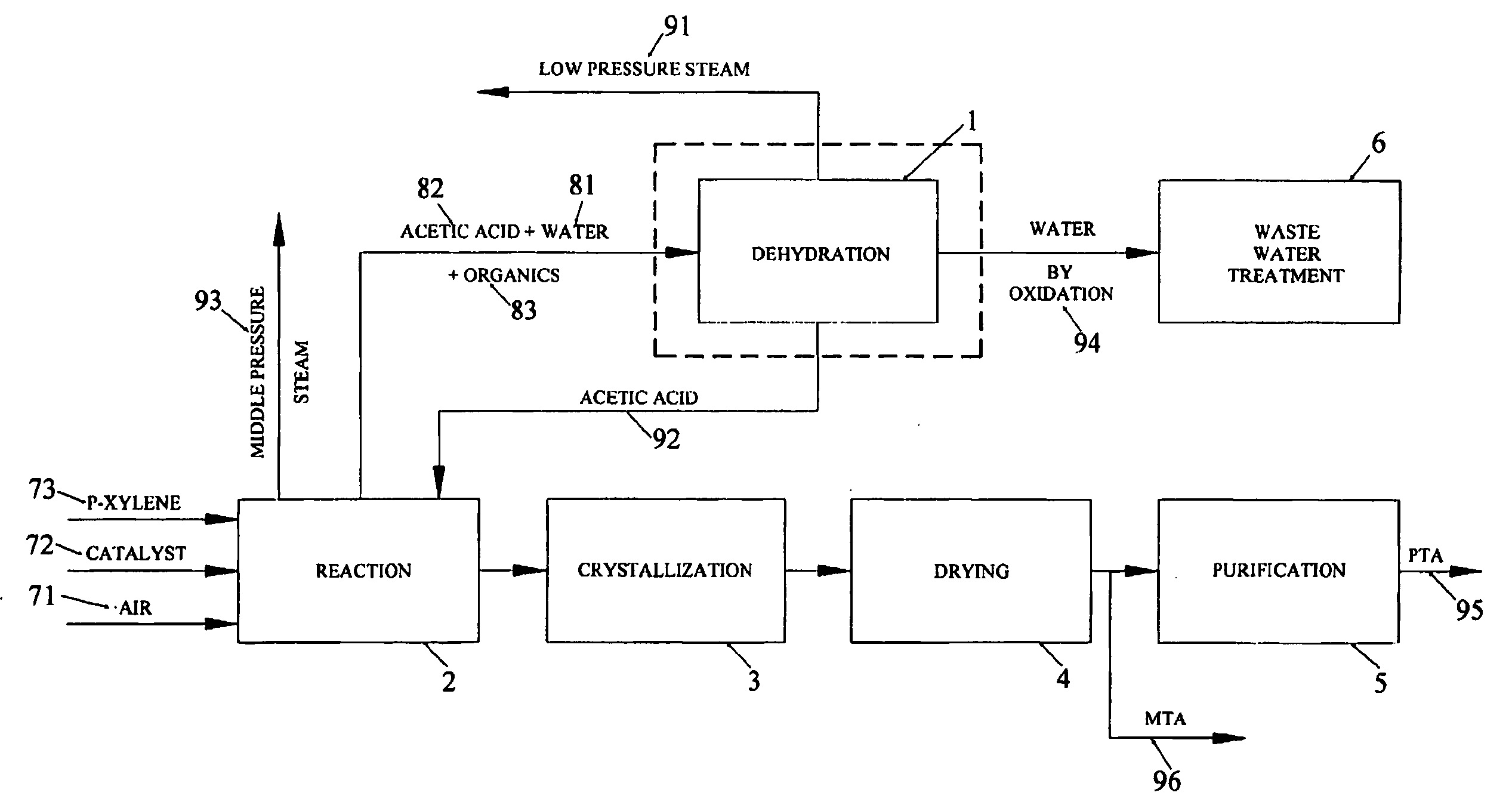

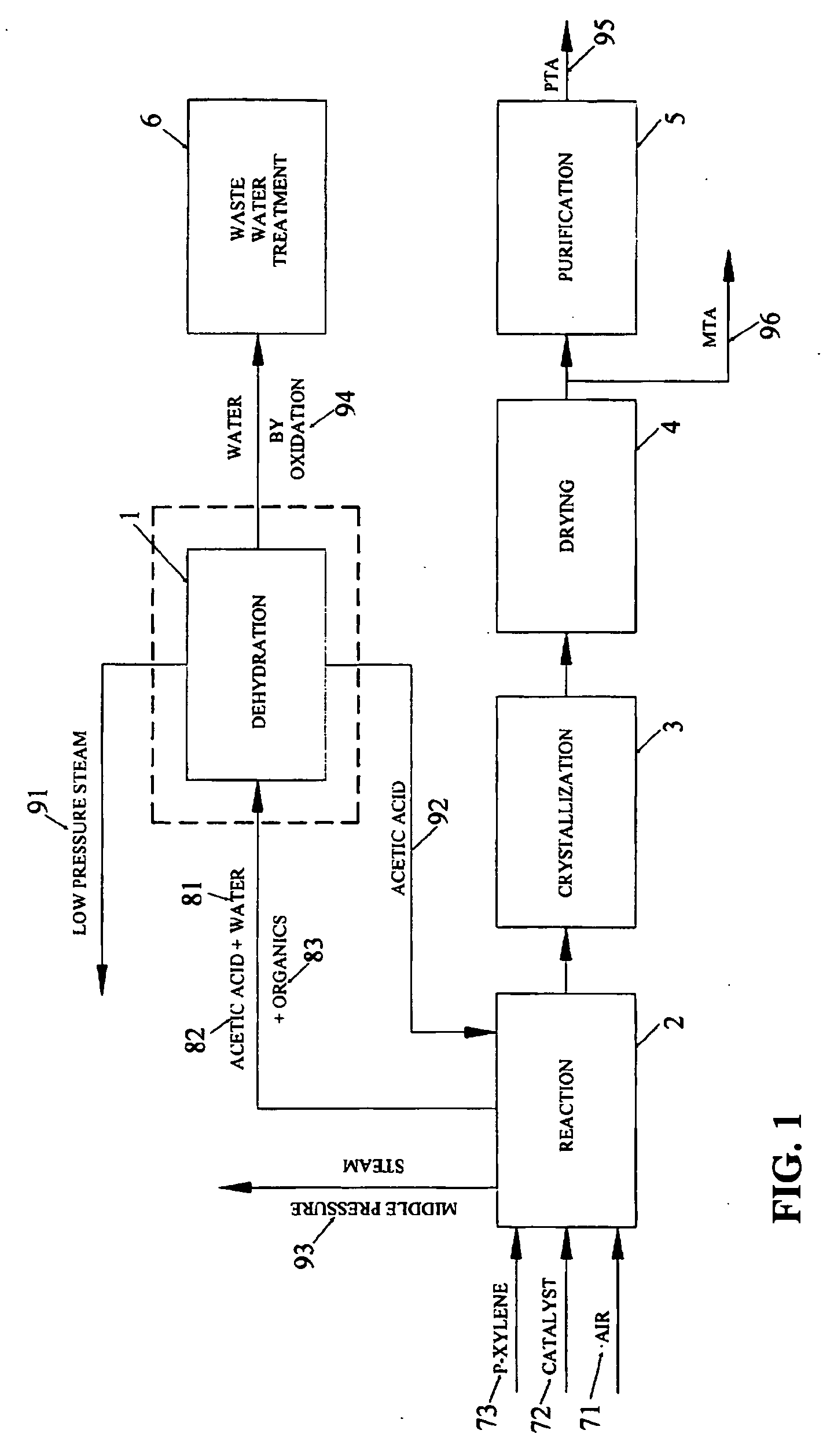

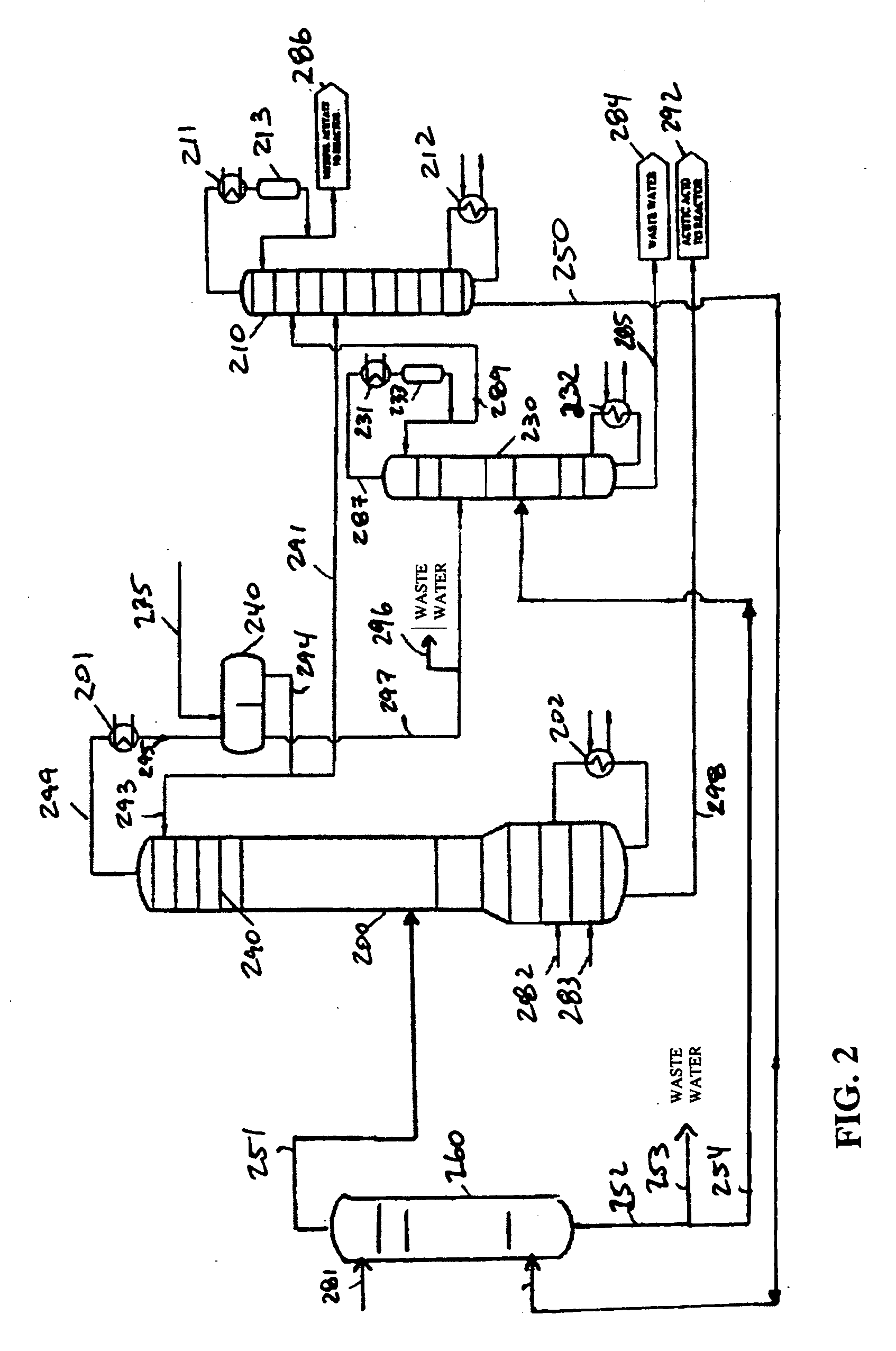

System and method for acetic acid dehydration

InactiveUS20070068792A1OptimizationOrganic compounds purification/separation/stabilisationOrganic compound preparationAcetic acidSteam condensation

Disclosed is a distillation system and method for recovering acetic acid from a feed stream containing acetic acid and water stream generated during terephthalic acid production. The invention includes a liquid-liquid extraction column and a dehydration distillation column utilizing azeotropic distillation or conventional to recover the acetic acid. The liquid-liquid extraction column is installed upstream from the dehydration distillation column. The liquid-liquid extraction column produces an extract of an extraction solvent and acetic acid which is sent to the dehydration distillation column to separate the extraction solvent and acetic acid. The dehydration distillation column may be used with or without a condenser system to recover the energy. The condenser system is a steam generator that condenses the vapor into a concentrated acetic acid stream while generating a low pressure steam. Any remaining acetic acid in water is sent to a waste water recycling facility.

