Nuclear grade platinum resistance thermometer and its method for reducing thermal response time

A platinum resistance thermometer technology, applied in the field of temperature measurement instruments, can solve the problems of long thermal response time, large thermal inertia, poor thermal conductivity of MgO powder, etc. of platinum resistance thermometers, and achieve the effect of reducing thermal response time and improving thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

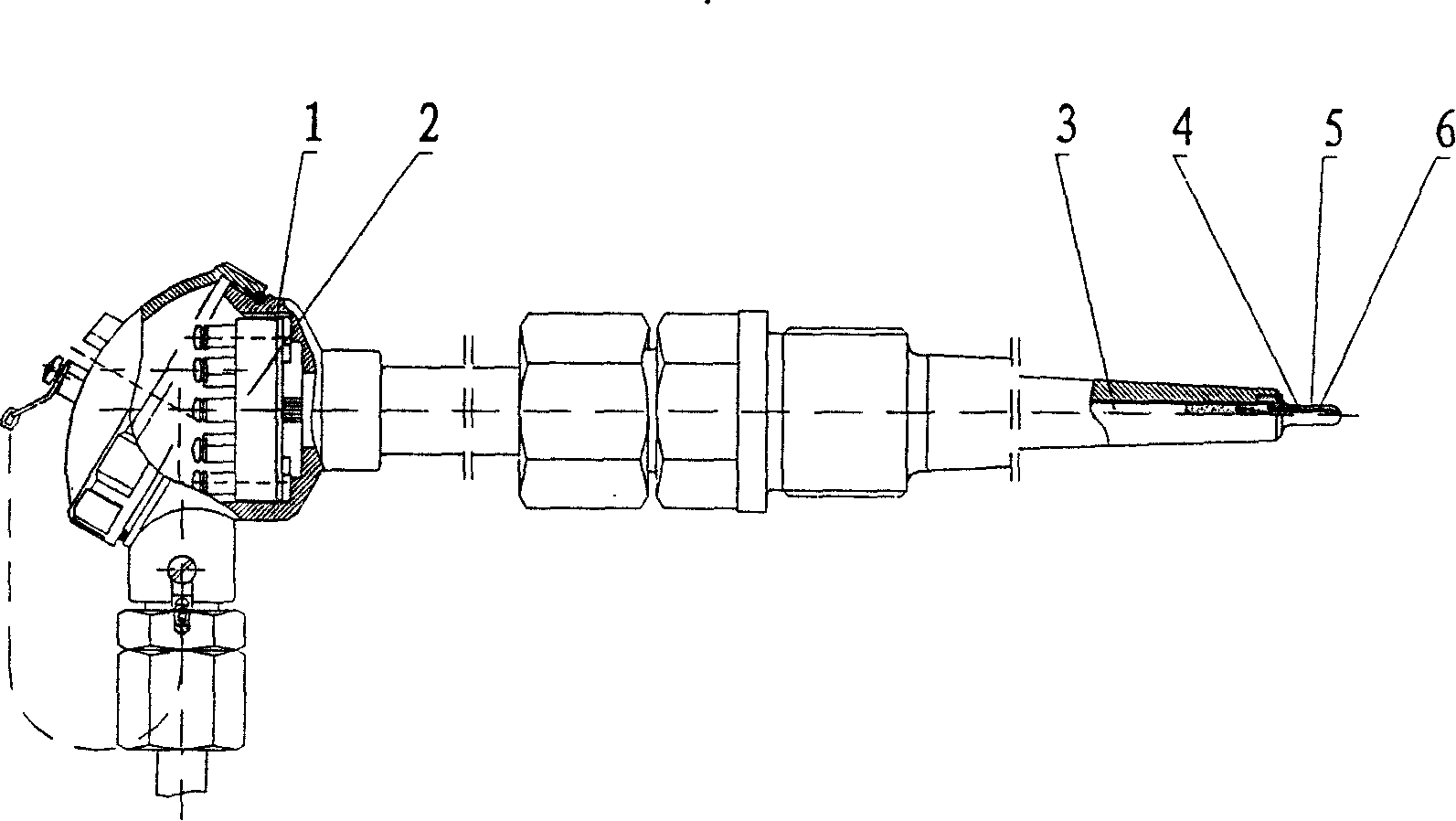

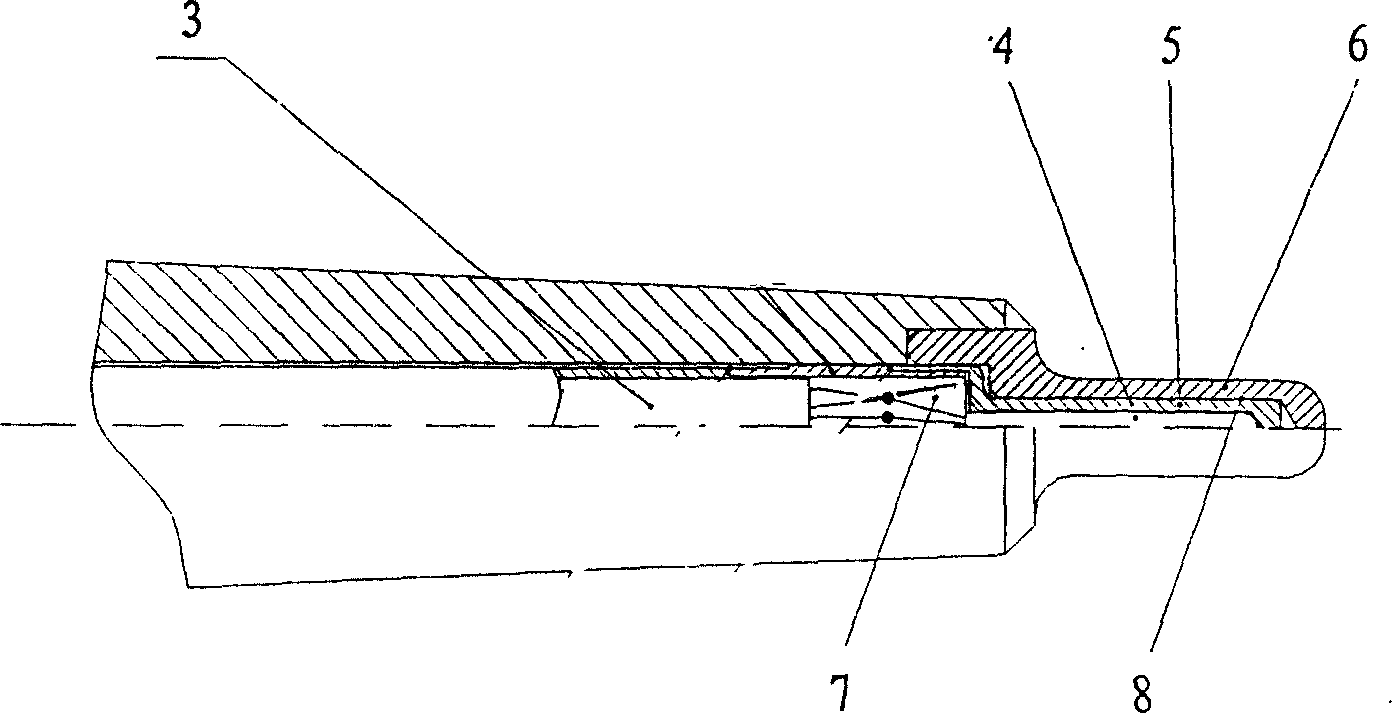

[0014] The nuclear-grade small inert platinum resistance thermometer includes: a junction box 1, a wiring wrench 2 placed in the junction box, and a protective sleeve 5 with a built-in platinum resistance element 4, which is characterized in that: the temperature sensing surface of the platinum resistance element 4 is connected to the protective The inner surface of the casing 5 is closely attached; the outer surface of the protective sleeve 5 is closely attached to the inner surface of the outer protective tube 6; the platinum resistance element 4 is welded to the armored lead wire 3, and the lead wire is filled with MgO powder 7 .

[0015] The gap between the platinum resistance element 4 and the inner surface of the protective sleeve 5 is 0.10 mm. The gap between the outer surface of the protective sleeve 5 and the inner surface of the outer protective tube 6 is 0.05 mm. The outer surface of the protective sleeve 5 is coated with a wear-resistant, heat-resistant and oxidat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com