Patents

Literature

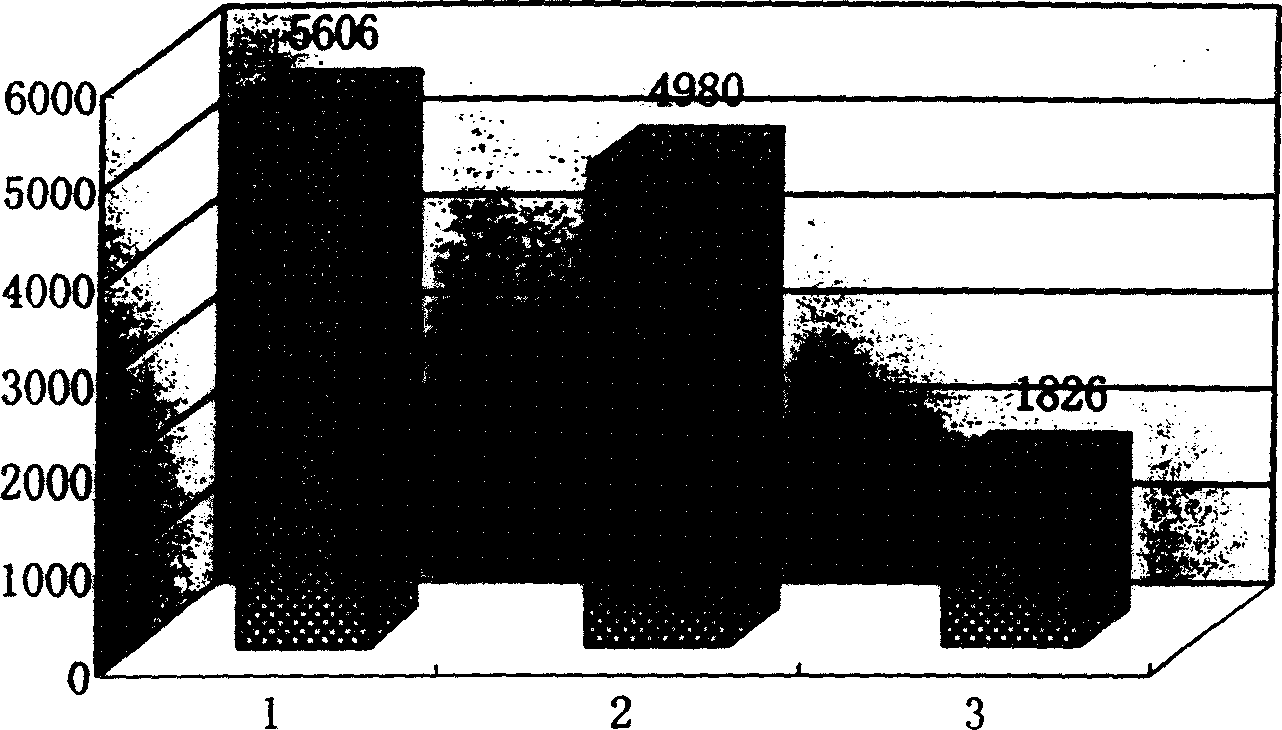

203 results about "Dimethyldiethoxysilane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dimethyldiethoxysilane, sometimes abbreviated DMDEOS or DMDES, is an organosilicon compound. DMDEOS is a precursor in the production of the silicone polymer polydimethylsiloxane (PDMS). DMDEOS is an intermediate silane useful for blocking hydroxyl and amino groups in organic synthesis reactions. This silylating step allows subsequent reactions to be carried out which would be adversely affected by the presence of active hydrogen in the hydroxyl or amine groups. Following the reaction step, hydroxyl or amine groups blocked with DMDEOS may be recovered by a hydrolysis procedure. DMDEOS is also used for preparing hydrophobic and release materials as well as enhancing flow of powders.

Water-proof and oil-repelling agent of colorless organic silicon resin for asphalt road surface

The waterproof and oil-repelling agent for asphalt road surface consists of silicone resin solution, penetrant and tackifier in the weight ratio of 92 to 2-4 to 4-6. The penetrant is isobutyl triethoxyl silane and the tackifier is gamma-aminopropyl triethoxyl silane. The silicone resin solution is prepared with methyl triethoxyl silane, ethyl silicate, dimethyl diethoxyl silane, ethanol, alkali liquid and water in certain proportion and through mixing at room temperature and reaction at 70-90 deg.c for 1-2 hr. The waterproof and oil-repelling agent is thrice sprayed to asphalt road to form film in the bottom, middle and upper part of asphalt road surface to raise the water penetration performance, reduce water damage and raise oil contamination performance with affecting the other performance of asphalt road.

Owner:WUHAN UNIV OF TECH +1

Hydrophobic lipophilic soft aerogel block and preparation method thereof

The invention relates to hydrophobic lipophilic soft aerogel block and a preparation method thereof. The hydrophobic lipophilic soft aerogel block is a complex prepared from diethoxydimethylsilane and a precursor methyltriethoxysilane, and has the density of 0.056-0.072 g / cm<3> and the organic solvent adsorption rate of 1280-1430%. The preparation method comprises: mixing diethoxydimethylsilane, the precursor methyltriethoxysilane,, an alcohol solution, a surfactant and water, and then respectively adding an acid catalyst and an alkaline catalyst, so as to obtain a sol; pouring the obtained sol into an enclosed container, and standing to obtain a gel; immersing the obtained gel in the alcohol solution for aging, removing the surfactant to enhance the skeleton strength of the gel, replacing water in the gel to reduce damage to the skeleton in a drying process and further to obtain a wet gel; and putting aged wet gel in a reaction kettle for drying, so as to obtain the hydrophobic lipophilic soft aerogel block.