Owner:AMT INT INC

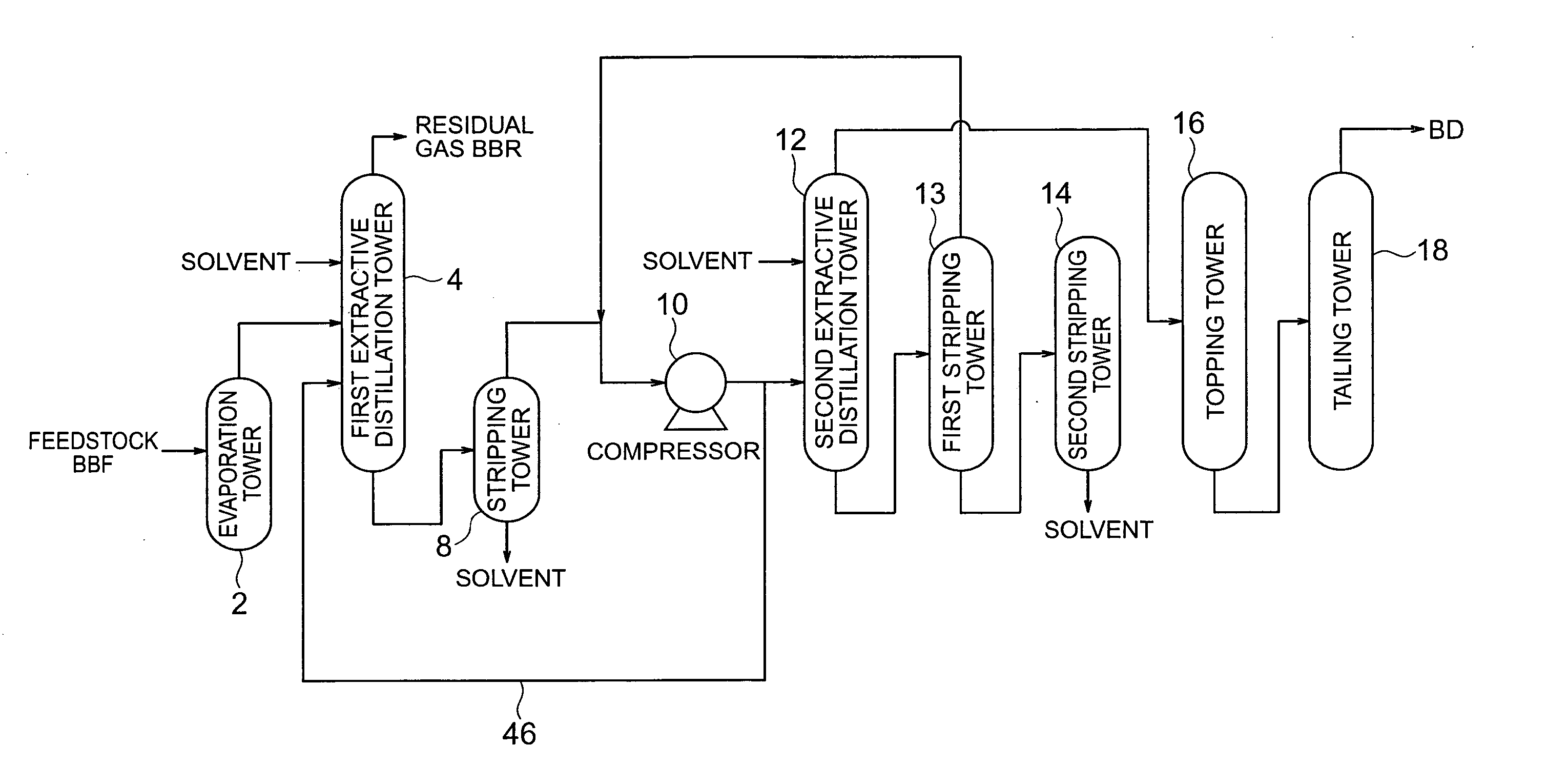

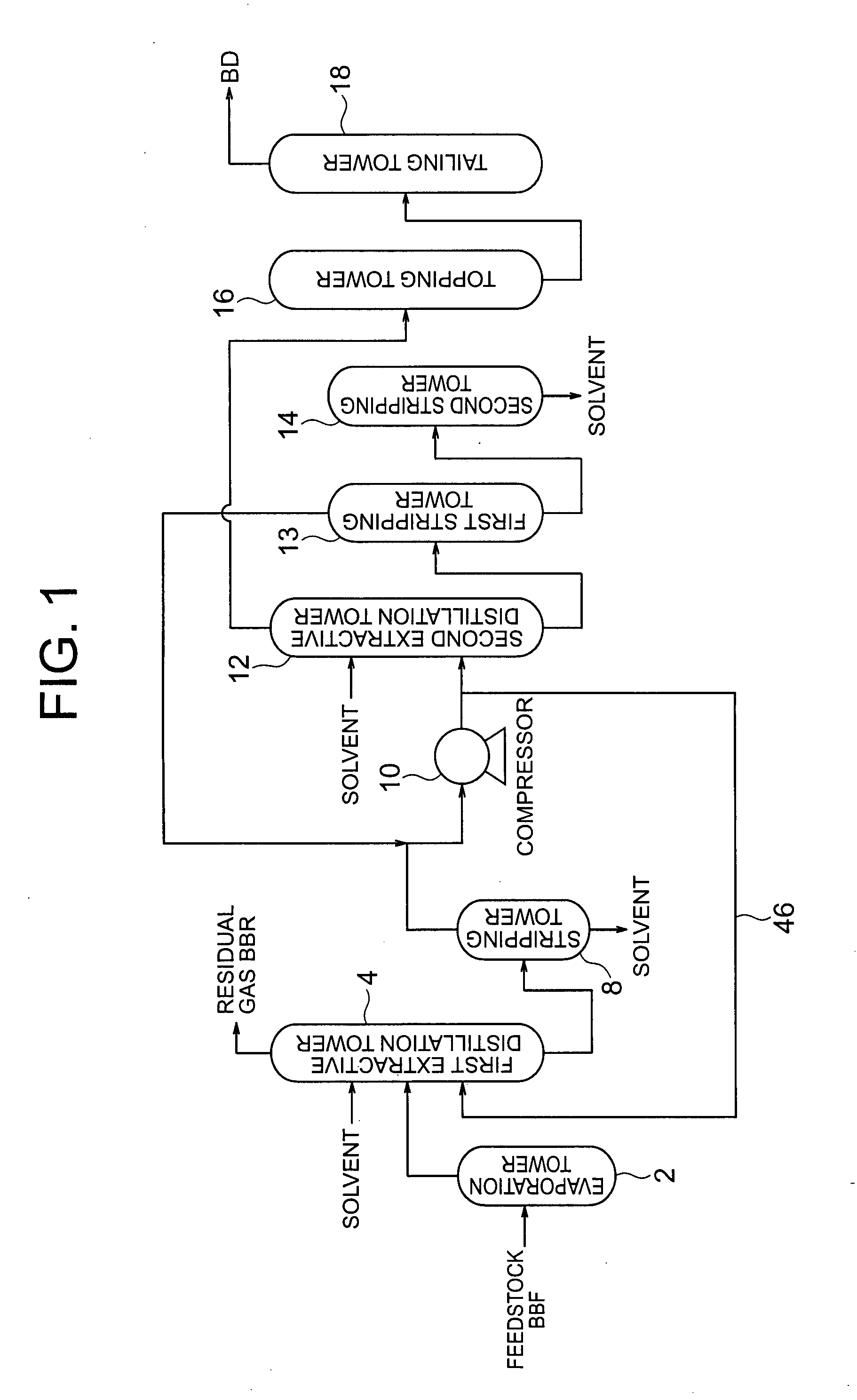

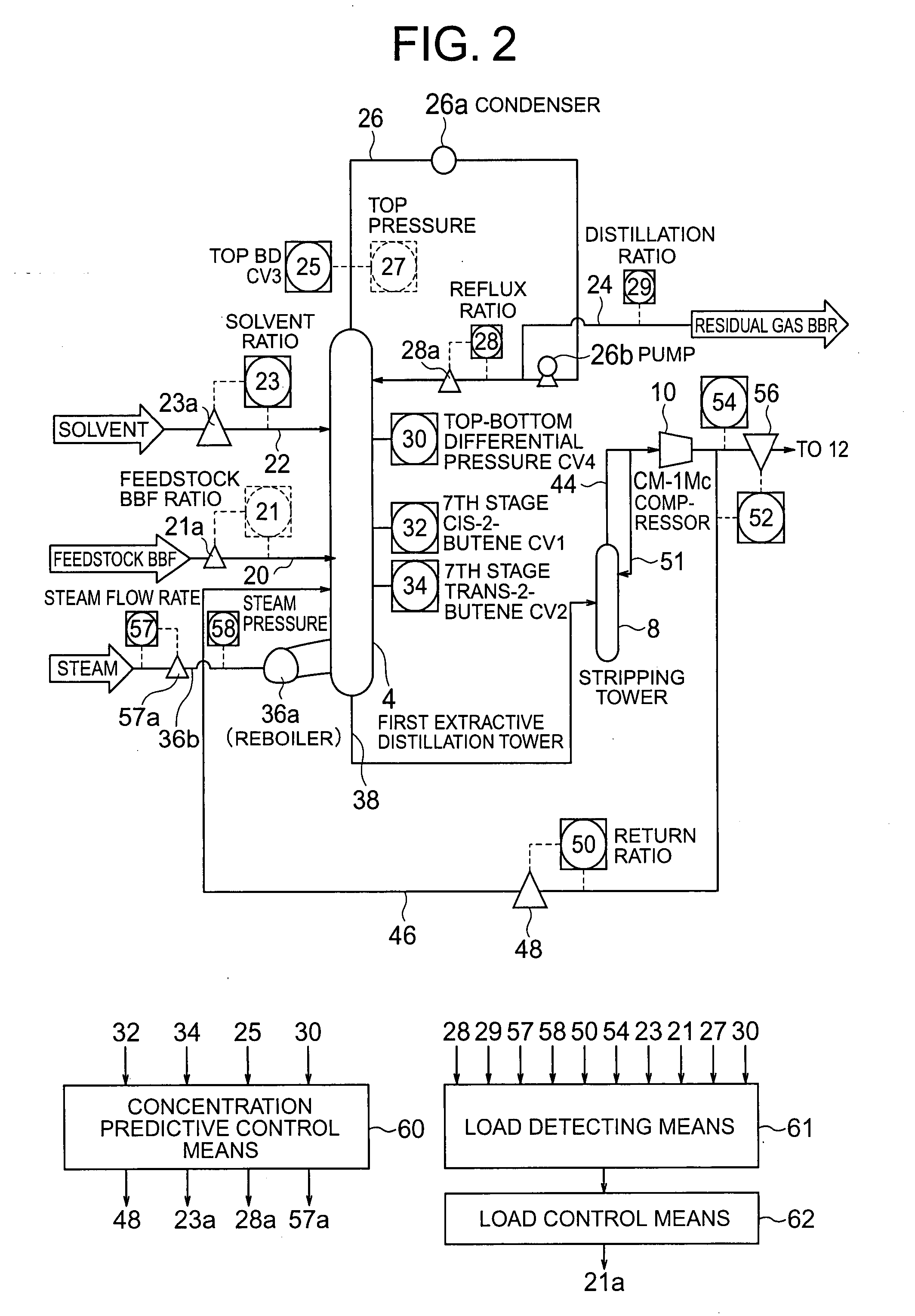

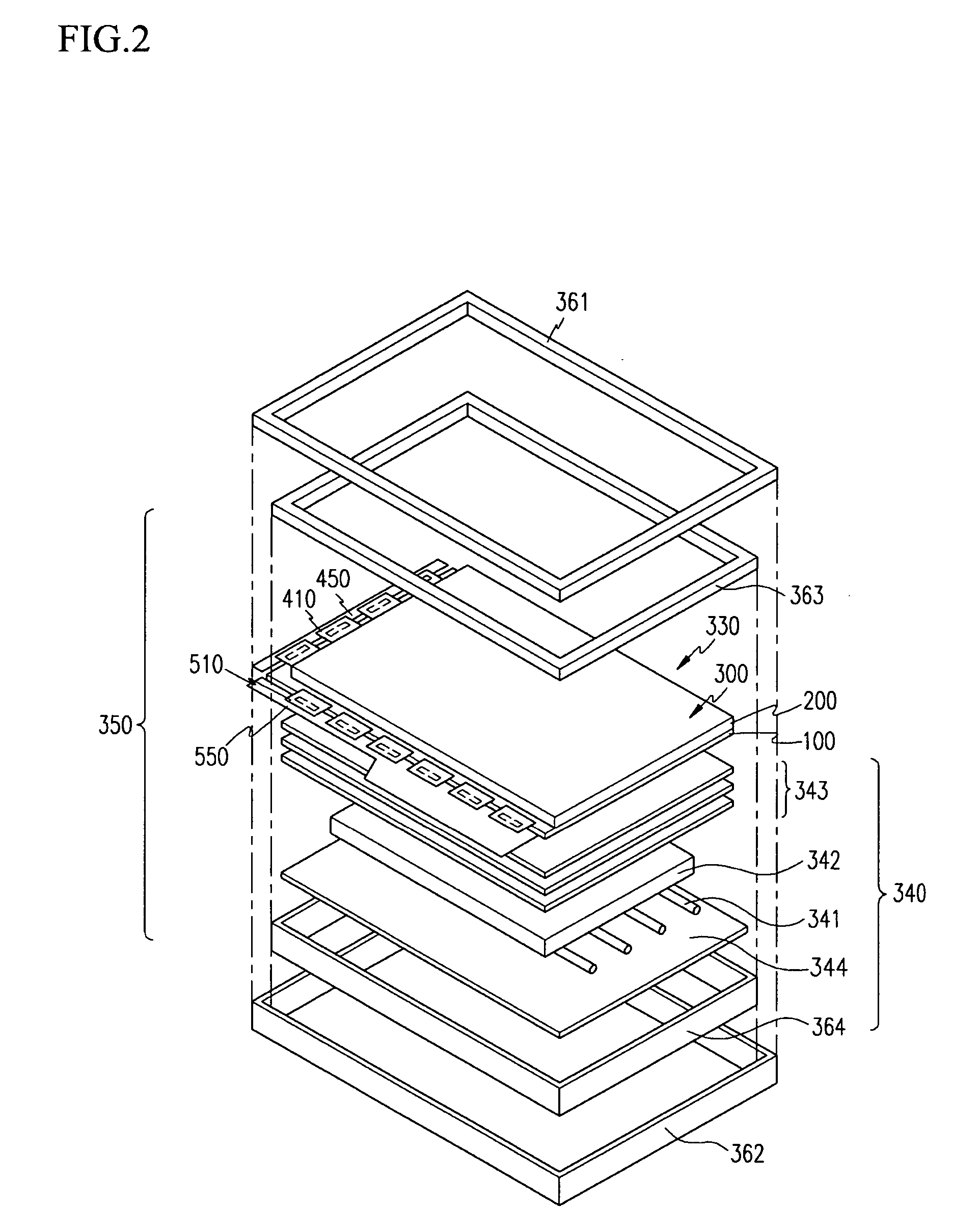

Separation and Purification Apparatus and Separation and Purification Method of Unsaturated Hydrocarbons

InactiveUS20070256920A1Increase production capacityImproves inventionDistillation regulation/controlDistillation in boilers/stillsPurification methodsExtractive distillation

For example, a separation and purification apparatus having an extractive distillation tower 4 for separating and purifying butadiene, impurity concentration sensors 32, 34 for detecting the concentrations of specific impurities other than butadiene, a target material concentration sensor for detecting the concentration of butadiene in the extractive distillation tower, and a differential pressure sensor 30 for detecting the differential pressure between the top and bottom of the extractive distillation tower 4 and a separation and purification method. The method calculates a concentration of a specific impurity after a predetermined time, a concentration of butadiene at the top, and a forecasted value of the differential pressure between the top and bottom based on the sensors and controls operations based on the forecasted values by a concentration predictive control means 60. It controls a feedstock flow rate control valve 21a controlling the rate of feedstock fed to the extractive distillation tower 4, a load detecting means 61 for detecting the load of the extractive distillation tower, and a feedstock flow rate control valve 21a by a load control means 62 in accordance with detection values detected by the load detecting means 61.

