Patents

Literature

85 results about "Resistance thermometer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Resistance thermometers, also called resistance temperature detectors (RTDs), are sensors used to measure temperature. Many RTD elements consist of a length of fine wire wrapped around a ceramic or glass core but other constructions are also used. The RTD wire is a pure material, typically platinum, nickel, or copper. The material has an accurate resistance/temperature relationship which is used to provide an indication of temperature. As RTD elements are fragile, they are often housed in protective probes.

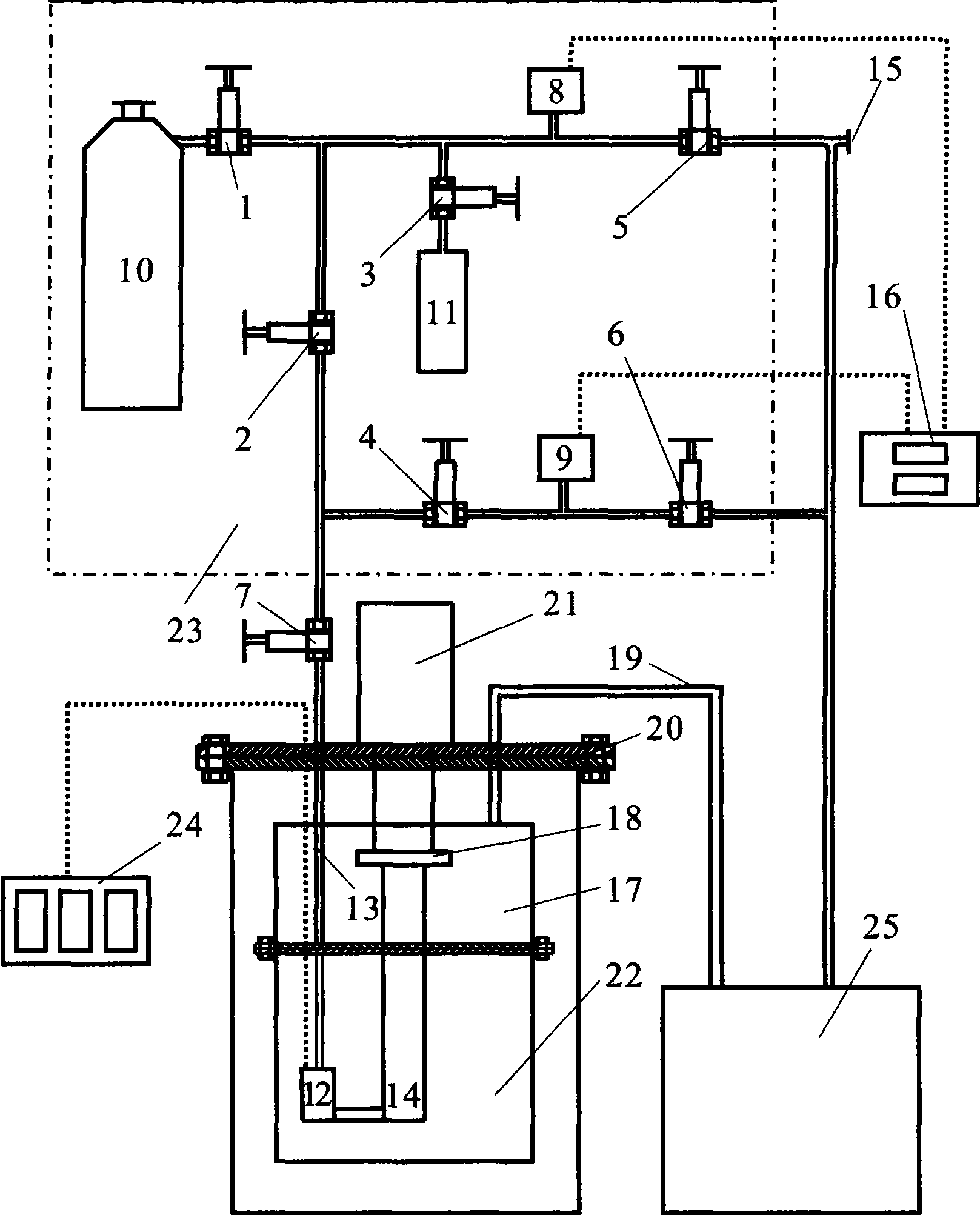

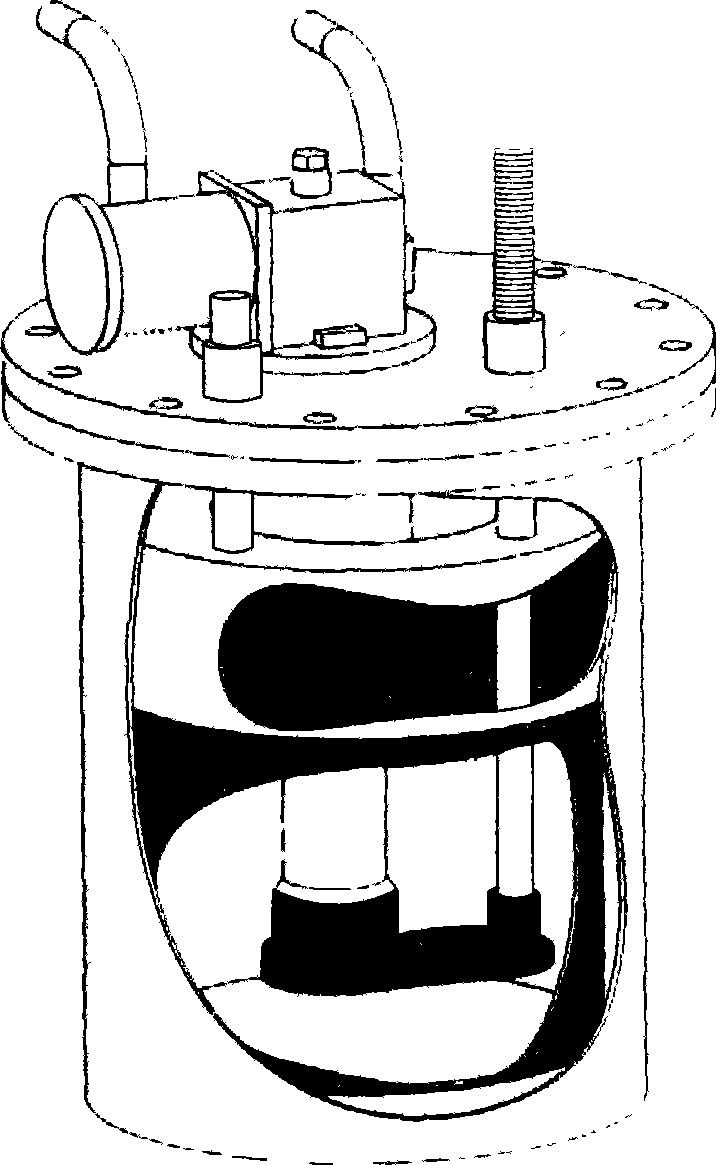

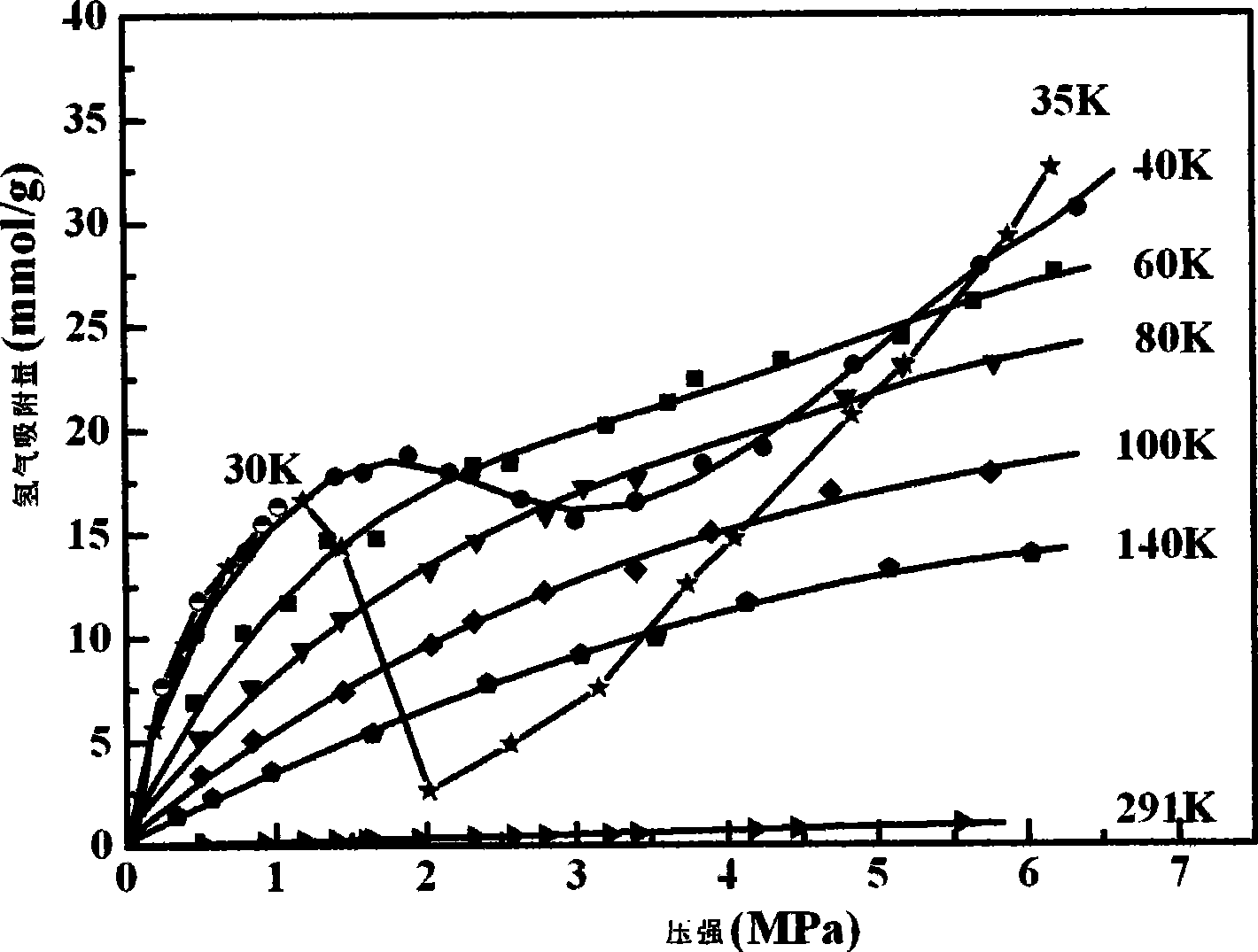

Low-temperature swing adsorption device

InactiveCN101391170AImprove accuracyEasy to installDispersed particle separationDesorptionEngineering

Disclosed is a cryogenic pressure swing adsorption device, comprising a cryogenic refrigeration machine, a stainless steel multi-layer cavity body, a vacuum pump assembly, a carrier gas pipeline and a matched measurement and control element; wherein, a first stage cold head and a second stage cold head of the cryogenic refrigeration machine are sealed and arranged in the stainless steel cavity body, the vacuum pump assembly vacuumizes the cavity body and the carrier gas pipeline, an adsorption chamber in the carrier gas pipeline is connected with the second stage cold head of the refrigerating machine, the temperature control instrument clings to the adsorption chamber, and a small-sized Rh-Fe resistance thermometer and a ceramic heating sheet are disposed on a red copper seat. The invention has the advantages that: the adsorption chamber can vary continuously and reversibly between 4K and the room temperature; surface parameters such as specific surface area, micropore volume and pore-size distribution of ultra-micropore powder material that can not be measured through nitrogen adsorption can be measured; and the temperature variation in the adsorption chamber between 4K and the room temperature spans critical temperature points of a plurality of gases, and the device can particularly acquire adsorption and desorption behaviors of hydrogen below liquid nitrogen temperature that can not be researched so far.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

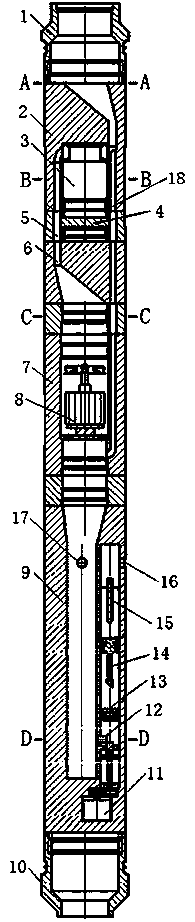

Layering water injection flow intelligent adjusting system under pit

ActiveCN109083623AReduce labor intensityReduced risk of getting stuckFluid removalWell/borehole valve arrangementsResistance thermometerThermistor

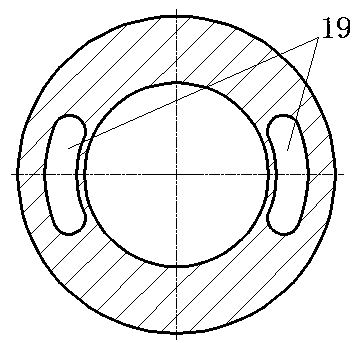

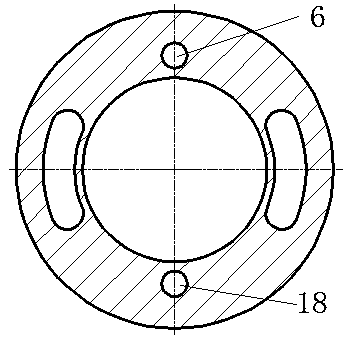

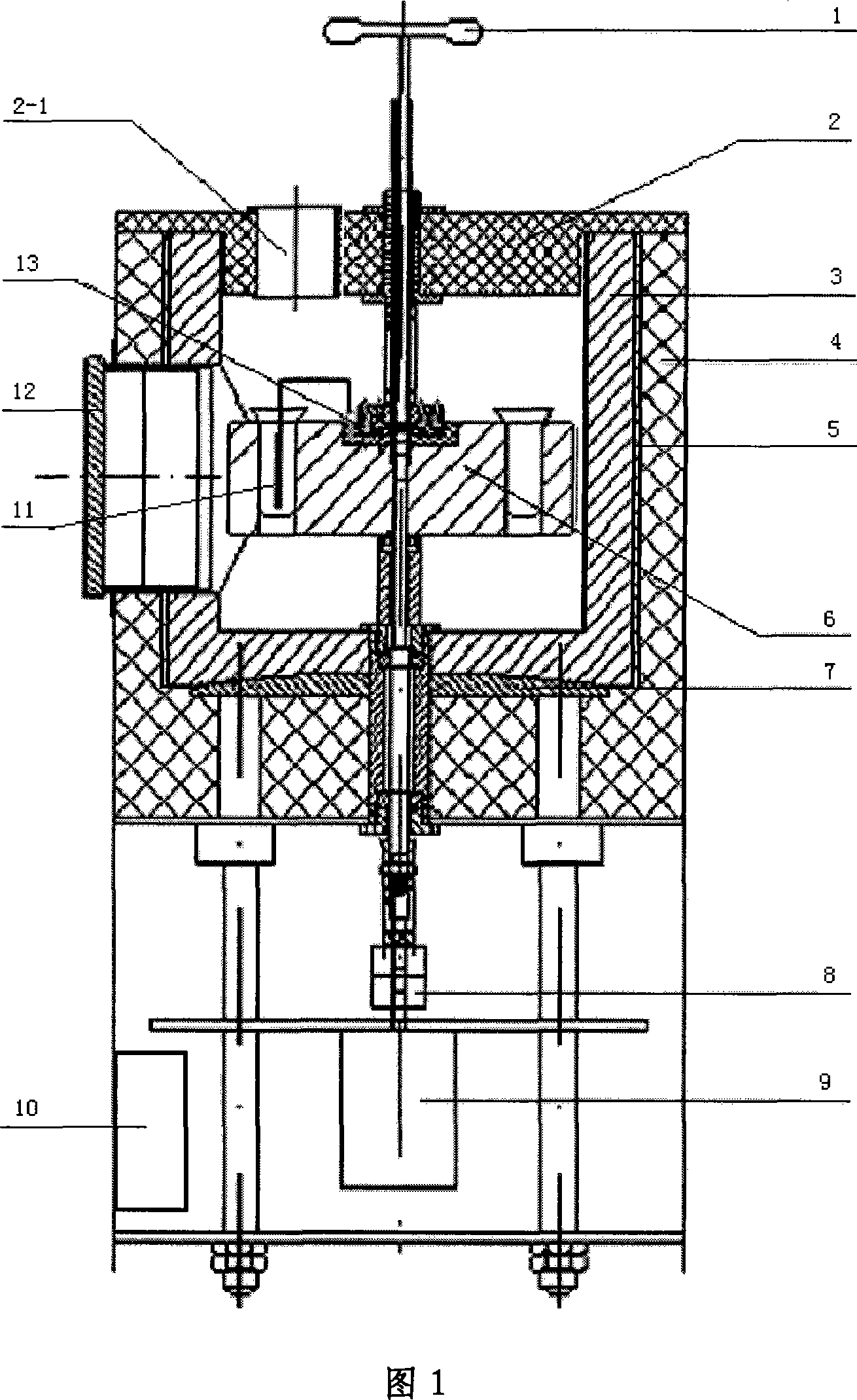

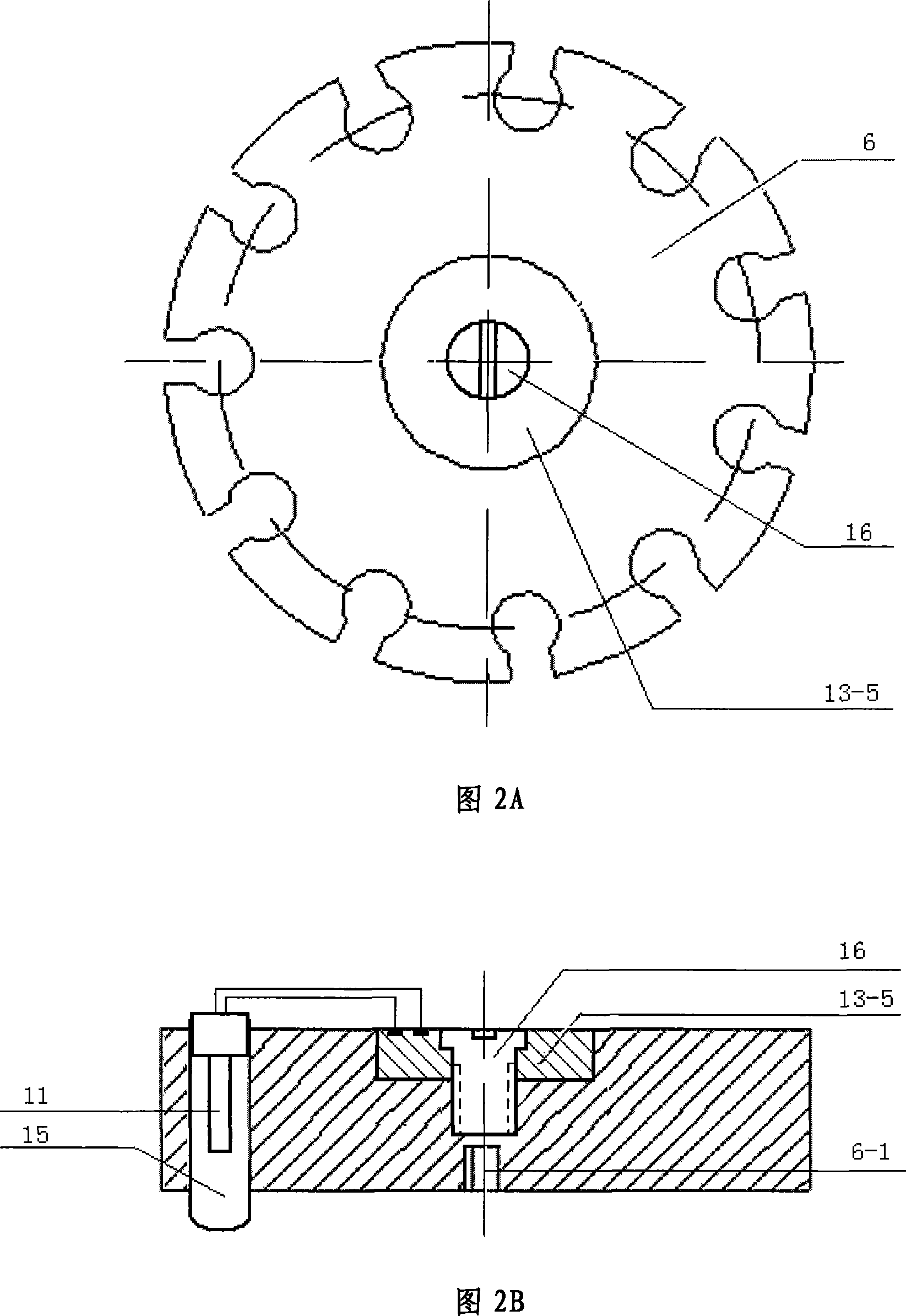

The invention relates to a layering water injection flow intelligent adjusting system under a pit. The layering water injection flow intelligent adjusting system under the pit comprises a PLC controlunit, an upper joint, a cone-hole flow passage converting pipe, a power generation unit, an intelligent water dispenser and a lower joint, wherein the upper joint, the cone-hole flow passage converting pipe, the power generation unit, the intelligent water dispenser and the lower joint are successively connected from top to bottom, two deflected holes are formed in both sides of the cone-hole flowpassage converter pipe, and an upper round taper hole is located between the two deflected holes; the tail end of the upper round taper hole is communicated with a power generation branch and a waterinjection branch, an electromagnetic valve is installed on the cone-hole flow passage converter pipe, and the tail end of the power generation branch is connected with a lower round taper hole; the lower round taper hole is communicated with the power generation unit, and an impeller power generator under the pit is arranged in the power generation unit; the lower end of the power generation unitand the water injection branch are connected with the intelligent water dispenser, a water dispensing cavity of the intelligent water dispenser is communicated with a water outlet cavity through an adjustable water nozzle, a platinum thermistor thermometer, a lever flowmeter and a silicon piezoresistive pressure meter are arranged in the water outlet cavity, and the adjustable water nozzle is connected with a gear motor. Repeated throwing and catching operations are not needed, and the water injection amount can be adjusted in real time.

Owner:华运隆腾机械制造有限公司

Vieri experiment thermostats

InactiveCN101118218AIncrease contactSimple structureHeating or cooling apparatusMaterial analysis by observing effect on chemical indicatorElectrical resistance and conductancePlatinum resistance

The present invention discloses a calorstat for a Christian Vieri experiment, and comprises a metal bath cavity body, an electrical heater, a sample cup bracket, a bracket driving mechanism, a temperature controller which contains a platinum resistance thermometer and a thermoregulator, and a temperature measured signal deduced mechanism which contains a conductive ring and a dynamic electrode group. The present invention is characterized in that the platinum resistance thermometer is directly positioned in a sample testing area. The conductive ring is connected with the output terminal of the platinum resistance thermometer. The dynamic electrode group is connected with the temperature signal input terminal of the thermoregulator. The lower end of the dynamic electrode group keeps a good contact with the conductive ring. When the bracket driving mechanism drives the sample cup bracket to rotate, the dynamic electrode group slides on the surface of the conductive ring, and the resistance value of the platinum resistance thermometer is transmitted to the thermoregulator, so the heating current of the electrical heater is controlled, Thereby the temperature of the sample placed area can be directly controlled and displayed in real time, and the standard requirement of the Christian Vieri experiment can be satisfied. The invention has the advantages of high temperature control precision, convenient use and low cost.

