Flash roasting treatment method for nickel laterite ores

A laterite nickel ore and flash roasting technology, applied in the metallurgical field, can solve the problems of large investment, high energy consumption, and low nickel reduction rate of products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

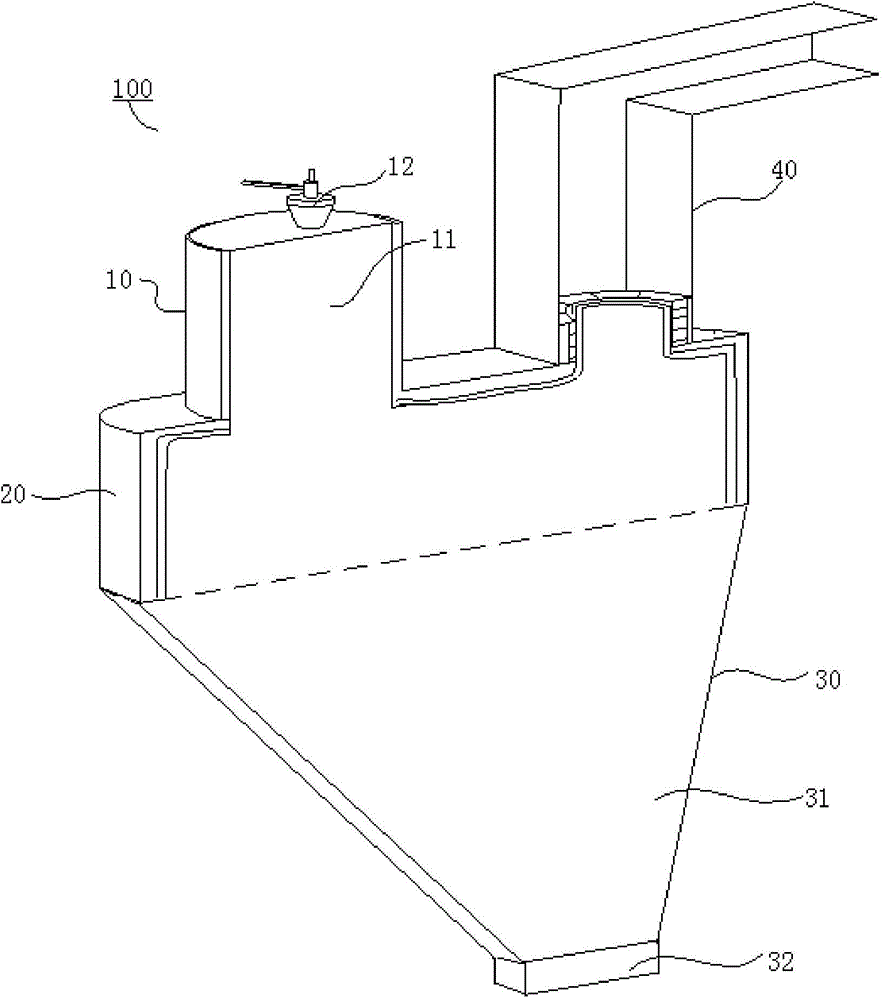

[0031] Such as figure 1 As shown, the laterite nickel ore is crushed to obtain laterite nickel ore powder ore with a particle size of 200 microns; the temperature in the flash roaster is controlled at 1200 degrees Celsius, and pulverized coal and oxygen are added to a suspension smelting pool with a diameter of 4 meters to make Wherein the atmosphere reaches the content of the reducing gas within 60±2%; the laterite nickel ore powder ore is sprayed into the flash roasting furnace for roasting treatment.

[0032] Through calculation, it is obtained that the reduction rate of nickel and cobalt in the product reaches more than 99%, and the comprehensive energy consumption is 179.77kg standard coal / ton ore.

Embodiment 2

[0034] Such as figure 1 As shown, the laterite nickel ore is crushed to obtain laterite nickel ore powder ore with a particle size of 200 microns; the temperature in the flash roaster is controlled at 1100 degrees Celsius, and pulverized coal and oxygen are added to a suspension smelting pool with a diameter of 4 meters to make The atmosphere reaches a reducing gas content of 35±2%. The laterite nickel ore powder is sprayed into the flash roasting furnace for roasting treatment, and a mixture containing nickel-cobalt-iron alloy and ferrous oxide is obtained.

[0035] By calculation, the reduction rate of nickel and cobalt reaches more than 90%, and the comprehensive energy consumption is 130kg standard coal / ton ore.

Embodiment 3

[0037] Such as figure 1As shown, the laterite nickel ore is crushed to obtain laterite nickel ore powder ore with a particle size of 200 microns; the temperature in the flash roaster is controlled at 1000 degrees Celsius, and pulverized coal and oxygen are added to a suspension smelting pool with a diameter of 4 meters to make Wherein the atmosphere reaches a reducing gas content of 28±2%; the laterite nickel ore powder ore is sprayed into the flash roasting furnace for roasting treatment.

[0038] By calculation, the reduction rate of nickel and cobalt reaches more than 80%, and the comprehensive energy consumption is 120kg standard coal / ton ore.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com