Owner:ZEON CORP

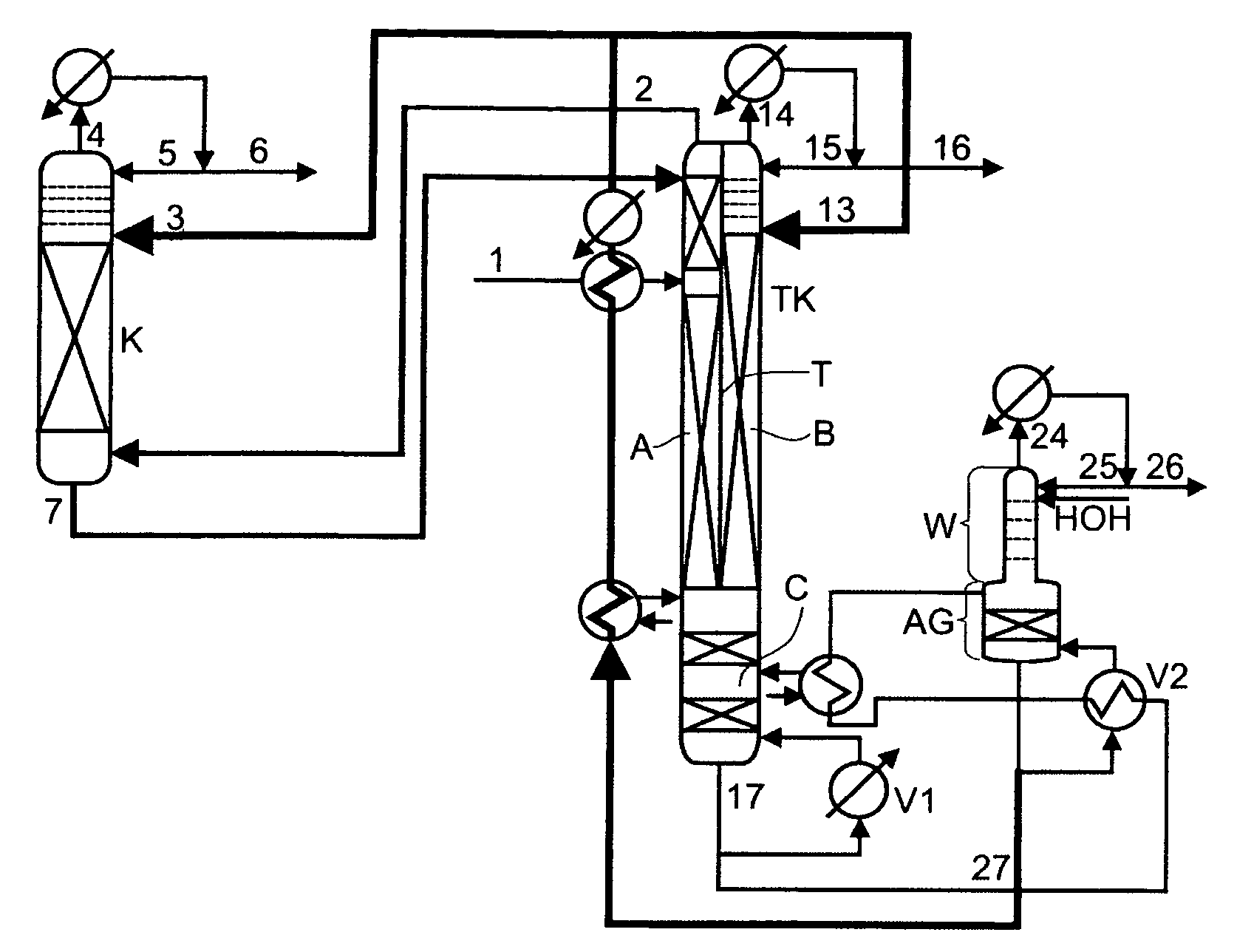

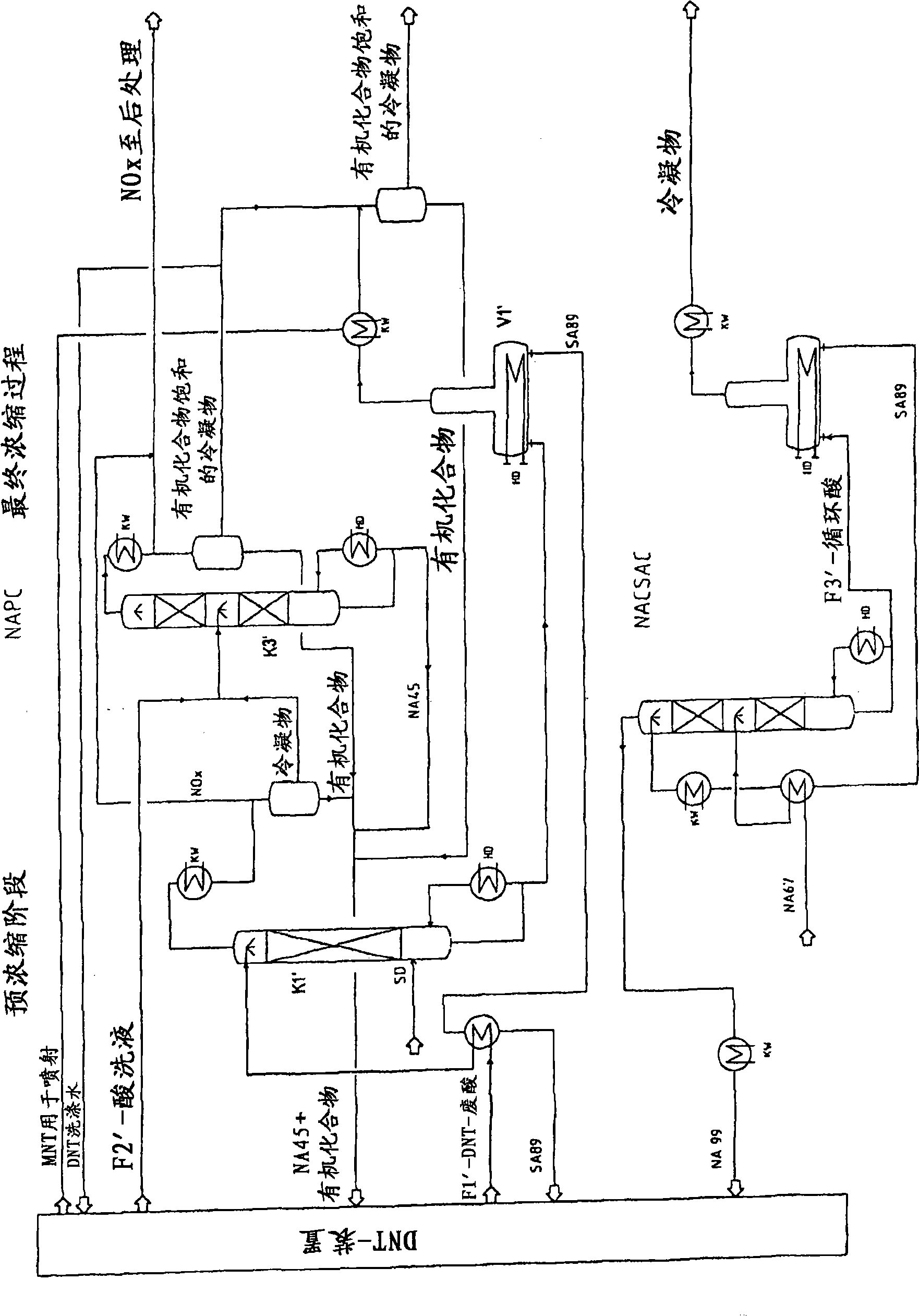

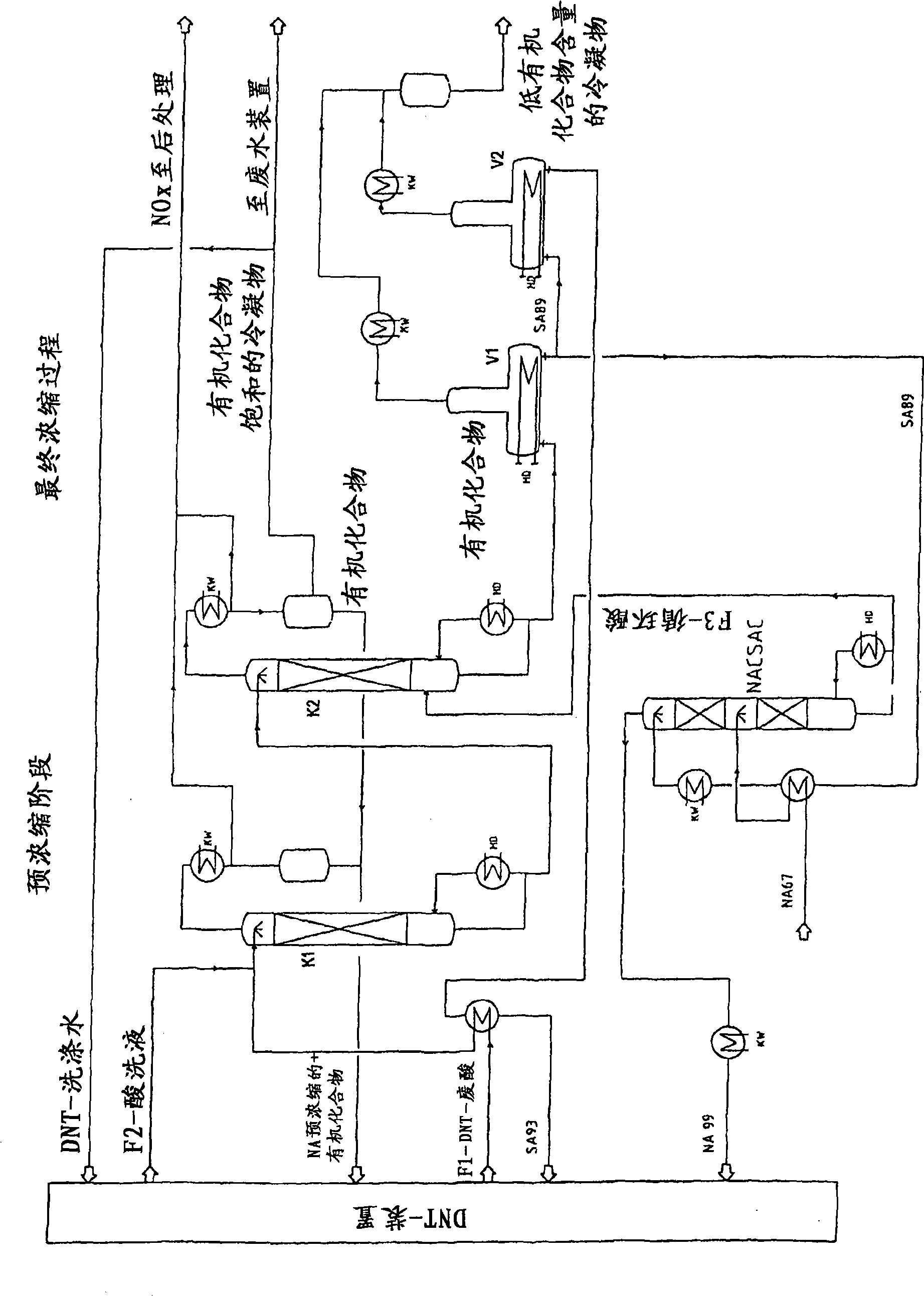

Process and installation for concentrating waste sulphuric acids from nitration processes

Disclosed is a method for recovering diluted waste sulfuric acid containing impurities from nitration processes, a highly concentrated nitric acid required in the nitration process being produced in association with the nitration process by means of extractive rectification with concentrated sulfuric acid which is re-concentrated in order to be reutilized. According to the inventive method, the waste sulfuric acid from the nitration process is fed to the top of a first, indirectly heated stripping column, optionally together with another waste sulfuric acid in the form of a DNT washing acid, and is divided into an overhead product containing nitric acid and nitro-organic compounds as well as a prepurified sulfuric acid in the bottom product. The prepurified sulfuric acid withdrawn from the bottom of the first stripping column is fed to the top of a second, serially connected additional indirectly heated stripping column, into the bottom zone of which another waste sulfuric acid is fed in the form of a diluted sulfuric acid recovered from the nitric acid concentration system such that the prepurified sulfuric acid from the first stripping column is further purified in the second stripping column and is preconcentrated along with the diluted sulfuric acid recovered from the extractive rectification of nitric acid.

