Method for preparing formed liquid silicone rubber with low permanent compression deformation

A permanent compression deformation, liquid silicone rubber technology, applied in the field of silicone rubber materials, can solve the problems of poor compression resistance, large permanent compression deformation, short compression time, etc., to achieve high tensile strength and tear strength, permanent The effect of small compression deformation and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Preparation of vinyl silicone oil:

[0037] In parts by weight, 100 parts of octamethylcyclotetrasiloxane are dehydrated, then 0.6 parts of vinyl double-caps and 2 parts of vinyl rings are added, and 0.3 parts of tetramethylammonium hydroxide is used as a catalyst. Equilibrium reaction at 120°C for 3 hours, then heated to 150°C to vacuumize and filter to remove small molecules to obtain vinyl silicone oil.

[0038] Preparation of liquid silicone rubber:

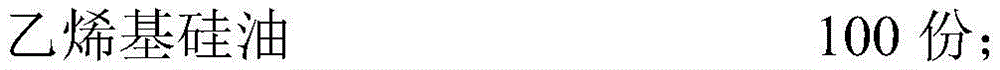

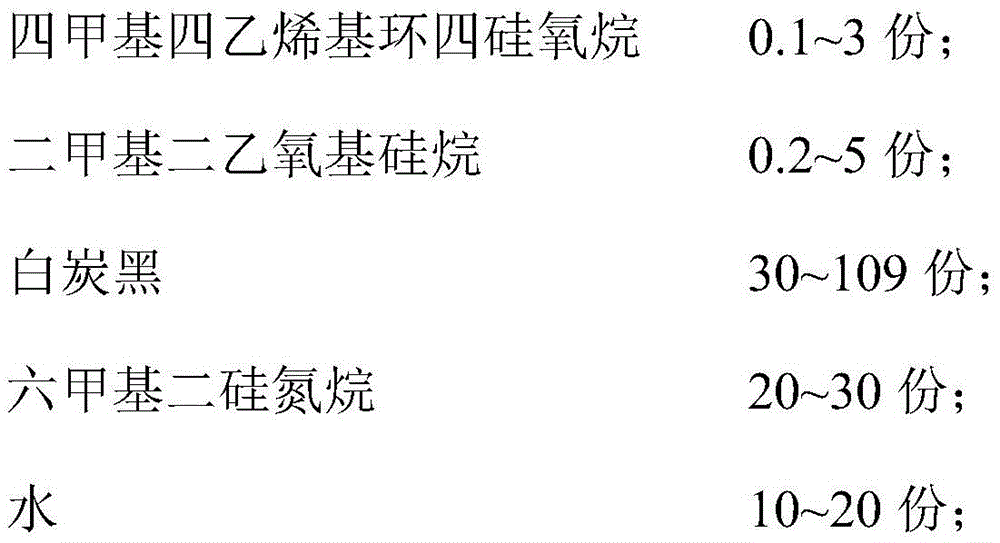

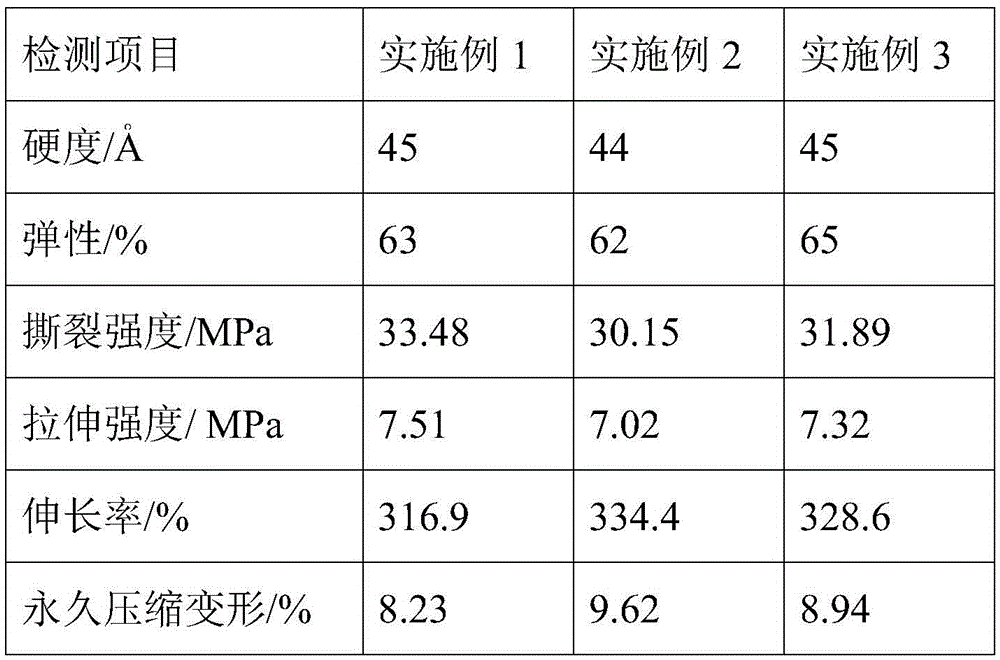

[0039] Mix 100 parts of vinyl silicone oil, 1.5 parts of tetramethyltetravinyl cyclotetrasiloxane and 2.5 parts of dimethyldiethoxysilane in parts by weight, add 20 parts of fumed silica, 45 parts of precipitated White carbon black, 25 parts of hexamethyldisilazane and 15 parts of water are kneaded in a kneader at a temperature of 55°C for 6 hours at the same time, and then heated to 130°C and vacuumed, the vacuum degree is above -0.09Mpa, Prepare the base rubber; the base rubber adopts a viscosity of 10000mpa s afte...

Embodiment 2

[0041] Preparation of vinyl silicone oil:

