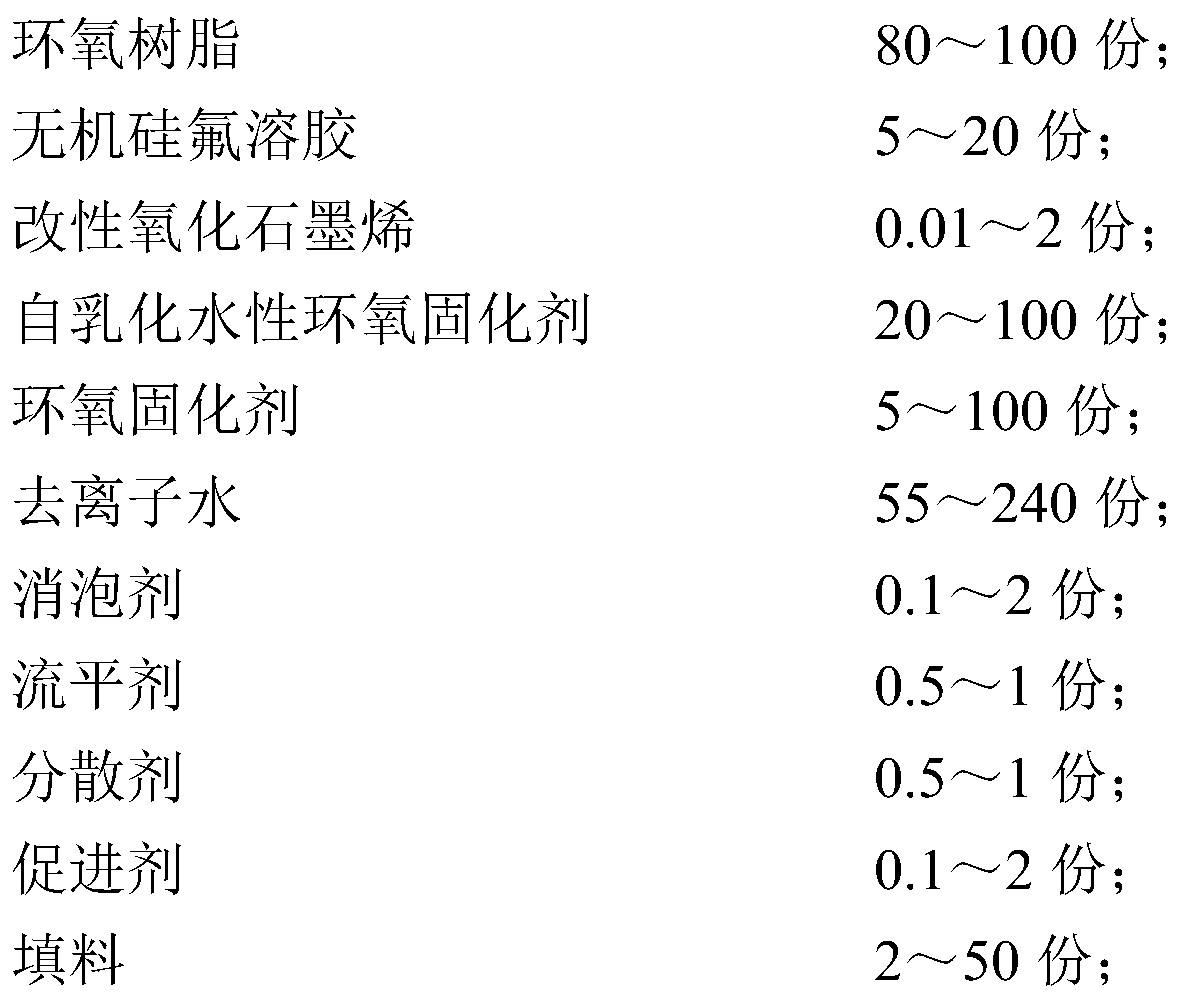

Low-surface-energy water-based epoxy anticorrosive coating and preparation and application thereof

A water-based epoxy and anti-corrosion coating technology, applied in anti-corrosion coatings, epoxy resin coatings, anti-fouling/underwater coatings, etc., can solve the problems of unsuitable graphene and difficult polymer uniform dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0085] (1) Preparation of inorganic silica fluorine sol:

[0086] Mix 50g of methyltriethoxysilane, 50g of dimethyldiethoxysilane, 100g of dodecafluoroheptylpropyltrimethoxysilane, 150g of absolute ethanol, 40g of deionized water, and 1g of ammonia water at 25 Hydrolysis and polycondensation reaction at ℃ for 24 hours, the nano-hybrid silicon fluoride sol with a solid content of about 51%, that is, inorganic silicon fluoride sol;