Owner:DE DIETRICH PROCESS SYST

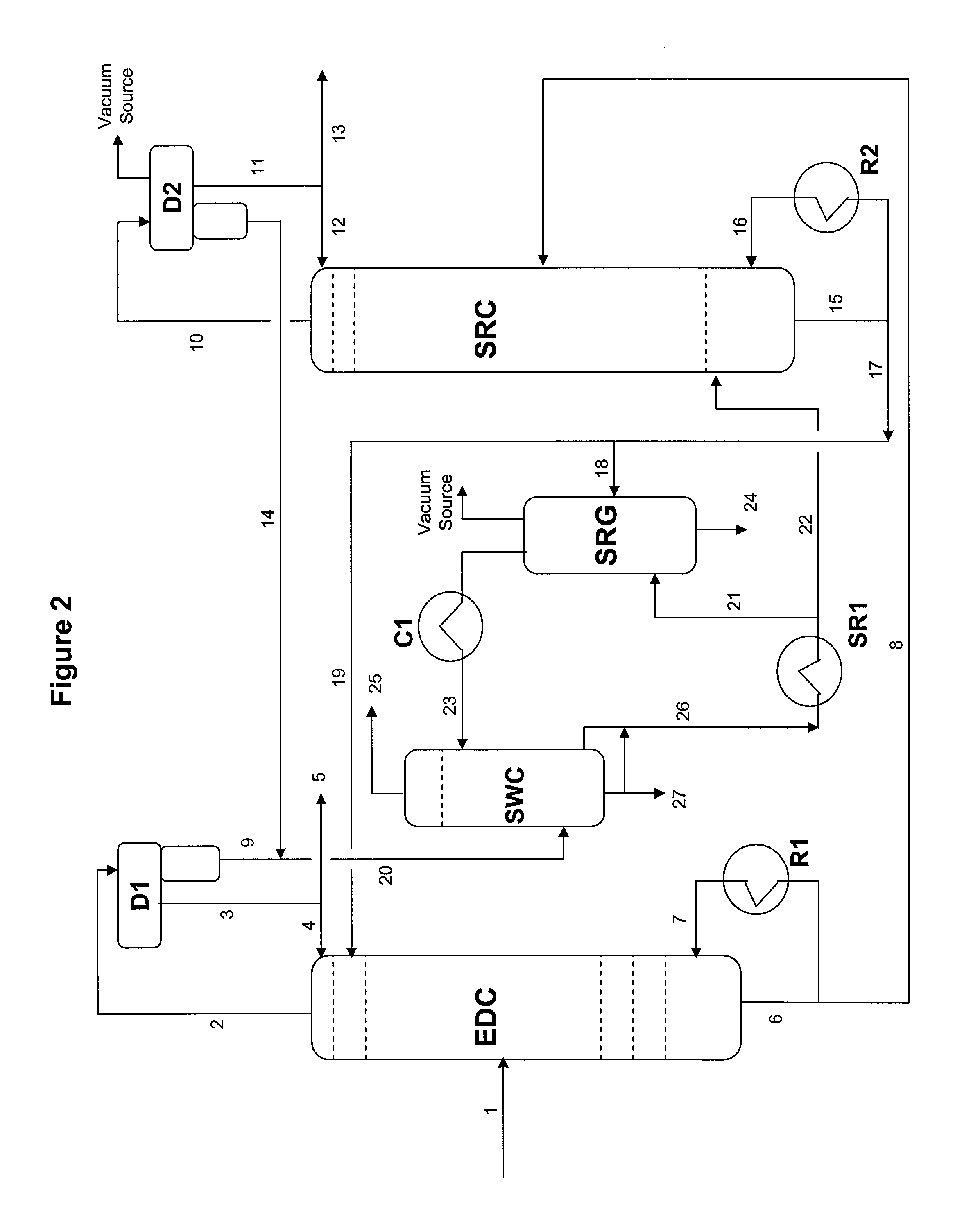

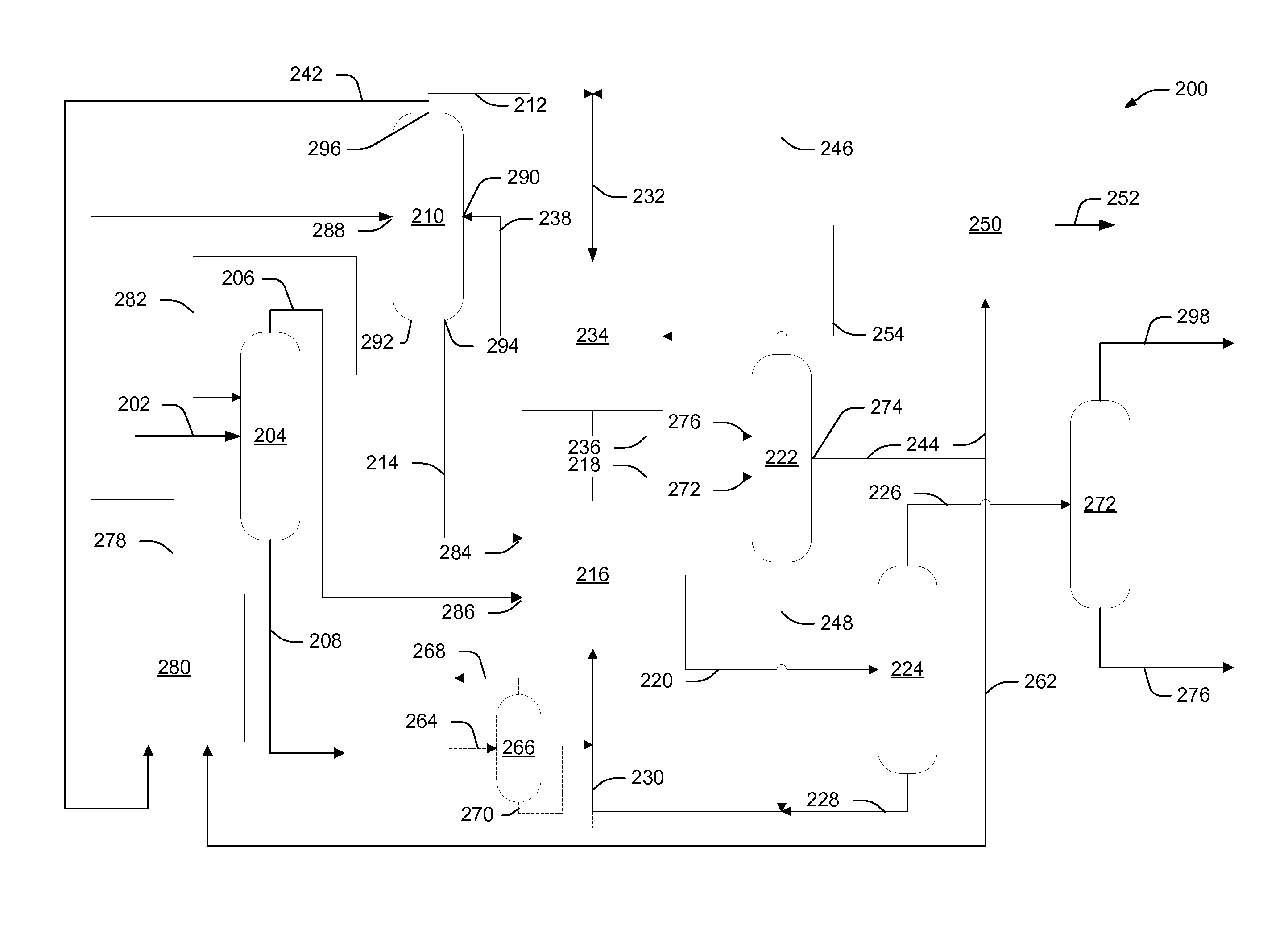

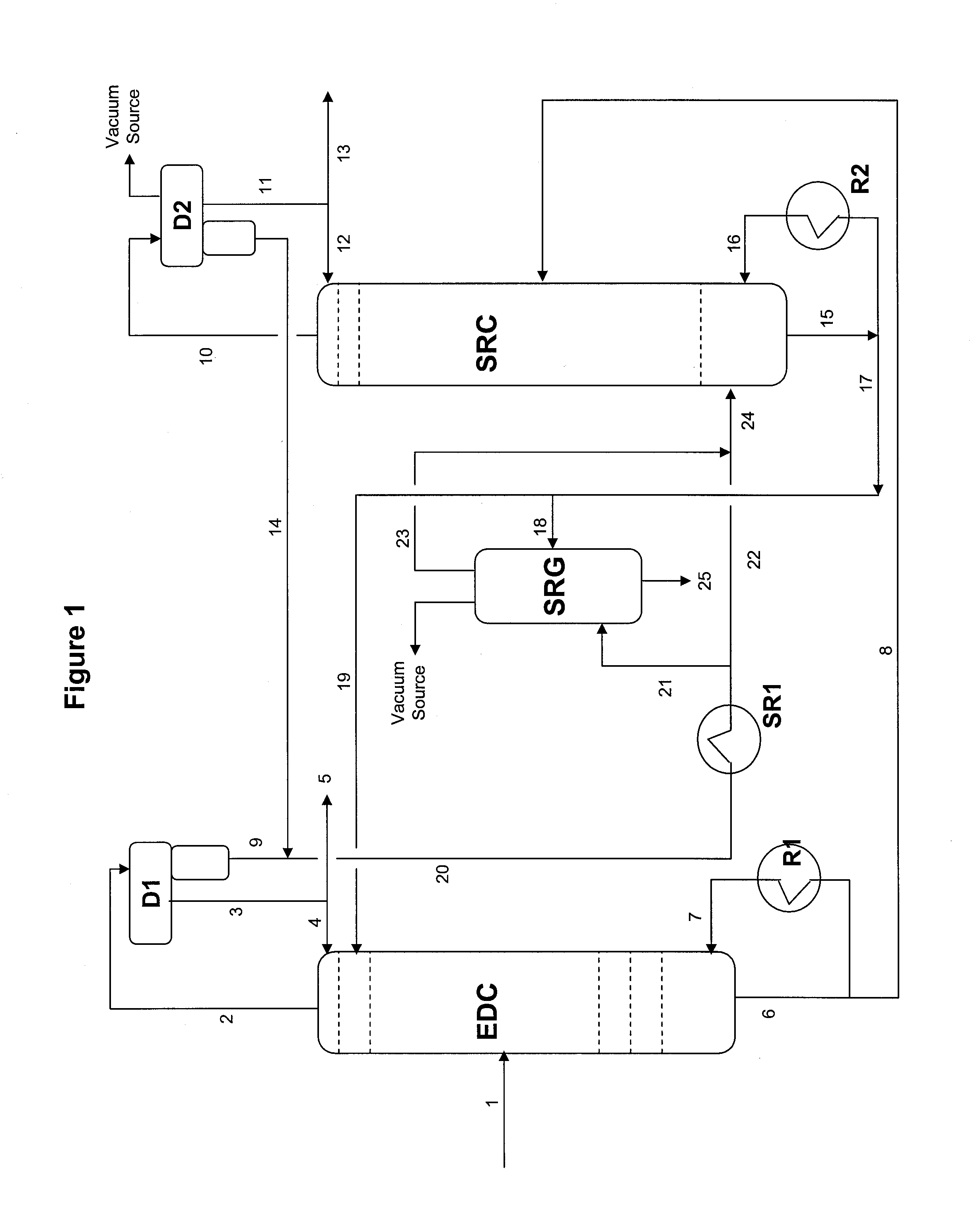

Novel Methods for Regeneration of Solvents for Extractive Processes

ActiveUS20120037542A1Save energyGood solvent performanceBiocideHydrocarbon distillationExtractive distillationAromatic hydrocarbon

An improved solvent regeneration system for extractive distillation and liquid-liquid extraction processes capable of effectively removing heavy hydrocarbons and polymeric materials that otherwise develop in a closed solvent loop. The improved process employs a light hydrocarbon displacement agent, which is at least partially soluble in the solvent to squeeze the heavy hydrocarbons and polymeric materials out of the solvent, with virtually no additional energy requirement. It has been demonstrated that the light non-aromatic hydrocarbons in the raffinate stream generated from the extractive distillation or the liquid-liquid extractive process for aromatic hydrocarbons recovery can displace not only the heavy non-aromatic hydrocarbons but also the heavy aromatic hydrocarbons from the extractive solvent, especially when the aromatic hydrocarbons in the solvent are in the C10+ molecular weight range.