Owner:XIAMEN UNIV

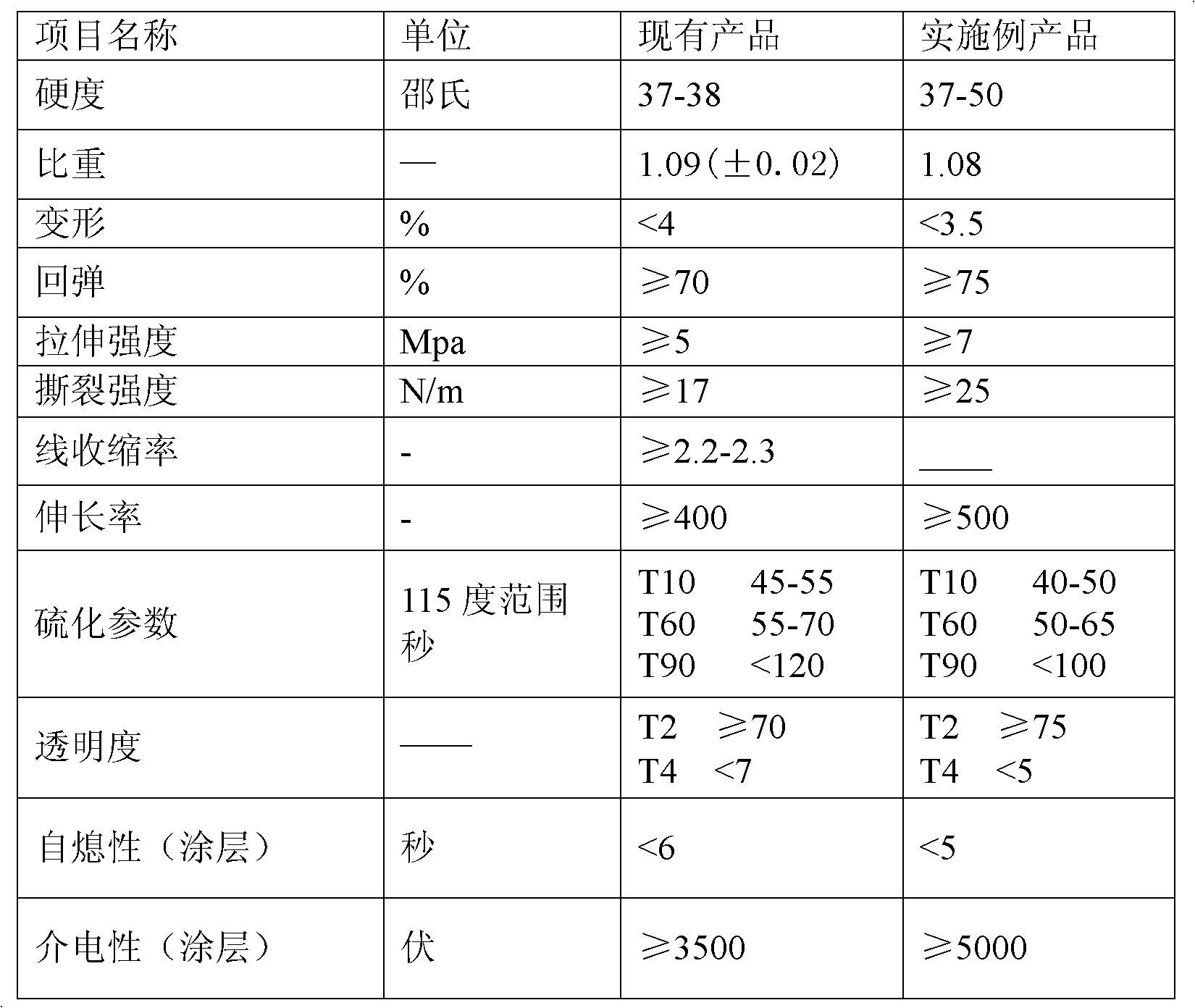

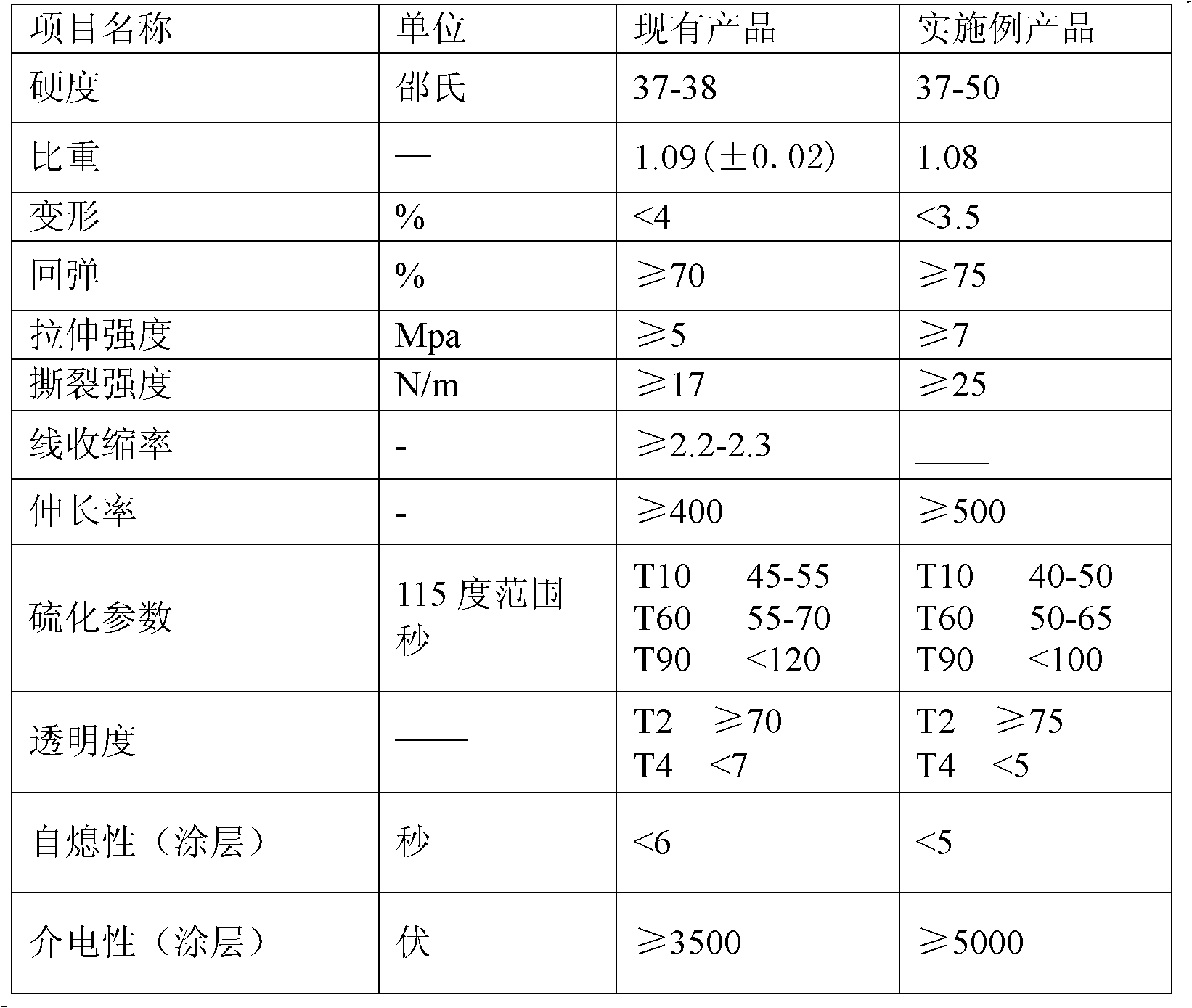

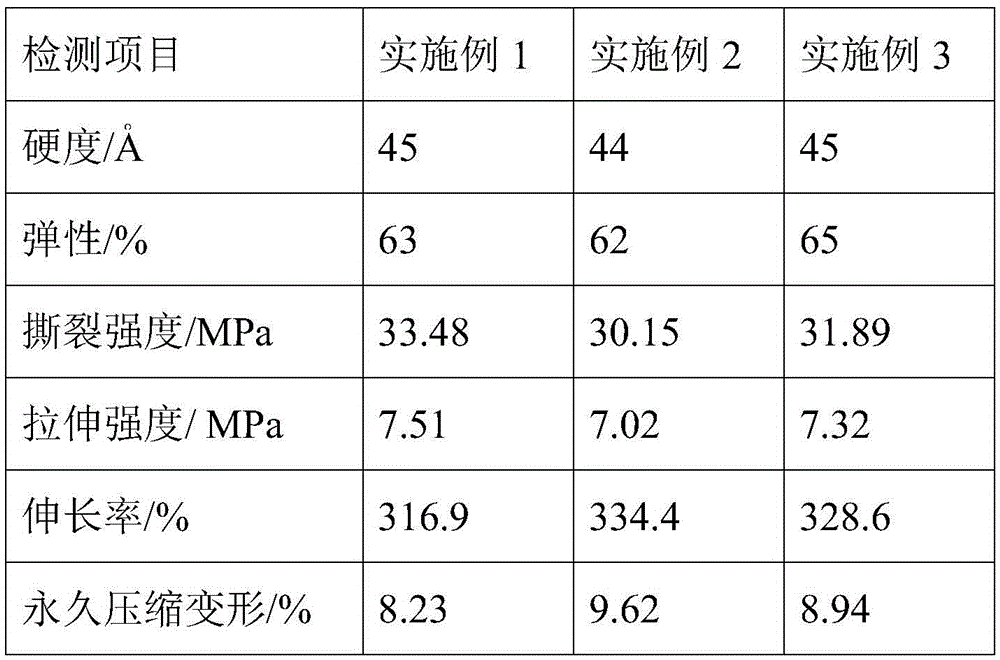

Silicone rubber and preparation method thereof

The invention discloses a silicone rubber and a preparation method thereof. The silicone rubber contains, by weight, 100 parts of methyl vinyl silicone rubber, 30 to 40 parts of white carbon black, 3 to 6 parts of dimethyldiethoxylsilane, 0.10 to 0.15 part of calcium stearate, 20 to 30 parts of quartz powder, 6 to 10 parts of calcium carbonate, 1 to 3 parts of cerium oxide, 0.1 to 0.7 part of an iron isocaprylate organic solution, 2 to 5 parts of vinyl MQ silicone resin and 1.5 parts of 2,5-dimethyl-2,5-bis(t-butylperoxy)hexane. According to embodiments in the invention, the silicone rubber has high resilience and low compression set performance at the same time.

Owner:MIDGOLD FINE PERFORMANCE MATERIALS SHENZHEN

Surface treatment of nanoparticles to control interfacial properties and method of manufacture

InactiveUS20050222325A1Material nanotechnologySynthetic resin layered productsPersonal care3-mercaptopropyltrimethoxysilane

A surface treated particle comprising a plurality of inorganic, metallic, semi-metallic, and / or metallic oxide particles and a star-graft copolymer with looped and / or linear polymeric structure on a star-graft copolymer, obtainable by a heterogeneous polymerization reaction in the particle surface proximity, encapsulating at least a portion of said particles and a method for making the same. The surface treatment comprises: Si (w, x, y, z), where: w, x, y, and z are mole percent tetrafunctional, trifunctional, difunctional, and monofunctional monomeric units, respectively; w, x, y, and z are about 0-50, 0-50, 5-99, and 0-5, respectively; w is tetraethylorthosilicate; x is selected from the group consisting of γ-glycidoxypropyltrimethoxysilane, γ-methacryloxypropyltrimethoxysilane, methyltrimethoxysilane, n-propyltrimethoxysilane, isobutyltrimethoxysilane, n-hexyltrimethoxysilane, n-octyltrimethoxysilane, n-octadecyltrimethoxysilane, phenyltrimethoxysilane, 3-(trimethoxysilyl)propylsuccinic anhydride, heptadecafluorotrimethoxysilane, 3-isocyanatopropyltrimethoxysilane, 2-(diphenylphosphino)ethyltrimethoxysilane, 3-aminopropyltrimethoxysilane, 3-mercaptopropyltrimethoxysilane, n-(trimethoxysilylpropyl)EDTA, pentafluorophenylpropyltrimethoxysilane, trifluoropropyltrimethoxysilane, and the triethoxy-containing counterparts of these monomers; y is selected from the group consisting of dicyclohexyldimethoxysilane, diethyldiethoxysilane, dimethyldichlorosilane, dimethyldiethoxysilane, dimethyldimethoxysilane, diphenyldiethoxysilane, diphenyldimethoxysilane, di-n-hexyldichlorosilane, n-hexylmethyldichlorosilane, methyldodecyldiethoxysilane, n-octylmethyldimethoxysilane, and the diethoxy-containing counterparts of these monomers; and z is selected form the group consisting of n-octadecyldimethylmethoxysilane, triethylsilanol, trimethylethoxysilane, trimethylmethoxysilane, and the ethoxy-containing counterparts of these monomers. Product(s) per se, defined as surface treated ZnO and / or TiO2, and the use of the product(s) per se in personal care formulations are excluded.

