Chemical fertilizer waste water treatment method

A wastewater treatment and fertilizer technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the large difference in the control of different process parameters, and many restrictions on wastewater treatment process management and other problems, to achieve the effects of shock load resistance, cost saving, and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

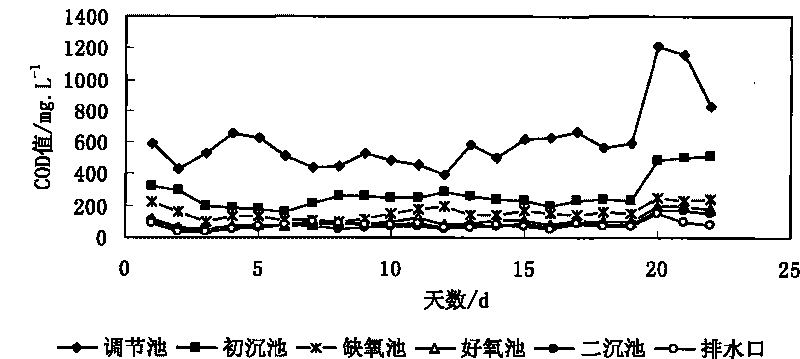

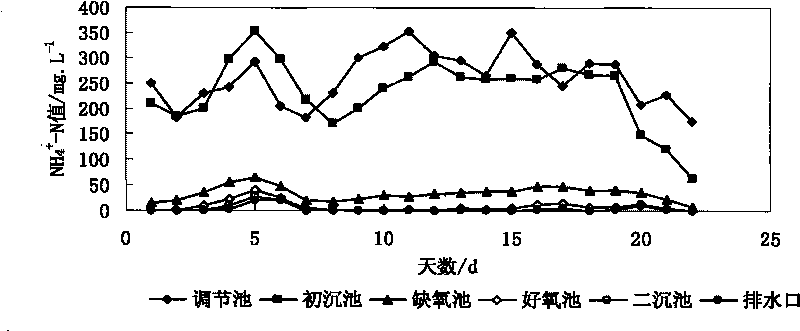

[0028] After being mixed by air blowing and aeration in the adjustment tank, the wastewater indicators of the fertilizer plant: CODcr=1000-1200mg / L, SS=200mg / L, NH 3 -N=200-300mg / L, pH=6~9. The incoming water from the regulating pool includes high-ammonia-nitrogen fertilizer wastewater from chemical fertilizer plants and organic production wastewater. The load of the regulating pool is configured according to the treatment capacity and the discharge of production wastewater, and the excess wastewater is temporarily stored in the emergency pool. The continuous water distribution method is adopted, and the ammonia nitrogen wastewater and organic wastewater are distributed into the regulating tank according to the flow ratio of 4:1, and the treatment capacity is 120m 3 / h.

[0029] The homogenized wastewater is pumped into the blast aeration complete mixing primary aeration tank to keep the dissolved oxygen at about 1.5mg / L, which can initially remove COD and maintain the remain...

Embodiment 2

[0034]After being mixed by blowing and aerating in the adjustment tank, the wastewater indicators of the fertilizer plant: COD=100-300mg / L, SS=50-100mg / L, NH 3 - N = 100-200 mg / L. The incoming water from the regulating pool includes high-ammonia-nitrogen fertilizer wastewater from chemical fertilizer plants and organic production wastewater. In an accident state, the concentration of organic wastewater is ultra-low, and the organic load of the entire system is reduced. The continuous water distribution method is adopted, and the ammonia nitrogen wastewater and organic wastewater are respectively distributed into the regulating tank, and the treatment capacity is 150m 3 / h.

[0035] The high-ammonia-nitrogen fertilizer wastewater from the chemical fertilizer plant is mixed evenly by blowing aeration in the regulating tank, and the residence time is 3 hours. The homogenized wastewater is pumped into the primary aeration tank, the dissolved oxygen is adjusted to 0.8mg / L, the co...

Embodiment 3

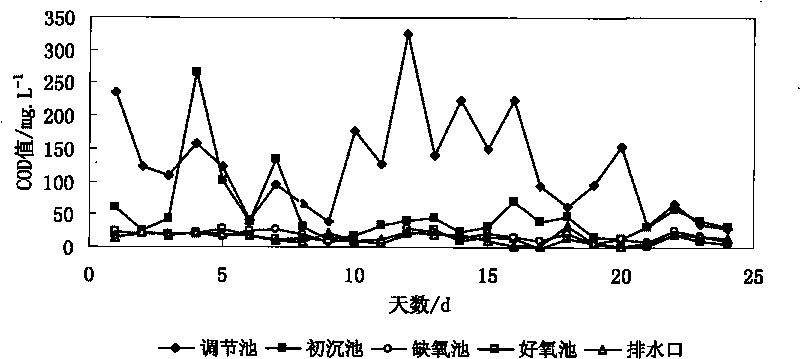

[0039] After being mixed by blowing and aerating in the adjustment tank, the wastewater indicators of the fertilizer plant: COD=600-1000mg / L, SS=50-100mg / L, NH 3 -N=100-200 mg / L, phenols=50 mg / L. The incoming water from the regulating pool includes high-ammonia-nitrogen fertilizer wastewater from chemical fertilizer plants and organic production wastewater. The load of the regulating pool is configured according to the treatment capacity and the discharge of production wastewater, and the excess wastewater is temporarily stored in the emergency pool. The continuous water distribution method is adopted, and the ammonia nitrogen wastewater and organic wastewater are respectively distributed into the regulating tank, and the treatment capacity is 120m 3 / h.

[0040] The homogenized wastewater is pumped into the primary aeration tank. In order to effectively remove phenolic substances and remove toxic and side effects for the subsequent biological denitrification unit, the dissol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com