Owner:AMT INT INC +1

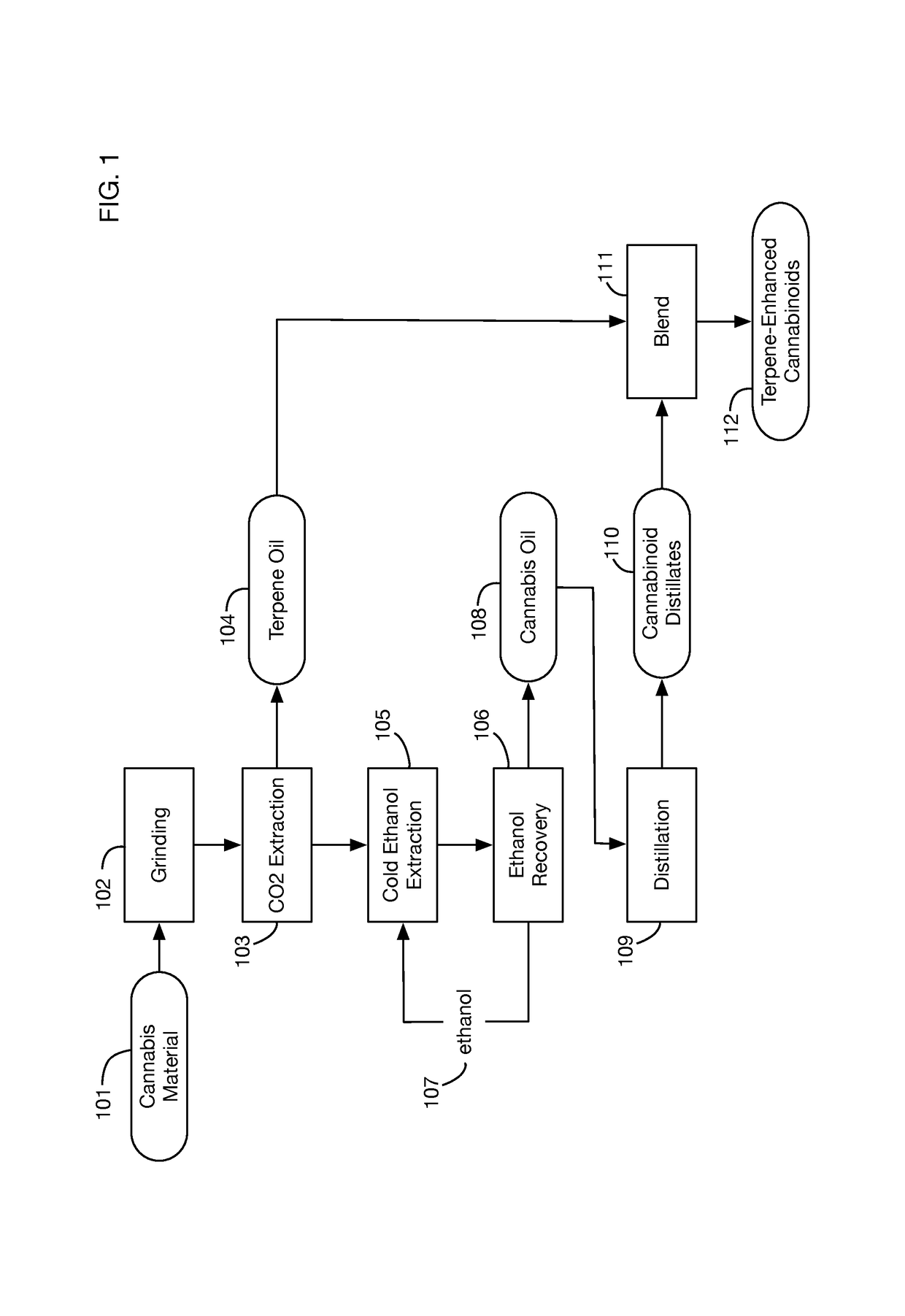

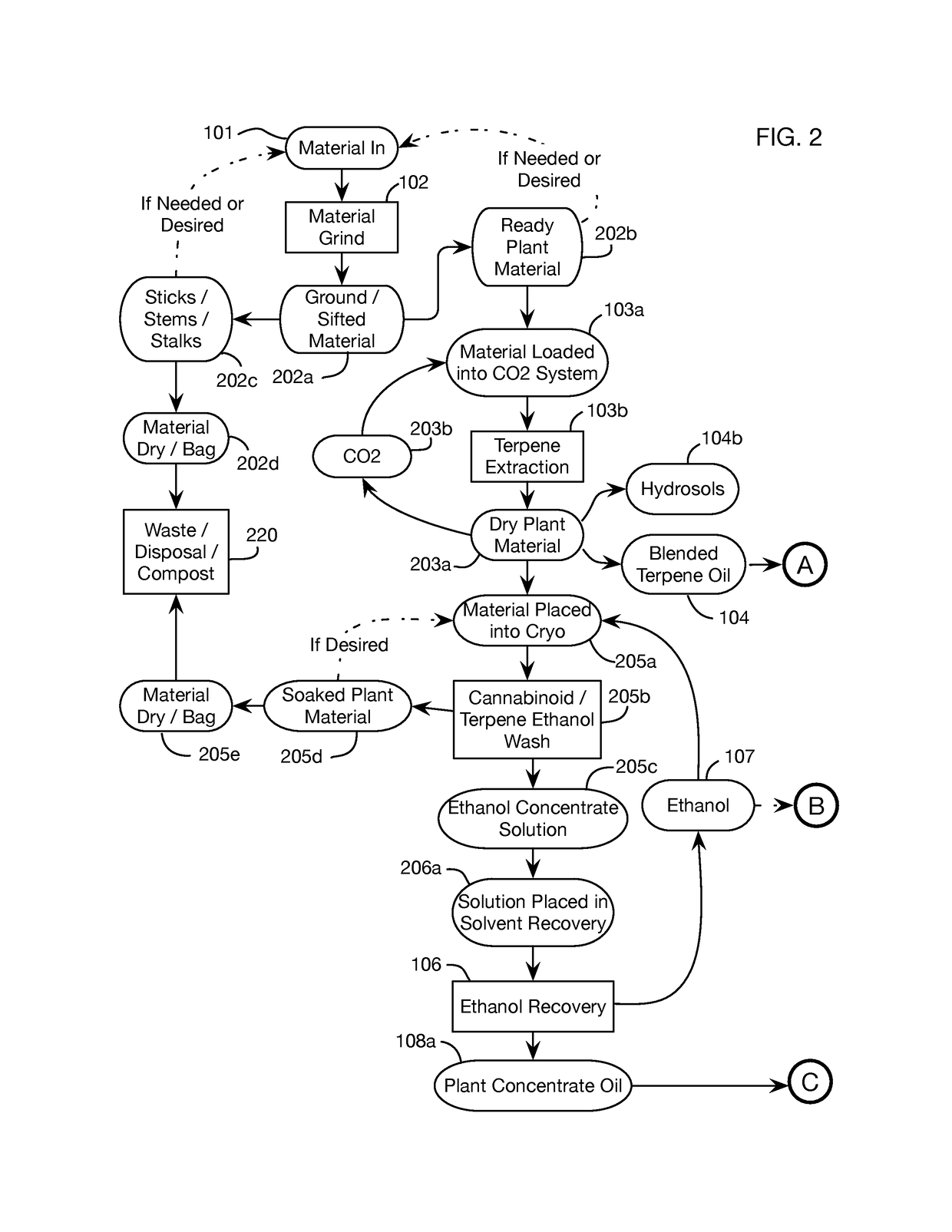

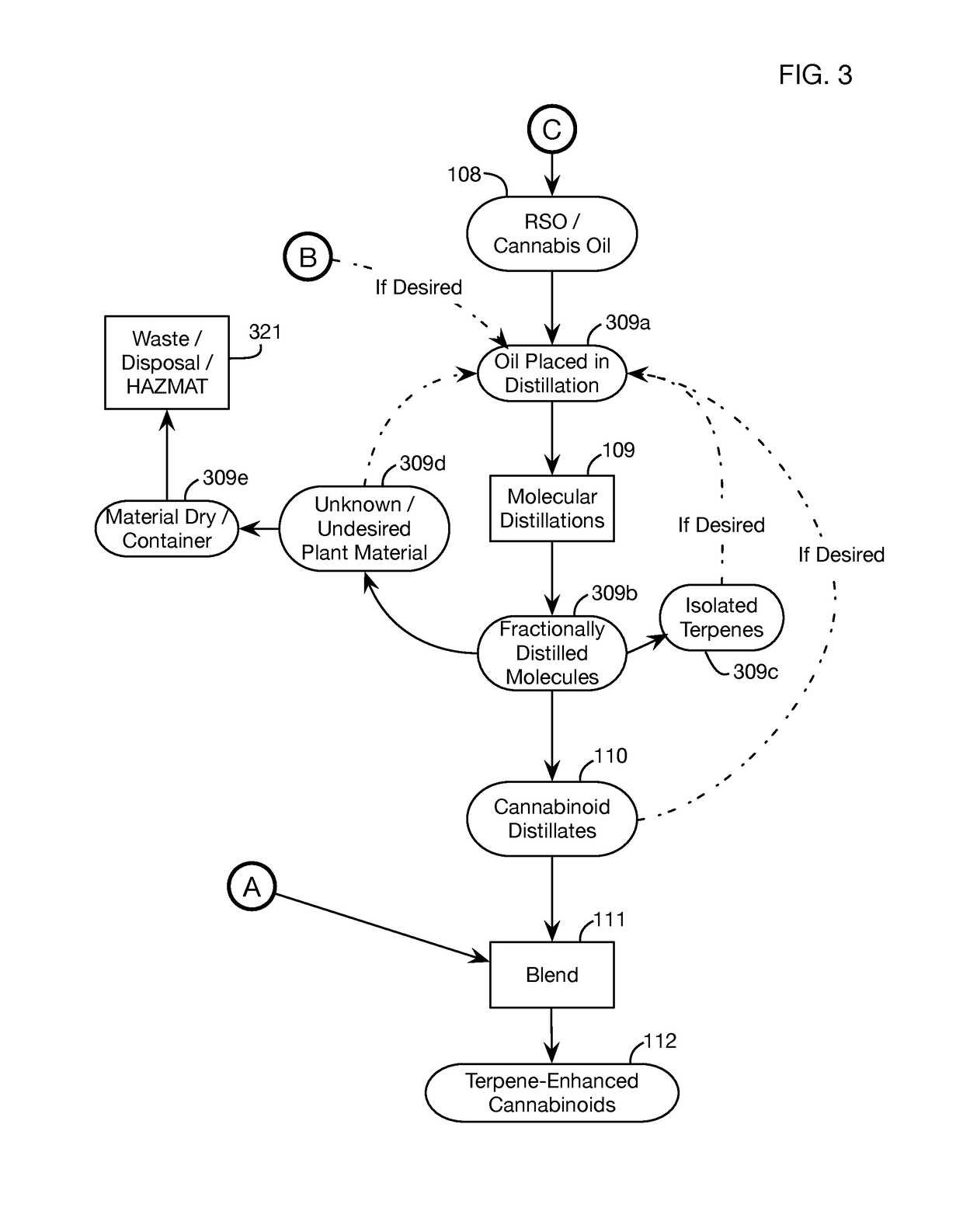

Method for removing contaminants from cannabinoid distillates

ActiveUS9956498B1Add flavorGood effectBiocideFermented solutions distillation/rectificationCannabisFungicide

A method for removing contaminants such as pesticides and fungicides from cannabinoid extracts. Cannabinoid extracts containing contaminants may be dissolved in a water and ethanol solution, and then cooled to allow water-soluble contaminants to settle out of the mixture. The water and ethanol may then be removed via evaporation or distillation, leaving purified cannabinoids without contaminants. Contaminant removal may be incorporated into a method for producing a blended extract of cannabinoids and terpenes, which extracts terpenes using supercritical CO2, and extracts a cannabinoid concentrate from the residual material using a cold ethanol flush followed by distillation and then by contaminant removal; the CO2-extracted terpenes are then added back to the purified cannabinoid concentrate in a final blending step. Blending terpenes at the end of extraction may enhance the flavor and effectiveness of the purified cannabinoid concentrate.

Owner:THE HOUSE OF GREEN

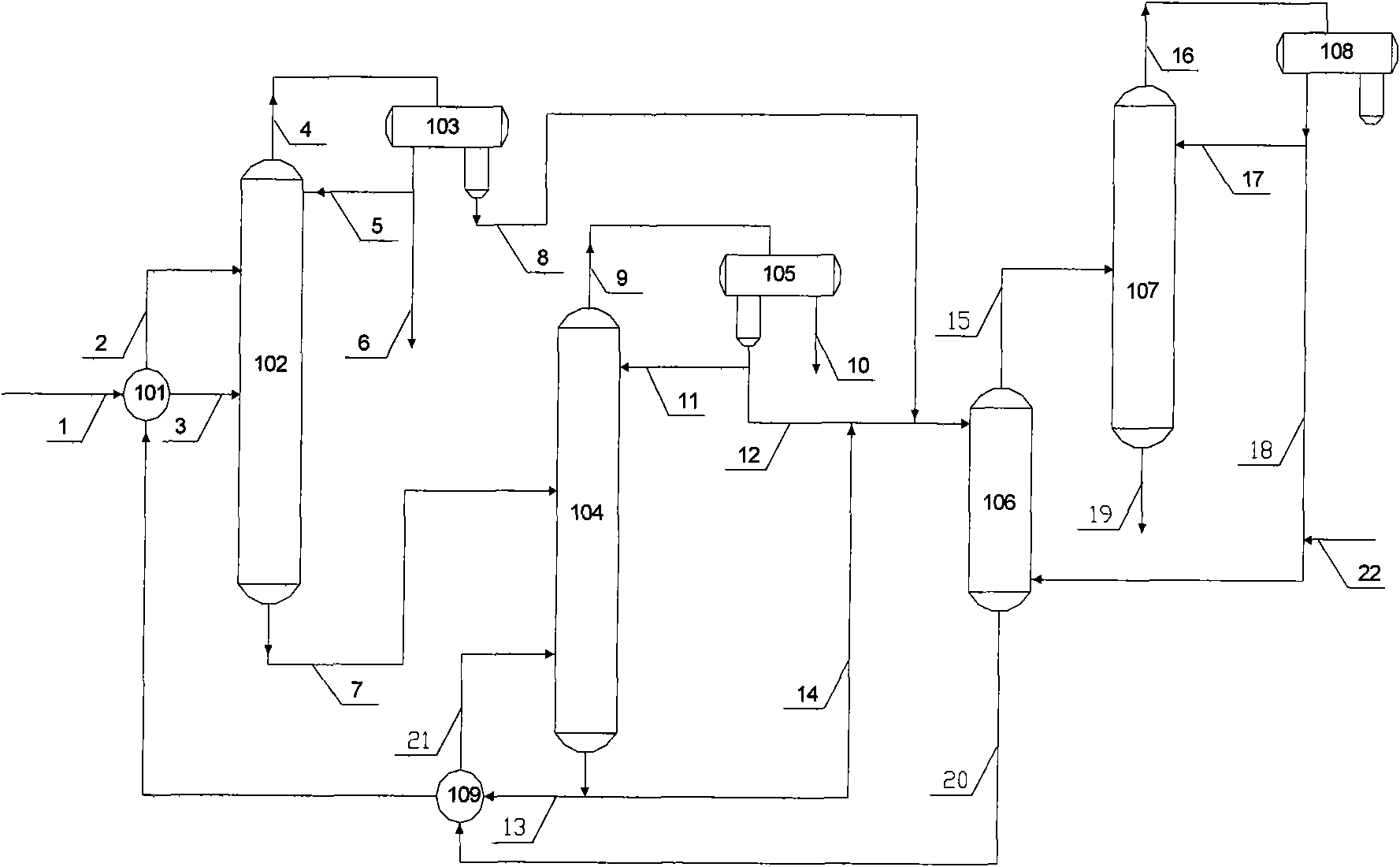

Regeneration method of extracting solvent for extracting, rectifying and separating styrene