Owner:XIAN MODERN CHEM RES INST

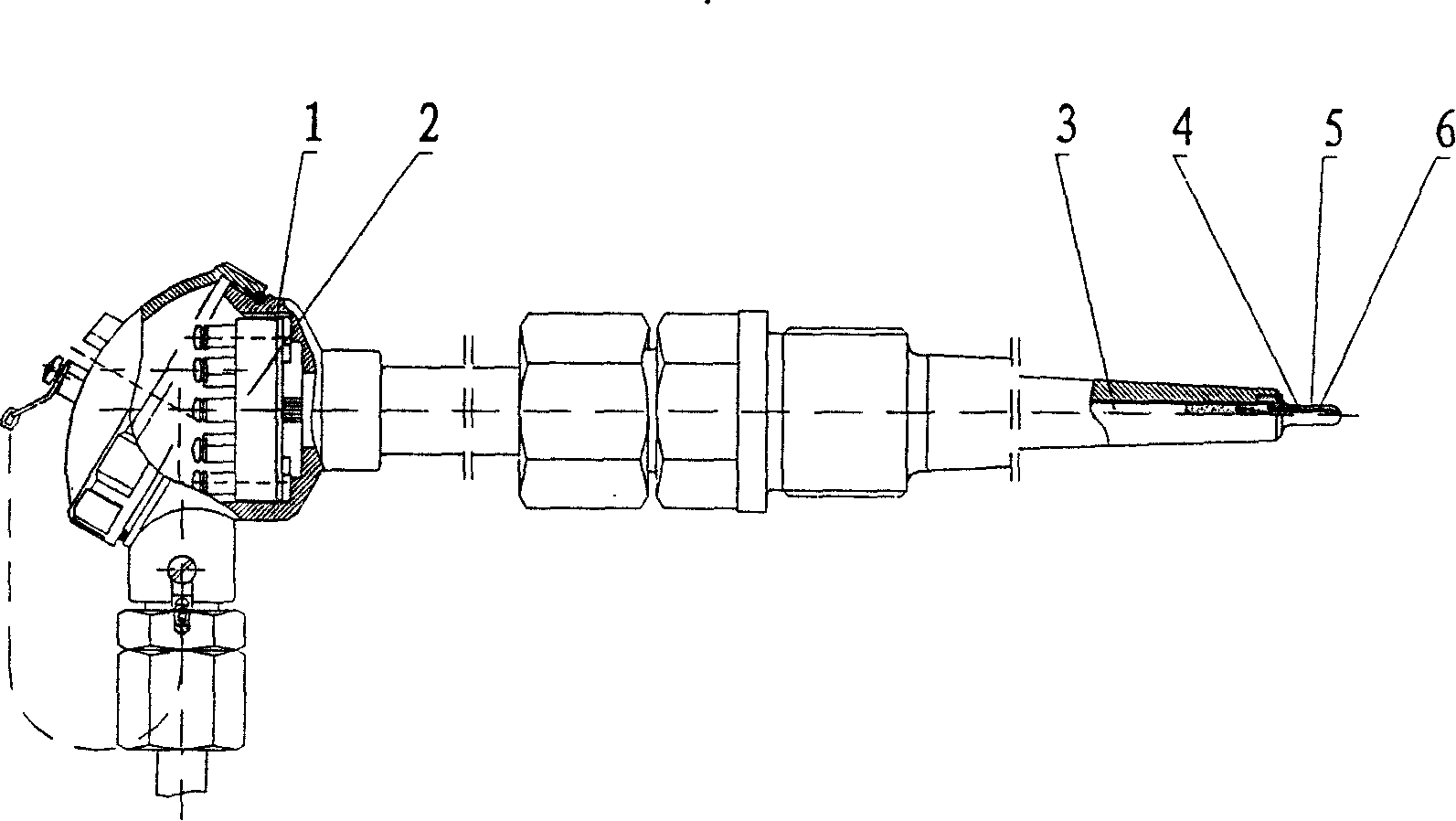

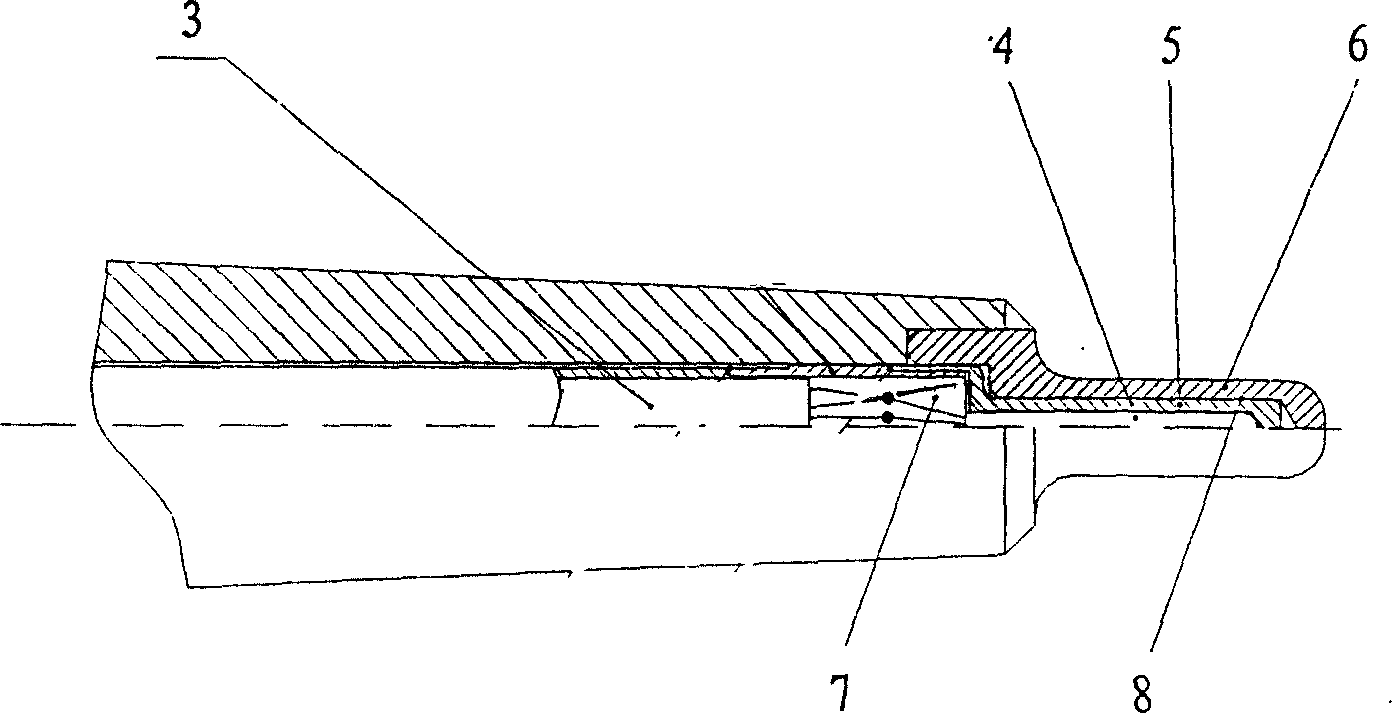

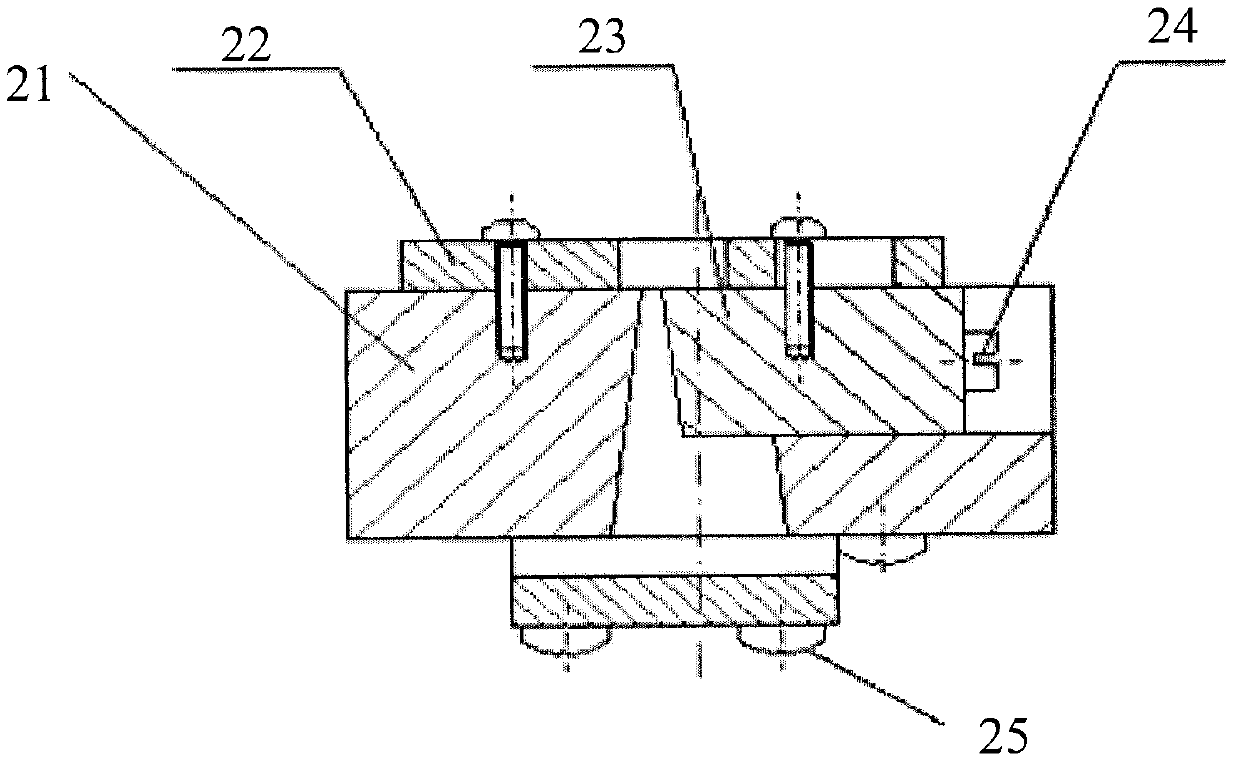

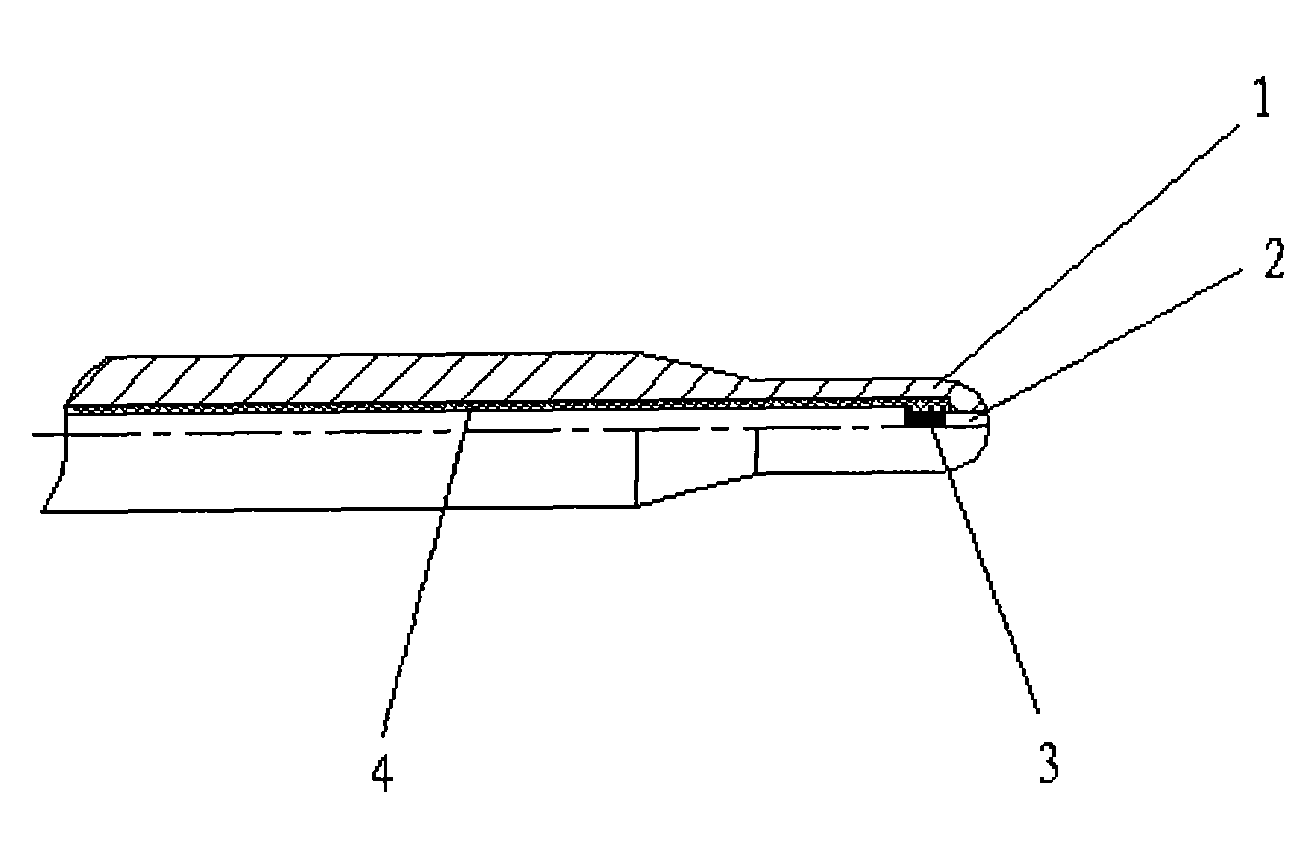

Nuclear grade platinum resistance thermometer and its method for reducing thermal response time

InactiveCN101173873AWill not stickShort thermal response timeThermometer detailsThermometers using electric/magnetic elementsPlatinum resistanceNuclear grade

The invention relates to a nuclear-grade platinum resistance thermometer and the method for reducing thermal response time with the invention, comprising a terminal box, a wiring board arranged in the terminal box, and a protective sleeve with a built-in platinum resistance element, wherein, the temperature sensing surface of the platinum resistance element is clung tightly to the inner surface of the protective sleeve, and no MgO powder is filled between the platinum resistance element and the protective sleeve; the outer surface of the protective sleeve is clung tightly to the inner surface of an external protective tube; the platinum resistance element is welded with an armored leading wire; MgO powder is filled in the armored leading wire; a metal coat is plated on the outer surface of the protective sleeve. The invention has the advantages that due to the temperature sensing surface of the platinum resistance element clung tightly to the protective sleeve and the protective sleeve clung tightly to the external protective tube, the heat conductivity of the thermometer is improved; the thermal response time is reduced; the earthquake resistant requirement for nuclear power station is satisfied; due to wear-resistant, heat-resistant, and oxidation-resistant special metal coating on the surface of the protecting sleeve, the protecting sleeve does not stick to the protective tube due to oxidation corrosion.

Owner:NO 3 AUTOMATION INSTR & METERS FACTORY SHANGHAI AUTOMATION INSTR & METERS CO LTD

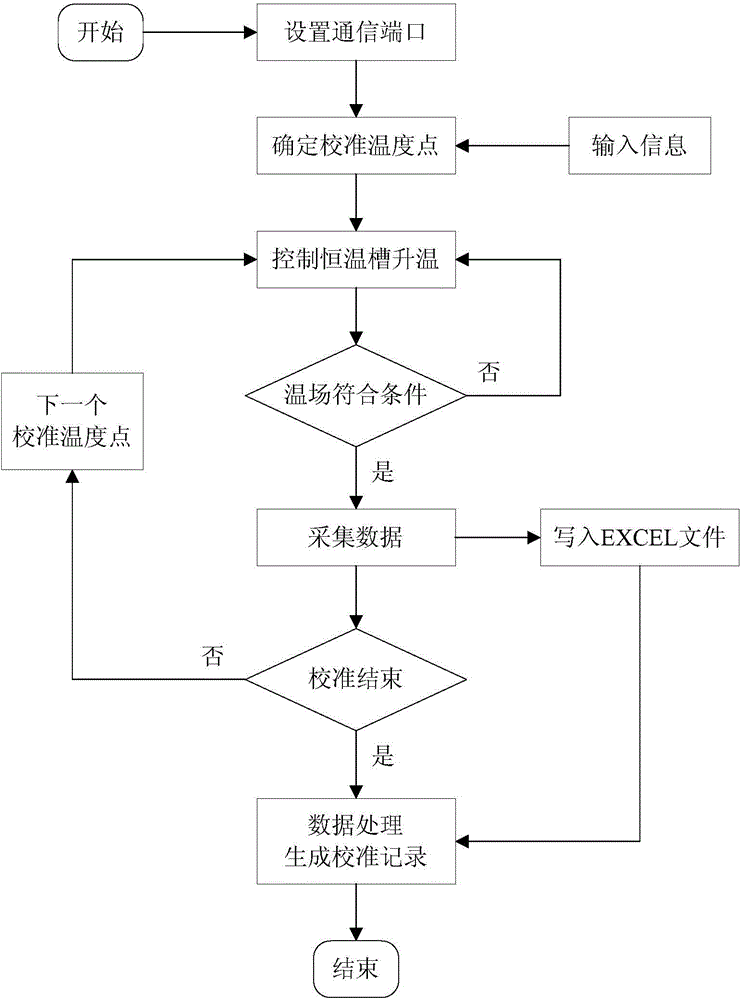

Scene automatic calibration system and method for integrative temperature transmitter

InactiveCN104677522ASolve complexitySolve the difficulty of carrying the instrument inconvenientlyThermometer testing/calibrationAutomatic controlMeasuring instrument

The invention belongs to the temperature measurement technical field, and in particular relates to a scene automatic calibration system and a scene automatic calibration method for an integrative temperature transmitter. The scene automatic calibration system comprises a computer, a standard platinum resistance thermometer and an integrated control module. The standard platinum resistance thermometer and the element to be measured are respectively connected with a multifunctional electric measuring instrument of the integrated control module; the standard platinum resistance thermometer and the element to be measured are positioned in a work cavity of a constant temperature working range to be heated; the temperature increase of the constant temperature oven is automatically controlled by the computer through the preset program, the resistance value of the standard platinum resistance thermometer is collected in real time for monitoring the temperature change in the work cavity; the computer analyzes and processes the collected data according to the preset program for automatically generating the calibration report after that the temperature field reaches to the calibration condition. The scene automatic calibration system and the scene automatic calibration method for the integrative temperature transmitter have the beneficial effects that the difficulty of complex field calibration connection circuit and inconvenient to carry instrument is solved, the computer is adopted for executing automatic calibration, and the new market of the scene automatic calibration device of the integration temperature transmitter is developed.

Owner:TIANJIN INST OF METROLOGICAL SUPERVISION & TESTING

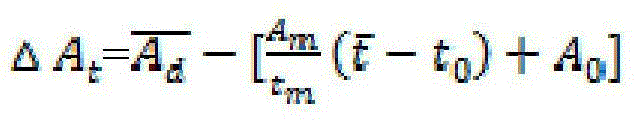

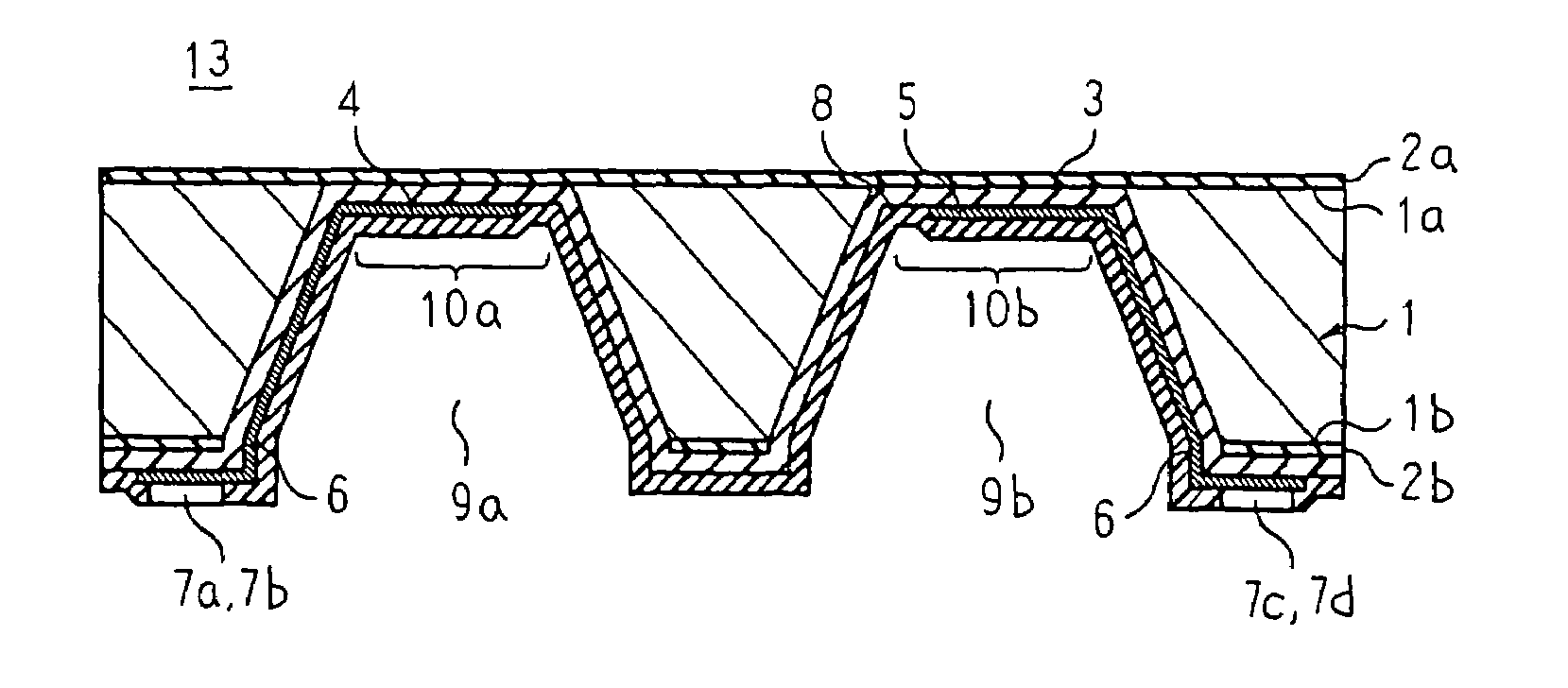

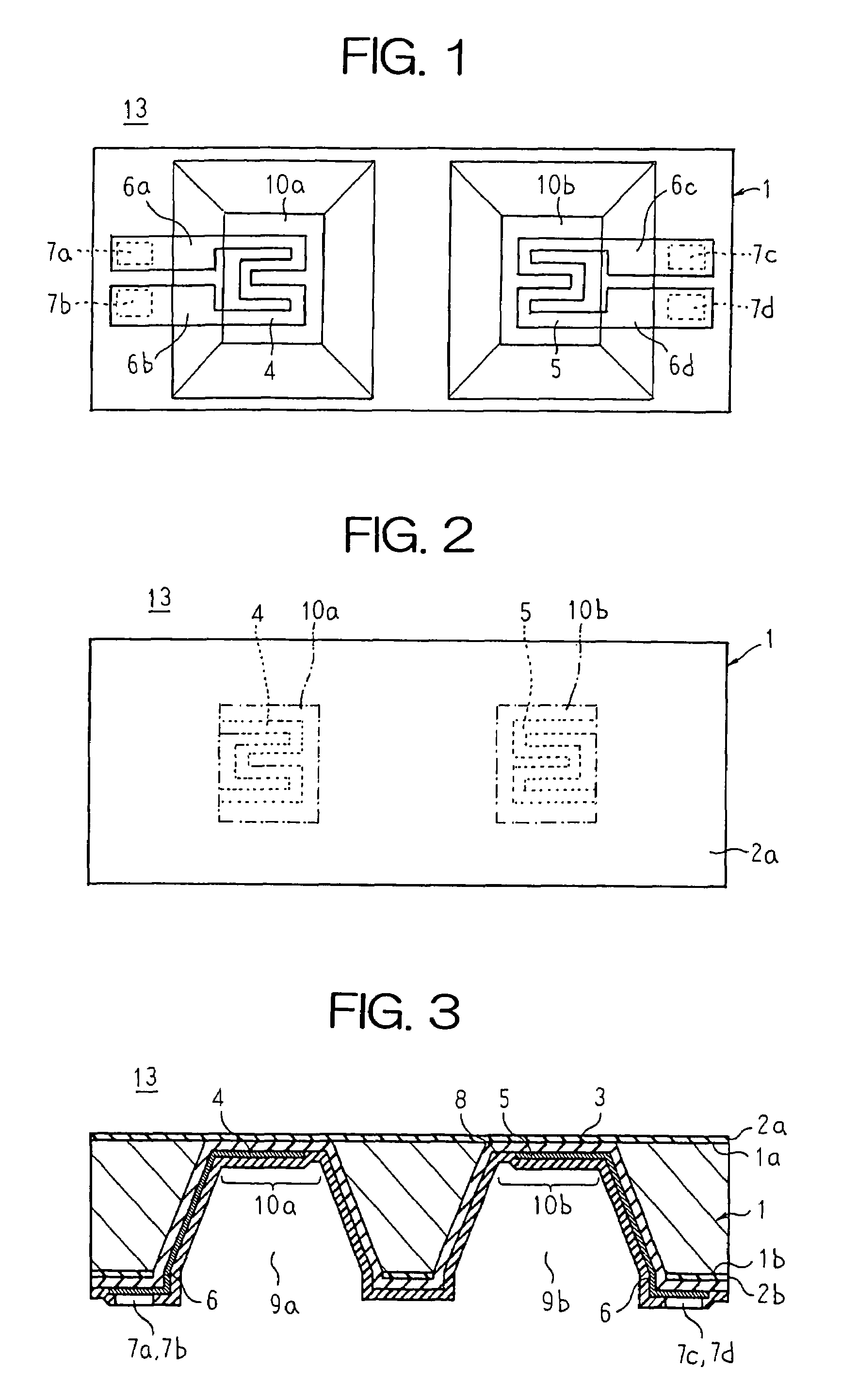

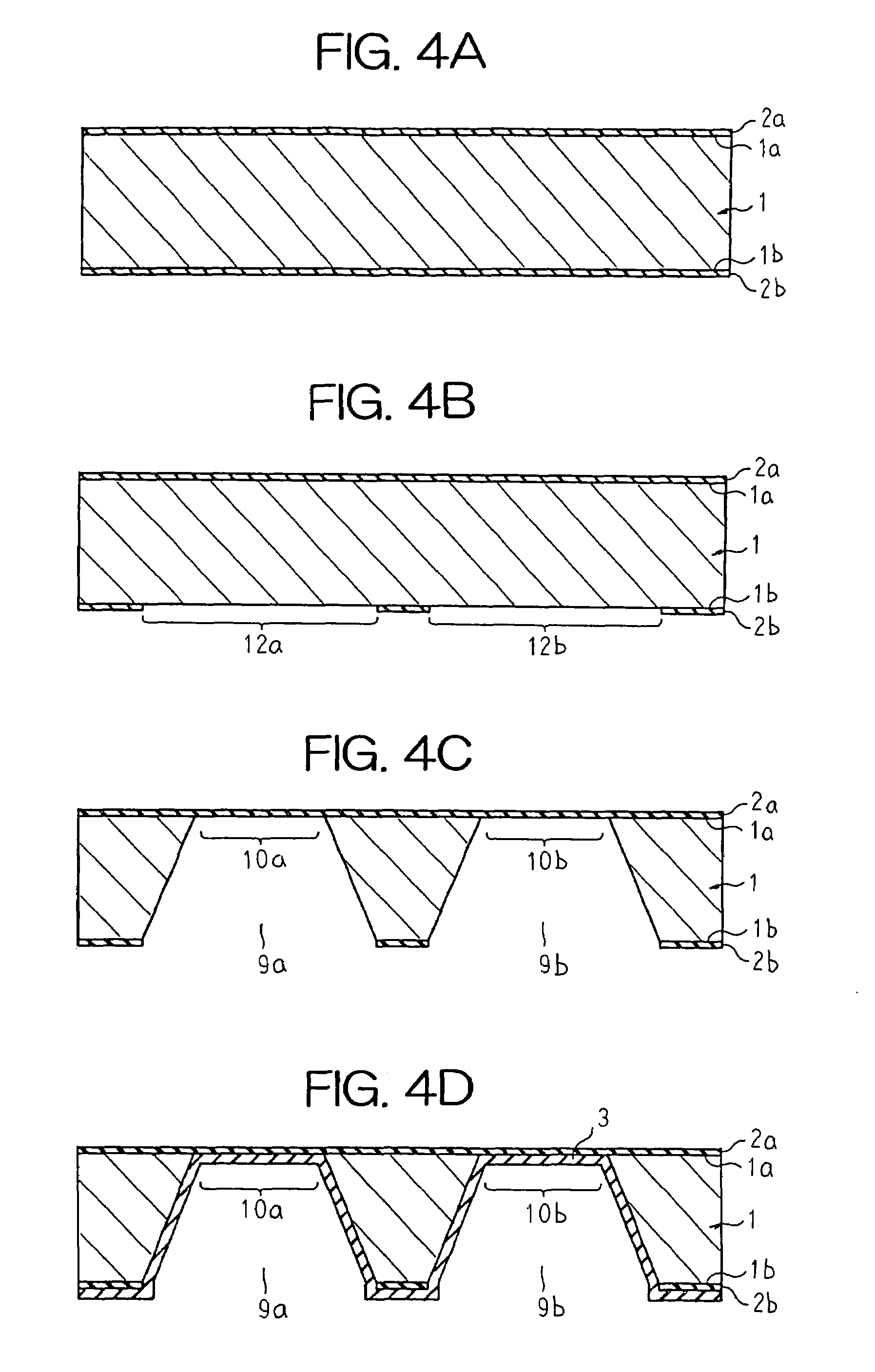

Thermosensitive flow rate detecting element and method for the manufacture thereof

