Mesoporous silicon dioxide nanoparticle with small particle size and large pore diameter and preparation method thereof

A mesoporous silica and nanoparticle technology, applied in the directions of silica, silicon oxide, nanotechnology, etc., can solve the problems of difficulty in ensuring the shape, uneven shape, large particle size of silica, etc. Uniform size, large pore size and small particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

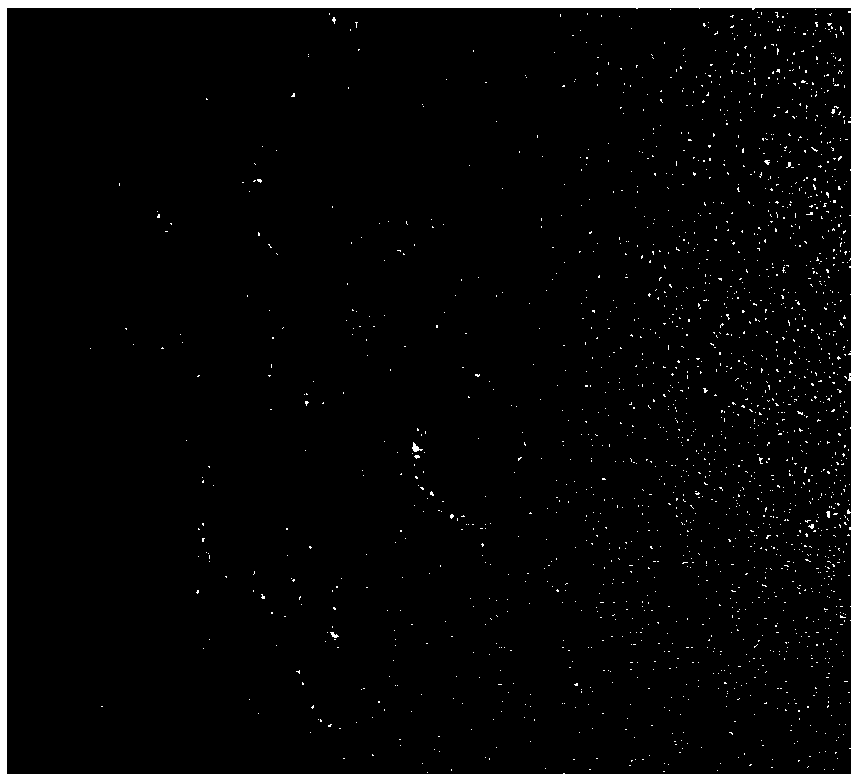

[0031] Mix 16mL ultrapure water, 2.8mL ethanol, 0.05g diethanolamine and 2.6mL 25wt% CTAC aqueous solution, add 1.3mL TMB, stir and react at 60°C for 6h; then add 1.75mLTEOS, continue stirring for 3h, and then add 1.2 mL DMDMS continued to react for 20h; after the reaction was completed, centrifuge and wash 3 times with a mixture of ethanol and water; dispersed in a mixture of hydrochloric acid and ethanol (7.5mL concentrated hydrochloric acid and 60mL ethanol), stirred and reacted at 60°C for 24h; finally , centrifuged and washed 3 times with a mixture of ethanol and water, and dispersed in ultrapure water to freeze-dry to obtain mesoporous silica nanoparticles with small particle size and large pore size. The TEM image of the sample is as follows figure 1 As shown, it can be seen from the figure that the particles have good dispersion, uniform size, the smallest particle size is about 50nm, and a pore structure.