Owner:NANOPHASE TECH CORP

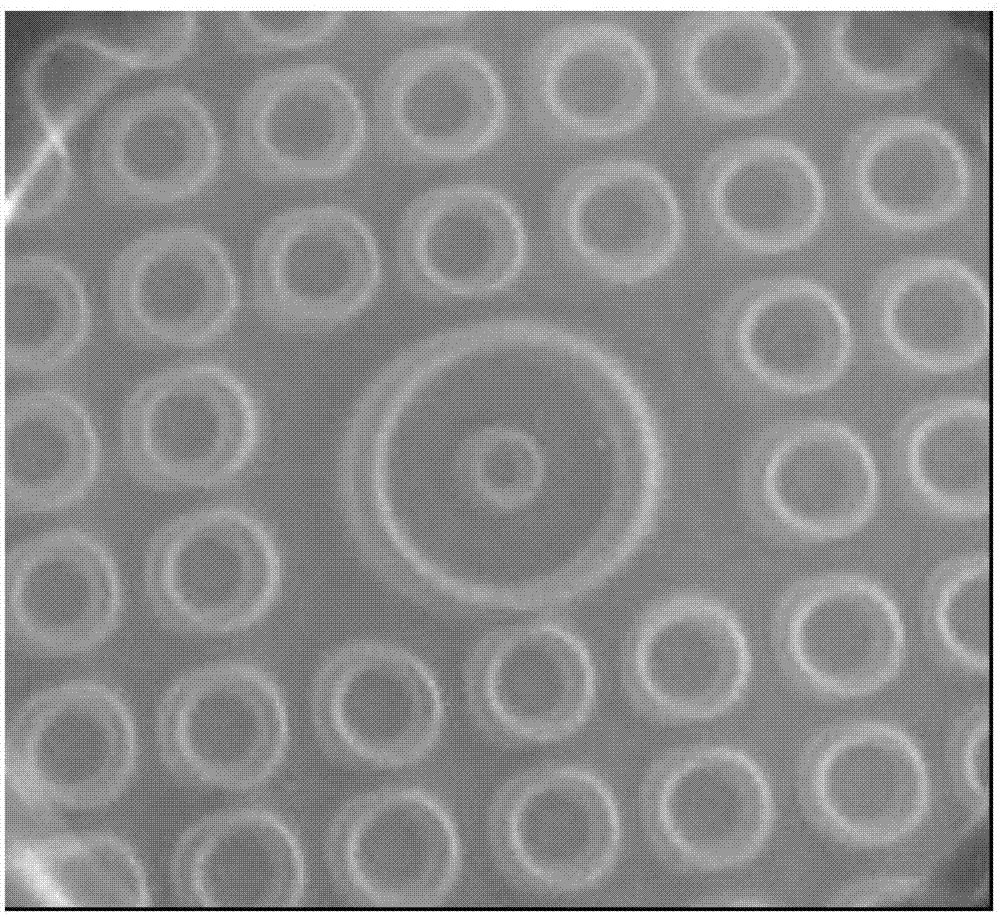

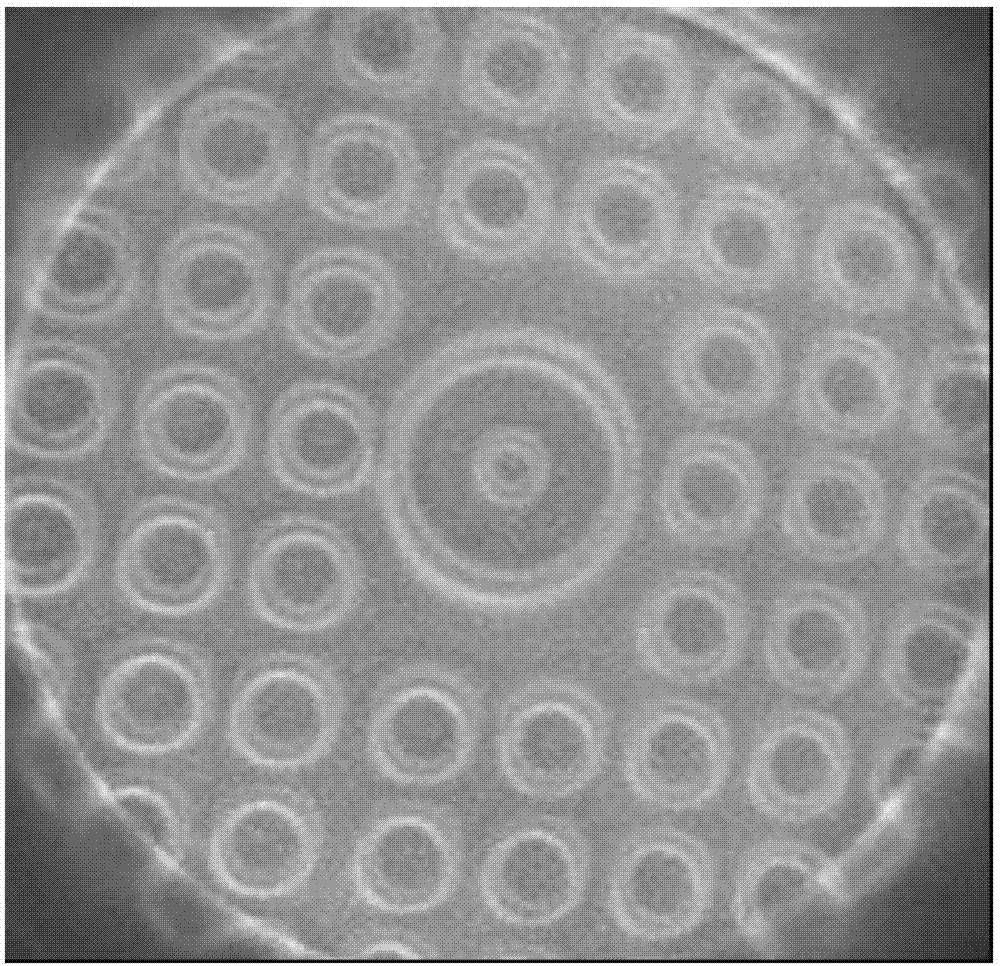

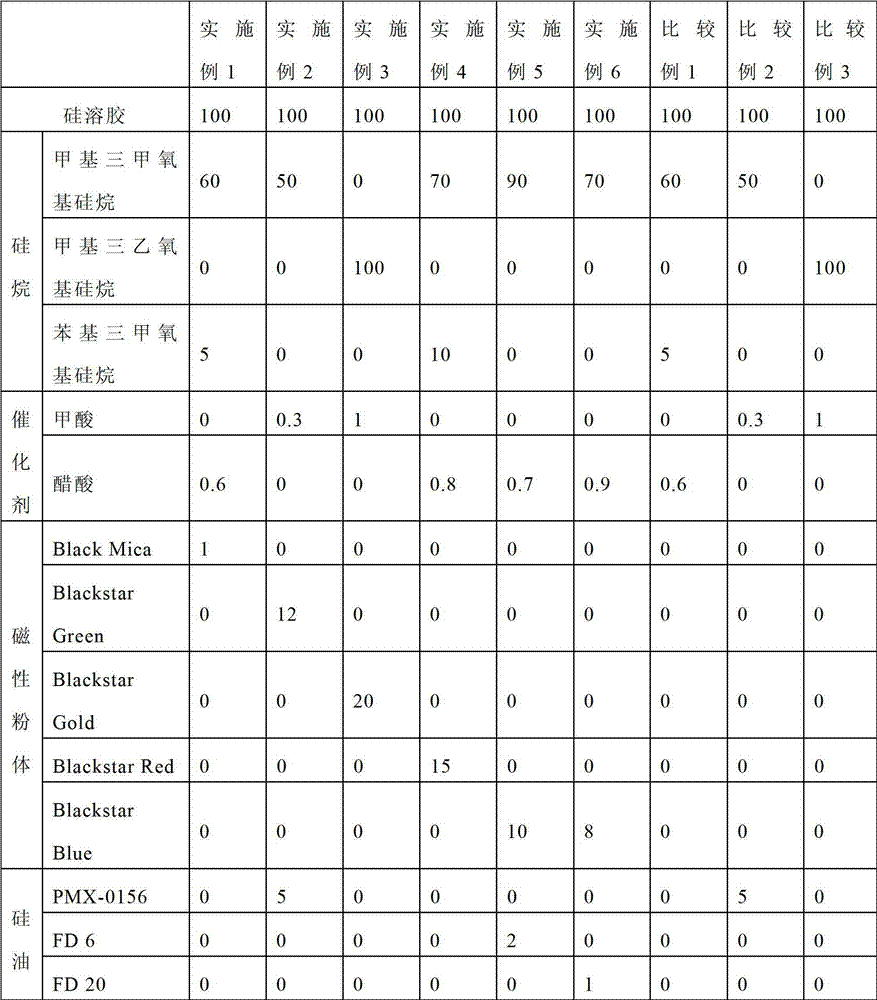

Ceramic paint and coating having stereoscopic effect

The invention relates to ceramic paint having a stereoscopic effect, which is characterized by comprising the following components in parts by weight: 100 parts of silica sol, 50-100 parts of organosilane, 0.3-1 part of catalyst, and 1-20 parts of magnetic powder, wherein the organosilane is methyltrimethoxy silane and / or methyltriethoxy silane; and the catalyst is one or a combination of formic acid, acetic acid, hydrochloric acid, citric acid, methyl formate, ethyl acetoacetate and maleic anhydride. The ceramic paint further comprises 1-5 parts by weight of silicone oil and 5-10 parts by weight of additional organosilane, wherein the additional organosilane is one or a combination of tetramethoxyl silane, tetraethoxy silane, dimethyldimethoxy silane, dimethyldiethoxy silane and phenyltrimethoxy silane. The ceramic paint provided by the invention has favorable cold / hot hardness and wear resistance; and the magnetic powder in the paint can form a coating having multiple stereoscopic patterns, thereby achieving good decorative effect.

Owner:INNOTEK TECH CHINA

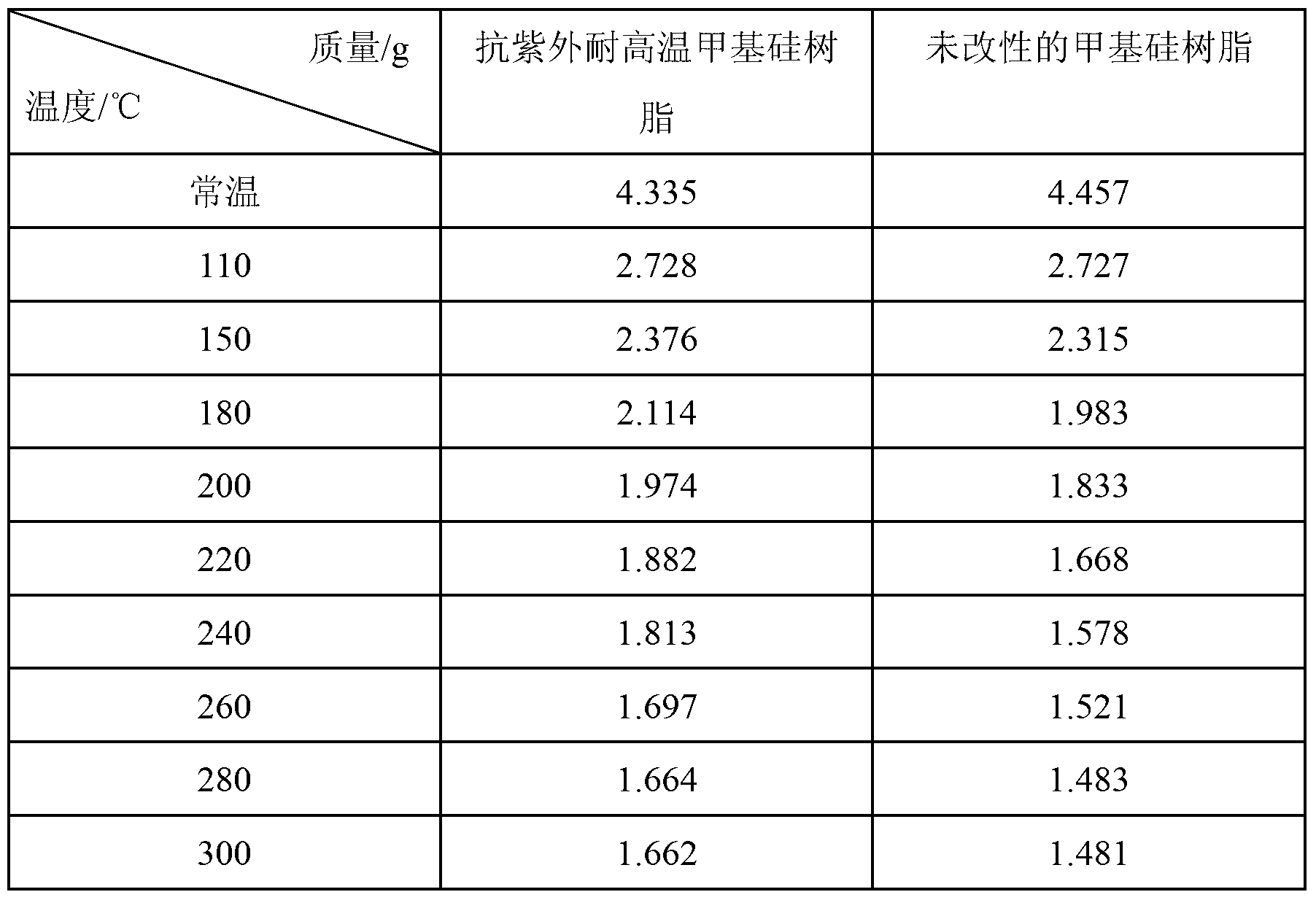

Preparation method of ultraviolet-resistant and high-temperature-resistant methyl silicone resin

The invention relates to a preparation method of ultraviolet-resistant and high-temperature-resistant methyl silicone resin, relates to the preparation method of modified methyl silicone resin, and is used for solving the problems that the existing methyl silicone resin is poor in high temperature and ultraviolet resistance, complicated in preparation method and high in cost. The preparation method comprises the following steps of:1, dispersing ethyl orthosilicate in anhydrous ethanol and then adding a mixing solution of deionized water, the anhydrous ethanol and ammonia, thereby obtaining a silica ethanol solution; 2, dispersing tetrabutyl titanate in the anhydrous ethanol and then adding the mixing solution of the deionized water, the anhydrous ethanol and hydrochloric acid, thereby obtaining a titania ethanol solution; 3, dispersing methyl triethoxysilane and diethoxydimethylsilane in the anhydrous ethanol, thereby preparing a methyl silicone resin prepolymer; and 4, regulating the pH values of the solutions obtained in the steps 1 and 2 to be 7 and performing a refluxing operation after adding the prepolymer, thereby obtaining the methyl silicone resin. The method is conventional in raw material preparation as well as simple and easy to implement. The thermal weight loss rate of the modified methyl silicone resin at the temperature of 300 DEG C is 0.6, so that the modified methyl silicone resin is good in ultraviolet resistance.

Owner:HARBIN INST OF TECH

A solvent-free addition type liquid silicone resin

A solvent-free addition type liquid silicone resin, characterized in that, in parts by weight, it comprises the following components: 100-130 parts of vinyl silicone oil with a weight ratio of ethylene content of 0.3% and a viscosity of 10,000-50,000 cs; a particle size of 10 ~20nm, 38-58 parts of fumed silica with a specific surface area of 160-300m2 / g; the treating agent includes 5-10 parts of hexamethylsilazane, 0.5-2 parts of vinyltriethoxysilane, dimethyl Diethoxysilane 0.5-2 parts; and water 2-5 parts; release agent stearic acid 0.06-0.09 parts; inhibitor methyl butynol 0.001-0.003 parts, cross-linking agent hydrogen-containing silicone oil 0.6-0.8 parts; prepared by the addition method. The invention solves the problems that the existing liquid silicone resin used for the surface coating of glass fiber sleeve, silicone tube, glass fiber cloth and other materials is not good enough in performance and storage is not stable enough.