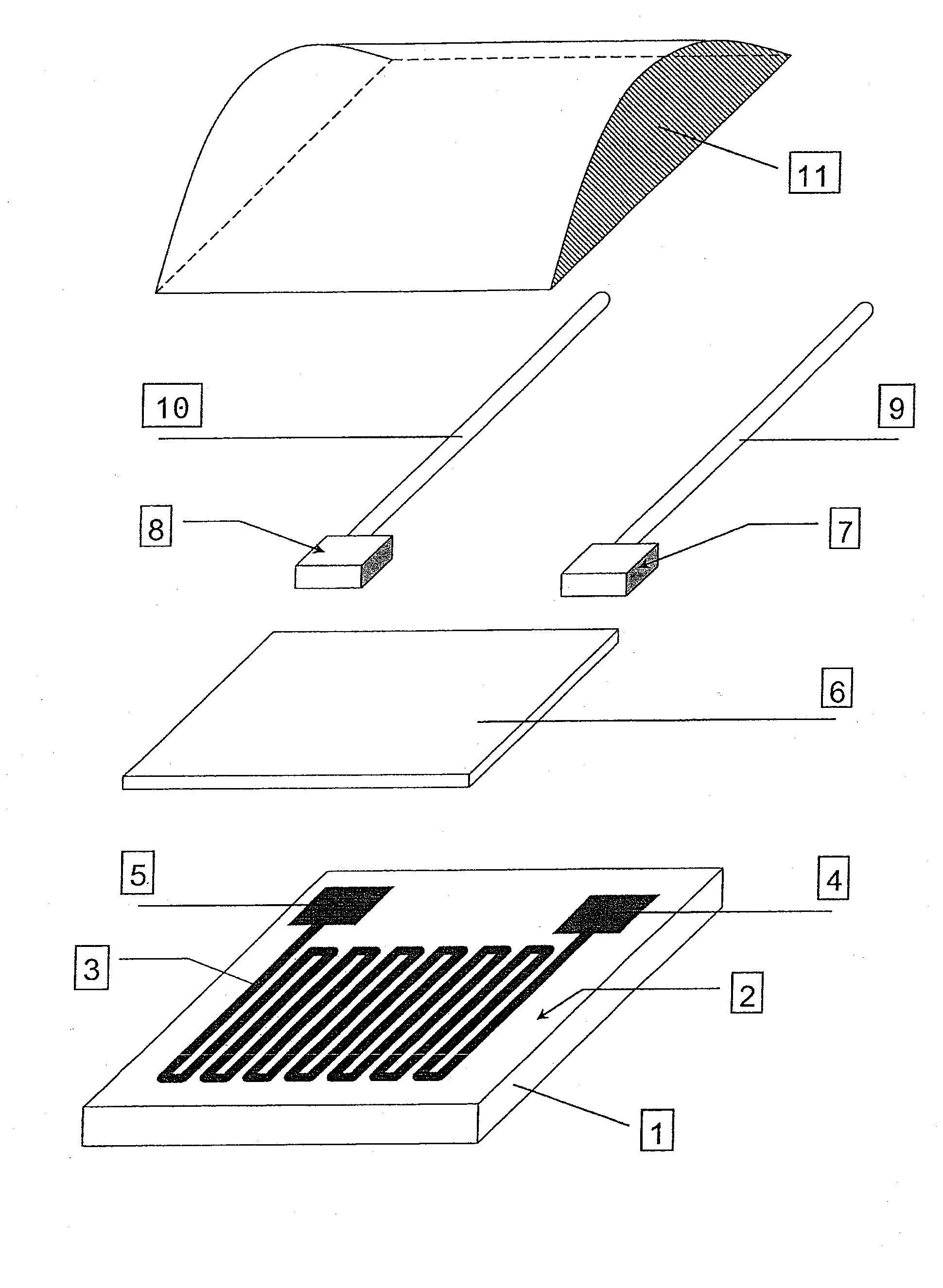

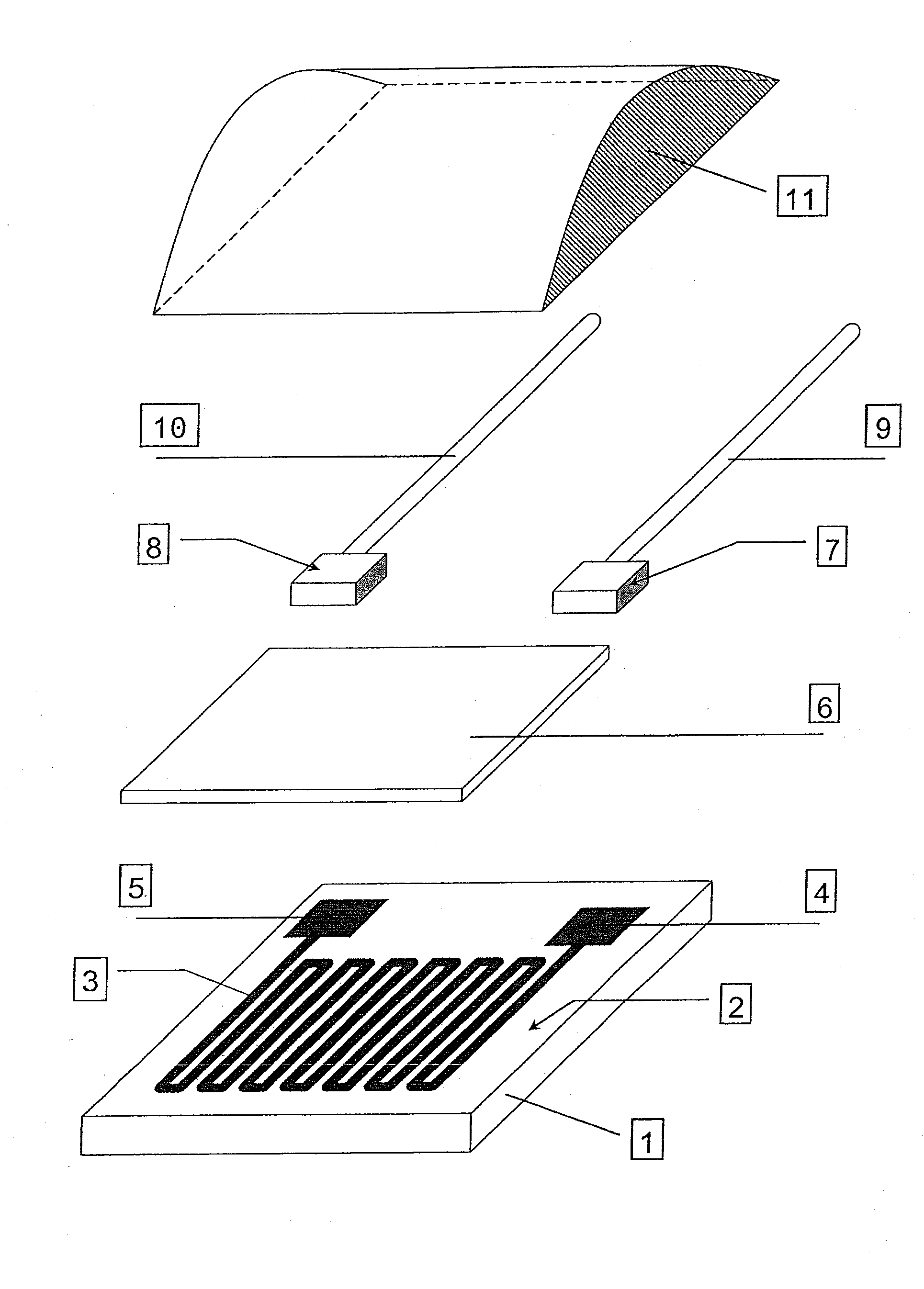

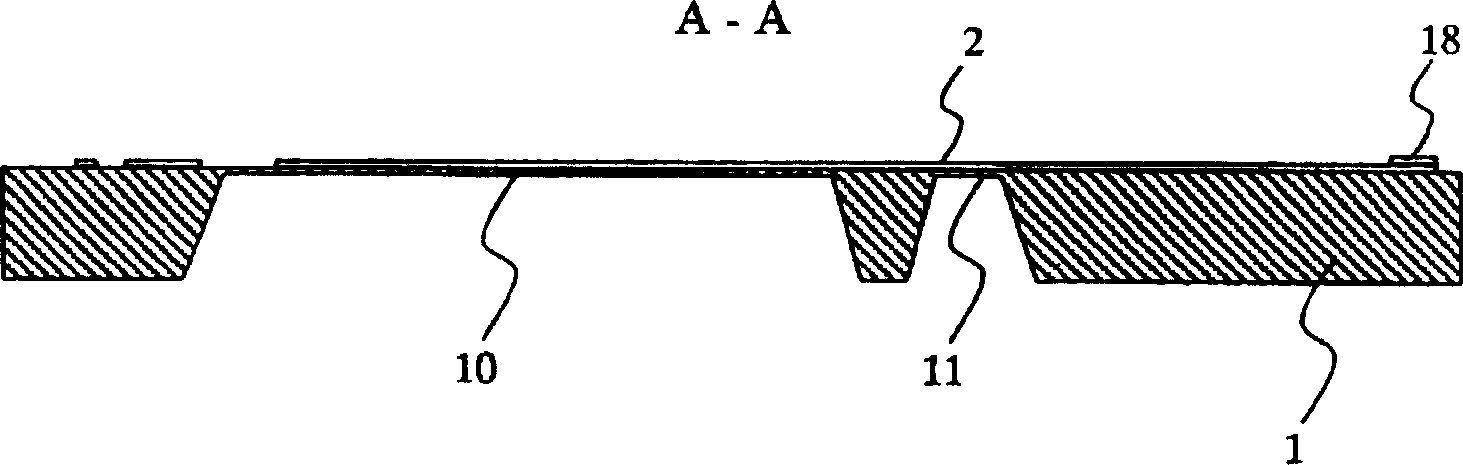

ActiveUS6971266B2Stable detectionSuppress interferenceSemi-permeable membranesVolume/mass flow by thermal effectsTectorial membraneElectricity

Cavities are formed so as to extend from a rear surface side of a base material to a protective film, an electrically-insulating film is formed on a rear surface of the base material, wall surfaces of the cavities, and exposed surfaces of the protective film, and a heating resistor portion and a fluid temperature resistance thermometer portion are formed on portions of the electrically-insulating film on the exposed surfaces of the protective film inside the cavities. In addition, leader patterns are formed on the electrically-insulating film so as to extend from end portions of the heating resistor portion and the fluid temperature resistance thermometer portion along the wall surfaces of the cavities onto the rear surface of the base material.

Owner:MITSUBISHI ELECTRIC CORP

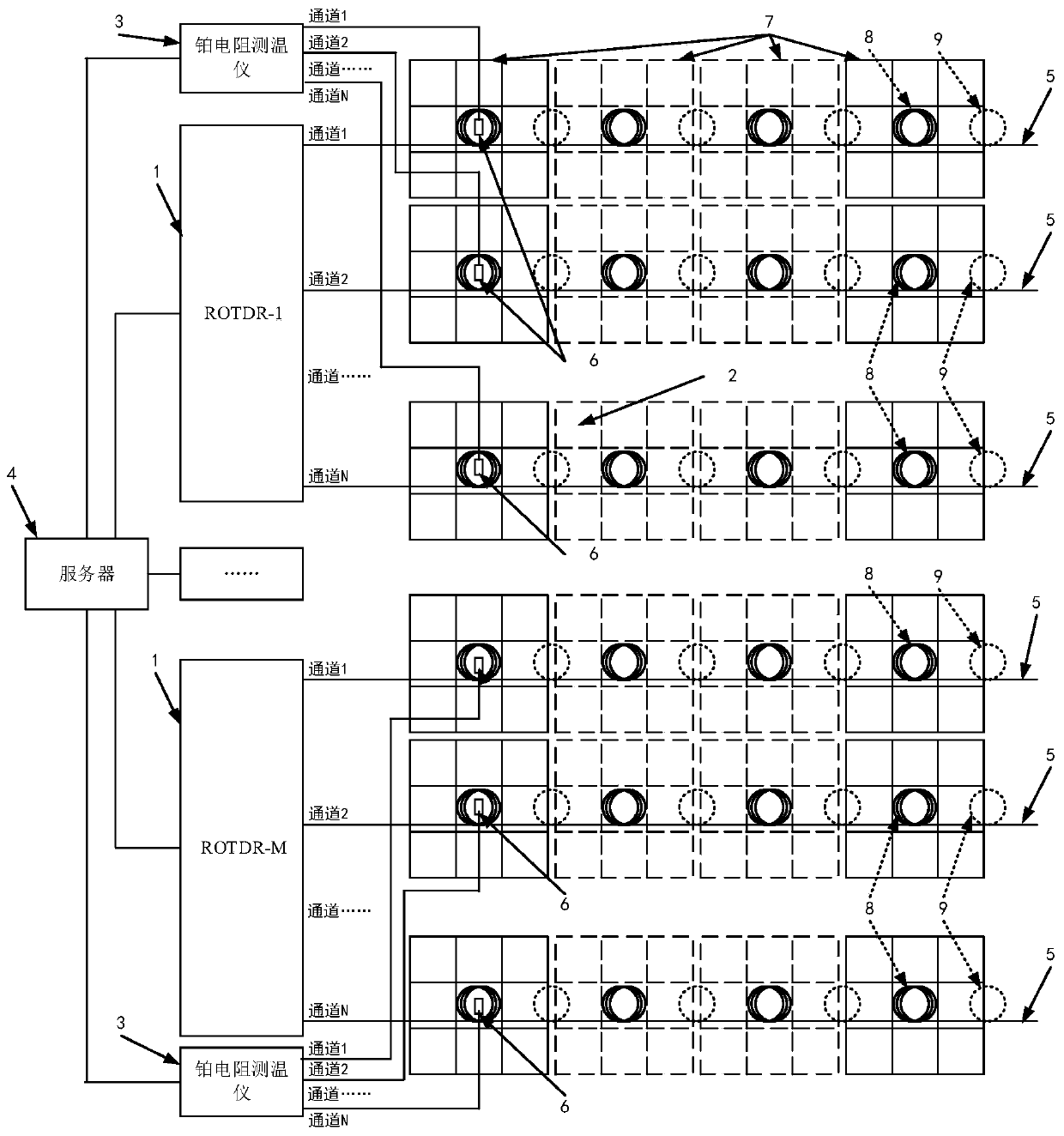

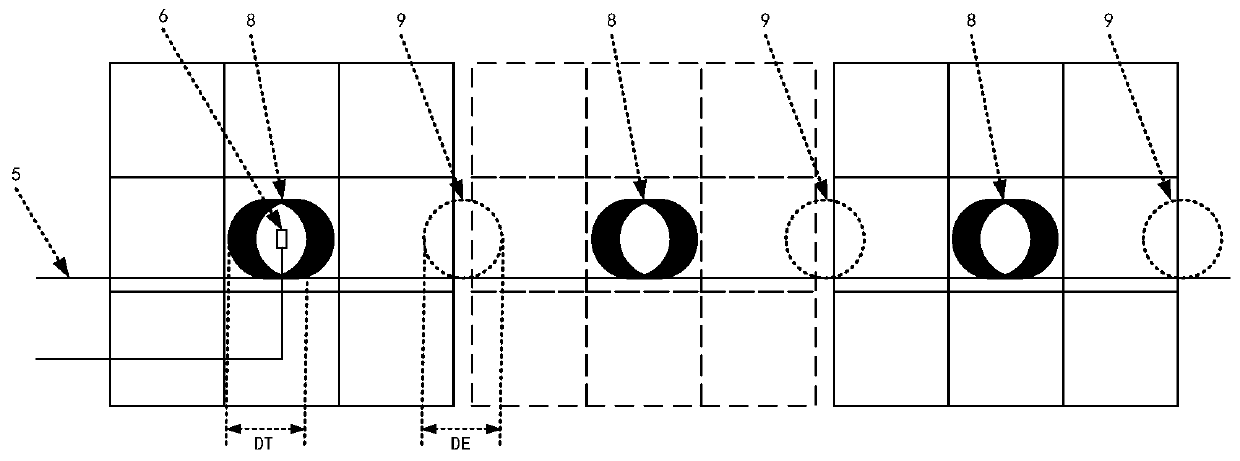

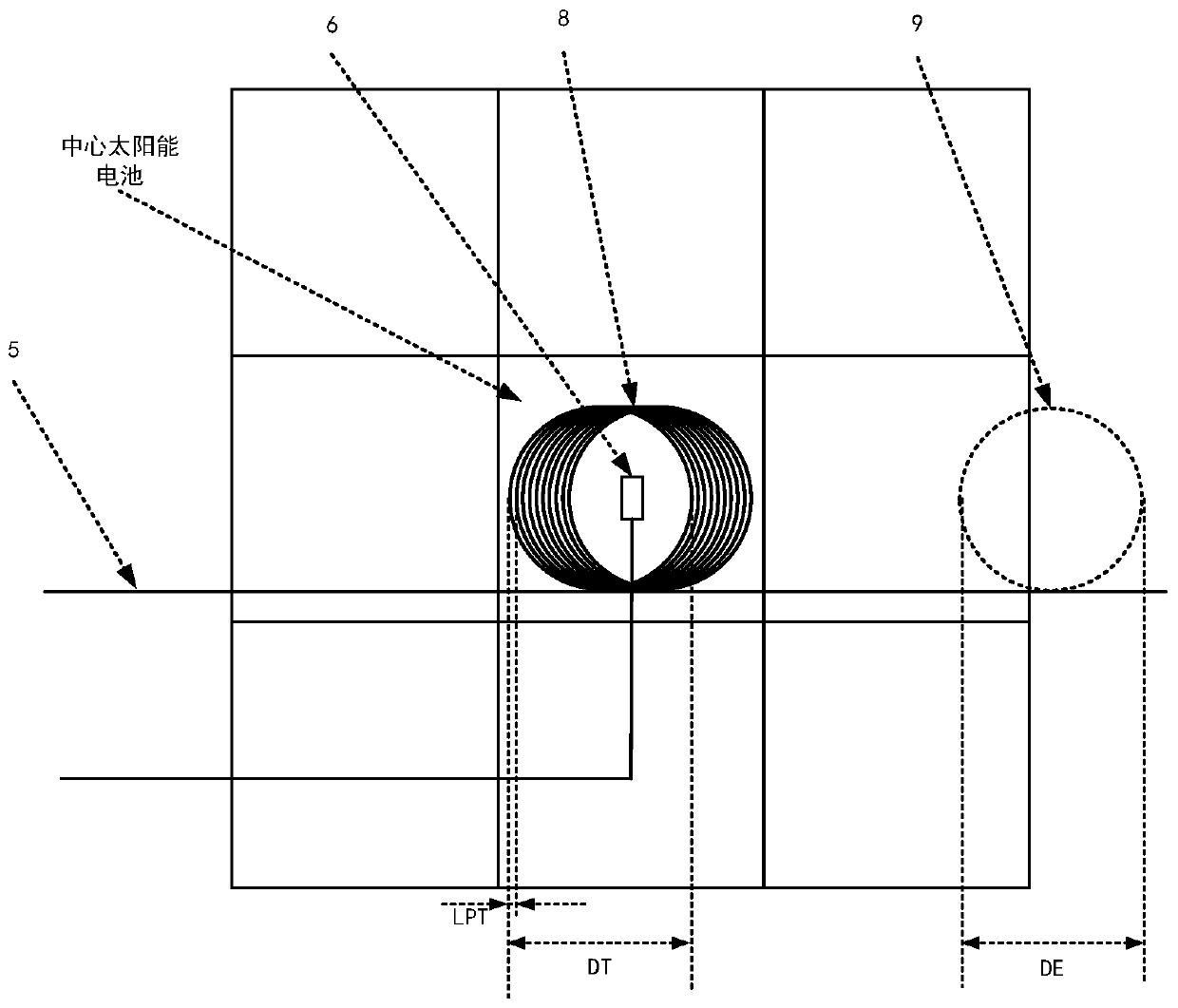

Solar panel temperature monitoring system based on optical fiber temperature distribution tester, and distribution monitoring method

InactiveCN110455437AImprove reliabilityReduce complexityPhotovoltaic monitoringThermometers using physical/chemical changesElectrical resistance and conductanceEngineering

The invention discloses a solar panel temperature monitoring system based on an optical fiber temperature distribution tester, and a distribution monitoring method. The system comprises an optical fiber temperature distribution tester, a solar panel component, a platinum resistance thermometer, and a server, wherein the optical fiber temperature distribution tester is provided with a temperature sensing cable that is bonded on a back panel of the solar panel component, the platinum resistance thermometer is connected with a platinum resistance probe which is fixed at a position where the temperature sensing cable is bonded on the back panel of the solar panel component, and both the platinum resistance thermometer and the optical fiber temperature distribution tester are connected with theserver. With distributed temperature test by the optical fiber temperature distribution tester as the core, the invention provides a method of distributing large-scale solar panel distributed temperature monitoring system, realizing temperature monitor of large-scale solar panel. The system has characteristics of lower complexity, high reliability, simple distribution, convenience in maintenance,real-time calibration during operating, and low cost.

Owner:THE 41ST INST OF CHINA ELECTRONICS TECH GRP

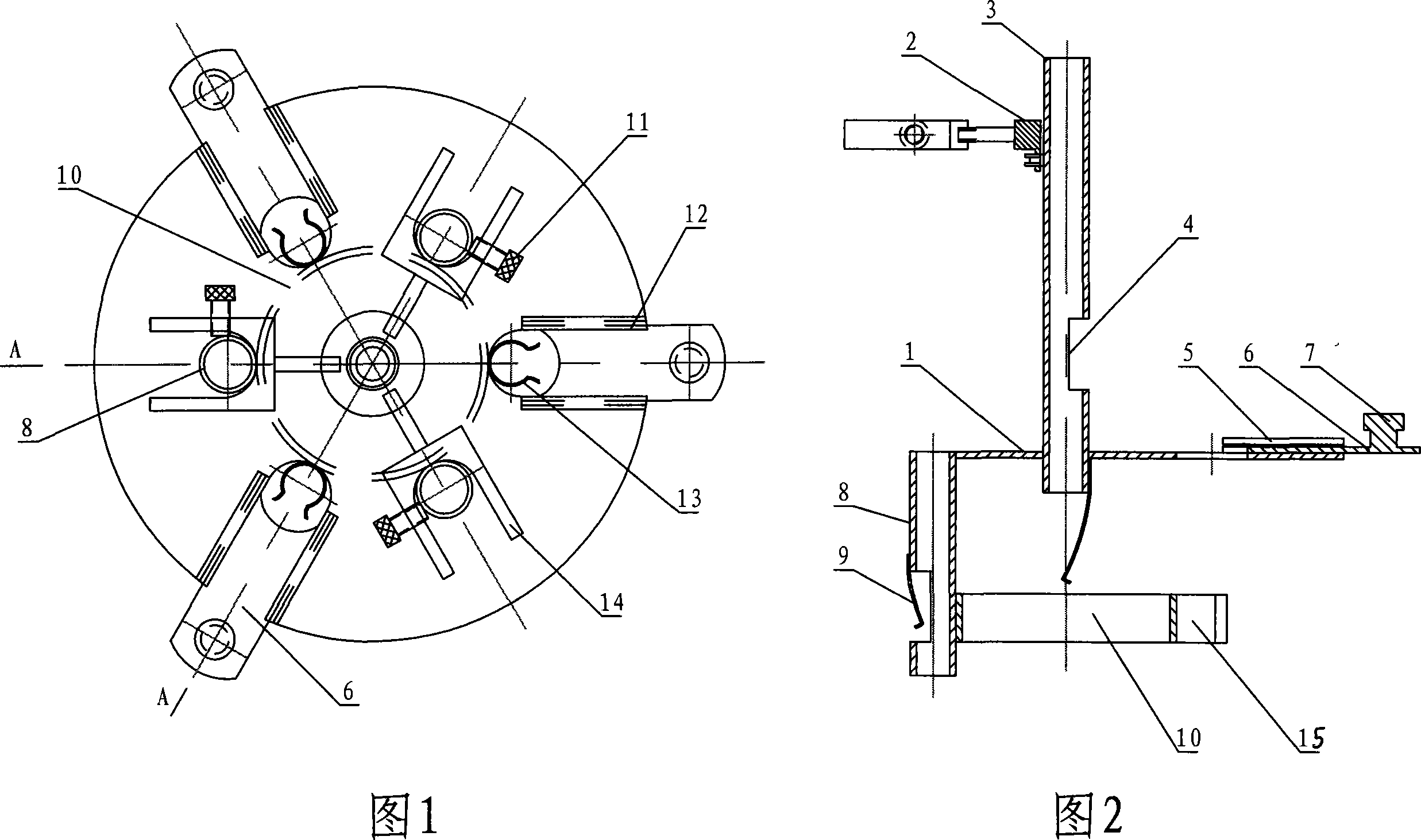

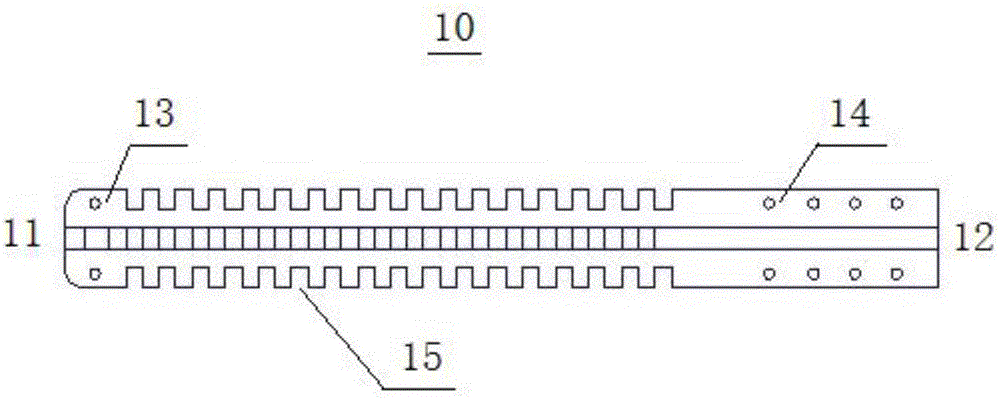

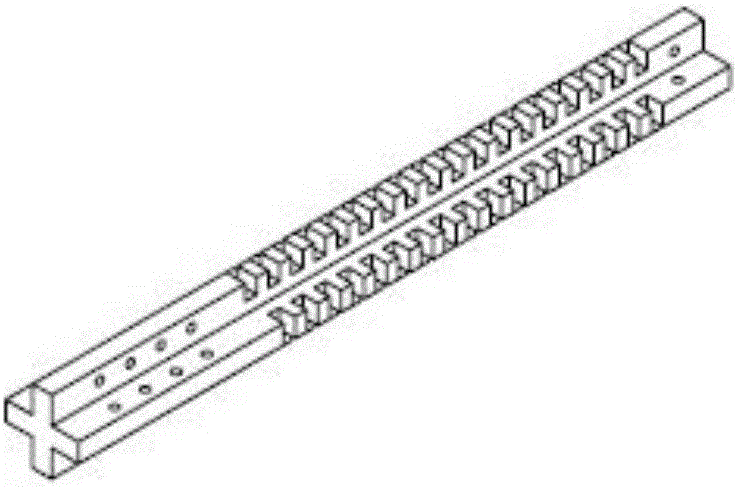

Thermal resistor thermometer test system multi-purpose tray and insert plate device

InactiveCN101216357AImprove work efficiencyGood constant temperatureThermometer testing/calibrationEngineeringResistance thermometer

The invention comprises a main support insert disk, side-opening jacks of a special joint thermal resistor to be detected, a guide holding tube of a standard thermometer, a guide holding tube of a thermometer to be detected, a positioning insert plate of the special joint thermal resistor to be detected, a rotary lifting righting clamp, a connection plate and annular collets. Three side-opening jacks of the special joint thermal resistor to be detected are uniformly distributed on the main support insert disk, the annular collets and a coiled clip reed are provided below the jacks, and an insert plate guide base is arranged on both sides of the side-opening jacks. The guide holding tube of the thermometer to be detected is provided below the main support insert disk, and the rotary lifting righting clamp is arranged on the guide holding tube of the standard thermometer. The thermometer of a thermal resistor to be detected can be detected by arranging in the guide holding tube, disposing in a constant-temperature bath and adjusting the height of the lifting righting clamp to fix the thermometer. The invention has the advantages of safe and reliable operation, high work efficiency, good thermostatic performance and accuracy detection.