ActiveCN101875592AImprove performanceLong cycle operationDistillation purification/separationExtractive distillationTowerSolvent

The invention provides a regeneration method of an extracting solvent for extracting, rectifying and separating styrene, comprising the following steps of: mixing water and a part of a lean solvent obtained by carrying out solvent recovery on extracted, rectified and separated styrene, and then introducing a mixture into the upper part of a solvent purification tower (106); enabling a solvent purifying agent to enter into the solvent purification tower (106) from the lower part; discharging the purified lean solvent containing water from a bottom pipeline of the solvent purification tower andthen introducing the purified lean solvent containing water into the lower part of a recovery tower for the extracted, rectified and separate styrene solvent, discharging a solvent purifying agent rich in a styrene polymer from the top of the solvent purifying tower, and introducing the solvent purifying agent rich in the styrene polymer into the middle of a solvent purifying agent recovery tower(107); discharging the solvent purifying agent subjected to styrene polymer removal from the top of the tower; and discharging the styrene polymer from the bottom of the solvent purifying agent recovery tower (107). The method can effectively remove the styrene polymer in the extracting solvent, ensure the performance of the extracting solvent and prolong the running time of a device for extracting, rectifying and separating styrene.

Owner:CHINA PETROLEUM & CHEM CORP +1

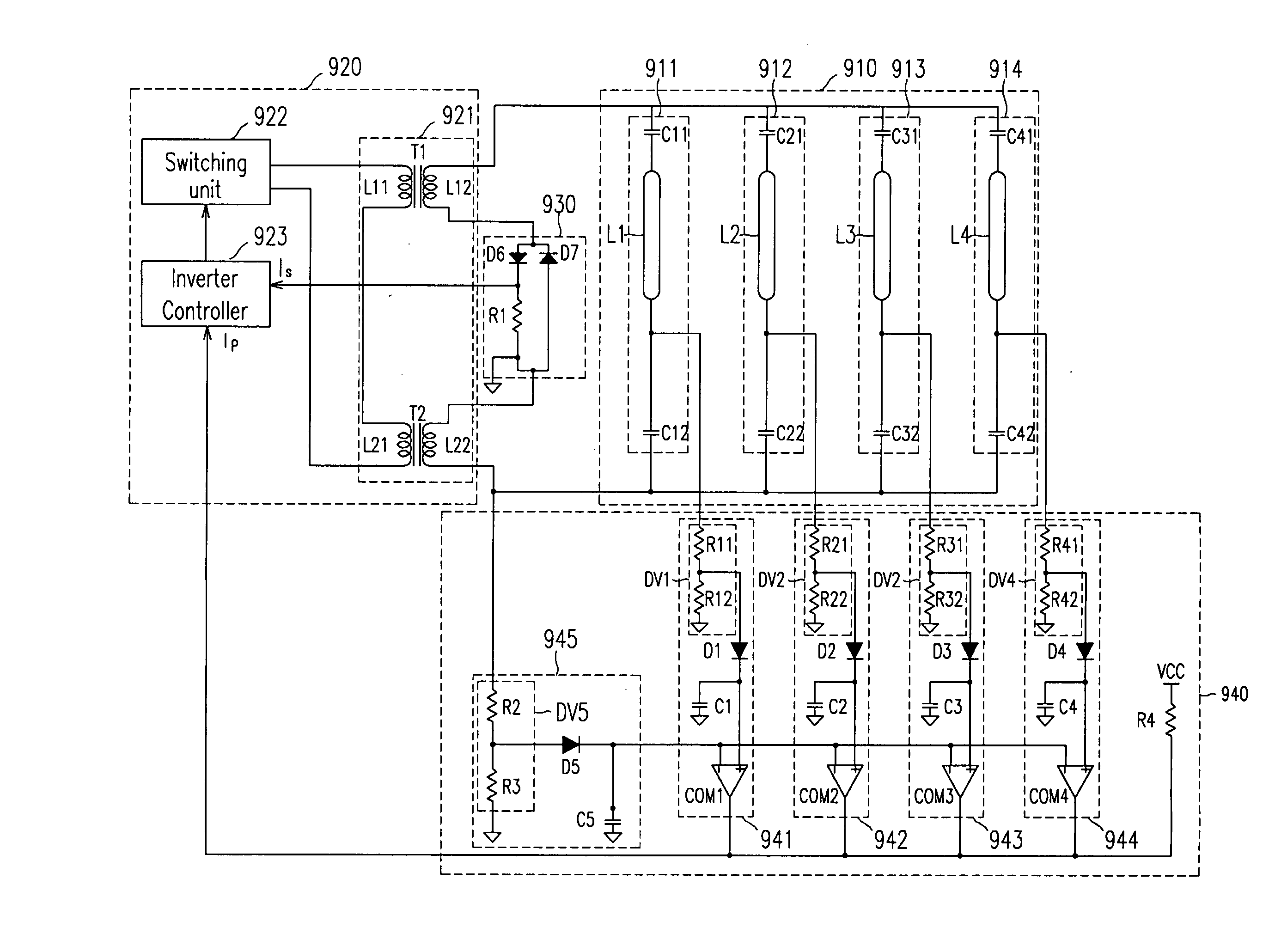

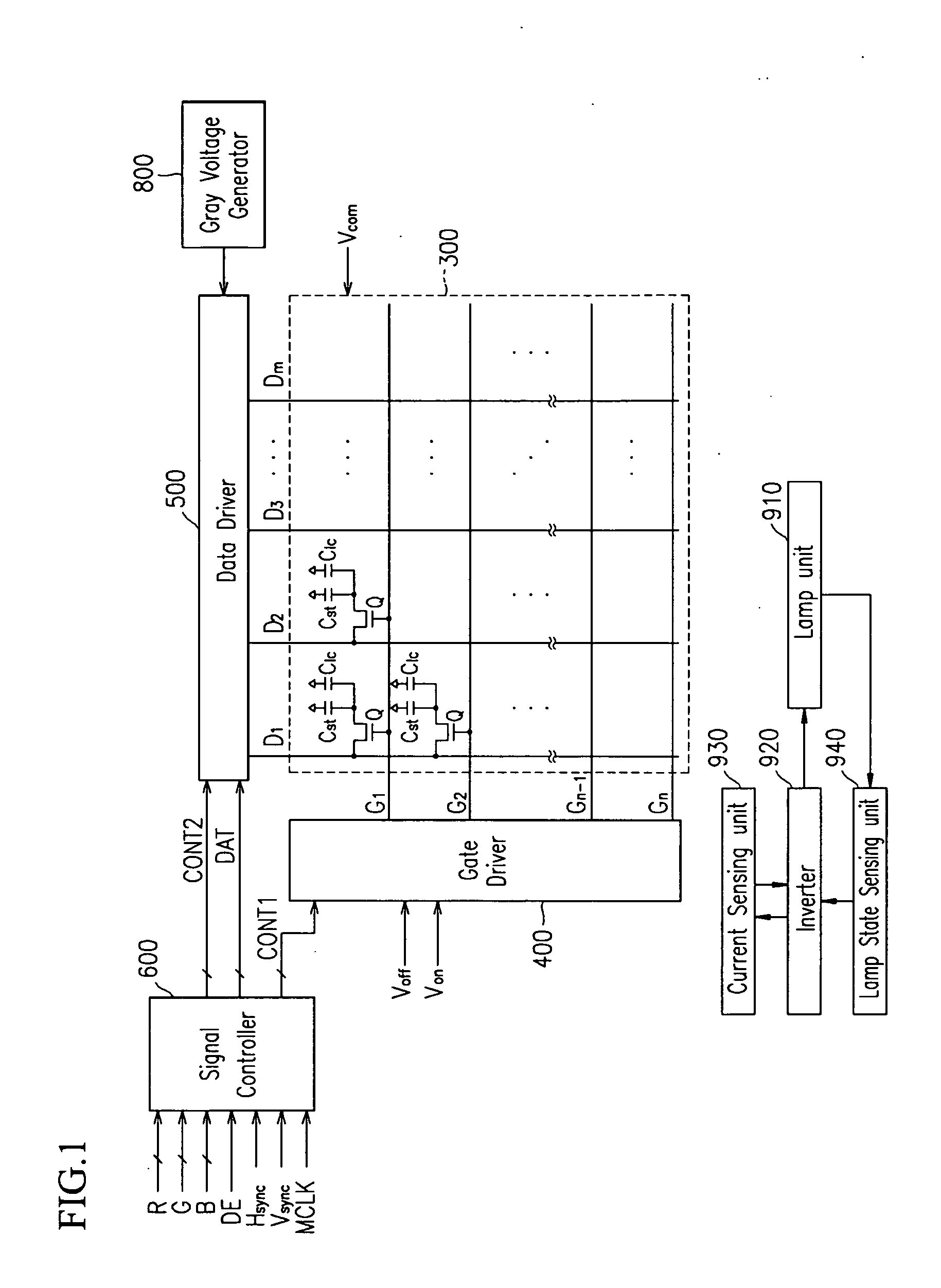

Driving device of light source for display device

A driving device of a light source for a display device is provided. The light source includes a plurality of lamps connected in parallel to each other and each lamp has a first terminal and a second terminal. The driving device also includes a lamp state sensing unit sensing driving voltages applied to the respective lamps, comparing the sensed driving voltages to a reference voltage, and outputting a lamp state sensing signal having an information informing an over-current state for at least one lamp; and an inverter turning the lamps on or off by applying an AC voltage to the lamps and controlling the AC voltage based on the lamp state sensing signal. The reference voltage is varied depending on the magnitude of the driving voltages applied to the respective lamps.