Owner:HUANGSHAN QIANGLU NEW MATERIALS

Solvent-free addition liquid state silicon resin and preparation method of solvent-free addition liquid state silicon resin

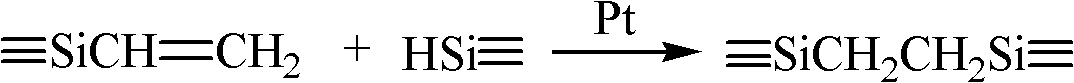

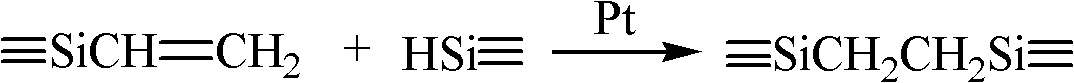

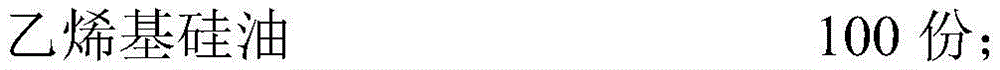

InactiveCN102220010AImprove insulation performanceImprove temperature resistanceGas phaseSolvent free

The invention relates to a preparation method of solvent-free addition liquid state silicon resin. The solvent-free addition liquid state silicon resin comprises the following raw materials according to part by weight: 100-130 parts of ethylene group silicone oil with, 0.3 percent by weight of ethylene and 10000-50000cs of viscosity, 38-58 parts of gas phase made silicon dioxide with 10-20nm of grain size and 160-300m2 / g of specific surface area, treatment agents comprising 5-10 parts of hexamethyldisilazane, 0.5-2 parts of vinyl triethoxy silicane, 0.5-2 parts of dimethyl ethoxydimethylsilane, 2-5 parts of water, 0.06-0.09 part of releasing agent stearic acid, 0.001-0.003 part of inhibitor methylbutynol, and 0.6-0.8 part of cross-linking agent containing hydrogen silicone oil. The addition preparation method comprises the following steps of preparing, kneading, banburying, grinding and filter pressing of ethylene group silicone oil, so as to obtain the liquid state silicon resin. The problems that the liquid state silicon resin for coating on the surfaces of materials such as glass fiber sleeves, silicone tubes, glass fiber cloths and the like has poor performance and is unstable for storage.

Owner:HUANGSHAN QIANGLU NEW MATERIALS

Two-component organic silicon pouring sealant

ActiveCN103387810ALow viscosityImprove the level ofNon-macromolecular adhesive additivesSemiconductor devicesVulcanizationEngineering

The invention provides a two-component organic silicon pouring sealant comprising a component A and a component B, wherein the component A is formed by mixing alpha,omega-dihydroxy polydimethylsiloxane, dimethicone, RTV-2 (room temperature vulcanization silicon rubber)-based rubber, silicon micro-powder, iron oxide black and black slurry at a weight ratio of 100:(50-65):(20-30):(20-30):(3-8):(2-4); the component B is formed by mixing dimethyl diethoxy silane, dimethicone, 3-amino propyl triethoxy silane, vinyl triethoxy silane and dibutyltin dilaurate at a weight ratio of 100:(50-65):(30-35):(30-35):(1-3). The two-component organic silicon pouring sealant is low in viscosity, good in leveling property and suitable for encapsulation of indoor and outdoor LED (Light-Emitting Diode) display screens and decorative lighting modules, has excellent heat resistance, moisture resistance and cold resistance, and can be used for prolonging the service life of electronic accessories, and the LED display screens can reach an IP65 waterproofing grade.

Owner:深圳市欧普特工业材料有限公司

Method for preparing composite film of carbon similar to generic diamond containing Nano granules of silicon dioxide

InactiveCN1796612ALow costEasy to operateElectrolytic inorganic material coatingComposite filmDiamond-like carbon

This invention relates to a preparation method for silicon dioxide nano-particle-contained diamond-like carbon composite thin films. In this method, graphite is adopted as anode, a monocrystal silicon wafer is adopted as cathode and a methanol solution of dimethyldiethoxysilane is adopted as deposition fluid. A silicon dioxide nano-particle-contained diamond-like carbon composite thin film is obtained on the cathode under a high DC voltage. This method has the advantages of simple facilities, low deposition temperature and large synthesis area for silicon dioxide nano-particle-contained diamond-like carbon films, and hopefully it would be applicable in the fields of mechanical friction, electrics and optics.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

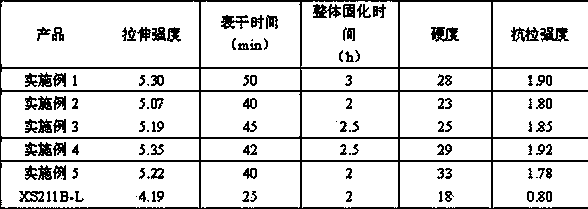

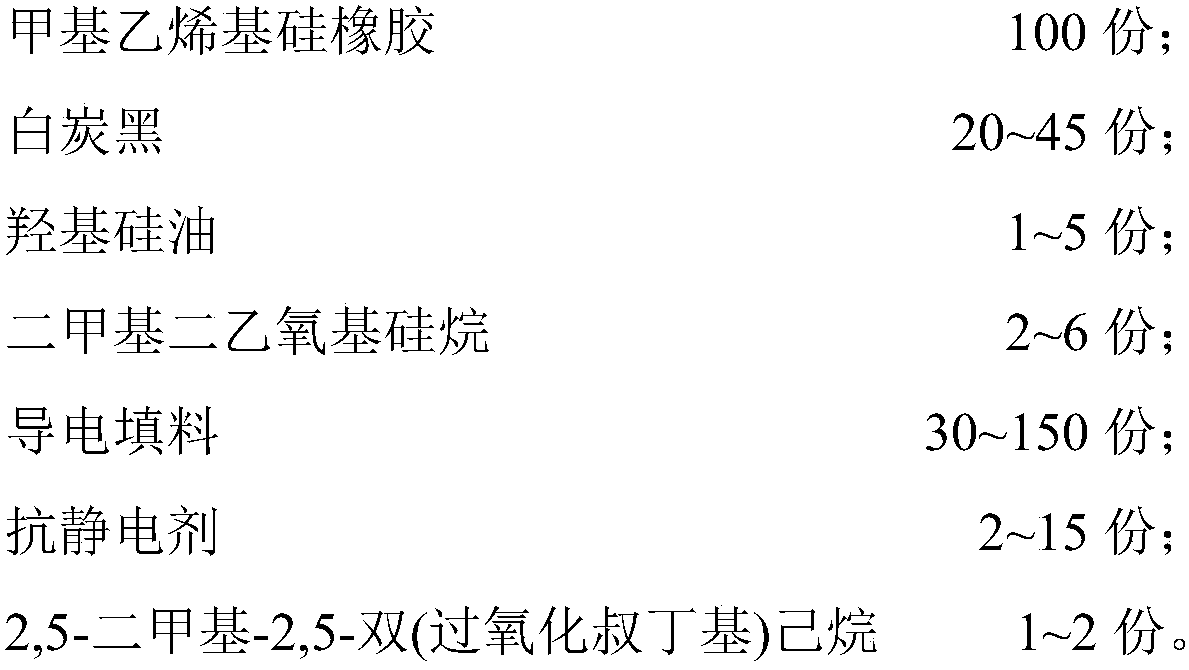

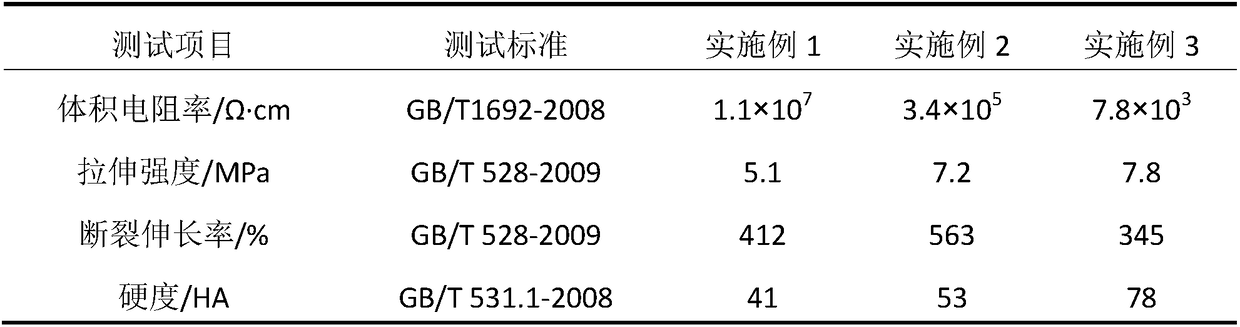

Non-black appearance conductive silicon rubber material and preparation method thereof

The invention relates to a non-black appearance conductive silicon rubber material and a preparation method thereof. The silicon rubber material comprises the following components in parts by weight:100 parts of methyl vinyl silicone rubber, 20-45 parts of white carbon black, 1-5 parts of hydroxyl silicone oil, 2-6 parts of dimethyl diethyoxyl silane, 30-150 parts of conductive packing, 2-15 parts of an anti-electrostatic agent and 1-2 parts of 2,5-dimethyl-2,5-di(tert-butyl peroxide) hexane. The preparation method specifically comprises the following steps: mixing the methyl vinyl silicone rubber, the white carbon black, the hydroxyl silicone oil, the dimethyl diethyoxyl silane, the conductive packing and the anti-electrostatic agent, further uniformly mixing with the 2,5-dimethyl-2,5-di(tert-butyl peroxide) hexane, and performing vulcanization, thereby obtaining the non-black appearance conductive silicon rubber material. Compared with the prior art, the silicon rubber material provided by the invention is relatively high in tension strength, excellent in electric property, excellent in high-temperature resistance and excellent in flame retardancy and has a non-black appearance.