Owner:BOHAI SHIP HEAVY IND CO LTD

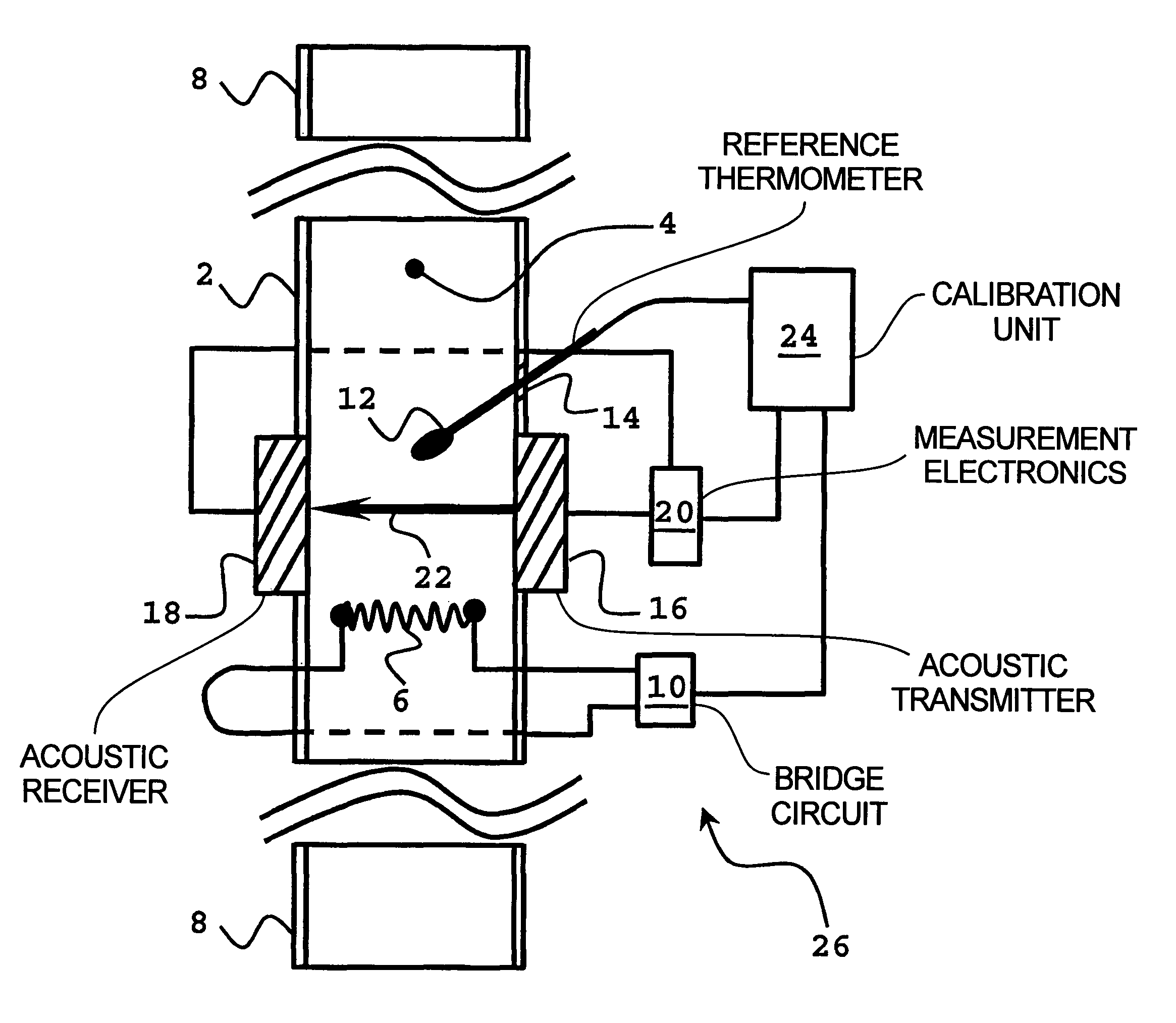

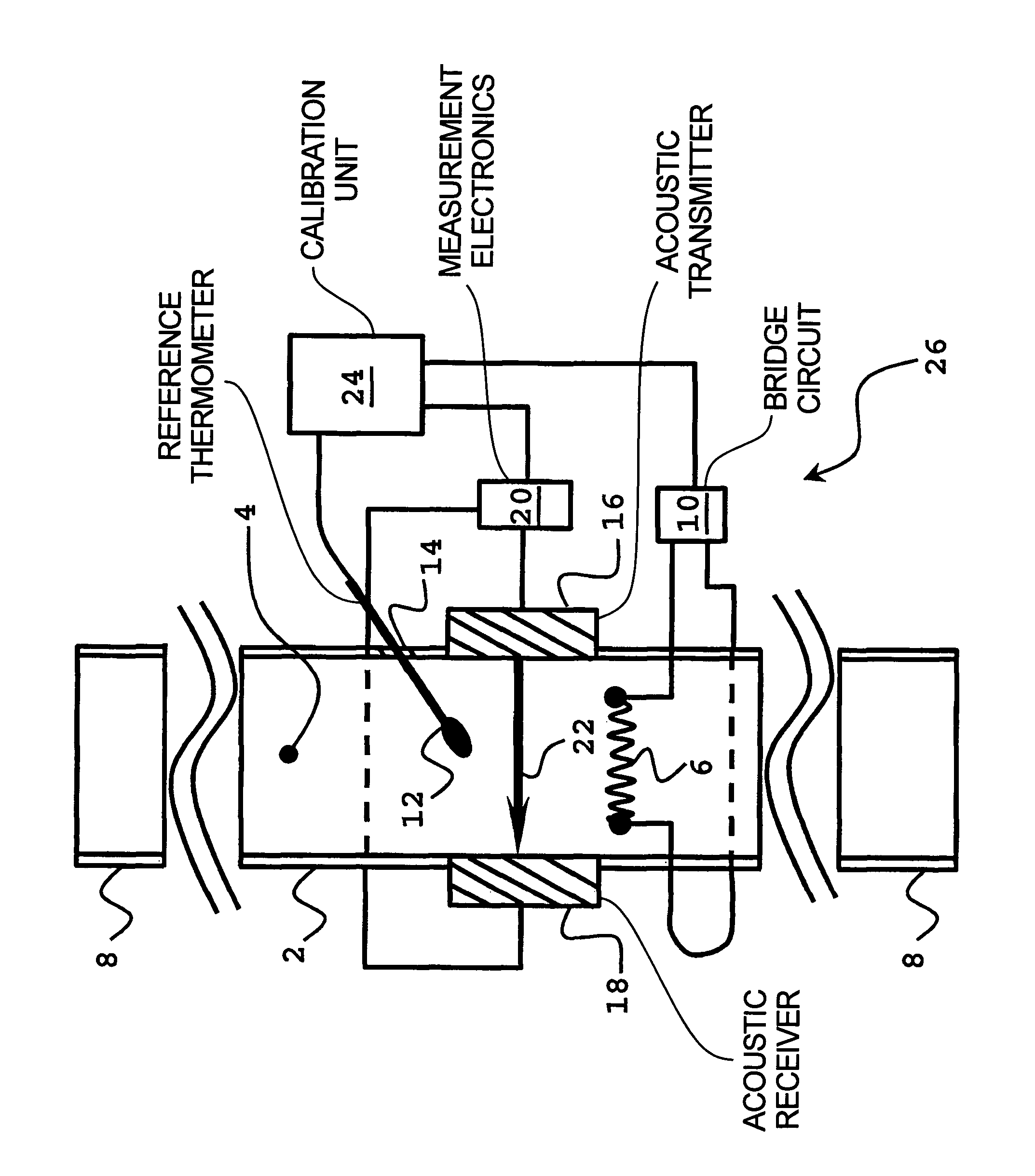

Apparatus and method for calibrating a resistance thermometer and gas analyzer employing same

InactiveUS7031861B2Lower component costsReduce calibration timeMaterial thermal conductivityThermometers using electric/magnetic elementsElectrical resistance and conductanceGas composition

In a calibration apparatus and method for a resistance thermometer a reference thermometer is located in thermal contact with a gas composition to generate, during a calibration period, a first reference temperature value for the gas composition at a first temperature, and an acoustic meter is located in acoustic contact with the gas composition and, during the calibration period, makes an acoustic velocity-related measurement for use in generating a second reference temperature value for the gas composition at a second temperature. A calibration unit coordinates the first and second reference temperature values with first and second measurement temperature values provided by the resistance thermometer at the first and the second temperatures, respectively, and establishes a calibration relationship therefrom.

Owner:MAQUET CRITICAL CARE

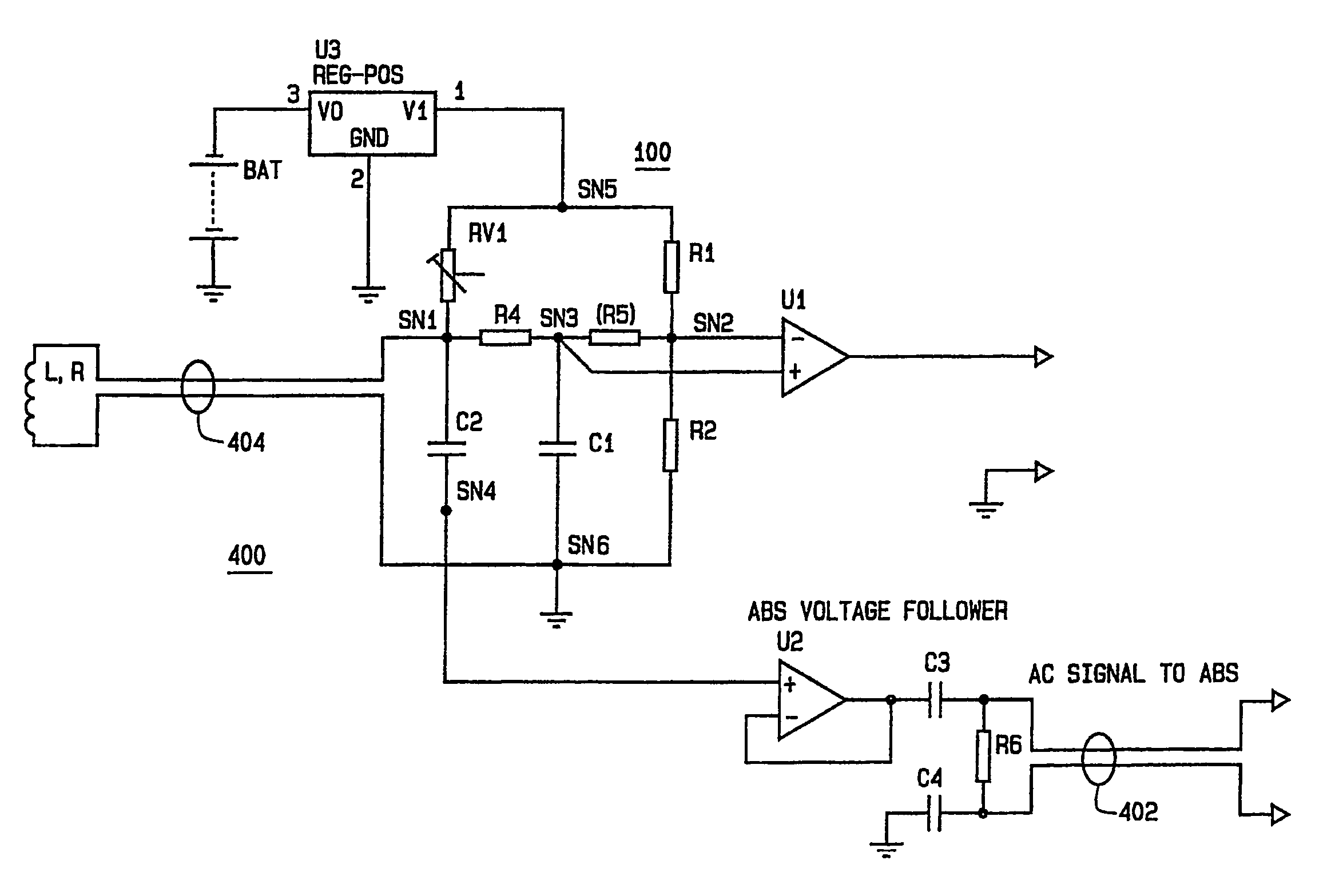

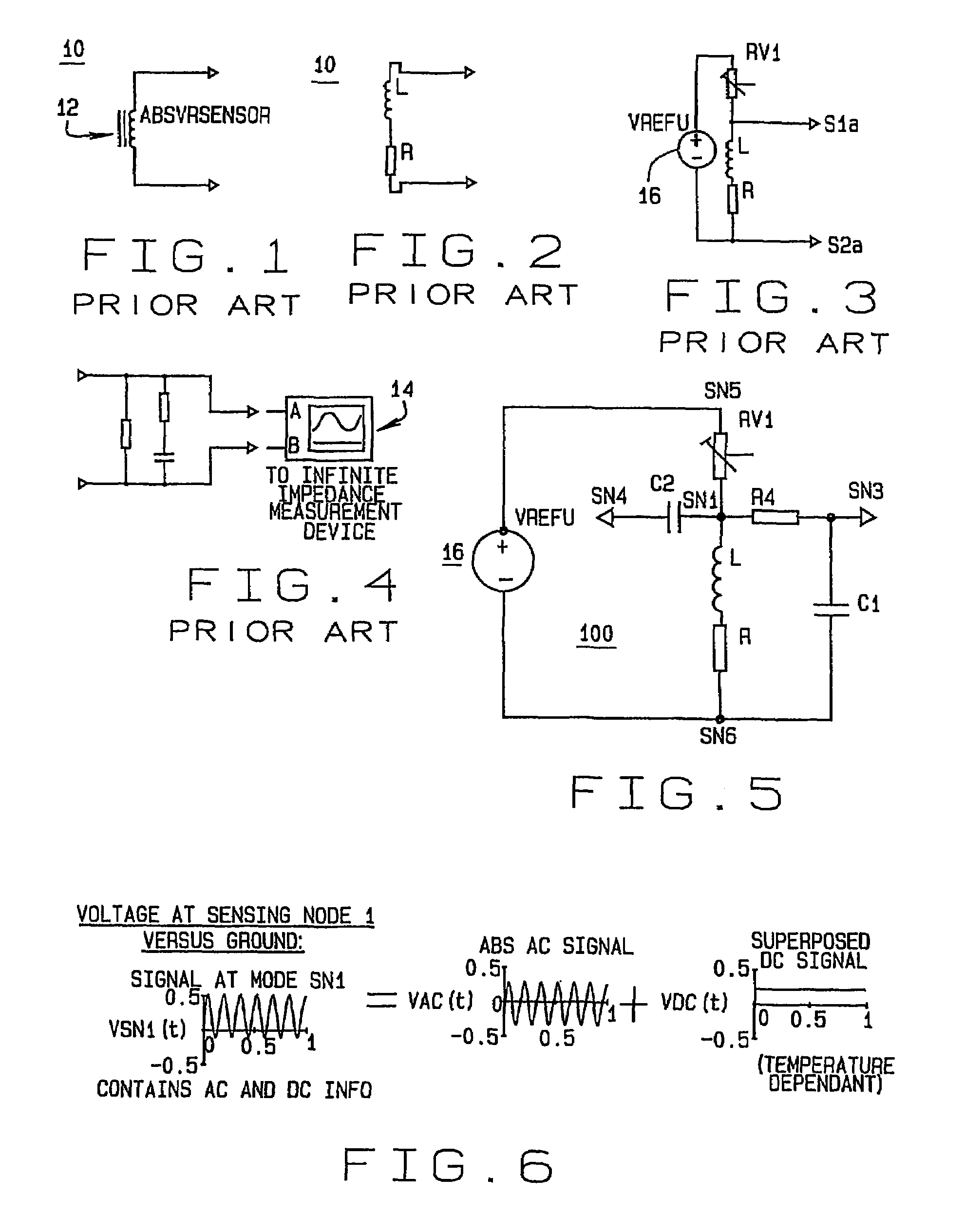

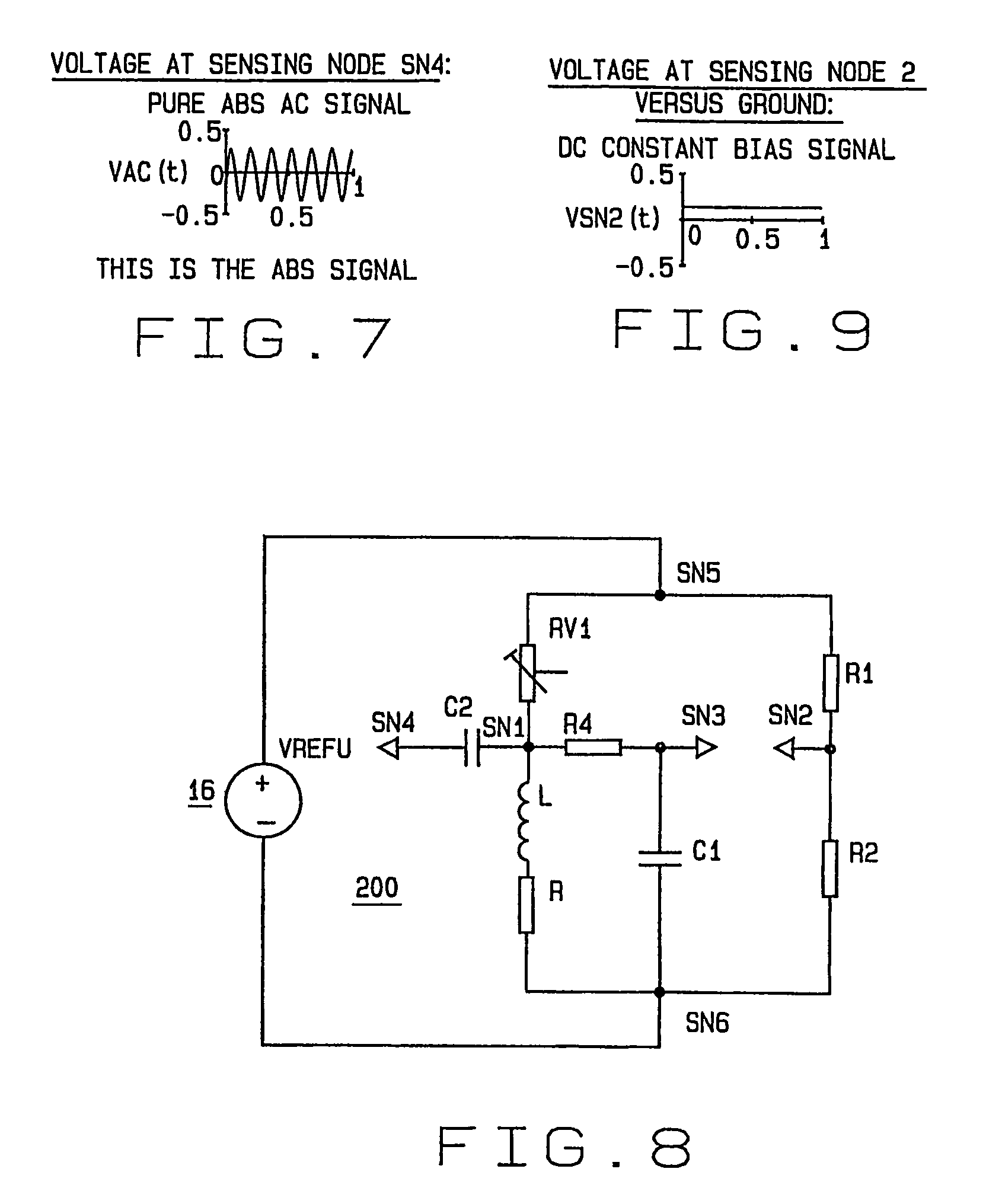

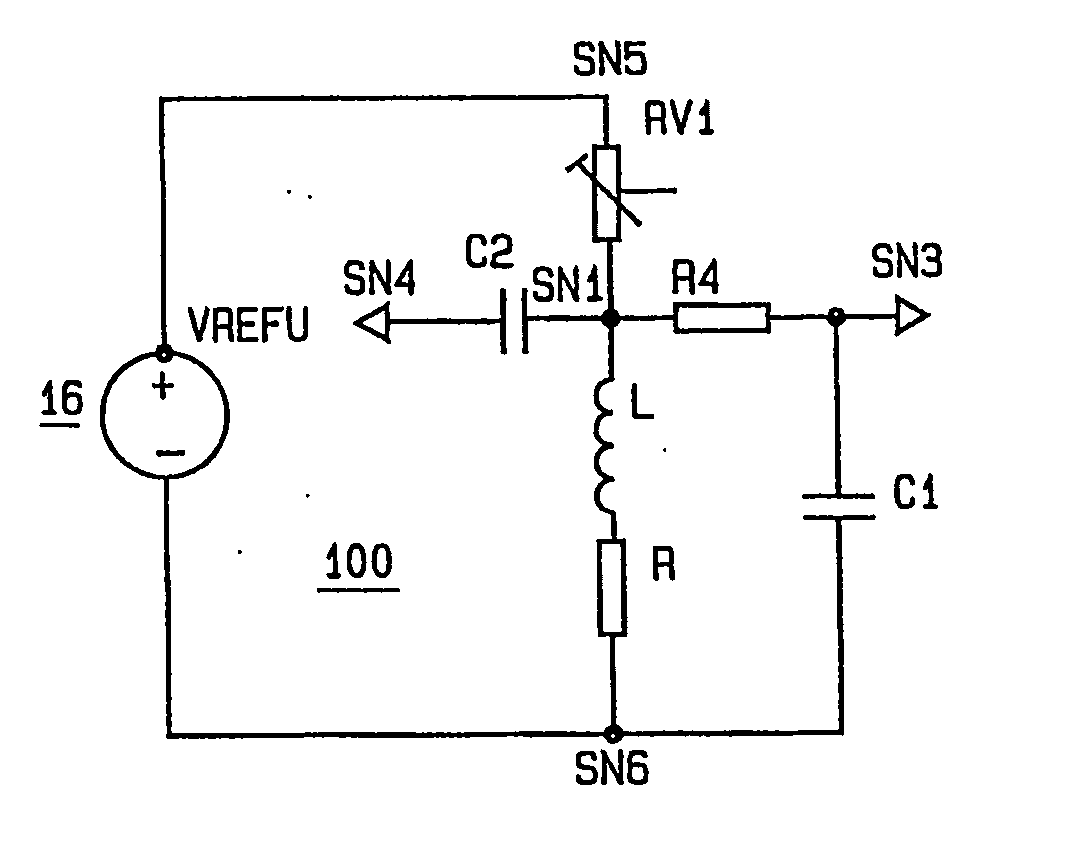

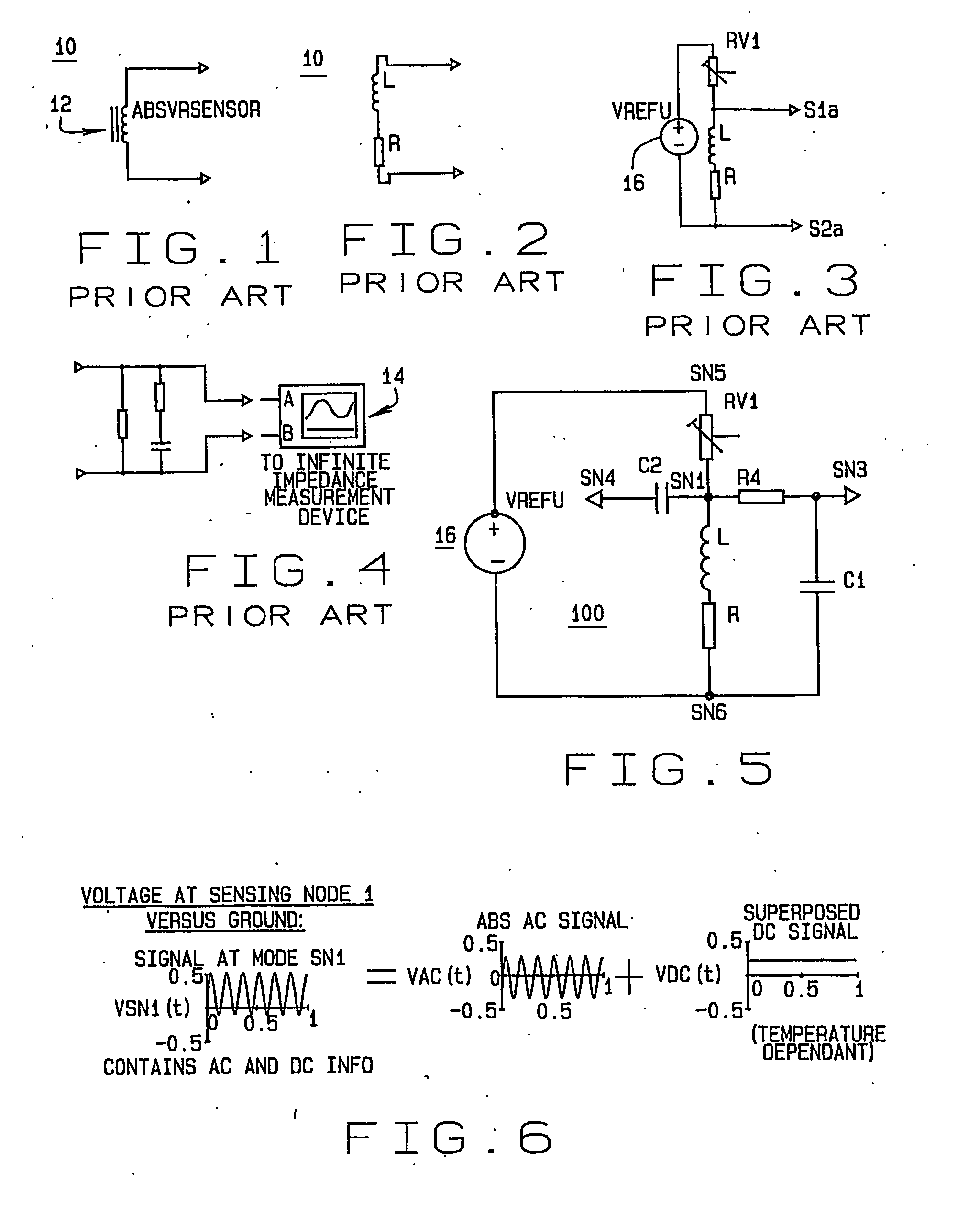

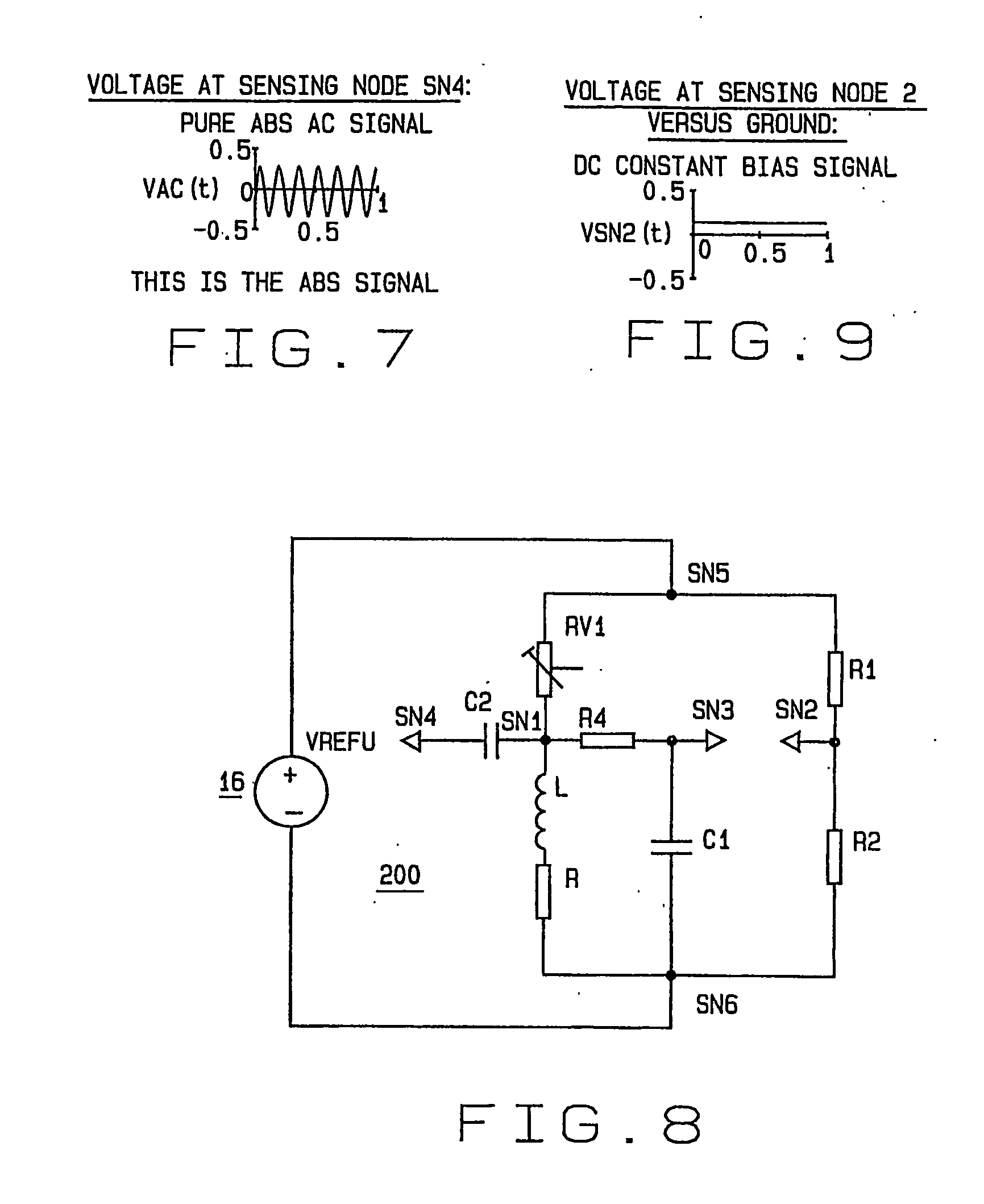

Rotation sensor with temperature measuring feature

InactiveUS7573391B2Thermometer detailsThermometers using material expansion/contactionTraction control systemVariable reluctance sensor

A temperature sensing system (100) for use with a variable reluctance sensor such as found in vehicle wheel bearing applications, which utilizes existing sensors (12) such as the antilock braking system or traction control system sensors as a direct current resistive temperature gauge. The temperature sensing system (100) includes electrical components (R4, C1) configured to separate the DC voltage (VDC(t)) representative of sensor temperature from the original magnetically induced AC voltage output signal (VSN1(t)) representative of the rotation such as vehicle wheel speed, thereby permitting the temperature sensing system (100) to be retrofitted and installed in vehicles or other components without significant alteration to an existing wiring harness or electrical components.

