Two-component organic silicon pouring sealant

A silicone potting glue, a two-component technology, applied in the direction of adhesives, adhesive additives, electrical components, etc., can solve the problems of insufficient adhesion, large influence of ambient temperature, oil leakage, etc., and achieve good impact resistance , good leveling, prolonging the life of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

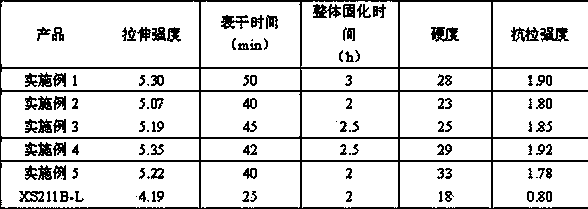

Examples

Embodiment 1

[0022] Preparation of RTV-2 base glue: Add simethicone, white carbon black, and hexamethyldisiloxane into the kneader in a weight ratio of 100:50:10 and knead for about 1 hour, then raise the temperature to 160°C, and turn on the vacuum pump , pressure to -0.1MPa, constant temperature and pressure reaction for about 4 hours, stop the reaction, turn off the kneader and vacuum pump in turn, deflate, let stand to cool, that is.

[0023] Component A consists of α, ω-dihydroxy polydimethylsiloxane (107 glue), dimethyl silicone oil (201 silicone oil), RTV-2 base glue, silica powder, iron black, and black paste in a weight ratio of 100: 65:20:20:5:3 Mix evenly, slowly raise the temperature to 90°C, stir at constant temperature for 4 hours, let stand to cool, and filter with a 100-mesh filter. The viscosity of component A is 2500CPS.

[0024] Component B consists of dimethyldiethoxysilane, dimethyl silicone oil (201 silicone oil), 3-aminopropyltriethoxysilane (KH-550), vinyltriethoxy...

Embodiment 2

[0027] Preparation of RTV-2 base glue: Add simethicone, white carbon black, and hexamethyldisiloxane into the kneader in a weight ratio of 100:50:10 and knead for about 1 hour, then raise the temperature to 170°C, and turn on the vacuum pump , pressure to -0.1MPa, constant temperature and pressure reaction for about 4 hours, stop the reaction, turn off the kneader and vacuum pump in turn, deflate, let stand to cool, that is.

[0028] Component A is composed of α, ω-dihydroxy polydimethylsiloxane, dimethyl silicone oil, RTV-2 base glue, silica powder, iron black, and black paste in a weight ratio of 100:50:30:20:5: 3 Mix and mix evenly, slowly raise the temperature to 100°C, stir at constant temperature for 3 hours, let stand to cool, and filter with a 100-mesh filter. The viscosity of component A is 5000CPS.

[0029] Component B consists of dimethyldiethoxysilane, dimethicone, 3-aminopropyltriethoxysilane, vinyltriethoxysilane, and dibutyltin dilaurate in a weight ratio of 10...

Embodiment 3

[0032]Preparation of RTV-2 base glue: add simethicone, white carbon black, and hexamethyldisiloxane into the kneader in a weight ratio of 100:80:30 and knead for about 1 hour, then raise the temperature to 170°C, and turn on the vacuum pump , pressure to -0.1MPa, constant temperature and pressure reaction for about 4 hours, stop the reaction, turn off the kneader and vacuum pump in turn, deflate, let stand to cool, that is.

[0033] Component A is composed of α, ω-dihydroxy polydimethylsiloxane, dimethyl silicone oil, RTV-2 base glue, silica powder, iron black, and black pulp in a weight ratio of 100:57:25:20:8: 3 Mix evenly, slowly heat up to 110°C, stir at constant temperature for 3 hours, let stand to cool, and filter with a 100-mesh filter. The viscosity of component A is 3750CPS.

[0034] Component B consists of dimethyldiethoxysilane, dimethicone, 3-aminopropyltriethoxysilane, vinyltriethoxysilane, and dibutyltin dilaurate in a weight ratio of 100:55:33 :30:1 Mix evenl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com