Owner:SHANGHAI JIAO TONG UNIV +1

Dealcoholization silicone weather-resistant sealant with low modulus and high displacement capability and preparation method of dealcoholization silicone weather-resistant sealant

ActiveCN108179003ALow modulusReduce stressNon-macromolecular adhesive additivesAdhesiveWater resistant

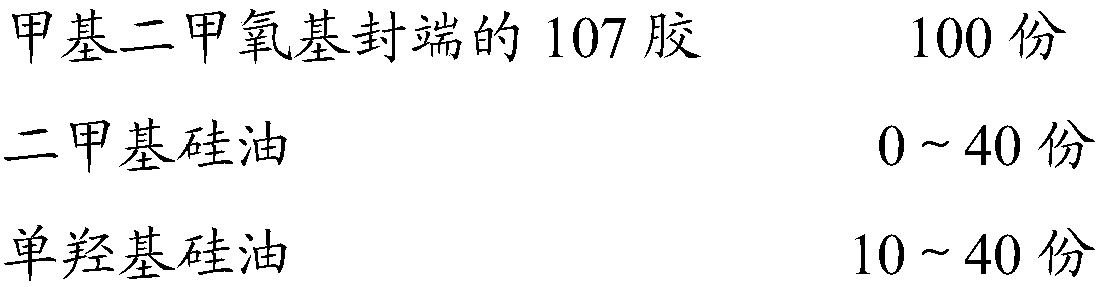

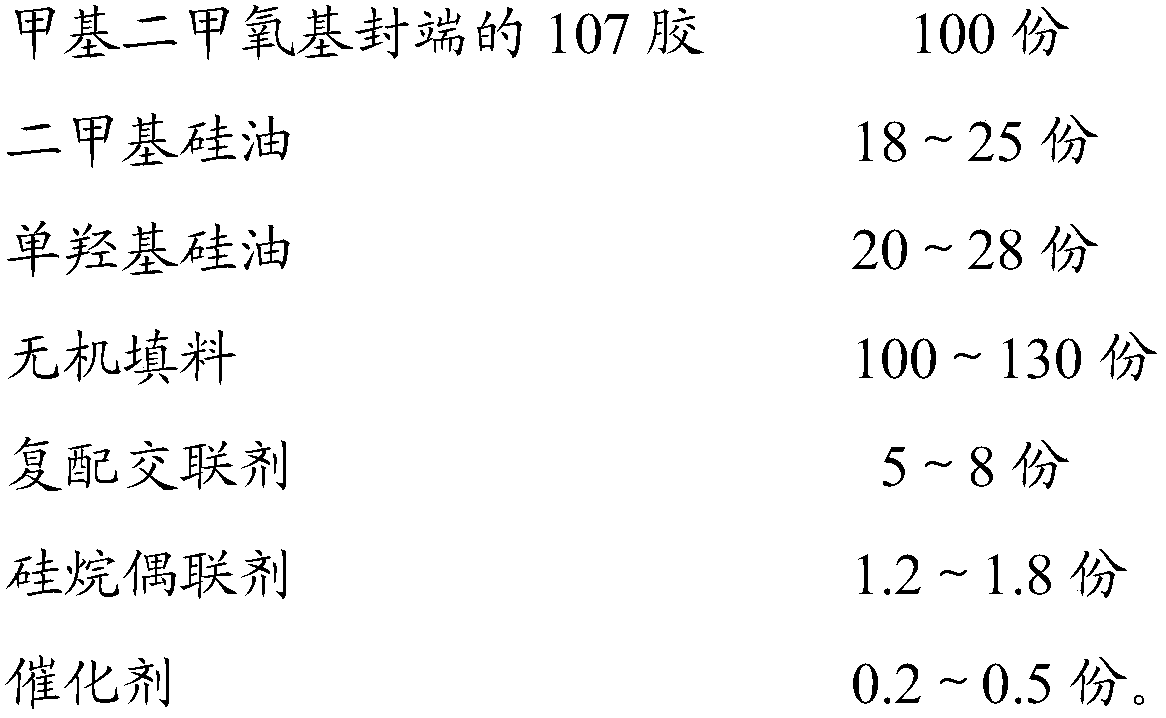

The invention relates to dealcoholization silicone weather-resistant sealant with low modulus and high displacement capability and a preparation method of dealcoholization silicone weather-resistant sealant. The silicone weather-resistant sealant is prepared from the following raw materials in parts by weight: 100 parts of methyldimethoxy-terminated 107 adhesive, 0 to 40 parts of dimethyl siliconeoil, 10 to 40 parts of monohydroxy silicone oil, 60 to 200 parts of inorganic filler, 2 to 10 parts of a compound cross-linking agent, 0.5 to 3 parts of a silane coupling agent, and 0.05 to 0.5 partof a catalyst; and the compound cross-linking agent is selected from at least two of methyltrimethoxysilane, methyl triethoxysilane, methyltri-n-propoxysilane, tetramethyl orthosilicate, tetraethoxysilane, isopropyl orthosilicate, dimethyl dimethoxy silicane, dimethyldiethoxysilane and dimethyl dipropylsilane. The silicone weather-resistant sealant has low modulus and high displacement capability,has small stress to a curtain wallboard, and has excellent weather resistance, good binding property and good water-resistant binding property.

Owner:GUANGZHOU BAIYUN CHEM IND

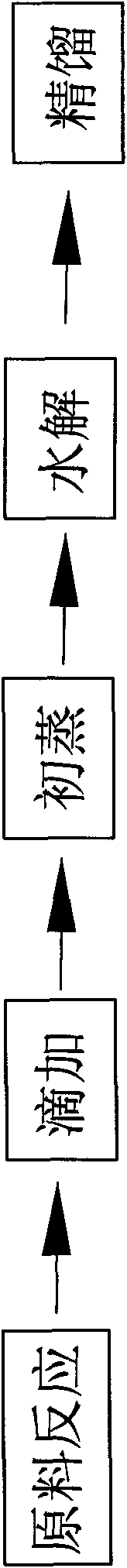

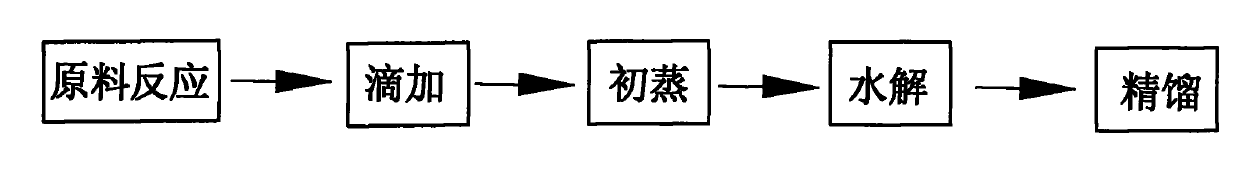

Production process of tetramethyldivinyldisiloxane

ActiveCN101792459AHarm reductionRelieve pressureSilicon organic compoundsEnvironmental engineeringDimethyldiethoxysilane

The invention relates to a production process of an organic material and discloses a production process of tetramethyldivinyldisiloxane. On the basis of the production process of the tetramethyldivinyldisiloxane in the prior art, a technical process of dripping dimethyldichlorosilane is adopted before a predistillation step, the dripped dimethyldichlorosilane reacts with sodium ethylate generated in a reaction to form dimethyldiethoxysilane and sodium chloride mainly, the sodium ethylate content of waste residues is reduced or zero, so the damages caused by sodium ethylate to human bodies and the environment are reduced, the risks in storage and transportation process are reduced, the production cost is reduced and the environmental protection burden is relieved.

Owner:浙江佳汇新材料有限公司

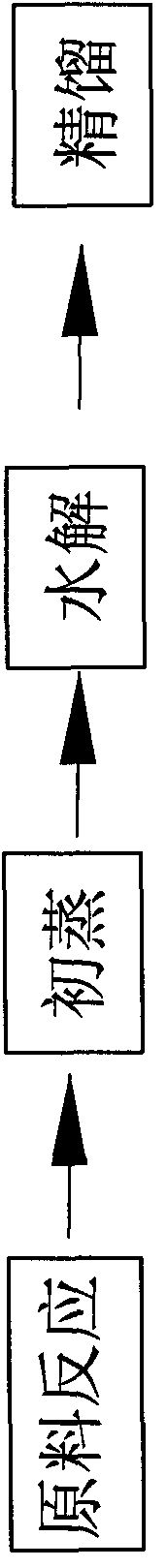

Preparation method and application of organic silicon resin adhesive

The invention relates to organic chemical synthesis. In order to solve the problem of lower storage stability of the product when the R / Si ratio of the organic silicon resin adhesive is lower, the invention provides a preparation method of an organic silicon resin adhesive, which comprises the following steps: adding tetraethyl orthosilicate, methyltriethoxysilane, dimethyldiethoxysilane and toluene into a reaction kettle, heating to 50-70 DEG C, adding a catalyst, dropwisely adding deionized water at 50-70 DEG C within 1-2 hours to perform hydrolysis, reacting for 2-4 hours, filtering out the catalyst, drying the liquid by distillation, heating the system to 105-115 DEG C to react for 5-10 minutes, adding a solvent for dissolution, cooling to room temperature, and blending with the solvent to obtain the organic silicon resin adhesive of which the solid content is 30-55%. The R / Si ratio in the organic silicon resin adhesive is smaller than 1; the storage stability of the product is enhanced; and the organic silicon resin adhesive is applicable to mica binding.