Owner:THE TIMKEN CO

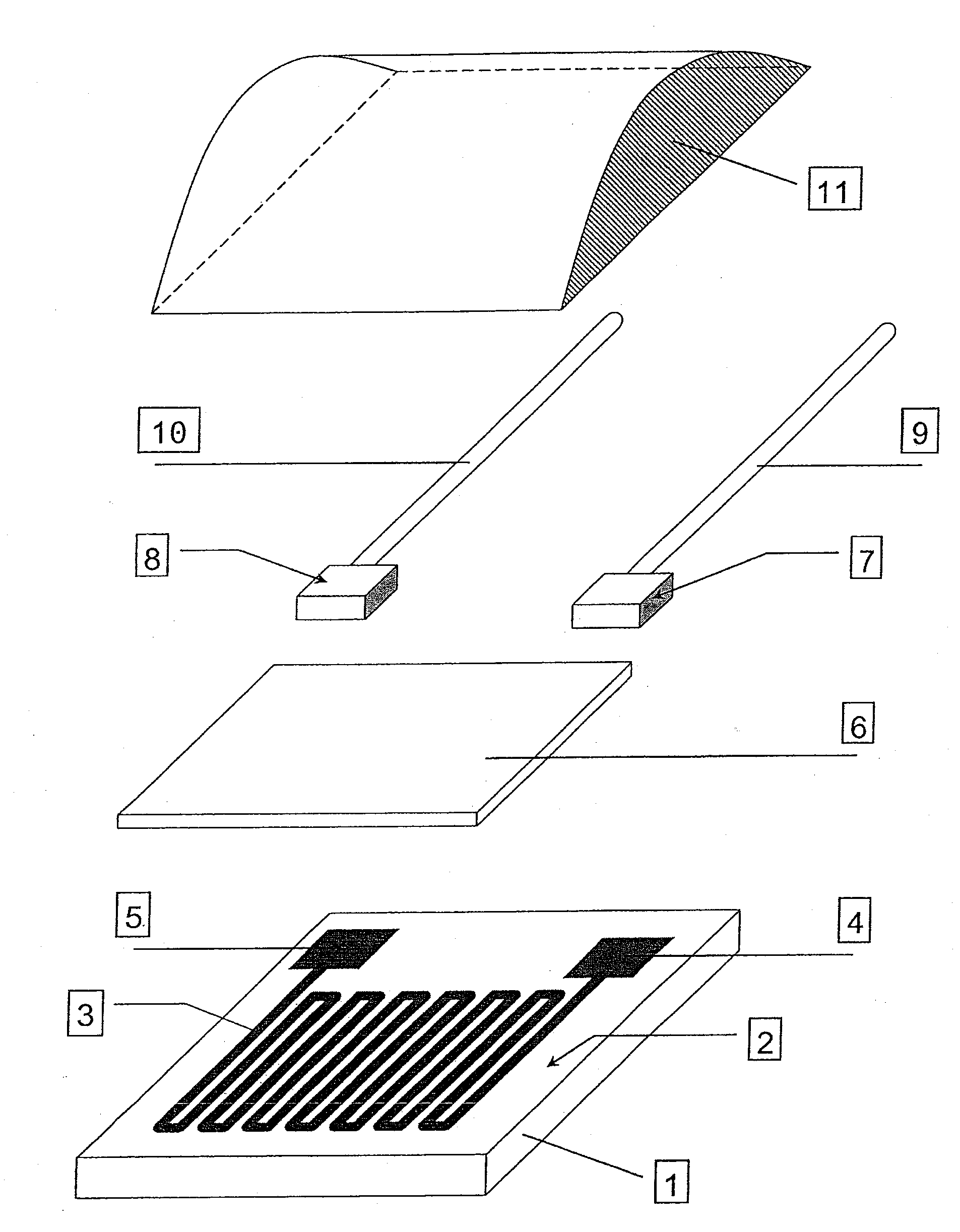

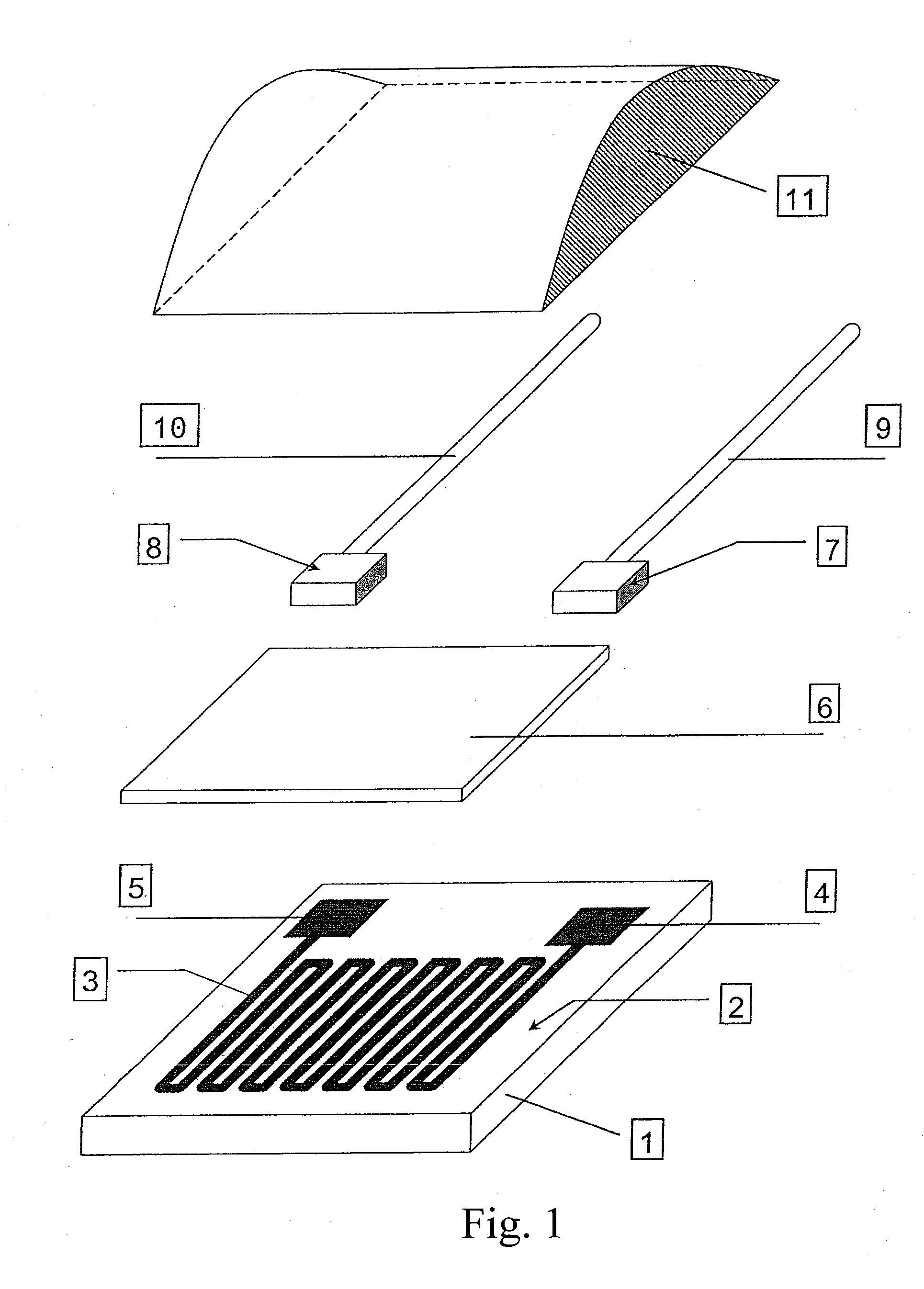

Non-conducting zirconium dioxide

ActiveUS20110305259A1Good reproducibilityIncrease productionTemperature measurement in motorsThermometers using electric/magnetic elementsZirconium hydrideNiobium

A resistance thermometer is provided having a measuring resistor in a form of a 0.1 to 10 μm thick structured platinum layer applied to an electrically insulated surface of a substrate and an electrically insulating coating layer covering the platinum layer. The substrate or its surface contains zirconium dioxide, which is stabilized with oxides of a trivalent and a pentavalent metal. Preferably, the trivalent metal is yttrium and the pentavalent metal is tantalum or niobium. The characteristic curve of the measuring resistor preferably conforms to DIN-IEC 751. For mass production of resistance thermometers having high and reproducible measurement accuracy, a structured platinum layer having a thickness of 0.1 to 10 μm is applied to an electrically insulating substrate having a thermal expansion coefficient in the range of 8.5 to 10.5×10−6 / ° K and a roughness less than 1 μm, and the structured platinum layer is covered by an electrical insulator. The resistance thermometers allow precise temperature measurement between −200° C. and +850° C., preferably as a sensor in an exhaust gas treatment system. In a substance-sensitive sensor having a circuit path structure on a substrate, the circuit path structure has an epitaxially applied base layer, and a substance-sensitive metal layer attached to the epitaxially applied base layer.

Owner:HERAEUS NEXENSOS GMBH

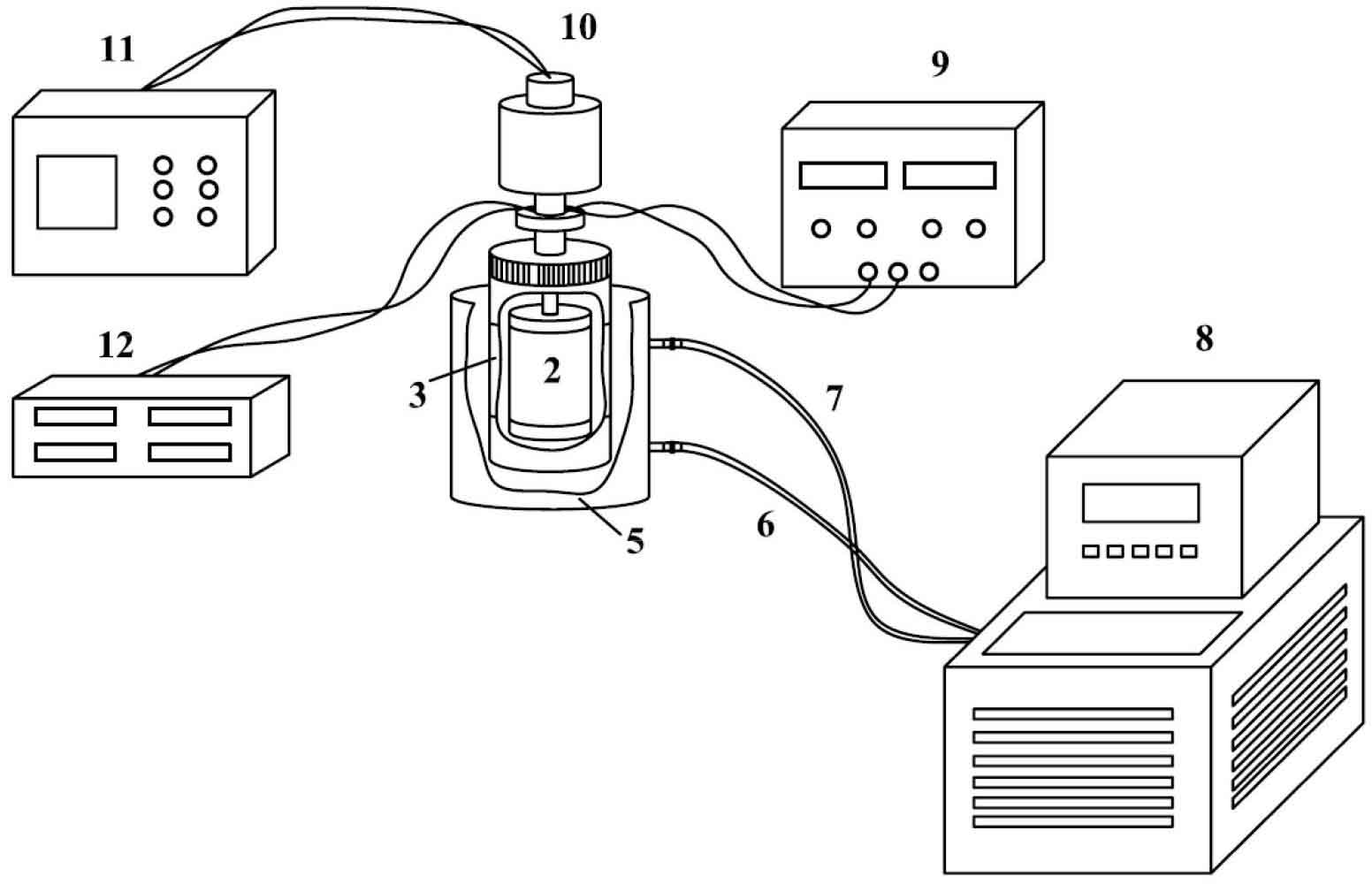

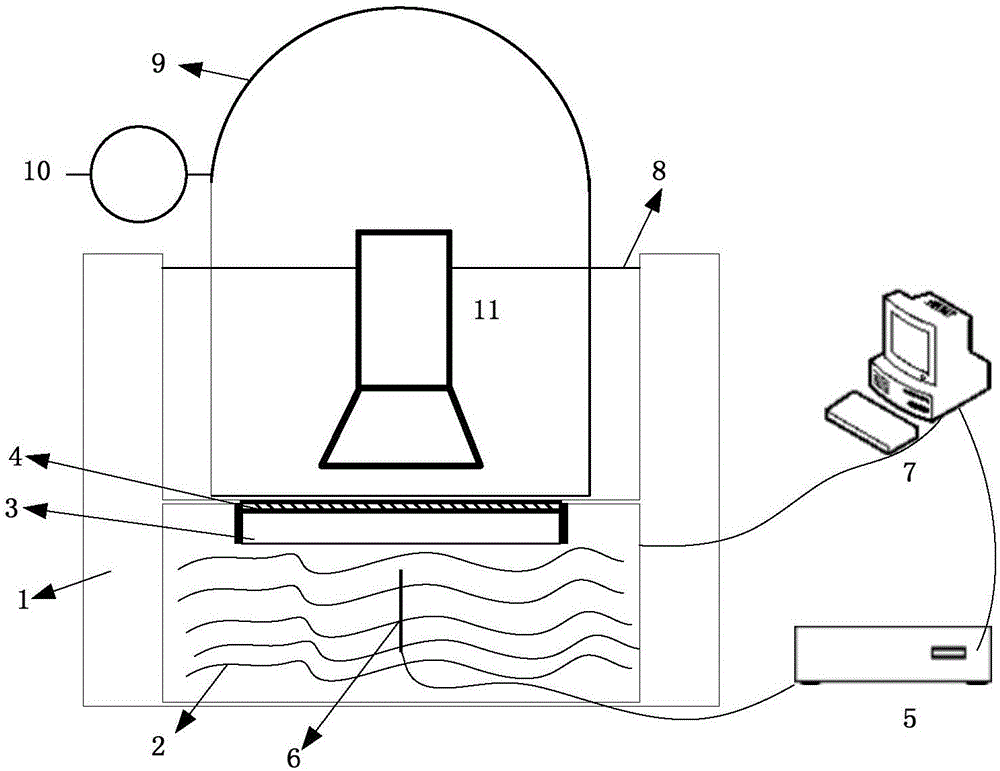

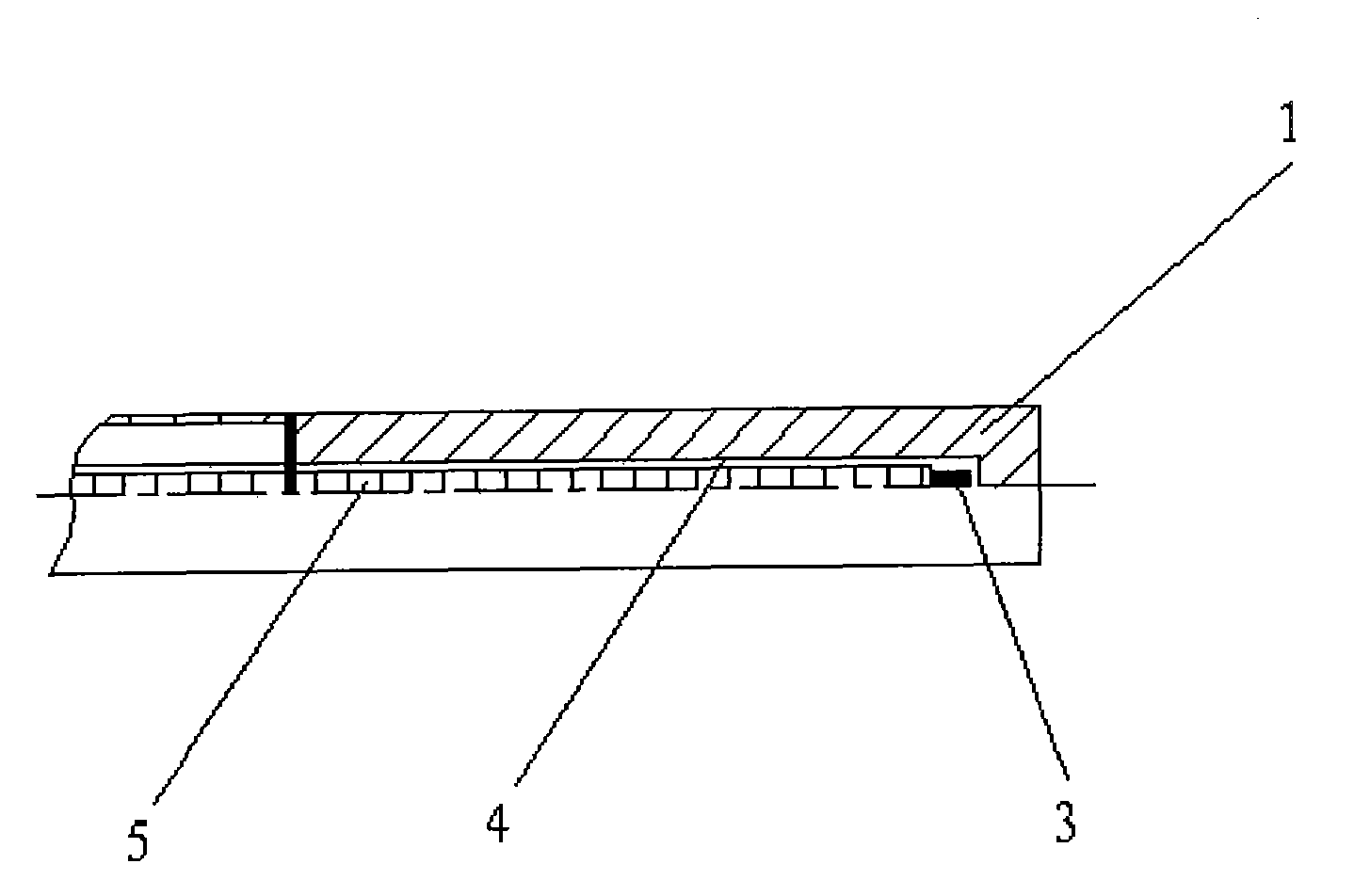

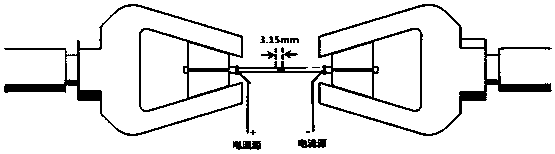

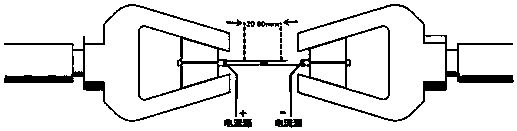

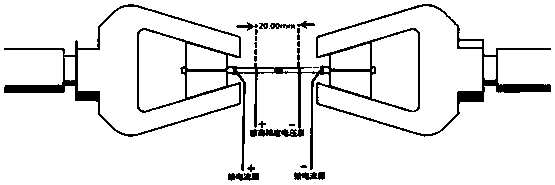

Liquid nitrogen temperature continuously and automatically measuring device

InactiveCN102661816AFast transmissionReduce temperature measurement errorThermometers using electric/magnetic elementsUsing electrical meansElectrical resistance and conductanceComputer control system