Embodiment 2

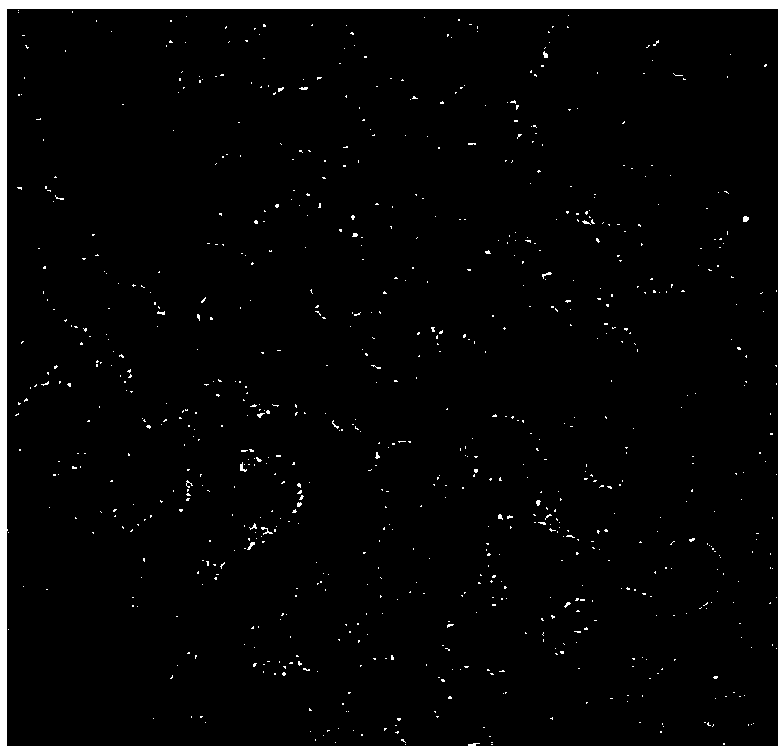

[0033] Mix 16mL ultrapure water, 2.8mL ethanol, 0.05g diethanolamine and 2.6mL 25wt% CTAC aqueous solution, add 2.6mL TMB, stir and react at 60°C for 6h; then add 1.75mL TEOS, continue stirring for 3h, then add 1.2mL DMDMS continued to react for 20h; after the reaction was completed, centrifuge and wash 3 times with a mixture of ethanol and water; dispersed in a mixture of hydrochloric acid and ethanol (7.5mL concentrated hydrochloric acid and 60mL ethanol), stirred and reacted at 60°C for 24h; finally , centrifuged and washed 3 times with a mixture of ethanol and water, dispersed in ultrapure water and freeze-dried to obtain mesoporous silica nanoparticles with small particle size and large pore size.

[0034] The TEM image of the sample is shown in figure 2 As shown, it can be seen from the figure that the particles have good dispersion, uniform size, and a pore structure.

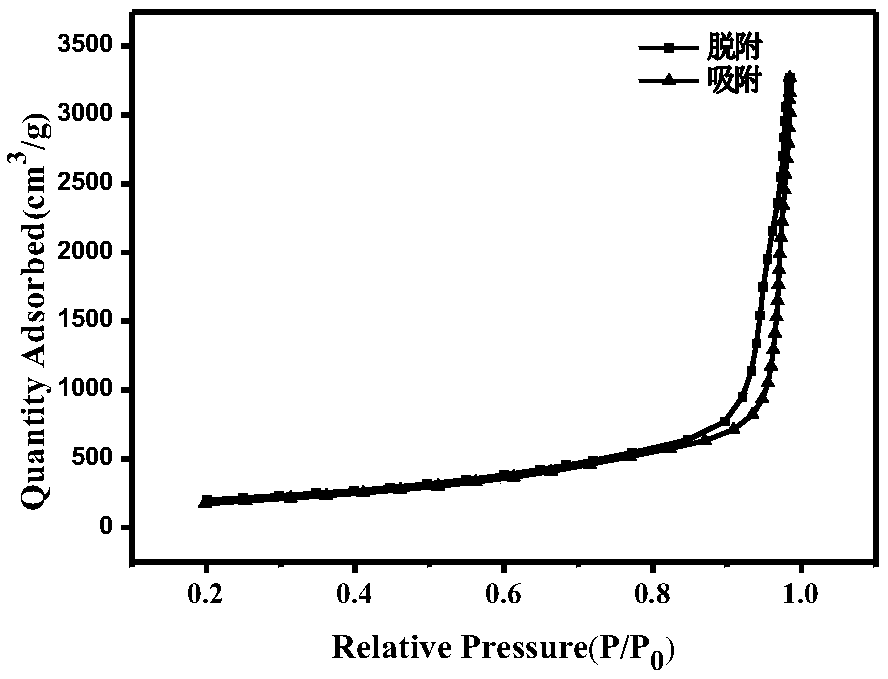

[0035] The nitrogen adsorption-desorption curve of the sample is as follows: image 3 As shown, it...

Embodiment 3

[0039] Mix 16mL ultrapure water, 2.8mL ethanol, 0.05g diethanolamine and 2.6mL 25wt% CTAC aqueous solution, add 2.6mL TMB, stir and react at 60°C for 8h; then add 1.75mL TEOS, continue stirring for 3h, then add 1.2mL DMDMS continued to react for 20h; after the reaction was completed, centrifuge and wash 3 times with a mixture of ethanol and water; dispersed in a mixture of hydrochloric acid and ethanol (7.5mL concentrated hydrochloric acid and 60mL ethanol), stirred and reacted at 60°C for 24h; Finally, the mixture of ethanol and water was centrifuged and washed 3 times, and dispersed in ultrapure water to freeze-dry to obtain mesoporous silica nanoparticles with small particle size and large pore size. The TEM image of the sample is as follows: Image 6 As shown, it can be seen that the particles have good dispersion, uniform size, particle diameter less than 50nm, and a pore structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com