Synthesis method of tetrapropyl fluoro rubber, and tetrapropyl fluoro rubber prepared by synthesis method

A technology of tetrapropylene fluororubber and a synthesis method, which is applied in the field of polymer material synthesis, can solve the problems of high compression set resistance value, unsuitable extrusion molding process, and high safety investment, achieves fast vulcanization speed and saves raw material costs , the effect of improving application performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

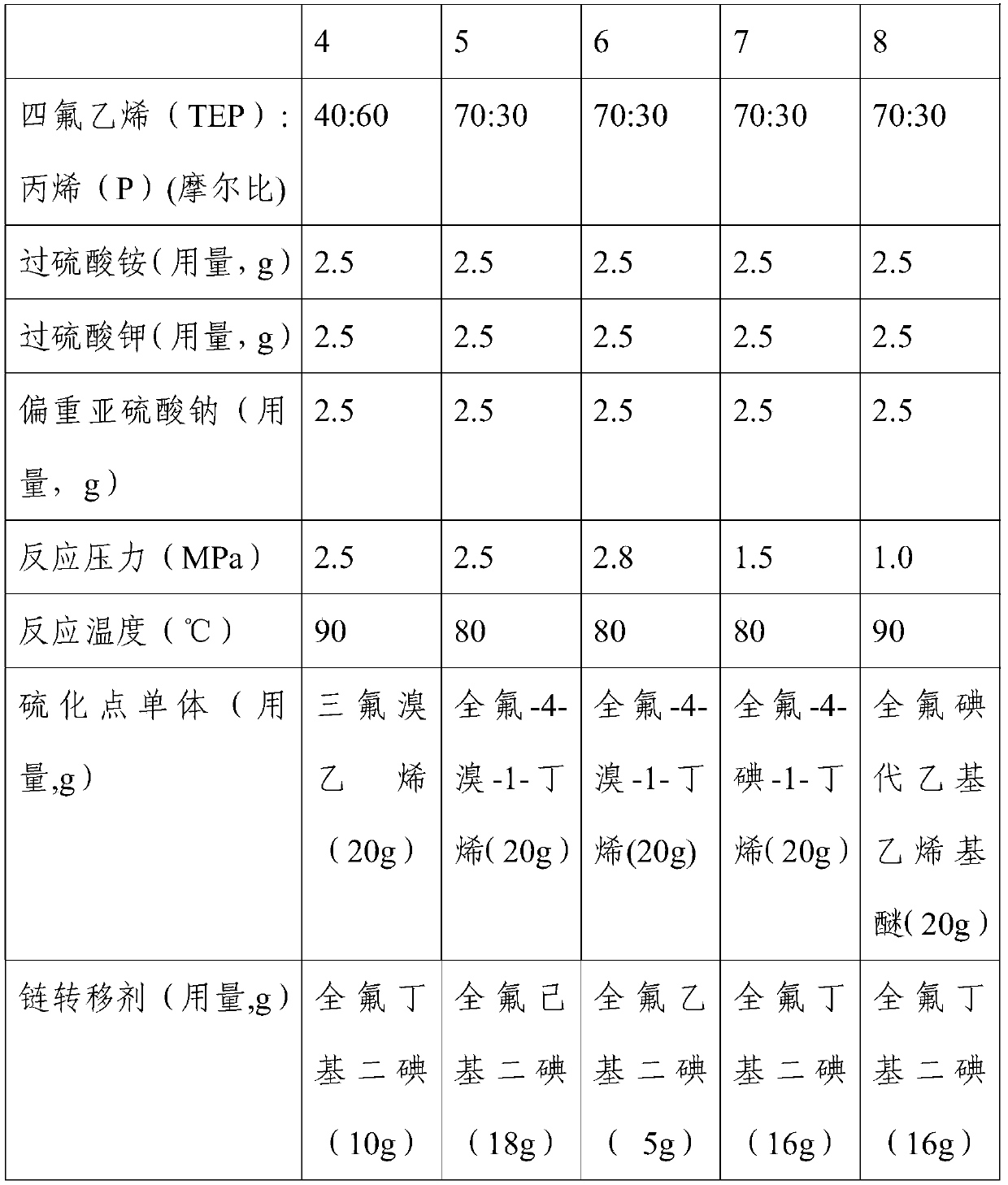

Embodiment 1

[0034] The present embodiment relates to a kind of preparation method of tetrapropylene fluorine rubber, comprises the steps:

[0035] In a 5L stainless steel reaction kettle with a stirrer, add 3L of deionized water, 2g of dipotassium hydrogen phosphate, and 3g of emulsifier perfluoropolyether ammonium carboxylate. After repeated nitrogen pressurization and evacuation and degassing, add The molar ratio of tetrafluoroethylene and propylene is 70:30 mixed monomer, the pressure rises to 0.5MPa, start the reactor stirrer, then raise the temperature to 70°C, continue to add the mixed monomer and raise the pressure to 2.0MPa, and add it through the metering pump Vulcanization point monomer perfluorobromoethyl vinyl ether 10g, redox initiator 2.5g ammonium persulfate and 2.5g potassium persulfate mixture, 2.5g sodium metabisulfite, initiator 5g I(CF 2 CF 2 ) 2 1 Polymerization starts, when reactor pressure drops every 0.01MPa, replenishes TFE / P mixed monomer in reactor, maintains ...

Embodiment 2

[0043] The present embodiment relates to a kind of preparation method of tetrapropylene fluorine rubber, comprises the steps:

[0044] In a 5L stainless steel reaction kettle with a stirrer, add 3L of deionized water, 2g of dipotassium hydrogen phosphate, and 3g of emulsifier. After repeated nitrogen pressurization and evacuation and degassing, a mixture of tetrafluoroethylene and propylene is added to the reaction kettle. Monomer, the molar ratio is TFE / P=70:30, the pressure rises to 0.5MPa, start the reactor agitator, then raise the temperature to 70°C, continue to add the mixed monomer of TFE / P=70:30 to raise the pressure to 3.0MPa , add vulcanization point monomer 10g perfluorobromoethyl vinyl ether by metering pump, redox initiator 2.5g ammonium persulfate and 2.5g potassium persulfate mix, 2.5g sodium metabisulfite, the I(CF of chain transfer agent 5g 2 CF 2 ) 21, start polymerization reaction, when reactor pressure drops every 0.01MPa, replenish TFE / P mixed monomer in...

Embodiment 3

[0047] The present embodiment relates to a kind of preparation method of tetrapropylene fluorine rubber, comprises the steps:

[0048] In a 5L stainless steel reaction kettle with a stirrer, add 3L of deionized water, 2g of dipotassium hydrogen phosphate, and 3g of emulsifier. After repeated nitrogen pressurization and evacuation and degassing, a mixture of tetrafluoroethylene and propylene is added to the reaction kettle. Monomer, the molar ratio is TFE / P=80:20, the pressure rises to 0.5MPa, start the reactor agitator, then raise the temperature to 70°C, continue to add the mixed monomer of TFE / P=80:20 to raise the pressure to 3.0MPa , add vulcanization point monomer 10g perfluorobromoethyl vinyl ether by metering pump, redox initiator 2.5g ammonium persulfate and 2.5g potassium persulfate mix, 2.5g sodium metabisulfite, chain transfer agent 5g of I( CF 2 CF 2 ) 2 1 Polymerization starts, when reactor pressure drops every 0.01MPa, replenishes TFE / P mixed monomer in reactor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com