Owner:HANGZHOU NORMAL UNIVERSITY

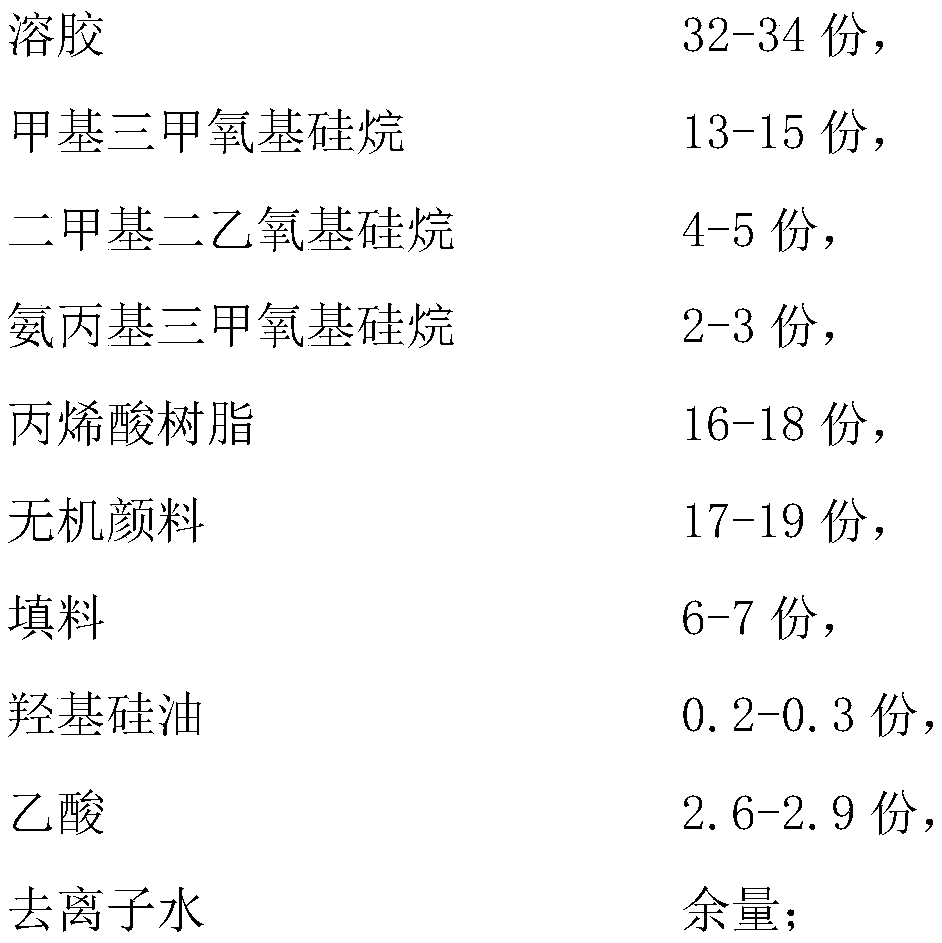

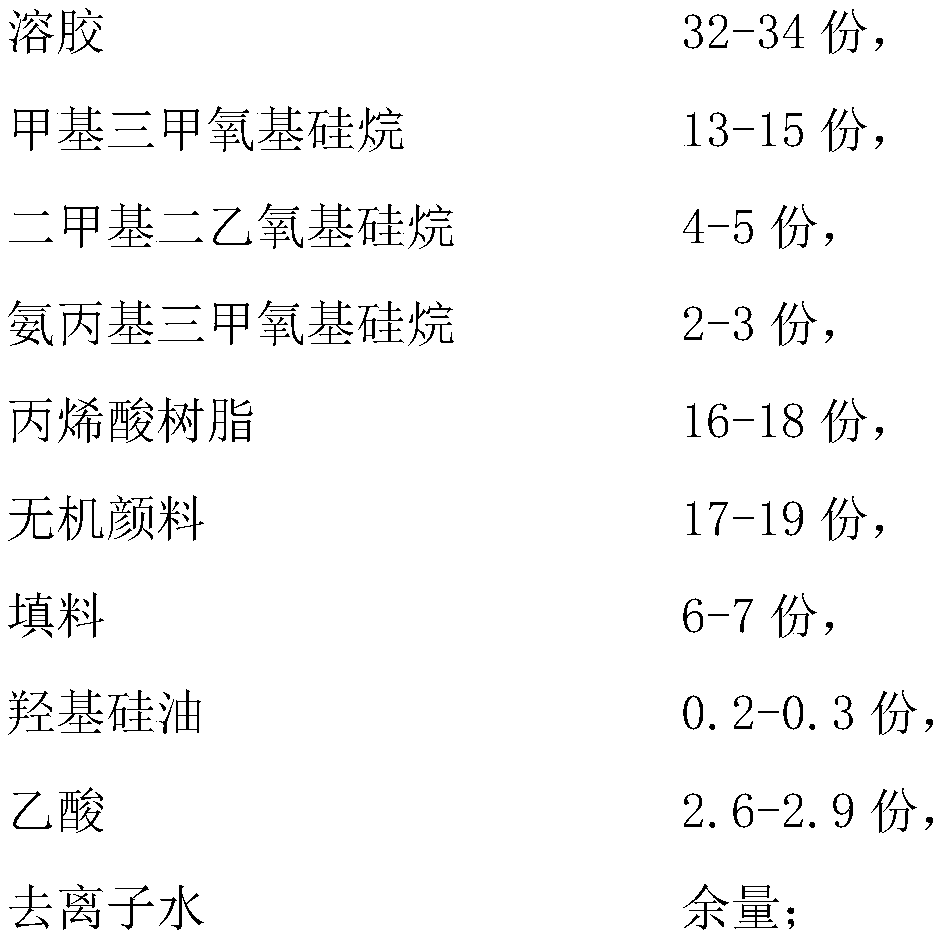

Water-based ceramic material for inner container of stainless steel vacuum cup and preparation method of water-based ceramic material

The invention discloses a water-based ceramic material for an inner container of a stainless steel vacuum cup and a preparation method of the water-based ceramic material. According to 100 parts of the total amount of the coating, the formula comprises 32 to 34 parts of sol, 13 to 15 parts of methyltrimethoxysilane, 4 to 5 parts of dimethyldiethoxysilane, 2 to 3 parts of aminopropyltrimethoxysilane, 16 to 18 parts of acrylic resin, 17 to 19 parts of an inorganic pigment, 6 to 7 parts of a filling material, 0.2 to 0.3 part of hydroxyl silicone oil, 2.6 to 2.9 parts of acetic acid and the balance being deionized water, wherein the sol is a mixture of silica sol and zirconium sol in a mass ratio of 2:1-3:1. The ceramic coating is sprayed on the inner surface of the stainless steel vacuum cup,the thickness of a coating layer is 35-40 [mu]m, the heat preservation effect of the vacuum cup can be remarkably improved, and after boiling water is poured into the vacuum cup for 6 h, the water temperature can be kept at 65 DEG C or above; and the ceramic coating has good adhesion with a base material, and even if the stainless steel base material is not subjected to sand blasting, a good adhesion effect can be achieved only through simple polishing.

Owner:SHANGHAI EXCILON NEW MATERIALS

Fibrillar silicate-reinforced super thermal-insulation heat-preserving paint and preparation method thereof

The invention provides a fibrillar silicate-reinforced super thermal-insulation heat-preserving paint. The paint is prepared from the following raw materials by weight: 34 to 38 parts of ethyl orthosilicate, a proper amount of hydrochloric acid, a proper amount of ammonia water, a proper amount of ethanol, a proper amount of deionized water, 1 to 2 parts of vinyltrimethoxy silane, 2.5 to 3 parts of dimethyldiethoxylsilane, 0.8 to 1.2 parts of 3-aminopropyltrihydroxysilane, 0.5 to 0.8 part of phenolic resin, 0.2 to 0.4 part of nanometer calcium carbonate, 0.6 to 0.9 part of fibrillar silicate, 70 to 75 parts of epoxy resin E-12, 9 to 12 parts of ethylene glycol diglycidylether and 7 to 7.5 parts of triethanolamine. According to the invention, through hydrophobic modification of aerogel, the phenomenon of fragmentation of the aerogel due to moisture absorption is reduced; and through hydrophilic modification, bonding strength between the aerogel and a film forming agent is improved.

Owner:DANGTU COUNTY KEHUI TRADING

Preparation method of silica gel with high flame retardant rating

The invention discloses a preparation method of silica gel with high flame retardant rating. The silica gel with high flame retardant rating is prepared by mixing the following raw materials in parts: a raw material A: methyl vinyl silicon rubber; a raw material B: methyl vinyl silicon rubber; a raw material C: precipitated silica; a raw material D: hydroxyl silicon oil; a raw material E: dimethyl diethoxy silane; a raw material F: zinc stearate; a raw material G: stearic acid; a raw material H: methyl silicone oil; a raw material I: aluminum hydroxide; a raw material J: zinc stannate; a raw material K: vinyl trimethoxy silane; a raw material L: platinum water; a raw material M: benzotriazole; a raw material N: ferric oxide; a raw material P: magnesium oxide; and a few of raw material Q: curing agent. The silica gel raw material prepared by mixing the raw materials is excellent in flame retardant performance which can reach 5VB and 5VA of UL94 flame retardant rating.

Owner:东莞市朗晟材料科技有限公司

Preparation method of heavy anti-corrosion coating containing nano titanium

InactiveCN104479549AImprove corrosion resistanceExcellent keys and performanceAnti-corrosive paintsManufacturing cost reductionTitanium

The invention discloses a preparation method of heavy anti-corrosion coating containing nano titanium, relates to a preparation method of heavy anti-corrosion coating added with nano titanium particles and particularly relates to a method of preparing heavy anti-corrosion coating by taking modified organic silicon resin as a matrix. The preparation method comprises the following steps: synthesizing low polymer organic silicon by phenyltriethoxysilane and dimethyldiethoxysilane, modifying by adopting epoxy resin E-20, and finally adding nano taitaium powder to uniformly stir, thereby preparing the heavy anti-corrosion coating containing nano titanium. According to the preparation method disclosed by the invention, firstly, the organic silicon resin is adopted as a film-forming agent, so that the heavy anti-corrosion coating has the advantages of being good in bonding strength, good in coating toughness, not prone to causing embrittlement, low in curing temperature, strong in corrosion resistance, and the like; secondly, the nano titanium particles are dispersed into the organic silicon resin, and the titanium is applied to the corrosion prevention field in the form of coating, so that not only can stainless steel be substituted to solve an industrial corrosion problem, but also the manufacturing cost can be greatly lowered.

Owner:广东华科新材料研究院有限公司 +1

Preparation method for organosilicone high temperature resisting black iron oxide

ActiveCN103421355AImprove high temperature stabilityImprove high temperature resistancePigment treatment with organosilicon compoundsPigment physical treatmentWater bathsSilanes

The invention discloses a preparation method for organosilicone high temperature resisting black iron oxide, wherein the black iron oxide is prepared by adopting the sodium hydroxide oxidation method, and the preparation method comprises the following steps: a black iron oxide filter cake, which is not kiln dried, is directly used; ethanol solution, the weight of which is 2-3% of that of the black iron oxide filter cake, and silica sand, the weight of which is 1-2% of that of the black iron oxide filter cake, are added; the mixture is ground for 15-20 minutes at the speed of 1500-2500 rpm; the powder is taken out and dried, appropriate water is added, pulping is performed for 20-25 minutes, and seriflux with the concentration of 55-60% is prepared; methyl triethoxy silane, the weight of which is 4-6% of that of the seriflux, dimethyl dioxethyl silane, the weight of which is 2-3% of that of the seriflux, phenyl triethoxy silane, the weight of which is 5-8% of that of the seriflux, and hollow floating beads, the weight of which is 0.3-0.4% of that of the seriflux, are added, and the mixture is heated in water bath to 60-70 DEG C and stirred for 2-3 hours; a colloid mill is utilized to grind the seriflux until the grain size is less than 40 Mum; filtering, drying and powdering are performed, and the finished product is generated. The black iron oxide, disclosed by the invention, has superior high temperature resisting property and can bear the high temperature of 500-600 DEG C.

Owner:ANHUI QILIN CHEM TECH +1

High-temperature resistant silicone rubber and preparation method thereof

The invention provides high-temperature resistant silicone rubber. The high-temperature resistant silicone rubber is prepared from the following ingredients in parts by mass: 100 parts of methylvinyl silicone raw rubber, 70-75 parts of polyorganometallosiloxane, 23-26 parts of alkoxy-terminated polysiloxane, 5-6 parts of dimethyl diethoxy silane, 20-22 parts of gaseous white carbon black, 4-5 parts of hydroxy silicone oil, 2-3 parts of methyl silicone oil with low hydrogen content, 6-8 parts of quartz powder, 1-2 parts of diatomite, 1-2 parts of barium silicate and 0.20-0.30 part of calcium stearate, wherein the methylvinyl silicone raw rubber contains 68+ / -2 parts (by weight) of methylvinyl silicone raw rubber with the vinyl content of 0.07-0.09% and 32+ / -2 parts (by weight) of methylvinyl silicone raw rubber with the vinyl content of 0.15-0.17%, and the number-average molecular weight of the methylvinyl silicone raw rubber with the vinyl content of 0.07-0.09% and the methylvinyl silicone raw rubber with the vinyl content of 0.15-0.17% is between 600,000 and 620,000. The silicone rubber provided by the invention has excellent heat resistance.

Owner:WUXI XINTENG EAST CABLE ACCESSORIES

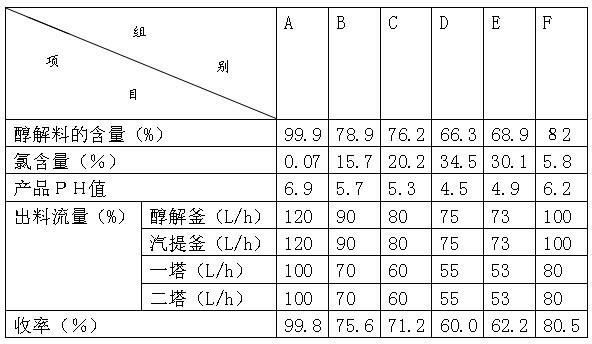

Preparation technology for dimethyl diethoxy silane

ActiveCN102070663AChlorine substitutionChlorine better replaceGroup 4/14 element organic compoundsFiltrationSilanes

The invention relates to improvement on preparation technology for dimethyl diethoxy silane. The referred dimethyl diethoxy silane comprises the following chemical raw materials and neutralization treating agents in part by weight: 100 parts of dimethyl dichloro silicane, 150 parts of absolute ethanol, 0.05 part of sodium ethylate, 0.02 part of hexamethyldisilazane and 0.01 part of amino monomer.The preparation technology has the advantages of increasing the height of an alcoholysis kettle to make the alcoholysis reaction more sufficient, raising the reaction temperature to make chlorine in the materials better substituted to ensure full reaction and increase the yield rate, enlarging a comprehensive tank to reduce the consumption of a neutralizing agent and save the neutralizing agent, adding an external circulating pump and a gas filtration pump to realize continuous production by the alcoholysis reaction, increase the reaction speed and reduce byproducts generated by the overlong reaction, adding a settling tank which is favorable for performing rectification reaction to isolate air, eliminate salt slurry, reduce corrosion and protect a rectification tower.