[0042] In parts by weight, 100 parts of octamethylcyclotetrasiloxane are dehydrated, then 0.6 parts of vinyl double-caps and 2 parts of vinyl rings are added, and 0.3 parts of tetramethylammonium hydroxide is used as a catalyst. Equilibrium reaction at 120°C for 3 hours, then heated to 150°C to vacuumize and filter to remove small molecules to obtain vinyl silicone oil.

[0043] Preparation of liquid silicone rubber:

[0044] Mix 100 parts of vinyl silicone oil, 0.3 parts of tetramethyltetravinylcyclotetrasiloxane and 0.45 parts of dimethyldiethoxysilane in parts by weight, add 11 parts of fumed silica, 23 parts of precipitated White carbon black, 10 parts of water and 20 parts of hexamethyldisilazane are kneaded and dispersed in a kneader at a temperature of 55°C for 6 hours at the same time, and then heated to 140°C and vacuumed, the vacuum degree is above -0.09Mpa , to obtain the base glue; the base glue is diluted with vinyl si...

Embodiment 3

[0046] Preparation of vinyl silicone oil:

[0047] In parts by weight, dehydrate 100 parts of octamethylcyclotetrasiloxane, then add 0.6 parts of vinyl double head and 2 parts of vinyl ring body, use 0.3 parts of potassium hydroxide as catalyst, at 120 °C After catalytic reaction for 3 hours, a crude product was obtained. Add 0.6 parts of glacial acetic acid to the crude product, heat up to 150°C, vacuumize, and filter to remove small molecules to obtain vinyl silicone oil.

[0048] Preparation of liquid silicone rubber:

[0049] Mix 100 parts of vinyl silicone oil, 3 parts of tetramethyltetravinylcyclotetrasiloxane and 4.5 parts of dimethyldiethoxysilane in parts by weight, add 35 parts of fumed silica, 70 parts of precipitated White carbon black, 20 parts of water and 30 parts of hexamethyldisilazane are kept at a temperature of 60°C for 4 hours, then heated to 150°C and vacuumed, and the vacuum degree is above -0.09Mpa to prepare the base glue; After the glue is diluted w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com