Owner:SAMSUNG DISPLAY CO LTD

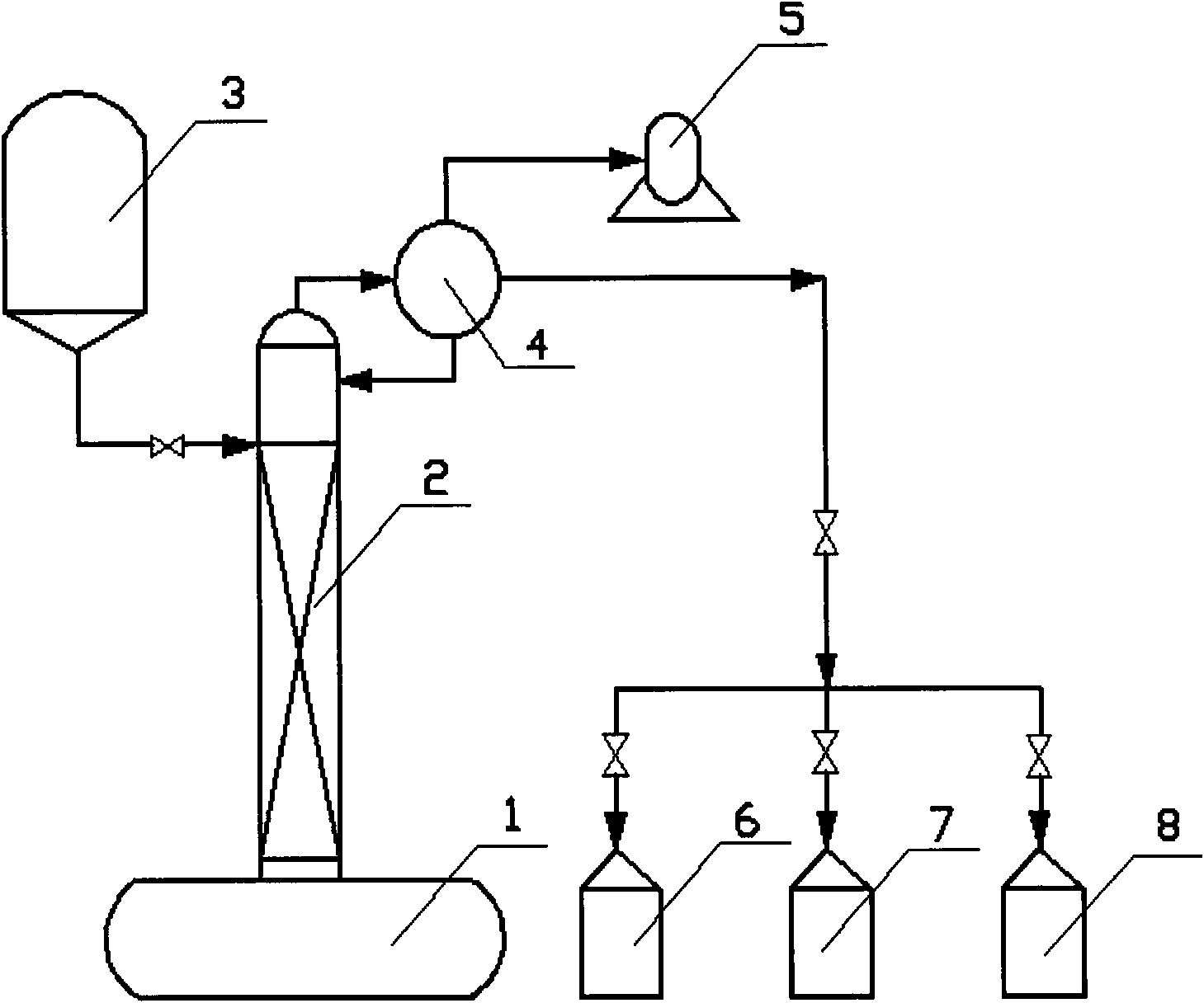

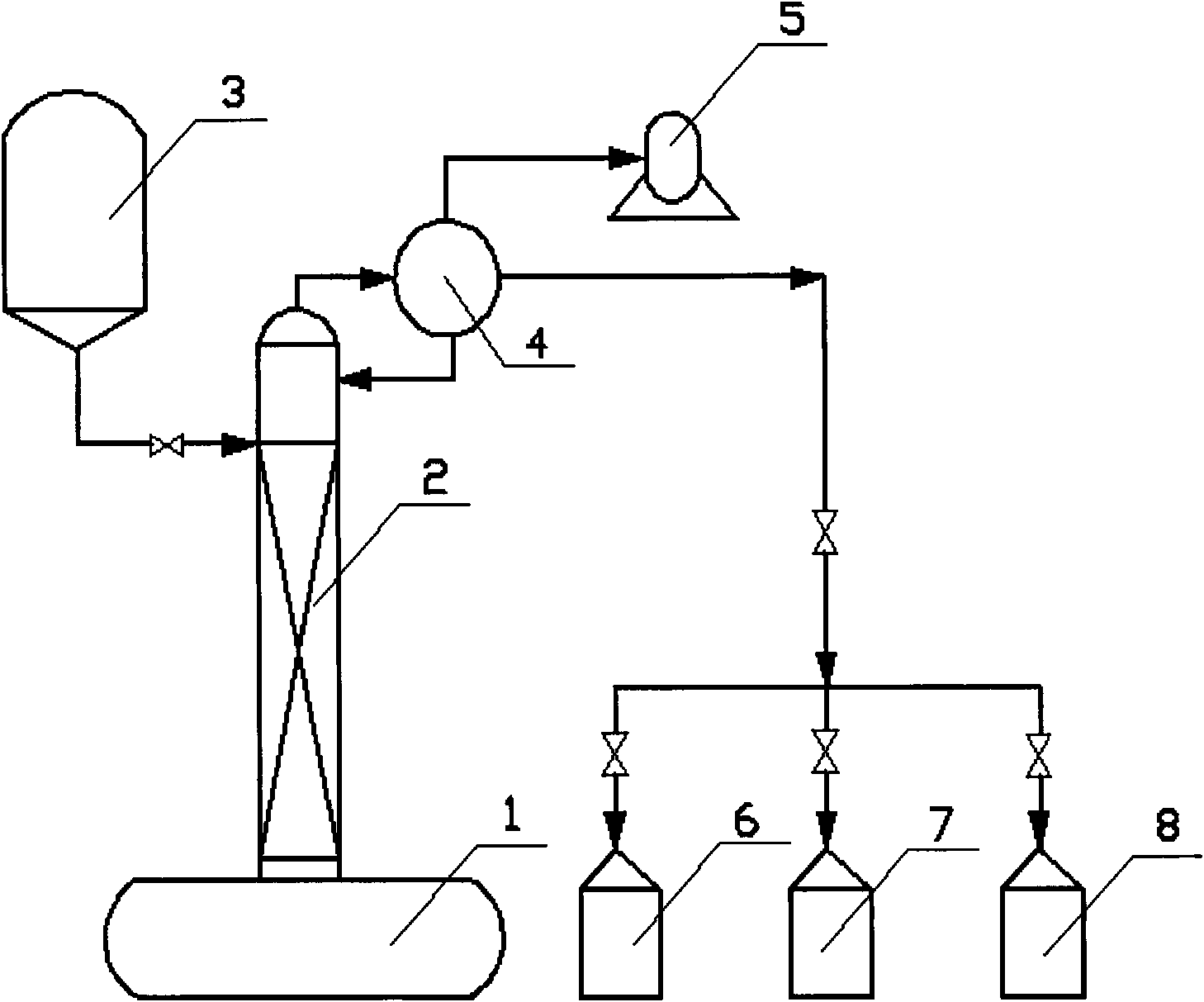

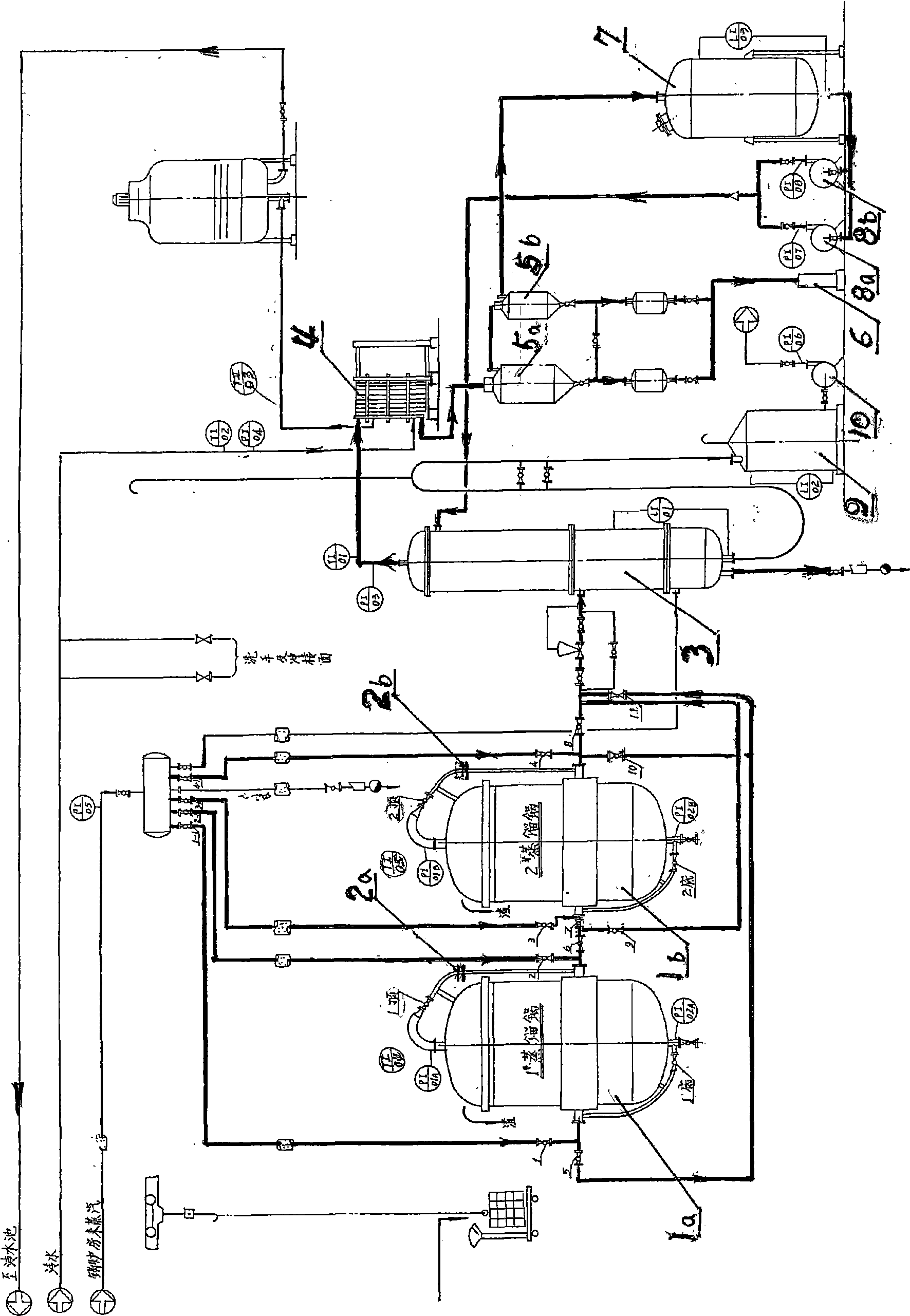

Process for extracting active ingredients of traditional Chinese medicine in unit and combined type and device thereof

ActiveCN101530674AReduce processing costsPlay a role in energy saving and emission reductionSolvent extractionSteam distillationMicrowaveExtractive distillation

The invention belongs to highly effective extraction and separation of the active ingredients in field of modernization of Chinese medicine and is characterized in that on the basis of an extraction process and a device consisting of the combination of 3 novel chemical engineering unit operations of water percolation distillation, extractive distillation, and highly efficient az dist azeotropic distilation, the traditional and advanced techniques and devices for water distillation extraction, extraction by semi-bionic method, extraction by ultrasonic waves, extraction by enzyme process, extraction by microbial fermentation and extraction by microwave are preferably selected to constitute the unit and combined type extraction process and the device thereof; the process and the device of the invention is especially suitable for extracting the majority of single Chinese medicine or compound Chinese medicine with both volatile and non-volatile components; in addition the device operates stably with stable parameters; compared with the traditional multifunctional traditional Chinese medicine extracting tank, the tank of the invention features an extraction rate above 95% and energy conservation by over 50%, contraction of the production period by over 50%, reduction of production cost per unit product by 50% and stable content of active ingredients and product quality.

Owner:王艺瑾

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com