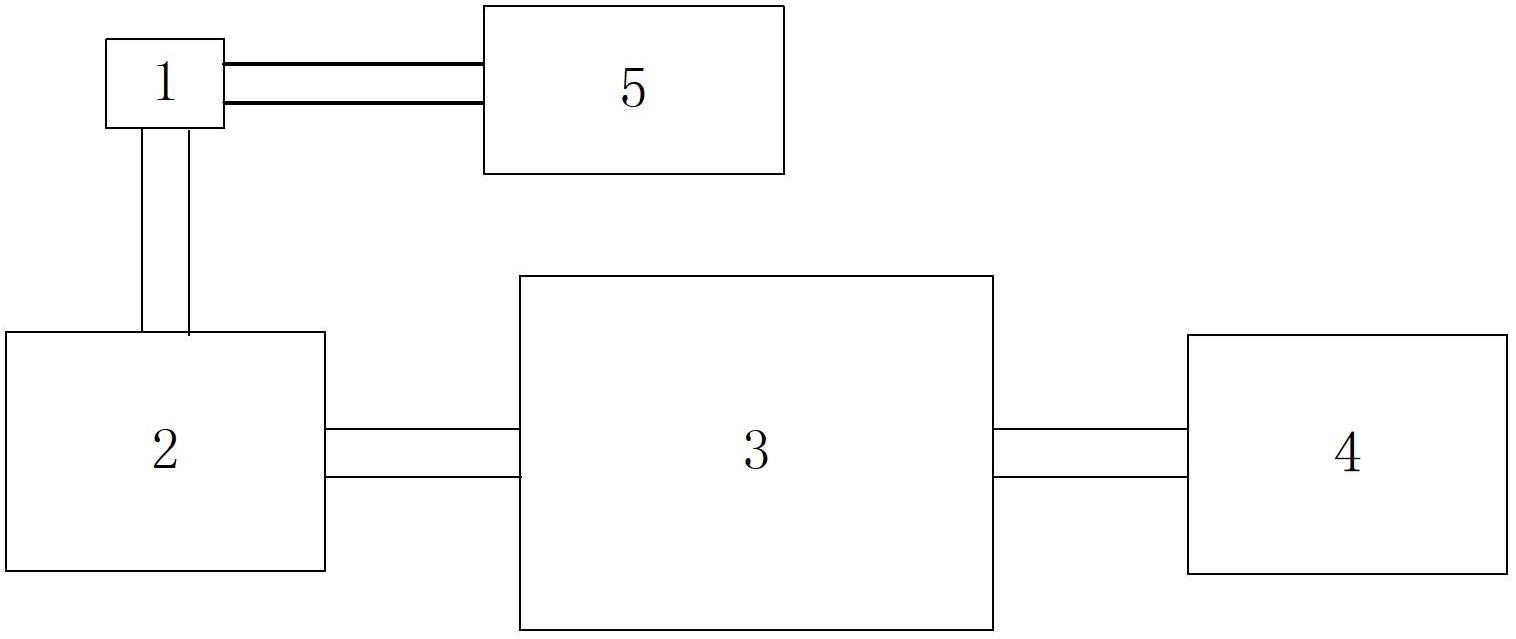

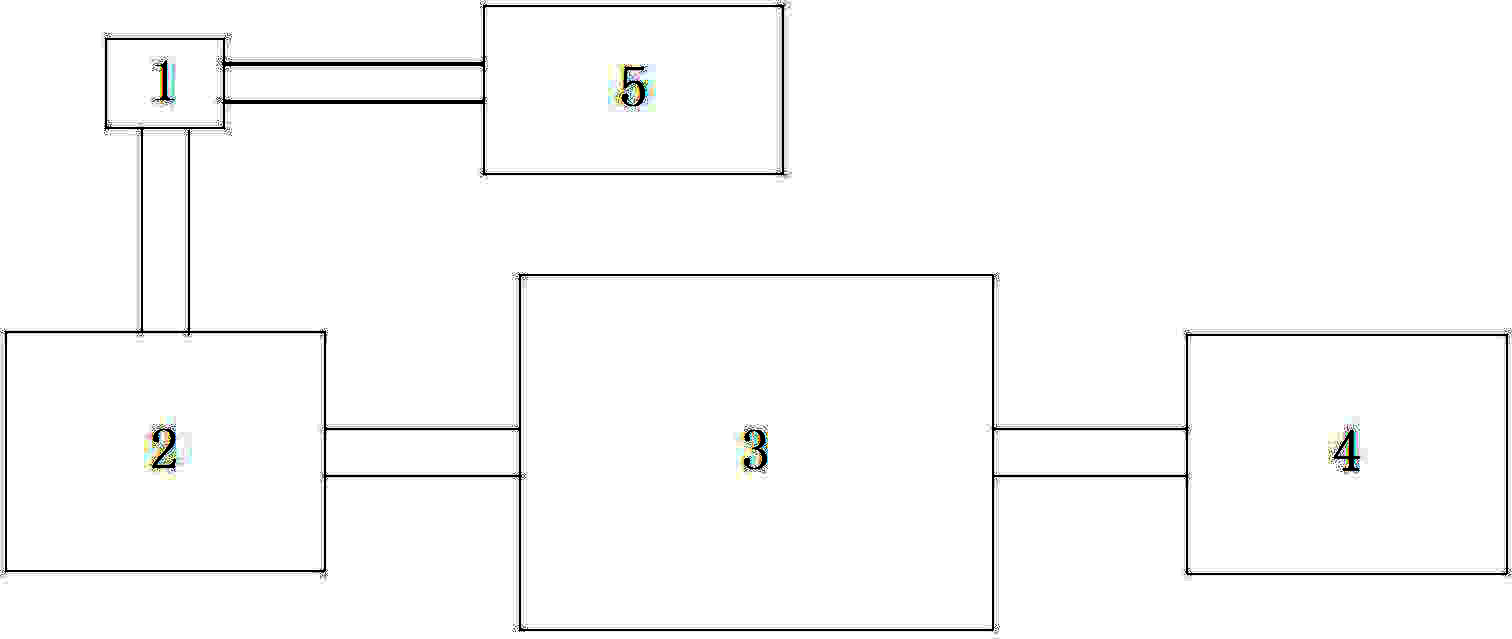

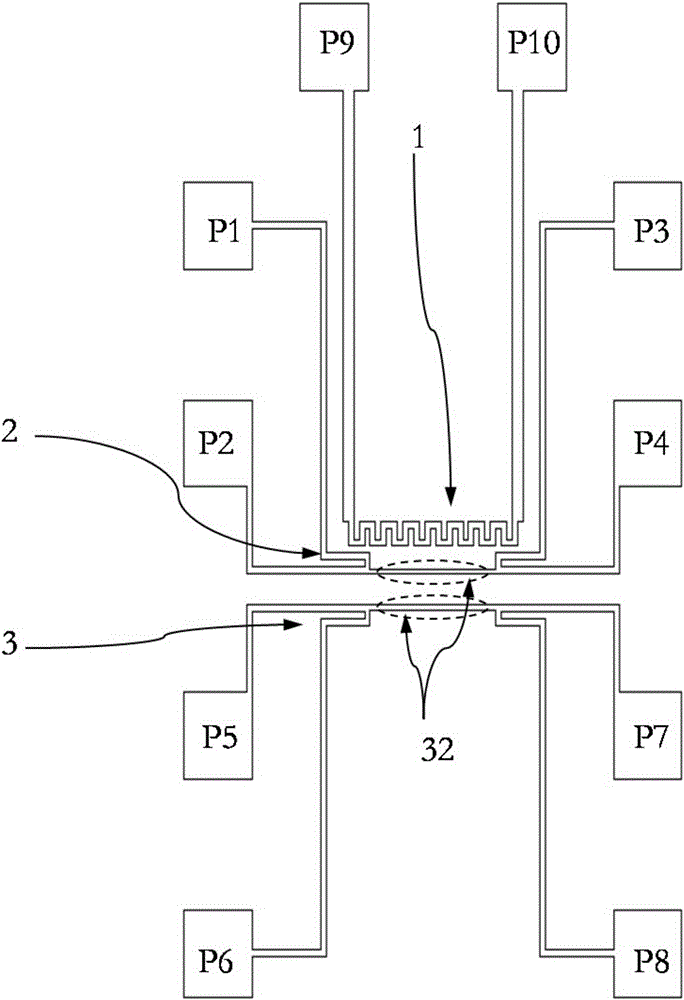

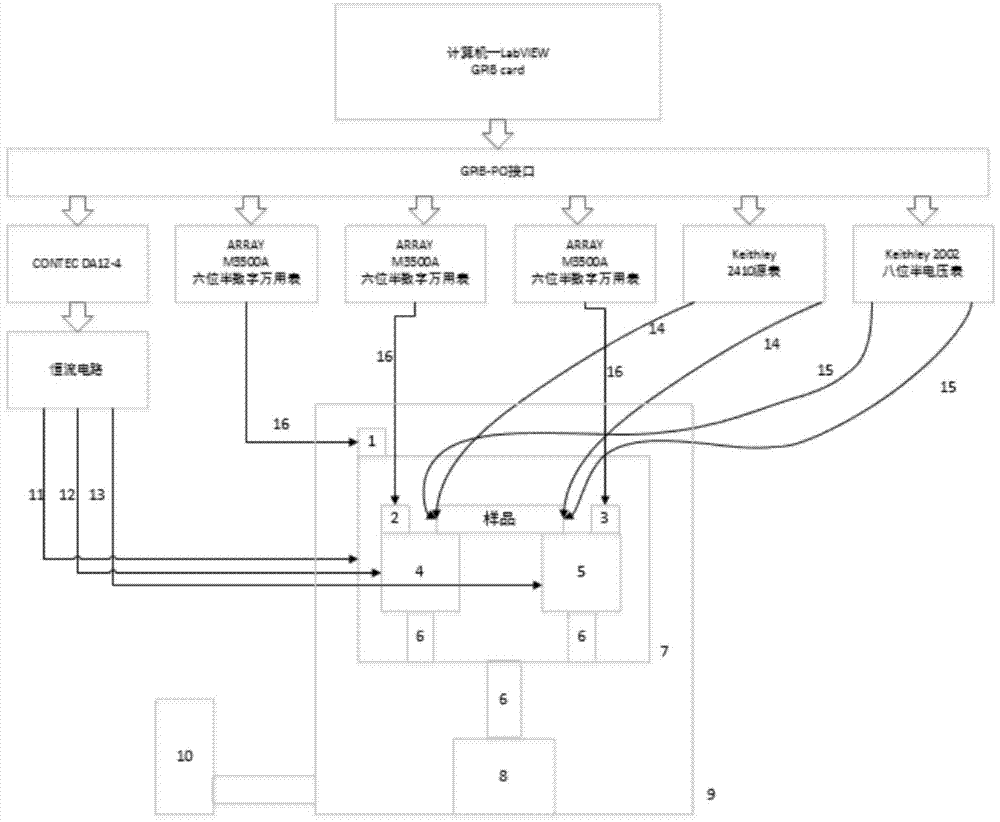

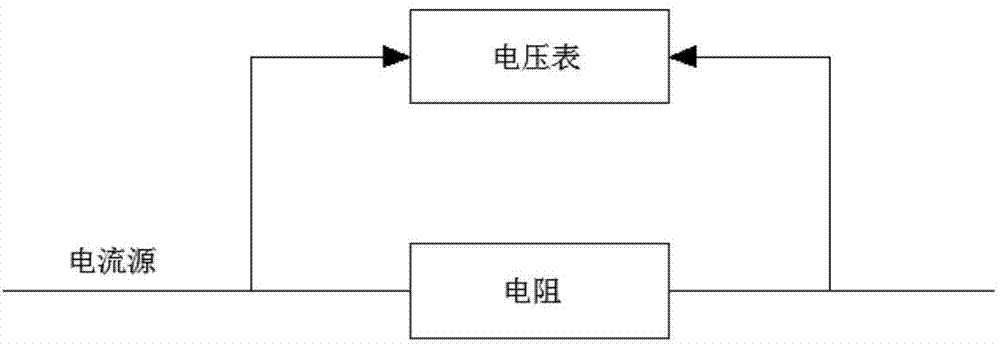

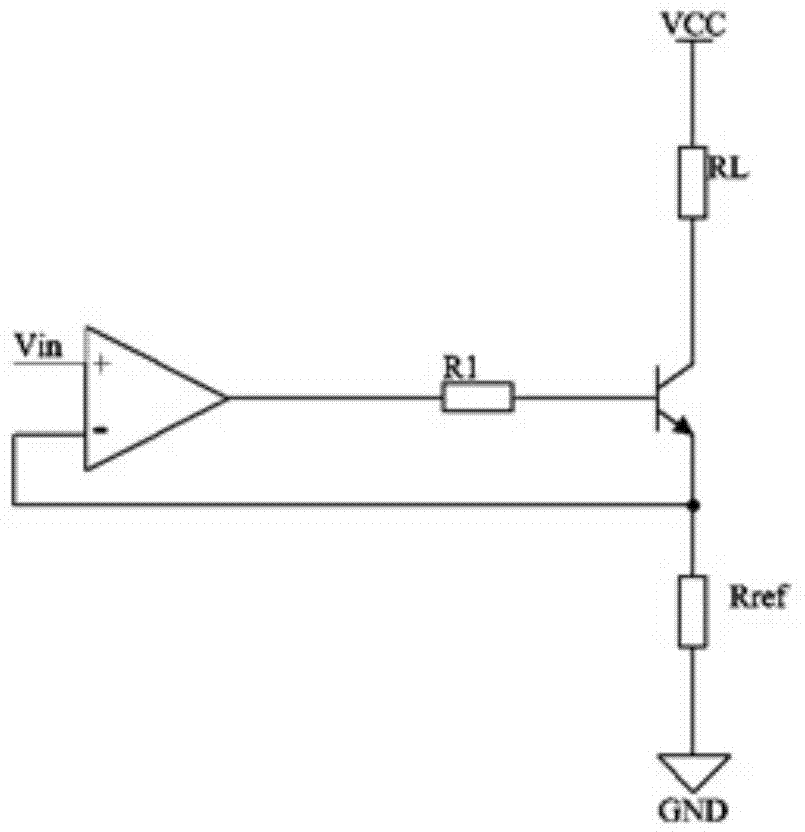

The invention relates to a liquid nitrogen temperature continuously and automatically measuring device. The measuring device is characterized by comprising a platinum resistance thermometer (1), a digital voltmeter (2), a computer control system (3) and a constant-current source (5), wherein the platinum resistance thermometer (1) is arranged on the required test temperature point and is fixed; the constant-current source (5) is placed close to the platinum resistance thermometer (1), the constant-current source (5) provides working current for the platinum resistance thermometer (1), and the output of the constant-current source (5) is connected with the two ends of a current lead of the platinum resistance thermometer (1); the digital voltmeter (2) is communicated with the computer control system (3); and a voltage testing line of the digital voltmeter (2) accesses to the voltage leads of the two ends of the platinum resistance thermometer (1), is used for testing the voltage value of the platinum resistance thermometer (1), and transmitting the detected voltage value to the computer control system (3).

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Non-conducting zirconium dioxide

ActiveUS8730002B2Good reproducibilityIncrease productionTemperature measurement in motorsThermometers using electric/magnetic elementsZirconium hydrideNiobium

A resistance thermometer is provided having a measuring resistor in a form of a 0.1 to 10 μm thick structured platinum layer applied to an electrically insulated surface of a substrate and an electrically insulating coating layer covering the platinum layer. The substrate or its surface contains zirconium dioxide, which is stabilized with oxides of a trivalent and a pentavalent metal. Preferably, the trivalent metal is yttrium and the pentavalent metal is tantalum or niobium. The characteristic curve of the measuring resistor preferably conforms to DIN-IEC 751. For mass production of resistance thermometers having high and reproducible measurement accuracy, a structured platinum layer having a thickness of 0.1 to 10 μm is applied to an electrically insulating substrate having a thermal expansion coefficient in the range of 8.5 to 10.5×10−6 / ° K and a roughness less than 1 μm, and the structured platinum layer is covered by an electrical insulator. The resistance thermometers allow precise temperature measurement between −200° C. and +850° C., preferably as a sensor in an exhaust gas treatment system. In a substance-sensitive sensor having a circuit path structure on a substrate, the circuit path structure has an epitaxially applied base layer, and a substance-sensitive metal layer attached to the epitaxially applied base layer.

Owner:HERAEUS NEXENSOS GMBH

Rotation sensor with temperature measuring feature

InactiveUS20070129908A1Thermometer detailsThermometers using material expansion/contactionEngineeringRotation sensor

A temperature sensing system (100) for use with a variable reluctance sensor such as found in vehicle wheel bearing applications, which utilizes existing sensors (12) such as the antilock braking system or traction control system sensors as a direct current resistive temperature gauge. The temperature sensing system (100) includes electrical components (R4, C1) configured to separate the DC voltage (VDC(t)) representative of sensor temperature from the original magnetically induced AC voltage output signal (VSN1(t)) representative of the rotation such as vehicle wheel speed, thereby permitting the temperature sensing system (100) to be retrofitted and installed in vehicles or other components without significant alteration to an existing wiring harness or electrical components.

Owner:THE TIMKEN CO

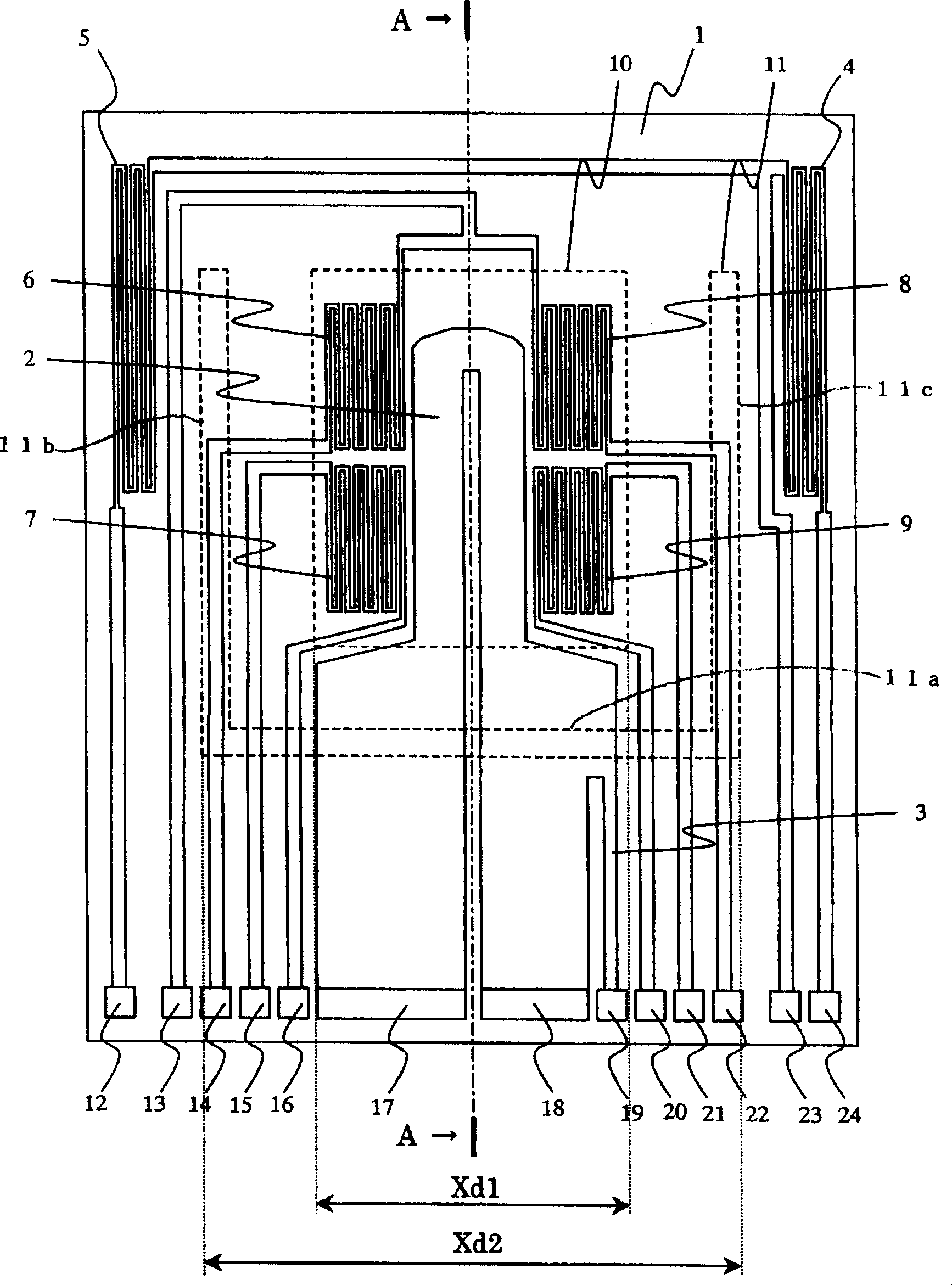

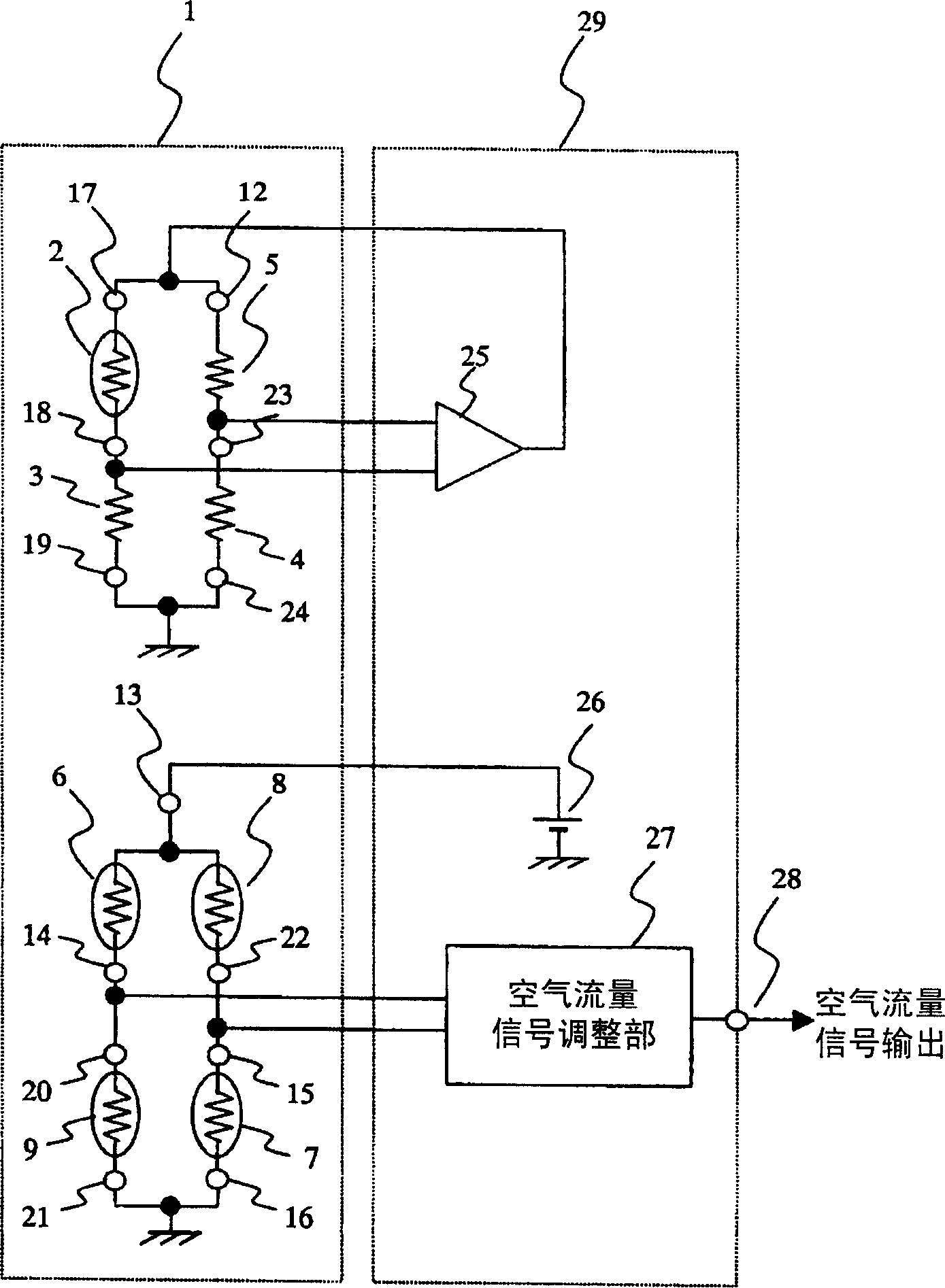

Gas flow measuring apparatus

InactiveCN1896697AAvoid sensitivityReduce stress transferVolume/mass flow by thermal effectsSemiconductor/solid-state device detailsElectrical resistance and conductanceStreamflow

To realize a gas flow rate measuring arrangement capable of suppressing the characteristic variation such as sensitivity, response by reducing stress transmission to a resister on a diaphragm without accompanying cost rise. The substrate around a diaphragm (10) is loaded with fixed resisters (3, 4) and a resistance thermometer bulb (5). These resisters are connected with exterior by terminals (12 ~ 24). To mitigate the stress transmission from a section the terminals (12 ~ 24) are arranged to the diaphragm (10), a groove (11) of U-shape is formed for length (Xd2) around the diaphragm (10). The groove (11) is formed of a horizontal groove 11a and two vertical grooves (11b, 11c). The region where the terminals (12 ~ 24) of the detection element 1 are formed and a region where the diaphragm (10) is formed are sectioned with the horizontal groove (11a) and the region where the terminals (12 ~ 24) are formed becomes a fixed part. The bottom of the fixed part is fixed to the substrate with adhesive bond and the actual stress to be transmitted to the region where the diaphragm (10) is formed is absorbed by the stress mitigating groove (11a).

Owner:HITACHI LTD

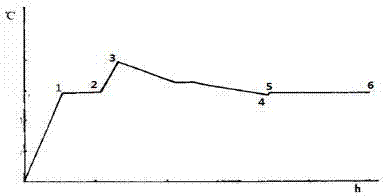

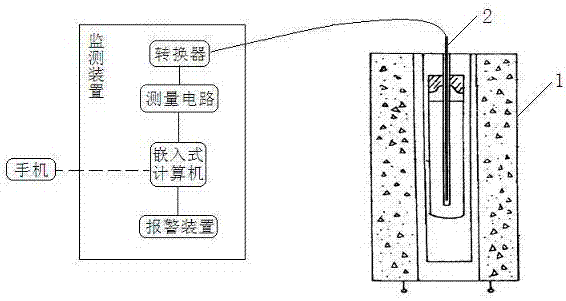

Standard platinum resistance fixed point coagulation plateau recurrence automatic monitoring device

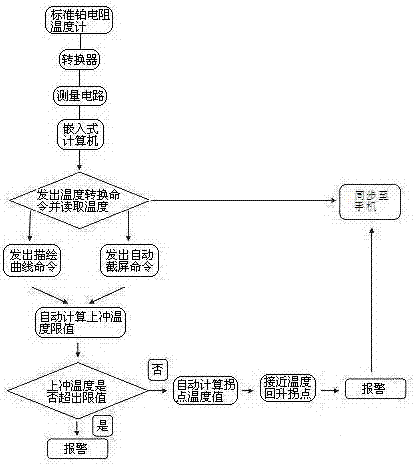

PendingCN107036736ARealize fully automatic monitoringEasy to viewThermometer testing/calibrationElectrical resistance and conductancePlatinum resistance

The invention relates to a standard platinum resistance fixed point coagulation plateau recurrence automatic monitoring device, including a converter, a measurement circuit, an embedded computer and an alarming device. The monitoring device is connected with a standard platinum resistance thermometer placed in a fixed point device through the converter, and sends a measurement value into the embedded computer for achieving monitoring via the measurement circuit. The embedded computer comprises a curve generation unit and a storage unit, the curve generation unit generates a time-temperature curve according to the obtained measurement value, and the storage unit automatically records the temperature plateau maintenance time and the corresponding temperature point and automatically cuts out the temperature plateau curve. The embedded computer also comprises an increased temperature generation unit capable of calculating the increased temperature range, and an inflection point calculation unit capable of calculating the inflection point temperature value. The standard platinum resistance fixed point coagulation plateau recurrence automatic monitoring device achieves automatic monitoring of standard platinum resistance fixed point coagulation plateau recurrence.

Owner:SHANDONG MEASUREMENT SCI RES INST

Device for measuring heat conductivity coefficient of powder on basis of transient plane heat source method

PendingCN106706701AThe thermal conductivity is quickly obtainedMaterial heat developmentElectrical resistance and conductanceEngineering

The invention discloses a device for measuring the heat conductivity coefficient of powder on the basis of a transient plane heat source method. The device comprises a vacuum container and a constant temperature system, wherein the vacuum container is arranged in the constant temperature system and comprises a vacuum container drum body, a vacuum container upper flange and a vacuumizing pipe; and the vacuum container drum body internally comprises a powder sample rack, a testing probe, a PT100 platinum resistance thermometer and a fixed ring. Compared with the traditional method for measuring the heat conductivity coefficient of the powder, the device disclosed by the invention has the advantages that the heat conductivity coefficient of a powdery insulating material can be rapidly obtained; and the heat conductivity coefficient of the powdery insulating material at certain temperature and vacuum degree can be measured, the testing temperature ranges from 30K to 473K, and the vacuum degree ranges from 10<-3>Pa to 1atm.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

