Method for preparing dimethyl phenyl ethoxy silane

A technology of dimethylphenylethoxysilane and dimethyldiethoxysilane is applied in the field of preparation of dimethylphenylethoxysilane and can solve environmental pollution, dimethylphenylethoxysilane The problems of low yield of silane and other problems have been overcome, and the effects of overcoming environmental pollution, high content of dimethylphenylethoxysilane, and overcoming the problem of solvent recovery and utilization have been achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

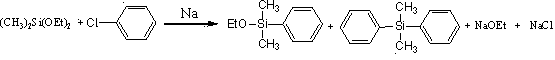

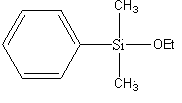

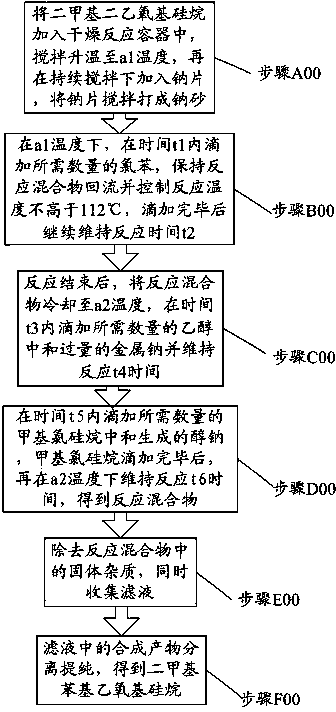

[0025] The reaction process of the preparation method of this dimethylphenylethoxysilane is as follows: 1) Add dimethyldiethoxysilane and metal sodium into the reaction kettle, heat up under stirring, and melt the metal sodium in dimethyl dimethoxysilane Form sodium sand in ethoxysilane; 2) Add chlorobenzene dropwise for reaction; 3) Add ethanol dropwise to neutralize excess metallic sodium; 4) Add methylchlorosilane dropwise to neutralize the generated sodium alkoxide; 5) Dilute the reaction mixture Suction filtration under reduced pressure to recover the filtrate; 6) Distill the filtrate under normal pressure and reduced pressure to obtain the target product dimethylphenylethoxysilane. The reaction equation of the above reaction process is shown in formula (1):

[0026] (1)

[0027] The preparation method of this dimethylphenylethoxysilane directly uses dimethyldiethoxysilane, one of the reaction raw materials, as a solvent and a reaction raw material, and disperses met...

Embodiment 1

[0052] Step A00: In a dry 250mL four-neck flask equipped with a reflux condenser, a mechanical stirrer and a Pt-100 platinum resistance thermometer, add 87g of dimethyldiethoxysilane, and add 18g of freshly cut sodium flakes under stirring, Raise the temperature to 102°C, beat the sodium flakes into sodium sand;

[0053] Step B00: Add 44g of chlorobenzene dropwise through a constant pressure dropping funnel within 4h, control the reaction temperature between 108~110°C, and continue to react for 2h after the dropwise addition;

[0054] Step C00: After cooling to 25°C, slowly add 1.5g of absolute ethanol to neutralize excess metal sodium within 0.5h, and then maintain at 25°C for 1h after the dropwise addition;

[0055] Step D00: Then, 23.4 mL of dimethyldichlorosilane was added dropwise to the mixture within 1 h to neutralize the generated sodium alkoxide. After the dropwise addition was completed, the reaction was continued at 25° C. for 3 h;

[0056] Step E00: Then the react...

Embodiment 2

[0058] Step A00: In a dry 1000mL four-necked flask equipped with a reflux condenser, a mechanical stirrer and a Pt-100 platinum resistor, add 450g of dimethyldiethoxysilane, and add 58.2g of freshly cut sodium flakes under stirring, Raise the temperature to 105°C, beat the sodium flakes into sodium sand;

[0059] Step B00: Add 142g of chlorobenzene dropwise through a constant pressure dropping funnel within 2h, control the reaction temperature between 102~105°C, and continue to react for 4h after the dropwise addition;

[0060] Step C00: After cooling to 30°C, slowly add 5.1g of absolute ethanol to neutralize excess metal sodium within 1.0h, and then maintain at 30°C for 1.5h after the dropwise addition;

[0061] Step D00: Then, 76 mL of dimethyldichlorosilane was added dropwise to the mixture within 2 hours to neutralize the generated sodium alkoxide; after the dropwise addition, the reaction was continued at 30° C. for 4 hours;

[0062] Step E00: Then, the reaction mixture ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com