Dealcoholization silicone weather-resistant sealant with low modulus and high displacement capability and preparation method of dealcoholization silicone weather-resistant sealant

A dealcohol-type, sealant technology, applied in the field of sealants, can solve environmental pollution, not enough environmental protection and other problems, and achieve the effect of convenient construction, long service life and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

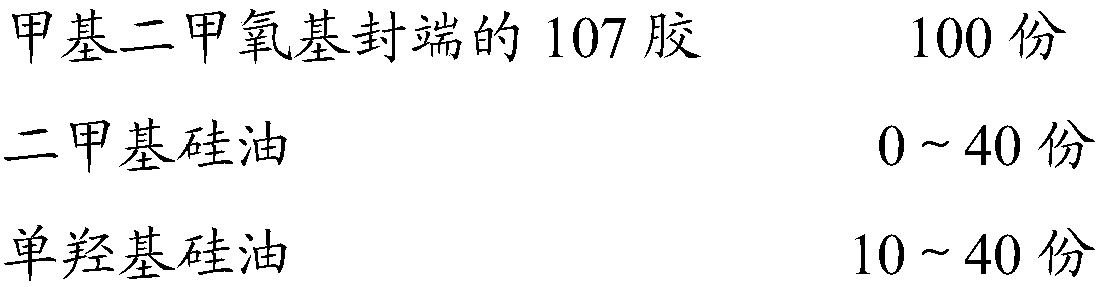

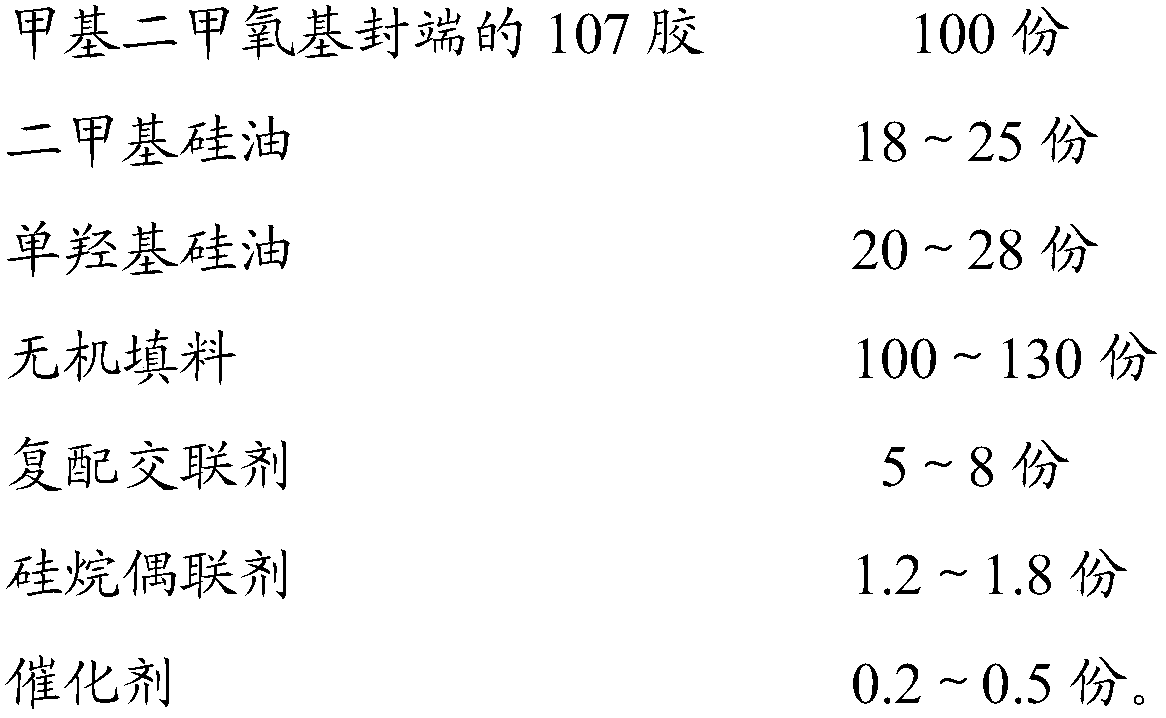

Method used

Image

Examples

Embodiment 1

[0039] The dealcoholized silicone weather-resistant sealant with low modulus and high displacement capacity in this example is prepared by the following formula and method: Methyldimethoxy-terminated 107 glue (viscosity 50000cp, 25±0.1°C) 100 Parts, 20 parts of simethicone oil (viscosity of 100 cp, 25 ± 0.1 ° C), 25 parts of monohydroxy silicone oil (viscosity of 500 cp, 25 ± 0.1 ° C), 120 parts of nano-active calcium carbonate, added to the kneader, at temperature Dehydration and blending at 110°C and vacuum degree of 0.09MPa for 90 minutes, cooling to room temperature to obtain the base material; adding the above base material to a planetary mixer, and then adding 3 parts of dimethyldimethoxysilane, methyltriethyl 3 parts of oxysilane, 1.5 parts of γ-aminopropyltriethoxysilane, 0.25 parts of dibutyltin dilaurate, and carry out the chemical reaction for 90 minutes under the conditions of vacuum degree of 0.09MPa and rotation speed of 300rpm to obtain low-mode The dealcoholize...

Embodiment 2

[0041] The dealcoholized silicone weather-resistant sealant with low modulus and high displacement capacity in this example is prepared by the following formula and method: Methyldimethoxy-terminated 107 glue (viscosity 50000cp, 25±0.1°C) 100 Parts, 40 parts of simethicone oil (viscosity of 100cp, 25±0.1°C), 40 parts of monohydroxy silicone oil (viscosity of 500cp, 25±0.1°C), 200 parts of nano-active calcium carbonate, added to the kneader, at temperature Dehydration and blending for 90 minutes at 120°C and a vacuum of 0.09MPa, cooling to room temperature to obtain the base material; adding the above base material to a planetary mixer, adding 4.5 parts of dimethyldiethoxysilane, methyltrimethoxy 5.5 parts of base silane, 3 parts of γ-aminopropyltriethoxysilane, 0.5 part of dibutyltin dilaurate, and carry out the chemical reaction for 90 minutes under the condition of vacuum degree of 0.09MPa and rotation speed of 300rpm to obtain low modulus , Dealcoholized silicone weather-re...

Embodiment 3

[0043]The dealcoholized silicone weather-resistant sealant with low modulus and high displacement capacity in this example is prepared by the following formula and method: Methyldimethoxy-terminated 107 glue (viscosity 50000cp, 25±0.1°C) 100 Parts, 0 parts of dimethyl silicone oil (viscosity of 100cp, 25±0.1°C), 35 parts of monohydroxy silicone oil (viscosity of 500cp, 25±0.1°C), 80 parts of nano-active calcium carbonate, added to the kneader, at temperature Dehydration and blending at 130°C and vacuum degree of 0.09MPa for 90 minutes, cooling to room temperature to obtain the base material; adding the above base material to a planetary mixer, and then adding 1 part of dimethyldimethoxysilane, methyltrimethoxy 1 part of base silane, 0.5 part of γ-aminopropyltriethoxysilane, 0.05 part of dibutyltin dilaurate, and carry out chemical reaction for 90 minutes under the condition of vacuum degree of 0.09MPa and rotation speed of 300rpm, and the low modulus can be obtained , Dealcoho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com