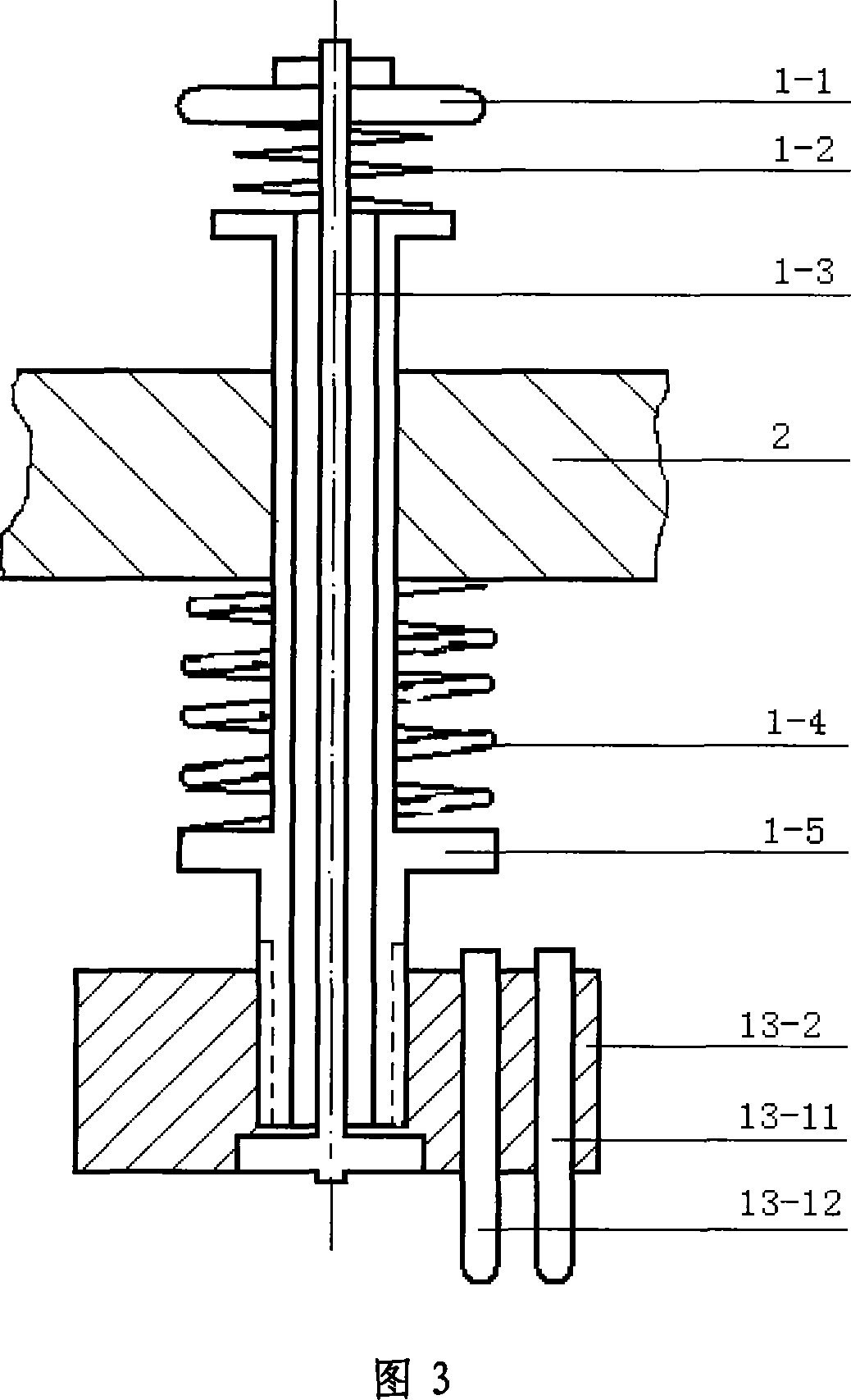

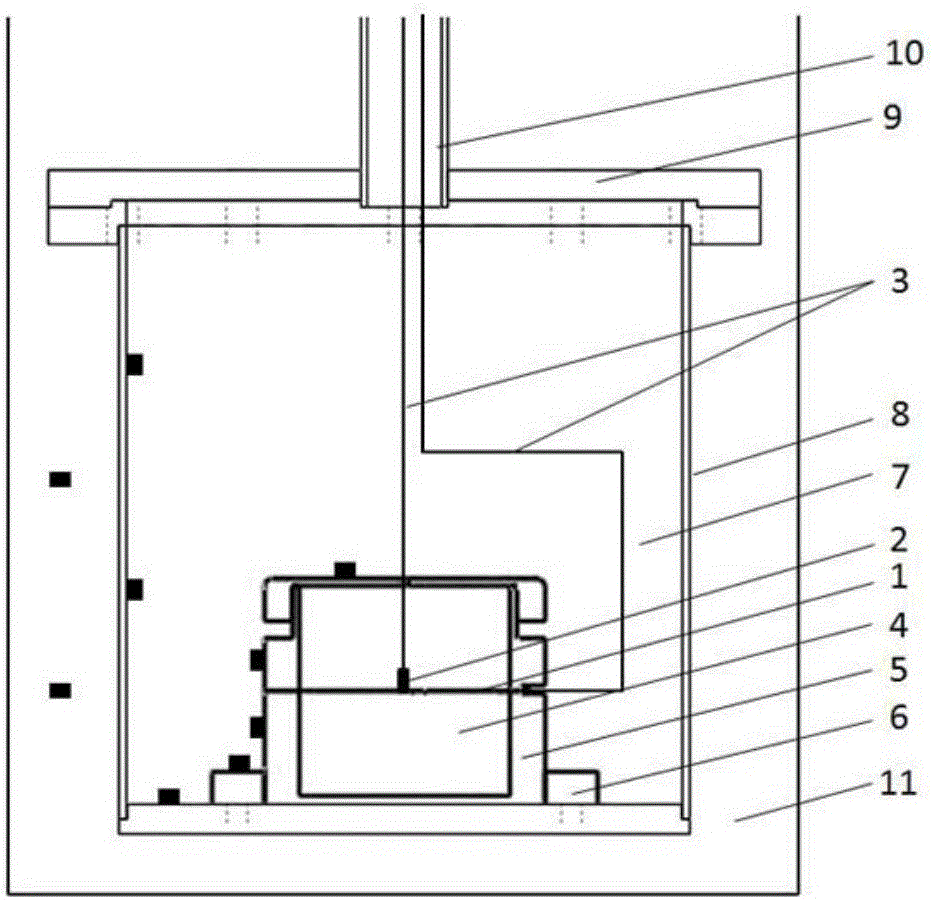

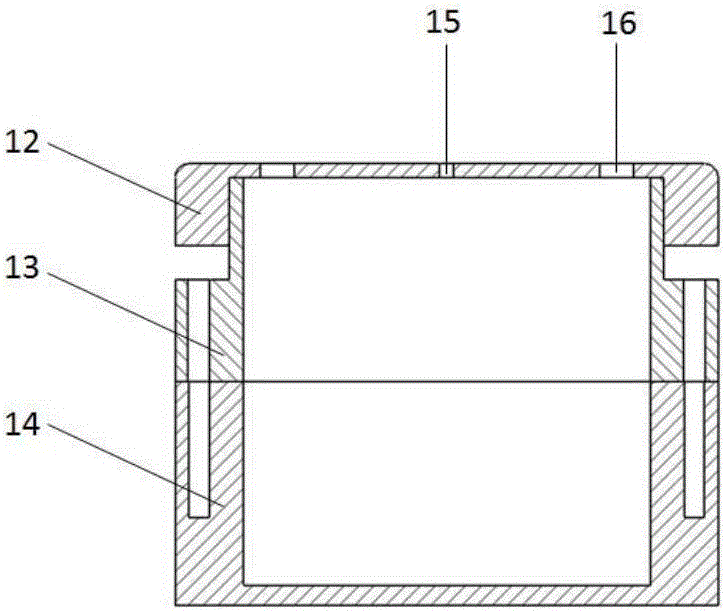

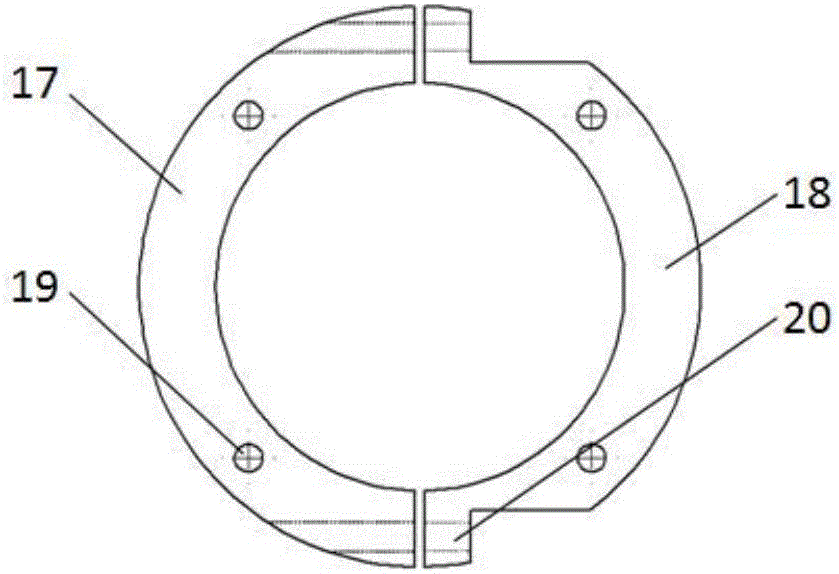

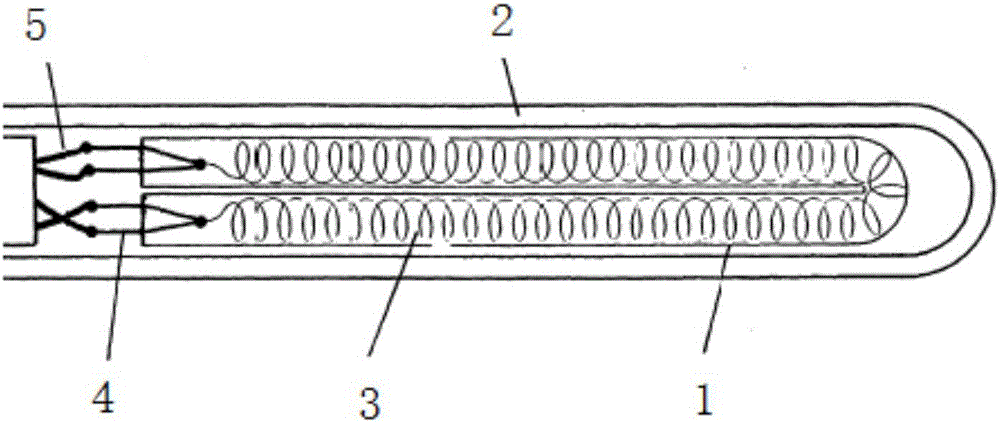

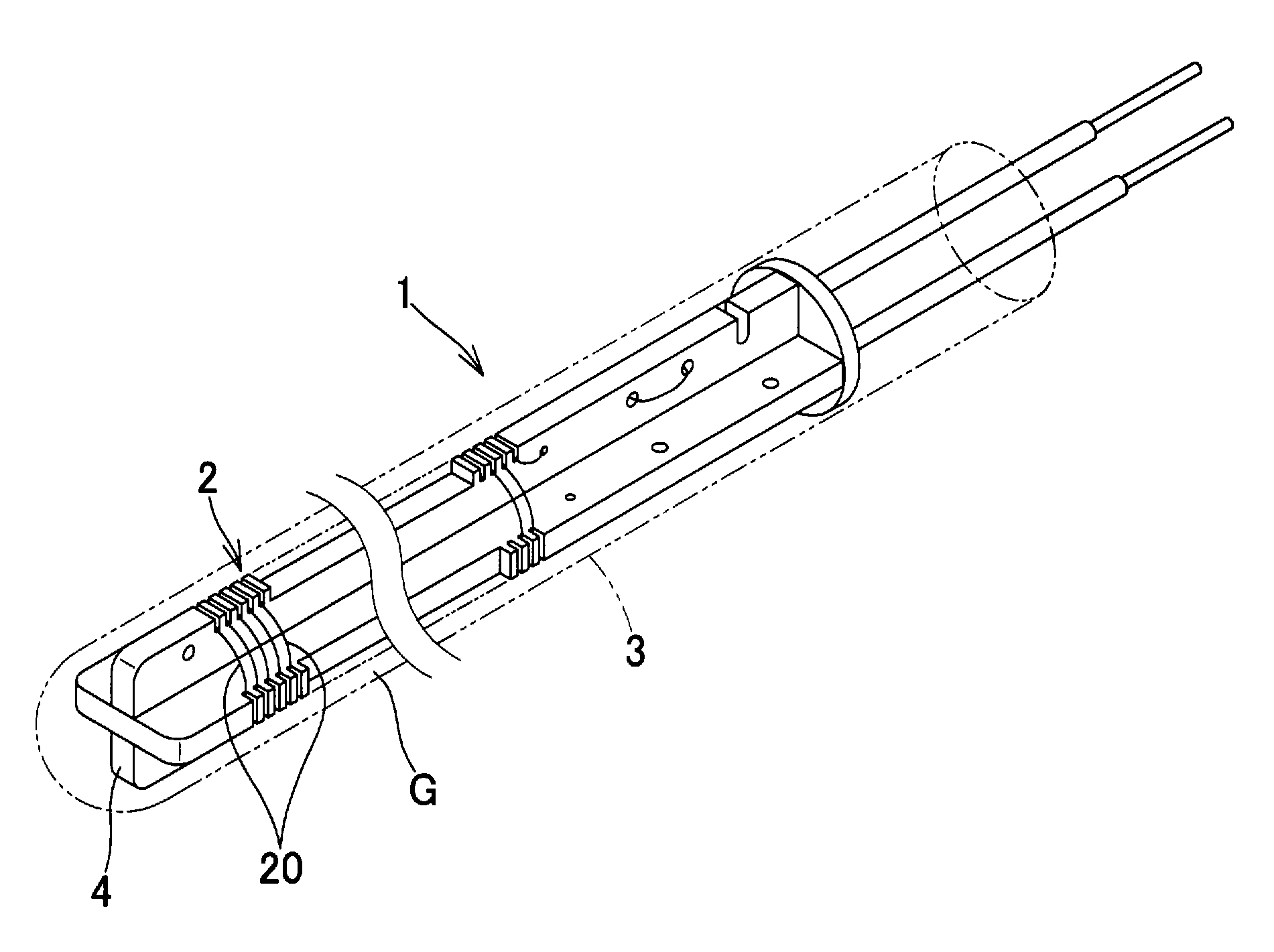

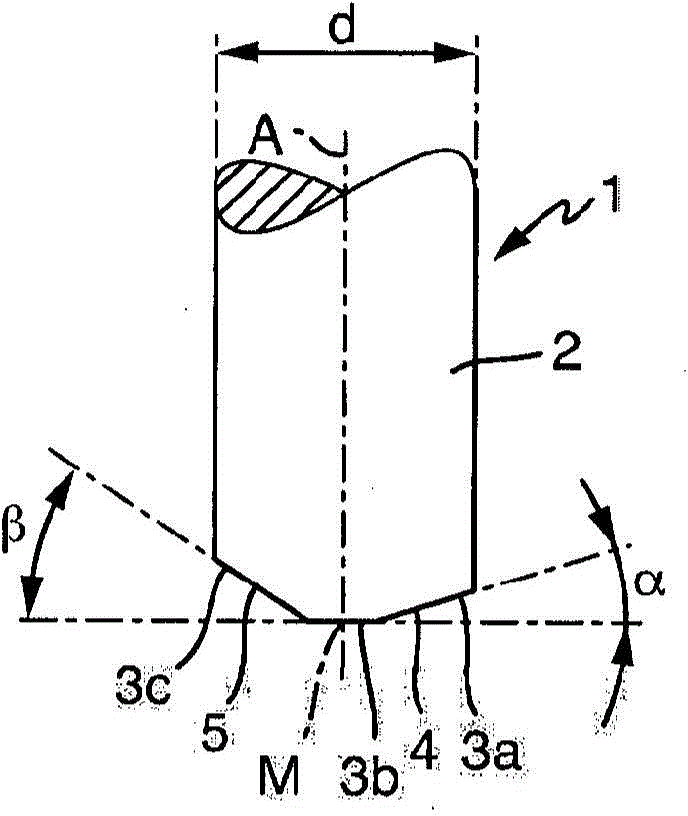

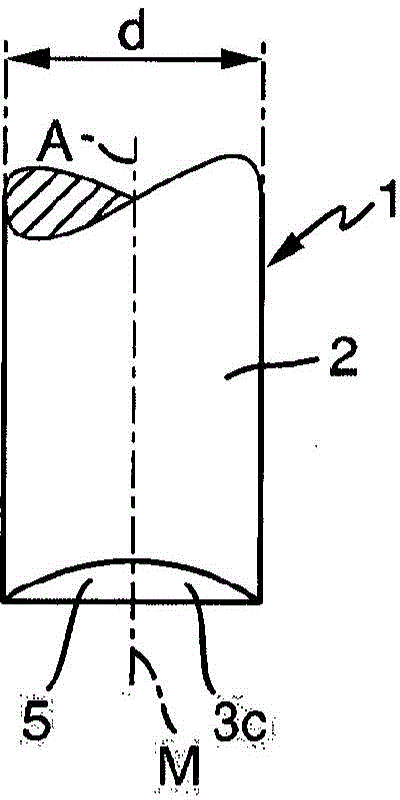

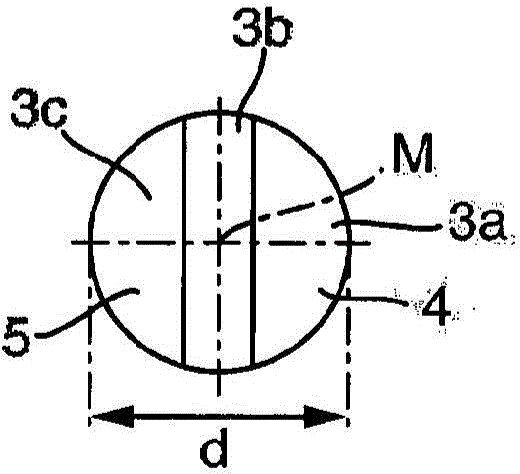

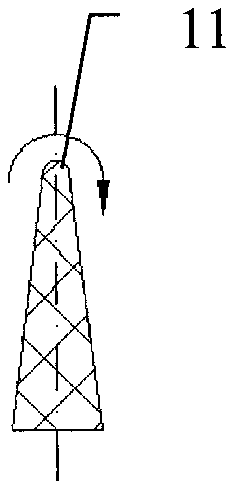

Novel standard rhodium-iron resistance thermometer

PendingCN106568522ALong-term temperature measurementLong-term stabilityThermometers using electric/magnetic elementsUsing electrical meansTemperature controlEngineering

The invention relates to a novel standard rhodium-iron resistance thermometer, which comprises a housing, a cross-shaped skeleton, lead wires and a rhodium-iron resistance wire, wherein the cross-shaped skeleton is arranged in the housing; the rhodium-iron resistance wire is wound on the cross-shaped skeleton; and the rhodium-iron resistance wire is led out through the lead wires. The novel standard rhodium-iron resistance thermometer adopts the cross-shaped skeleton to wind the wire and is capable of realizing both temperature sensing wire support and free telescoping; the thermometer is good in stability, stable in structure, and high in resistance to vibration and impact; the skeleton is made of a quartz material, wherein the material is stable in components and does not pollute the resistance wire; and temperature measurement and temperature control stability of the standard rhodium-iron resistance thermometer can be kept for a long term.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

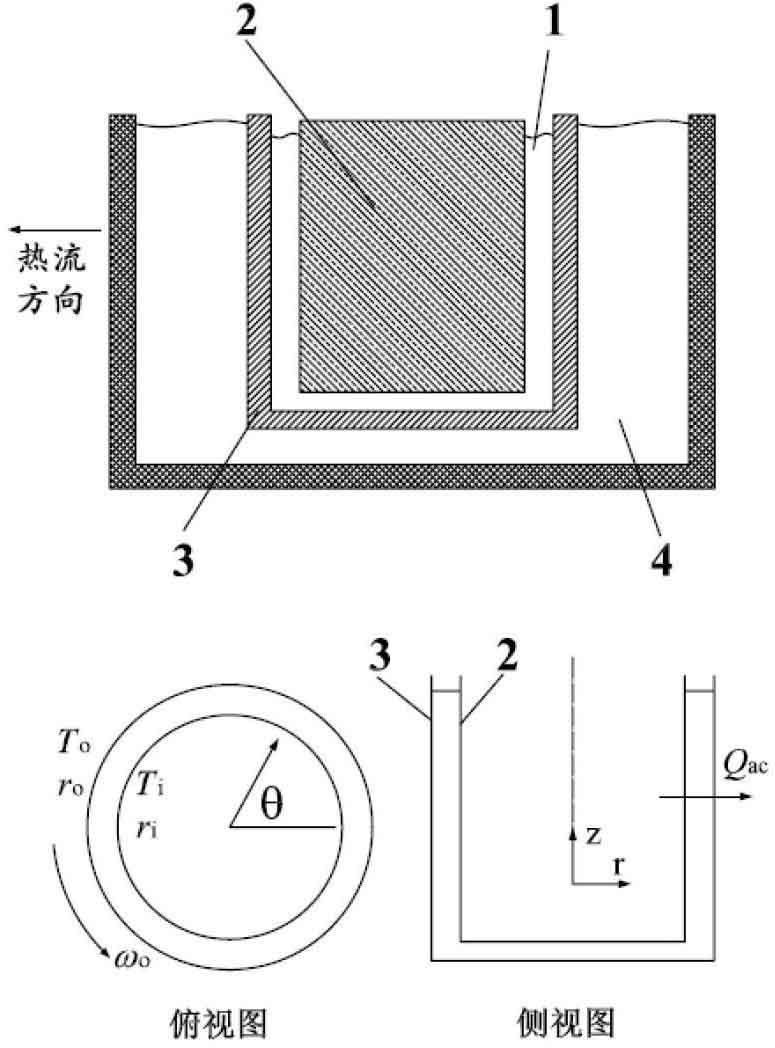

Measuring device for equivalent thermal conductivity of non-Newtonian fluid in shear flow

ActiveCN102680513AAnalyzing Flow EffectsMaterial heat developmentWater bathsThermal conductivity measurement

The invention discloses a measuring device for the equivalent thermal conductivity of a non-Newtonian fluid in a shear flow. The measuring device comprises a rotating system and a heating system, wherein the rotating system consists of two coaxial cylinders; the inner cylinder is fixed and the outer cylinder rotates; the heating system comprises a heating film attached to the inner wall of the inner cylinder and is connected with an adjustable direct current power supply; a resistance thermometer connected with a temperature display screen is also arranged on the inner cylinder; a circulating cup filled with constant temperature water is arranged on the outer side of the outer cylinder; a thermoelectric thermometer is arranged in the constant temperature water close to the wall surface of the outer cylinder; a water inlet pipe and a water outlet pipe are arranged on the circulating cup; and the constant temperature water is connected with a constant temperature water bath through the water inlet pipe and the water outlet pipe. According to the measuring device disclosed by the invention, the equivalent thermal conductivity of the typical non-Newtonian fluid at different shear speed rates can be completely and accurately measured.

Owner:XI AN JIAOTONG UNIV

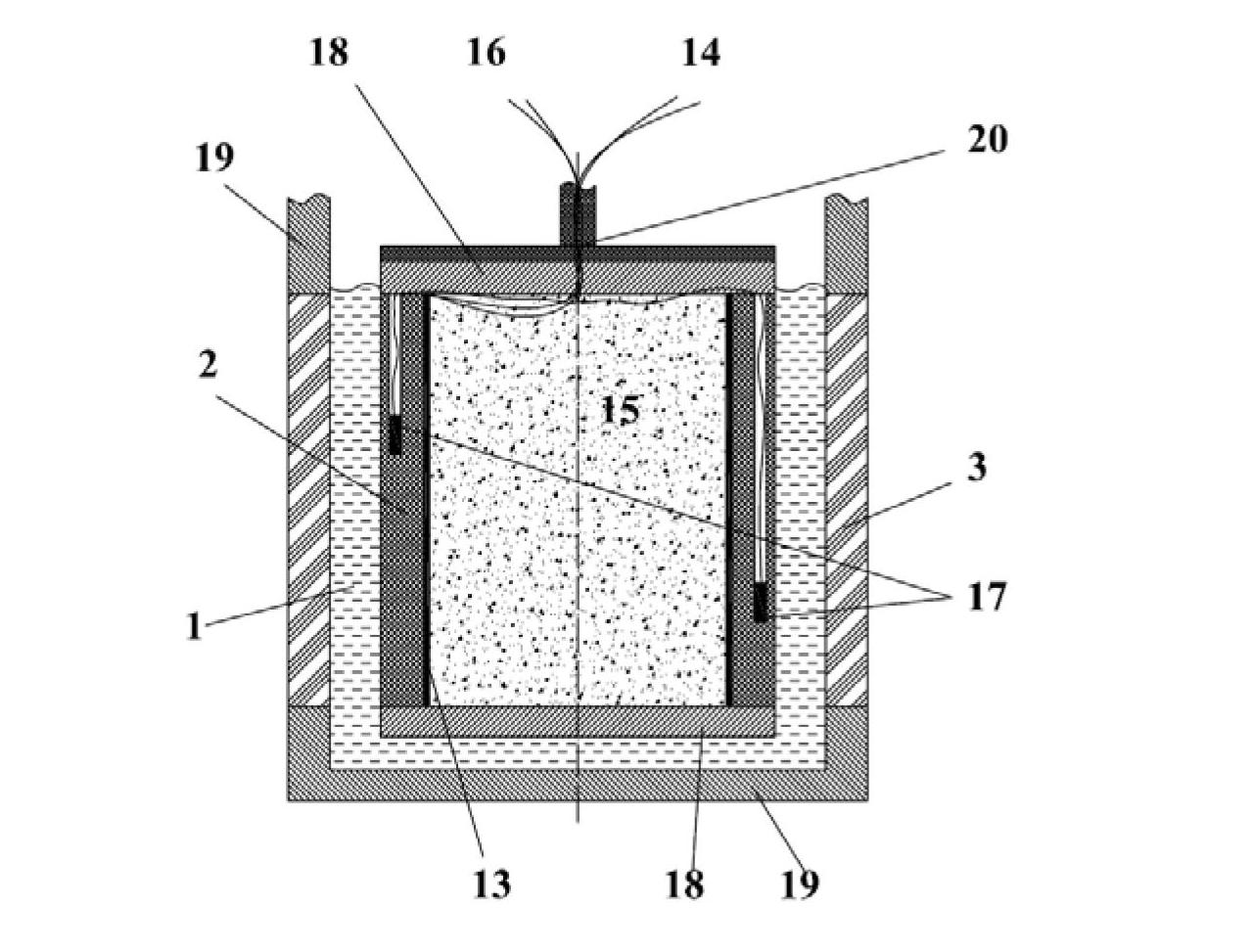

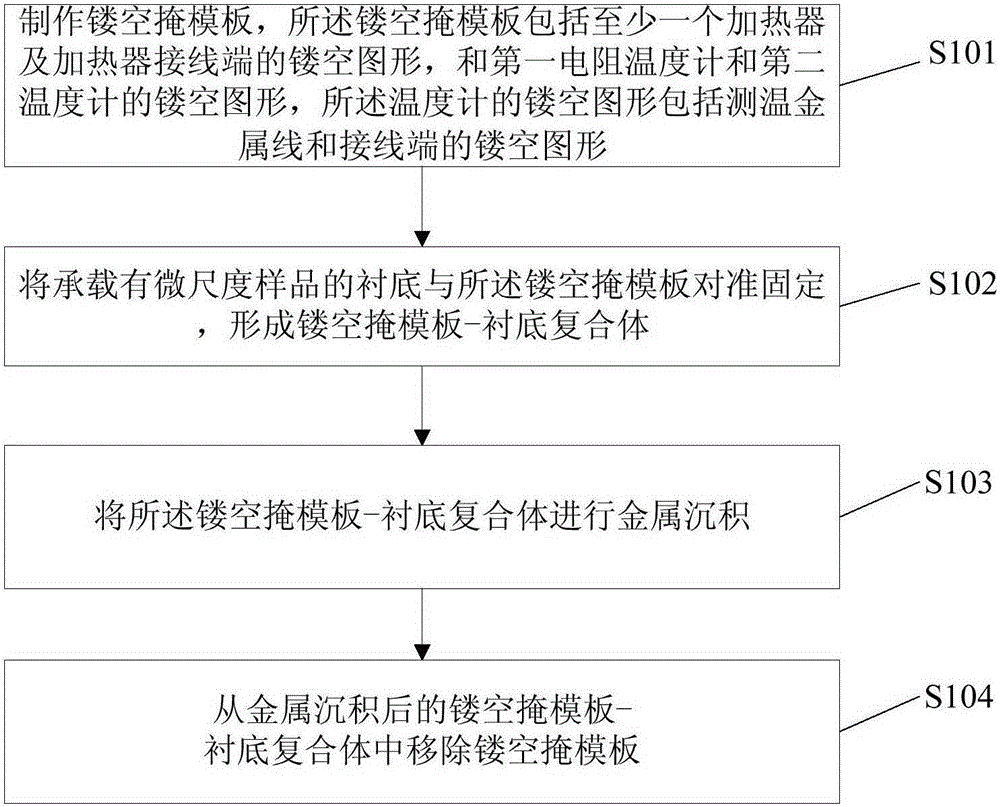

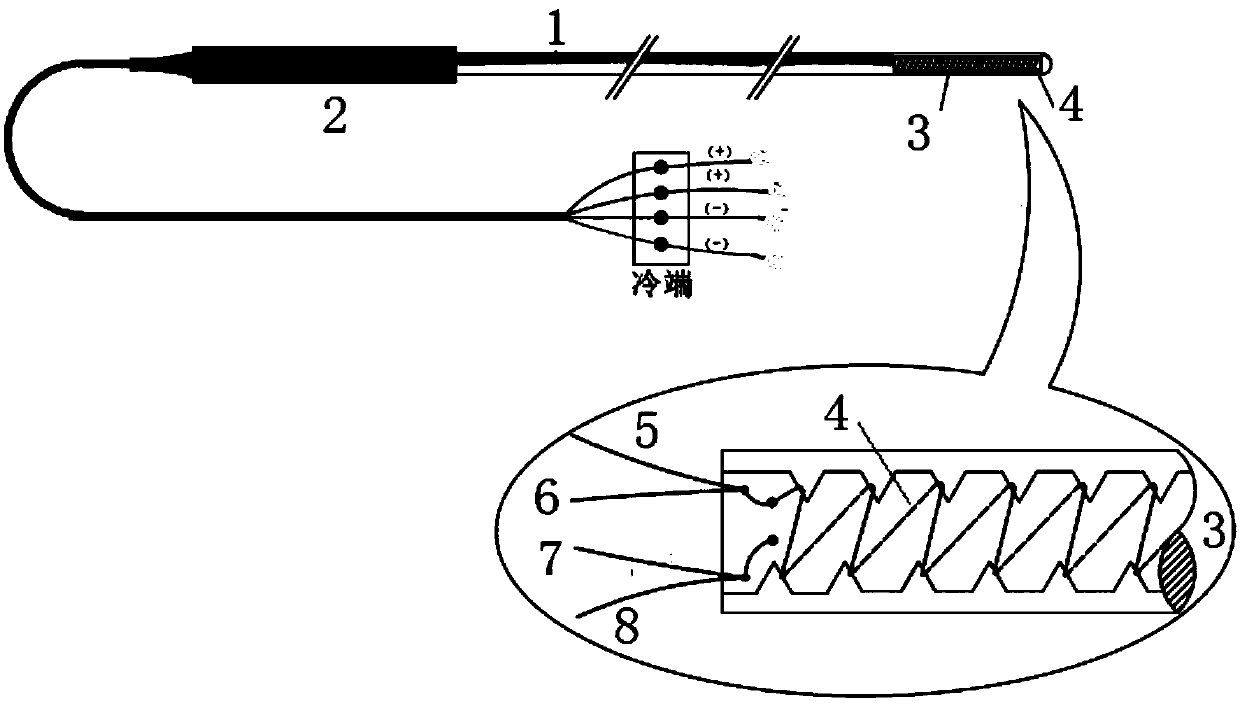

Manufacturing method of micro measuring electrode, measuring method of thermoelectrical potential and related device

ActiveCN105203825AImprove reliabilityAvoid changing situationsCurrent/voltage measurementManufacture of electrical instrumentsElectrical resistance and conductanceEngineering

The embodiment of the invention discloses a manufacturing method of a micro measuring electrode, a measuring method of thermoelectrical potential and a related device. The manufacturing method of the micro measuring electrode includes the following steps that: a hollowed mask plate is manufactured, wherein the hollowed mask plate comprises at least one heater, hollowed patterns of heater wiring ends, and hollowed patterns of a first resistance thermometer and a second thermometer, wherein the hollowed patterns of the thermometers include temperature measuring metal wires and hollowed patterns of wiring ends; a substrate carrying a micro-scale sample is aligned with and fixed to the hollowed mask plate, so that a hollowed mask plate-substrate complex can be formed; metal deposition is performed on the hollowed mask plate-substrate complex; and the hollowed mask plate is removed. With the manufacturing method of the micro measuring electrode provided by the technical schemes of the invention adopted, modification of thermoelectric transport properties of the sample, which is caused by chemical pollution generated by a photoetching-stripping process can be avoided, and therefore, the reliability of measurement of the thermoelectric transport properties of the micro-scale sample can be improved.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

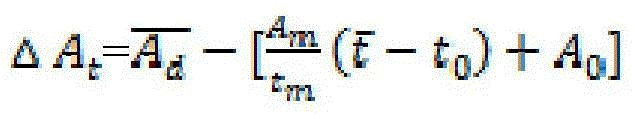

Method for increasing measured seebeck coefficient accuracy of thermoelectric material

InactiveCN104122469AGuaranteed accuracyEnsure accuracy andElectrical testingMaterial thermal analysisTemperature controlElectrical resistance and conductance

Disclosed is a method for increasing measured seebeck coefficient accuracy of a thermoelectric material. The resistance of electrical resistance thermometers is measured by a four-wire method, lead resistance is effectively eliminated, reading accuracy of the electrical resistance thermometers can be guaranteed, the temperature control accuracy is increased through a PID temperature control algorithm, temperatures of two ends of the thermoelectric material can be accurately adjusted to a required numerical value, according to a temperature backward method, the influence of parasitic potential on a measuring result can be eliminated, and the measured seebeck coefficient accuracy can be guaranteed. According to the method for increasing the measured seebeck coefficient accuracy of the thermoelectric material, measuring accuracy is guaranteed in a series of measuring steps of measuring the temperature of the thermoelectric material, changing the temperature values of the two ends of the thermoelectric material, eliminating the parasitic potential and the like, and the method for increasing the measured seebeck coefficient accuracy of the thermoelectric material is effective, easy to implement and significant to application occasions with high requirements for the seebeck coefficient accuracy.