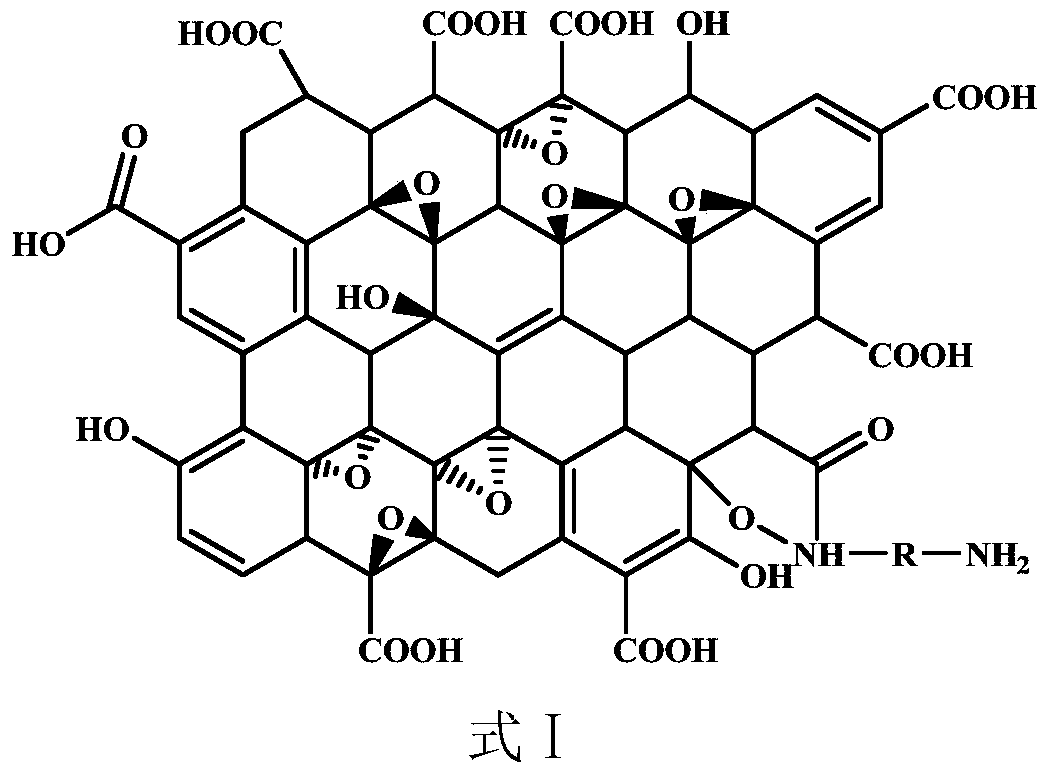

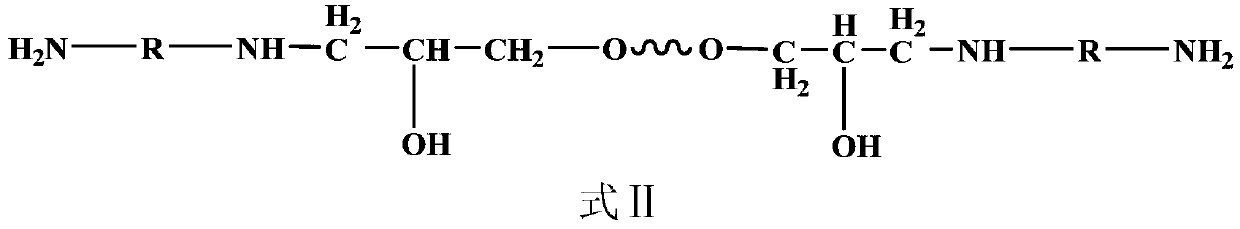

[0087] (2) Preparation of graphene oxide modified by a single polyamine compound:

[0088] The graphene oxide (GO) of 1 mass part is dispersed in 90g deionized water by ultrasonic 30min under the condition of power 300W, obtains graphene oxide suspension, then adds in the graphene oxide suspension under the stirring condition of 300rad / min 35 parts by mass of triethylenetetramine, sonicated for 30min, in N 2 Under protection, react at 60°C for 15 hours. After the reaction, add absolute ethanol to the obtained product, remove the supernatant after ...

Embodiment 2

[0094] (1) Preparation of inorganic silica fluorine sol:

[0095] Mix 50g of methyltriethoxysilane, 50g of dimethyldiethoxysilane, 100g of dodecafluoroheptylpropyltrimethoxysilane, 150g of absolute ethanol, 40g of deionized water, and 1g of ammonia water at 25 Hydrolysis and polycondensation reaction at ℃ for 24 hours to obtain a nano-hybrid silicon-fluorine sol with a solid content of about 51%, that is, an inorganic silicon-fluoride sol;

[0096](2) Preparation of graphene oxide modified by a single polyamine compound:

[0097] Graphene oxide (GO) of 1 mass part is dispersed in 92g deionized water under the condition of ultrasonic 30min under the power of 400W, obtains graphene oxide suspension, then adds in the graphene oxide suspension under the stirring condition of 310rad / min 35 parts by mass of triethylenetetramine, sonicated for 30min, in N 2 Under protection, react at 70°C for 15 hours. After the reaction, add absolute ethanol to the obtained product, remove the sup...

Embodiment 3

[0103] (1) Mix 50g methyltriethoxysilane, 50g dimethyldiethoxysilane, 100g dodecafluoroheptylpropyltrimethoxysilane, 150g absolute ethanol, 40g deionized water and 1g ammonia water After hydrolysis and polycondensation reaction at 25°C for 24 hours, a nano-hybrid silicon-fluoride sol with a solid content of about 51%, that is, an inorganic silicon-fluorine sol, was obtained;

[0104] (2) Preparation of graphene oxide modified by a single polyamine compound:

[0105] The graphene oxide (GO) of 1 mass part is dispersed in 95g deionized water by ultrasonic 30min under the condition of power 400W, obtains graphene oxide suspension, then adds in the graphene oxide suspension under the stirring condition of 320rad / min 35 parts by mass of triethylenetetramine, sonicated for 30min, in N 2 Under protection, react at 70°C for 15 hours. After the reaction, add absolute ethanol to the obtained product, remove the supernatant after standing, filter the lower precipitate with filter paper,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com