Owner:JIANGXI BLUESTAR XINGHUO SILICONE CO LTD

Heat curing silicone rubber crosslinked with polyamine compound and preparation method thereof

The invention discloses heat curing silicone rubber crosslinked with a polyamine compound and a preparation method thereof. The preparation method comprises the following steps of: cohydrolyzing dimethyldiethoxysilane and chloropropyl-methyl-2-silane to obtain chloropropyl-7-central-4-methyl siloxane; cohydrolyzing the chloropropyl-7-central-4-methyl siloxane and 8-central-4-methyl siloxane to obtain chloropropyl methyl polysiloxane; using the chloropropyl methyl polysiloxane as a based adhesive, polyamines as a coupler, a gas-phase-method white carbon black as a reinforcing material and zinc oxide as an acid absorbent; and preparing by heat curing. The heat curing silicone rubber of the invention not only has excellent mechanical properties, but also overcomes some defects of a traditional curing system and has favorable economic benefits and popularization application values.

Owner:SHANDONG UNIV

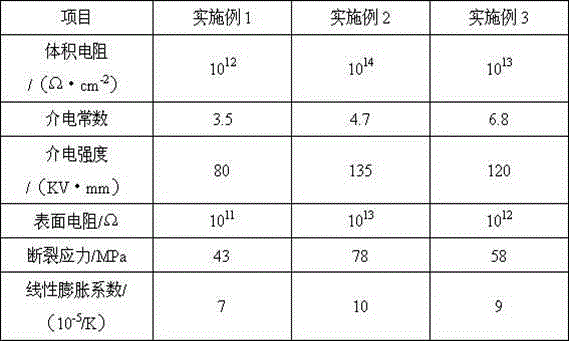

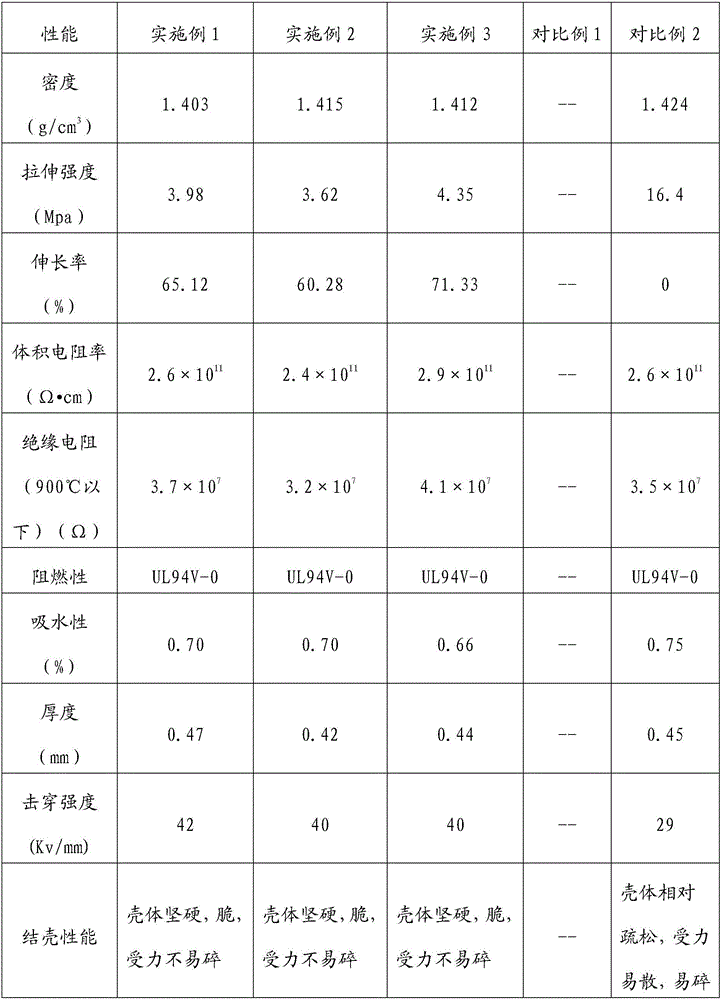

Electrical insulating packaging material and preparation method thereof

The invention discloses an electrical insulating packaging material and a preparation method thereof. The electrical insulating packaging material is mainly prepared from a carrier material, adhesive resin and organic silicon resin, wherein the carrier material is prepared from the following raw materials in parts by weight: 25-50 parts of epoxy resin, 15-35 parts of phenolic resin, 12-30 parts of PVC (polyvinyl chloride); 8-25 parts of weather-resistant acrylic resin; the adhesive resin is melamino-formaldehyde resin or melamine urea-formaldehyde resin suitable for being impregnated, wherein the solid content of the resin is 35-55%; the organic silicon resin is prepared from the following raw materials in parts by weight: 15-40 parts of methyl triethoxysilane, 12-30 parts of diethoxydimethylsilane, 8-25 parts of silicon carbide and 25-55 parts of an organic solvent. The packaging material disclosed by the invention has a good electric insulating property and good weather resistance, and the curing property of the epoxy resin is improved.

Owner:SUZHOU DINGLI PACKAGING

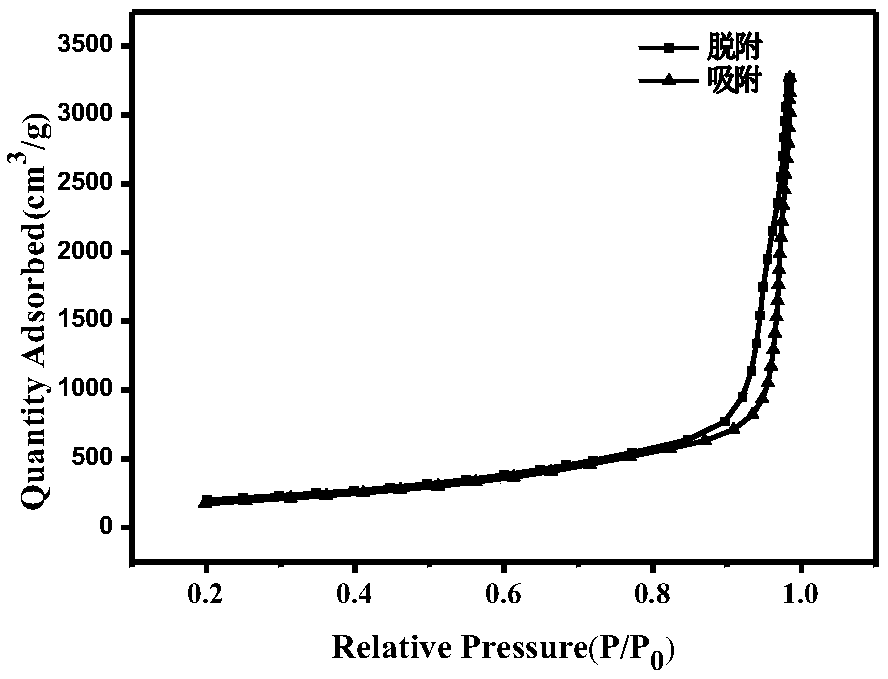

Mesoporous silicon dioxide nanoparticle with small particle size and large pore diameter and preparation method thereof

ActiveCN108862289ASmall particle sizeLarge apertureSilicaNanotechnologyMesoporous silicaSilicon dioxide

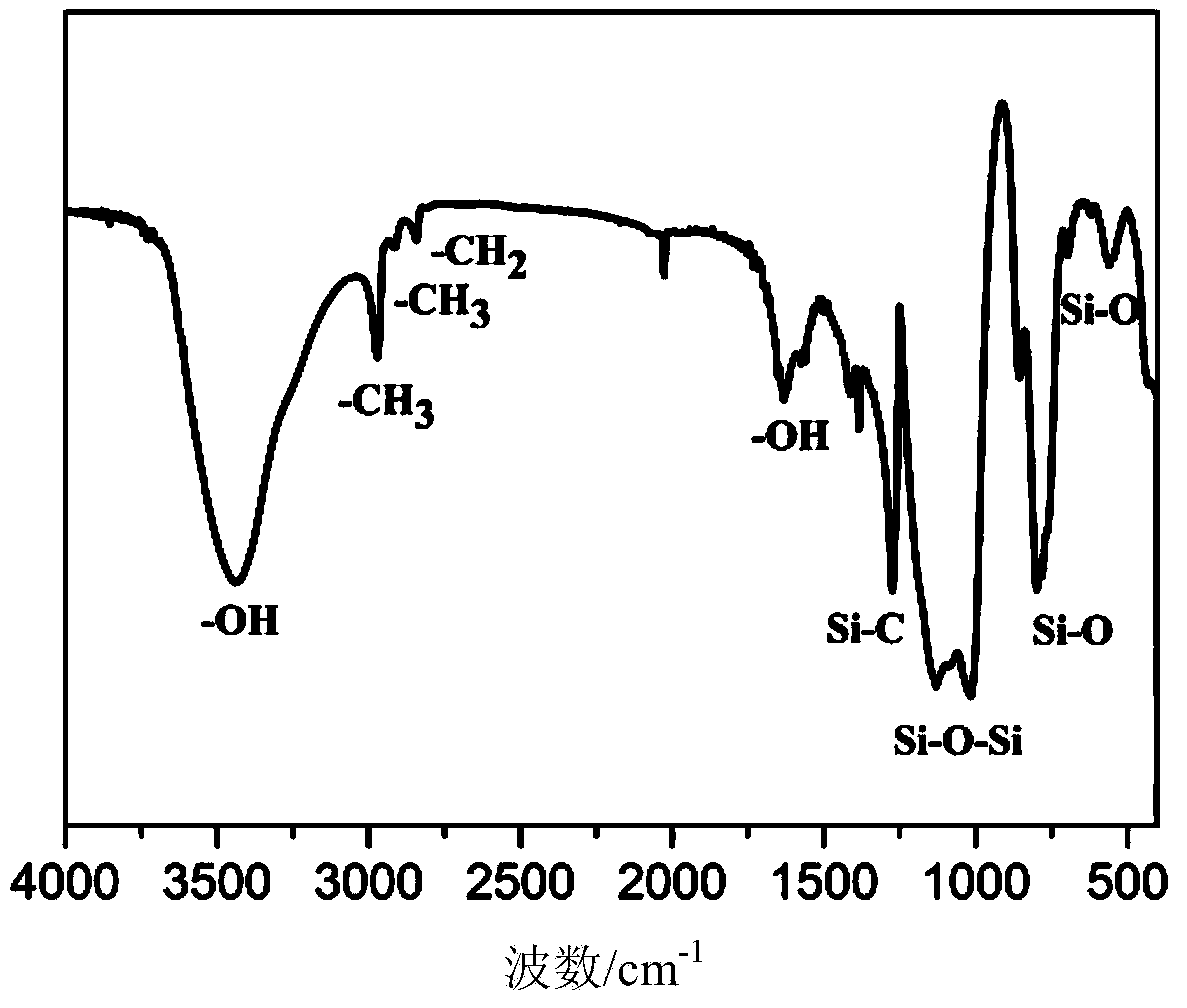

The invention discloses a mesoporous silicon dioxide nanoparticle with small particle size and large pore diameter and a preparation method thereof. The preparation method comprises the following steps of using a surfactant CATC (aetyl trimethylammonium chloride) and a TMB (1,3,5-trimethylbenzene) co-solvent as templates, using TEOS (tetraethoxysilane) and DMDMS (dimethyl diethoxysilane) as silicon sources, and reacting by a one-step method under certain conditions, so as to obtain the mesoporous silicon dioxide nanoparticle. The prepared mesoporous silicon dioxide nanoparticle has the advantages that the particle size is smaller, the pore diameter is larger, the size is uniform, the specific surface area is large, and the like; the important application prospect is realized in the fieldsof biomedicine, chemical engineering, functional materials and the like.