Owner:SHANDONG UNIV

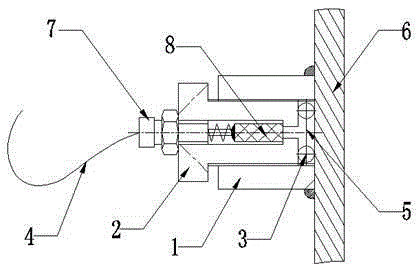

Insulation type bus shell temperature measurement installation structure

The invention discloses an insulation type bus shell temperature measurement installation structure. The structure comprises an installation seat, an insulation block, a heat conduction cavity, a temperature probe, an enclosed busbar shell, and a platinum resistance thermometer, the installation seat is fixed on the enclosed busbar shell, the installation seat is provided with threads, the insulation block is a hollow internal and external thread structure, an outer wall of the insulation block is connected with the installation seat through external threads, the upper edge of the insulation block is connected with the temperature probe through internal threads, the heat conduction cavity is reserved between the insulation block and the enclosed busbar shell, and the temperature probe is connected with a signal output cable through the platinum resistance thermometer. According to the installation structure, the structure is simple, the design is reasonable, the temperature of the heat conduction cavity attached to the busbar shell is directly detected by employing the temperature probe, the temperature of the busbar shell is further obtained, and the structure can achieve a protection effect of effectively preventing the electromagnetic impact on the probe.

Owner:江苏大全封闭母线有限公司

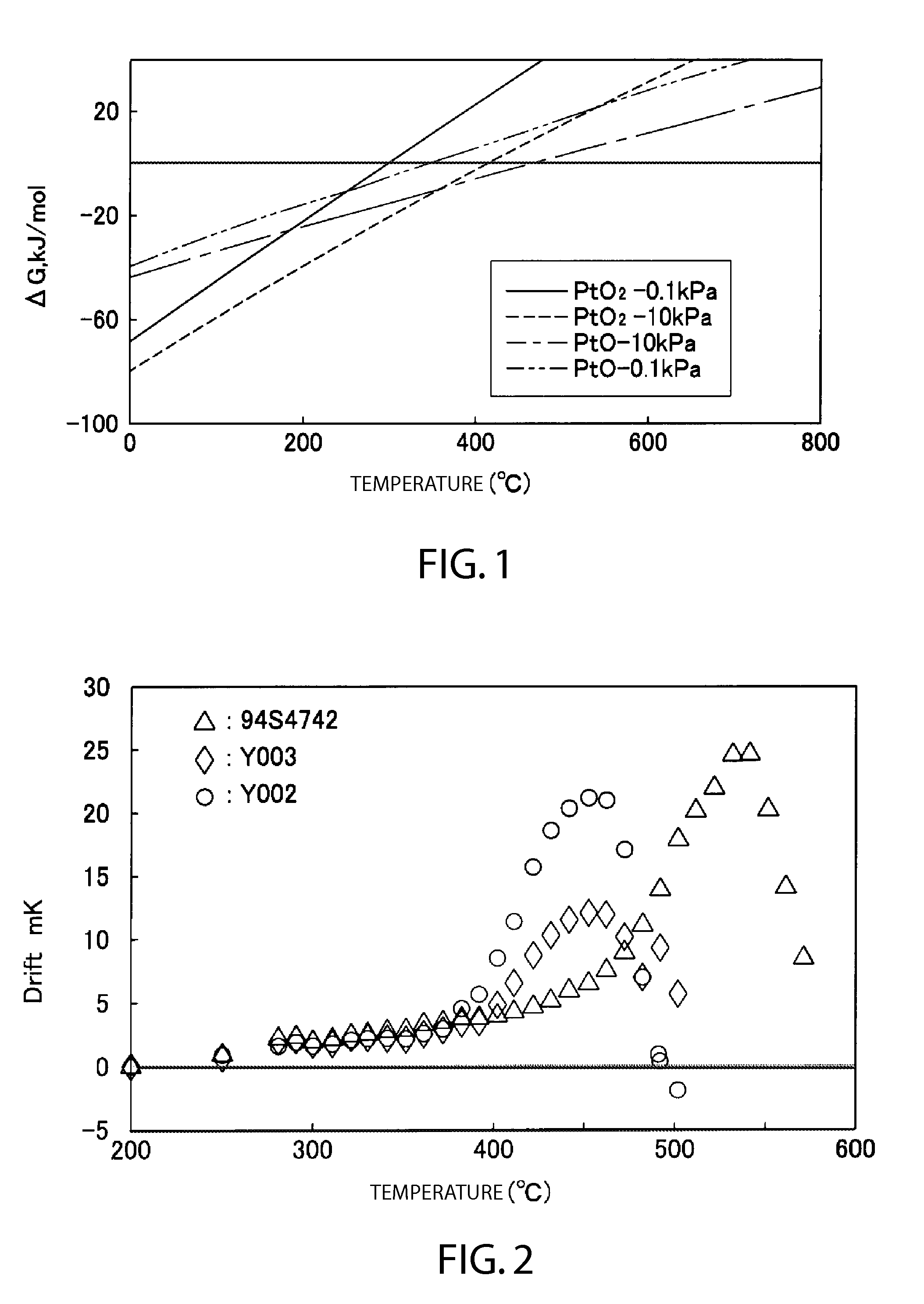

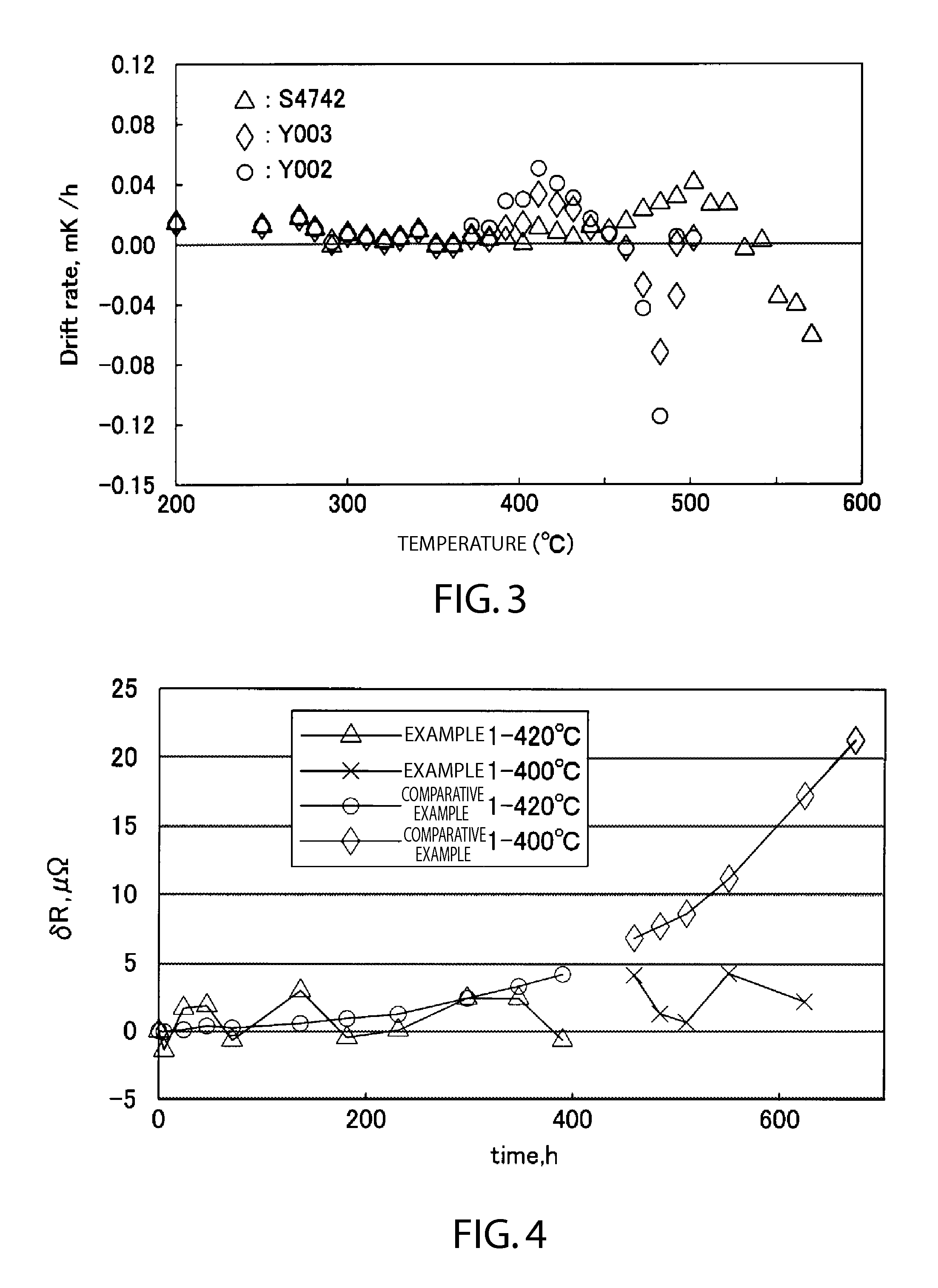

Process for manufacturing platinum resistance thermometer

InactiveUS20100150204A1Little change in resistance valueStable resistanceThermometer detailsThermometers using electric/magnetic elementsPlatinum resistanceFree energies

A process for manufacturing a platinum resistance thermometer that is stable with reduced resistance value variation over service temperature range through clarification of a quantitative mechanism of resistance value variation with respect to the oxidation / reduction of platinum resistance wire. The process including the steps of (S1) enclosing a purge gas containing an inert gas and oxygen in a protection tube provided with a thermosensitive part of platinum resistance wire; (S2) raising the internal temperature of the protection tube to a temperature region in which the platinum is in reduced form at a partial pressure of oxygen in the purge gas as determined from platinum oxide formation free energy; (S3) replacing the purge gas with an inert gas wherein oxygen is 1 kPa or below; and (S4) sealing the protection tube under the replaced condition.

Owner:YAMATAKE HONEYWELL CO LTD

Thermal flow rate measurement device

ActiveCN104797941ADetermine and/or monitor mass flowVolume/mass flow measurementFluid speed measurement using thermal variablesElectrical resistance and conductanceEngineering

Owner:ENDRESS HAUSER FLOWTEC AG

Device for testing performance of high-sensitivity infrared remote sensors

ActiveCN106781430AHigh temperature control accuracyImprove temperature measurement accuracyNon-electrical signal transmission systemsInfrared remote sensingPerformance index

The invention provides a device for testing performance of high-sensitivity infrared remote sensors. The performance index that the heterogeneity of an infrared calibration radiation source is superior to 0.005 DEG C and the stability of accurately-measured temperature is superior to 0.01 DEG C is realized through combination of a liquid tank radiation source with extremely high temperature uniformity and extremely high stability, a high-accuracy electrical bridge and a standard platinum resistance temperature gauge. Compared with the existing blackbody products, the radiation uniformity and the stability are better; the influence of various adverse factors on the accuracy of test results in the testing process can be reduced; the requirements on performance test of various remote sensors with increasingly high sensitivity can be better met.

Owner:BEIJING RES INST OF SPATIAL MECHANICAL & ELECTRICAL TECH

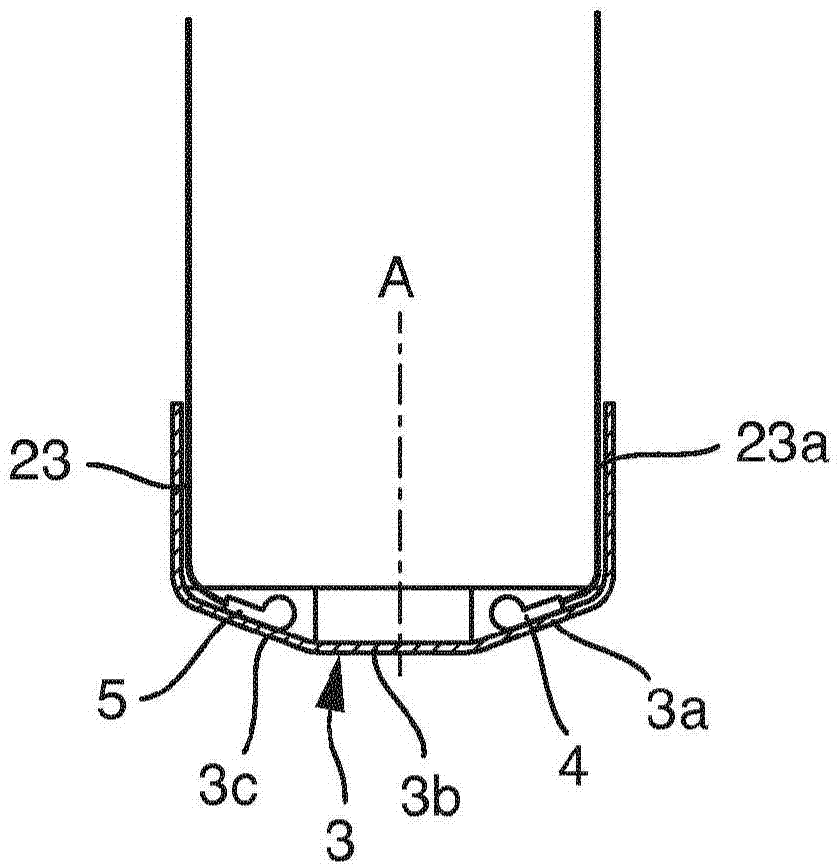

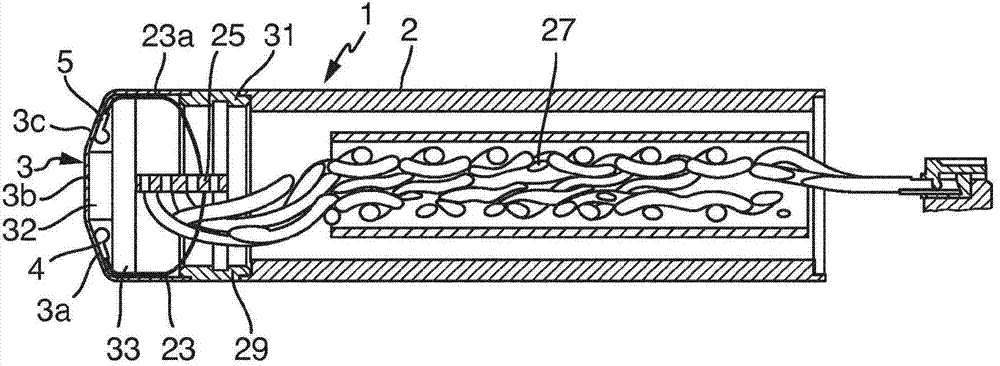

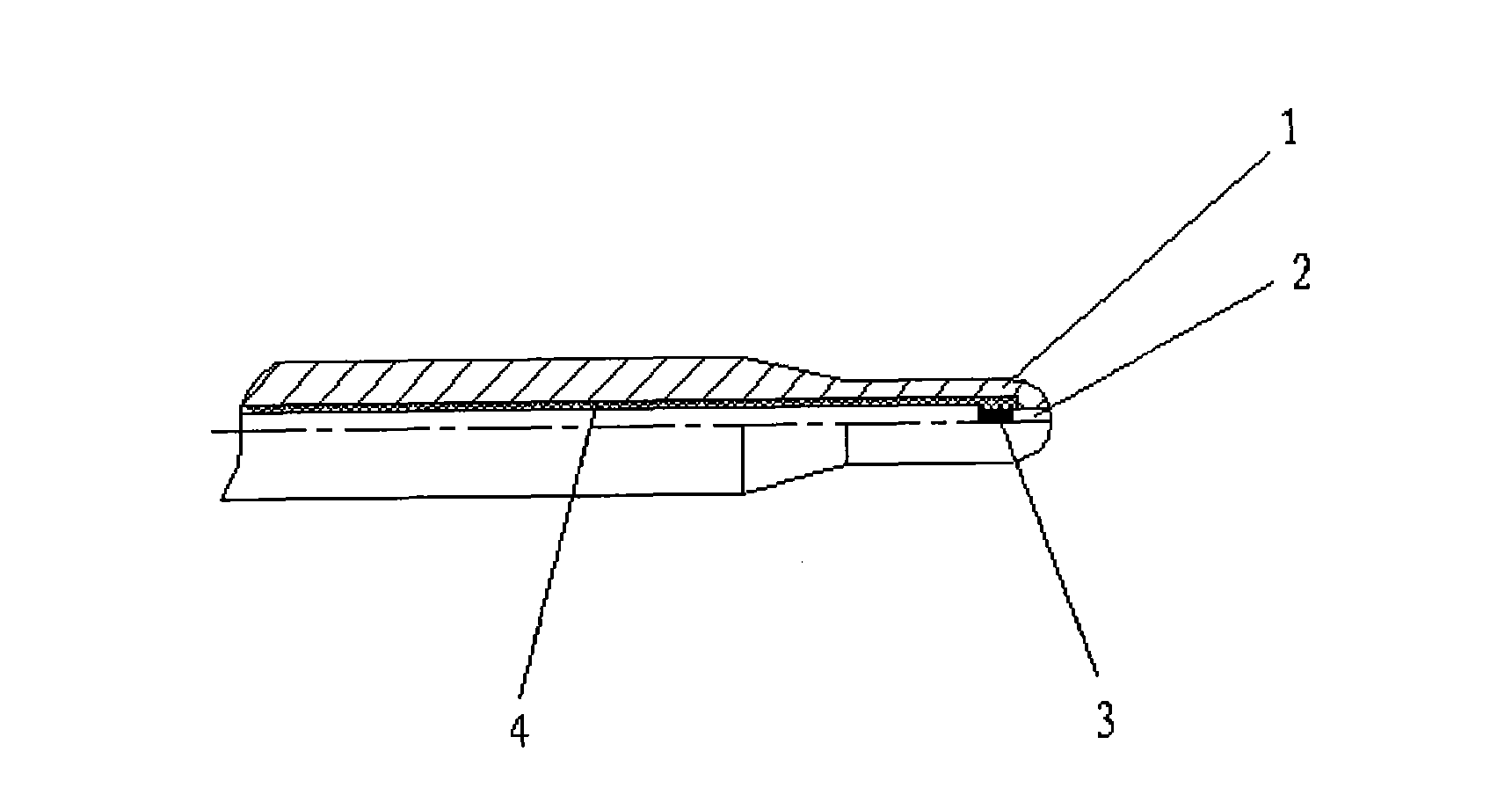

Temperature sensor and thermal flow rate measurement device

ActiveCN104736980AAvoid separationThermometer detailsThermometers using electric/magnetic elementsElectrical resistance and conductanceTwo temperature

The invention relates to a temperature sensor having a housing (1), comprising a housing body and a housing chamber, in which housing chamber two temperature sensor elements are arranged at each end, which temperature sensor elements are in particular formed as thin-film resistance thermometers (4 or 5), wherein one of the temperature sensor elements can be heated, wherein at least one connection wire (23) leads from each temperature sensor element, which connection wire is connected to a printed circuit board (25), wherein the printed circuit board (25) is arranged in the housing chamber (1), wherein the printed circuit board (25) is positioned in said housing chamber by means of a latch connection (28), wherein a connection wire (23a) of a first temperature sensor element is routed in a strain-relieved manner in a first direction through the printed circuit board (25) and is connected to the latter, wherein the housing chamber has at least one first elastic body for routing the connection wire (23) and / or wherein the printed circuit board (25) is arranged in the housing chamber, wherein the printed circuit board (25) has a first number of material cut-outs, in particular holes, for the connection of connection wires and / or cables and a second number of material cut-outs, in particular holes, for reducing the thermal expansion of the printed circuit board, and a thermal flow rate measurement device.

Owner:ENDRESS HAUSER FLOWTEC AG

Self-calibrated double-thermocouple thermometer based on standard platinum resistance thermometer, and temperature measuring method implemented by self-calibrated double-thermocouple thermometer

InactiveCN109540316AAccurate temperature measurementThermometers using electric/magnetic elementsUsing electrical meansEngineeringThermocouple

The invention relates to a self-calibrated double-thermocouple thermometer based on a standard platinum resistance thermometer. The self-calibrated double-thermocouple thermometer comprises a casing,a handle part matched with the casing, and a platinum resistance temperature-sensing element located in the casing, wherein the platinum resistance temperature-sensing element comprises a first end and a second end; the first end of the platinum resistance temperature-sensing element is connected with a first thermocouple; and the second end of the platinum resistance temperature-sensing element is connected with a second thermocouple. The self-calibrated double-thermocouple thermometer provided by the invention has the advantages that online calibration of the thermocouples can be achieved through the platinum resistance temperature-sensing element, and the two thermocouples can be checked by each other, so that temperature measuring is quick and accurate.

Owner:NAT INST OF METROLOGY CHINA

Manufacture method for membrane resistance thermometer

ActiveCN102749148AAccurate measurementAvoid destructionThermometers using electric/magnetic elementsVacuum evaporation coatingLeading edgePlatinum

The invention discloses a manufacture method for a membrane resistance thermometer. The membrane resistance thermometer is used for measuring sharp leading-edge stagnation heat flux. The manufacture method for the membrane resistance thermometer comprises the following steps of: cleaning a glass substrate which comprises a sharp leading edge; (2) plating a platinum membrane on the sharp leading edge of the glass substrate along the length direction of the glass substrate; (3) carrying out thermal treatment to the platinum membrane to age the platinum membrane; (4) coating silver slurry on the glass substrate, and drying and sintering the sliver slurry; and (5) plating a Gamma alloy membrane on the sharp leading edge along the circumference of the sharp leading edge, then plating a silver membrane on the Gamma alloy membrane, and connecting two ends of the platinum membrane with the sliver slurry by the silver film. With the method disclosed by the invention, a purpose of plating the membrane on the sharp leading edge part can be realized, so that the film becomes firmer and more resistant to cleaning, and therefore the sharp leading-edge stagnation heat flux can be more accurately measured.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

Wear-resistant quick temperature measuring platinum resistance thermometer

InactiveCN102062643AFast thermal response timeImprove temperature measurement accuracyThermometers using electric/magnetic elementsUsing electrical meansPlatinum resistanceWear resistant

The invention discloses a wear-resistance quick temperature measuring platinum resistance thermometer, which comprises a wear-resistant protecting tube and a platinum resistance thermometer arranged in the protecting tube, and is characterized in that: in the protecting tube, a quick heat conducting body connected with the platinum resistance thermometer is arranged at the temperature sensing end; the platinum resistance thermometer is tightly matched with the inner wall of the protecting tube; and a heat conducting material is filled in small gaps between the platinum resistance thermometer and the inner wall of the protecting tube. The wear-resistance quick temperature measuring platinum resistance thermometer has the advantages that: by selecting the material of the protecting tube and the platinum resistance thermometer, the wear resistance and corrosion resistance are improved by more than three times compared with those of the conventional wear-resistant protecting tube; and the platinum resistance thermometer is tightly matched with the protecting tube, the heat conducting material is filled in the gaps, and the quick heat conducting body is arranged at the temperature sensing end (heat end) of the protecting tube, so that the heat conductivity is improved by 8 times. The wear-resistance quick temperature measuring platinum resistance thermometer has a compact structure, has the thermal response time of less than 5 seconds, meets the performance requirements for corrosion resistance and wear resistance in the tyre rubber vulcanizing process, improves the effect of quickly and accurately measuring temperature of a temperature sensor, is convenient and practical to use, and has obvious effect.

Owner:上海岗崎控制仪表有限公司

Method for measuring temperature of test piece in thermo-electric-force coupling test system

InactiveCN109100043ASimple structureLow priceThermometers using electric/magnetic elementsUsing electrical meansElectric forceMeasuring instrument

The invention discloses a method for measuring temperature of a test piece in a thermo-electric-force coupling test system, and relates to electronic package material mechanical property testing technology. The test piece is welded by two copper rods and clamped on a stretcher. A certain intensity current is applied to the test piece at the same time. The rmocouple thermometer and thermal resistance thermometer cannot directly contact the surface of the test piece since the test piece itself passes a relatively strong current. Before the test begins, the test piece is gauged by using a verniercaliper, and two contacts of a voltage measuring instrument is connected to two ends of the gauge length to measure voltage drop in the gauge length; the segment comprises solder joints to accuratelymeasure the voltage drop; and the temperature-voltage relationship of the test piece is calculated according to the resistivity-temperature curve of the copper and SAC305 solder, combined with the cross-sectional shape of the test piece and the gauge length to obtain the corresponding relationship between the temperature and the voltage drop of the test piece. The method for measuring temperatureof the test piece is simple, and has high measurement accuracy and is easy to test and record.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com