Process and installation for concentrating waste sulphuric acids from nitration processes

A technology for nitrating waste acid and waste sulfuric acid, applied in chemical instruments and methods, sulfur trioxide/sulfuric acid, separation methods, etc., can solve problems such as failure to achieve success, increase in steam consumption and waste water volume, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

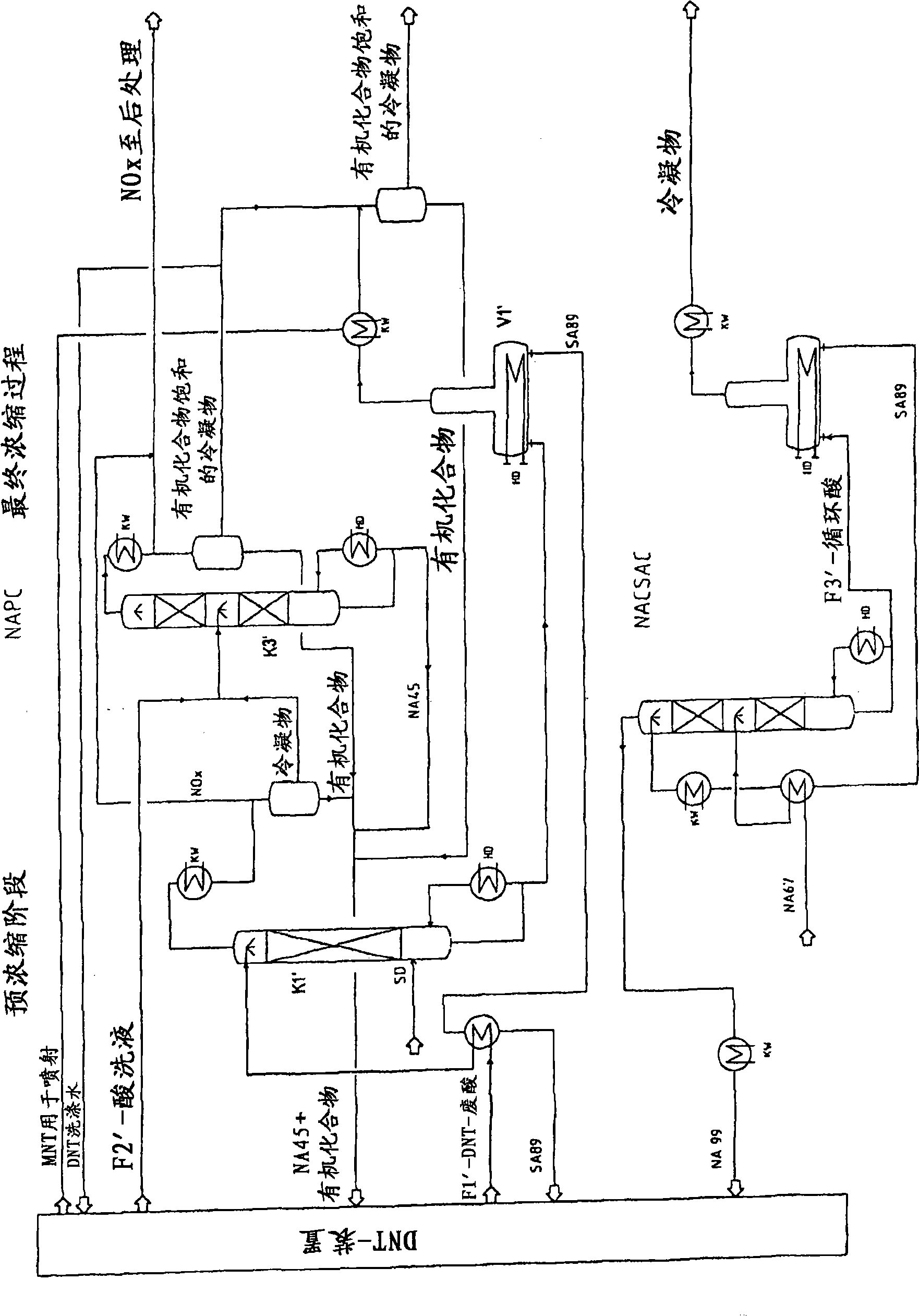

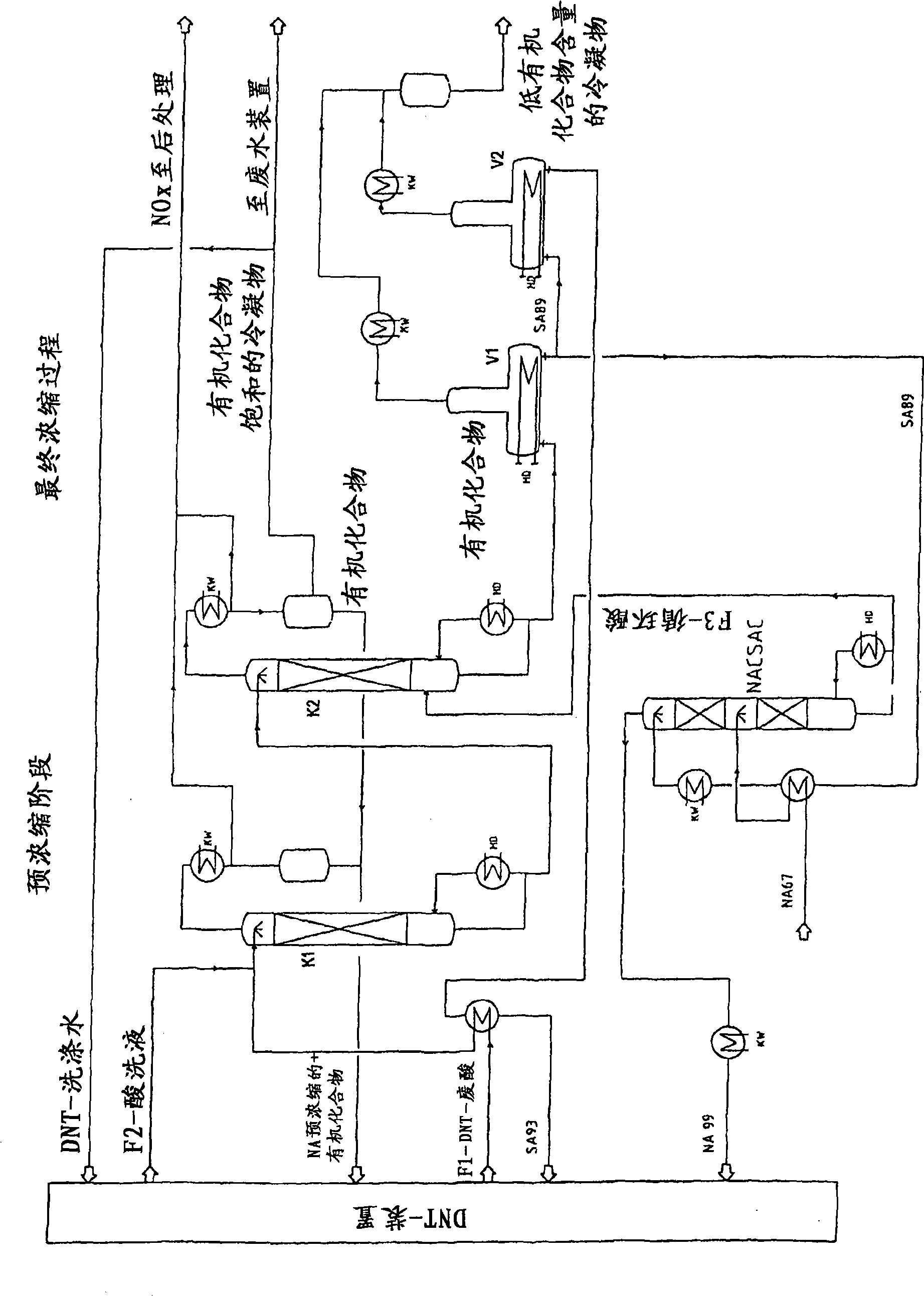

[0070] The method of the invention will now be explained in more detail on the basis of non-limiting illustrated examples, wherein reference is made to figure 2 The various process streams are labeled with abbreviations, which are explained above immediately following the general figure description.

[0071] As hot steam for all evaporators, steam with a pressure of 17 bar (overpressure (ü)) was used. The heater surface is made of tantalum.

[0072] The feed streams F1 to F3 worked up together according to the process according to the invention according to figure 2 The details are as follows:

[0073] F1: Nitrification waste acid from DNT-unit (preheated and added to the top of K1)

[0074] Material throughput: about 33500kg / h

[0075] Temperature: about 50°C

[0076] Composition: sulfuric acid: about 70.5% by mass

[0077] Nitric acid: about 1.0% by mass

[0078] HNO 2 : About 1.3% by mass

[0079] (3.5% by mass NSS)

[0080] DNT / MNT about 0.4% ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com