Owner:NANJING UNIV OF POSTS & TELECOMM

Preparation method of inorganic hard film plastic material added with organic silicon

The invention discloses a preparation method of an inorganic hard film plastic material added with organosilicon. The process utilizes active organosilicon solutions such as methyltriethoxysilane, dimethyldiethoxysilane and ethyl orthosilicate Coating and modifying polyester plastic materials; aggregating raw materials such as butylated amino resin, methyl etherified amino resin, melamine phosphate, etc., heating and calcining in a horse boiling furnace, adding coupling agent, defoaming agent, and curing agent , toughening agent and other ingredients to improve the performance of the composite material, and then a composite plastic material is obtained after a series of operations such as film drawing solidification, surface activation treatment, coating, suspension leveling, drying and cooling. The prepared film plastic material has high transparency, heat resistance and corrosion resistance, and has good application prospects. At the same time, it also discloses the application of the film plastic material prepared by the preparation method in the fields of optical wear-resistant layer, heat-resistant anti-corrosion coating and the like.

Owner:SUZHOU XUANLANG PLASTIC PROD CO LTD

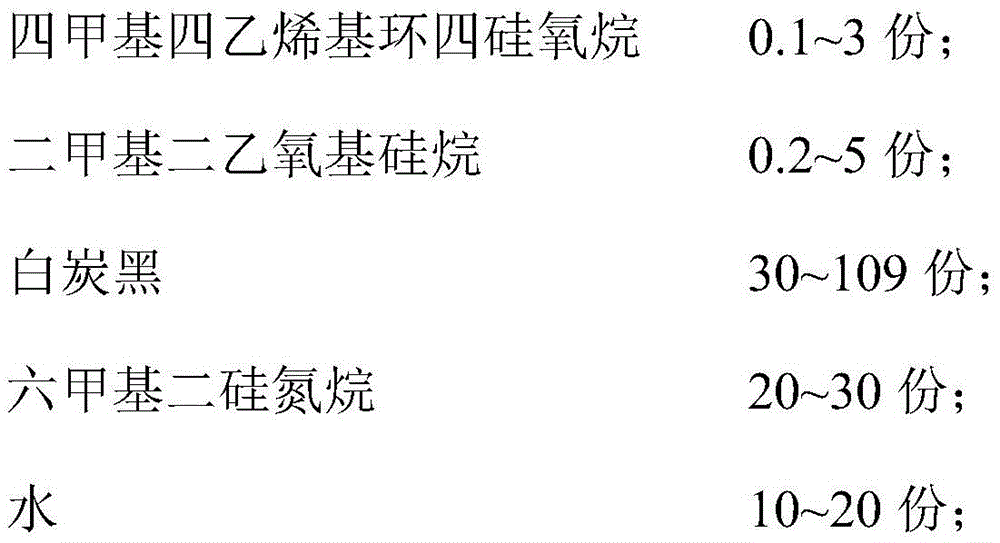

Method for preparing formed liquid silicone rubber with low permanent compression deformation

ActiveCN105670299ALow permanent compression set capacitySmall permanent compression deformationPolymer scienceBis(trimethylsilyl)amine

The invention discloses a method for preparing formed liquid silicone rubber with low permanent compression deformation. The method is characterized in that the formed liquid silicone rubber is made of base rubber, silicone oil and 1-acetenyl cyclohexanol, and the liquid silicone rubber is prepared under the effects of platinum catalysts; the base rubber comprises vinyl silicone oil, 2, 4, 6, 8-tetravinyl-2, 4, 6, 8-tetramethylcyclotetrasiloxane, diethoxydimethylsilane, white carbon black, hexamethyl disilazane and water. The base rubber is made of the vinyl silicone oil, the 2, 4, 6, 8-tetravinyl-2, 4, 6, 8-tetramethylcyclotetrasiloxane, the diethoxydimethylsilane, the white carbon black, the hexamethyl disilazane and the water, the base rubber, the silicone oil and the 1-acetenyl cyclohexanol are mixed with one another, and accordingly the liquid silicone rubber with the low permanent compression deformation can be prepared under the effects of the platinum catalysts. Compared with the prior art, the method has the advantages that the liquid silicone rubber is high in tensile strength and tear strength, low in permanent compression deformation and long in service life, and accordingly the method has a broad application prospect.

Owner:东莞新东方科技有限公司

Extra-high-pressure-resistant high-temperature-resistant mixed silicone rubber and preparation method thereof

The invention belongs to the technical field of silicone rubber, and particularly relates to extra-high-pressure-resistant high-temperature-resistant mixed silicone rubber and a preparation method thereof. The extra-high-pressure-resistant high-temperature-resistant mixed silicone rubber provided by the invention comprises the following components in parts by weight: 70-120 parts of raw methyl vinyl silicone rubber, 20-30 parts of fumed silica, 3-6 parts of hexamethyldisilazane, 1-3 parts of dimethyldiethoxysilane, 0.1-1 part of zinc stearate, 5-30 parts of silica powder, 5-20 parts of a nitrogen compound, 5-20 parts of iron oxide, 1-5 parts of titanium dioxide, 0.1-1 part of vinyltriethoxysilane, 0.5-3 parts of distilled water, 1-5 parts of cerium oxide and 1-3 parts of a flame retardant.According to the extra-high-voltage-resistant high-temperature-resistant mixed silicone rubber provided by the invention, the flame retardance, the electrical property stability and the breakdown voltage of a silicone rubber material are remarkably improved. An electric power product produced by using the silicone rubber is higher in safety and more stable in quality.

Owner:XINAN TIANYU SILICONE CO LTD

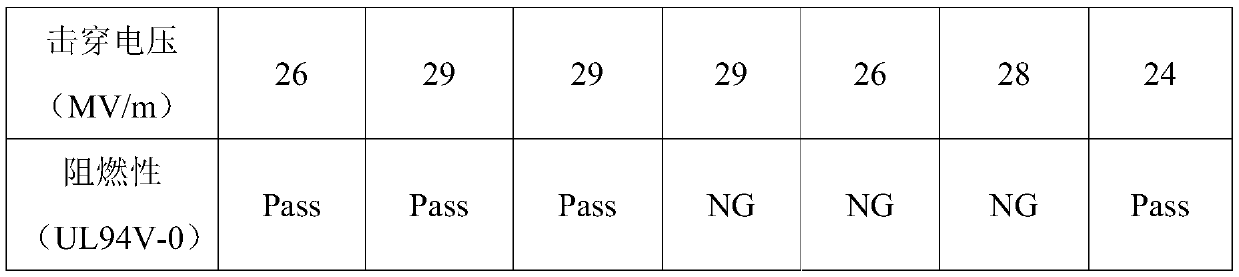

Ceramic fireproof and fire-resistant silicone rubber, method for preparing same, ceramic compound belt with ceramic fireproof and fire-resistant silicone rubber and method for preparing ceramic compound belt

ActiveCN106349698AImprove flame retardant performanceImprove insulation performanceSynthetic resin layered productsRubber layered productsStearic acidFire retardant

The invention discloses ceramic fireproof and fire-resistant silicone rubber, a method for preparing the same, a ceramic compound belt with the ceramic fireproof and fire-resistant silicone rubber and a method for preparing the ceramic compound belt, and belongs to the technical field of ceramic compound belts. The ceramic fireproof and fire-resistant silicone rubber is made of, by weight, 100 parts of silicone rubber, 20-70 parts of silicon dioxide, 1-15 parts of dimethyldiethoxysilane, 20-60 parts of ceramic powder, 1-5 parts of stearic acid, 20-100 parts of flame retardants, 1-30 parts of magnesium oxide, 20-60 parts of magnesium hydroxide and 0.5-5 parts of silane coupling agents. The ceramic fireproof and fire-resistant silicone rubber and polyimide rubber belts are vulcanized and compounded with one another to obtain the ceramic compound belt with high breakdown resistance and fireproof and fire-resistant performance. The ceramic fireproof and fire-resistant silicone rubber, the methods and the ceramic compound belt have the advantages that the ceramic compound belt is excellent in breakdown-resistant performance, good in fireproof and fire-resistant performance and convenient to wind and coat, and has certain tensile properties.

Owner:东莞市裕天硅橡胶科技有限公司

High-elasticity film

InactiveCN104341660AHigh tensile strengthIncrease elasticityPolytetramethylene terephthalatePolymer science

The invention relates to a high-elasticity film which is prepared from the following raw materials in parts by weight: 9-14 parts of silicone resin, 6-8 parts of polybutylene terephthalate, 7-11 parts of glycerol, 3-7 parts of polyvinylidene fluoride resin, 2-6 parts of kaolin, 5-7 parts of polyvinyl alcohol, 4-11 parts of polytetrafluoroethylene resin, 4-10 parts of polyoxyethylene, 5-10 parts of dimethyldiethoxysilane, 4-7 parts of isocyanate, 5-8 parts of nano SiO2 powder, 1-5 parts of coupling agent, 14-20 parts of HDPE (high-density polyethylene), 5-7 parts of allyl siloxane and 9-14 parts of polyethylene. The high-elasticity film has the advantages of favorable elasticity, high tensile strength and favorable impact resistance.

Owner:QINGDAO TOPLINK INFORMATION TECH

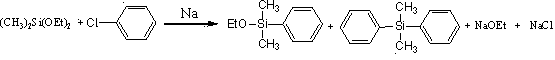

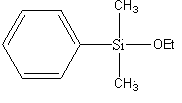

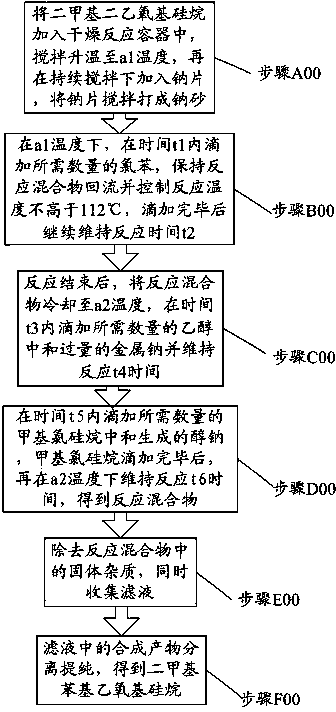

Method for preparing dimethyl phenyl ethoxy silane

InactiveCN103613609AIncrease profitSolving Recycling ProblemsGroup 4/14 element organic compoundsChlorobenzeneSilanes

The invention discloses a method for preparing dimethyl phenyl ethoxy silane. The process comprises the following steps: 1) adding diethoxydimethylsilane and metal sodium into a reaction kettle, and heating while stirring so as to melt the metal sodium in the diethoxydimethylsilane to form sodium sand; 2) dropwise adding chlorobenzene and reacting; 3) dropwise adding ethanol to neutralize the excessive metal sodium; 4) dropwise adding methyl chlorosilane to neutralize the generated sodium alkoxide; 5) carrying out reduced-pressure suction filtering on a reaction mixture and recycling filtrate; and 6) distilling the filtrate at normal pressure and reduced pressure to obtain the target product dimethyl phenyl ethoxy silane. According to the method disclosed by the invention, no additional solvent is needed in the process of a sodium condensation method, the reaction raw material diethoxydimethylsilane is directly used as the solvent to prepare the sodium sand, the reaction conditions are mild, the process is simple, the conversion rate of the raw material chlorobenzene is high, the content of the target product dimethyl phenyl ethoxy silane is high, the product selectivity is good, and the utilization rate of reaction equipment is high.

Owner:佛山市华联有机硅有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com